fuse DODGE NEON 1999 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 315 of 1200

DIAGNOSIS AND TESTING

WINDSHIELD WIPER CONDITION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

The following is a list of general wiper motor sys-

tem problems, the tests that are to be performed to

locate the faulty part, and the corrective action to be

taken.

Whatever the problem, disconnect motor wire har-

ness and clean the terminals, then connect motor

wire harness and test.

MOTOR WILL NOT OPERATE IN SOME OR ALL

SWITCH POSITIONS

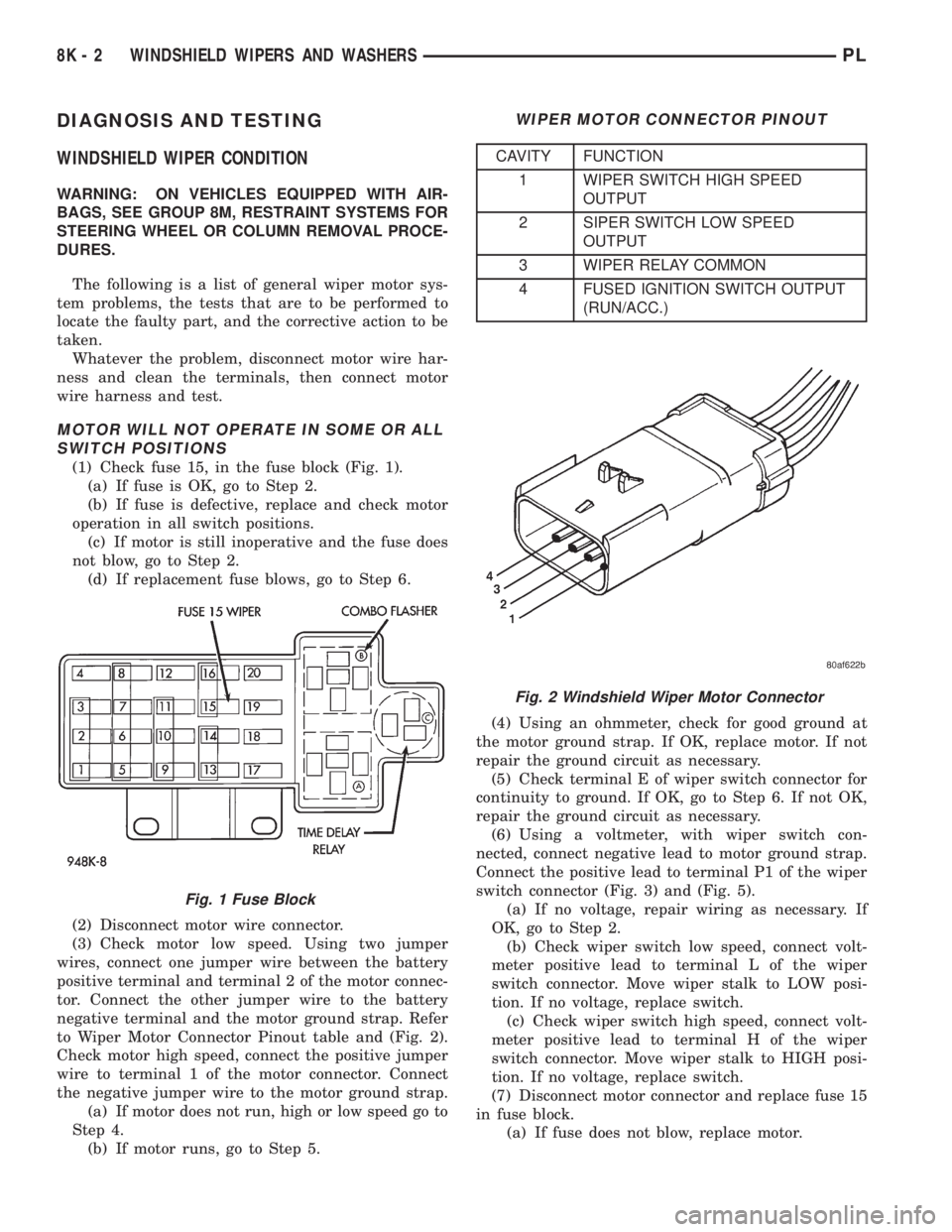

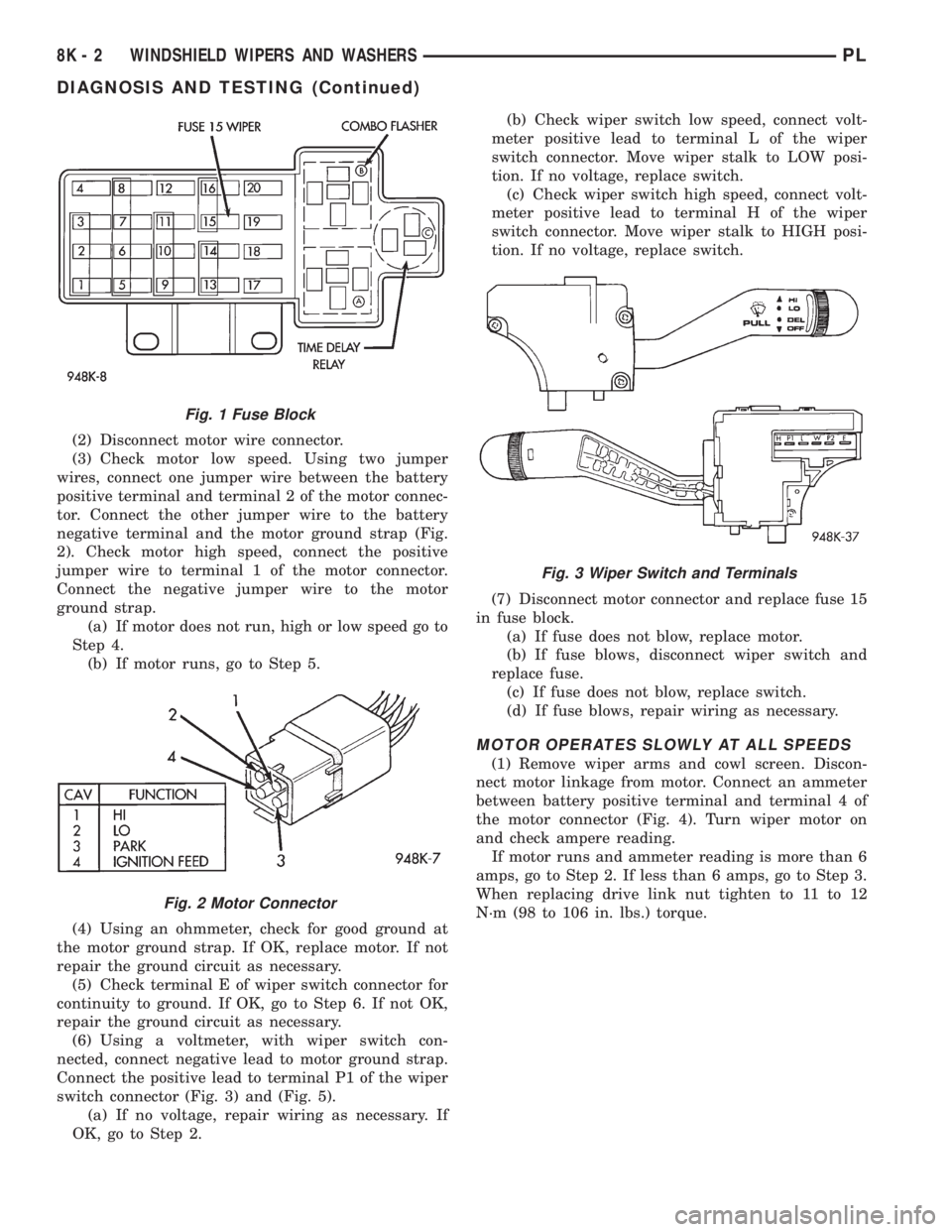

(1) Check fuse 15, in the fuse block (Fig. 1).

(a) If fuse is OK, go to Step 2.

(b) If fuse is defective, replace and check motor

operation in all switch positions.

