drain bolt DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 210 of 1200

COOLING SYSTEMÐREFILLING

First clean system to remove old glycol, see Cooling

System Cleaning.

Fill system using antifreeze described in Coolant

section. Fill 50 percent of capacity with 100 percent

glycol. Then complete filling system with water.

Continue filling system until full, this provides bet-

ter heater performance.Be careful not to spill

coolant on drive belts or the generator.

Fill coolant reserve system to at least the FULL

mark with 50/50 solution. It may be necessary to add

coolant to the reserve tank after three or four warm-

up/cool down cycles to maintain coolant level between

the FULL and ADD marks; if any trapped air was

removed from the system.

REMOVAL AND INSTALLATION

WATER PUMP

REMOVAL

(1) Raise vehicle on a hoist. Remove right inner

splash shield.

(2) Remove accessory drive belts and power steer-

ing pump. Refer to Accessory Drive Belt service in

this section.

(3) Drain cooling system. Refer to Cooling System

Draining in this section.

(4) Support engine from the bottom and remove

right engine mount.

(5) Remove power steering pump bracket bolts and

set pump and bracket assembly aside. Power steering

lines do not need to be disconnected.

(6) Remove right engine mount bracket.

(7) Remove timing belt and timing belt tensioner.

Refer to Group 9, Engine for procedure.

(8) Remove camshaft sprockets and inner timing

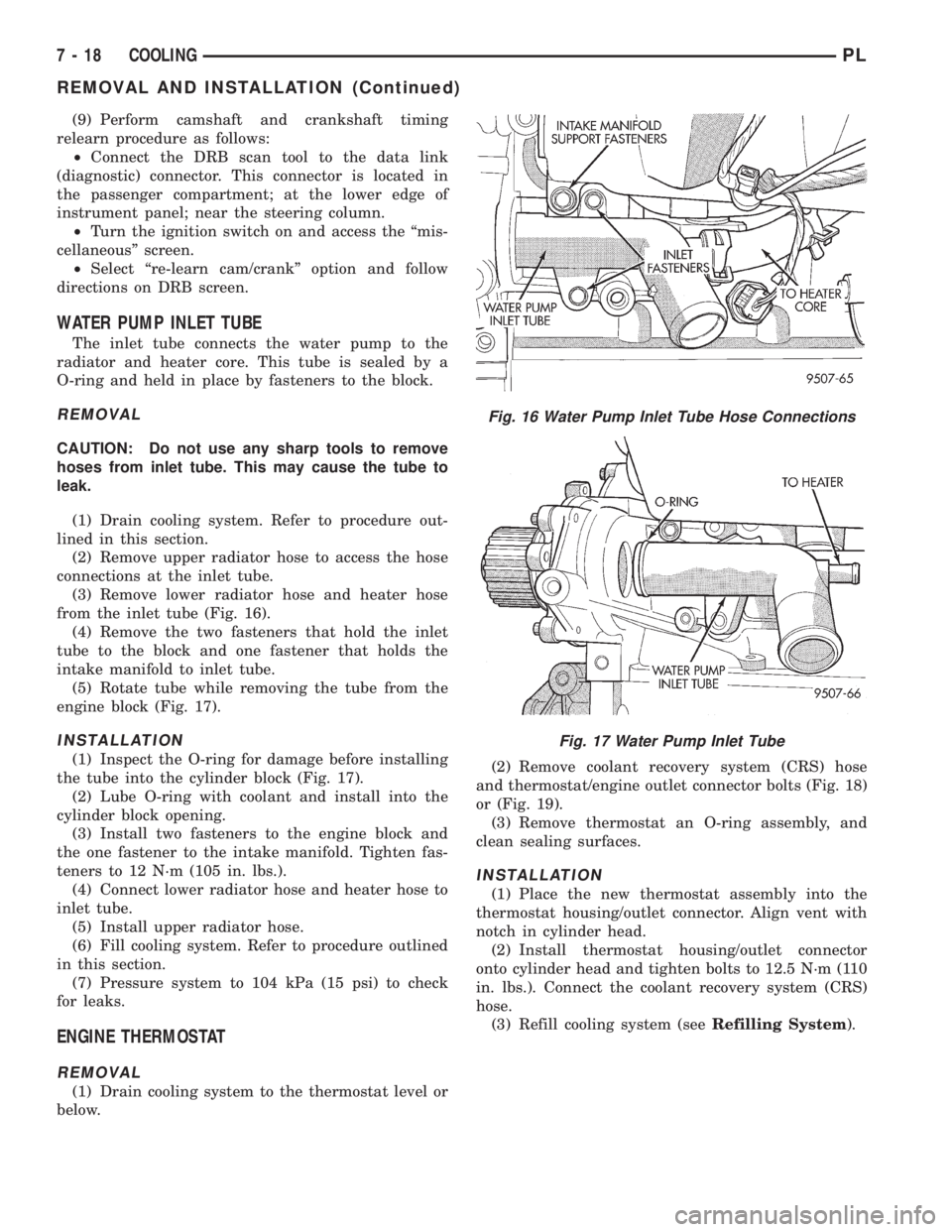

belt cover. Refer to Group 9, Engine for procedure.(9) Remove water pump attaching screws to engine

(Fig. 14).

INSTALLATION

(1) Install new O-ring gasket in water pump body

O-ring groove (Fig. 15). Use small dabs of Mopart

Silicone Rubber Adhesive Sealant around the water

pump body to secure O-ring in place during installa-

tion.

CAUTION: Make sure O-ring gasket is properly

seated in water pump groove before tightening

screws. An improperly located O-ring may cause

damage to the O-ring and cause a coolant leak.

(2) Assemble pump body to block and tighten

screws to 12 N´m (105 in. lbs.). Pressurize cooling

system to 15 psi with pressure tester and check

water pump shaft seal and O-ring for leaks.

(3) Rotate pump by hand to check for freedom of

movement.

(4) Install inner timing belt cover.

(5) Install timing belt. Refer to Group 9, Engine

for procedures.

(6) Install right engine mount bracket and engine

mount. Refer to Group 9, Engine for procedure.

(7) Fill cooling system. SeeCooling System

Refilling.

