battery replacement DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 89 of 1200

either through the park brake switch, the fluid level

sensor in the master cylinder reservoir, or the igni-

tion switch in the crank position.

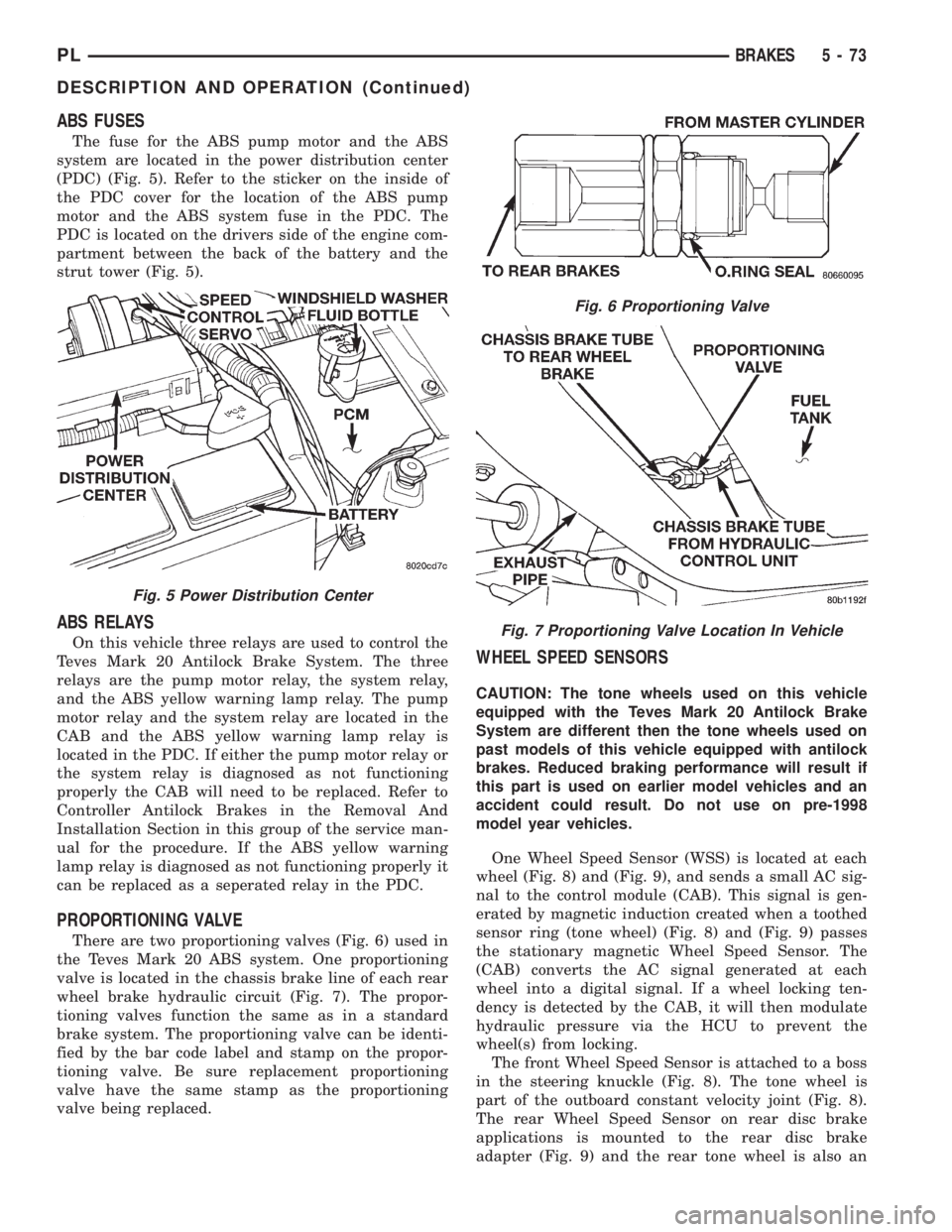

The Brake Fluid Level sensor is located in the

brake fluid reservoir of the master cylinder assembly

(Fig. 18). The purpose of the sensor is to provide the

driver with an early warning that the brake fluid

level in the master cylinder reservoir has dropped to

below normal. This may indicate an abnormal loss of

brake fluid in the master cylinder fluid reservoir

resulting from a leak in the hydraulic system.

As the fluid drops below the minimum level, the

fluid level sensor closes the brake warning light cir-

cuit. This will turn on the red brake warning light.

At this time, master cylinder fluid reservoir shouldbe checked and filled to the full mark with DOT 3

brake fluid.If brake fluid level has dropped in

master cylinder fluid reservoir, the entire

brake hydraulic system should be checked for

evidence of a leak.

STOP LAMP SWITCH

The stop lamp switch controls operation of the

vehicles stop lamps. Also, if the vehicle is equipped

with speed control, the stop lamp switch will deacti-

vate speed control when the brake pedal is

depressed.

The stop lamp switch controls operation of the

right and left tail, stop and turn signal lamp and

CHMSL lamp, by supplying battery current to these

lamps.

The stop lamp switch controls the lamp operation

by opening and closing the electrical circuit to the

stop lamps.

REAR WHEEL HUB/BEARING

CAUTION: If a vehicle is equipped with antilock

brakes the tone wheels for the rear wheel speed

sensors are pressed onto the hub. The tone wheels

used on this vehicle equipped with the Teves Mark

20 Antilock Brake System are different then those

used on past models of this vehicle equipped with

antilock brakes. Reduced braking performance will

result if this part is used on earlier model vehicles

and an accident could result. Do not use on

pre-1998 model year vehicles.