(c) If motor is still inoperative and the fuse does

not blow, go to Step 2.

(d) If replacement fuse blows, go to Step 6.

(2) Disconnect motor wire connector.

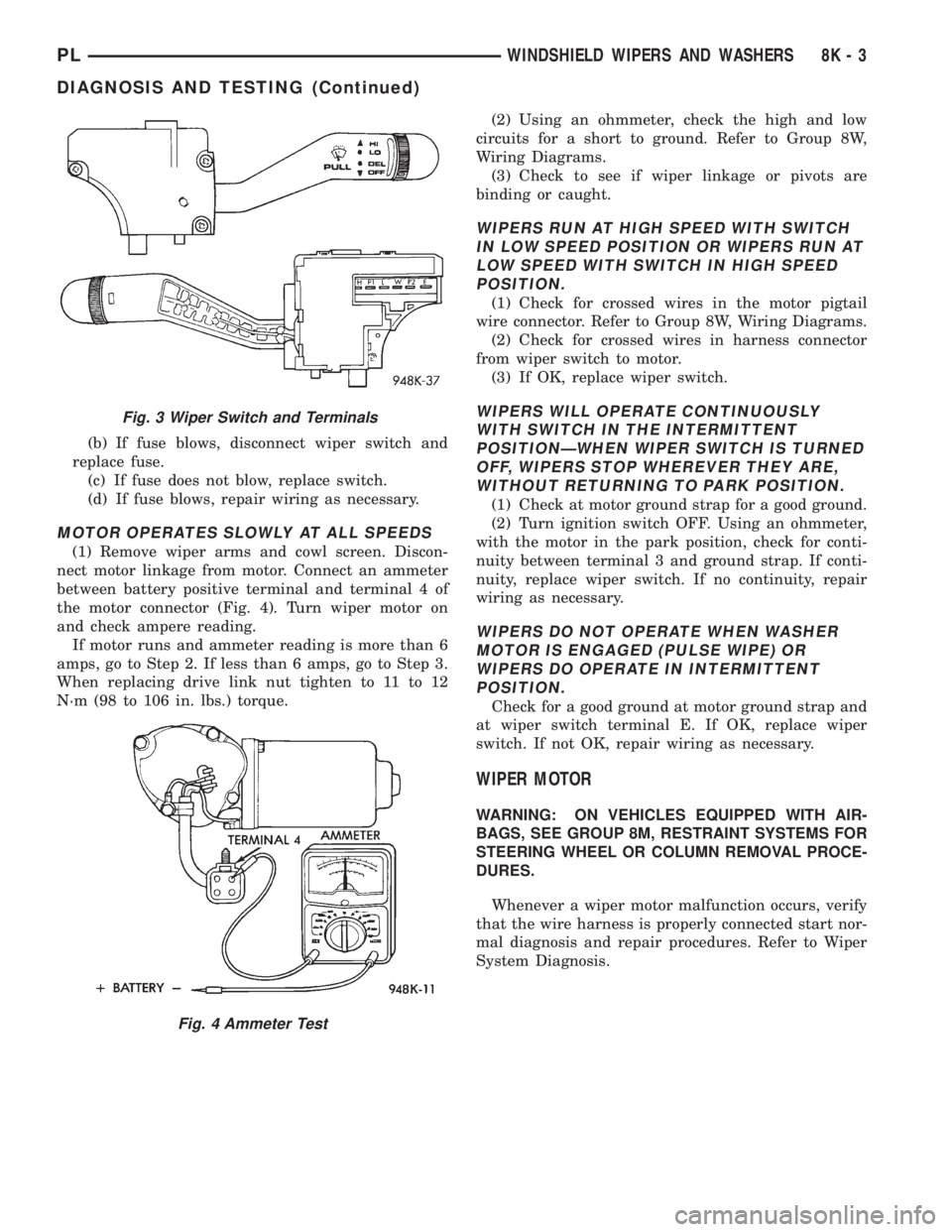

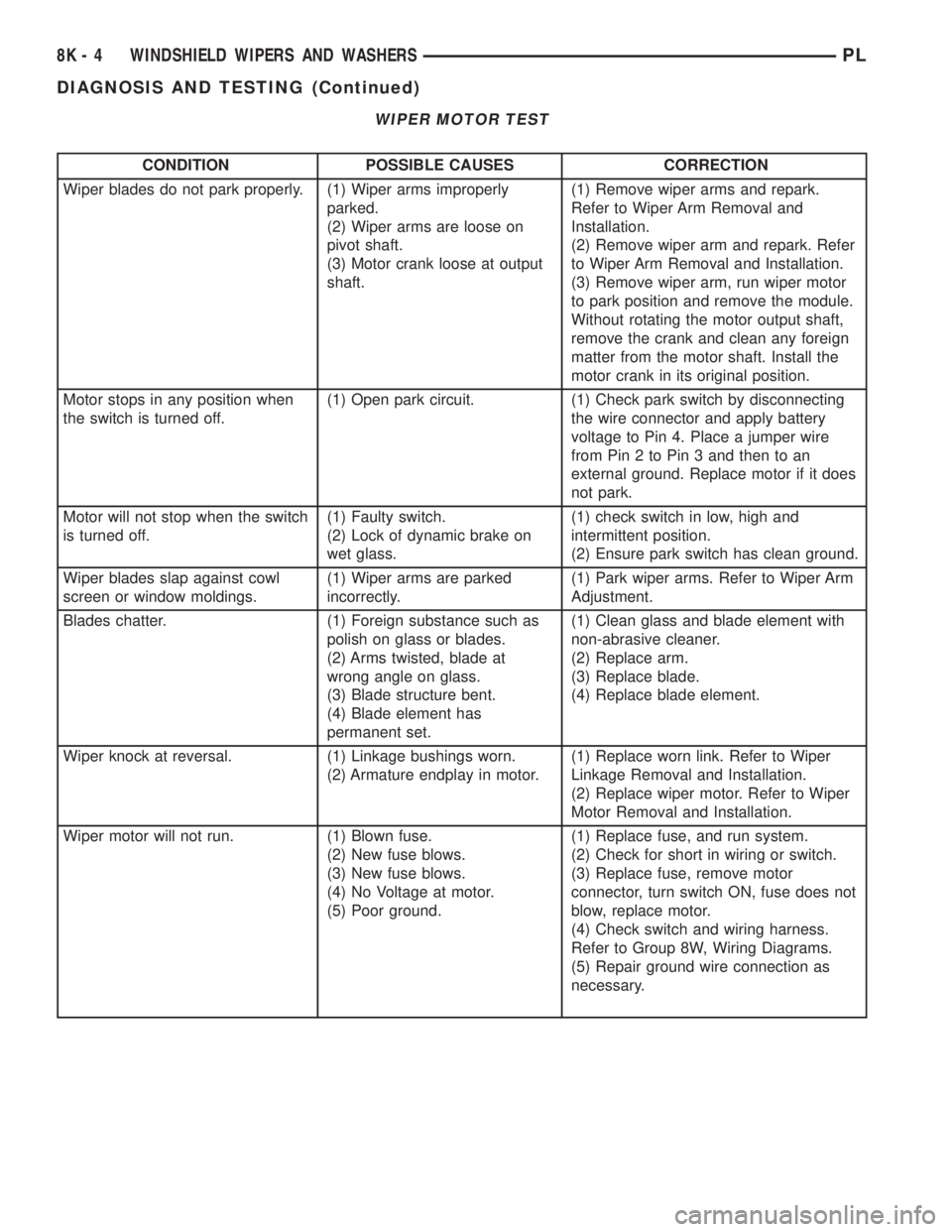

(3) Check motor low speed. Using two jumper

wires, connect one jumper wire between the battery

positive terminal and terminal 2 of the motor connec-

tor. Connect the other jumper wire to the battery

negative terminal and the motor ground strap. Refer

to Wiper Motor Connector Pinout table and (Fig. 2).

Check motor high speed, connect the positive jumper

wire to terminal 1 of the motor connector. Connect

the negative jumper wire to the motor ground strap.