(8) Install power steering pump and accessory

drive belts, Refer to Accessory Drive Belts, in this

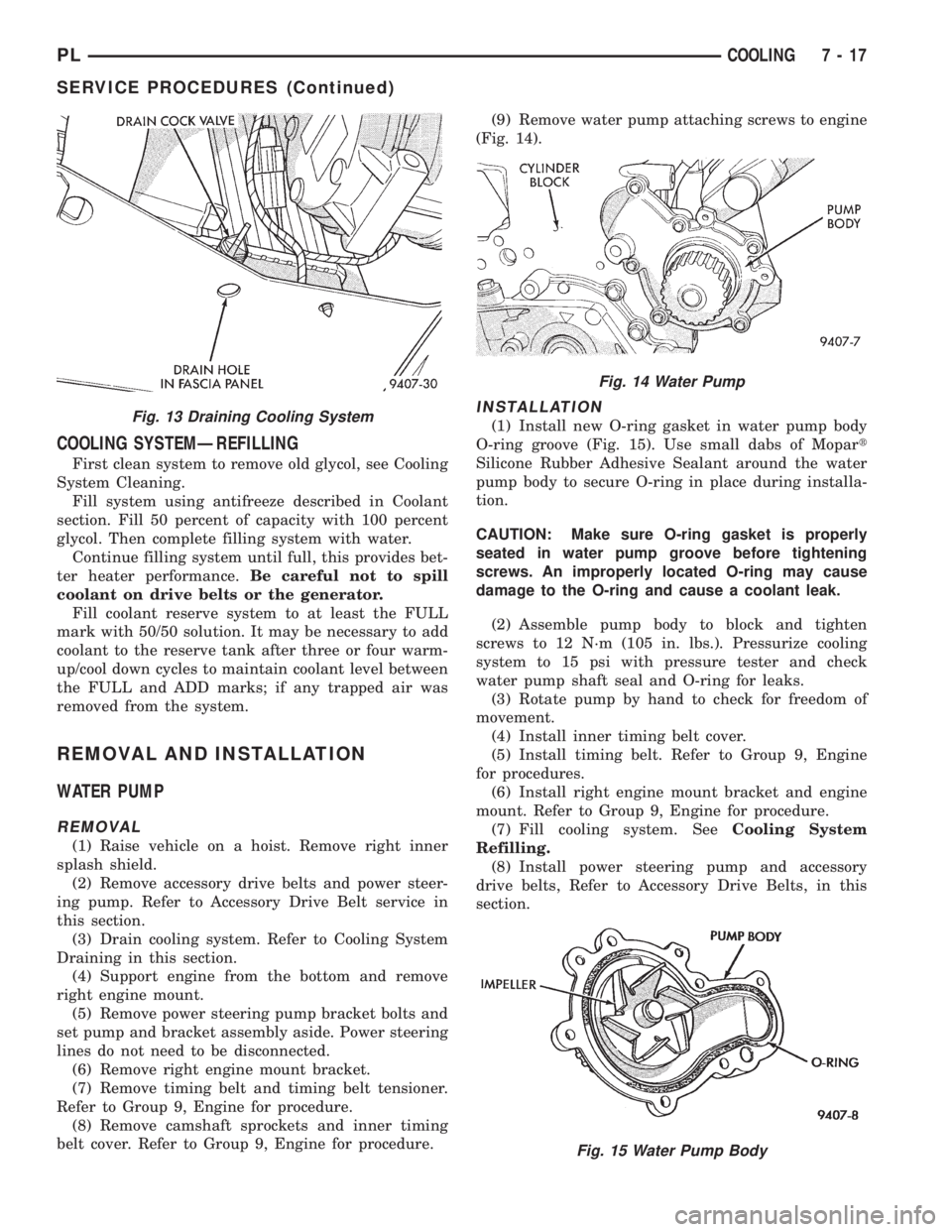

section.Fig. 13 Draining Cooling System

Fig. 14 Water Pump

Fig. 15 Water Pump Body

PLCOOLING 7 - 17

SERVICE PROCEDURES (Continued)

Page 211 of 1200

(9) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

WATER PUMP INLET TUBE

The inlet tube connects the water pump to the

radiator and heater core. This tube is sealed by a

O-ring and held in place by fasteners to the block.

REMOVAL

CAUTION: Do not use any sharp tools to remove

hoses from inlet tube. This may cause the tube to

leak.

(1) Drain cooling system. Refer to procedure out-

lined in this section.

(2) Remove upper radiator hose to access the hose

connections at the inlet tube.

(3) Remove lower radiator hose and heater hose

from the inlet tube (Fig. 16).

(4) Remove the two fasteners that hold the inlet

tube to the block and one fastener that holds the

intake manifold to inlet tube.

(5) Rotate tube while removing the tube from the

engine block (Fig. 17).

INSTALLATION

(1) Inspect the O-ring for damage before installing

the tube into the cylinder block (Fig. 17).

(2) Lube O-ring with coolant and install into the

cylinder block opening.

(3) Install two fasteners to the engine block and

the one fastener to the intake manifold. Tighten fas-

teners to 12 N´m (105 in. lbs.).

(4) Connect lower radiator hose and heater hose to

inlet tube.

(5) Install upper radiator hose.

(6) Fill cooling system. Refer to procedure outlined

in this section.

(7) Pressure system to 104 kPa (15 psi) to check

for leaks.

ENGINE THERMOSTAT

REMOVAL

(1) Drain cooling system to the thermostat level or

below.(2) Remove coolant recovery system (CRS) hose

and thermostat/engine outlet connector bolts (Fig. 18)

or (Fig. 19).

(3) Remove thermostat an O-ring assembly, and

clean sealing surfaces.

INSTALLATION

(1) Place the new thermostat assembly into the

thermostat housing/outlet connector. Align vent with

notch in cylinder head.

(2) Install thermostat housing/outlet connector

onto cylinder head and tighten bolts to 12.5 N´m (110

in. lbs.). Connect the coolant recovery system (CRS)

hose.

(3) Refill cooling system (seeRefilling System).

Fig. 16 Water Pump Inlet Tube Hose Connections

Fig. 17 Water Pump Inlet Tube

7 - 18 COOLINGPL

REMOVAL AND INSTALLATION (Continued)

Page 214 of 1200

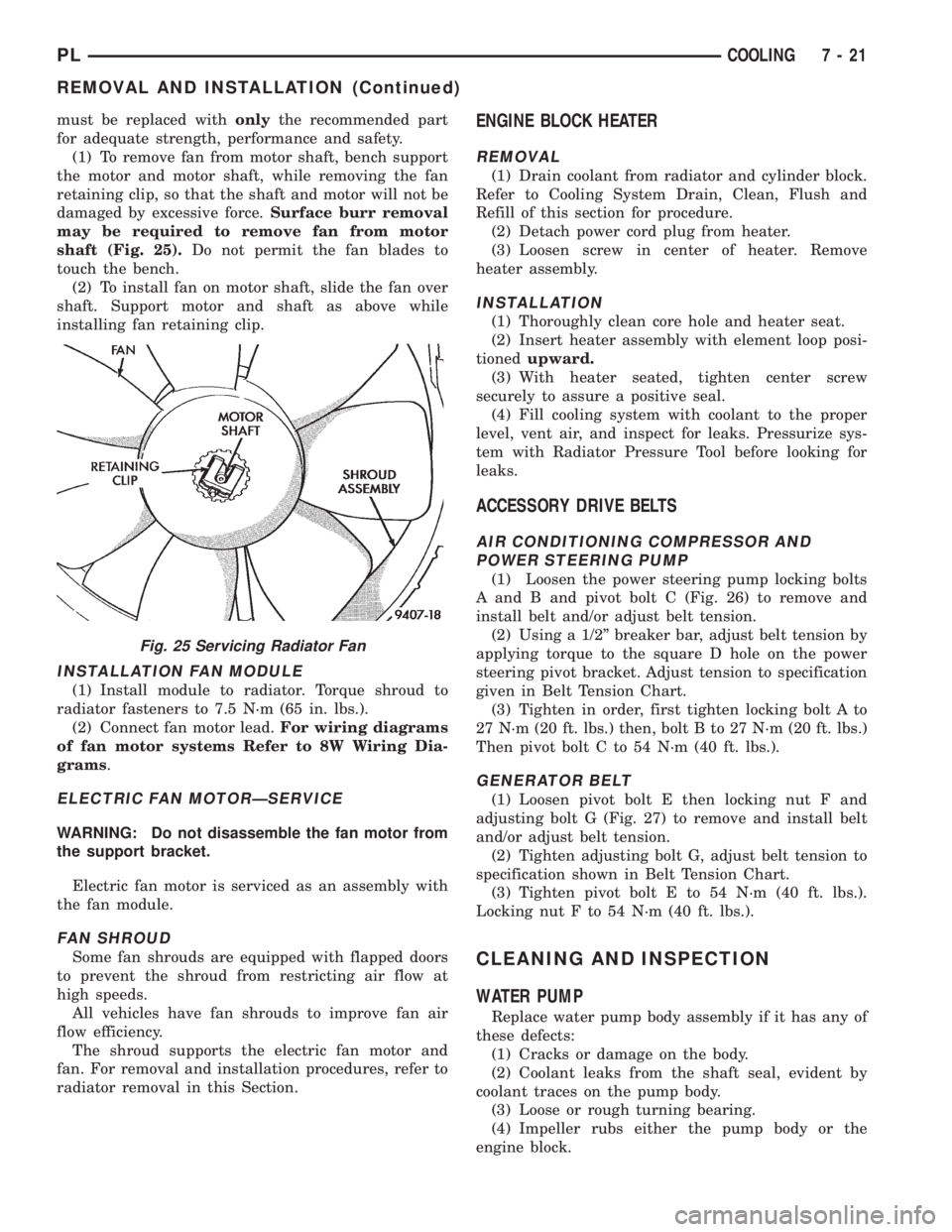

must be replaced withonlythe recommended part

for adequate strength, performance and safety.