All vehicles are equipped with permanently lubri-

cated and sealed for life rear wheel bearings. There

is no periodic lubrication or maintenance recom-

mended for these units. However, if servicing of a

rear wheel bearing is required, refer to procedures in

the diagnosis and testing section and the removal

and installation section in this group of the service

manual for the inspection and replacement of the

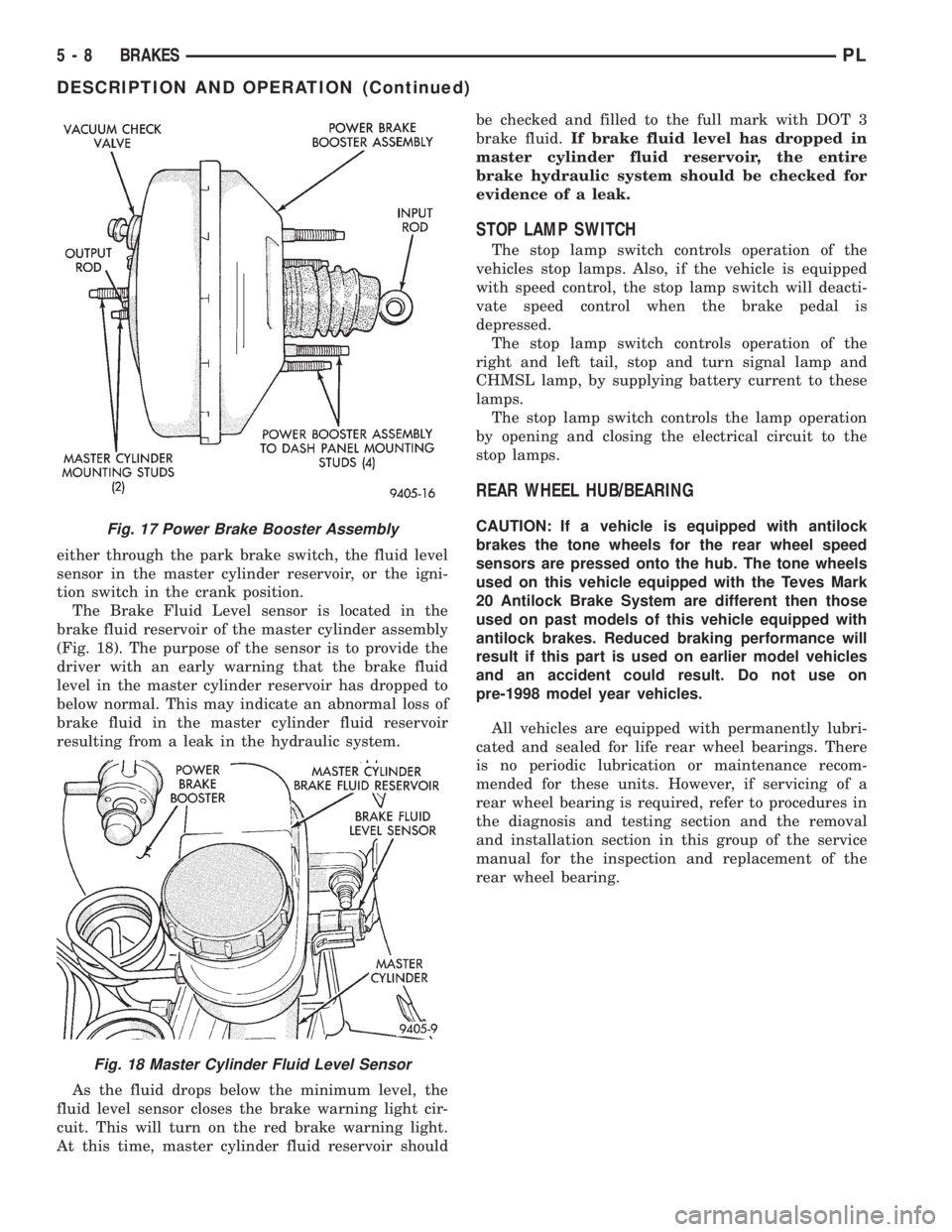

rear wheel bearing.Fig. 17 Power Brake Booster Assembly

Fig. 18 Master Cylinder Fluid Level Sensor

5 - 8 BRAKESPL

DESCRIPTION AND OPERATION (Continued)

Page 154 of 1200

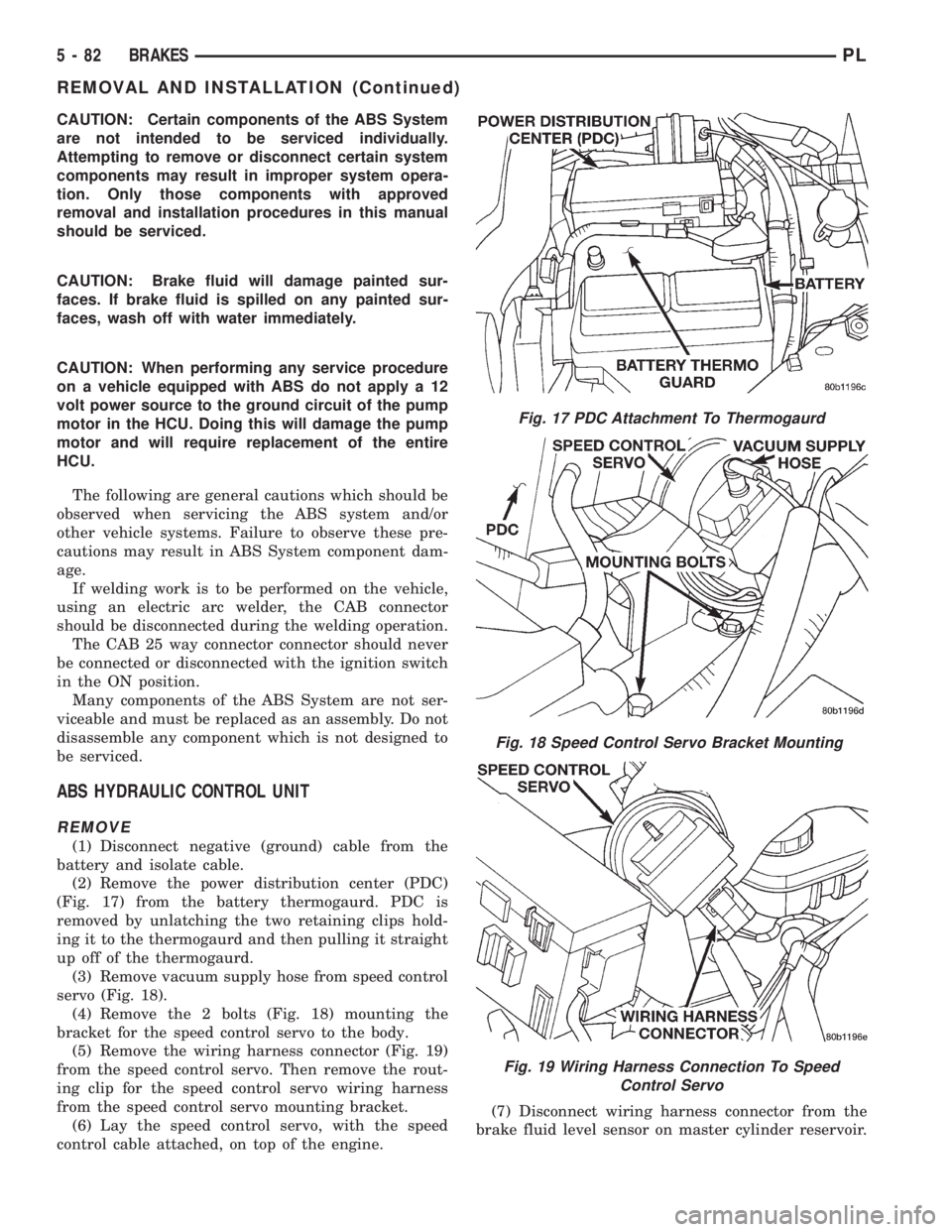

ABS FUSES

The fuse for the ABS pump motor and the ABS

system are located in the power distribution center

(PDC) (Fig. 5). Refer to the sticker on the inside of

the PDC cover for the location of the ABS pump

motor and the ABS system fuse in the PDC. The

PDC is located on the drivers side of the engine com-

partment between the back of the battery and the

strut tower (Fig. 5).

ABS RELAYS

On this vehicle three relays are used to control the

Teves Mark 20 Antilock Brake System. The three

relays are the pump motor relay, the system relay,

and the ABS yellow warning lamp relay. The pump

motor relay and the system relay are located in the

CAB and the ABS yellow warning lamp relay is

located in the PDC. If either the pump motor relay or

the system relay is diagnosed as not functioning

properly the CAB will need to be replaced. Refer to

Controller Antilock Brakes in the Removal And

Installation Section in this group of the service man-

ual for the procedure. If the ABS yellow warning

lamp relay is diagnosed as not functioning properly it

can be replaced as a seperated relay in the PDC.

PROPORTIONING VALVE

There are two proportioning valves (Fig. 6) used in

the Teves Mark 20 ABS system. One proportioning

valve is located in the chassis brake line of each rear

wheel brake hydraulic circuit (Fig. 7). The propor-

tioning valves function the same as in a standard

brake system. The proportioning valve can be identi-

fied by the bar code label and stamp on the propor-

tioning valve. Be sure replacement proportioning

valve have the same stamp as the proportioning

valve being replaced.

WHEEL SPEED SENSORS

CAUTION: The tone wheels used on this vehicle

equipped with the Teves Mark 20 Antilock Brake

System are different then the tone wheels used on

past models of this vehicle equipped with antilock

brakes. Reduced braking performance will result if

this part is used on earlier model vehicles and an

accident could result. Do not use on pre-1998

model year vehicles.

