length DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 60 of 1200

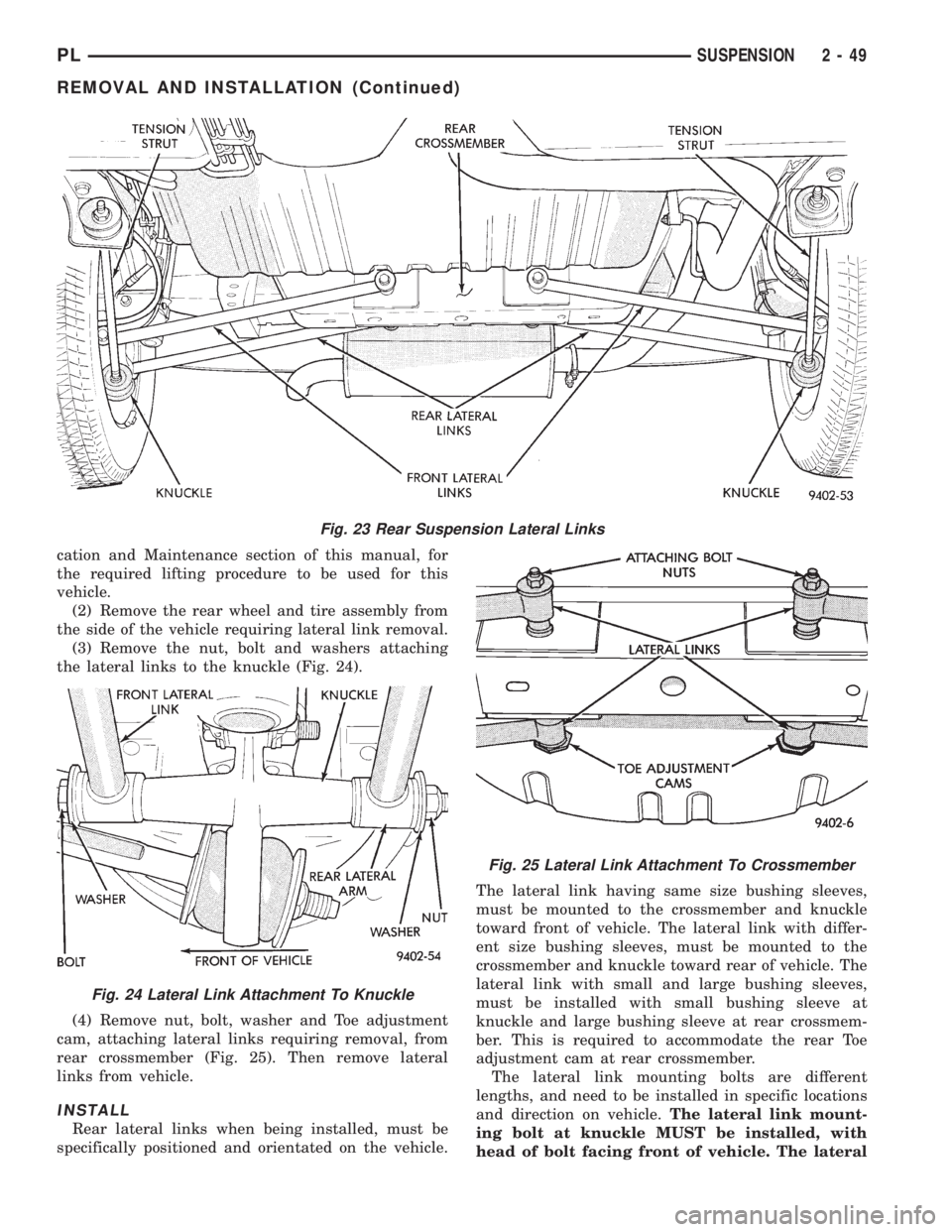

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(2) Remove the rear wheel and tire assembly from

the side of the vehicle requiring lateral link removal.

(3) Remove the nut, bolt and washers attaching

the lateral links to the knuckle (Fig. 24).

(4) Remove nut, bolt, washer and Toe adjustment

cam, attaching lateral links requiring removal, from

rear crossmember (Fig. 25). Then remove lateral

links from vehicle.

INSTALL

Rear lateral links when being installed, must be

specifically positioned and orientated on the vehicle.The lateral link having same size bushing sleeves,

must be mounted to the crossmember and knuckle

toward front of vehicle. The lateral link with differ-

ent size bushing sleeves, must be mounted to the

crossmember and knuckle toward rear of vehicle. The

lateral link with small and large bushing sleeves,

must be installed with small bushing sleeve at

knuckle and large bushing sleeve at rear crossmem-

ber. This is required to accommodate the rear Toe

adjustment cam at rear crossmember.

