washer fluid DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 4 of 1200

MAINTENANCE SCHEDULES

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 3

SCHEDULE ± A.......................... 3SCHEDULE ± B.......................... 4

UNSCHEDULED INSPECTION............... 3

GENERAL INFORMATION

INTRODUCTION

Service and maintenance procedures for compo-

nents and systems listed in Schedule ± A or B can be

found by using the Group Tab Locator index at the

front of this manual. If it is not clear which group

contains the information needed, refer to the index at

the back of this manual.

There are two maintenance schedules that show

proper service based on the conditions that the vehi-

cle is subjected to. Use the schedule that best

describes these conditions.

Schedule ±A, lists maintenance recommended for

vehicles used for general transportation.

Schedule ±B, lists maintenance recommended for

vehicles used under the following conditions:

²Frequent short trip driving less than 5 miles (8

km)

²Frequent driving in dusty conditions

²Frequent trailer towing

²Extensive idling

²More than 50% of your driving is at sustained

high speeds during hot weather, above 90ÉF (32ÉC)

Where time and mileage are listed, follow the

interval that occurs first.

EMISSION CONTROL SYSTEM MAINTENANCE

The scheduled emission maintenance listed inbold

typeon the Maintenance Schedules, must be done at

the mileage specified to assure the continued proper

functioning of the emission control system. These,

and all other maintenance services included in this

manual, should be done to provide the best vehicle

performance and reliability. More frequent mainte-

nance may be needed for vehicles in severe operating

conditions such as dusty areas and very short trip

driving.

UNSCHEDULED INSPECTION

At Each Stop For Fuel

²Check engine oil level, add as required.

²Check windshield washer solvent and add if

required.

Once A Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect battery, clean, and tighten terminals as

required.

²Check fluid levels of coolant reservoir, power

steering and automatic transmission and add as

required.

²Check all lights and all other electrical items for

correct operation.

At Each Oil Change

²Inspect exhaust system.

²Inspect brake hoses.

²Inspect the CV joints and front suspension com-

ponents.

²Rotate the tires at each oil change interval

shown on Schedule ± A (7,500 miles) or every other

interval shown on schedule ± B (6,000 miles).

²Check coolant level, hoses and clamps.

²Check the manual transaxle fluid level.

²If the mileage is less than 7,500 miles (12 000

km) yearly, replace the engine oil filter at each oil

change.

SCHEDULE ± A

7,500 Miles (12 000 km) or at 6 months

²Change engine oil.

15,000 Miles (24 000 km) or at 12 months

²Change engine oil.

²Replace engine oil filter.

²Adjust drive belt tension.

22,500 Miles (36 000 km) or at 18 months

²Change engine oil.

²Inspect the front brake pads and rear brake lin-

ings.

30,000 Miles (48 000 km) or at 24 months

²Change engine oil.

²Replace engine oil filter.

²Lubricate front suspension ball joints.

²Adjust drive belt tension.

PLLUBRICATION AND MAINTENANCE 0 - 3

Page 53 of 1200

a unique bolt and nut assembly at each end. The lat-

eral arm to rear crossmember attaching bolts are

longer than the lateral arm to knuckle attaching

bolts. Each lateral arm to knuckle attaching bolt and

nut assembly uses 2 flat washers. Each lateral arm

to rear crossmember attaching bolt uses 1 flat

washer and 1 adjustment cam to provide a means for

rear wheel Toe adjustment. The tension strut assem-

bly attaches to a bracket on the frame rail and to the

bottom of the knuckle.

Lateral arms, tension struts and knuckles are nor-

mally replaced only when the part has been damaged

or when the vehicle has been involved in an accident.

If a suspension part has been damaged, be sure to

check the underbody dimensions of the car. If under-

body dimensions of the vehicle are not correct, the

frame must be straightened before replacement sus-

pension components are installed.

DIAGNOSIS AND TESTING

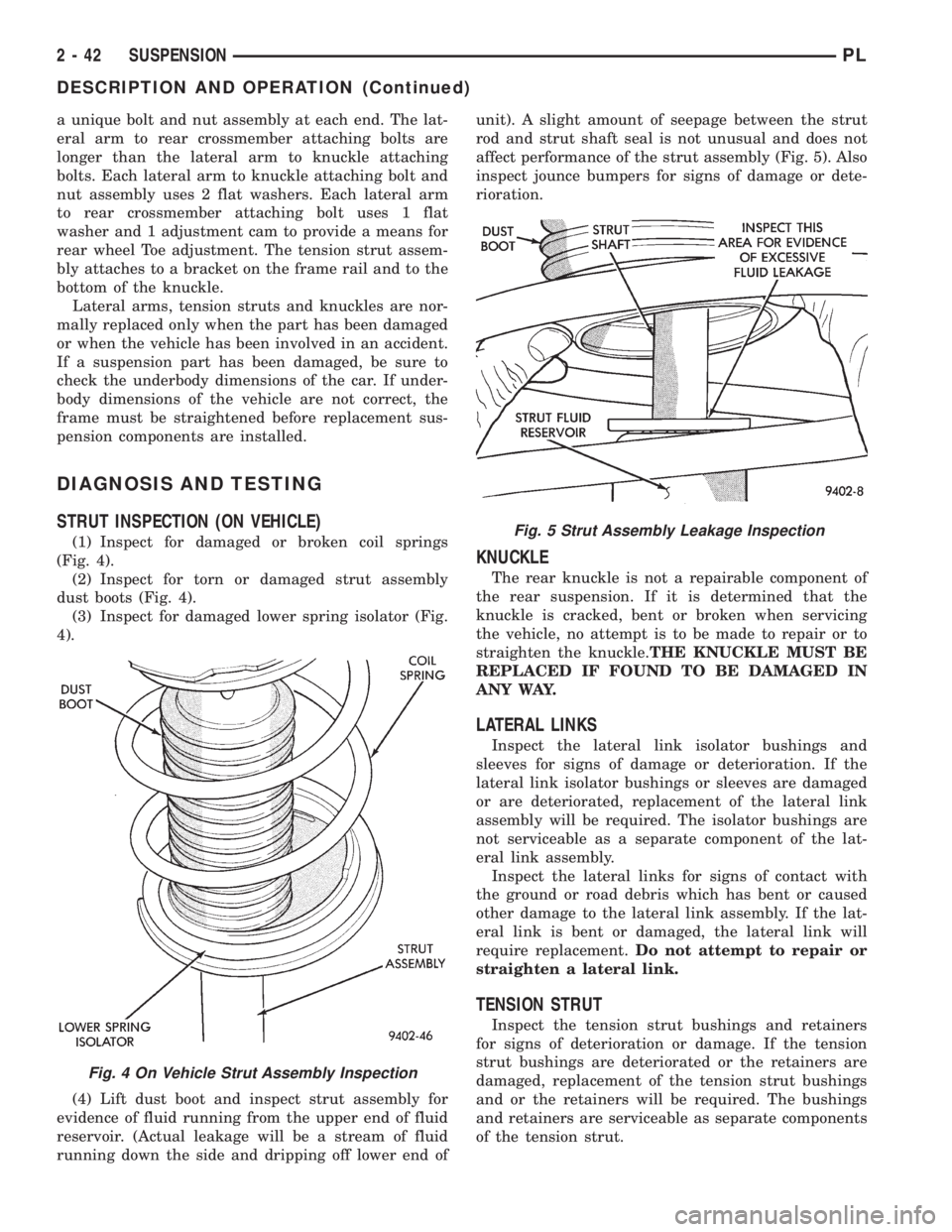

STRUT INSPECTION (ON VEHICLE)

(1) Inspect for damaged or broken coil springs

(Fig. 4).

