fuse DODGE NEON 1999 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 365 of 1200

(6) If turning the switch ON produced no distinct

current draw on the ammeter the problem should be

isolated in the following manner:

(a) Confirm the ignition switch is ON.

(b) Ensure that the heated rear glass feed wire

is connected to the terminal or pigtail and that the

ground wire is in fact grounded.

(c) Ensure that the maxi-fuse and control circuit

fuse are OK and all electrical connections are

secure.

(7) When the above steps have been completed and

the system is still inoperative, one or more of the fol-

lowing is defective:

(a) Control switch/timer relay module.

(b) All rear window grid lines would have to be

broken or one of the feed wires are not connected

for the system to be inoperative.

(8) If turning the switch ON produces severe volt-

meter deflection, the circuit should be closely checked

for a shorting condition.

(9) If the system operation has been verified but

indicator lamp does not light, replace the switch.

(10) For detailed wiring information, refer to group

8W, Wiring Diagrams.

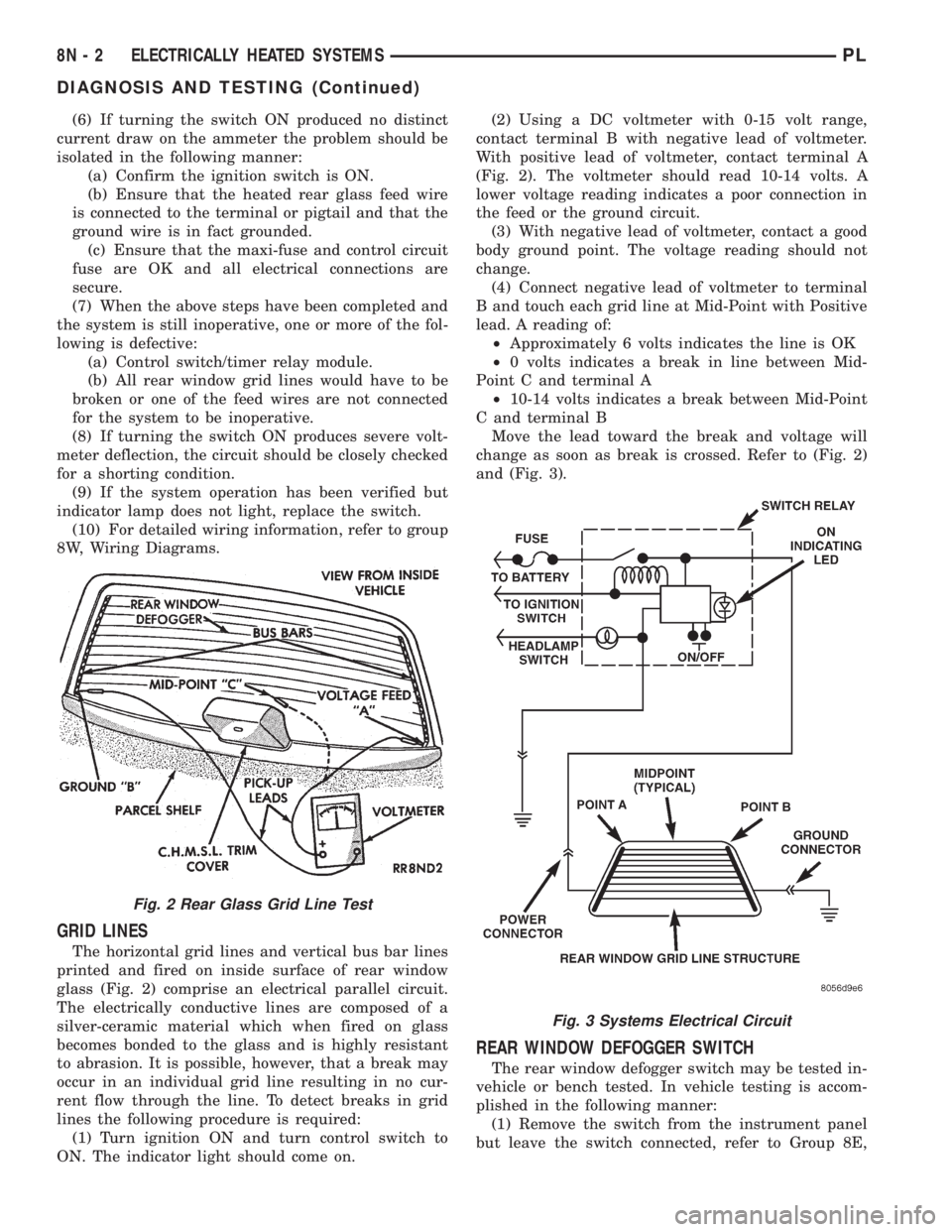

GRID LINES

The horizontal grid lines and vertical bus bar lines

printed and fired on inside surface of rear window

glass (Fig. 2) comprise an electrical parallel circuit.

The electrically conductive lines are composed of a

silver-ceramic material which when fired on glass

becomes bonded to the glass and is highly resistant

to abrasion. It is possible, however, that a break may

occur in an individual grid line resulting in no cur-

rent flow through the line. To detect breaks in grid

lines the following procedure is required:

(1) Turn ignition ON and turn control switch to

ON. The indicator light should come on.(2) Using a DC voltmeter with 0-15 volt range,

contact terminal B with negative lead of voltmeter.

With positive lead of voltmeter, contact terminal A

(Fig. 2). The voltmeter should read 10-14 volts. A

lower voltage reading indicates a poor connection in

the feed or the ground circuit.

(3) With negative lead of voltmeter, contact a good

body ground point. The voltage reading should not

change.

(4) Connect negative lead of voltmeter to terminal

B and touch each grid line at Mid-Point with Positive

lead. A reading of:

²Approximately 6 volts indicates the line is OK

²0 volts indicates a break in line between Mid-

Point C and terminal A

²10-14 volts indicates a break between Mid-Point

C and terminal B

Move the lead toward the break and voltage will

change as soon as break is crossed. Refer to (Fig. 2)

and (Fig. 3).