The lateral link mounting bolts are different

lengths, and need to be installed in specific locations

and direction on vehicle.The lateral link mount-

ing bolt at knuckle MUST be installed, with

head of bolt facing front of vehicle. The lateral

Fig. 23 Rear Suspension Lateral Links

Fig. 24 Lateral Link Attachment To Knuckle

Fig. 25 Lateral Link Attachment To Crossmember

PLSUSPENSION 2 - 49

REMOVAL AND INSTALLATION (Continued)

Page 66 of 1200

DIFFERENTIAL AND DRIVELINE

CONTENTS

page page

GENERAL INFORMATION

FRONT DRIVESHAFTS.................... 1

DIAGNOSIS AND TESTING

DRIVESHAFT DIAGNOSIS.................. 2

REMOVAL AND INSTALLATION

FRONT DRIVESHAFTS.................... 2

DISASSEMBLY AND ASSEMBLY

DRIVESHAFT RECONDITION............... 7INNER TRIPOD JOINT SEAL BOOT.......... 9

OUTER C/V JOINT SEAL BOOT............ 13

SPECIFICATIONS

TORQUE.............................. 16

SPECIAL TOOLS

DRIVESHAFT........................... 16

GENERAL INFORMATION

FRONT DRIVESHAFTS

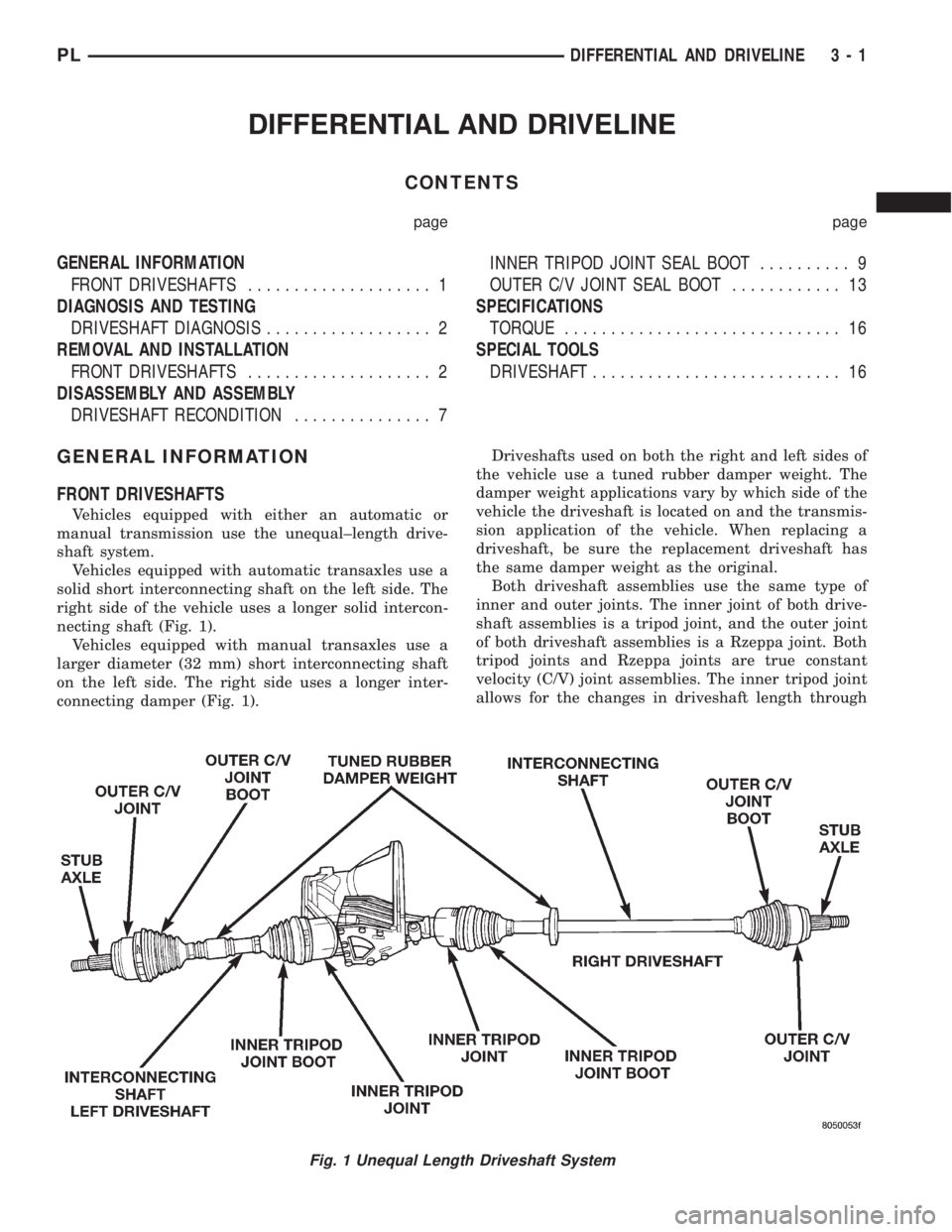

Vehicles equipped with either an automatic or

manual transmission use the unequal±length drive-

shaft system.