(1) To remove fan from motor shaft, bench support

the motor and motor shaft, while removing the fan

retaining clip, so that the shaft and motor will not be

damaged by excessive force.Surface burr removal

may be required to remove fan from motor

shaft (Fig. 25).Do not permit the fan blades to

touch the bench.

(2) To install fan on motor shaft, slide the fan over

shaft. Support motor and shaft as above while

installing fan retaining clip.

INSTALLATION FAN MODULE

(1) Install module to radiator. Torque shroud to

radiator fasteners to 7.5 N´m (65 in. lbs.).

(2) Connect fan motor lead.For wiring diagrams

of fan motor systems Refer to 8W Wiring Dia-

grams.

ELECTRIC FAN MOTORÐSERVICE

WARNING: Do not disassemble the fan motor from

the support bracket.

Electric fan motor is serviced as an assembly with

the fan module.

FAN SHROUD

Some fan shrouds are equipped with flapped doors

to prevent the shroud from restricting air flow at

high speeds.

All vehicles have fan shrouds to improve fan air

flow efficiency.

The shroud supports the electric fan motor and

fan. For removal and installation procedures, refer to

radiator removal in this Section.

ENGINE BLOCK HEATER

REMOVAL

(1) Drain coolant from radiator and cylinder block.

Refer to Cooling System Drain, Clean, Flush and

Refill of this section for procedure.

(2) Detach power cord plug from heater.

(3) Loosen screw in center of heater. Remove

heater assembly.

INSTALLATION

(1) Thoroughly clean core hole and heater seat.

(2) Insert heater assembly with element loop posi-

tionedupward.

(3) With heater seated, tighten center screw

securely to assure a positive seal.

(4) Fill cooling system with coolant to the proper

level, vent air, and inspect for leaks. Pressurize sys-

tem with Radiator Pressure Tool before looking for

leaks.

ACCESSORY DRIVE BELTS

AIR CONDITIONING COMPRESSOR AND

POWER STEERING PUMP

(1) Loosen the power steering pump locking bolts

A and B and pivot bolt C (Fig. 26) to remove and

install belt and/or adjust belt tension.

(2) Using a 1/2º breaker bar, adjust belt tension by

applying torque to the square D hole on the power

steering pivot bracket. Adjust tension to specification

given in Belt Tension Chart.

(3) Tighten in order, first tighten locking bolt A to

27 N´m (20 ft. lbs.) then, bolt B to 27 N´m (20 ft. lbs.)

Then pivot bolt C to 54 N´m (40 ft. lbs.).

GENERATOR BELT

(1) Loosen pivot bolt E then locking nut F and

adjusting bolt G (Fig. 27) to remove and install belt

and/or adjust belt tension.

(2) Tighten adjusting bolt G, adjust belt tension to

specification shown in Belt Tension Chart.

(3) Tighten pivot bolt E to 54 N´m (40 ft. lbs.).

Locking nut F to 54 N´m (40 ft. lbs.).

CLEANING AND INSPECTION

WATER PUMP

Replace water pump body assembly if it has any of

these defects:

(1) Cracks or damage on the body.

(2) Coolant leaks from the shaft seal, evident by

coolant traces on the pump body.

(3) Loose or rough turning bearing.

(4) Impeller rubs either the pump body or the

engine block.

Fig. 25 Servicing Radiator Fan

PLCOOLING 7 - 21

REMOVAL AND INSTALLATION (Continued)

Page 732 of 1200

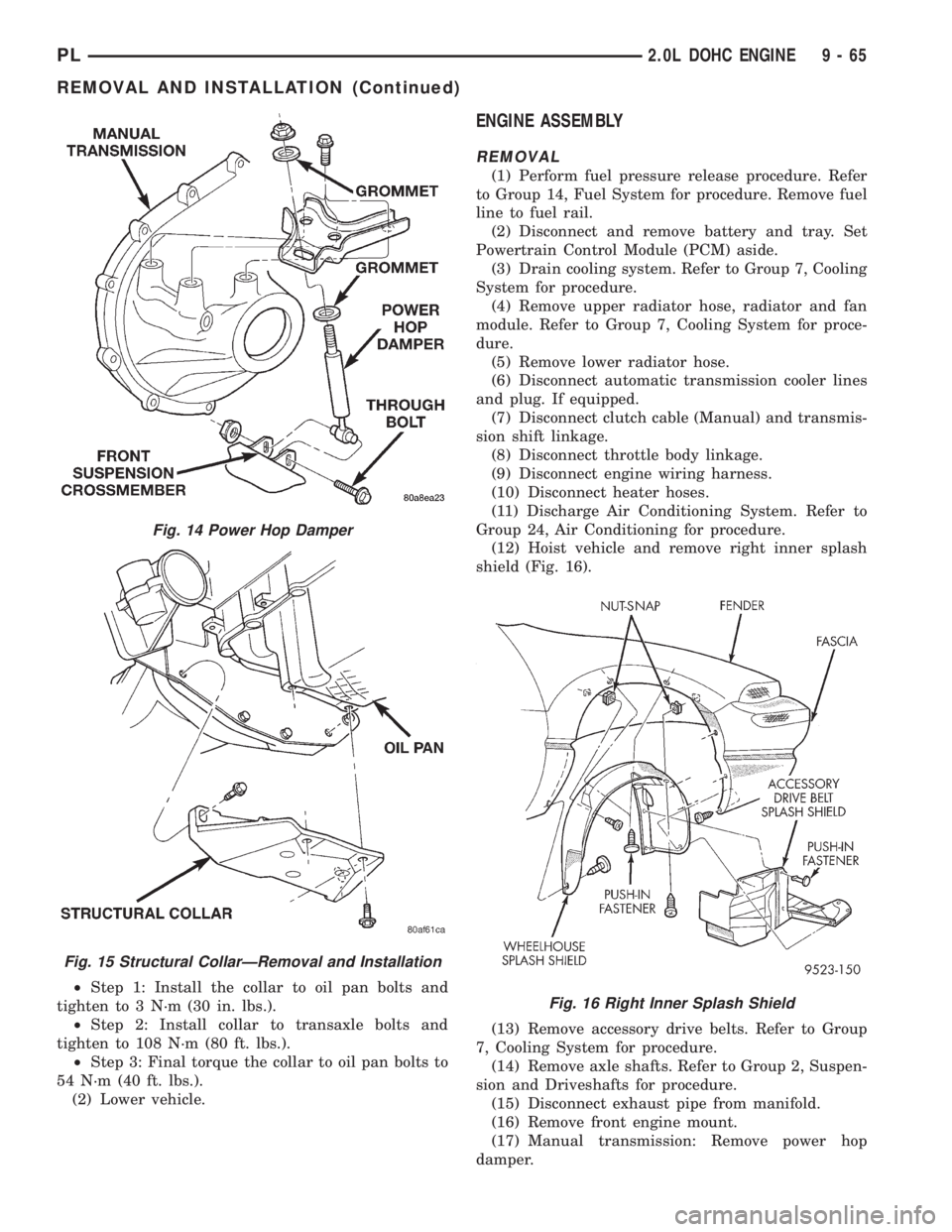

(3) Remove the power hop damper bracket, if nec-

essary.

(4) Reverse removal procedure for installation.

Tighten all bolts and nuts to 54 N´m (40 ft. lbs.)

