power steering fluid DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 3 of 1200

ENGINE OIL

SAE VISCOSITY RATING INDICATES ENGINE OIL VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. SAE 30 specifies a single viscos-

ity engine oil. Engine oils also have multiple

viscosities. These are specified with a dual SAE vis-

cosity grade which indicates the cold-to-hot tempera-

ture viscosity range.

²SAE 30 = single grade engine oil.

²SAE 10W-30 = multiple grade engine oil.

API QUALITY CLASSIFICATION

The API Service Grade specifies the type of perfor-

mance the engine oil is intended to provide. The API

Service Grade specifications also apply to energy con-

serving engine oils.

Use engine oils that are API Service Certified.

5W-30 and 10W-30 MOPAR engine oils conform to

specifications.

Refer to Group 9, Engine for engine oil specifica-

tion.

GEAR LUBRICANTS

SAE ratings also apply to multiple grade gear

lubricants. In addition, API classification defines the

lubricants usage.

LUBRICANTS AND GREASES

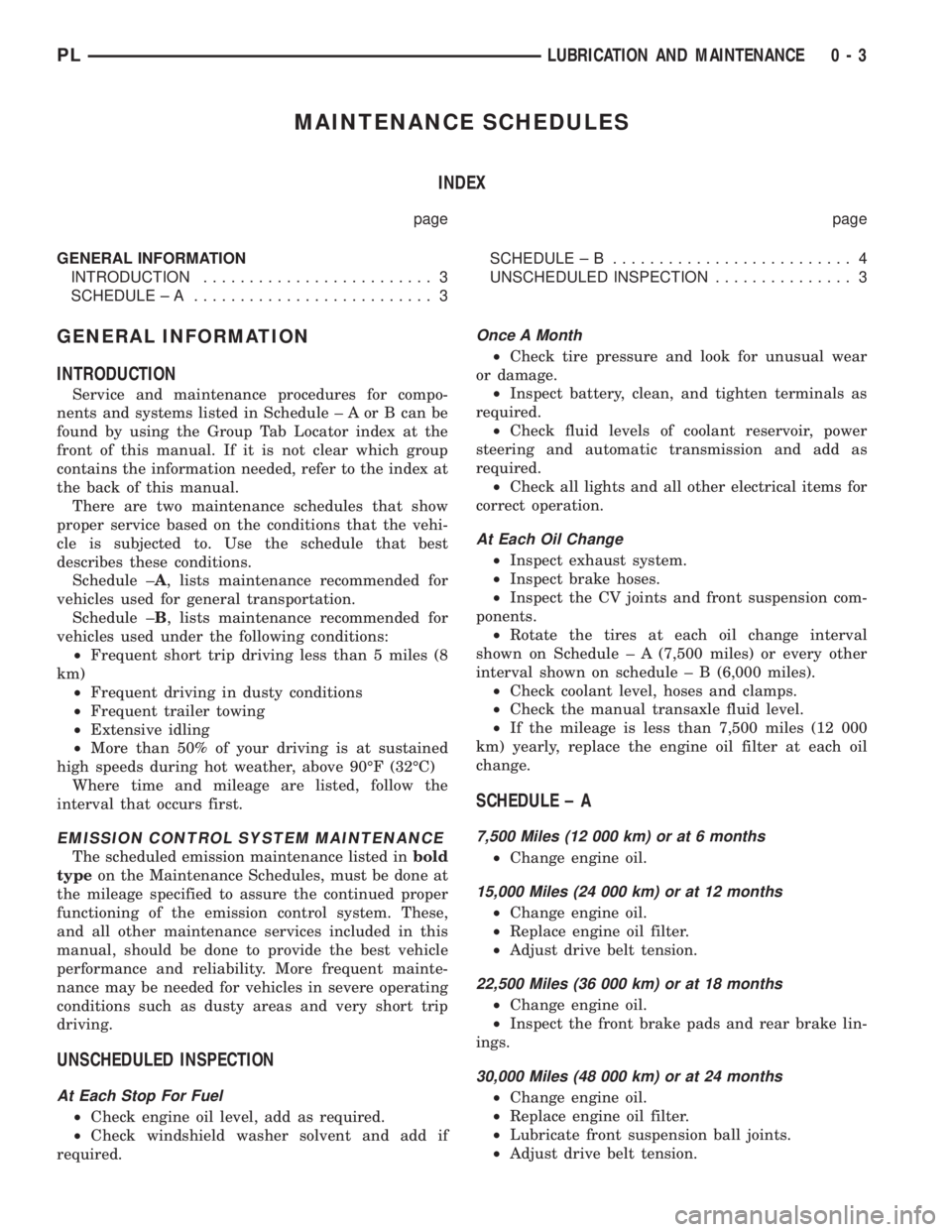

Lubricating grease is rated for quality and usage

by the NLGI. All approved products have the NLGI

symbol (Fig. 3) on the label. At the bottom NLGI

symbol is the usage and quality identification letters.

Wheel bearing lubricant is identified by the letterªGº. Chassis lubricant is identified by the latter ªLº.

The letter following the usage letter indicates the

quality of the lubricant. The following symbols indi-

cate the highest quality.

FLUID CAPACITIES

FUEL TANK

All ..........................47.3 L (12.5 gal.)

ENGINE OIL W/FILTER CHANGE

All...........................4.25 L (4.5 qts.)

ENGINE OIL W/OUT FILTER CHANGE

All............................3.8 L (4.0 qts.)

COOLING SYSTEM

All*.............................6L(6.5 qts.)

*Includes heater and coolant recovery bottle

AUTOMATIC TRANSAXLE

NOTE: Overhaul Fill Capacity with Torque Con-

verter Empty

31TH .........................8.4 L (8.9 qts.)

31 TH (Fleet Vehicles).............8.7 L (9.2 qts.)

MANUAL TRANSAXLE

NV T350.................1.9-2.2 L (4.0-4.6 pts.)

POWER STEERING

All...........................0.95 L (2.0 pts.)