One Wheel Speed Sensor (WSS) is located at each

wheel (Fig. 8) and (Fig. 9), and sends a small AC sig-

nal to the control module (CAB). This signal is gen-

erated by magnetic induction created when a toothed

sensor ring (tone wheel) (Fig. 8) and (Fig. 9) passes

the stationary magnetic Wheel Speed Sensor. The

(CAB) converts the AC signal generated at each

wheel into a digital signal. If a wheel locking ten-

dency is detected by the CAB, it will then modulate

hydraulic pressure via the HCU to prevent the

wheel(s) from locking.

The front Wheel Speed Sensor is attached to a boss

in the steering knuckle (Fig. 8). The tone wheel is

part of the outboard constant velocity joint (Fig. 8).

The rear Wheel Speed Sensor on rear disc brake

applications is mounted to the rear disc brake

adapter (Fig. 9) and the rear tone wheel is also an

Fig. 5 Power Distribution Center

Fig. 6 Proportioning Valve

Fig. 7 Proportioning Valve Location In Vehicle

PLBRAKES 5 - 73

DESCRIPTION AND OPERATION (Continued)

Page 163 of 1200

CAUTION: Certain components of the ABS System

are not intended to be serviced individually.

Attempting to remove or disconnect certain system

components may result in improper system opera-

tion. Only those components with approved

removal and installation procedures in this manual

should be serviced.

CAUTION: Brake fluid will damage painted sur-

faces. If brake fluid is spilled on any painted sur-

faces, wash off with water immediately.

CAUTION: When performing any service procedure

on a vehicle equipped with ABS do not apply a 12

volt power source to the ground circuit of the pump

motor in the HCU. Doing this will damage the pump

motor and will require replacement of the entire

HCU.

The following are general cautions which should be

observed when servicing the ABS system and/or

other vehicle systems. Failure to observe these pre-

cautions may result in ABS System component dam-

age.

If welding work is to be performed on the vehicle,

using an electric arc welder, the CAB connector

should be disconnected during the welding operation.

The CAB 25 way connector connector should never

be connected or disconnected with the ignition switch

in the ON position.

Many components of the ABS System are not ser-

viceable and must be replaced as an assembly. Do not

disassemble any component which is not designed to

be serviced.

ABS HYDRAULIC CONTROL UNIT

REMOVE

(1) Disconnect negative (ground) cable from the

battery and isolate cable.

(2) Remove the power distribution center (PDC)

(Fig. 17) from the battery thermogaurd. PDC is

removed by unlatching the two retaining clips hold-

ing it to the thermogaurd and then pulling it straight

up off of the thermogaurd.

(3) Remove vacuum supply hose from speed control

servo (Fig. 18).

(4) Remove the 2 bolts (Fig. 18) mounting the

bracket for the speed control servo to the body.

(5) Remove the wiring harness connector (Fig. 19)

from the speed control servo. Then remove the rout-

ing clip for the speed control servo wiring harness

from the speed control servo mounting bracket.

(6) Lay the speed control servo, with the speed

control cable attached, on top of the engine.(7) Disconnect wiring harness connector from the

brake fluid level sensor on master cylinder reservoir.

Fig. 17 PDC Attachment To Thermogaurd

Fig. 18 Speed Control Servo Bracket Mounting

Fig. 19 Wiring Harness Connection To Speed

Control Servo

5 - 82 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 173 of 1200

The clutch cable has a unique self-adjuster mecha-

nism built into the cable which compensates for

clutch disc wear. The cable requires no maintenance

or lubrication. There are no serviceable components

on the cable assembly.

The clutch pedal is connected to the cable through

a plastic spacer. The upper end of the clutch pedal

pivots in the pedal bracket on two nylon bushings

and a shaft. These bushings are greased at assembly

and do not require periodic lubrication.

CLUTCH DISC AND COVER APPLICATION

The 2.0 single overhead cam engine uses a 216 mm

(8.5 in.) clutch disc. The manual transaxle is avail-

able only with the 2.0 liter engine.

CLUTCH REPLACEMENT

The transaxle must be removed to service the

clutch disc, pressure plate, flywheel/drive plate,

and/or clutch release bearing and lever.

DESCRIPTION AND OPERATION

CLUTCH CABLE

The manual transaxle clutch release system has a

unique self-adjusting mechanism to compensate for

clutch disc wear. This adjuster mechanism is located

within the clutch cable assembly. The preload spring

maintains tension on the cable. This tension keeps

the clutch release bearing continuously loaded

against the fingers of the clutch cover assembly.

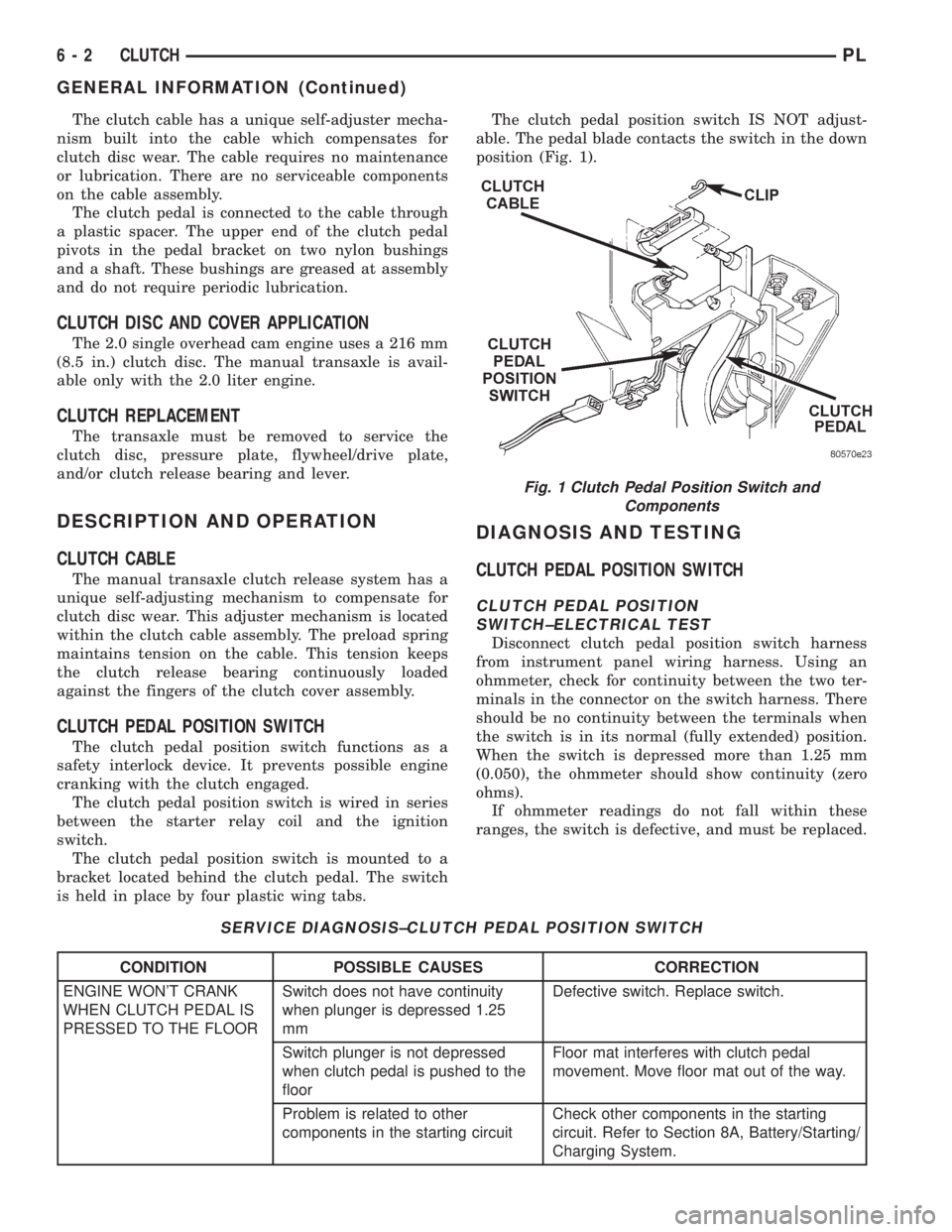

CLUTCH PEDAL POSITION SWITCH

The clutch pedal position switch functions as a

safety interlock device. It prevents possible engine

cranking with the clutch engaged.