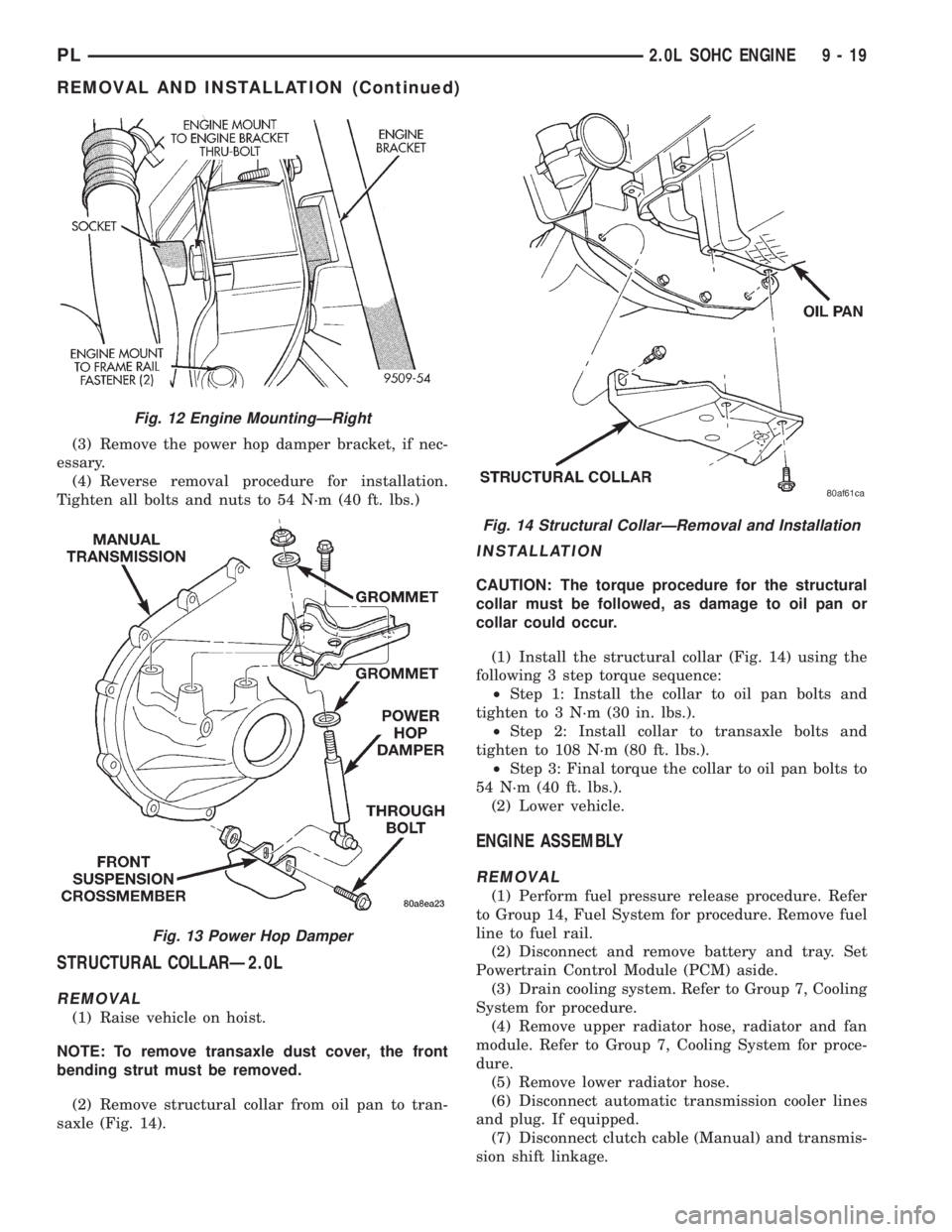

STRUCTURAL COLLARÐ2.0L

REMOVAL

(1) Raise vehicle on hoist.

NOTE: To remove transaxle dust cover, the front

bending strut must be removed.

(2) Remove structural collar from oil pan to tran-

saxle (Fig. 14).

INSTALLATION

CAUTION: The torque procedure for the structural

collar must be followed, as damage to oil pan or

collar could occur.

(1) Install the structural collar (Fig. 14) using the

following 3 step torque sequence:

²Step 1: Install the collar to oil pan bolts and

tighten to 3 N´m (30 in. lbs.).

²Step 2: Install collar to transaxle bolts and

tighten to 108 N´m (80 ft. lbs.).

²Step 3: Final torque the collar to oil pan bolts to

54 N´m (40 ft. lbs.).

(2) Lower vehicle.

ENGINE ASSEMBLY

REMOVAL

(1) Perform fuel pressure release procedure. Refer

to Group 14, Fuel System for procedure. Remove fuel

line to fuel rail.

(2) Disconnect and remove battery and tray. Set

Powertrain Control Module (PCM) aside.

(3) Drain cooling system. Refer to Group 7, Cooling

System for procedure.

(4) Remove upper radiator hose, radiator and fan

module. Refer to Group 7, Cooling System for proce-

dure.

(5) Remove lower radiator hose.

(6) Disconnect automatic transmission cooler lines

and plug. If equipped.

(7) Disconnect clutch cable (Manual) and transmis-

sion shift linkage.

Fig. 12 Engine MountingÐRight

Fig. 13 Power Hop Damper

Fig. 14 Structural CollarÐRemoval and Installation

PL2.0L SOHC ENGINE 9 - 19

REMOVAL AND INSTALLATION (Continued)

Page 738 of 1200

INSTALLATION

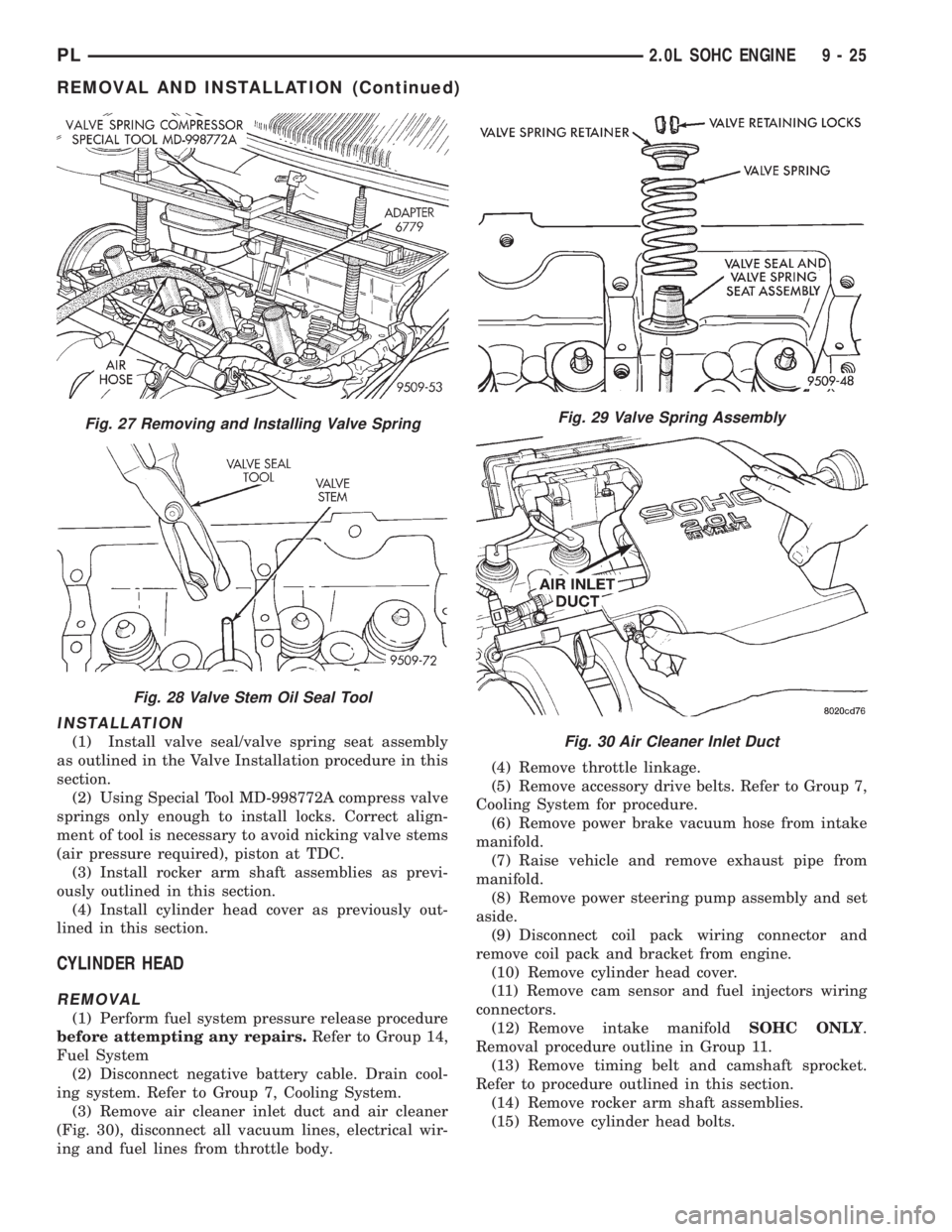

(1) Install valve seal/valve spring seat assembly

as outlined in the Valve Installation procedure in this

section.