(2) Inspect for torn or damaged strut assembly

dust boots (Fig. 4).

(3) Inspect for damaged lower spring isolator (Fig.

4).

(4) Lift dust boot and inspect strut assembly for

evidence of fluid running from the upper end of fluid

reservoir. (Actual leakage will be a stream of fluid

running down the side and dripping off lower end ofunit). A slight amount of seepage between the strut

rod and strut shaft seal is not unusual and does not

affect performance of the strut assembly (Fig. 5). Also

inspect jounce bumpers for signs of damage or dete-

rioration.

KNUCKLE

The rear knuckle is not a repairable component of

the rear suspension. If it is determined that the

knuckle is cracked, bent or broken when servicing

the vehicle, no attempt is to be made to repair or to

straighten the knuckle.THE KNUCKLE MUST BE

REPLACED IF FOUND TO BE DAMAGED IN

ANY WAY.

LATERAL LINKS

Inspect the lateral link isolator bushings and

sleeves for signs of damage or deterioration. If the

lateral link isolator bushings or sleeves are damaged

or are deteriorated, replacement of the lateral link

assembly will be required. The isolator bushings are

not serviceable as a separate component of the lat-

eral link assembly.

Inspect the lateral links for signs of contact with

the ground or road debris which has bent or caused

other damage to the lateral link assembly. If the lat-

eral link is bent or damaged, the lateral link will

require replacement.Do not attempt to repair or

straighten a lateral link.

TENSION STRUT

Inspect the tension strut bushings and retainers

for signs of deterioration or damage. If the tension

strut bushings are deteriorated or the retainers are

damaged, replacement of the tension strut bushings

and or the retainers will be required. The bushings

and retainers are serviceable as separate components

of the tension strut.

Fig. 4 On Vehicle Strut Assembly Inspection

Fig. 5 Strut Assembly Leakage Inspection

2 - 42 SUSPENSIONPL

DESCRIPTION AND OPERATION (Continued)

Page 71 of 1200

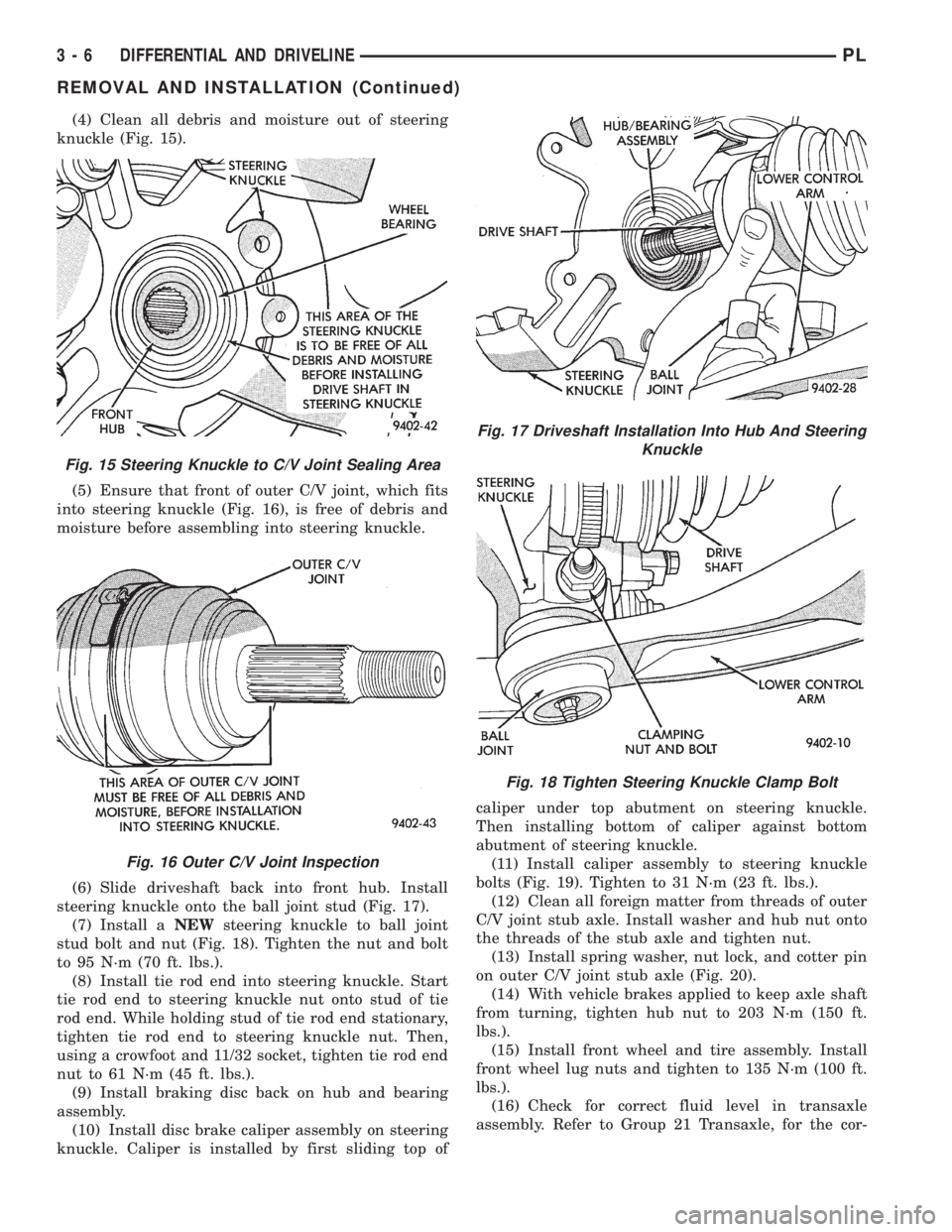

(4) Clean all debris and moisture out of steering

knuckle (Fig. 15).

(5) Ensure that front of outer C/V joint, which fits

into steering knuckle (Fig. 16), is free of debris and

moisture before assembling into steering knuckle.

(6) Slide driveshaft back into front hub. Install

steering knuckle onto the ball joint stud (Fig. 17).

(7) Install aNEWsteering knuckle to ball joint

stud bolt and nut (Fig. 18). Tighten the nut and bolt

to 95 N´m (70 ft. lbs.).

(8) Install tie rod end into steering knuckle. Start

tie rod end to steering knuckle nut onto stud of tie

rod end. While holding stud of tie rod end stationary,

tighten tie rod end to steering knuckle nut. Then,

using a crowfoot and 11/32 socket, tighten tie rod end

nut to 61 N´m (45 ft. lbs.).

(9) Install braking disc back on hub and bearing

assembly.

(10) Install disc brake caliper assembly on steering

knuckle. Caliper is installed by first sliding top ofcaliper under top abutment on steering knuckle.

Then installing bottom of caliper against bottom

abutment of steering knuckle.