(a) If motor does not run, high or low speed go to

Step 4.

(b) If motor runs, go to Step 5.(4) Using an ohmmeter, check for good ground at

the motor ground strap. If OK, replace motor. If not

repair the ground circuit as necessary.

(5) Check terminal E of wiper switch connector for

continuity to ground. If OK, go to Step 6. If not OK,

repair the ground circuit as necessary.

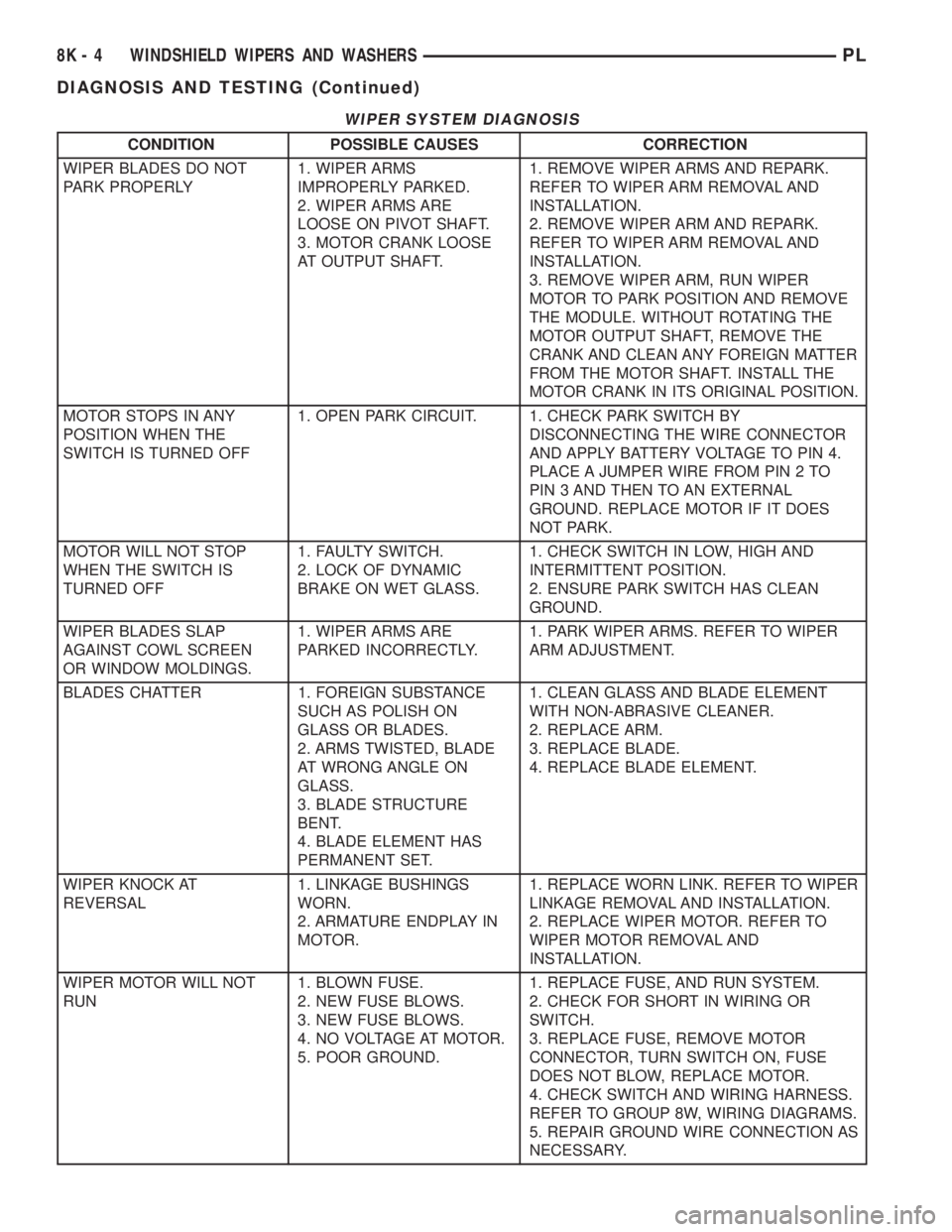

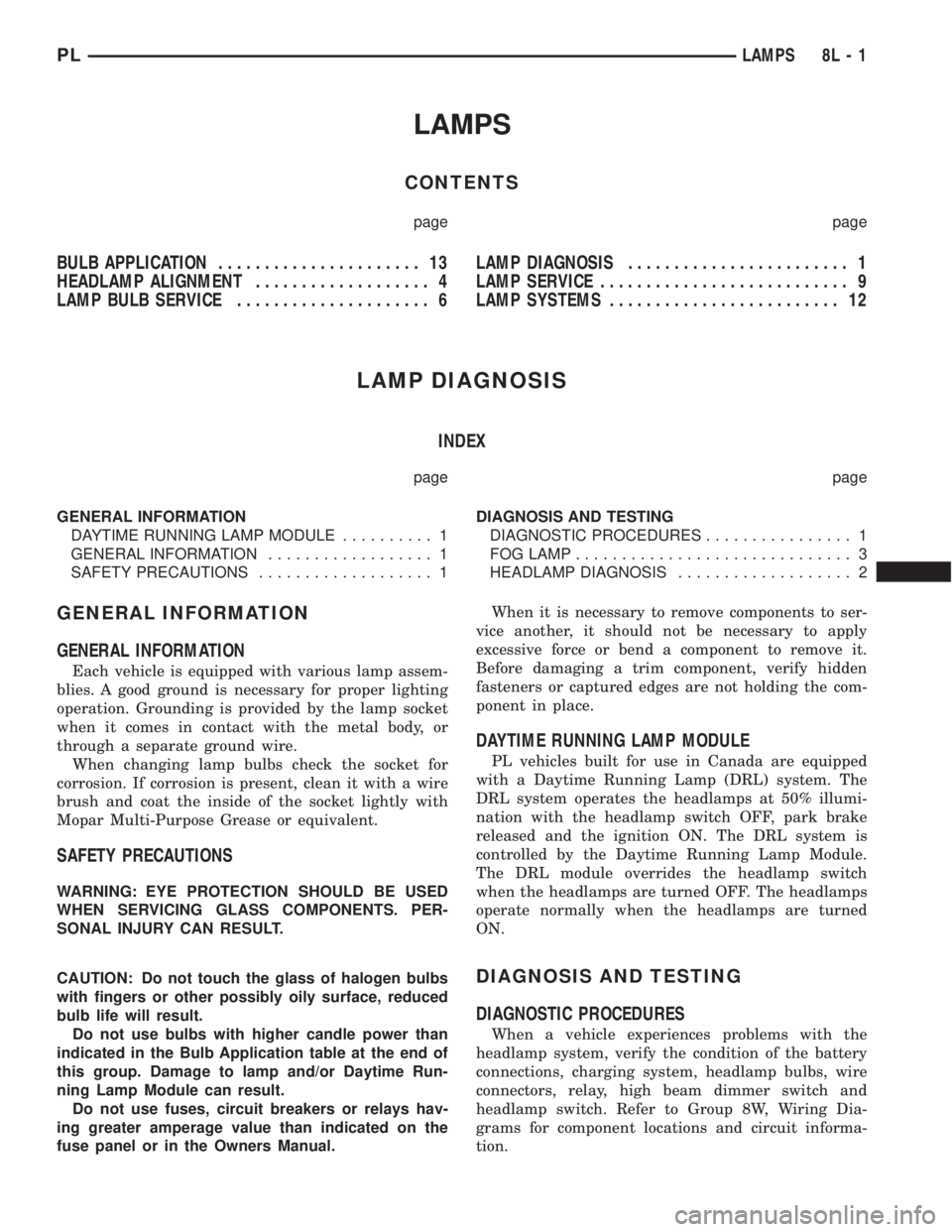

(6) Using a voltmeter, with wiper switch con-

nected, connect negative lead to motor ground strap.

Connect the positive lead to terminal P1 of the wiper

switch connector (Fig. 3) and (Fig. 5).

(a) If no voltage, repair wiring as necessary. If

OK, go to Step 2.