(2) Using Special Tool MD-998772A compress valve

springs only enough to install locks. Correct align-

ment of tool is necessary to avoid nicking valve stems

(air pressure required), piston at TDC.

(3) Install rocker arm shaft assemblies as previ-

ously outlined in this section.

(4) Install cylinder head cover as previously out-

lined in this section.

CYLINDER HEAD

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs.Refer to Group 14,

Fuel System

(2) Disconnect negative battery cable. Drain cool-

ing system. Refer to Group 7, Cooling System.

(3) Remove air cleaner inlet duct and air cleaner

(Fig. 30), disconnect all vacuum lines, electrical wir-

ing and fuel lines from throttle body.(4) Remove throttle linkage.

(5) Remove accessory drive belts. Refer to Group 7,

Cooling System for procedure.

(6) Remove power brake vacuum hose from intake

manifold.

(7) Raise vehicle and remove exhaust pipe from

manifold.

(8) Remove power steering pump assembly and set

aside.

(9) Disconnect coil pack wiring connector and

remove coil pack and bracket from engine.

(10) Remove cylinder head cover.

(11) Remove cam sensor and fuel injectors wiring

connectors.

(12) Remove intake manifoldSOHC ONLY.

Removal procedure outline in Group 11.

(13) Remove timing belt and camshaft sprocket.

Refer to procedure outlined in this section.

(14) Remove rocker arm shaft assemblies.

(15) Remove cylinder head bolts.

Fig. 27 Removing and Installing Valve Spring

Fig. 28 Valve Stem Oil Seal Tool

Fig. 29 Valve Spring Assembly

Fig. 30 Air Cleaner Inlet Duct

PL2.0L SOHC ENGINE 9 - 25

REMOVAL AND INSTALLATION (Continued)

Page 749 of 1200

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

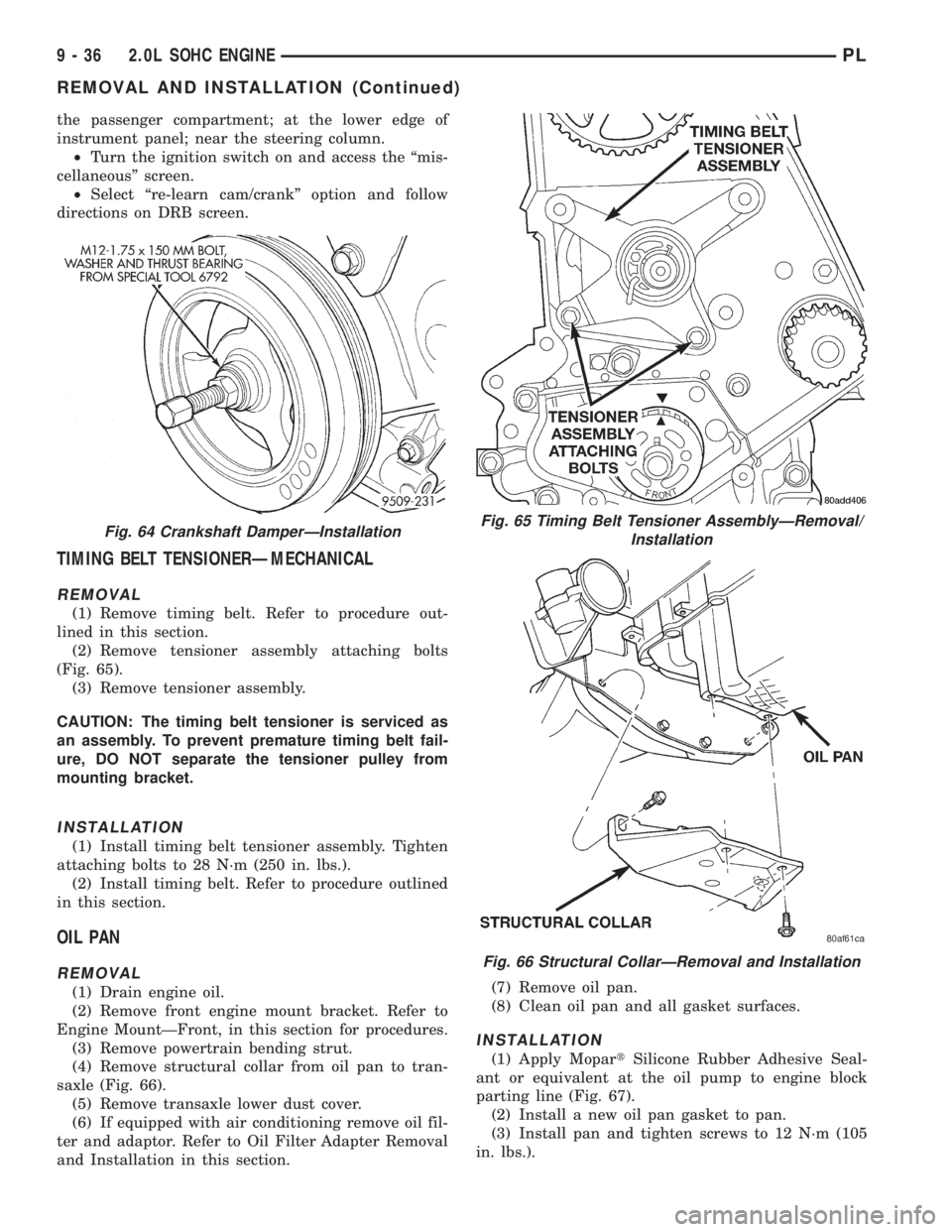

TIMING BELT TENSIONERÐMECHANICAL

REMOVAL

(1) Remove timing belt. Refer to procedure out-

lined in this section.

(2) Remove tensioner assembly attaching bolts

(Fig. 65).

(3) Remove tensioner assembly.

CAUTION: The timing belt tensioner is serviced as

an assembly. To prevent premature timing belt fail-

ure, DO NOT separate the tensioner pulley from

mounting bracket.

INSTALLATION

(1) Install timing belt tensioner assembly. Tighten

attaching bolts to 28 N´m (250 in. lbs.).

(2) Install timing belt. Refer to procedure outlined

in this section.

OIL PAN

REMOVAL

(1) Drain engine oil.

(2) Remove front engine mount bracket. Refer to

Engine MountÐFront, in this section for procedures.

(3) Remove powertrain bending strut.

(4) Remove structural collar from oil pan to tran-

saxle (Fig. 66).

(5) Remove transaxle lower dust cover.

(6) If equipped with air conditioning remove oil fil-

ter and adaptor. Refer to Oil Filter Adapter Removal

and Installation in this section.(7) Remove oil pan.

(8) Clean oil pan and all gasket surfaces.

INSTALLATION

(1) Apply MopartSilicone Rubber Adhesive Seal-

ant or equivalent at the oil pump to engine block

parting line (Fig. 67).

(2) Install a new oil pan gasket to pan.

(3) Install pan and tighten screws to 12 N´m (105

in. lbs.).

Fig. 64 Crankshaft DamperÐInstallationFig. 65 Timing Belt Tensioner AssemblyÐRemoval/

Installation

Fig. 66 Structural CollarÐRemoval and Installation

9 - 36 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 763 of 1200

CAUTION: When depressing the valve spring

retainers with valve spring compressor the locks

can become dislocated. Check to make sure both

locks are in their correct location after removing

tool.

(4) Check the valve spring installed height B after

refacing the valve and seat (Fig. 108). Make sure

measurements are taken from top of spring seat to

the bottom surface of spring retainer. If height is

greater than 40.18 mm (1.58 in.), install a 0.762 mm

(0.030 in.) spacer under the valve spring seat to

bring spring height back within specification.

(5) Install rocker arm shafts as previously

described in this section.