The clutch pedal position switch is wired in series

between the starter relay coil and the ignition

switch.

The clutch pedal position switch is mounted to a

bracket located behind the clutch pedal. The switch

is held in place by four plastic wing tabs.The clutch pedal position switch IS NOT adjust-

able. The pedal blade contacts the switch in the down

position (Fig. 1).

DIAGNOSIS AND TESTING

CLUTCH PEDAL POSITION SWITCH

CLUTCH PEDAL POSITION

SWITCH±ELECTRICAL TEST

Disconnect clutch pedal position switch harness

from instrument panel wiring harness. Using an

ohmmeter, check for continuity between the two ter-

minals in the connector on the switch harness. There

should be no continuity between the terminals when

the switch is in its normal (fully extended) position.

When the switch is depressed more than 1.25 mm

(0.050), the ohmmeter should show continuity (zero

ohms).

If ohmmeter readings do not fall within these

ranges, the switch is defective, and must be replaced.

SERVICE DIAGNOSIS±CLUTCH PEDAL POSITION SWITCH

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WON'T CRANK

WHEN CLUTCH PEDAL IS

PRESSED TO THE FLOORSwitch does not have continuity

when plunger is depressed 1.25

mmDefective switch. Replace switch.

Switch plunger is not depressed

when clutch pedal is pushed to the

floorFloor mat interferes with clutch pedal

movement. Move floor mat out of the way.

Problem is related to other

components in the starting circuitCheck other components in the starting

circuit. Refer to Section 8A, Battery/Starting/

Charging System.

Fig. 1 Clutch Pedal Position Switch and

Components

6 - 2 CLUTCHPL

GENERAL INFORMATION (Continued)

Page 237 of 1200

A battery temperature sensor located on the front

bumper beam is used to sense battery temperature.

This temperature data, along with data from moni-

tored line voltage, is used by the PCM to vary the

battery charging rate. This is done by cycling the

ground path to control the strength of the rotor mag-

netic field. The PCM then compensates and regulates

generator current output accordingly and to maintain

the proper voltage depending on battery tempera-

ture.

All vehicles are equipped with On-Board Diagnos-

tics (OBD). All OBD-sensed systems, including the

EVR (field control) circuitry, are monitored by the

PCM. Each monitored circuit is assigned a Diagnos-

tic Trouble Code (DTC). The PCM will store a DTC in

electronic memory for any failure it detects. See On-

Board Diagnostic System Test in this group for more

information.

GENERATOR

The generator is belt-driven by the engine. It is

serviced only as a complete assembly. If the genera-

tor fails for any reason, the entire assembly must be

replaced.

As the energized rotor begins to rotate within the

generator, the spinning magnetic field induces a cur-

rent into the windings of the stator coil. Once the

generator begins producing sufficient current, it also

provides the current needed to energize the rotor.

The Y type stator winding connections deliver the

induced AC current to 3 positive and 3 negative

diodes for rectification. From the diodes, rectified DC

current is delivered to the vehicle electrical system

through the generator, battery, and ground terminals.

Noise emitting from the generator may be caused

by:

²Worn, loose or defective bearings

²Loose or defective drive pulley

²Incorrect, worn, damaged or misadjusted drive

belt

²Loose mounting bolts

²Misaligned drive pulley

²Defective stator or diode

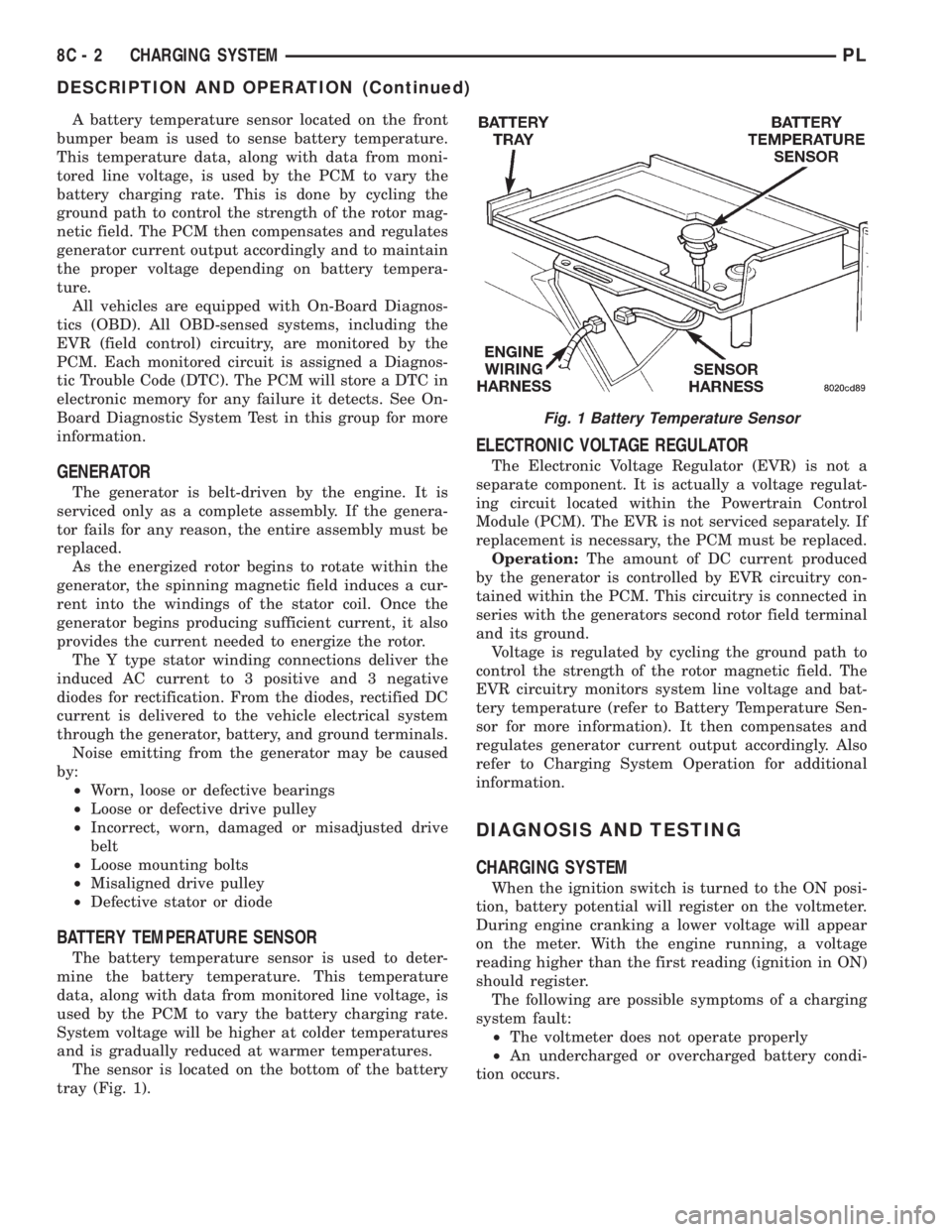

BATTERY TEMPERATURE SENSOR

The battery temperature sensor is used to deter-

mine the battery temperature. This temperature

data, along with data from monitored line voltage, is

used by the PCM to vary the battery charging rate.

System voltage will be higher at colder temperatures

and is gradually reduced at warmer temperatures.

The sensor is located on the bottom of the battery

tray (Fig. 1).