Vehicles equipped with automatic transaxles use a

solid short interconnecting shaft on the left side. The

right side of the vehicle uses a longer solid intercon-

necting shaft (Fig. 1).

Vehicles equipped with manual transaxles use a

larger diameter (32 mm) short interconnecting shaft

on the left side. The right side uses a longer inter-

connecting damper (Fig. 1).Driveshafts used on both the right and left sides of

the vehicle use a tuned rubber damper weight. The

damper weight applications vary by which side of the

vehicle the driveshaft is located on and the transmis-

sion application of the vehicle. When replacing a

driveshaft, be sure the replacement driveshaft has

the same damper weight as the original.

Both driveshaft assemblies use the same type of

inner and outer joints. The inner joint of both drive-

shaft assemblies is a tripod joint, and the outer joint

of both driveshaft assemblies is a Rzeppa joint. Both

tripod joints and Rzeppa joints are true constant

velocity (C/V) joint assemblies. The inner tripod joint

allows for the changes in driveshaft length through

Fig. 1 Unequal Length Driveshaft System

PLDIFFERENTIAL AND DRIVELINE 3 - 1

Page 77 of 1200

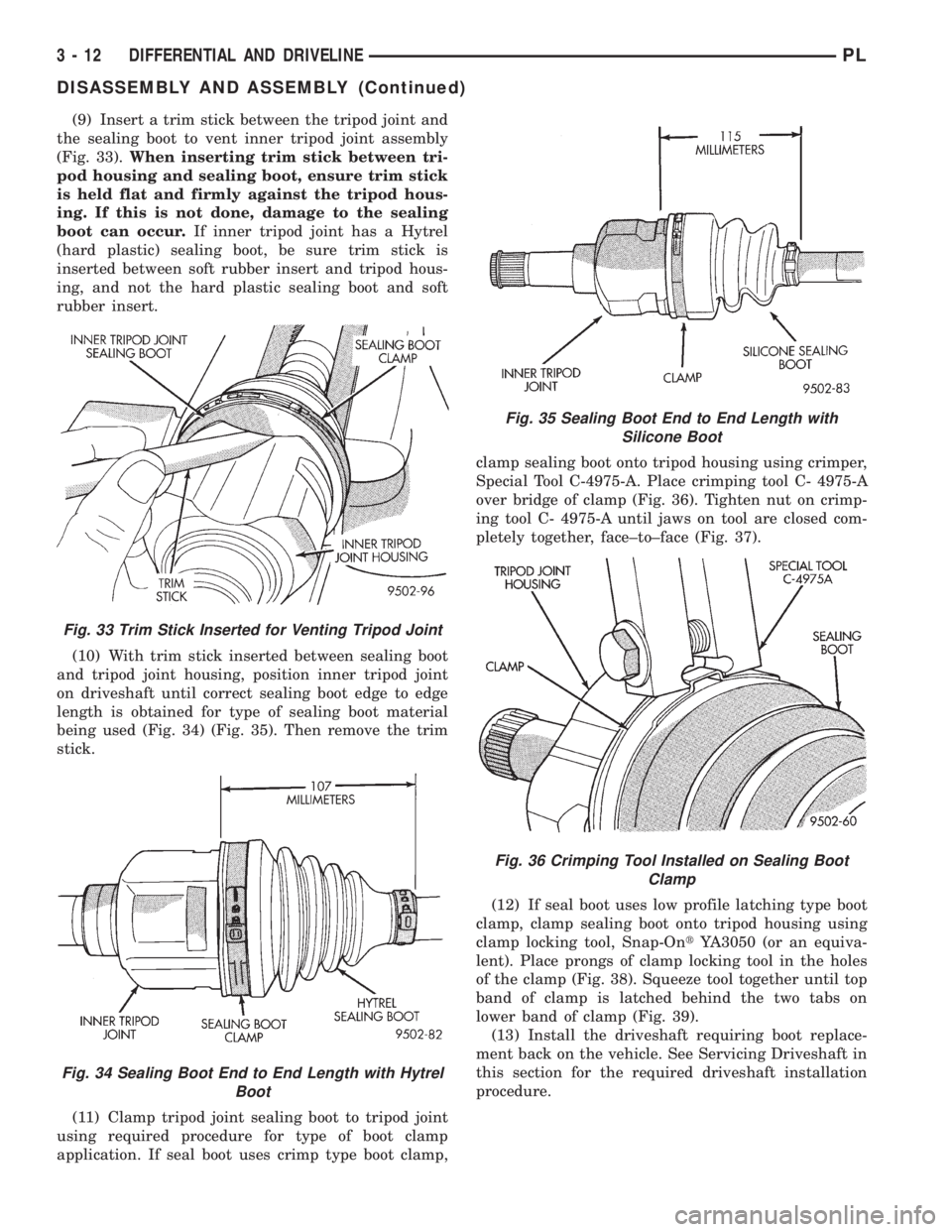

(9) Insert a trim stick between the tripod joint and

the sealing boot to vent inner tripod joint assembly

(Fig. 33).When inserting trim stick between tri-

pod housing and sealing boot, ensure trim stick

is held flat and firmly against the tripod hous-

ing. If this is not done, damage to the sealing

boot can occur.If inner tripod joint has a Hytrel

(hard plastic) sealing boot, be sure trim stick is

inserted between soft rubber insert and tripod hous-

ing, and not the hard plastic sealing boot and soft

rubber insert.

(10) With trim stick inserted between sealing boot

and tripod joint housing, position inner tripod joint

on driveshaft until correct sealing boot edge to edge

length is obtained for type of sealing boot material

being used (Fig. 34) (Fig. 35). Then remove the trim

stick.

(11) Clamp tripod joint sealing boot to tripod joint

using required procedure for type of boot clamp

application. If seal boot uses crimp type boot clamp,clamp sealing boot onto tripod housing using crimper,

Special Tool C-4975-A. Place crimping tool C- 4975-A

over bridge of clamp (Fig. 36). Tighten nut on crimp-

ing tool C- 4975-A until jaws on tool are closed com-

pletely together, face±to±face (Fig. 37).

(12) If seal boot uses low profile latching type boot

clamp, clamp sealing boot onto tripod housing using

clamp locking tool, Snap-OntYA3050 (or an equiva-

lent). Place prongs of clamp locking tool in the holes

of the clamp (Fig. 38). Squeeze tool together until top