(6) Checking dry lash. Dry lash is the amount of

clearance that exists between the base circle of an

installed cam and the rocker arm roller when the

adjuster is drained of oil and completely collapsed.

Specified dry lash is 1.17 mm (0.046 in.) for intake

and 1.28 mm (0.050 in.) for exhaust. After performing

dry lash check, refill adjuster with oil and allow 10

minutes for adjuster/s to bleed down before rotating

cam.

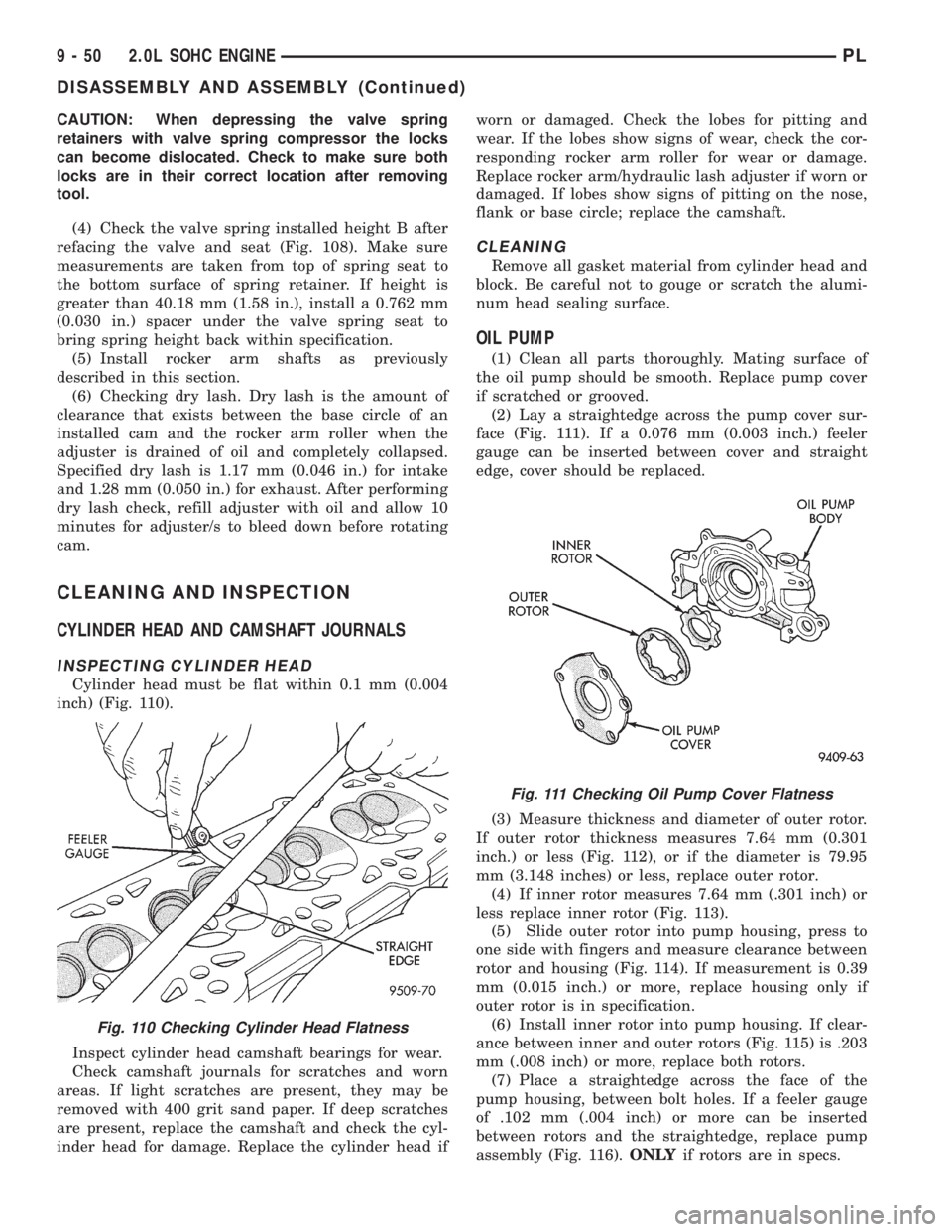

CLEANING AND INSPECTION

CYLINDER HEAD AND CAMSHAFT JOURNALS

INSPECTING CYLINDER HEAD

Cylinder head must be flat within 0.1 mm (0.004

inch) (Fig. 110).

Inspect cylinder head camshaft bearings for wear.

Check camshaft journals for scratches and worn

areas. If light scratches are present, they may be

removed with 400 grit sand paper. If deep scratches

are present, replace the camshaft and check the cyl-

inder head for damage. Replace the cylinder head ifworn or damaged. Check the lobes for pitting and

wear. If the lobes show signs of wear, check the cor-

responding rocker arm roller for wear or damage.

Replace rocker arm/hydraulic lash adjuster if worn or

damaged. If lobes show signs of pitting on the nose,

flank or base circle; replace the camshaft.

CLEANING

Remove all gasket material from cylinder head and

block. Be careful not to gouge or scratch the alumi-

num head sealing surface.

OIL PUMP

(1) Clean all parts thoroughly. Mating surface of

the oil pump should be smooth. Replace pump cover

if scratched or grooved.

(2) Lay a straightedge across the pump cover sur-

face (Fig. 111). If a 0.076 mm (0.003 inch.) feeler

gauge can be inserted between cover and straight

edge, cover should be replaced.

(3) Measure thickness and diameter of outer rotor.

If outer rotor thickness measures 7.64 mm (0.301

inch.) or less (Fig. 112), or if the diameter is 79.95

mm (3.148 inches) or less, replace outer rotor.

(4) If inner rotor measures 7.64 mm (.301 inch) or

less replace inner rotor (Fig. 113).

(5) Slide outer rotor into pump housing, press to

one side with fingers and measure clearance between

rotor and housing (Fig. 114). If measurement is 0.39

mm (0.015 inch.) or more, replace housing only if

outer rotor is in specification.

(6) Install inner rotor into pump housing. If clear-

ance between inner and outer rotors (Fig. 115) is .203

mm (.008 inch) or more, replace both rotors.

(7) Place a straightedge across the face of the

pump housing, between bolt holes. If a feeler gauge

of .102 mm (.004 inch) or more can be inserted

between rotors and the straightedge, replace pump

assembly (Fig. 116).ONLYif rotors are in specs.

Fig. 110 Checking Cylinder Head Flatness

Fig. 111 Checking Oil Pump Cover Flatness

9 - 50 2.0L SOHC ENGINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 767 of 1200