ELECTRONIC VOLTAGE REGULATOR

The Electronic Voltage Regulator (EVR) is not a

separate component. It is actually a voltage regulat-

ing circuit located within the Powertrain Control

Module (PCM). The EVR is not serviced separately. If

replacement is necessary, the PCM must be replaced.

Operation:The amount of DC current produced

by the generator is controlled by EVR circuitry con-

tained within the PCM. This circuitry is connected in

series with the generators second rotor field terminal

and its ground.

Voltage is regulated by cycling the ground path to

control the strength of the rotor magnetic field. The

EVR circuitry monitors system line voltage and bat-

tery temperature (refer to Battery Temperature Sen-

sor for more information). It then compensates and

regulates generator current output accordingly. Also

refer to Charging System Operation for additional

information.

DIAGNOSIS AND TESTING

CHARGING SYSTEM

When the ignition switch is turned to the ON posi-

tion, battery potential will register on the voltmeter.

During engine cranking a lower voltage will appear

on the meter. With the engine running, a voltage

reading higher than the first reading (ignition in ON)

should register.

The following are possible symptoms of a charging

system fault:

²The voltmeter does not operate properly

²An undercharged or overcharged battery condi-

tion occurs.

Fig. 1 Battery Temperature Sensor

8C - 2 CHARGING SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 315 of 1200

DIAGNOSIS AND TESTING

WINDSHIELD WIPER CONDITION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

The following is a list of general wiper motor sys-

tem problems, the tests that are to be performed to

locate the faulty part, and the corrective action to be

taken.

Whatever the problem, disconnect motor wire har-

ness and clean the terminals, then connect motor

wire harness and test.

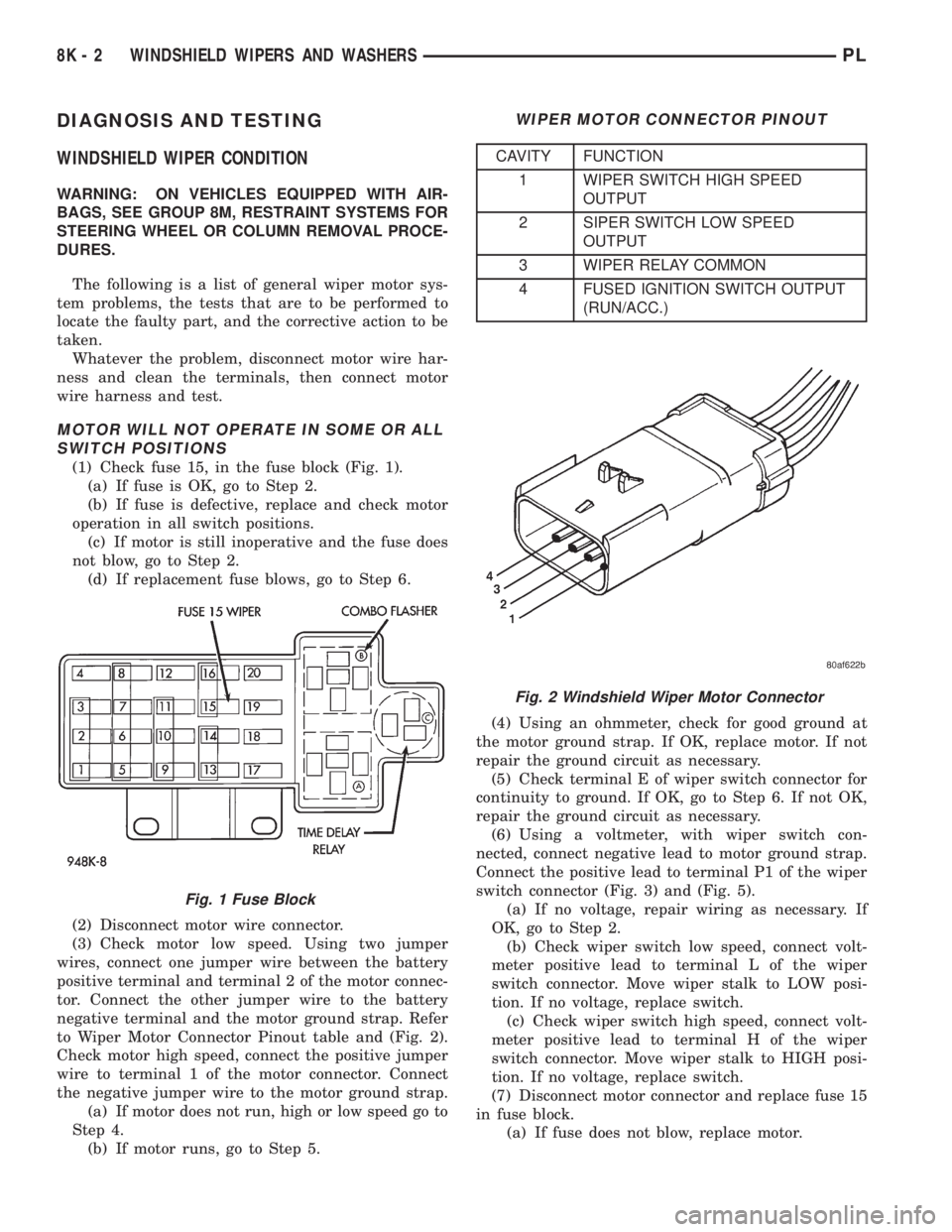

MOTOR WILL NOT OPERATE IN SOME OR ALL

SWITCH POSITIONS

(1) Check fuse 15, in the fuse block (Fig. 1).

(a) If fuse is OK, go to Step 2.

(b) If fuse is defective, replace and check motor

operation in all switch positions.

(c) If motor is still inoperative and the fuse does

not blow, go to Step 2.

(d) If replacement fuse blows, go to Step 6.

(2) Disconnect motor wire connector.

(3) Check motor low speed. Using two jumper

wires, connect one jumper wire between the battery

positive terminal and terminal 2 of the motor connec-

tor. Connect the other jumper wire to the battery

negative terminal and the motor ground strap. Refer

to Wiper Motor Connector Pinout table and (Fig. 2).

Check motor high speed, connect the positive jumper

wire to terminal 1 of the motor connector. Connect

the negative jumper wire to the motor ground strap.

(a) If motor does not run, high or low speed go to

Step 4.

(b) If motor runs, go to Step 5.(4) Using an ohmmeter, check for good ground at

the motor ground strap. If OK, replace motor. If not

repair the ground circuit as necessary.

(5) Check terminal E of wiper switch connector for

continuity to ground. If OK, go to Step 6. If not OK,

repair the ground circuit as necessary.

(6) Using a voltmeter, with wiper switch con-

nected, connect negative lead to motor ground strap.

Connect the positive lead to terminal P1 of the wiper

switch connector (Fig. 3) and (Fig. 5).

(a) If no voltage, repair wiring as necessary. If

OK, go to Step 2.

(b) Check wiper switch low speed, connect volt-

meter positive lead to terminal L of the wiper

switch connector. Move wiper stalk to LOW posi-

tion. If no voltage, replace switch.

(c) Check wiper switch high speed, connect volt-

meter positive lead to terminal H of the wiper

switch connector. Move wiper stalk to HIGH posi-

tion. If no voltage, replace switch.

(7) Disconnect motor connector and replace fuse 15

in fuse block.

(a) If fuse does not blow, replace motor.

Fig. 1 Fuse Block

WIPER MOTOR CONNECTOR PINOUT

CAVITY FUNCTION

1 WIPER SWITCH HIGH SPEED

OUTPUT

2 SIPER SWITCH LOW SPEED

OUTPUT

3 WIPER RELAY COMMON

4 FUSED IGNITION SWITCH OUTPUT

(RUN/ACC.)