Fig. 2 API Symbol

Fig. 3 NLGI Symbol

0 - 2 LUBRICATION AND MAINTENANCEPL

GENERAL INFORMATION (Continued)

Page 4 of 1200

MAINTENANCE SCHEDULES

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 3

SCHEDULE ± A.......................... 3SCHEDULE ± B.......................... 4

UNSCHEDULED INSPECTION............... 3

GENERAL INFORMATION

INTRODUCTION

Service and maintenance procedures for compo-

nents and systems listed in Schedule ± A or B can be

found by using the Group Tab Locator index at the

front of this manual. If it is not clear which group

contains the information needed, refer to the index at

the back of this manual.

There are two maintenance schedules that show

proper service based on the conditions that the vehi-

cle is subjected to. Use the schedule that best

describes these conditions.

Schedule ±A, lists maintenance recommended for

vehicles used for general transportation.

Schedule ±B, lists maintenance recommended for

vehicles used under the following conditions:

²Frequent short trip driving less than 5 miles (8

km)

²Frequent driving in dusty conditions

²Frequent trailer towing

²Extensive idling

²More than 50% of your driving is at sustained

high speeds during hot weather, above 90ÉF (32ÉC)

Where time and mileage are listed, follow the

interval that occurs first.

EMISSION CONTROL SYSTEM MAINTENANCE

The scheduled emission maintenance listed inbold

typeon the Maintenance Schedules, must be done at

the mileage specified to assure the continued proper

functioning of the emission control system. These,

and all other maintenance services included in this

manual, should be done to provide the best vehicle

performance and reliability. More frequent mainte-

nance may be needed for vehicles in severe operating

conditions such as dusty areas and very short trip

driving.

UNSCHEDULED INSPECTION

At Each Stop For Fuel

²Check engine oil level, add as required.

²Check windshield washer solvent and add if

required.

Once A Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect battery, clean, and tighten terminals as

required.

²Check fluid levels of coolant reservoir, power

steering and automatic transmission and add as

required.

²Check all lights and all other electrical items for

correct operation.

At Each Oil Change

²Inspect exhaust system.

²Inspect brake hoses.

²Inspect the CV joints and front suspension com-

ponents.

²Rotate the tires at each oil change interval

shown on Schedule ± A (7,500 miles) or every other

interval shown on schedule ± B (6,000 miles).

²Check coolant level, hoses and clamps.

²Check the manual transaxle fluid level.

²If the mileage is less than 7,500 miles (12 000

km) yearly, replace the engine oil filter at each oil

change.

SCHEDULE ± A

7,500 Miles (12 000 km) or at 6 months

²Change engine oil.

15,000 Miles (24 000 km) or at 12 months

²Change engine oil.

²Replace engine oil filter.

²Adjust drive belt tension.

22,500 Miles (36 000 km) or at 18 months

²Change engine oil.

²Inspect the front brake pads and rear brake lin-

ings.

30,000 Miles (48 000 km) or at 24 months

²Change engine oil.

²Replace engine oil filter.

²Lubricate front suspension ball joints.

²Adjust drive belt tension.