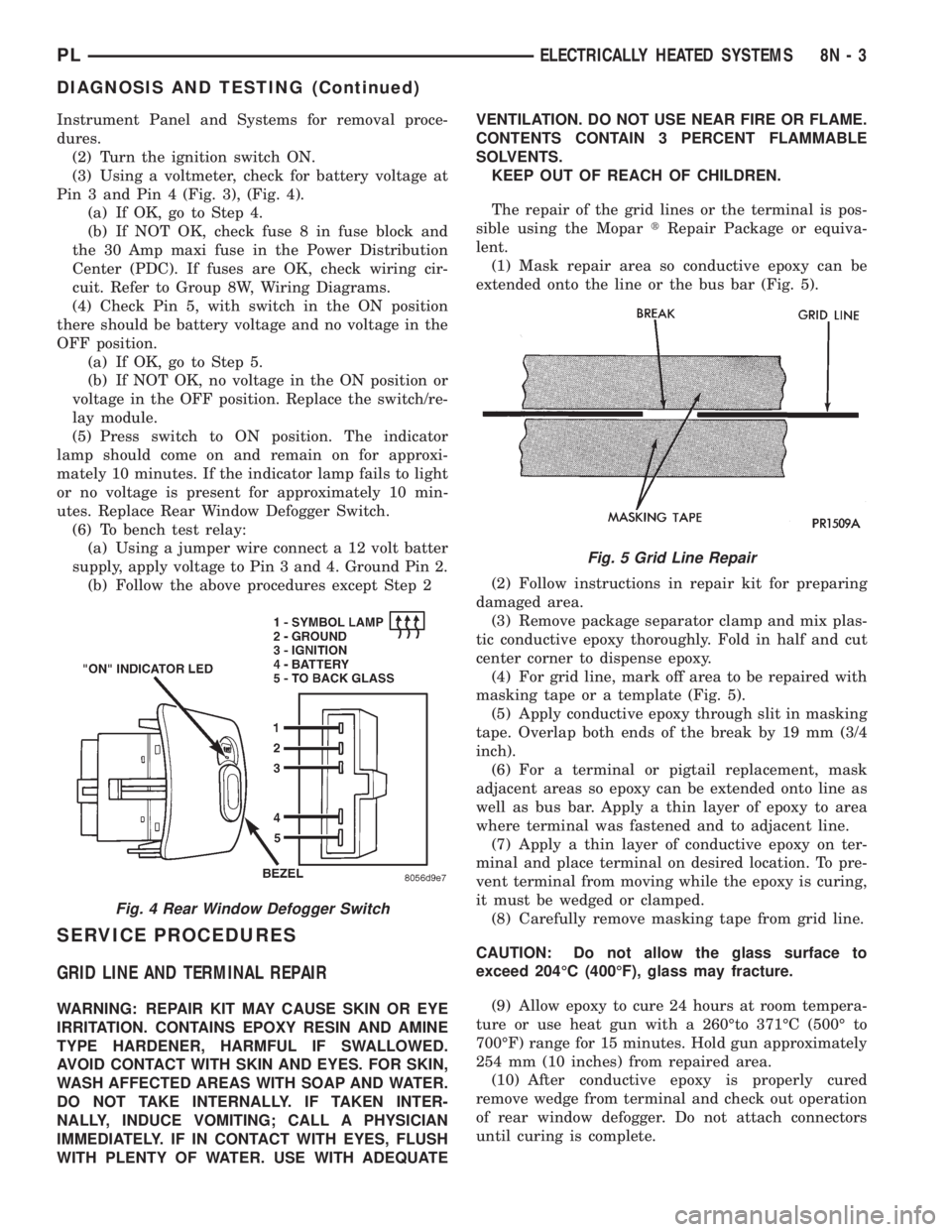

REAR WINDOW DEFOGGER SWITCH

The rear window defogger switch may be tested in-

vehicle or bench tested. In vehicle testing is accom-

plished in the following manner:

(1) Remove the switch from the instrument panel

but leave the switch connected, refer to Group 8E,

Fig. 2 Rear Glass Grid Line Test

Fig. 3 Systems Electrical Circuit

8N - 2 ELECTRICALLY HEATED SYSTEMSPL

DIAGNOSIS AND TESTING (Continued)

Page 366 of 1200

Instrument Panel and Systems for removal proce-

dures.

(2) Turn the ignition switch ON.

(3) Using a voltmeter, check for battery voltage at

Pin 3 and Pin 4 (Fig. 3), (Fig. 4).

(a) If OK, go to Step 4.

(b) If NOT OK, check fuse 8 in fuse block and

the 30 Amp maxi fuse in the Power Distribution

Center (PDC). If fuses are OK, check wiring cir-

cuit. Refer to Group 8W, Wiring Diagrams.

(4) Check Pin 5, with switch in the ON position

there should be battery voltage and no voltage in the

OFF position.

(a) If OK, go to Step 5.

(b) If NOT OK, no voltage in the ON position or

voltage in the OFF position. Replace the switch/re-

lay module.

(5) Press switch to ON position. The indicator

lamp should come on and remain on for approxi-

mately 10 minutes. If the indicator lamp fails to light

or no voltage is present for approximately 10 min-

utes. Replace Rear Window Defogger Switch.

(6) To bench test relay:

(a) Using a jumper wire connect a 12 volt batter

supply, apply voltage to Pin 3 and 4. Ground Pin 2.

(b) Follow the above procedures except Step 2

SERVICE PROCEDURES

GRID LINE AND TERMINAL REPAIR

WARNING: REPAIR KIT MAY CAUSE SKIN OR EYE

IRRITATION. CONTAINS EPOXY RESIN AND AMINE

TYPE HARDENER, HARMFUL IF SWALLOWED.

AVOID CONTACT WITH SKIN AND EYES. FOR SKIN,

WASH AFFECTED AREAS WITH SOAP AND WATER.

DO NOT TAKE INTERNALLY. IF TAKEN INTER-

NALLY, INDUCE VOMITING; CALL A PHYSICIAN

IMMEDIATELY. IF IN CONTACT WITH EYES, FLUSH

WITH PLENTY OF WATER. USE WITH ADEQUATEVENTILATION. DO NOT USE NEAR FIRE OR FLAME.

CONTENTS CONTAIN 3 PERCENT FLAMMABLE

SOLVENTS.

KEEP OUT OF REACH OF CHILDREN.

The repair of the grid lines or the terminal is pos-

sible using the MopartRepair Package or equiva-

lent.

(1) Mask repair area so conductive epoxy can be

extended onto the line or the bus bar (Fig. 5).

(2) Follow instructions in repair kit for preparing

damaged area.

(3) Remove package separator clamp and mix plas-

tic conductive epoxy thoroughly. Fold in half and cut

center corner to dispense epoxy.

(4) For grid line, mark off area to be repaired with

masking tape or a template (Fig. 5).

(5) Apply conductive epoxy through slit in masking

tape. Overlap both ends of the break by 19 mm (3/4

inch).

(6) For a terminal or pigtail replacement, mask

adjacent areas so epoxy can be extended onto line as

well as bus bar. Apply a thin layer of epoxy to area

where terminal was fastened and to adjacent line.

(7) Apply a thin layer of conductive epoxy on ter-

minal and place terminal on desired location. To pre-

vent terminal from moving while the epoxy is curing,

it must be wedged or clamped.

(8) Carefully remove masking tape from grid line.

CAUTION: Do not allow the glass surface to

exceed 204ÉC (400ÉF), glass may fracture.