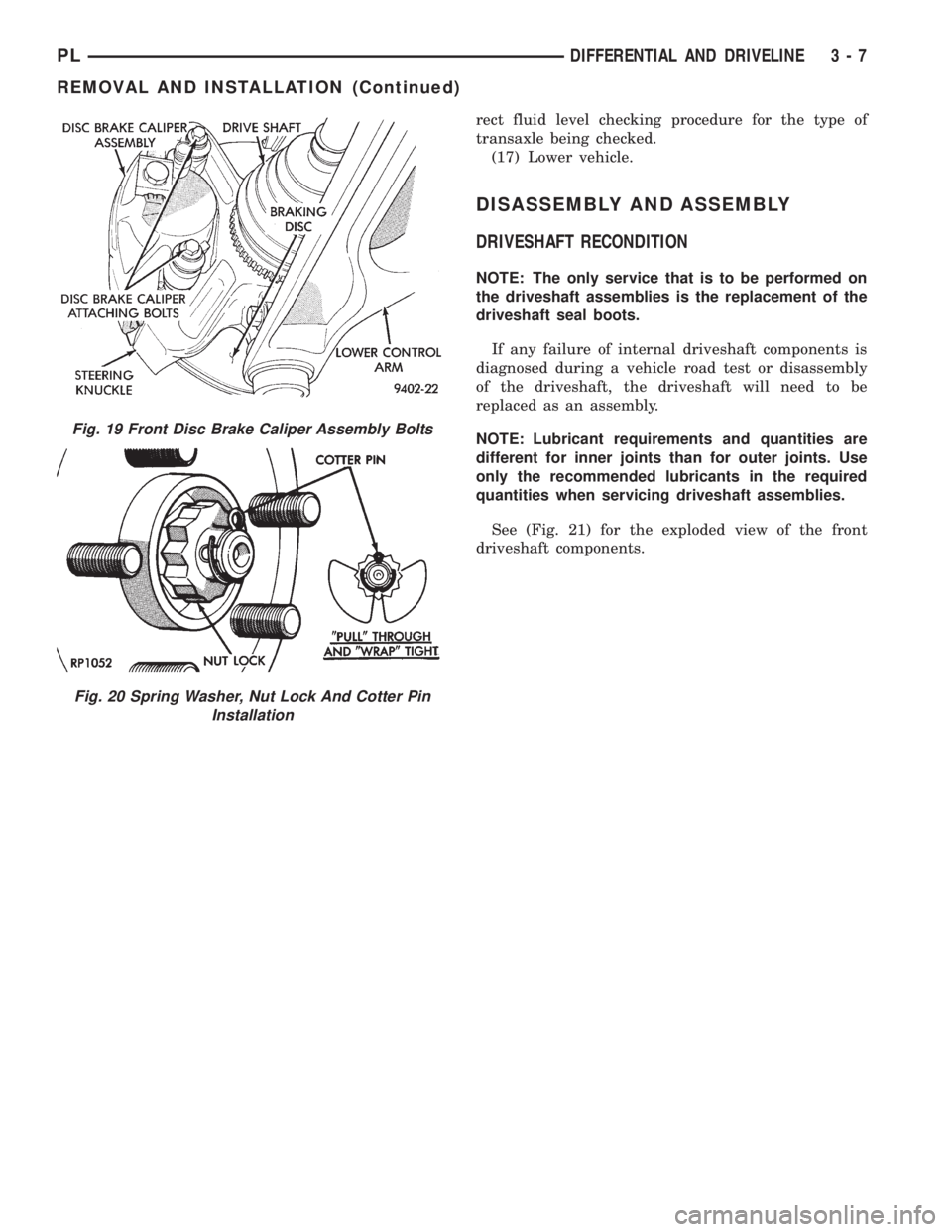

(11) Install caliper assembly to steering knuckle

bolts (Fig. 19). Tighten to 31 N´m (23 ft. lbs.).

(12) Clean all foreign matter from threads of outer

C/V joint stub axle. Install washer and hub nut onto

the threads of the stub axle and tighten nut.

(13) Install spring washer, nut lock, and cotter pin

on outer C/V joint stub axle (Fig. 20).

(14) With vehicle brakes applied to keep axle shaft

from turning, tighten hub nut to 203 N´m (150 ft.

lbs.).

(15) Install front wheel and tire assembly. Install

front wheel lug nuts and tighten to 135 N´m (100 ft.

lbs.).

(16) Check for correct fluid level in transaxle

assembly. Refer to Group 21 Transaxle, for the cor-

Fig. 15 Steering Knuckle to C/V Joint Sealing Area

Fig. 16 Outer C/V Joint Inspection

Fig. 17 Driveshaft Installation Into Hub And Steering

Knuckle

Fig. 18 Tighten Steering Knuckle Clamp Bolt

3 - 6 DIFFERENTIAL AND DRIVELINEPL

REMOVAL AND INSTALLATION (Continued)

Page 72 of 1200

rect fluid level checking procedure for the type of

transaxle being checked.

(17) Lower vehicle.

DISASSEMBLY AND ASSEMBLY

DRIVESHAFT RECONDITION

NOTE: The only service that is to be performed on

the driveshaft assemblies is the replacement of the

driveshaft seal boots.

If any failure of internal driveshaft components is

diagnosed during a vehicle road test or disassembly

of the driveshaft, the driveshaft will need to be

replaced as an assembly.

NOTE: Lubricant requirements and quantities are

different for inner joints than for outer joints. Use

only the recommended lubricants in the required

quantities when servicing driveshaft assemblies.

See (Fig. 21) for the exploded view of the front

driveshaft components.

Fig. 19 Front Disc Brake Caliper Assembly Bolts

Fig. 20 Spring Washer, Nut Lock And Cotter Pin

Installation

PLDIFFERENTIAL AND DRIVELINE 3 - 7

REMOVAL AND INSTALLATION (Continued)

Page 128 of 1200

(9) Position master cylinder on studs of power

brake unit, aligning push rod on power brake vac-

uum booster with master cylinder push rod.

(10) Install the 2 master cylinder mounting nuts

(Fig. 117) and torque to 28 N´m (250 in. lbs.) torque.

(11) Connect brake tubes to master cylinder pri-

mary and secondary ports (Fig. 115) and (Fig. 116).

Torque all tube nuts to 17 N´m (145 in. lbs.) torque.

(12) Reconnect wiring connector to fluid level sen-

sor.

(13) Adjust stop lamp switch as necessary.

(14) Bleed brake system.

CHASSIS TUBES AND HOSES

Always use Mopar replacement brake hose assem-

blies to ensure quality, correct length and superior

fatigue life. Care should be taken to make sure that

the tube and hose mating surfaces are clean and free

from nicks and burrs.Hose assemblies for each

brake are unique and not interchangeable.

Use new copper seal washers on all connections

using Banjo Bolts and tighten all fittings to their

specified torques.

The flexible front hydraulic brake hose should

always be installed on the vehicle by first attaching

the Banjo connector to the caliper assembly. Then

bolt the intermediate hose bracket to the strut

assembly allowing the bracket to position the hose to

prevent twisting. Attach the hose to brake tubing,

before attaching to front frame rail. Then tighten all

brake line fittings to specified torque.

On vehicles equipped with rear drum brakes,

install rear brake hoses first to wheel cylinders and

rear struts and then attach hose bracket to body. On

vehicles equipped with rear disc brakes, attach brake

hoses to calipers and struts first and then attach

brake hose bracket to body. Following this procedure

will reduce potential for twisting brake during instal-

lation procedure.

Only double wall 4.75mm (3/16 in.) steel brake line

tubing, with Al- Rich/ZN-AL alloy coating should be

used for replacement. Care must be taken when

replacing brake tubing, to be sure the proper bending

and flaring tools and procedures are used to avoid

kinking. Do not route the tubes against sharp edges,

moving components or into hot areas. All tubes

should be properly attached with recommended

retaining clips.