(b) Check wiper switch low speed, connect volt-

meter positive lead to terminal L of the wiper

switch connector. Move wiper stalk to LOW posi-

tion. If no voltage, replace switch.

(c) Check wiper switch high speed, connect volt-

meter positive lead to terminal H of the wiper

switch connector. Move wiper stalk to HIGH posi-

tion. If no voltage, replace switch.

(7) Disconnect motor connector and replace fuse 15

in fuse block.

(a) If fuse does not blow, replace motor.

Fig. 1 Fuse Block

WIPER MOTOR CONNECTOR PINOUT

CAVITY FUNCTION

1 WIPER SWITCH HIGH SPEED

OUTPUT

2 SIPER SWITCH LOW SPEED

OUTPUT

3 WIPER RELAY COMMON

4 FUSED IGNITION SWITCH OUTPUT

(RUN/ACC.)

Fig. 2 Windshield Wiper Motor Connector

8K - 2 WINDSHIELD WIPERS AND WASHERSPL

Page 316 of 1200

(b) If fuse blows, disconnect wiper switch and

replace fuse.

(c) If fuse does not blow, replace switch.

(d) If fuse blows, repair wiring as necessary.

MOTOR OPERATES SLOWLY AT ALL SPEEDS

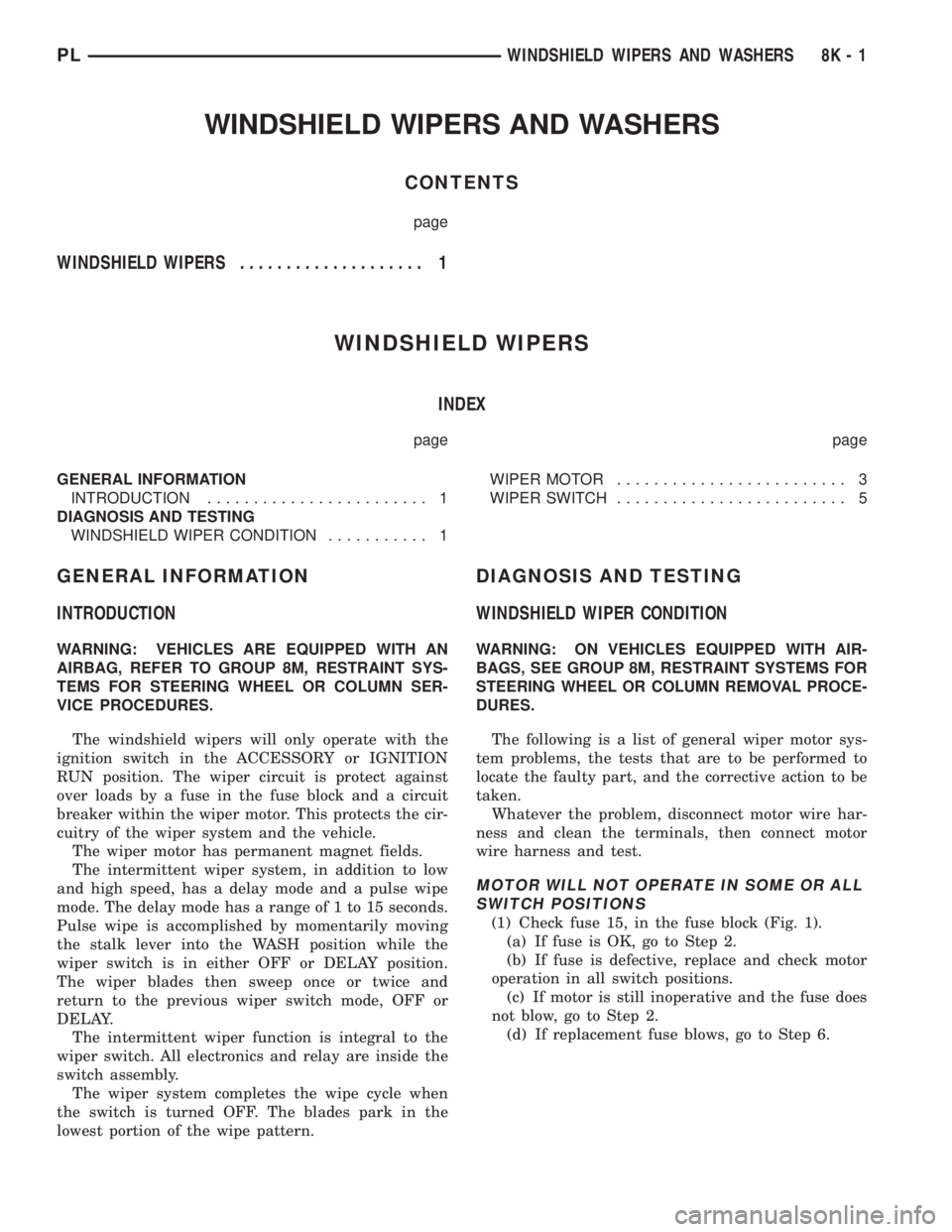

(1) Remove wiper arms and cowl screen. Discon-

nect motor linkage from motor. Connect an ammeter

between battery positive terminal and terminal 4 of

the motor connector (Fig. 4). Turn wiper motor on

and check ampere reading.

If motor runs and ammeter reading is more than 6

amps, go to Step 2. If less than 6 amps, go to Step 3.

When replacing drive link nut tighten to 11 to 12

N´m (98 to 106 in. lbs.) torque.(2) Using an ohmmeter, check the high and low

circuits for a short to ground. Refer to Group 8W,

Wiring Diagrams.

(3) Check to see if wiper linkage or pivots are

binding or caught.

WIPERS RUN AT HIGH SPEED WITH SWITCH

IN LOW SPEED POSITION OR WIPERS RUN AT

LOW SPEED WITH SWITCH IN HIGH SPEED

POSITION.

(1) Check for crossed wires in the motor pigtail

wire connector. Refer to Group 8W, Wiring Diagrams.

(2) Check for crossed wires in harness connector

from wiper switch to motor.

(3) If OK, replace wiper switch.

WIPERS WILL OPERATE CONTINUOUSLY

WITH SWITCH IN THE INTERMITTENT

POSITIONÐWHEN WIPER SWITCH IS TURNED

OFF, WIPERS STOP WHEREVER THEY ARE,

WITHOUT RETURNING TO PARK POSITION.

(1) Check at motor ground strap for a good ground.

(2) Turn ignition switch OFF. Using an ohmmeter,

with the motor in the park position, check for conti-

nuity between terminal 3 and ground strap. If conti-

nuity, replace wiper switch. If no continuity, repair

wiring as necessary.

WIPERS DO NOT OPERATE WHEN WASHER

MOTOR IS ENGAGED (PULSE WIPE) OR

WIPERS DO OPERATE IN INTERMITTENT

POSITION.

Check for a good ground at motor ground strap and

at wiper switch terminal E. If OK, replace wiper

switch. If not OK, repair wiring as necessary.

WIPER MOTOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

Whenever a wiper motor malfunction occurs, verify

that the wire harness is properly connected start nor-

mal diagnosis and repair procedures. Refer to Wiper

System Diagnosis.

Fig. 3 Wiper Switch and Terminals

Fig. 4 Ammeter Test

PLWINDSHIELD WIPERS AND WASHERS 8K - 3

DIAGNOSIS AND TESTING (Continued)

Page 317 of 1200

WIPER SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

WIPER BLADES DO NOT

PARK PROPERLY1. WIPER ARMS

IMPROPERLY PARKED.

2. WIPER ARMS ARE

LOOSE ON PIVOT SHAFT.

3. MOTOR CRANK LOOSE

AT OUTPUT SHAFT.1. REMOVE WIPER ARMS AND REPARK.

REFER TO WIPER ARM REMOVAL AND

INSTALLATION.

2. REMOVE WIPER ARM AND REPARK.

REFER TO WIPER ARM REMOVAL AND

INSTALLATION.