(9) Allow epoxy to cure 24 hours at room tempera-

ture or use heat gun with a 260Éto 371ÉC (500É to

700ÉF) range for 15 minutes. Hold gun approximately

254 mm (10 inches) from repaired area.

(10) After conductive epoxy is properly cured

remove wedge from terminal and check out operation

of rear window defogger. Do not attach connectors

until curing is complete.

Fig. 4 Rear Window Defogger Switch

Fig. 5 Grid Line Repair

PLELECTRICALLY HEATED SYSTEMS 8N - 3

DIAGNOSIS AND TESTING (Continued)

Page 368 of 1200

ELECTRICALLY HEATED SYSTEMS

CONTENTS

page page

DIAGNOSIS AND TESTING

REAR WINDOW DEFOGGER SWITCH....... 1REMOVAL AND INSTALLATION

REAR WINDOW DEFOGGER AND/OR REAR

FOG LAMP SWITCH................... 2

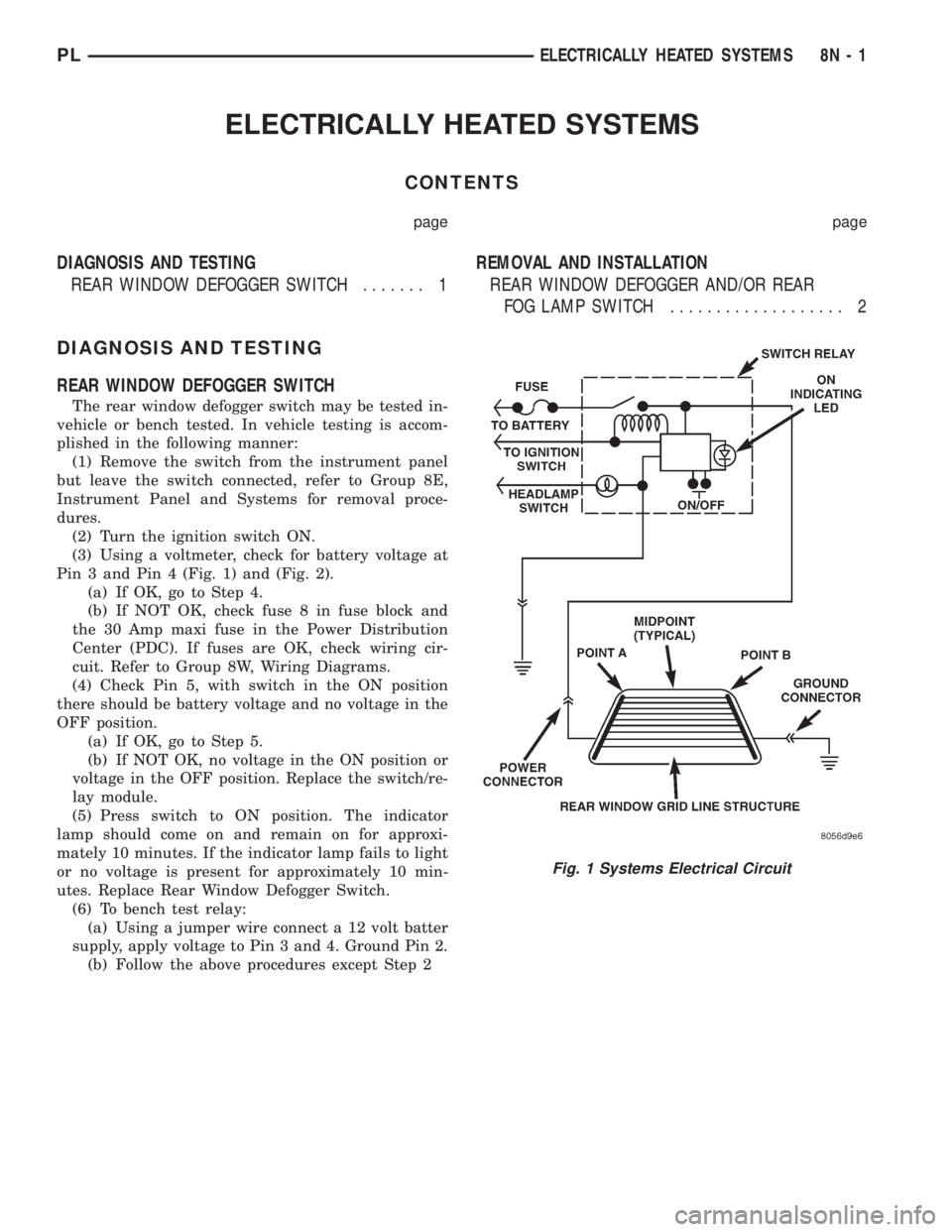

DIAGNOSIS AND TESTING

REAR WINDOW DEFOGGER SWITCH

The rear window defogger switch may be tested in-

vehicle or bench tested. In vehicle testing is accom-

plished in the following manner:

(1) Remove the switch from the instrument panel

but leave the switch connected, refer to Group 8E,

Instrument Panel and Systems for removal proce-

dures.

(2) Turn the ignition switch ON.

(3) Using a voltmeter, check for battery voltage at

Pin 3 and Pin 4 (Fig. 1) and (Fig. 2).

(a) If OK, go to Step 4.

(b) If NOT OK, check fuse 8 in fuse block and

the 30 Amp maxi fuse in the Power Distribution

Center (PDC). If fuses are OK, check wiring cir-

cuit. Refer to Group 8W, Wiring Diagrams.

(4) Check Pin 5, with switch in the ON position

there should be battery voltage and no voltage in the

OFF position.

(a) If OK, go to Step 5.

(b) If NOT OK, no voltage in the ON position or

voltage in the OFF position. Replace the switch/re-

lay module.

(5) Press switch to ON position. The indicator

lamp should come on and remain on for approxi-

mately 10 minutes. If the indicator lamp fails to light

or no voltage is present for approximately 10 min-

utes. Replace Rear Window Defogger Switch.

(6) To bench test relay:

(a) Using a jumper wire connect a 12 volt batter

supply, apply voltage to Pin 3 and 4. Ground Pin 2.