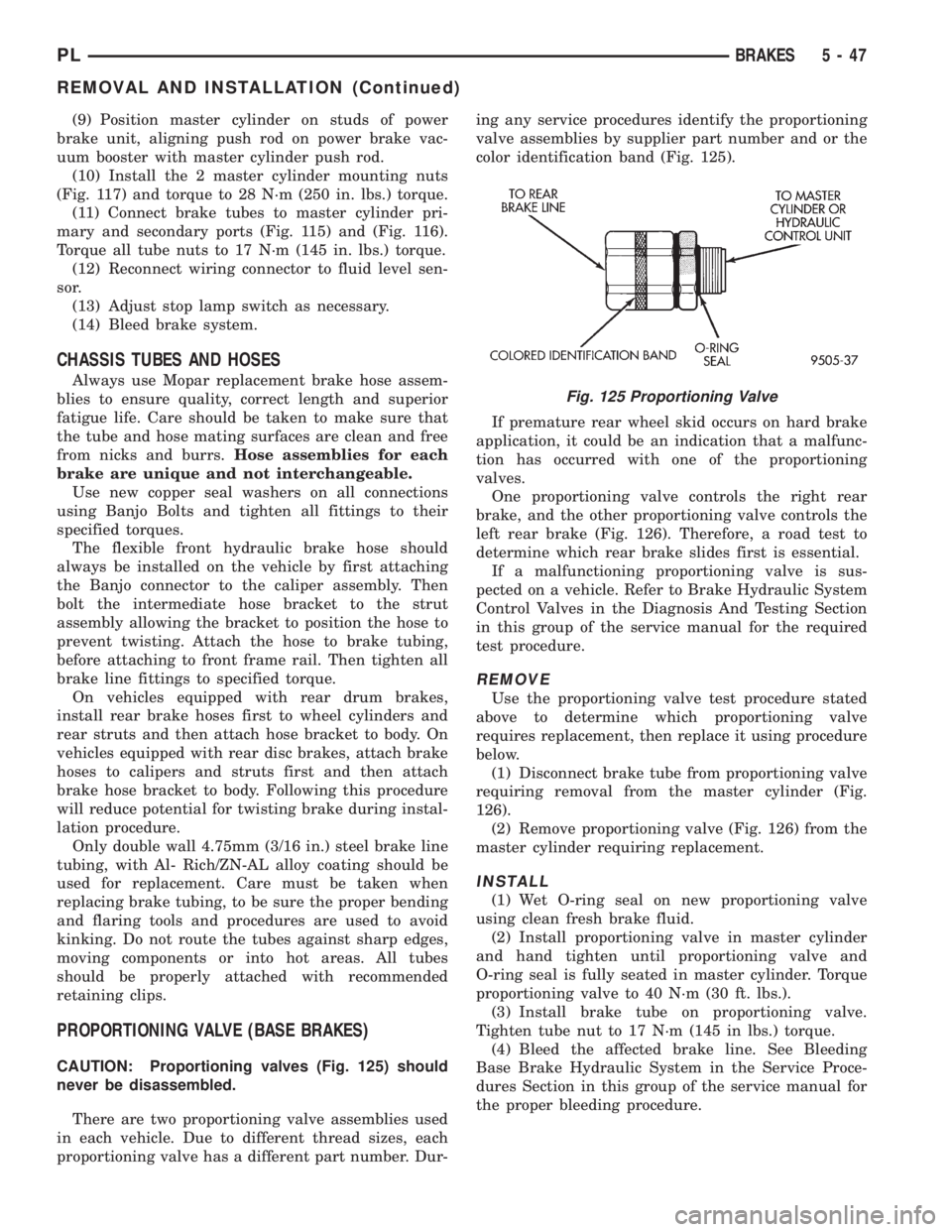

PROPORTIONING VALVE (BASE BRAKES)

CAUTION: Proportioning valves (Fig. 125) should

never be disassembled.

There are two proportioning valve assemblies used

in each vehicle. Due to different thread sizes, each

proportioning valve has a different part number. Dur-ing any service procedures identify the proportioning

valve assemblies by supplier part number and or the

color identification band (Fig. 125).

If premature rear wheel skid occurs on hard brake

application, it could be an indication that a malfunc-

tion has occurred with one of the proportioning

valves.

One proportioning valve controls the right rear

brake, and the other proportioning valve controls the

left rear brake (Fig. 126). Therefore, a road test to

determine which rear brake slides first is essential.

If a malfunctioning proportioning valve is sus-

pected on a vehicle. Refer to Brake Hydraulic System

Control Valves in the Diagnosis And Testing Section

in this group of the service manual for the required

test procedure.

REMOVE

Use the proportioning valve test procedure stated

above to determine which proportioning valve

requires replacement, then replace it using procedure

below.

(1) Disconnect brake tube from proportioning valve

requiring removal from the master cylinder (Fig.

126).

(2) Remove proportioning valve (Fig. 126) from the

master cylinder requiring replacement.

INSTALL

(1) Wet O-ring seal on new proportioning valve

using clean fresh brake fluid.

(2) Install proportioning valve in master cylinder

and hand tighten until proportioning valve and

O-ring seal is fully seated in master cylinder. Torque

proportioning valve to 40 N´m (30 ft. lbs.).

(3) Install brake tube on proportioning valve.

Tighten tube nut to 17 N´m (145 in lbs.) torque.

(4) Bleed the affected brake line. See Bleeding

Base Brake Hydraulic System in the Service Proce-

dures Section in this group of the service manual for

the proper bleeding procedure.

Fig. 125 Proportioning Valve

PLBRAKES 5 - 47

REMOVAL AND INSTALLATION (Continued)