PLLUBRICATION AND MAINTENANCE 0 - 3

Page 15 of 1200

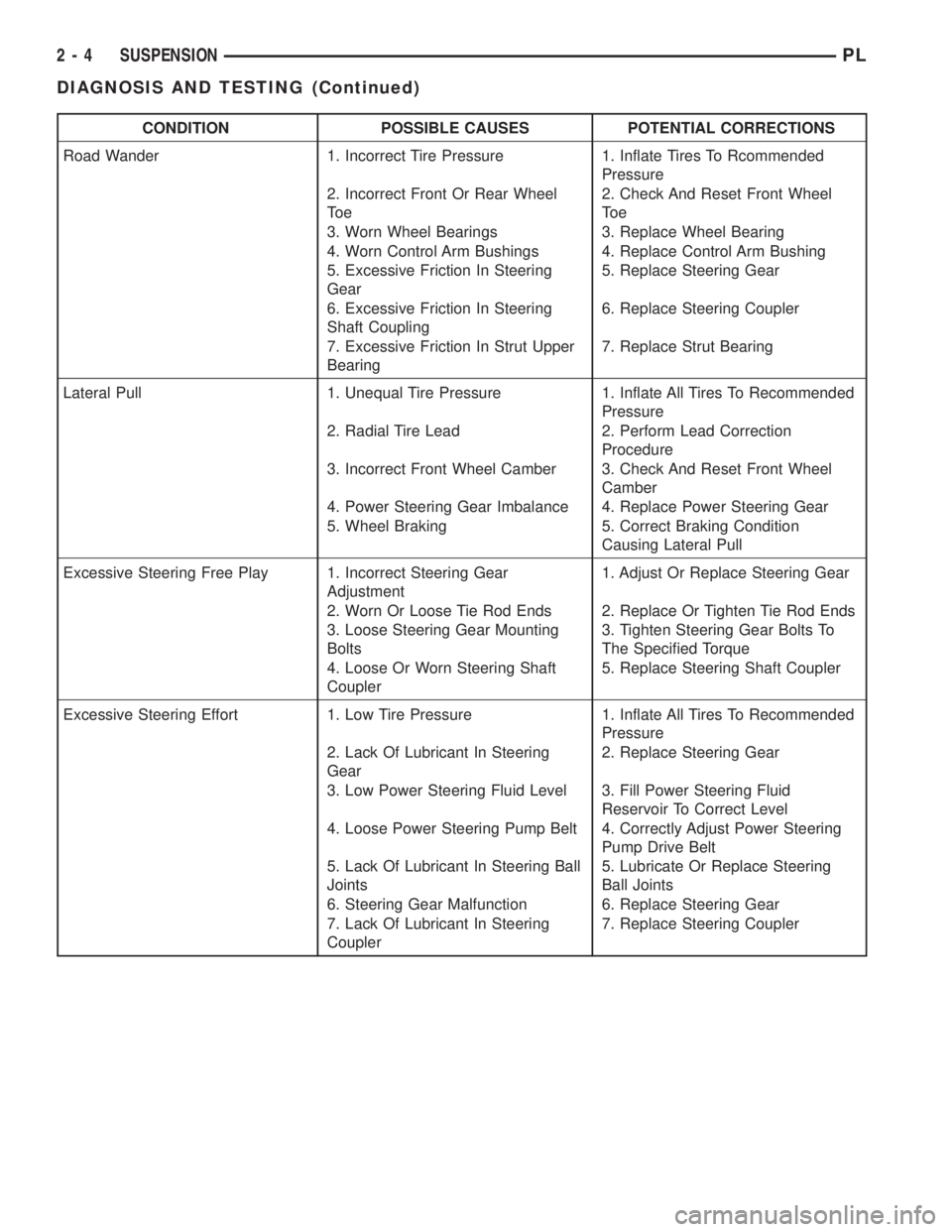

CONDITION POSSIBLE CAUSES POTENTIAL CORRECTIONS

Road Wander 1. Incorrect Tire Pressure 1. Inflate Tires To Rcommended

Pressure

2. Incorrect Front Or Rear Wheel

To e2. Check And Reset Front Wheel

To e

3. Worn Wheel Bearings 3. Replace Wheel Bearing

4. Worn Control Arm Bushings 4. Replace Control Arm Bushing

5. Excessive Friction In Steering

Gear5. Replace Steering Gear

6. Excessive Friction In Steering

Shaft Coupling6. Replace Steering Coupler

7. Excessive Friction In Strut Upper

Bearing7. Replace Strut Bearing

Lateral Pull 1. Unequal Tire Pressure 1. Inflate All Tires To Recommended

Pressure

2. Radial Tire Lead 2. Perform Lead Correction

Procedure

3. Incorrect Front Wheel Camber 3. Check And Reset Front Wheel

Camber

4. Power Steering Gear Imbalance 4. Replace Power Steering Gear

5. Wheel Braking 5. Correct Braking Condition

Causing Lateral Pull

Excessive Steering Free Play 1. Incorrect Steering Gear

Adjustment1. Adjust Or Replace Steering Gear

2. Worn Or Loose Tie Rod Ends 2. Replace Or Tighten Tie Rod Ends

3. Loose Steering Gear Mounting

Bolts3. Tighten Steering Gear Bolts To

The Specified Torque

4. Loose Or Worn Steering Shaft

Coupler5. Replace Steering Shaft Coupler

Excessive Steering Effort 1. Low Tire Pressure 1. Inflate All Tires To Recommended

Pressure

2. Lack Of Lubricant In Steering

Gear2. Replace Steering Gear

3. Low Power Steering Fluid Level 3. Fill Power Steering Fluid

Reservoir To Correct Level

4. Loose Power Steering Pump Belt 4. Correctly Adjust Power Steering

Pump Drive Belt

5. Lack Of Lubricant In Steering Ball

Joints5. Lubricate Or Replace Steering

Ball Joints

6. Steering Gear Malfunction 6. Replace Steering Gear

7. Lack Of Lubricant In Steering

Coupler7. Replace Steering Coupler

2 - 4 SUSPENSIONPL

DIAGNOSIS AND TESTING (Continued)

Page 148 of 1200

(3) Remove the rubber plug from the adjusting

hole in the brake shoe backing plate on both sides of

the vehicle.

(4)Driver (left) side park brake shoe adjust-

ment procedure.Insert a medium size screwdriver

through adjustment hole in backing plate. Position

the srewdriver against the starwheel on the park

brake shoe adjuster mechanism. Using the screw-

driver rotate the starwheeldownwarduntil a slight

drag is felt when turning the rear tire and wheel.

Then, using the screwdriver rotate the starwheel

upwardjust until the rear tire and wheel can be

rotated with no park brake shoe drag. From the

point where there is no more park brake drag rotate

the starwheelupwarda maximum of two additional

clicks. The park brake shoe to drum clearance is

know properly adjusted.

(5)Passenger (right) side park brake shoe

adjustment procedure.Insert a medium size

screwdriver through adjustment hole in backing

plate. Position the srewdriver against the starwheel

on the park brake shoe adjuster mechanism. Using

the screwdriver rotate the starwheelupwarduntil a

slight drag is felt when turning the rear tire and

wheel. Then, using the screwdriver rotate the star-

wheeldownwardjust until the rear tire and wheel

can be rotated with no park brake shoe drag. From

the point where there is no more park brake drag

rotate the starwheeldownwarda maximum of two

additional clicks. The park brake shoe to drum clear-

ance is know properly adjusted.

(6) Install the rubber plug in the adjusting hole on

the brake shoe backing plate on both sides of the

vehicle.

(7) Lower vehicle far enough to allow access the

park brake lever. The rear tires must not be on the

ground.

(8) Fully apply and release the park brakes two

times after adjusting the park brake shoes. Then

rotate both rear wheels to ensure that the park

brake shoes do not drag on the brake drum following

the application and release of the park brakes.

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications and SAE J1703 standards.

No other type of brake fluid is recommended or

approved for usage in the vehicle brake system. Use

only Mopar brake fluid or an equivalent from a

tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. Anopen container will absorb moisture from the air

and contaminate the fluid.

CAUTION: Never use any type of a petroleum-

based fluid in the brake hydraulic system. Use of

such type fluids will result in seal damage of the

vehicle brake hydraulic system causing a failure of

the vehicle brake system. Petroleum based fluids

would be items such as engine oil, transmission

fluid, power steering fluid ect.

BRAKE ACTUATION SYSTEM

ACTUATION:

Vacuum Operated Power Brakes.........Standard

Hydraulic System...........Dual-Diagonally Split

MASTER CYLINDER ASSEMBLY:

Type ...........................Dual Tandem

Body Material...............Anodized Aluminum

Reservoir Material................Polypropelene

MASTER CYLINDER BORE / STROKE

AND SPLIT:

NonABS ....21mmx32.6 mm (.875 in. x 1.28 in.)

ABS........21mmx32.7 mm (.874 in. x 1.29 in.)

Displacement Split.....................50/50

MASTER CYLINDER FLUID OUTLET PORTS:

ABS ..........Primary 3/8±24 Secondary 7/16±24

Non ABS . . .Primary Inboard And Outboard 7/16±24

Non ABS . . .Secondary Inboard And Outboard 3/8±23

Outlet Fitting Type.......SAE 45 É Inverted Flare

ABS HYDRAULIC CONTROL UNIT:

Hydraulic Tube Fitting Type.SAE 45 É Inverted Flare

BOOSTER:

Make/Type.........Bendix Vacuum W/&W/O ABS

Mounting Studs.....................M8x1.25

Type ..........................230 mm Single

Boost At 20 inches Of Manifold Vacuum. . . .4690 All

PROPORTIONING VALVE:

Material...........................Aluminum

Function........Hydraulic Pressure Proportioning

BRAKE PEDAL

Pedal Ratio.............................3.28

BRAKE FASTENER TORQUE SPECIFICATIONS

DESCRIPTION TORQUE

BRAKE TUBES:

Tube Nuts To Fittings And

Components Except HCU. . . . 17 N´m (145 in. lbs.)