(b) Follow the above procedures except Step 2

Fig. 1 Systems Electrical Circuit

PLELECTRICALLY HEATED SYSTEMS 8N - 1

Page 371 of 1200

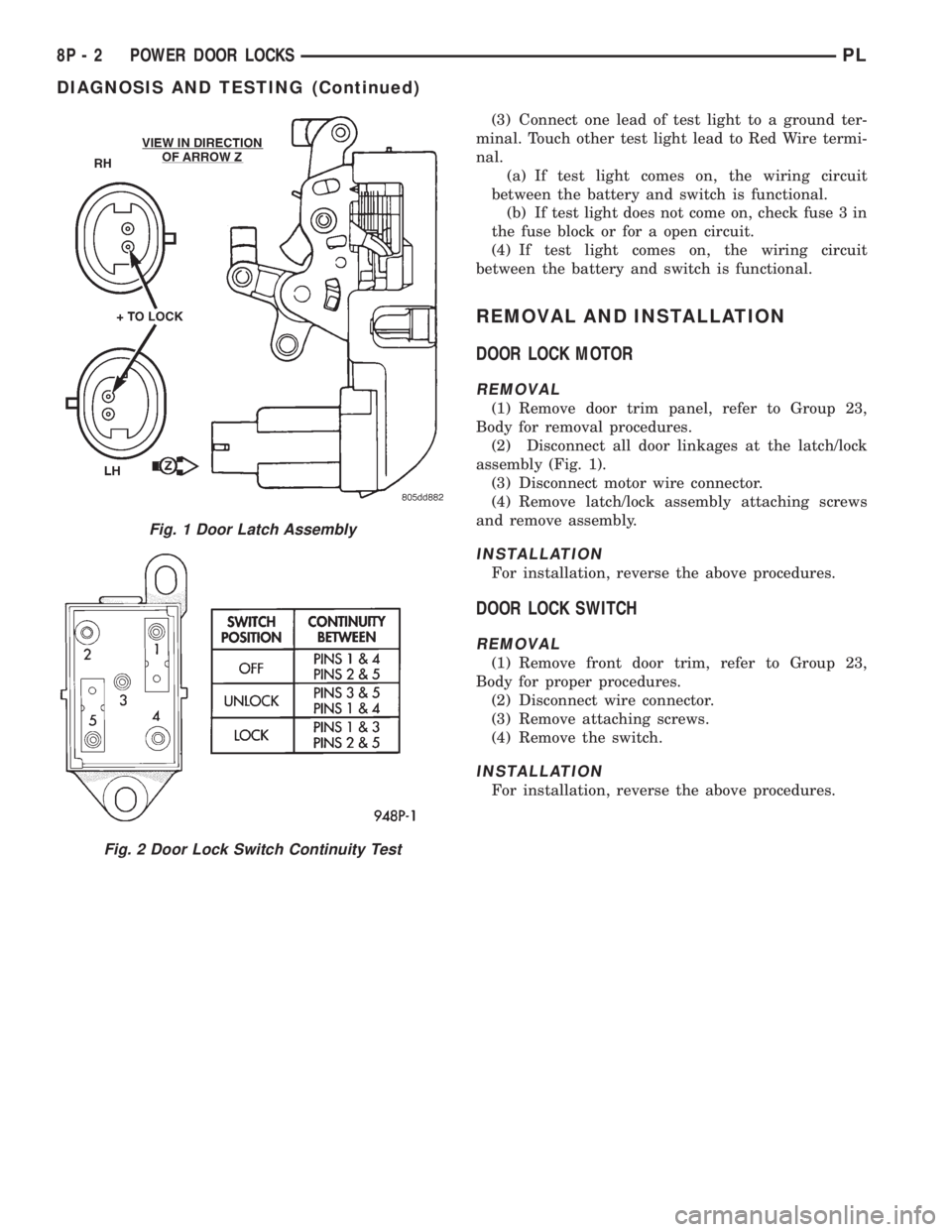

(3) Connect one lead of test light to a ground ter-

minal. Touch other test light lead to Red Wire termi-

nal.

(a) If test light comes on, the wiring circuit

between the battery and switch is functional.

(b) If test light does not come on, check fuse 3 in

the fuse block or for a open circuit.

(4) If test light comes on, the wiring circuit

between the battery and switch is functional.

REMOVAL AND INSTALLATION

DOOR LOCK MOTOR

REMOVAL

(1) Remove door trim panel, refer to Group 23,

Body for removal procedures.

(2) Disconnect all door linkages at the latch/lock

assembly (Fig. 1).

(3) Disconnect motor wire connector.

(4) Remove latch/lock assembly attaching screws

and remove assembly.

INSTALLATION

For installation, reverse the above procedures.

DOOR LOCK SWITCH

REMOVAL

(1) Remove front door trim, refer to Group 23,

Body for proper procedures.

(2) Disconnect wire connector.

(3) Remove attaching screws.

(4) Remove the switch.

INSTALLATION

For installation, reverse the above procedures.

Fig. 1 Door Latch Assembly

Fig. 2 Door Lock Switch Continuity Test

8P - 2 POWER DOOR LOCKSPL

DIAGNOSIS AND TESTING (Continued)

Page 374 of 1200

parking lamps out put. Press the panic button and

check for a voltage pulse (Fig. 2).

(2) If no voltage pulse is measured, replace the

receiver. If voltage OK, repair circuit to the parking

lamps as necessary.

(3) Connect the meter to Pin 5 of the black connec-

tor and to ground to test head lamps out put. Press

the panic button and check for a voltage pulse (Fig.

2).

(4) If no voltage pulse is measured, replace the

receiver. If voltage OK, repair circuit to the head

lamps as necessary.

REMOTE KEYLESS ENTRY SYSTEM

When trouble shooting problems with the Remote

Keyless Entry System, always verify that the power

door lock/unlock switches are functional. If the doors

do not lock/unlock refer to Group 8W, Wiring Dia-

gram for Pin and wiring locations.

If the following items do not work:

²Remote keyless entry system

²Radio/clock

²Door lock switches

A blown fuse is the probable cause. Check fuses 2,

3 and 11 in the fuse block. To check for a blown fuse,

pull the fuse out slightly, but maintain contact

between the fuse terminals and the terminals in fuse

block. Using the voltmeter probe, check both termi-

nals for 12 volts. If only one terminal measures bat-

tery voltage, the circuit breaker is defective and must

be replaced. If neither terminal measures battery

voltage, check the high current fuses 3 and 11 in the

Power Distribution Center (PDC). The PDC is located

in the engine compartment. If fuse(s) are NOT OK,

replace fuse(s) or repair as necessary. If fuses are

OK, check for an open or shorted circuit to the Power

Distribution Center, repair as needed.

SERVICE PROCEDURES

HORN CHIRP CANCELLATION

During the programming operation the horn chirp

can be disabled or enable using the following proce-

dure. One or both transmitters can be program to be

disabled or enable.

(1) Retrieve the programming line from the upper

edge of the passenger side cowl trim panel upper

edge. The RKE Programming Line is a green wire

with a red bullet connector.

(2) Using a jumper wire, ground the RKE pro-

gramming line.

(3) Turn ignition switch to the ON position.

(4) Press any button on the transmitter. The locks

will cycle to confirm programming,

(5) To disable or enable horn chirp press the lock

button on the transmitter four times and the hornwill sound to confirm programming. Press the lock

button on the second transmitter four times and the

horn will sound to confirm programming.

(6) Disconnect the programming line from ground.

This returns the system to its normal operation

mode.