Page 143 of 1200

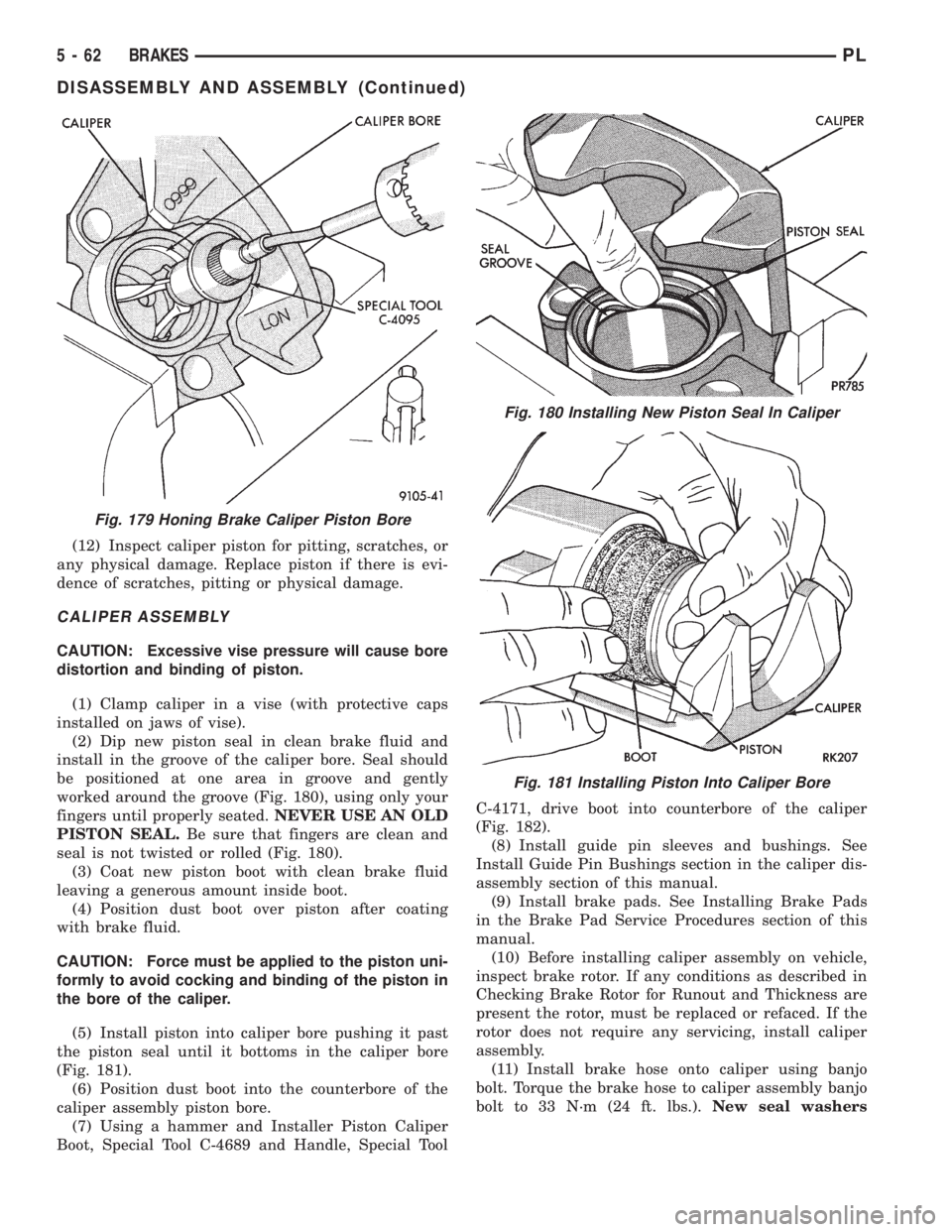

(12) Inspect caliper piston for pitting, scratches, or

any physical damage. Replace piston if there is evi-

dence of scratches, pitting or physical damage.

CALIPER ASSEMBLY

CAUTION: Excessive vise pressure will cause bore

distortion and binding of piston.

(1) Clamp caliper in a vise (with protective caps

installed on jaws of vise).

(2) Dip new piston seal in clean brake fluid and

install in the groove of the caliper bore. Seal should

be positioned at one area in groove and gently

worked around the groove (Fig. 180), using only your

fingers until properly seated.NEVER USE AN OLD

PISTON SEAL.Be sure that fingers are clean and

seal is not twisted or rolled (Fig. 180).

(3) Coat new piston boot with clean brake fluid

leaving a generous amount inside boot.

(4) Position dust boot over piston after coating

with brake fluid.

CAUTION: Force must be applied to the piston uni-

formly to avoid cocking and binding of the piston in

the bore of the caliper.

(5) Install piston into caliper bore pushing it past

the piston seal until it bottoms in the caliper bore

(Fig. 181).

(6) Position dust boot into the counterbore of the

caliper assembly piston bore.

(7) Using a hammer and Installer Piston Caliper

Boot, Special Tool C-4689 and Handle, Special ToolC-4171, drive boot into counterbore of the caliper

(Fig. 182).

(8) Install guide pin sleeves and bushings. See

Install Guide Pin Bushings section in the caliper dis-

assembly section of this manual.

(9) Install brake pads. See Installing Brake Pads

in the Brake Pad Service Procedures section of this

manual.

(10) Before installing caliper assembly on vehicle,

inspect brake rotor. If any conditions as described in

Checking Brake Rotor for Runout and Thickness are

present the rotor, must be replaced or refaced. If the

rotor does not require any servicing, install caliper

assembly.

(11) Install brake hose onto caliper using banjo

bolt. Torque the brake hose to caliper assembly banjo

bolt to 33 N´m (24 ft. lbs.).New seal washers

Fig. 179 Honing Brake Caliper Piston Bore

Fig. 180 Installing New Piston Seal In Caliper

Fig. 181 Installing Piston Into Caliper Bore

5 - 62 BRAKESPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 181 of 1200

INSTALLATION

(1) The pivot ball pocket in the fork is Teflon

coated and should be installed WITHOUT any lubri-

cant such as grease. Using grease will break down

the Teflon coating. Be sure the ball stud and fork

pocket are clean of contamination and dirt.

(2) Assemble the fork to the bearing. The small

pegs on the bearing must go over the fork arms.

(3) Slide the bearing and fork assembly onto the

input shaft bearing retainer, as a unit.

(4) Snap the clutch fork onto the pivot ball.

(5) Reinstall transaxle assembly. Refer to Group

21, Transaxle for further information.

CLEANING AND INSPECTION

CLUTCH CONTAMINATION

Fluid contamination is a frequent cause of clutch

malfunctions. Oil, grease, water, or other fluids on

the clutch contact surfaces will cause faulty opera-

tion.

During inspection, note if any components are con-

taminated. Look for evidence of oil, grease, or water/

road splash on clutch components.

OIL CONTAMINATION

Oil contamination indicates a leak at the rear main

seal and/or transaxle input shaft. Oil leaks produce a

residue of oil on the transaxle housing interior, clutch

cover and flywheel. Heat buildup caused by slippage

can bake the oil residue onto the components. This

glaze-like residue ranges in color from amber to

black.

GREASE CONTAMINATION

Grease contamination is usually a product of over-

lubrication. During clutch service, apply only a small

amount of grease to the input shaft splines. Excess

grease may be thrown off during operation, contami-

nating the disc.

ROAD SPLASH/WATER CONTAMINATION

Road splash contamination is usually caused by

driving the vehicle through deep water puddles.

Water can be forced into the clutch housing, causing

clutch components to become contaminated. Facing of

disc will absorb moisture and bond to the flywheel

and/or, pressure plate, if vehicle is allowed to stand

for some time before use. If this condition occurs,

replacement of clutch assembly may be required.

Drive the vehicle until normal clutch operating tem-

perature has been obtained. This will dry off disc

assembly, pressure plate, and flywheel.

CLEANING PRECAUTIONS

Condensation from steam vapors tend to accumu-

late on the internal clutch mechanism when the vehi-

cle is steam cleaned. Facing of disc will absorb

moisture and will bond to flywheel and/or pressure

plate, if vehicle is allowed to stand for some time

before use. If this condition occurs, it may require

replacement of clutch assembly. After cleaning, drive

the vehicle to its normal clutch operating tempera-

ture. This will dry off disc assembly, pressure plate,

and flywheel.