From Master Cylinder To

HCU At HCU Ports........21N´m(185 in. lbs.)

BRAKE HOSE:

To Caliper Banjo Bolt..........48N´m(35ft.lbs.)

Intermediate Bracket.........12N´m(105 in. lbs.)

PLBRAKES 5 - 67

ADJUSTMENTS (Continued)

Page 150 of 1200

ANTILOCK BRAKE SYSTEM±TEVES MARK 20

INDEX

page page

DESCRIPTION AND OPERATION

ABS BRAKE SYSTEM COMPONENTS........ 71

ABS BRAKES OPERATION AND VEHICLE

PERFORMANCE....................... 69

ABS COMPONENT ABBREVIATION LIST...... 69

ABS FLUID ACCUMULATORS.............. 72

ABS FUSES............................ 73

ABS MASTER CYLINDER AND POWER BRAKE

BOOSTER............................ 71

ABS RELAYS........................... 73

ABS WARNING LAMP (YELLOW)............ 75

ANTILOCK BRAKES OPERATION

DESCRIPTION........................ 69

CONTROLLER ANTILOCK BRAKES (CAB)..... 74

HCU PUMP/MOTOR..................... 72

HYDRAULIC CIRCUITS AND VALVE

OPERATION.......................... 75

INLET VALVES AND SOLENOIDS............ 72

INTEGRATED CONTROL UNIT (ICU)......... 71

OUTLET VALVES AND SOLENOIDS.......... 72

PROPORTIONING VALVE................. 73

WHEEL SPEED SENSORS................. 73

DIAGNOSIS AND TESTING

ABS DIAGNOSTIC TROUBLE CODES........ 78

ABS DIAGNOSTICS MANUAL.............. 76

ABS GENERAL DIAGNOSTICS INFORMATION . 75

ABS SERVICE PRECAUTIONS.............. 76

ABS SYSTEM SELF DIAGNOSTICS.......... 77ABS WIRING DIAGRAM INFORMATION....... 76

BRAKE FLUID CONTAMINATION............ 80

DRB DIAGNOSTIC CONNECTOR............ 77

DRB DIAGNOSTIC SCAN TOOL USAGE...... 77

INTERMITTENT DIAGNOSTIC TROUBLE

CODES.............................. 78

PROPORTIONING VALVE................. 79

TEST DRIVING ABS COMPLAINT VEHICLE.... 80

TONEWHEEL INSPECTION................ 79

SERVICE PROCEDURES

BLEEDING TEVES MARK 20 HYDRAULIC

SYSTEM............................. 81

BRAKE FLUID LEVEL INSPECTION.......... 80

REMOVAL AND INSTALLATION

ABS GENERAL SERVICE PRECAUTIONS..... 81

ABS HYDRAULIC CONTROL UNIT........... 82

CONTROLLER ANTILOCK BRAKES (CAB)..... 86

FRONT WHEEL SPEED SENSOR........... 87

MASTER CYLINDER AND POWER BRAKE

BOOSTER............................ 86

PROPORTIONING VALVES................ 86

REAR WHEEL SPEED SENSOR............ 88

SPECIFICATIONS

BRAKE FASTENER TORQUE SPECIFICATIONS . 89

SPEED SENSOR TONE WHEEL RUNOUT..... 89

WHEEL SPEED SENSOR TO TONE WHEEL

CLEARANCE.......................... 89

DESCRIPTION AND OPERATION

ANTILOCK BRAKES OPERATION DESCRIPTION

The purpose of an Antilock Brake System (ABS) is

to prevent wheel lock-up under braking conditions on

virtually any type of road surface. Antilock Braking

is desirable because a vehicle which is stopped with-

out locking the wheels will retain directional stability

and some steering capability. This allows the driver

to retain greater control of the vehicle during brak-

ing.

This section of the service manual covers the

description and on car service for the ITT Teves

Mark 20 ABS Brake System. If other service is

required on the non ABS related components of the

brake system, refer to the appropriate section in this

group of the service manual for the specific service

procedure required.

ABS COMPONENT ABBREVIATION LIST

In this section of the service manual, several

abbreviations are used for the components of the

Teves Mark 20 ABS Brake System. They are listed

below for your reference.

²CAB±Controller Antilock Brake

²ICU±Integrated Control Unit

²HCU±Hydraulic Control Unit

²ABS±Antilock Brake System

²PSI±Pounds Per Square Inch (pressure)

²WSS±Wheel Speed Sensor

²FWD±Front Wheel Drive

²DTC±Diagnostic Trouble Code

ABS BRAKES OPERATION AND VEHICLE

PERFORMANCE

This ABS System represents the current state-of-

the-art in vehicle braking systems and offers the

driver increased safety and control during braking.

PLBRAKES 5 - 69

Page 152 of 1200

PREMATURE ABS CYCLING

NOTE: When working on a vehicle which has a

complaint of premature ABS cycling it may be nec-

essary to use a DRB Scan Tool to detect and verify

the condition.

There is one complaint called Premature ABS

Cycling in which neither the Red Brake Warning

Lamp nor the Amber Antilock Lamp were illumi-

nated and no fault codes were stored in the CAB.

Symptoms of Premature ABS Cycling, include click-

ing sounds from the solenoids valves, pump motor

running and pulsations in the brake pedal. This con-

dition can occur at any braking rate of the vehicle

and on any type of road surface. This creates an

additional condition which needs to be correctly

assessed when diagnosing problems with the antilock

brake system.

The following conditions are common causes that

need to be checked when diagnosing a condition of

Premature ABS Cycling. Damaged tone wheels,

incorrect tone wheels, damage to a wheel speed sen-

sor mounting boss on a steering knuckle, a loose

wheel speed sensor mounting bolt, and excessive tone

wheel runout. Also, an excessively large tone wheel

to wheel speed sensor air gap can lead to the condi-

tion of Premature ABS Cycling. Special attention is

to be given to these components when diagnosing a

vehicle exhibiting the condition of Premature ABS

Cycling. After diagnosing the defective component,

repair or replace as required.