(7) Replace any removed components. Return pro-

gramming line chirpto its original position. Check for

system operation.

PANIC FUNCTION CANCELLATION

During the programming operation the panic func-

tion can be disabled or enable using the following

procedure. One or both transmitters can be program

to be disabled or enable.

(1) Retrieve the programming line from the upper

edge of the passenger side cowl trim panel. The RKE

Program Line is a green wire with a red bullet con-

nector.

(2) Using a jumper wire, ground the RKE Pro-

gramming Line.

(3) Turn ignition switch to the ON position.

(4) Press any button on the transmitter. The locks

will cycle to confirm programming,

(5) To disable or enable panic function press the

panic button on the transmitter four times and the

horn will sound to confirm programming. Press the

panic button on the second transmitter four times

and the horn will sound to confirm programming.

(6) Disconnect the programming line from ground.

This returns the system to its normal operation

mode.

(7) Replace any removed components. Return the

programming line to its original position. Check for

system operation.

PROGRAM REMOTE KEYLESS ENTRY MODULE

(1) Retrieve the programming line from the upper

edge of the passenger side cowl trim panel. The RKE

Programming Line is a green wire with a red bullet

connector.

(2) Using a jumper wire, ground the RKE pro-

gramming line.

(3) Turn ignition switch to the ON position.

(4) Press any button on the transmitter to set

code. The locks will cycle to confirm programming. If

there is a second transmitter it must be set at this

time. Press any button on the second transmitter and

wait for the locks to cycle to confirm programming.

(5) Disconnect the programming line from ground.

This returns the system to its normal operation

mode.

(6) Replace all removed components. Return pro-

gramming line to its original position. Check for sys-

tem operation.

PLPOWER DOOR LOCKS 8P - 5

DIAGNOSIS AND TESTING (Continued)

Page 378 of 1200

SERVICE PROCEDURES

VEHICLE IMMOBILIZER SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: The following tests may not prove conclu-

sive in the diagnosis of this system. The most reli-

able, efficient, and accurate means to diagnose the

Vehicle Immobilizer System involves the use of a

DRB scan tool. Refer to the Vehicle Theft Security

System menu item on the DRB scan tool for the

procedures.

The vehicle immobilizer system and the Chrysler

Collision Detection (CCD) data bus network should

be diagnosed using the DRB scan tool. The DRB will

allow confirmation that the CCD data bus is func-

tional, that the immobilizer receiver is placing the

proper messages on the CCD data bus, and that the

Powertrain Control Module (PCM) is receiving the

CCD data bus messages. Refer to the Vehicle Theft

Security System menu item on the DRB scan tool for

the procedures. Refer to 8W-39 - Vehicle Theft Secu-

rity System in Group 8W - Wiring Diagrams for com-

plete circuit descriptions and diagrams.

(1) With the ignition switch in the Off position,

depress the Lock or Unlock button of the immobilizer

transmitter. Listen for the immobilizer receiver to

issue an audible chirp (Unlock) or chirps (Lock). If

OK, go to Step 2. If not OK, replace the transmitter

batteries with known good units and repeat Step 1. If

still not OK, go to Step 2.

(2) Check the fuse in the Power Distribution Cen-

ter (PDC). If OK, go to Step 3. If not OK, repair the

shorted circuit or component as required and replace

the faulty fuse.

(3) Disconnect and isolate the battery negative

cable. Unplug the wire harness connector at the

immobilizer receiver. Check for continuity between

the ground circuit cavity of the immobilizer receiver

wire harness connector and a good ground. There

should be continuity. If OK, go to Step 4. If not OK,

repair the open circuit to ground as required.

(4) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

immobilizer receiver wire harness connector. If OK,

refer to the Vehicle Theft Security System menu itemon the DRB scan tool for further diagnosis. If not

OK, repair the open circuit to the PDC fuse as

required.REMOVAL AND INSTALLATION

IMMOBILIZER RECEIVER

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

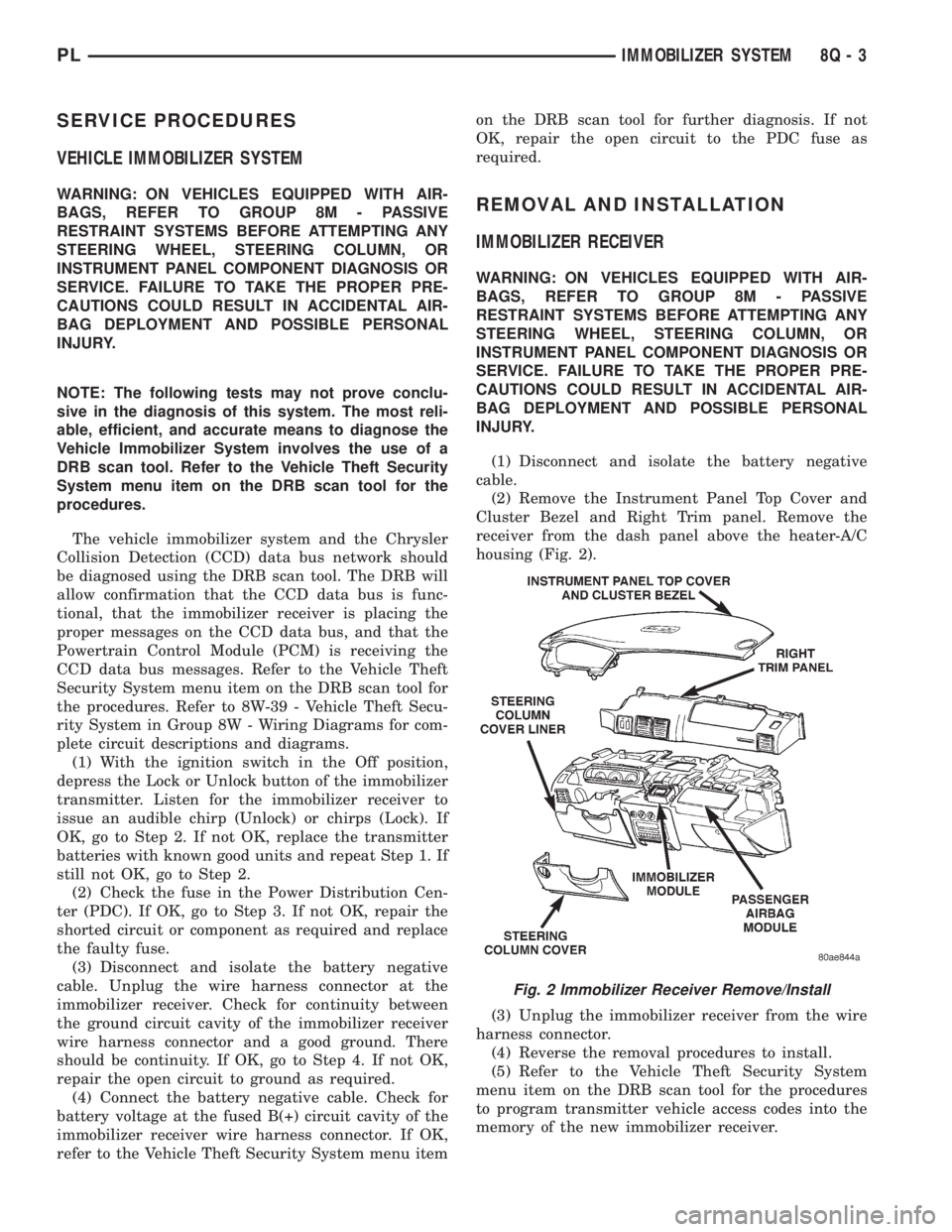

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the Instrument Panel Top Cover and

Cluster Bezel and Right Trim panel. Remove the

receiver from the dash panel above the heater-A/C

housing (Fig. 2).