ADJUSTMENTS

CLUTCH CABLE

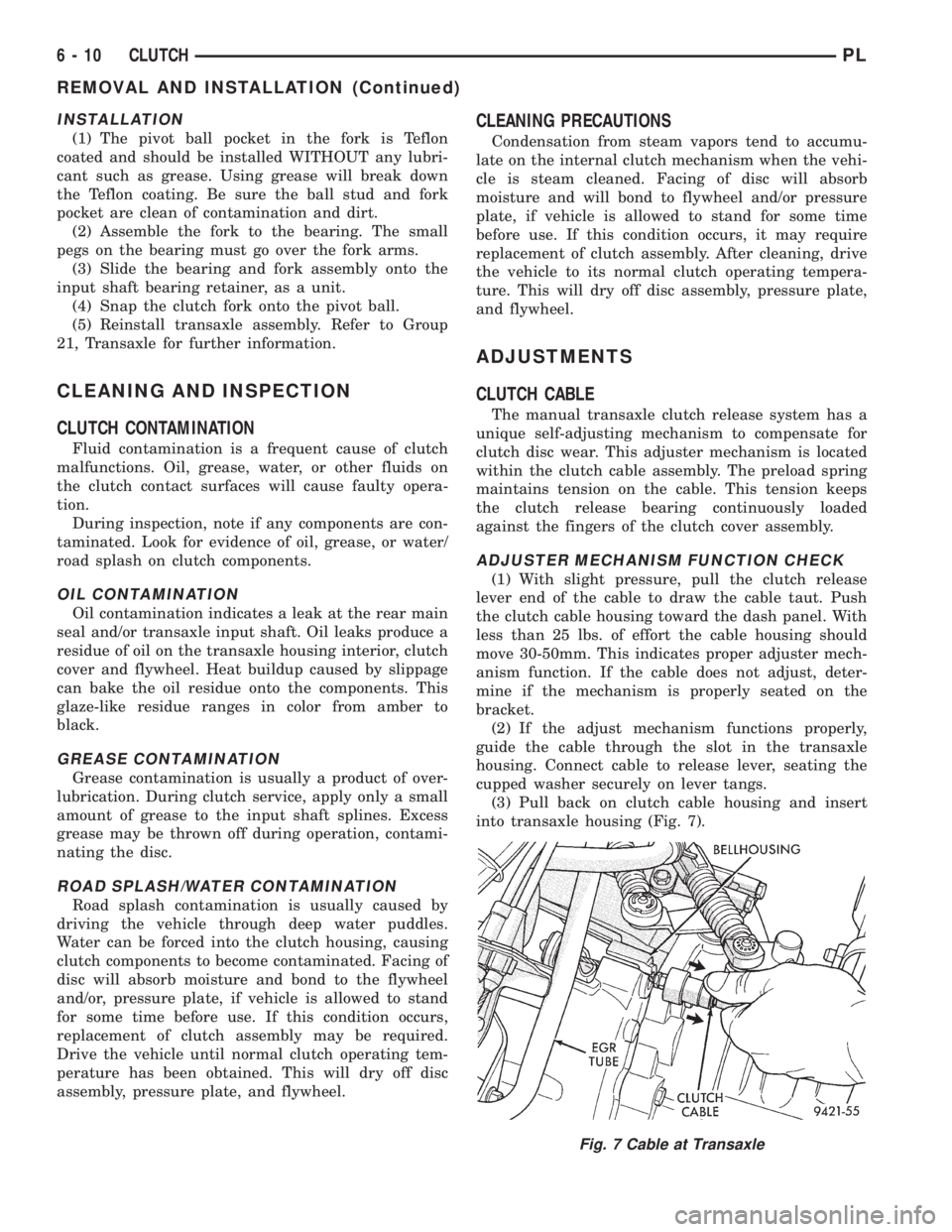

The manual transaxle clutch release system has a

unique self-adjusting mechanism to compensate for

clutch disc wear. This adjuster mechanism is located

within the clutch cable assembly. The preload spring

maintains tension on the cable. This tension keeps

the clutch release bearing continuously loaded

against the fingers of the clutch cover assembly.

ADJUSTER MECHANISM FUNCTION CHECK

(1) With slight pressure, pull the clutch release

lever end of the cable to draw the cable taut. Push

the clutch cable housing toward the dash panel. With

less than 25 lbs. of effort the cable housing should

move 30-50mm. This indicates proper adjuster mech-

anism function. If the cable does not adjust, deter-

mine if the mechanism is properly seated on the

bracket.

(2) If the adjust mechanism functions properly,

guide the cable through the slot in the transaxle

housing. Connect cable to release lever, seating the

cupped washer securely on lever tangs.

(3) Pull back on clutch cable housing and insert

into transaxle housing (Fig. 7).

Fig. 7 Cable at Transaxle

6 - 10 CLUTCHPL

REMOVAL AND INSTALLATION (Continued)

Page 261 of 1200

other operating conditions are causing engine over-

heating.

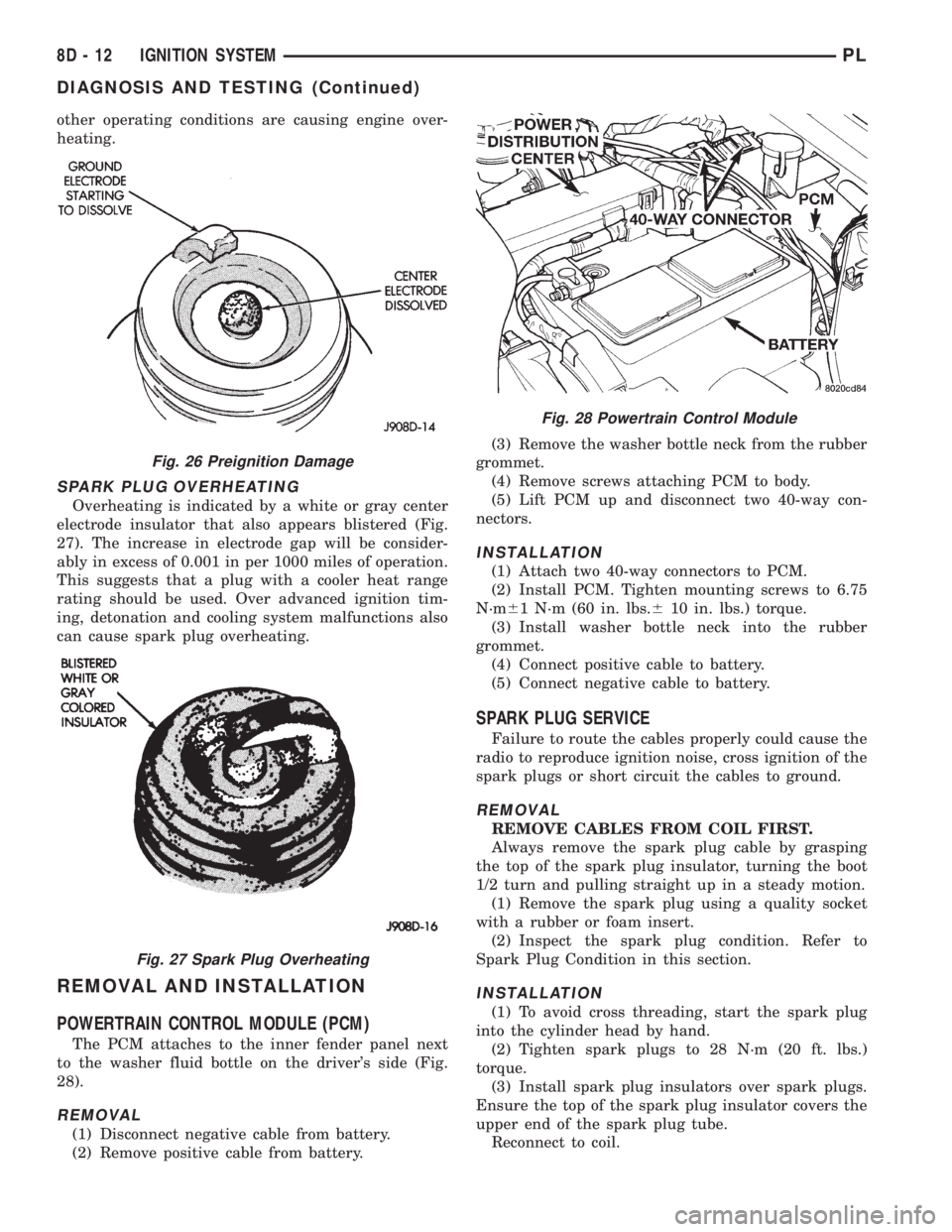

SPARK PLUG OVERHEATING

Overheating is indicated by a white or gray center

electrode insulator that also appears blistered (Fig.