When the component repair or replacement is com-

pleted, test drive the vehicle to verify the condition of

Premature ABS Cycling has been corrected.

ABS BRAKE SYSTEM COMPONENTS

The following is a detailed description of the Teves

Mark 20 ABS brake system components. For infor-

mation on servicing the base brake system compo-

nents, see the base Brake System section of this

Service Manual.

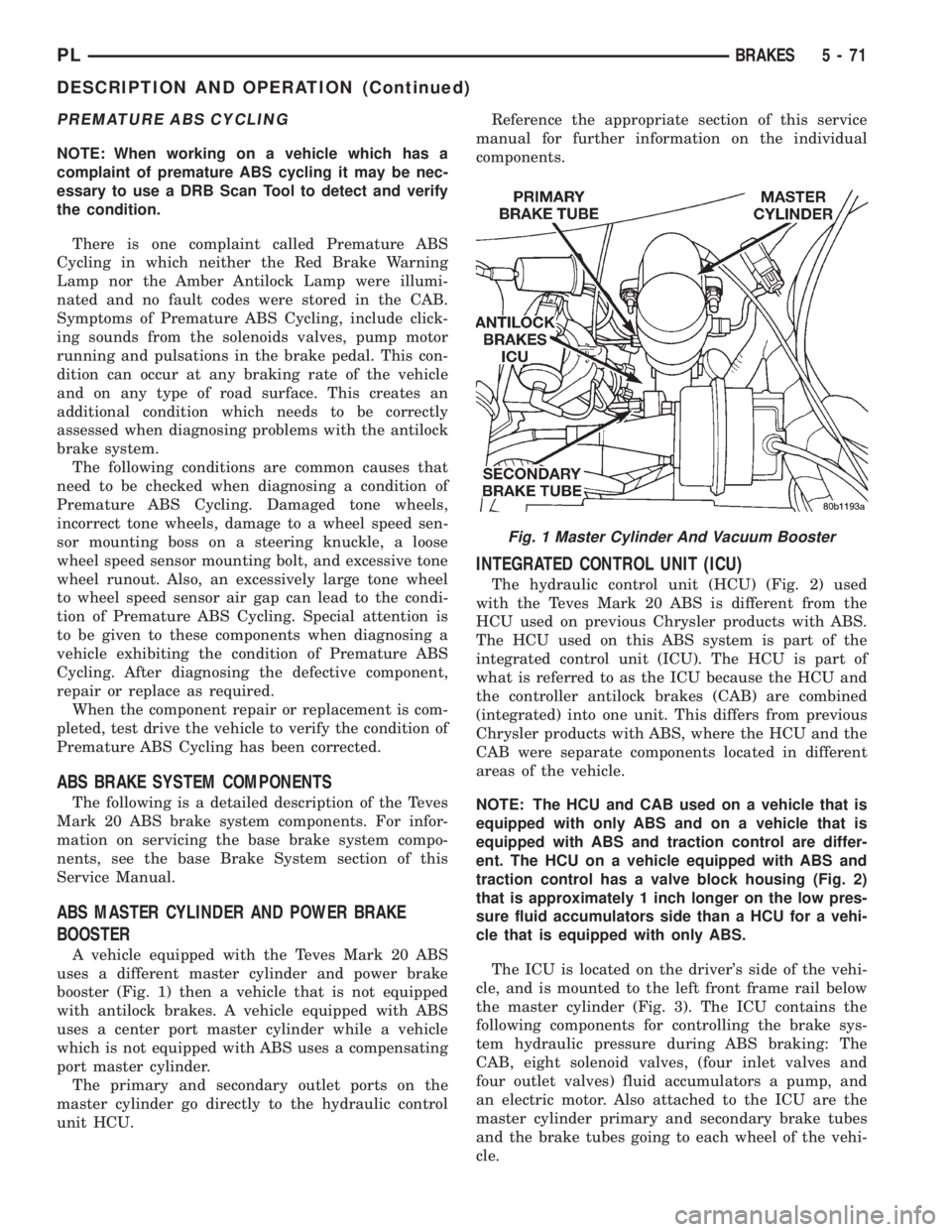

ABS MASTER CYLINDER AND POWER BRAKE

BOOSTER

A vehicle equipped with the Teves Mark 20 ABS

uses a different master cylinder and power brake

booster (Fig. 1) then a vehicle that is not equipped

with antilock brakes. A vehicle equipped with ABS

uses a center port master cylinder while a vehicle

which is not equipped with ABS uses a compensating

port master cylinder.

The primary and secondary outlet ports on the

master cylinder go directly to the hydraulic control

unit HCU.Reference the appropriate section of this service

manual for further information on the individual

components.

INTEGRATED CONTROL UNIT (ICU)

The hydraulic control unit (HCU) (Fig. 2) used

with the Teves Mark 20 ABS is different from the

HCU used on previous Chrysler products with ABS.

The HCU used on this ABS system is part of the

integrated control unit (ICU). The HCU is part of

what is referred to as the ICU because the HCU and

the controller antilock brakes (CAB) are combined

(integrated) into one unit. This differs from previous

Chrysler products with ABS, where the HCU and the

CAB were separate components located in different

areas of the vehicle.

NOTE: The HCU and CAB used on a vehicle that is

equipped with only ABS and on a vehicle that is

equipped with ABS and traction control are differ-

ent. The HCU on a vehicle equipped with ABS and

traction control has a valve block housing (Fig. 2)

that is approximately 1 inch longer on the low pres-

sure fluid accumulators side than a HCU for a vehi-

cle that is equipped with only ABS.

The ICU is located on the driver's side of the vehi-

cle, and is mounted to the left front frame rail below

the master cylinder (Fig. 3). The ICU contains the

following components for controlling the brake sys-

tem hydraulic pressure during ABS braking: The

CAB, eight solenoid valves, (four inlet valves and

four outlet valves) fluid accumulators a pump, and

an electric motor. Also attached to the ICU are the

master cylinder primary and secondary brake tubes

and the brake tubes going to each wheel of the vehi-

cle.

Fig. 1 Master Cylinder And Vacuum Booster

PLBRAKES 5 - 71

DESCRIPTION AND OPERATION (Continued)

Page 858 of 1200

(2) Disconnect vapor tube from rollover valve.