3. REMOVE WIPER ARM, RUN WIPER

MOTOR TO PARK POSITION AND REMOVE

THE MODULE. WITHOUT ROTATING THE

MOTOR OUTPUT SHAFT, REMOVE THE

CRANK AND CLEAN ANY FOREIGN MATTER

FROM THE MOTOR SHAFT. INSTALL THE

MOTOR CRANK IN ITS ORIGINAL POSITION.

MOTOR STOPS IN ANY

POSITION WHEN THE

SWITCH IS TURNED OFF1. OPEN PARK CIRCUIT. 1. CHECK PARK SWITCH BY

DISCONNECTING THE WIRE CONNECTOR

AND APPLY BATTERY VOLTAGE TO PIN 4.

PLACE A JUMPER WIRE FROM PIN 2 TO

PIN 3 AND THEN TO AN EXTERNAL

GROUND. REPLACE MOTOR IF IT DOES

NOT PARK.

MOTOR WILL NOT STOP

WHEN THE SWITCH IS

TURNED OFF1. FAULTY SWITCH.

2. LOCK OF DYNAMIC

BRAKE ON WET GLASS.1. CHECK SWITCH IN LOW, HIGH AND

INTERMITTENT POSITION.

2. ENSURE PARK SWITCH HAS CLEAN

GROUND.

WIPER BLADES SLAP

AGAINST COWL SCREEN

OR WINDOW MOLDINGS.1. WIPER ARMS ARE

PARKED INCORRECTLY.1. PARK WIPER ARMS. REFER TO WIPER

ARM ADJUSTMENT.

BLADES CHATTER 1. FOREIGN SUBSTANCE

SUCH AS POLISH ON

GLASS OR BLADES.

2. ARMS TWISTED, BLADE

AT WRONG ANGLE ON

GLASS.

3. BLADE STRUCTURE

BENT.

4. BLADE ELEMENT HAS

PERMANENT SET.1. CLEAN GLASS AND BLADE ELEMENT

WITH NON-ABRASIVE CLEANER.

2. REPLACE ARM.

3. REPLACE BLADE.

4. REPLACE BLADE ELEMENT.

WIPER KNOCK AT

REVERSAL1. LINKAGE BUSHINGS

WORN.

2. ARMATURE ENDPLAY IN

MOTOR.1. REPLACE WORN LINK. REFER TO WIPER

LINKAGE REMOVAL AND INSTALLATION.

2. REPLACE WIPER MOTOR. REFER TO

WIPER MOTOR REMOVAL AND

INSTALLATION.

WIPER MOTOR WILL NOT

RUN1. BLOWN FUSE.

2. NEW FUSE BLOWS.

3. NEW FUSE BLOWS.

4. NO VOLTAGE AT MOTOR.

5. POOR GROUND.1. REPLACE FUSE, AND RUN SYSTEM.

2. CHECK FOR SHORT IN WIRING OR

SWITCH.

3. REPLACE FUSE, REMOVE MOTOR

CONNECTOR, TURN SWITCH ON, FUSE

DOES NOT BLOW, REPLACE MOTOR.

4. CHECK SWITCH AND WIRING HARNESS.

REFER TO GROUP 8W, WIRING DIAGRAMS.

5. REPAIR GROUND WIRE CONNECTION AS

NECESSARY.

8K - 4 WINDSHIELD WIPERS AND WASHERSPL

DIAGNOSIS AND TESTING (Continued)

Page 324 of 1200

WINDSHIELD WIPERS AND WASHERS

CONTENTS

page

WINDSHIELD WIPERS.................... 1

WINDSHIELD WIPERS

INDEX

page page

GENERAL INFORMATION

INTRODUCTION........................ 1

DIAGNOSIS AND TESTING

WINDSHIELD WIPER CONDITION........... 1WIPER MOTOR......................... 3

WIPER SWITCH......................... 5

GENERAL INFORMATION

INTRODUCTION

WARNING: VEHICLES ARE EQUIPPED WITH AN

AIRBAG, REFER TO GROUP 8M, RESTRAINT SYS-

TEMS FOR STEERING WHEEL OR COLUMN SER-

VICE PROCEDURES.

The windshield wipers will only operate with the

ignition switch in the ACCESSORY or IGNITION

RUN position. The wiper circuit is protect against

over loads by a fuse in the fuse block and a circuit

breaker within the wiper motor. This protects the cir-

cuitry of the wiper system and the vehicle.

The wiper motor has permanent magnet fields.

The intermittent wiper system, in addition to low

and high speed, has a delay mode and a pulse wipe

mode. The delay mode has a range of 1 to 15 seconds.

Pulse wipe is accomplished by momentarily moving

the stalk lever into the WASH position while the

wiper switch is in either OFF or DELAY position.

The wiper blades then sweep once or twice and

return to the previous wiper switch mode, OFF or

DELAY.

The intermittent wiper function is integral to the

wiper switch. All electronics and relay are inside the

switch assembly.

The wiper system completes the wipe cycle when

the switch is turned OFF. The blades park in the

lowest portion of the wipe pattern.

DIAGNOSIS AND TESTING

WINDSHIELD WIPER CONDITION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

The following is a list of general wiper motor sys-

tem problems, the tests that are to be performed to

locate the faulty part, and the corrective action to be

taken.

Whatever the problem, disconnect motor wire har-

ness and clean the terminals, then connect motor

wire harness and test.

MOTOR WILL NOT OPERATE IN SOME OR ALL

SWITCH POSITIONS

(1) Check fuse 15, in the fuse block (Fig. 1).

(a) If fuse is OK, go to Step 2.

(b) If fuse is defective, replace and check motor

operation in all switch positions.

(c) If motor is still inoperative and the fuse does

not blow, go to Step 2.

(d) If replacement fuse blows, go to Step 6.

PLWINDSHIELD WIPERS AND WASHERS 8K - 1

Page 325 of 1200

(2) Disconnect motor wire connector.

(3) Check motor low speed. Using two jumper

wires, connect one jumper wire between the battery

positive terminal and terminal 2 of the motor connec-

tor. Connect the other jumper wire to the battery

negative terminal and the motor ground strap (Fig.

2). Check motor high speed, connect the positive

jumper wire to terminal 1 of the motor connector.

Connect the negative jumper wire to the motor

ground strap.

(a) If motor does not run, high or low speed go to

Step 4.

(b) If motor runs, go to Step 5.

(4) Using an ohmmeter, check for good ground at

the motor ground strap. If OK, replace motor. If not

repair the ground circuit as necessary.

(5) Check terminal E of wiper switch connector for

continuity to ground. If OK, go to Step 6. If not OK,

repair the ground circuit as necessary.

(6) Using a voltmeter, with wiper switch con-

nected, connect negative lead to motor ground strap.

Connect the positive lead to terminal P1 of the wiper

switch connector (Fig. 3) and (Fig. 5).

(a) If no voltage, repair wiring as necessary. If

OK, go to Step 2.(b) Check wiper switch low speed, connect volt-

meter positive lead to terminal L of the wiper

switch connector. Move wiper stalk to LOW posi-

tion. If no voltage, replace switch.

(c) Check wiper switch high speed, connect volt-

meter positive lead to terminal H of the wiper

switch connector. Move wiper stalk to HIGH posi-

tion. If no voltage, replace switch.

(7) Disconnect motor connector and replace fuse 15

in fuse block.

(a) If fuse does not blow, replace motor.

(b) If fuse blows, disconnect wiper switch and

replace fuse.

(c) If fuse does not blow, replace switch.

(d) If fuse blows, repair wiring as necessary.

MOTOR OPERATES SLOWLY AT ALL SPEEDS

(1) Remove wiper arms and cowl screen. Discon-

nect motor linkage from motor. Connect an ammeter

between battery positive terminal and terminal 4 of

the motor connector (Fig. 4). Turn wiper motor on

and check ampere reading.

If motor runs and ammeter reading is more than 6

amps, go to Step 2. If less than 6 amps, go to Step 3.

When replacing drive link nut tighten to 11 to 12

N´m (98 to 106 in. lbs.) torque.