(3) Unplug the immobilizer receiver from the wire

harness connector.

(4) Reverse the removal procedures to install.

(5) Refer to the Vehicle Theft Security System

menu item on the DRB scan tool for the procedures

to program transmitter vehicle access codes into the

memory of the new immobilizer receiver.

Fig. 2 Immobilizer Receiver Remove/Install

PLIMMOBILIZER SYSTEM 8Q - 3

Page 380 of 1200

POWER WINDOWS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DIAGNOSIS AND TESTING

WINDOW MOTOR TEST................... 1

WINDOW SWITCH TEST.................. 1WIRING TEST........................... 1

REMOVAL AND INSTALLATION

2 DOOR WINDOW MOTOR................ 2

4 DOOR WINDOW MOTOR................ 3

WINDOW SWITCH....................... 2

GENERAL INFORMATION

INTRODUCTION

The window lift motors are of the permanent mag-

net type. A battery positive and negative connection

to either of the two motor terminals will cause the

motor to rotate in one direction. Reversing current

through these same two connections will cause the

motor to rotate in the opposite direction.

Each individual motor is grounded through the

master switch.

DIAGNOSIS AND TESTING

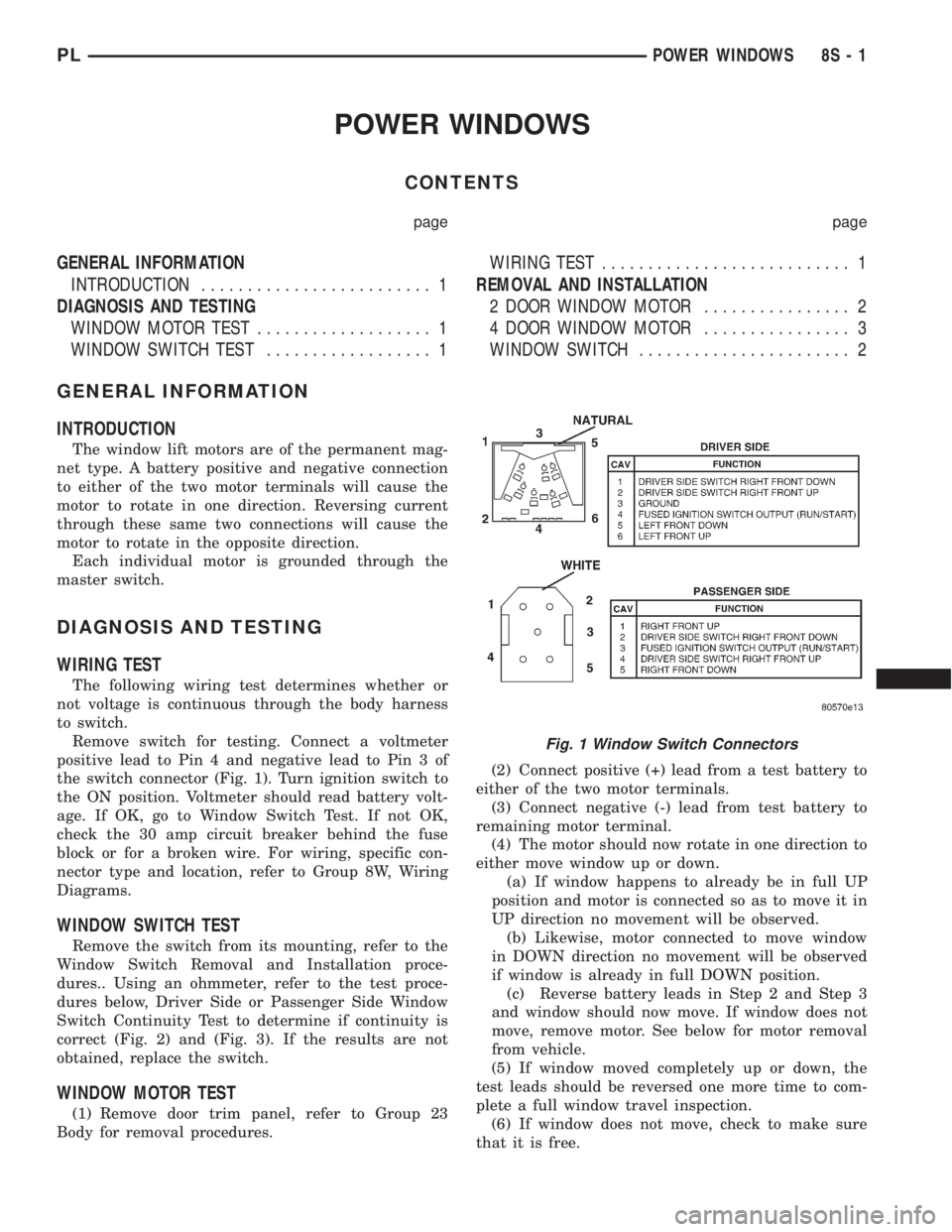

WIRING TEST

The following wiring test determines whether or

not voltage is continuous through the body harness

to switch.

Remove switch for testing. Connect a voltmeter

positive lead to Pin 4 and negative lead to Pin 3 of

the switch connector (Fig. 1). Turn ignition switch to

the ON position. Voltmeter should read battery volt-

age. If OK, go to Window Switch Test. If not OK,

check the 30 amp circuit breaker behind the fuse

block or for a broken wire. For wiring, specific con-

nector type and location, refer to Group 8W, Wiring

Diagrams.

WINDOW SWITCH TEST

Remove the switch from its mounting, refer to the

Window Switch Removal and Installation proce-

dures.. Using an ohmmeter, refer to the test proce-

dures below, Driver Side or Passenger Side Window

Switch Continuity Test to determine if continuity is

correct (Fig. 2) and (Fig. 3). If the results are not

obtained, replace the switch.