(3) Using a straight screwdriver, pry the valve out

of the grommet in the fuel filler tube.

INSTALLATION

(1) Apply a light coating of power steering fluid to

the grommet.

(2) Install valve in grommet.

(3) Attach vapor tube to valve.

(4) Install fuel filler tube cap.

ACCELERATOR PEDAL

CAUTION: When servicing the accelerator pedal,

throttle cable or speed control cable, do not dam-

age or kink the core wire inside the cable sheath-

ing.

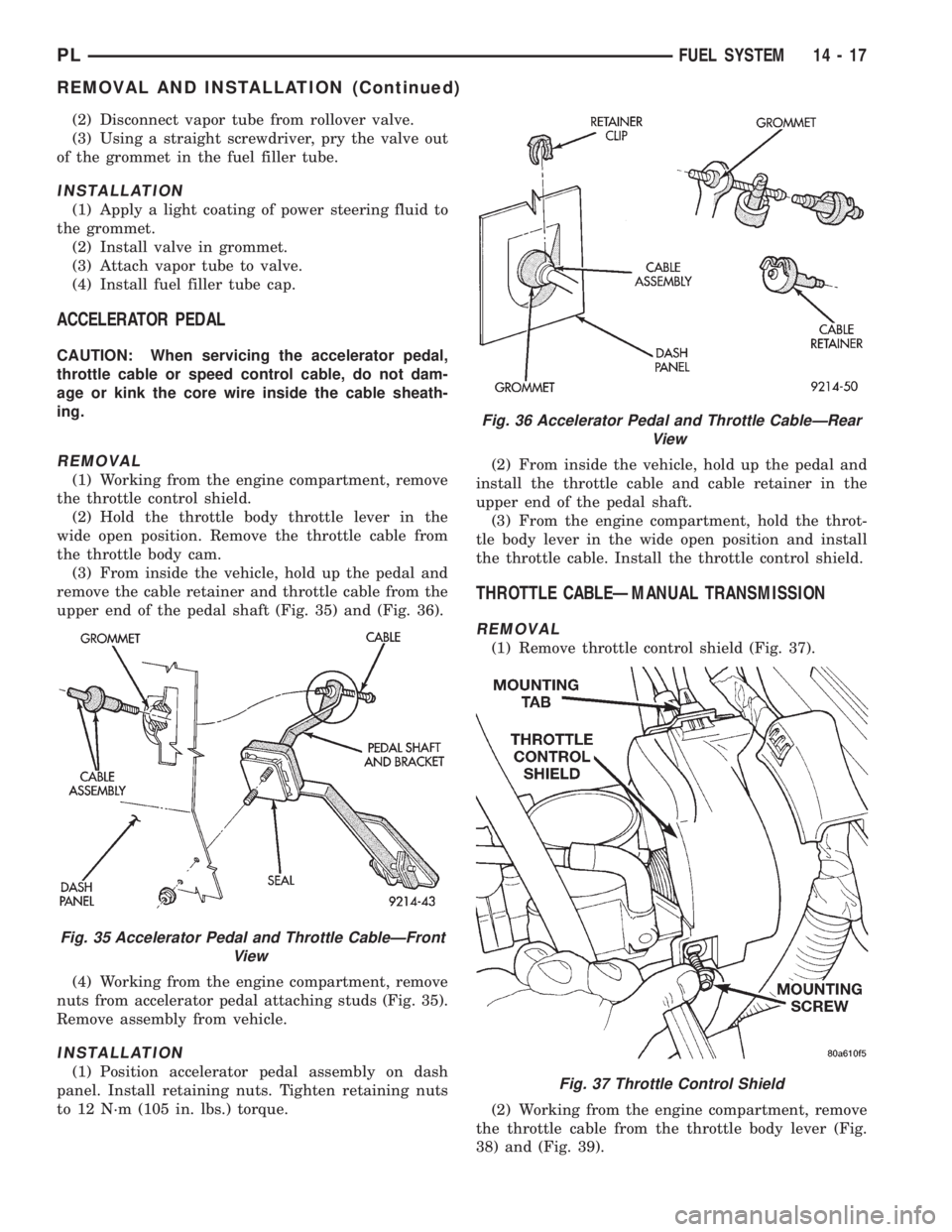

REMOVAL

(1) Working from the engine compartment, remove

the throttle control shield.

(2) Hold the throttle body throttle lever in the

wide open position. Remove the throttle cable from

the throttle body cam.

(3) From inside the vehicle, hold up the pedal and

remove the cable retainer and throttle cable from the

upper end of the pedal shaft (Fig. 35) and (Fig. 36).

(4) Working from the engine compartment, remove

nuts from accelerator pedal attaching studs (Fig. 35).

Remove assembly from vehicle.

INSTALLATION

(1) Position accelerator pedal assembly on dash

panel. Install retaining nuts. Tighten retaining nuts

to 12 N´m (105 in. lbs.) torque.(2) From inside the vehicle, hold up the pedal and

install the throttle cable and cable retainer in the

upper end of the pedal shaft.

(3) From the engine compartment, hold the throt-

tle body lever in the wide open position and install

the throttle cable. Install the throttle control shield.

THROTTLE CABLEÐMANUAL TRANSMISSION

REMOVAL

(1) Remove throttle control shield (Fig. 37).

(2) Working from the engine compartment, remove

the throttle cable from the throttle body lever (Fig.

38) and (Fig. 39).

Fig. 35 Accelerator Pedal and Throttle CableÐFront

View

Fig. 36 Accelerator Pedal and Throttle CableÐRear

View

Fig. 37 Throttle Control Shield

PLFUEL SYSTEM 14 - 17

REMOVAL AND INSTALLATION (Continued)

Page 902 of 1200

STEERING

CONTENTS

page page

GENERAL INFORMATION................... 1

POWER STEERING PUMP.................. 9STEERING COLUMN...................... 35

STEERING GEAR........................ 26

GENERAL INFORMATION

INDEX

page page

GENERAL INFORMATION

STEERING SYSTEM AND COMPONENT

DESCRIPTION......................... 1DIAGNOSIS AND TESTING

STEERING SYSTEM DIAGNOSIS CHARTS..... 2

GENERAL INFORMATION

STEERING SYSTEM AND COMPONENT

DESCRIPTION

This vehicle comes with power steering as stan-

dard equipment and is the only steering system

available.