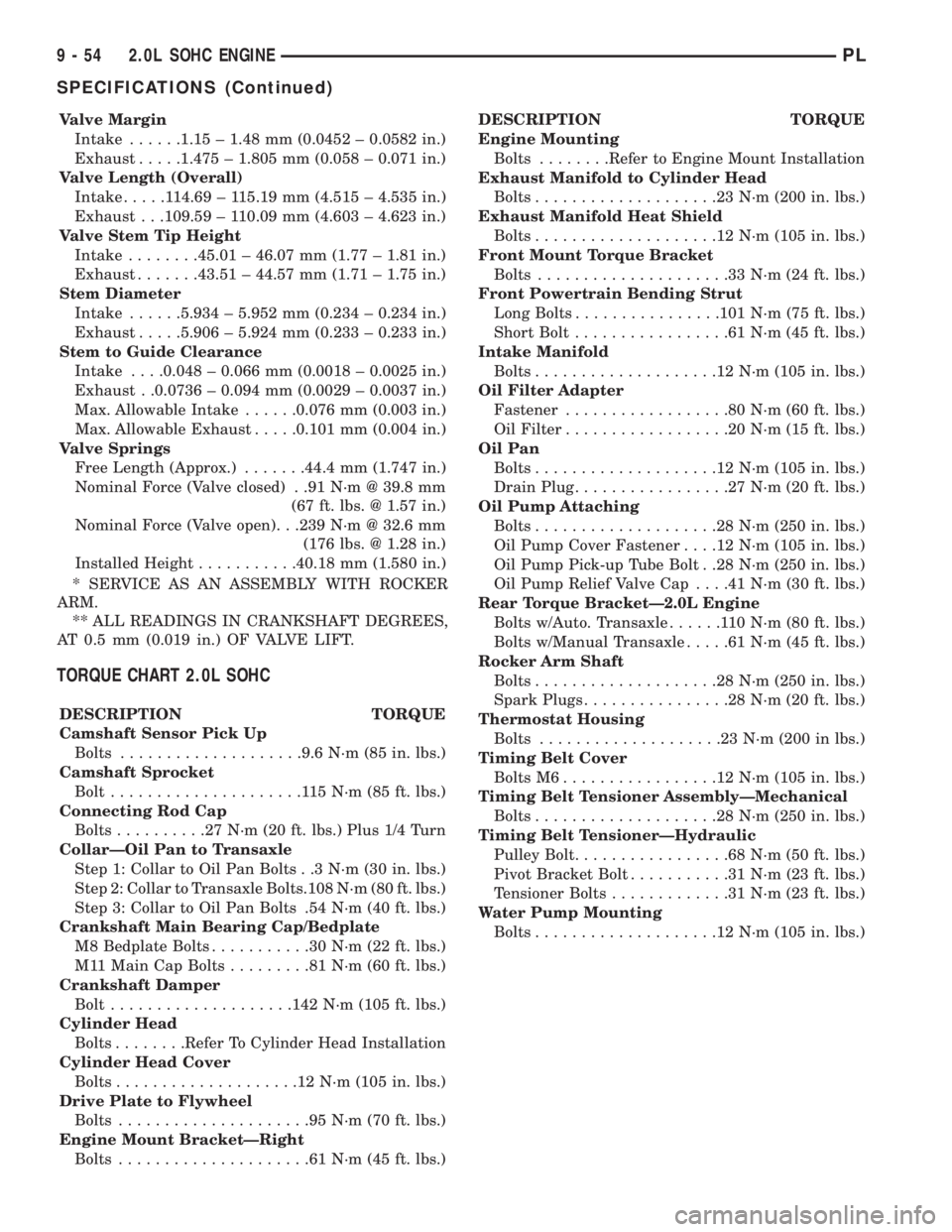

Valve Margin

Intake......1.15 ± 1.48 mm (0.0452 ± 0.0582 in.)

Exhaust.....1.475 ± 1.805 mm (0.058 ± 0.071 in.)

Valve Length (Overall)

Intake.....114.69 ± 115.19 mm (4.515 ± 4.535 in.)

Exhaust . . .109.59 ± 110.09 mm (4.603 ± 4.623 in.)

Valve Stem Tip Height

Intake........45.01 ± 46.07 mm (1.77 ± 1.81 in.)

Exhaust.......43.51 ± 44.57 mm (1.71 ± 1.75 in.)

Stem Diameter

Intake......5.934 ± 5.952 mm (0.234 ± 0.234 in.)

Exhaust.....5.906 ± 5.924 mm (0.233 ± 0.233 in.)

Stem to Guide Clearance

Intake. . . .0.048 ± 0.066 mm (0.0018 ± 0.0025 in.)

Exhaust . .0.0736 ± 0.094 mm (0.0029 ± 0.0037 in.)

Max. Allowable Intake......0.076 mm (0.003 in.)

Max. Allowable Exhaust.....0.101 mm (0.004 in.)

Valve Springs

Free Length (Approx.).......44.4 mm (1.747 in.)

Nominal Force (Valve closed) . .91 N´m @ 39.8 mm

(67 ft. lbs. @ 1.57 in.)

Nominal Force (Valve open). . .239 N´m @ 32.6 mm

(176 lbs. @ 1.28 in.)

Installed Height...........40.18 mm (1.580 in.)

* SERVICE AS AN ASSEMBLY WITH ROCKER

ARM.

** ALL READINGS IN CRANKSHAFT DEGREES,

AT 0.5 mm (0.019 in.) OF VALVE LIFT.

TORQUE CHART 2.0L SOHC

DESCRIPTION TORQUE

Camshaft Sensor Pick Up

Bolts....................9.6 N´m (85 in. lbs.)

Camshaft Sprocket

Bolt.....................115N´m(85ft.lbs.)

Connecting Rod Cap

Bolts..........27N´m(20ft.lbs.) Plus 1/4 Turn

CollarÐOil Pan to Transaxle

Step 1: Collar to Oil Pan Bolts . .3 N´m (30 in. lbs.)

Step 2: Collar to Transaxle Bolts.108 N´m (80 ft. lbs.)

Step 3: Collar to Oil Pan Bolts .54 N´m (40 ft. lbs.)

Crankshaft Main Bearing Cap/Bedplate

M8 Bedplate Bolts...........30N´m(22ft.lbs.)

M11 Main Cap Bolts.........81N´m(60ft.lbs.)

Crankshaft Damper

Bolt....................142 N´m (105 ft. lbs.)

Cylinder Head

Bolts........Refer To Cylinder Head Installation

Cylinder Head Cover

Bolts....................12N´m(105 in. lbs.)

Drive Plate to Flywheel

Bolts.....................95N´m(70ft.lbs.)

Engine Mount BracketÐRight

Bolts.....................61N´m(45ft.lbs.)DESCRIPTION TORQUE

Engine Mounting

Bolts........Refer to Engine Mount Installation

Exhaust Manifold to Cylinder Head

Bolts....................23N´m(200 in. lbs.)

Exhaust Manifold Heat Shield

Bolts....................12N´m(105 in. lbs.)

Front Mount Torque Bracket

Bolts.....................33N´m(24ft.lbs.)

Front Powertrain Bending Strut

Long Bolts................101 N´m (75 ft. lbs.)

Short Bolt.................61N´m(45ft.lbs.)

Intake Manifold

Bolts....................12N´m(105 in. lbs.)

Oil Filter Adapter

Fastener..................80N´m(60ft.lbs.)

Oil Filter..................20N´m(15ft.lbs.)

Oil Pan

Bolts....................12N´m(105 in. lbs.)

Drain Plug.................27N´m(20ft.lbs.)

Oil Pump Attaching

Bolts....................28N´m(250 in. lbs.)

Oil Pump Cover Fastener. . . .12 N´m (105 in. lbs.)

Oil Pump Pick-up Tube Bolt . .28 N´m (250 in. lbs.)

Oil Pump Relief Valve Cap. . . .41 N´m (30 ft. lbs.)

Rear Torque BracketÐ2.0L Engine

Bolts w/Auto. Transaxle......110N´m(80ft.lbs.)

Bolts w/Manual Transaxle.....61N´m(45ft.lbs.)

Rocker Arm Shaft

Bolts....................28N´m(250 in. lbs.)

Spark Plugs................28N´m(20ft.lbs.)

Thermostat Housing

Bolts....................23N´m(200 in lbs.)

Timing Belt Cover

Bolts M6.................12N´m(105 in. lbs.)

Timing Belt Tensioner AssemblyÐMechanical

Bolts....................28N´m(250 in. lbs.)

Timing Belt TensionerÐHydraulic

Pulley Bolt.................68N´m(50ft.lbs.)

Pivot Bracket Bolt...........31N´m(23ft.lbs.)

Tensioner Bolts.............31N´m(23ft.lbs.)

Water Pump Mounting

Bolts....................12N´m(105 in. lbs.)

9 - 54 2.0L SOHC ENGINEPL

SPECIFICATIONS (Continued)

Page 778 of 1200

²Step 1: Install the collar to oil pan bolts and

tighten to 3 N´m (30 in. lbs.).

²Step 2: Install collar to transaxle bolts and

tighten to 108 N´m (80 ft. lbs.).

²Step 3: Final torque the collar to oil pan bolts to

54 N´m (40 ft. lbs.).

(2) Lower vehicle.

ENGINE ASSEMBLY

REMOVAL

(1) Perform fuel pressure release procedure. Refer

to Group 14, Fuel System for procedure. Remove fuel

line to fuel rail.

(2) Disconnect and remove battery and tray. Set

Powertrain Control Module (PCM) aside.