27). The increase in electrode gap will be consider-

ably in excess of 0.001 in per 1000 miles of operation.

This suggests that a plug with a cooler heat range

rating should be used. Over advanced ignition tim-

ing, detonation and cooling system malfunctions also

can cause spark plug overheating.

REMOVAL AND INSTALLATION

POWERTRAIN CONTROL MODULE (PCM)

The PCM attaches to the inner fender panel next

to the washer fluid bottle on the driver's side (Fig.

28).

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove positive cable from battery.(3) Remove the washer bottle neck from the rubber

grommet.

(4) Remove screws attaching PCM to body.

(5) Lift PCM up and disconnect two 40-way con-

nectors.

INSTALLATION

(1) Attach two 40-way connectors to PCM.

(2) Install PCM. Tighten mounting screws to 6.75

N´m61 N´m (60 in. lbs.610 in. lbs.) torque.

(3) Install washer bottle neck into the rubber

grommet.

(4) Connect positive cable to battery.

(5) Connect negative cable to battery.

SPARK PLUG SERVICE

Failure to route the cables properly could cause the

radio to reproduce ignition noise, cross ignition of the

spark plugs or short circuit the cables to ground.

REMOVAL

REMOVE CABLES FROM COIL FIRST.

Always remove the spark plug cable by grasping

the top of the spark plug insulator, turning the boot

1/2 turn and pulling straight up in a steady motion.

(1) Remove the spark plug using a quality socket

with a rubber or foam insert.

(2) Inspect the spark plug condition. Refer to

Spark Plug Condition in this section.

INSTALLATION

(1) To avoid cross threading, start the spark plug

into the cylinder head by hand.

(2) Tighten spark plugs to 28 N´m (20 ft. lbs.)

torque.

(3) Install spark plug insulators over spark plugs.

Ensure the top of the spark plug insulator covers the

upper end of the spark plug tube.

Reconnect to coil.

Fig. 26 Preignition Damage

Fig. 27 Spark Plug Overheating

Fig. 28 Powertrain Control Module

8D - 12 IGNITION SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 321 of 1200