The power steering system consists of these six

major components. Power Steering Pump, Power

Steering Gear, Power Steering Reservoir, Power

Steering Supply and Pressure Hoses, and Power

Steering Fluid Return Hose. Turning of the steering

wheel is converted into linear travel through themeshing of the helical pinion teeth with the rack

teeth. Power assist steering is provided by an open

center, rotary type control valve. It is used to direct

oil from the power steering pump to either side of the

integral steering rack piston.

Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. As steering

effort increases as in a turn, the torsion bar twists,

causing relative rotary motion between the rotary

valve body and valve spool. This movement directs

oil behind the integral rack piston, which in turn,

builds up hydraulic pressure and assists in the turn-

ing effort.

PLSTEERING 19 - 1

Page 903 of 1200

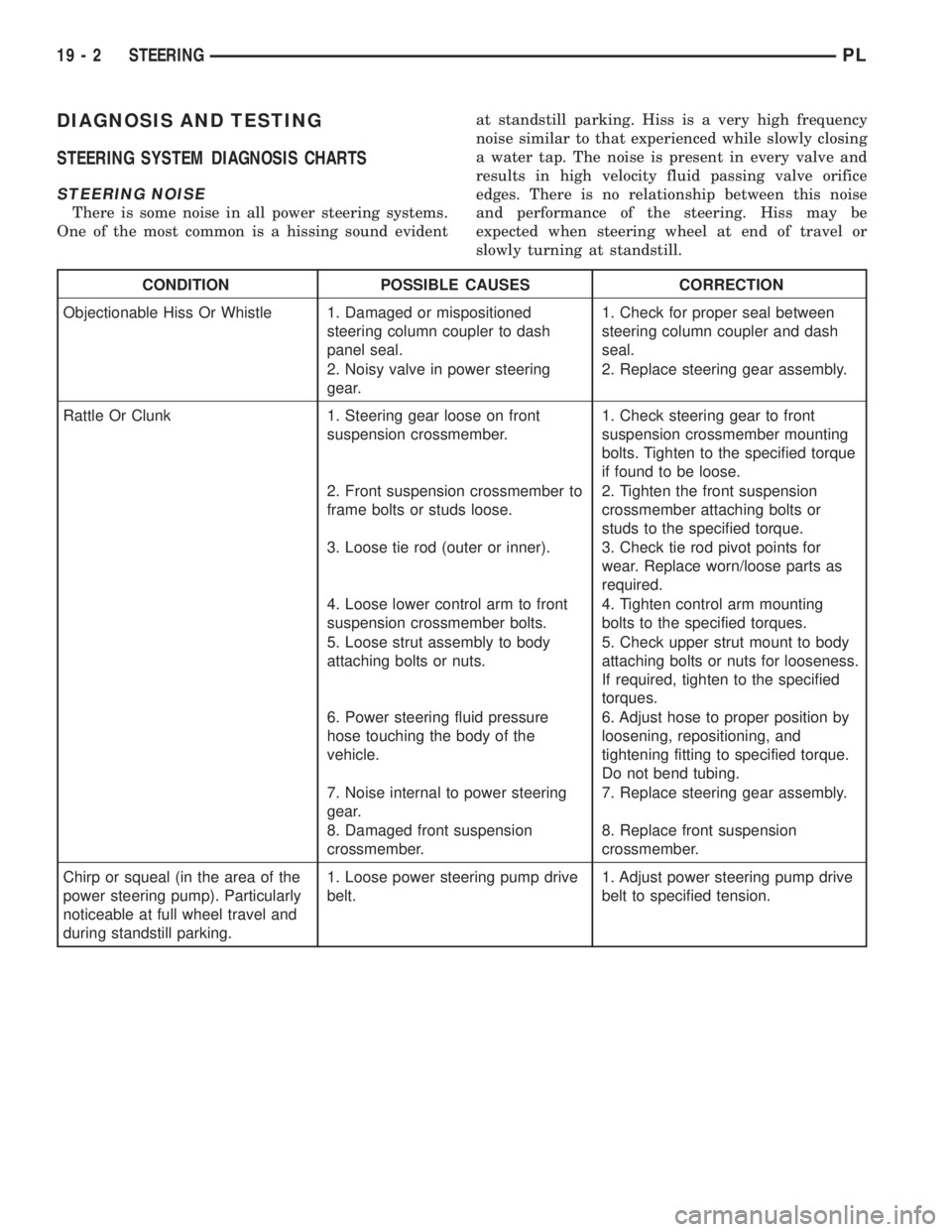

DIAGNOSIS AND TESTING

STEERING SYSTEM DIAGNOSIS CHARTS

STEERING NOISE

There is some noise in all power steering systems.

One of the most common is a hissing sound evidentat standstill parking. Hiss is a very high frequency

noise similar to that experienced while slowly closing

a water tap. The noise is present in every valve and

results in high velocity fluid passing valve orifice

edges. There is no relationship between this noise

and performance of the steering. Hiss may be

expected when steering wheel at end of travel or

slowly turning at standstill.

CONDITION POSSIBLE CAUSES CORRECTION

Objectionable Hiss Or Whistle 1. Damaged or mispositioned

steering column coupler to dash

panel seal.1. Check for proper seal between

steering column coupler and dash

seal.

2. Noisy valve in power steering

gear.2. Replace steering gear assembly.

Rattle Or Clunk 1. Steering gear loose on front

suspension crossmember.1. Check steering gear to front

suspension crossmember mounting

bolts. Tighten to the specified torque

if found to be loose.

2. Front suspension crossmember to

frame bolts or studs loose.2. Tighten the front suspension

crossmember attaching bolts or

studs to the specified torque.

3. Loose tie rod (outer or inner). 3. Check tie rod pivot points for

wear. Replace worn/loose parts as

required.

4. Loose lower control arm to front

suspension crossmember bolts.4. Tighten control arm mounting

bolts to the specified torques.

5. Loose strut assembly to body

attaching bolts or nuts.5. Check upper strut mount to body

attaching bolts or nuts for looseness.

If required, tighten to the specified

torques.

6. Power steering fluid pressure

hose touching the body of the

vehicle.6. Adjust hose to proper position by

loosening, repositioning, and

tightening fitting to specified torque.