WINDOW MOTOR TEST

(1) Remove door trim panel, refer to Group 23

Body for removal procedures.(2) Connect positive (+) lead from a test battery to

either of the two motor terminals.

(3) Connect negative (-) lead from test battery to

remaining motor terminal.

(4) The motor should now rotate in one direction to

either move window up or down.

(a) If window happens to already be in full UP

position and motor is connected so as to move it in

UP direction no movement will be observed.

(b) Likewise, motor connected to move window

in DOWN direction no movement will be observed

if window is already in full DOWN position.

(c) Reverse battery leads in Step 2 and Step 3

and window should now move. If window does not

move, remove motor. See below for motor removal

from vehicle.

(5) If window moved completely up or down, the

test leads should be reversed one more time to com-

plete a full window travel inspection.

(6) If window does not move, check to make sure

that it is free.

Fig. 1 Window Switch Connectors

PLPOWER WINDOWS 8S - 1

Page 384 of 1200

POWER MIRRORS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DIAGNOSIS AND TESTING

MIRROR MOTOR........................ 2

MIRROR SWITCH TEST................... 1REMOVAL AND INSTALLATION

INSIDE MIRROR/READING LAMPS

ASSEMBLY............................ 2

INSIDE MIRROR/READING LAMPS

BULB/LENS........................... 2

MIRROR ASSEMBLY..................... 2

MIRROR SWITCH........................ 2

GENERAL INFORMATION

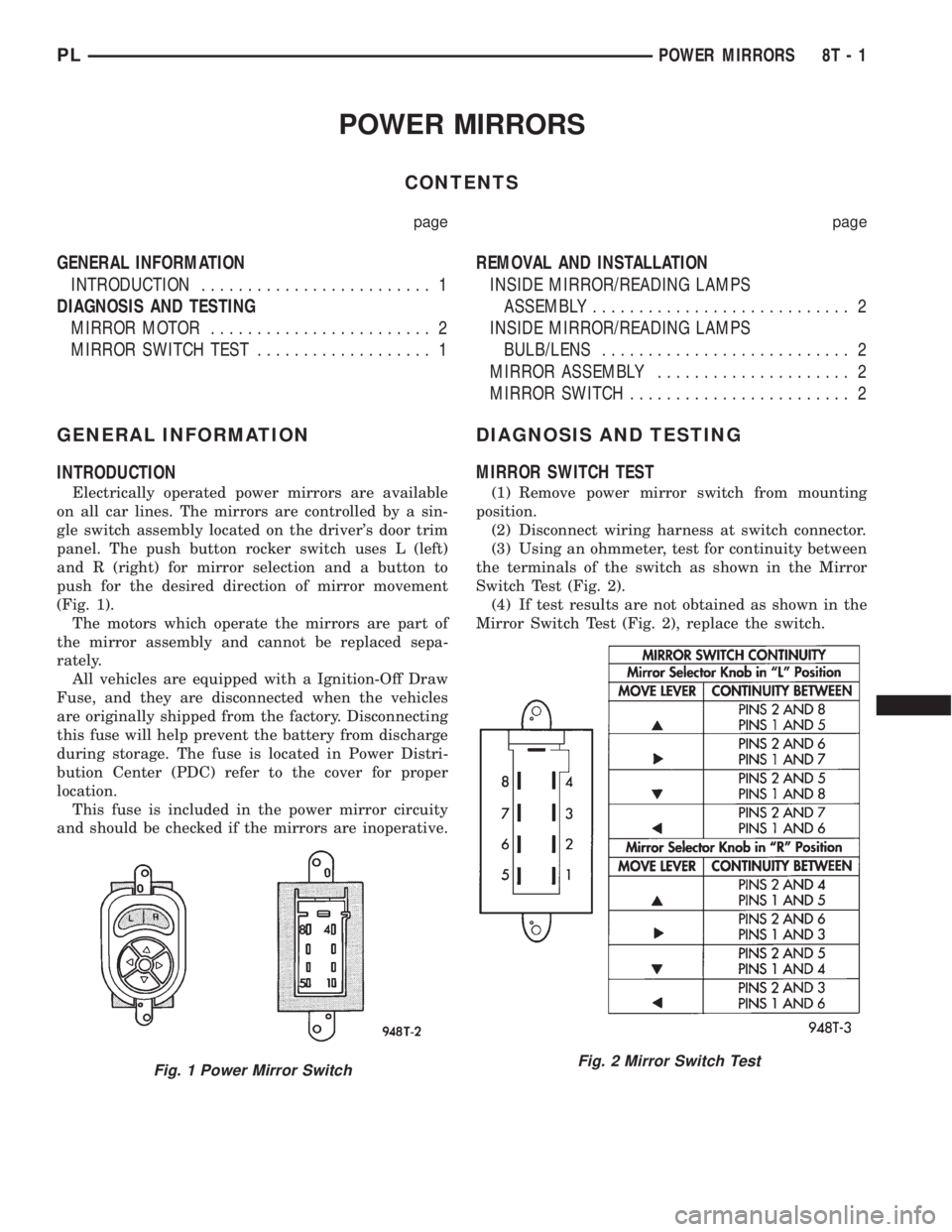

INTRODUCTION

Electrically operated power mirrors are available

on all car lines. The mirrors are controlled by a sin-

gle switch assembly located on the driver's door trim

panel. The push button rocker switch uses L (left)

and R (right) for mirror selection and a button to

push for the desired direction of mirror movement

(Fig. 1).

The motors which operate the mirrors are part of

the mirror assembly and cannot be replaced sepa-

rately.

All vehicles are equipped with a Ignition-Off Draw

Fuse, and they are disconnected when the vehicles

are originally shipped from the factory. Disconnecting

this fuse will help prevent the battery from discharge

during storage. The fuse is located in Power Distri-

bution Center (PDC) refer to the cover for proper

location.

This fuse is included in the power mirror circuity

and should be checked if the mirrors are inoperative.

DIAGNOSIS AND TESTING

MIRROR SWITCH TEST

(1) Remove power mirror switch from mounting

position.

(2) Disconnect wiring harness at switch connector.

(3) Using an ohmmeter, test for continuity between

the terminals of the switch as shown in the Mirror

Switch Test (Fig. 2).

(4) If test results are not obtained as shown in the

Mirror Switch Test (Fig. 2), replace the switch.