Fig. 1 Fuse Block

Fig. 2 Motor Connector

Fig. 3 Wiper Switch and Terminals

8K - 2 WINDSHIELD WIPERS AND WASHERSPL

DIAGNOSIS AND TESTING (Continued)

Page 327 of 1200

WIPER MOTOR TEST

CONDITION POSSIBLE CAUSES CORRECTION

Wiper blades do not park properly. (1) Wiper arms improperly

parked.

(2) Wiper arms are loose on

pivot shaft.

(3) Motor crank loose at output

shaft.(1) Remove wiper arms and repark.

Refer to Wiper Arm Removal and

Installation.

(2) Remove wiper arm and repark. Refer

to Wiper Arm Removal and Installation.

(3) Remove wiper arm, run wiper motor

to park position and remove the module.

Without rotating the motor output shaft,

remove the crank and clean any foreign

matter from the motor shaft. Install the

motor crank in its original position.

Motor stops in any position when

the switch is turned off.(1) Open park circuit. (1) Check park switch by disconnecting

the wire connector and apply battery

voltage to Pin 4. Place a jumper wire

from Pin 2 to Pin 3 and then to an

external ground. Replace motor if it does

not park.

Motor will not stop when the switch

is turned off.(1) Faulty switch.

(2) Lock of dynamic brake on

wet glass.(1) check switch in low, high and

intermittent position.

(2) Ensure park switch has clean ground.

Wiper blades slap against cowl

screen or window moldings.(1) Wiper arms are parked

incorrectly.(1) Park wiper arms. Refer to Wiper Arm

Adjustment.

Blades chatter. (1) Foreign substance such as

polish on glass or blades.

(2) Arms twisted, blade at

wrong angle on glass.

(3) Blade structure bent.

(4) Blade element has

permanent set.(1) Clean glass and blade element with

non-abrasive cleaner.

(2) Replace arm.

(3) Replace blade.

(4) Replace blade element.

Wiper knock at reversal. (1) Linkage bushings worn.

(2) Armature endplay in motor.(1) Replace worn link. Refer to Wiper

Linkage Removal and Installation.

(2) Replace wiper motor. Refer to Wiper

Motor Removal and Installation.

Wiper motor will not run. (1) Blown fuse.

(2) New fuse blows.

(3) New fuse blows.

(4) No Voltage at motor.

(5) Poor ground.(1) Replace fuse, and run system.

(2) Check for short in wiring or switch.

(3) Replace fuse, remove motor

connector, turn switch ON, fuse does not

blow, replace motor.

(4) Check switch and wiring harness.

Refer to Group 8W, Wiring Diagrams.

(5) Repair ground wire connection as

necessary.

8K - 4 WINDSHIELD WIPERS AND WASHERSPL

DIAGNOSIS AND TESTING (Continued)

Page 330 of 1200

LAMPS

CONTENTS

page page

BULB APPLICATION...................... 13

HEADLAMP ALIGNMENT................... 4

LAMP BULB SERVICE..................... 6LAMP DIAGNOSIS........................ 1

LAMP SERVICE........................... 9

LAMP SYSTEMS......................... 12

LAMP DIAGNOSIS

INDEX

page page

GENERAL INFORMATION

DAYTIME RUNNING LAMP MODULE.......... 1

GENERAL INFORMATION.................. 1

SAFETY PRECAUTIONS................... 1DIAGNOSIS AND TESTING

DIAGNOSTIC PROCEDURES................ 1

FOG LAMP.............................. 3

HEADLAMP DIAGNOSIS................... 2

GENERAL INFORMATION

GENERAL INFORMATION

Each vehicle is equipped with various lamp assem-

blies. A good ground is necessary for proper lighting

operation. Grounding is provided by the lamp socket

when it comes in contact with the metal body, or

through a separate ground wire.

When changing lamp bulbs check the socket for

corrosion. If corrosion is present, clean it with a wire

brush and coat the inside of the socket lightly with

Mopar Multi-Purpose Grease or equivalent.

SAFETY PRECAUTIONS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result.

Do not use bulbs with higher candle power than

indicated in the Bulb Application table at the end of

this group. Damage to lamp and/or Daytime Run-

ning Lamp Module can result.

Do not use fuses, circuit breakers or relays hav-

ing greater amperage value than indicated on the

fuse panel or in the Owners Manual.When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges are not holding the com-

ponent in place.

DAYTIME RUNNING LAMP MODULE

PL vehicles built for use in Canada are equipped

with a Daytime Running Lamp (DRL) system. The

DRL system operates the headlamps at 50% illumi-

nation with the headlamp switch OFF, park brake

released and the ignition ON. The DRL system is

controlled by the Daytime Running Lamp Module.

The DRL module overrides the headlamp switch

when the headlamps are turned OFF. The headlamps

operate normally when the headlamps are turned

ON.

DIAGNOSIS AND TESTING

DIAGNOSTIC PROCEDURES

When a vehicle experiences problems with the

headlamp system, verify the condition of the battery

connections, charging system, headlamp bulbs, wire

connectors, relay, high beam dimmer switch and

headlamp switch. Refer to Group 8W, Wiring Dia-

grams for component locations and circuit informa-

tion.

PLLAMPS 8L - 1

Page 331 of 1200

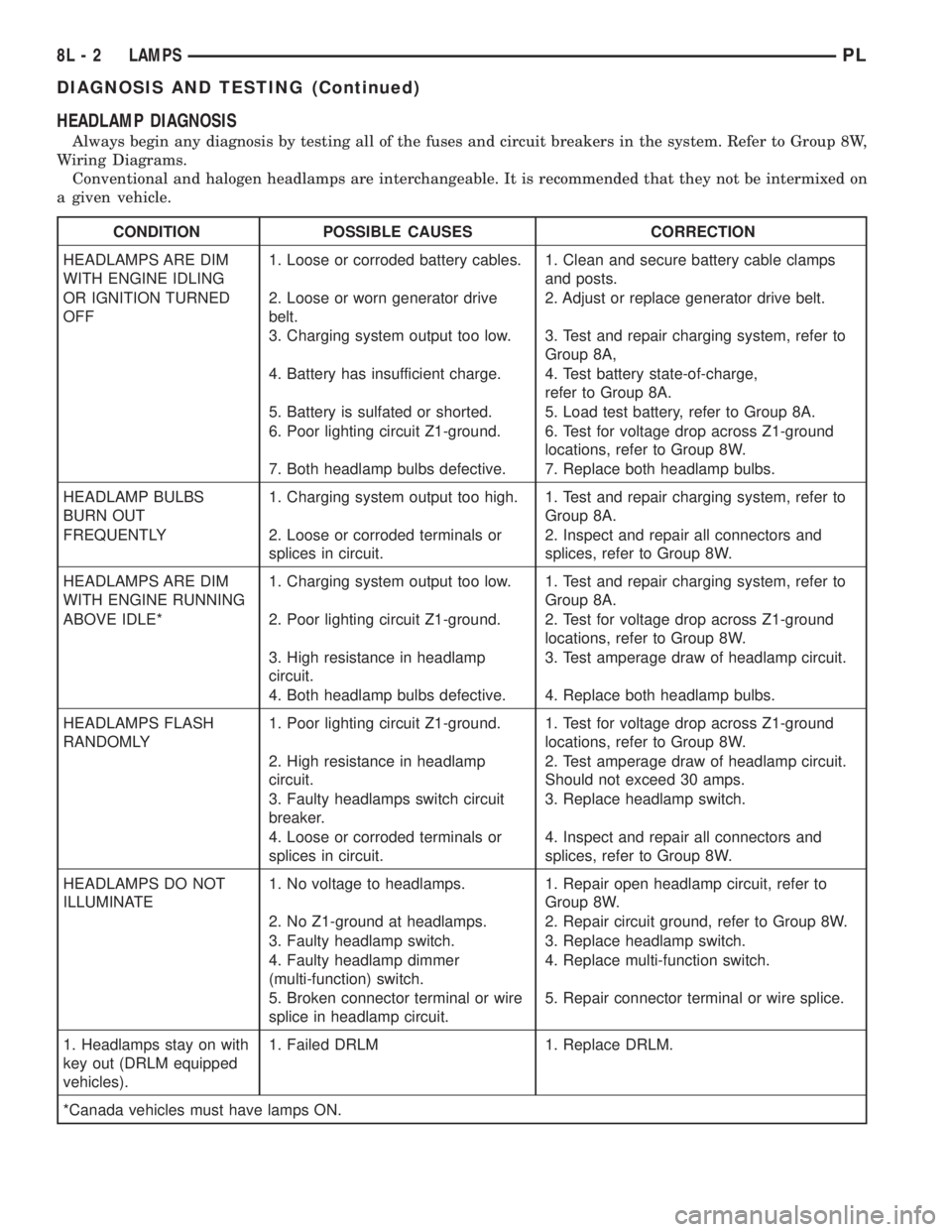

HEADLAMP DIAGNOSIS

Always begin any diagnosis by testing all of the fuses and circuit breakers in the system. Refer to Group 8W,

Wiring Diagrams.