Do not bend tubing.

7. Noise internal to power steering

gear.7. Replace steering gear assembly.

8. Damaged front suspension

crossmember.8. Replace front suspension

crossmember.

Chirp or squeal (in the area of the

power steering pump). Particularly

noticeable at full wheel travel and

during standstill parking.1. Loose power steering pump drive

belt.1. Adjust power steering pump drive

belt to specified tension.

19 - 2 STEERINGPL

Page 904 of 1200

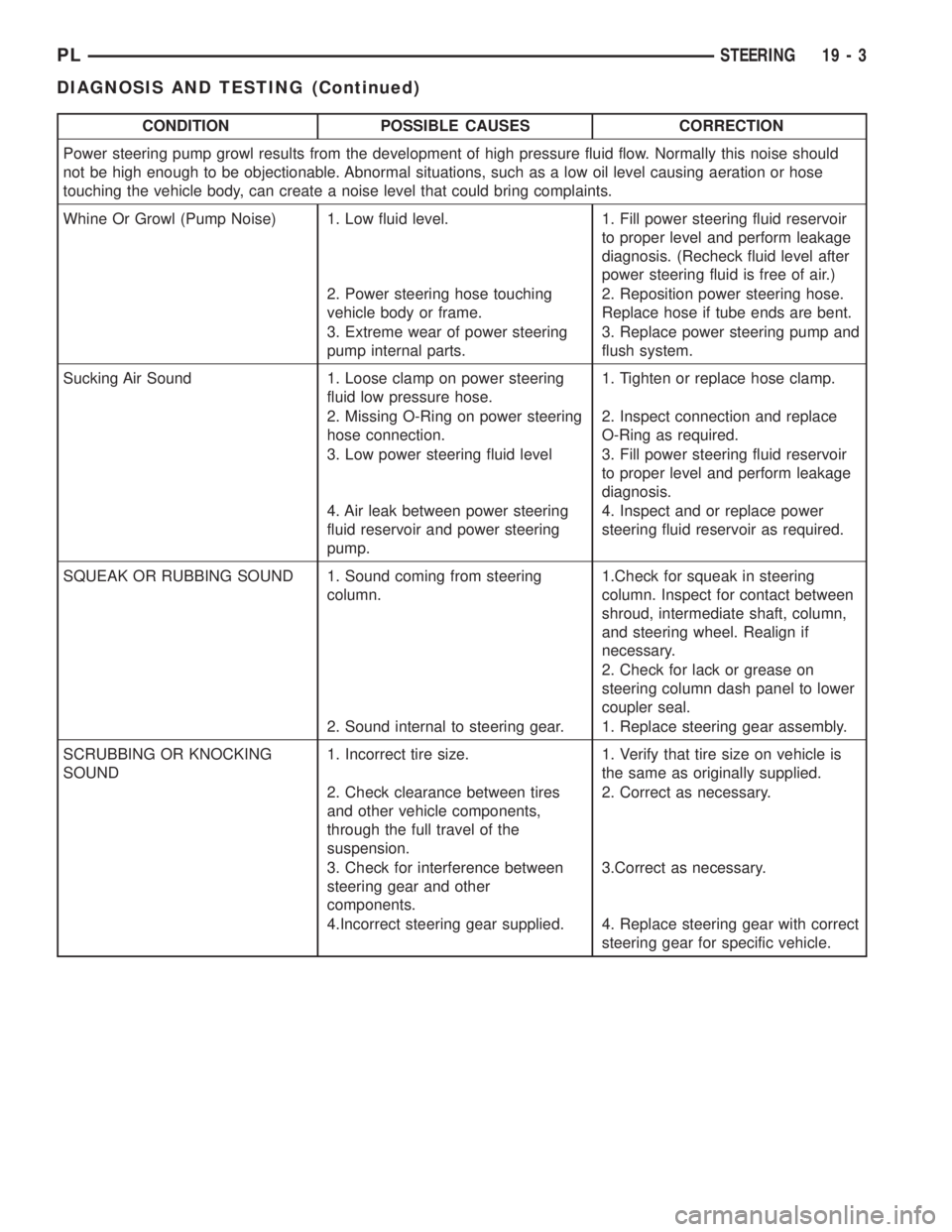

CONDITION POSSIBLE CAUSES CORRECTION

Power steering pump growl results from the development of high pressure fluid flow. Normally this noise should

not be high enough to be objectionable. Abnormal situations, such as a low oil level causing aeration or hose

touching the vehicle body, can create a noise level that could bring complaints.

Whine Or Growl (Pump Noise) 1. Low fluid level. 1. Fill power steering fluid reservoir

to proper level and perform leakage

diagnosis. (Recheck fluid level after

power steering fluid is free of air.)

2. Power steering hose touching

vehicle body or frame.2. Reposition power steering hose.

Replace hose if tube ends are bent.

3. Extreme wear of power steering

pump internal parts.3. Replace power steering pump and

flush system.

Sucking Air Sound 1. Loose clamp on power steering

fluid low pressure hose.1. Tighten or replace hose clamp.

2. Missing O-Ring on power steering

hose connection.2. Inspect connection and replace

O-Ring as required.

3. Low power steering fluid level 3. Fill power steering fluid reservoir

to proper level and perform leakage

diagnosis.

4. Air leak between power steering

fluid reservoir and power steering

pump.4. Inspect and or replace power

steering fluid reservoir as required.

SQUEAK OR RUBBING SOUND 1. Sound coming from steering

column.1.Check for squeak in steering

column. Inspect for contact between

shroud, intermediate shaft, column,

and steering wheel. Realign if

necessary.

2. Check for lack or grease on

steering column dash panel to lower

coupler seal.

2. Sound internal to steering gear. 1. Replace steering gear assembly.

SCRUBBING OR KNOCKING

SOUND1. Incorrect tire size. 1. Verify that tire size on vehicle is

the same as originally supplied.

2. Check clearance between tires

and other vehicle components,

through the full travel of the

suspension.2. Correct as necessary.

3. Check for interference between

steering gear and other

components.3.Correct as necessary.

4.Incorrect steering gear supplied. 4. Replace steering gear with correct

steering gear for specific vehicle.

PLSTEERING 19 - 3

DIAGNOSIS AND TESTING (Continued)