WINDSHIELD WASHER SYSTEM

INDEX

page page

DESCRIPTION AND OPERATION

WASHER NOZZLE........................ 8

DIAGNOSIS AND TESTING

WINDSHIELD WASHERS................... 8REMOVAL AND INSTALLATION

WASHER NOZZLE........................ 9

WASHER RESERVOIR PUMP.............. 10

WASHER RESERVOIR..................... 9

DESCRIPTION AND OPERATION

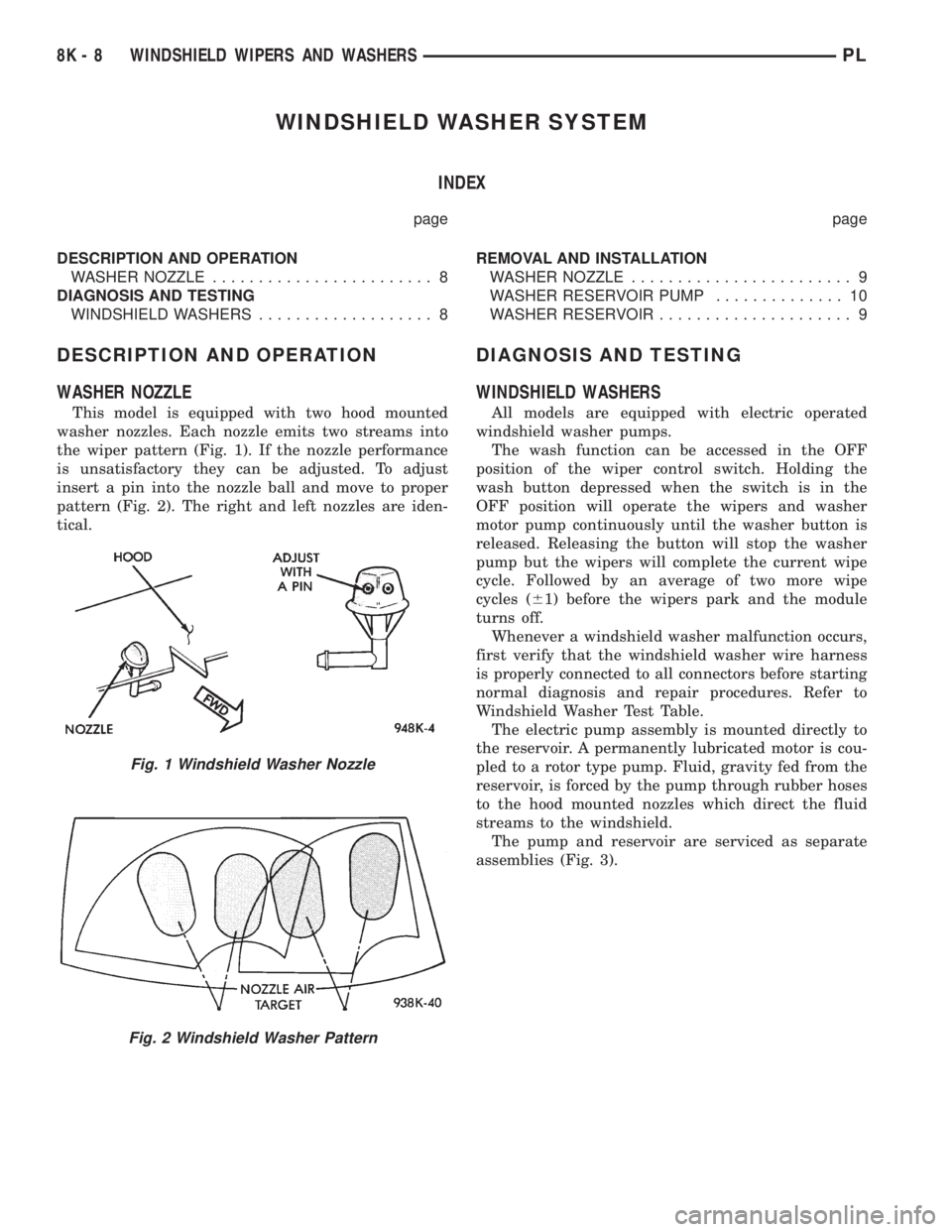

WASHER NOZZLE

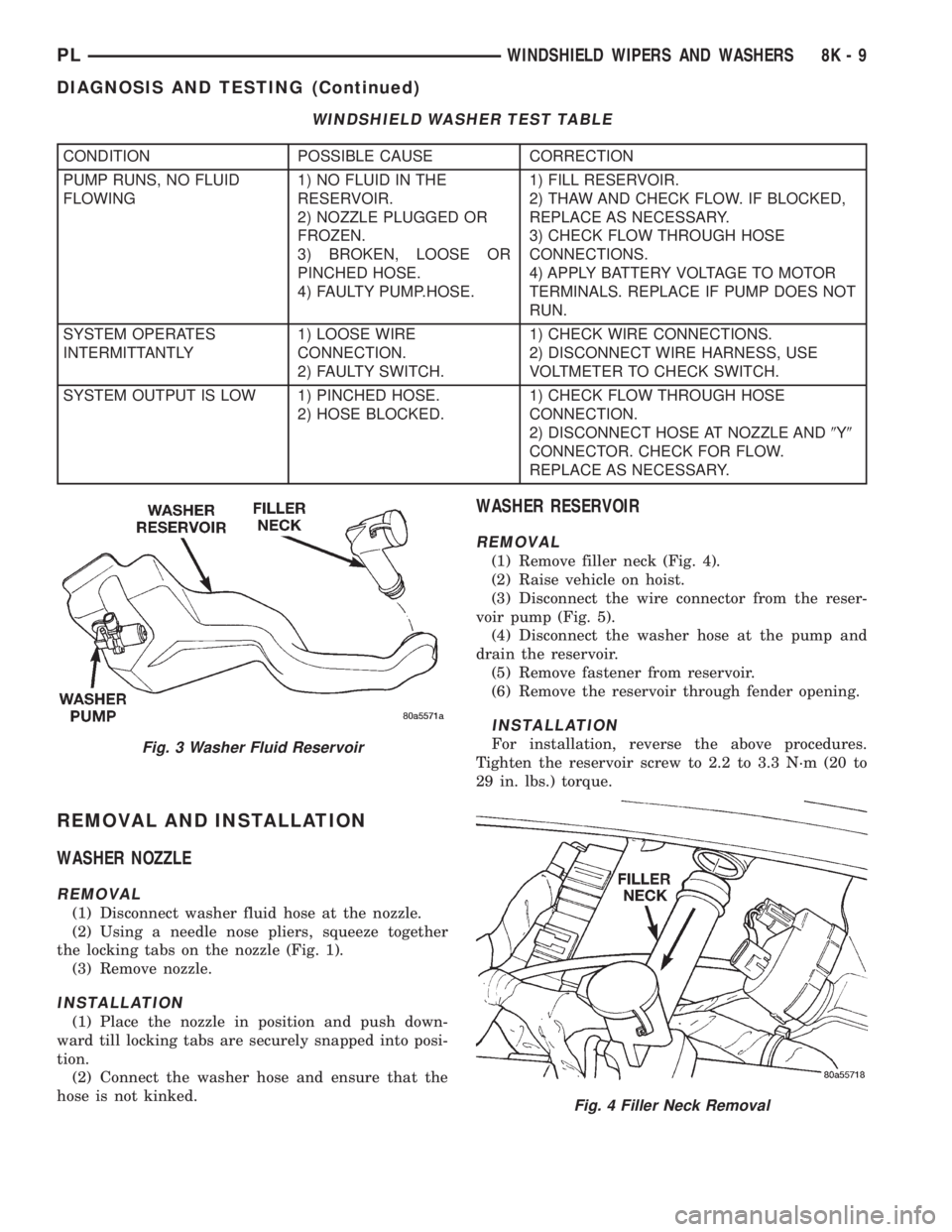

This model is equipped with two hood mounted

washer nozzles. Each nozzle emits two streams into

the wiper pattern (Fig. 1). If the nozzle performance

is unsatisfactory they can be adjusted. To adjust

insert a pin into the nozzle ball and move to proper

pattern (Fig. 2). The right and left nozzles are iden-

tical.

DIAGNOSIS AND TESTING

WINDSHIELD WASHERS

All models are equipped with electric operated

windshield washer pumps.

The wash function can be accessed in the OFF

position of the wiper control switch. Holding the

wash button depressed when the switch is in the

OFF position will operate the wipers and washer

motor pump continuously until the washer button is

released. Releasing the button will stop the washer

pump but the wipers will complete the current wipe

cycle. Followed by an average of two more wipe

cycles (61) before the wipers park and the module

turns off.

Whenever a windshield washer malfunction occurs,

first verify that the windshield washer wire harness

is properly connected to all connectors before starting

normal diagnosis and repair procedures. Refer to

Windshield Washer Test Table.

The electric pump assembly is mounted directly to

the reservoir. A permanently lubricated motor is cou-

pled to a rotor type pump. Fluid, gravity fed from the

reservoir, is forced by the pump through rubber hoses

to the hood mounted nozzles which direct the fluid

streams to the windshield.

The pump and reservoir are serviced as separate

assemblies (Fig. 3).

Fig. 1 Windshield Washer Nozzle

Fig. 2 Windshield Washer Pattern

8K - 8 WINDSHIELD WIPERS AND WASHERSPL

Page 322 of 1200

REMOVAL AND INSTALLATION

WASHER NOZZLE

REMOVAL

(1) Disconnect washer fluid hose at the nozzle.

(2) Using a needle nose pliers, squeeze together

the locking tabs on the nozzle (Fig. 1).

(3) Remove nozzle.

INSTALLATION

(1) Place the nozzle in position and push down-

ward till locking tabs are securely snapped into posi-

tion.

(2) Connect the washer hose and ensure that the

hose is not kinked.

WASHER RESERVOIR

REMOVAL

(1) Remove filler neck (Fig. 4).

(2) Raise vehicle on hoist.

(3) Disconnect the wire connector from the reser-

voir pump (Fig. 5).

(4) Disconnect the washer hose at the pump and

drain the reservoir.

(5) Remove fastener from reservoir.

(6) Remove the reservoir through fender opening.

INSTALLATION

For installation, reverse the above procedures.

Tighten the reservoir screw to 2.2 to 3.3 N´m (20 to

29 in. lbs.) torque.

WINDSHIELD WASHER TEST TABLE

CONDITION POSSIBLE CAUSE CORRECTION

PUMP RUNS, NO FLUID

FLOWING1) NO FLUID IN THE

RESERVOIR.

2) NOZZLE PLUGGED OR

FROZEN.

3) BROKEN, LOOSE OR

PINCHED HOSE.

4) FAULTY PUMP.HOSE.1) FILL RESERVOIR.

2) THAW AND CHECK FLOW. IF BLOCKED,

REPLACE AS NECESSARY.

3) CHECK FLOW THROUGH HOSE

CONNECTIONS.

4) APPLY BATTERY VOLTAGE TO MOTOR

TERMINALS. REPLACE IF PUMP DOES NOT

RUN.

SYSTEM OPERATES

INTERMITTANTLY1) LOOSE WIRE

CONNECTION.

2) FAULTY SWITCH.1) CHECK WIRE CONNECTIONS.

2) DISCONNECT WIRE HARNESS, USE

VOLTMETER TO CHECK SWITCH.

SYSTEM OUTPUT IS LOW 1) PINCHED HOSE.

2) HOSE BLOCKED.1) CHECK FLOW THROUGH HOSE

CONNECTION.

2) DISCONNECT HOSE AT NOZZLE AND9Y9

CONNECTOR. CHECK FOR FLOW.

REPLACE AS NECESSARY.

Fig. 3 Washer Fluid Reservoir

Fig. 4 Filler Neck Removal

PLWINDSHIELD WIPERS AND WASHERS 8K - 9

DIAGNOSIS AND TESTING (Continued)