Fig. 2 Windshield Wiper Motor Connector

8K - 2 WINDSHIELD WIPERS AND WASHERSPL

Page 352 of 1200

RESTRAINT SYSTEM

CONTENTS

page page

GENERAL INFORMATION

WARNINGS AND PRECAUTIONS............ 1

DESCRIPTION AND OPERATION

AIRBAG CONTROL MODULE............... 1

CLOCKSPRING.......................... 2

DRIVER AND PASSENGER AIRBAG MODULE . . 2

DIAGNOSIS AND TESTING

AIRBAG SYSTEM TEST................... 3

SERVICE PROCEDURES

CLEANUP PROCEDURE................... 3HANDLING AIRBAG MODULE.............. 3

MAINTENANCE INSPECTION............... 4

REMOVAL AND INSTALLATION

AIRBAG CONTROL MODULE (ACM)......... 4

CLOCKSPRING.......................... 8

DRIVER AIRBAG MODULE................. 9

PASSENGER AIRBAG MODULE............. 9

STEERING WHEEL...................... 10

ADJUSTMENTS

CLOCKSPRING CENTERING PROCEDURE.... 11

GENERAL INFORMATION

WARNINGS AND PRECAUTIONS

WARNING: THIS SYSTEM IS A SENSITIVE, COM-

PLEX ELECTRO±MECHANICAL UNIT. DISCONNECT

AND ISOLATE THE BATTERY NEGATIVE CABLE

BEFORE BEGINNING AIRBAG SYSTEM COMPO-

NENT REMOVAL OR INSTALLATION PROCEDURES.

THIS WILL DISABLE THE AIRBAG SYSTEM. FAIL-

URE TO DISCONNECT THE BATTERY COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

ALLOW SYSTEM CAPACITOR TO DISCHARGE

FOR TWO MINUTES BEFORE REMOVING AIRBAG

COMPONENTS.

DO NOT PLACE AN INTACT UNDEPLOYED AIR-

BAG FACE DOWN ON A SOLID SURFACE, THE AIR-

BAG WILL PROPEL INTO THE AIR IF

ACCIDENTALLY DEPLOYED AND COULD RESULT

IN PERSONAL INJURY. WHEN CARRYING OR HAN-

DLING AN UNDEPLOYED AIRBAG MODULE, THE

TRIM SIDE OF THE AIRBAG SHOULD BE POINTING

AWAY FROM THE BODY TO MINIMIZE POSSIBILITY

OF INJURY IF ACCIDENTAL DEPLOYMENT

OCCURS.

REPLACE AIRBAG SYSTEM COMPONENTS WITH

MOPARTREPLACEMENT PARTS. SUBSTITUTE

PARTS MAY APPEAR INTERCHANGEABLE, BUT

INTERNAL DIFFERENCES MAY RESULT IN INFE-

RIOR OCCUPANT PROTECTION.

WEAR SAFETY GLASSES, RUBBER GLOVES,

AND LONG SLEEVES CLOTHING WHEN CLEANING

POWDER RESIDUE FROM VEHICLE AFTER AIRBAG

DEPLOYMENT. SODIUM HYDROXIDE POWDER

RESIDUE EMITTED FROM A DEPLOYED AIRBAGCAN CAUSE SKIN IRRITATION. FLUSH AFFECTED

AREA WITH COOL WATER IF IRRITATION IS EXPE-

RIENCED. IF NASAL OR THROAT IRRITATION IS

EXPERIENCED, EXIT THE VEHICLE FOR FRESH AIR

UNTIL THE IRRITATION CEASES. IF IRRITATION

CONTINUES, SEE A PHYSICIAN.

DO NOT USE A REPLACEMENT AIRBAG THAT IS

NOT IN THE ORIGINAL PACKAGING, IMPROPER

DEPLOYMENT AND PERSONAL INJURY CAN

RESULT.

THE FACTORY INSTALLED FASTENERS,

SCREWS AND BOLTS USED TO FASTEN AIRBAG

COMPONENTS, ARE SPECIFICALLY DESIGNED

FOR THE AIRBAG SYSTEM. DO NOT USE SUBSTI-

TUTE FASTENERS, USE ONLY ORIGINAL EQUIP-

MENT FASTENERS LISTED IN THE PARTS

CATALOG WHEN FASTENER REPLACEMENT IS

REQUIRED.

NOTE: Airbags should be stored in a cool dry loca-

tion away from excessive heat and static electrical

activity with the fabric airbag facing UP, or a prema-

ture deployment can result.

If the Driver/Passenger Airbag Module is defective

and not deployed, refer to Chrysler Corporation cur-

rent return list for proper handling procedures.

DESCRIPTION AND OPERATION

AIRBAG CONTROL MODULE

The Airbag Control Module (ACM) contains the

safing sensor and energy reserve capacitor. The saf-

ing sensor is located inside the ACM. The module is

mounted on the tunnel/floor pan between the gear

PLRESTRAINT SYSTEM 8M - 1

Page 366 of 1200

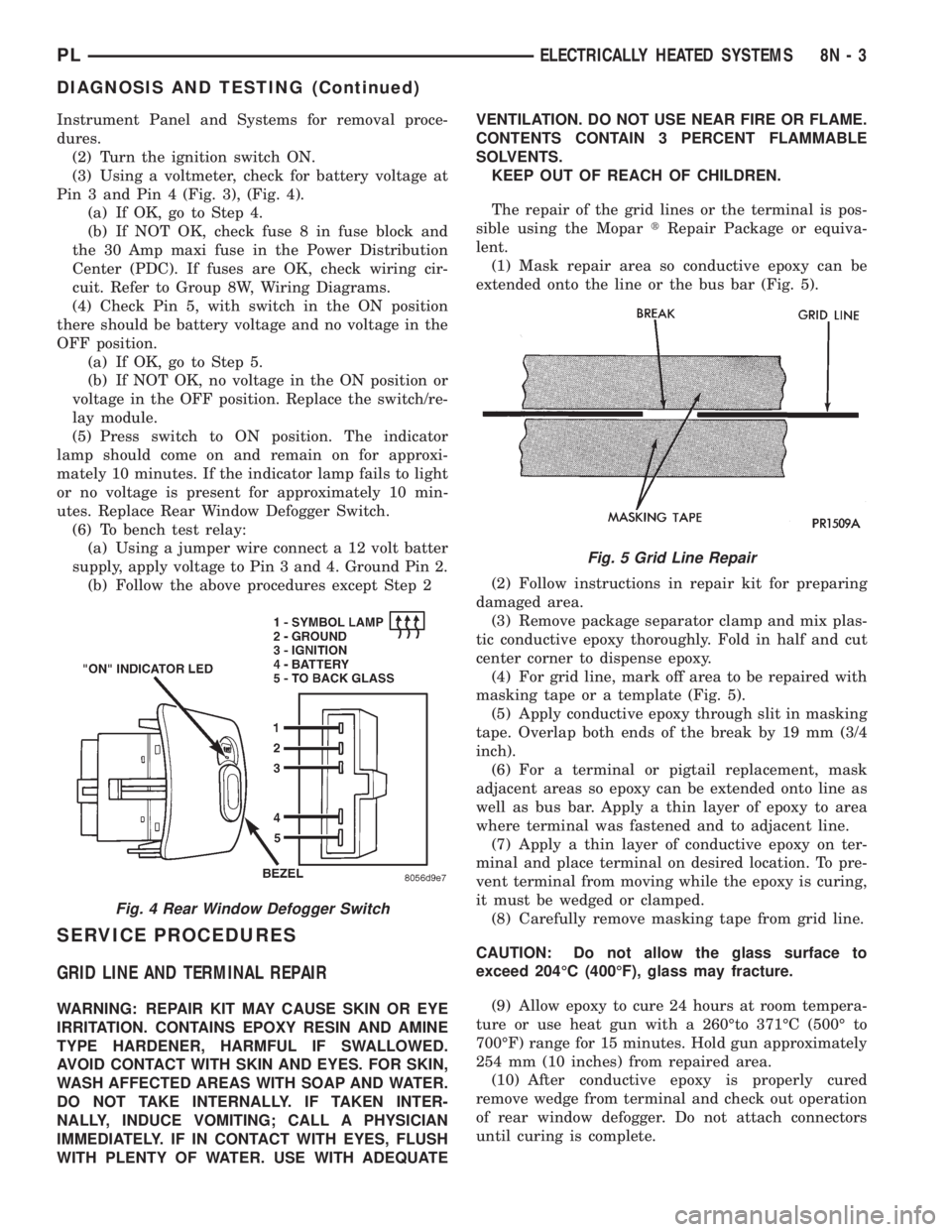

Instrument Panel and Systems for removal proce-

dures.