Conventional and halogen headlamps are interchangeable. It is recommended that they not be intermixed on

a given vehicle.

CONDITION POSSIBLE CAUSES CORRECTION

HEADLAMPS ARE DIM

WITH ENGINE IDLING1. Loose or corroded battery cables. 1. Clean and secure battery cable clamps

and posts.

OR IGNITION TURNED

OFF2. Loose or worn generator drive

belt.2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system, refer to

Group 8A,

4. Battery has insufficient charge. 4. Test battery state-of-charge,

refer to Group 8A.

5. Battery is sulfated or shorted. 5. Load test battery, refer to Group 8A.

6. Poor lighting circuit Z1-ground. 6. Test for voltage drop across Z1-ground

locations, refer to Group 8W.

7. Both headlamp bulbs defective. 7. Replace both headlamp bulbs.

HEADLAMP BULBS

BURN OUT1. Charging system output too high. 1. Test and repair charging system, refer to

Group 8A.

FREQUENTLY 2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors and

splices, refer to Group 8W.

HEADLAMPS ARE DIM

WITH ENGINE RUNNING1. Charging system output too low. 1. Test and repair charging system, refer to

Group 8A.

ABOVE IDLE* 2. Poor lighting circuit Z1-ground. 2. Test for voltage drop across Z1-ground

locations, refer to Group 8W.

3. High resistance in headlamp

circuit.3. Test amperage draw of headlamp circuit.

4. Both headlamp bulbs defective. 4. Replace both headlamp bulbs.

HEADLAMPS FLASH

RANDOMLY1. Poor lighting circuit Z1-ground. 1. Test for voltage drop across Z1-ground

locations, refer to Group 8W.

2. High resistance in headlamp

circuit.2. Test amperage draw of headlamp circuit.

Should not exceed 30 amps.

3. Faulty headlamps switch circuit

breaker.3. Replace headlamp switch.

4. Loose or corroded terminals or

splices in circuit.4. Inspect and repair all connectors and

splices, refer to Group 8W.

HEADLAMPS DO NOT

ILLUMINATE1. No voltage to headlamps. 1. Repair open headlamp circuit, refer to

Group 8W.

2. No Z1-ground at headlamps. 2. Repair circuit ground, refer to Group 8W.

3. Faulty headlamp switch. 3. Replace headlamp switch.

4. Faulty headlamp dimmer

(multi-function) switch.4. Replace multi-function switch.

5. Broken connector terminal or wire

splice in headlamp circuit.5. Repair connector terminal or wire splice.

1. Headlamps stay on with

key out (DRLM equipped

vehicles).1. Failed DRLM 1. Replace DRLM.

*Canada vehicles must have lamps ON.

8L - 2 LAMPSPL

DIAGNOSIS AND TESTING (Continued)

Page 332 of 1200

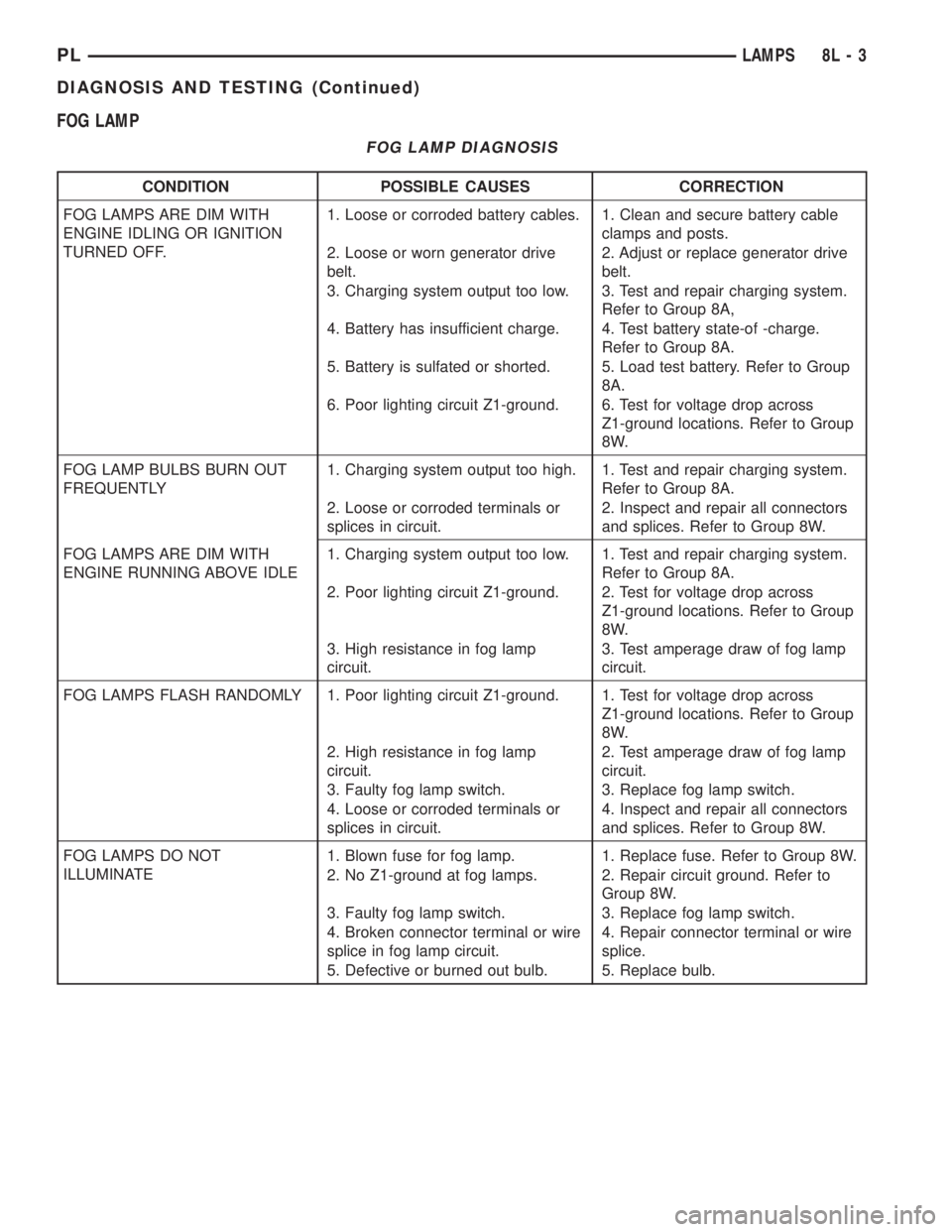

FOG LAMP

FOG LAMP DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

FOG LAMPS ARE DIM WITH

ENGINE IDLING OR IGNITION

TURNED OFF.1. Loose or corroded battery cables. 1. Clean and secure battery cable

clamps and posts.

2. Loose or worn generator drive

belt.2. Adjust or replace generator drive

belt.

3. Charging system output too low. 3. Test and repair charging system.

Refer to Group 8A,

4. Battery has insufficient charge. 4. Test battery state-of -charge.

Refer to Group 8A.

5. Battery is sulfated or shorted. 5. Load test battery. Refer to Group

8A.

6. Poor lighting circuit Z1-ground. 6. Test for voltage drop across

Z1-ground locations. Refer to Group

8W.