Fig. 1 Power Mirror SwitchFig. 2 Mirror Switch Test

PLPOWER MIRRORS 8T - 1

Page 386 of 1200

POWER MIRRORS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION........................ 1

DIAGNOSIS AND TESTING

MIRROR MOTOR....................... 2MIRROR SWITCH TEST.................. 1

GENERAL INFORMATION

INTRODUCTION

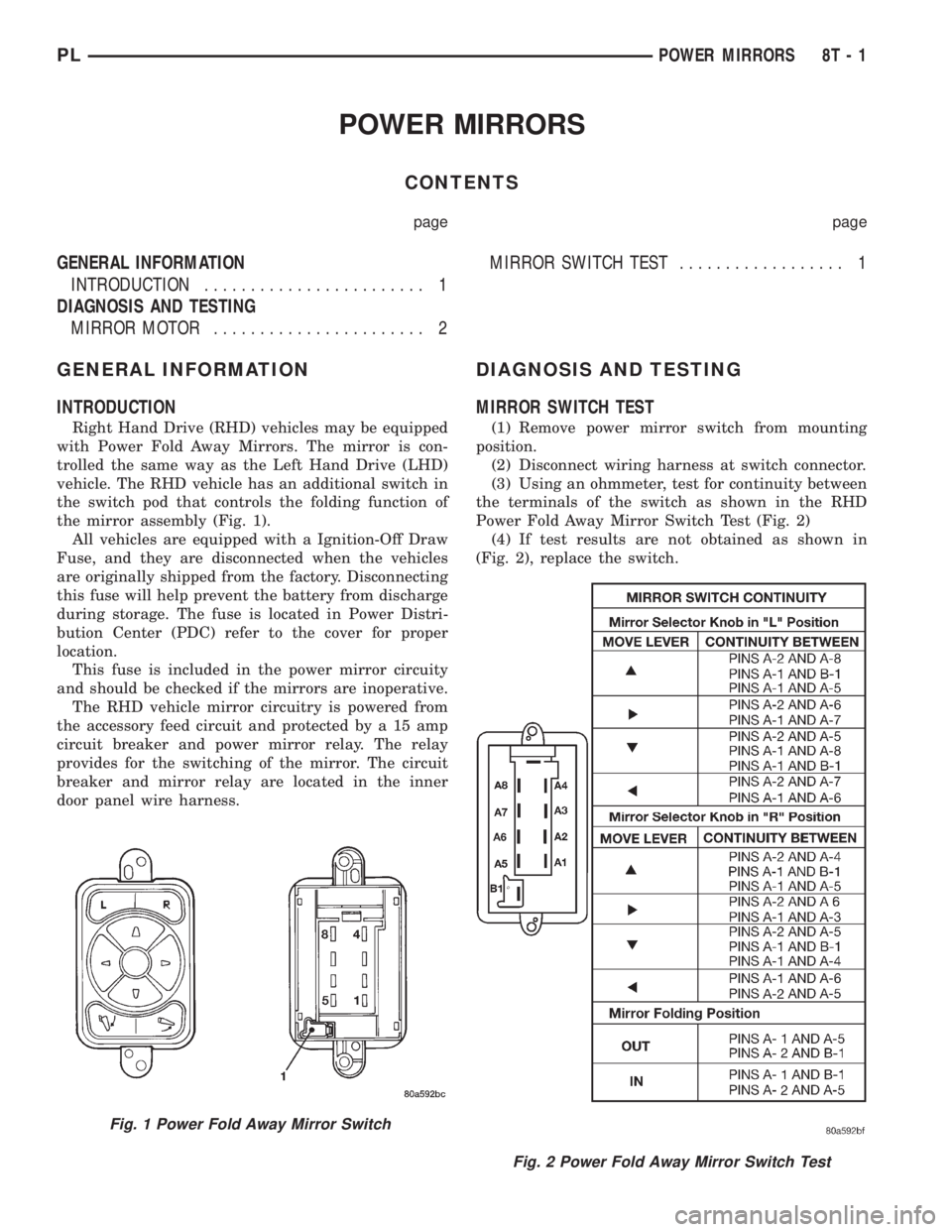

Right Hand Drive (RHD) vehicles may be equipped

with Power Fold Away Mirrors. The mirror is con-

trolled the same way as the Left Hand Drive (LHD)

vehicle. The RHD vehicle has an additional switch in

the switch pod that controls the folding function of

the mirror assembly (Fig. 1).

All vehicles are equipped with a Ignition-Off Draw

Fuse, and they are disconnected when the vehicles

are originally shipped from the factory. Disconnecting

this fuse will help prevent the battery from discharge

during storage. The fuse is located in Power Distri-

bution Center (PDC) refer to the cover for proper

location.

This fuse is included in the power mirror circuity

and should be checked if the mirrors are inoperative.

The RHD vehicle mirror circuitry is powered from

the accessory feed circuit and protected by a 15 amp

circuit breaker and power mirror relay. The relay

provides for the switching of the mirror. The circuit

breaker and mirror relay are located in the inner

door panel wire harness.

DIAGNOSIS AND TESTING

MIRROR SWITCH TEST

(1) Remove power mirror switch from mounting

position.

(2) Disconnect wiring harness at switch connector.

(3) Using an ohmmeter, test for continuity between

the terminals of the switch as shown in the RHD

Power Fold Away Mirror Switch Test (Fig. 2)

(4) If test results are not obtained as shown in

(Fig. 2), replace the switch.

Fig. 1 Power Fold Away Mirror Switch

Fig. 2 Power Fold Away Mirror Switch Test

PLPOWER MIRRORS 8T - 1

Page 392 of 1200

WIRING DIAGRAMS

CONTENTS

page page

AIR CONDITIONING-HEATER.......... 8W-42-1

AIRBAG SYSTEM................... 8W-43-1

ANTI-LOCK BRAKES................. 8W-35-1

AUDIO SYSTEMS................... 8W-47-1

CHARGING SYSTEM................. 8W-20-1

COMPONENT INDEX................. 8W-02-1

CONNECTOR/GROUND LOCATIONS..... 8W-90-1

CONNECTOR PIN-OUTS.............. 8W-80-1

FRONT LIGHTING................... 8W-50-1

FUEL/IGNITION SYSTEMS............ 8W-30-1

FUSE BLOCK....................... 8W-11-1

GENERAL INFORMATION............. 8W-01-1

GROUND DISTRIBUTION............. 8W-15-1

HORN/CIGAR LIGHTER............... 8W-41-1INSTRUMENT CLUSTER.............. 8W-40-1

INTERIOR LIGHTING................. 8W-44-1

POWER DISTRIBUTION.............. 8W-10-1

POWER DOOR LOCKS............... 8W-61-1

POWER MIRRORS.................. 8W-62-1

POWER SUNROOF.................. 8W-64-1

POWER WINDOWS.................. 8W-60-1

REAR LIGHTING.................... 8W-51-1

REAR WINDOW DEFOGGER........... 8W-48-1

SPLICE INFORMATION............... 8W-70-1

SPLICE LOCATIONS................. 8W-95-1

STARTING SYSTEM................. 8W-21-1

TURN SIGNALS..................... 8W-52-1

WIPERS........................... 8W-53-1

PLWIRING DIAGRAMS 8W - 1