(2) Turn the ignition switch ON.

(3) Using a voltmeter, check for battery voltage at

Pin 3 and Pin 4 (Fig. 3), (Fig. 4).

(a) If OK, go to Step 4.

(b) If NOT OK, check fuse 8 in fuse block and

the 30 Amp maxi fuse in the Power Distribution

Center (PDC). If fuses are OK, check wiring cir-

cuit. Refer to Group 8W, Wiring Diagrams.

(4) Check Pin 5, with switch in the ON position

there should be battery voltage and no voltage in the

OFF position.

(a) If OK, go to Step 5.

(b) If NOT OK, no voltage in the ON position or

voltage in the OFF position. Replace the switch/re-

lay module.

(5) Press switch to ON position. The indicator

lamp should come on and remain on for approxi-

mately 10 minutes. If the indicator lamp fails to light

or no voltage is present for approximately 10 min-

utes. Replace Rear Window Defogger Switch.

(6) To bench test relay:

(a) Using a jumper wire connect a 12 volt batter

supply, apply voltage to Pin 3 and 4. Ground Pin 2.

(b) Follow the above procedures except Step 2

SERVICE PROCEDURES

GRID LINE AND TERMINAL REPAIR

WARNING: REPAIR KIT MAY CAUSE SKIN OR EYE

IRRITATION. CONTAINS EPOXY RESIN AND AMINE

TYPE HARDENER, HARMFUL IF SWALLOWED.

AVOID CONTACT WITH SKIN AND EYES. FOR SKIN,

WASH AFFECTED AREAS WITH SOAP AND WATER.

DO NOT TAKE INTERNALLY. IF TAKEN INTER-

NALLY, INDUCE VOMITING; CALL A PHYSICIAN

IMMEDIATELY. IF IN CONTACT WITH EYES, FLUSH

WITH PLENTY OF WATER. USE WITH ADEQUATEVENTILATION. DO NOT USE NEAR FIRE OR FLAME.

CONTENTS CONTAIN 3 PERCENT FLAMMABLE

SOLVENTS.

KEEP OUT OF REACH OF CHILDREN.

The repair of the grid lines or the terminal is pos-

sible using the MopartRepair Package or equiva-

lent.

(1) Mask repair area so conductive epoxy can be

extended onto the line or the bus bar (Fig. 5).

(2) Follow instructions in repair kit for preparing

damaged area.

(3) Remove package separator clamp and mix plas-

tic conductive epoxy thoroughly. Fold in half and cut

center corner to dispense epoxy.

(4) For grid line, mark off area to be repaired with

masking tape or a template (Fig. 5).

(5) Apply conductive epoxy through slit in masking

tape. Overlap both ends of the break by 19 mm (3/4

inch).

(6) For a terminal or pigtail replacement, mask

adjacent areas so epoxy can be extended onto line as

well as bus bar. Apply a thin layer of epoxy to area

where terminal was fastened and to adjacent line.

(7) Apply a thin layer of conductive epoxy on ter-

minal and place terminal on desired location. To pre-

vent terminal from moving while the epoxy is curing,

it must be wedged or clamped.

(8) Carefully remove masking tape from grid line.

CAUTION: Do not allow the glass surface to

exceed 204ÉC (400ÉF), glass may fracture.

(9) Allow epoxy to cure 24 hours at room tempera-

ture or use heat gun with a 260Éto 371ÉC (500É to

700ÉF) range for 15 minutes. Hold gun approximately

254 mm (10 inches) from repaired area.

(10) After conductive epoxy is properly cured

remove wedge from terminal and check out operation

of rear window defogger. Do not attach connectors

until curing is complete.

Fig. 4 Rear Window Defogger Switch

Fig. 5 Grid Line Repair

PLELECTRICALLY HEATED SYSTEMS 8N - 3

DIAGNOSIS AND TESTING (Continued)

Page 405 of 1200

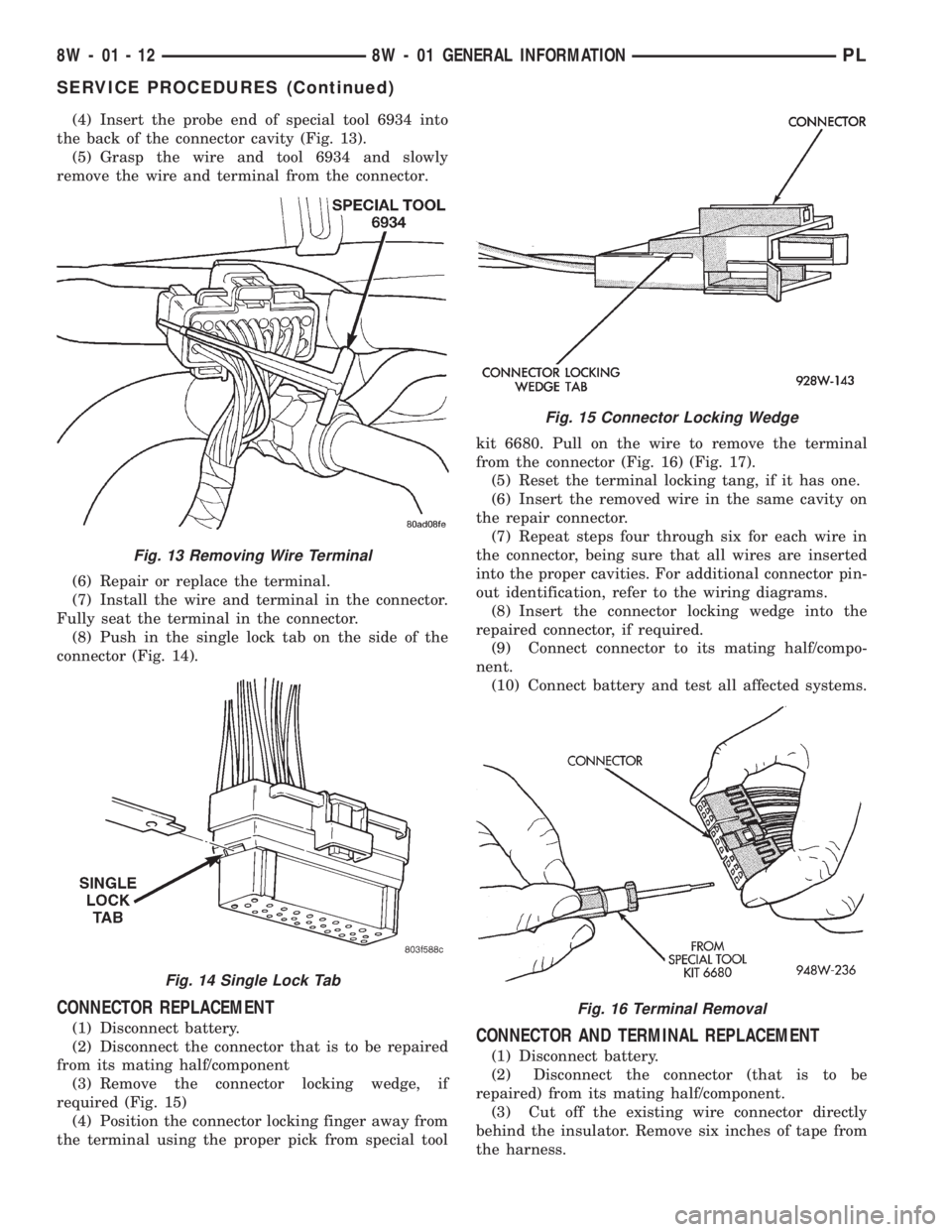

(4) Insert the probe end of special tool 6934 into

the back of the connector cavity (Fig. 13).