FOG LAMP BULBS BURN OUT

FREQUENTLY1. Charging system output too high. 1. Test and repair charging system.

Refer to Group 8A.

2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors

and splices. Refer to Group 8W.

FOG LAMPS ARE DIM WITH

ENGINE RUNNING ABOVE IDLE1. Charging system output too low. 1. Test and repair charging system.

Refer to Group 8A.

2. Poor lighting circuit Z1-ground. 2. Test for voltage drop across

Z1-ground locations. Refer to Group

8W.

3. High resistance in fog lamp

circuit.3. Test amperage draw of fog lamp

circuit.

FOG LAMPS FLASH RANDOMLY 1. Poor lighting circuit Z1-ground. 1. Test for voltage drop across

Z1-ground locations. Refer to Group

8W.

2. High resistance in fog lamp

circuit.2. Test amperage draw of fog lamp

circuit.

3. Faulty fog lamp switch. 3. Replace fog lamp switch.

4. Loose or corroded terminals or

splices in circuit.4. Inspect and repair all connectors

and splices. Refer to Group 8W.

FOG LAMPS DO NOT

ILLUMINATE1. Blown fuse for fog lamp. 1. Replace fuse. Refer to Group 8W.

2. No Z1-ground at fog lamps. 2. Repair circuit ground. Refer to

Group 8W.

3. Faulty fog lamp switch. 3. Replace fog lamp switch.

4. Broken connector terminal or wire

splice in fog lamp circuit.4. Repair connector terminal or wire

splice.

5. Defective or burned out bulb. 5. Replace bulb.

PLLAMPS 8L - 3

DIAGNOSIS AND TESTING (Continued)

Page 364 of 1200

ELECTRICALLY HEATED SYSTEMS

CONTENTS

page page

DESCRIPTION AND OPERATION

INTRODUCTION......................... 1

REAR WINDOW DEFOGGER SWITCH........ 1

DIAGNOSIS AND TESTING

DEFOGGER SYSTEM..................... 1GRID LINES............................ 2

REAR WINDOW DEFOGGER SWITCH........ 2

SERVICE PROCEDURES

GRID LINE AND TERMINAL REPAIR......... 3

DESCRIPTION AND OPERATION

INTRODUCTION

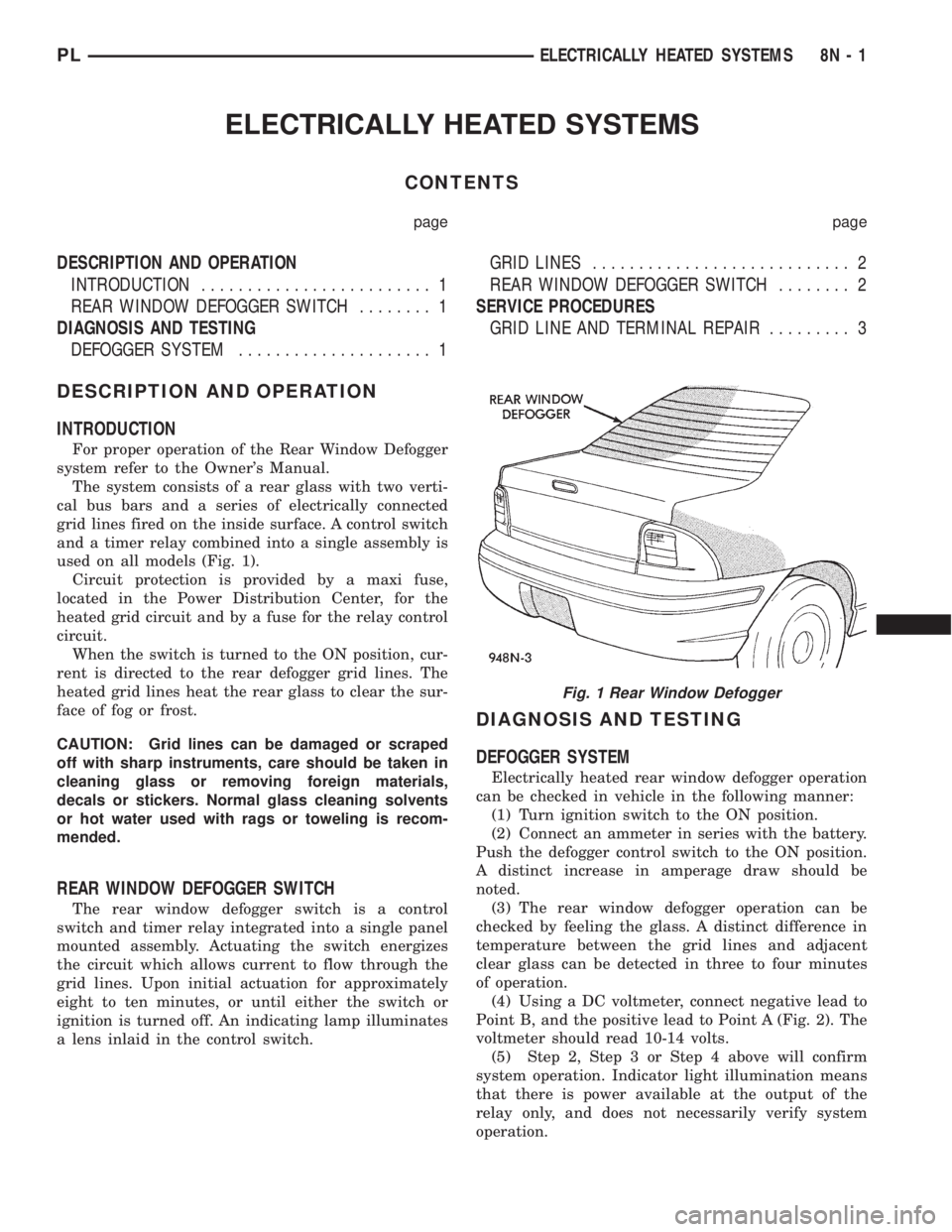

For proper operation of the Rear Window Defogger

system refer to the Owner's Manual.

The system consists of a rear glass with two verti-

cal bus bars and a series of electrically connected

grid lines fired on the inside surface. A control switch

and a timer relay combined into a single assembly is

used on all models (Fig. 1).

Circuit protection is provided by a maxi fuse,

located in the Power Distribution Center, for the

heated grid circuit and by a fuse for the relay control

circuit.

When the switch is turned to the ON position, cur-

rent is directed to the rear defogger grid lines. The

heated grid lines heat the rear glass to clear the sur-

face of fog or frost.

CAUTION: Grid lines can be damaged or scraped

off with sharp instruments, care should be taken in

cleaning glass or removing foreign materials,

decals or stickers. Normal glass cleaning solvents

or hot water used with rags or toweling is recom-

mended.

REAR WINDOW DEFOGGER SWITCH

The rear window defogger switch is a control

switch and timer relay integrated into a single panel

mounted assembly. Actuating the switch energizes

the circuit which allows current to flow through the

grid lines. Upon initial actuation for approximately

eight to ten minutes, or until either the switch or

ignition is turned off. An indicating lamp illuminates

a lens inlaid in the control switch.

DIAGNOSIS AND TESTING

DEFOGGER SYSTEM

Electrically heated rear window defogger operation

can be checked in vehicle in the following manner:

(1) Turn ignition switch to the ON position.

(2) Connect an ammeter in series with the battery.

Push the defogger control switch to the ON position.

A distinct increase in amperage draw should be

noted.

(3) The rear window defogger operation can be

checked by feeling the glass. A distinct difference in

temperature between the grid lines and adjacent

clear glass can be detected in three to four minutes

of operation.

(4) Using a DC voltmeter, connect negative lead to

Point B, and the positive lead to Point A (Fig. 2). The

voltmeter should read 10-14 volts.

(5) Step 2, Step 3 or Step 4 above will confirm

system operation. Indicator light illumination means

that there is power available at the output of the

relay only, and does not necessarily verify system

operation.

Fig. 1 Rear Window Defogger

PLELECTRICALLY HEATED SYSTEMS 8N - 1