(3) Drain cooling system. Refer to Group 7, Cooling

System for procedure.

(4) Remove upper radiator hose, radiator and fan

module. Refer to Group 7, Cooling System for proce-

dure.

(5) Remove lower radiator hose.

(6) Disconnect automatic transmission cooler lines

and plug. If equipped.

(7) Disconnect clutch cable (Manual) and transmis-

sion shift linkage.

(8) Disconnect throttle body linkage.

(9) Disconnect engine wiring harness.

(10) Disconnect heater hoses.

(11) Discharge Air Conditioning System. Refer to

Group 24, Air Conditioning for procedure.

(12) Hoist vehicle and remove right inner splash

shield (Fig. 16).

(13) Remove accessory drive belts. Refer to Group

7, Cooling System for procedure.

(14) Remove axle shafts. Refer to Group 2, Suspen-

sion and Driveshafts for procedure.

(15) Disconnect exhaust pipe from manifold.

(16) Remove front engine mount.

(17) Manual transmission: Remove power hop

damper.

Fig. 14 Power Hop Damper

Fig. 15 Structural CollarÐRemoval and Installation

Fig. 16 Right Inner Splash Shield

PL2.0L DOHC ENGINE 9 - 65

REMOVAL AND INSTALLATION (Continued)

Page 785 of 1200

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs.Refer to Group 14,

Fuel System.

(2) Disconnect negative battery cable. Drain cool-

ing system. Refer to Group 7, Cooling System.

(3) Remove air cleaner duct and air cleaner, dis-

connect all vacuum lines, electrical wiring and fuel

line from fuel rail and throttle body.

(4) Remove throttle linkage.

(5) Remove accessory drive belts. Refer to Group 7,

Cooling System for procedure.

(6) Remove power brake vacuum hose from intake

manifold.

(7) Raise vehicle and remove exhaust pipe from

manifold.

(8) Remove power steering pump assembly and set

aside.

(9) Disconnect coil pack wiring connector and

remove coil pack from engine.

(10) Remove cam sensor and fuel injectors wiring

connectors.

(11) Remove timing belt, timing belt tensioner, and

camshaft sprocket. Refer to procedure outlined in

this section.

(12) Remove inner timing belt cover.

(13) Remove cylinder head cover.

(14) Remove camshaft and cam follower assem-

blies. Refer to Camshaft Service for removal proce-

dure outlined in this section.

(15) Remove cylinder head bolts.

CAUTION: Use only a plastic scraper to remove

gasket material on the aluminum head sealing sur-

faces to prevent damage to cylinder head.

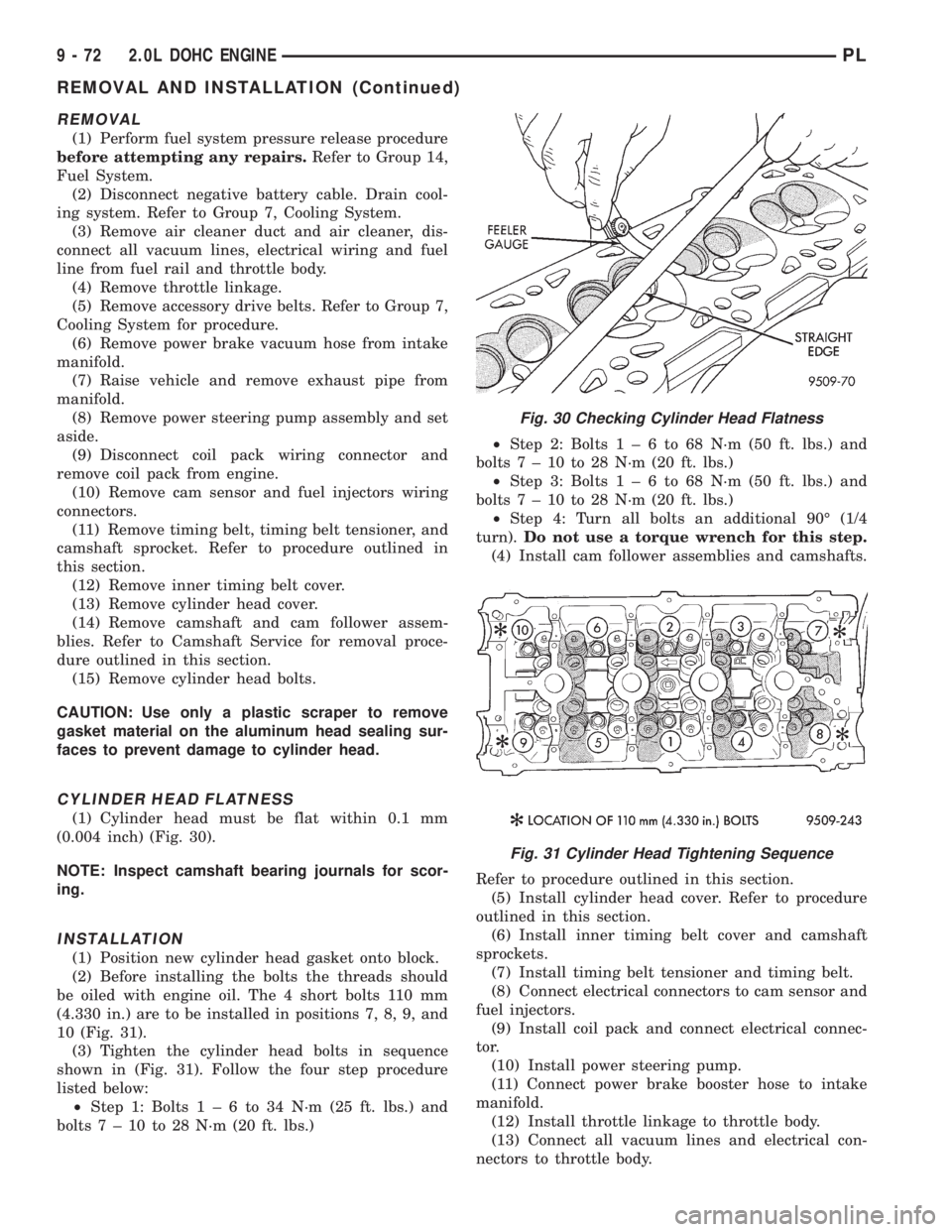

CYLINDER HEAD FLATNESS

(1) Cylinder head must be flat within 0.1 mm

(0.004 inch) (Fig. 30).

NOTE: Inspect camshaft bearing journals for scor-

ing.

INSTALLATION

(1) Position new cylinder head gasket onto block.

(2) Before installing the bolts the threads should

be oiled with engine oil. The 4 short bolts 110 mm

(4.330 in.) are to be installed in positions 7, 8, 9, and

10 (Fig. 31).

(3) Tighten the cylinder head bolts in sequence

shown in (Fig. 31). Follow the four step procedure

listed below:

²Step 1: Bolts1±6to34N´m(25ft.lbs.) and

bolts7±10to28N´m(20ft.lbs.)²Step 2: Bolts1±6to68N´m(50ft.lbs.) and

bolts7±10to28N´m(20ft.lbs.)

²Step 3: Bolts1±6to68N´m(50ft.lbs.) and

bolts7±10to28N´m(20ft.lbs.)

²Step 4: Turn all bolts an additional 90É (1/4

turn).Do not use a torque wrench for this step.

(4) Install cam follower assemblies and camshafts.

Refer to procedure outlined in this section.

(5) Install cylinder head cover. Refer to procedure

outlined in this section.

(6) Install inner timing belt cover and camshaft

sprockets.

(7) Install timing belt tensioner and timing belt.

(8) Connect electrical connectors to cam sensor and

fuel injectors.

(9) Install coil pack and connect electrical connec-

tor.

(10) Install power steering pump.

(11) Connect power brake booster hose to intake

manifold.

(12) Install throttle linkage to throttle body.

(13) Connect all vacuum lines and electrical con-

nectors to throttle body.

Fig. 30 Checking Cylinder Head Flatness

Fig. 31 Cylinder Head Tightening Sequence

9 - 72 2.0L DOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)