(5) Grasp the wire and tool 6934 and slowly

remove the wire and terminal from the connector.

(6) Repair or replace the terminal.

(7) Install the wire and terminal in the connector.

Fully seat the terminal in the connector.

(8) Push in the single lock tab on the side of the

connector (Fig. 14).

CONNECTOR REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector that is to be repaired

from its mating half/component

(3) Remove the connector locking wedge, if

required (Fig. 15)

(4) Position the connector locking finger away from

the terminal using the proper pick from special toolkit 6680. Pull on the wire to remove the terminal

from the connector (Fig. 16) (Fig. 17).

(5) Reset the terminal locking tang, if it has one.

(6) Insert the removed wire in the same cavity on

the repair connector.

(7) Repeat steps four through six for each wire in

the connector, being sure that all wires are inserted

into the proper cavities. For additional connector pin-

out identification, refer to the wiring diagrams.

(8) Insert the connector locking wedge into the

repaired connector, if required.

(9) Connect connector to its mating half/compo-

nent.

(10) Connect battery and test all affected systems.CONNECTOR AND TERMINAL REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector (that is to be

repaired) from its mating half/component.

(3) Cut off the existing wire connector directly

behind the insulator. Remove six inches of tape from

the harness.

Fig. 13 Removing Wire Terminal

Fig. 14 Single Lock Tab

Fig. 15 Connector Locking Wedge

Fig. 16 Terminal Removal

8W - 01 - 12 8W - 01 GENERAL INFORMATIONPL

SERVICE PROCEDURES (Continued)

Page 406 of 1200

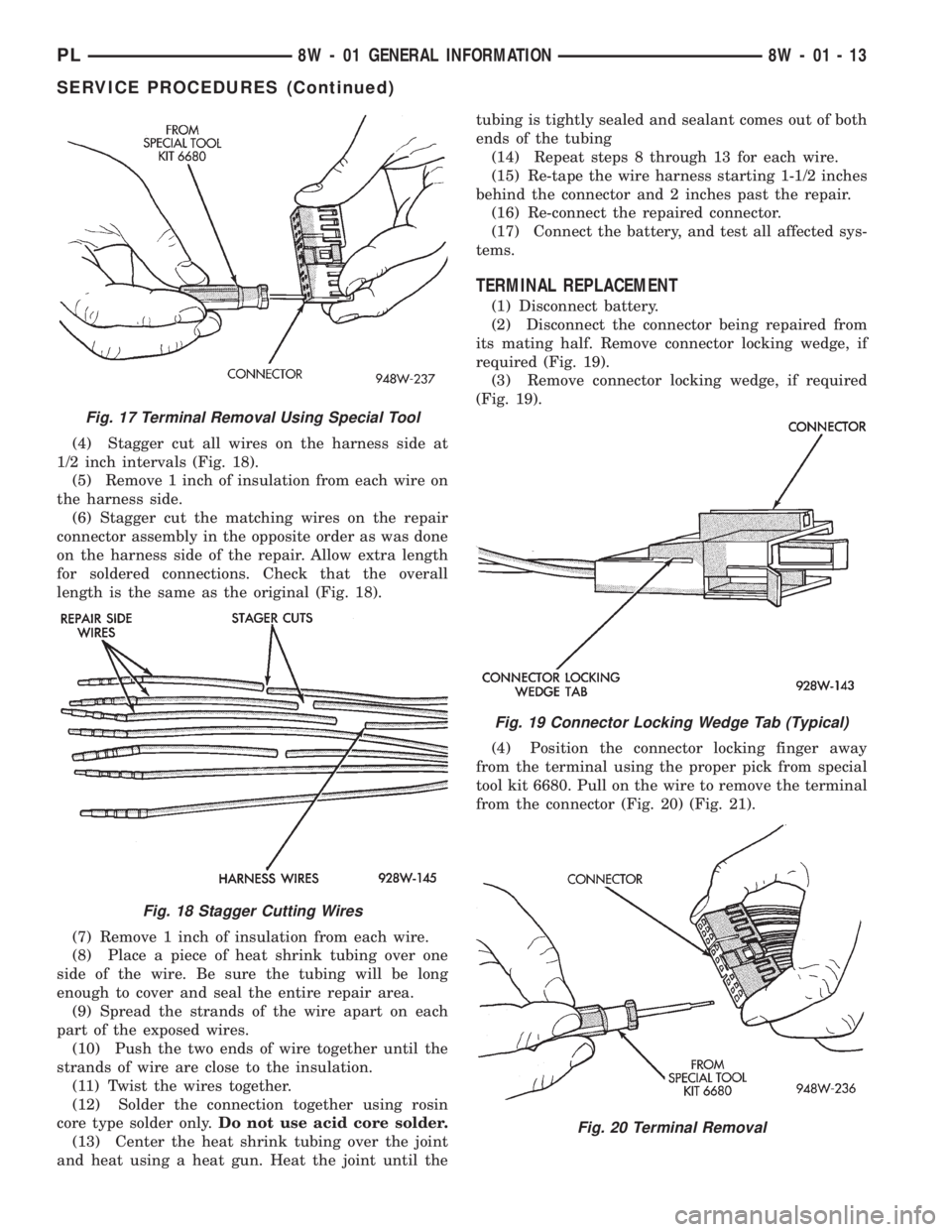

(4) Stagger cut all wires on the harness side at

1/2 inch intervals (Fig. 18).

(5) Remove 1 inch of insulation from each wire on

the harness side.

(6) Stagger cut the matching wires on the repair

connector assembly in the opposite order as was done

on the harness side of the repair. Allow extra length

for soldered connections. Check that the overall

length is the same as the original (Fig. 18).

(7) Remove 1 inch of insulation from each wire.

(8) Place a piece of heat shrink tubing over one

side of the wire. Be sure the tubing will be long

enough to cover and seal the entire repair area.

(9) Spread the strands of the wire apart on each

part of the exposed wires.

(10) Push the two ends of wire together until the

strands of wire are close to the insulation.

(11) Twist the wires together.

(12) Solder the connection together using rosin

core type solder only.Do not use acid core solder.

(13) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until thetubing is tightly sealed and sealant comes out of both

ends of the tubing

(14) Repeat steps 8 through 13 for each wire.

(15) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair.

(16) Re-connect the repaired connector.

(17) Connect the battery, and test all affected sys-

tems.

TERMINAL REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector being repaired from

its mating half. Remove connector locking wedge, if

required (Fig. 19).

(3) Remove connector locking wedge, if required

(Fig. 19).

(4) Position the connector locking finger away

from the terminal using the proper pick from special

tool kit 6680. Pull on the wire to remove the terminal

from the connector (Fig. 20) (Fig. 21).

Fig. 17 Terminal Removal Using Special Tool

Fig. 18 Stagger Cutting Wires

Fig. 19 Connector Locking Wedge Tab (Typical)

Fig. 20 Terminal Removal

PL8W - 01 GENERAL INFORMATION 8W - 01 - 13

SERVICE PROCEDURES (Continued)