band of clamp is latched behind the two tabs on

lower band of clamp (Fig. 39).

(13) Install the driveshaft requiring boot replace-

ment back on the vehicle. See Servicing Driveshaft in

this section for the required driveshaft installation

procedure.

Fig. 33 Trim Stick Inserted for Venting Tripod Joint

Fig. 34 Sealing Boot End to End Length with Hytrel

Boot

Fig. 35 Sealing Boot End to End Length with

Silicone Boot

Fig. 36 Crimping Tool Installed on Sealing Boot

Clamp

3 - 12 DIFFERENTIAL AND DRIVELINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 128 of 1200

(9) Position master cylinder on studs of power

brake unit, aligning push rod on power brake vac-

uum booster with master cylinder push rod.

(10) Install the 2 master cylinder mounting nuts

(Fig. 117) and torque to 28 N´m (250 in. lbs.) torque.

(11) Connect brake tubes to master cylinder pri-

mary and secondary ports (Fig. 115) and (Fig. 116).

Torque all tube nuts to 17 N´m (145 in. lbs.) torque.

(12) Reconnect wiring connector to fluid level sen-

sor.

(13) Adjust stop lamp switch as necessary.

(14) Bleed brake system.

CHASSIS TUBES AND HOSES

Always use Mopar replacement brake hose assem-

blies to ensure quality, correct length and superior

fatigue life. Care should be taken to make sure that

the tube and hose mating surfaces are clean and free

from nicks and burrs.Hose assemblies for each

brake are unique and not interchangeable.

Use new copper seal washers on all connections

using Banjo Bolts and tighten all fittings to their

specified torques.

The flexible front hydraulic brake hose should

always be installed on the vehicle by first attaching

the Banjo connector to the caliper assembly. Then

bolt the intermediate hose bracket to the strut

assembly allowing the bracket to position the hose to

prevent twisting. Attach the hose to brake tubing,

before attaching to front frame rail. Then tighten all

brake line fittings to specified torque.

On vehicles equipped with rear drum brakes,

install rear brake hoses first to wheel cylinders and

rear struts and then attach hose bracket to body. On

vehicles equipped with rear disc brakes, attach brake

hoses to calipers and struts first and then attach

brake hose bracket to body. Following this procedure

will reduce potential for twisting brake during instal-

lation procedure.

Only double wall 4.75mm (3/16 in.) steel brake line

tubing, with Al- Rich/ZN-AL alloy coating should be

used for replacement. Care must be taken when

replacing brake tubing, to be sure the proper bending

and flaring tools and procedures are used to avoid

kinking. Do not route the tubes against sharp edges,

moving components or into hot areas. All tubes

should be properly attached with recommended

retaining clips.

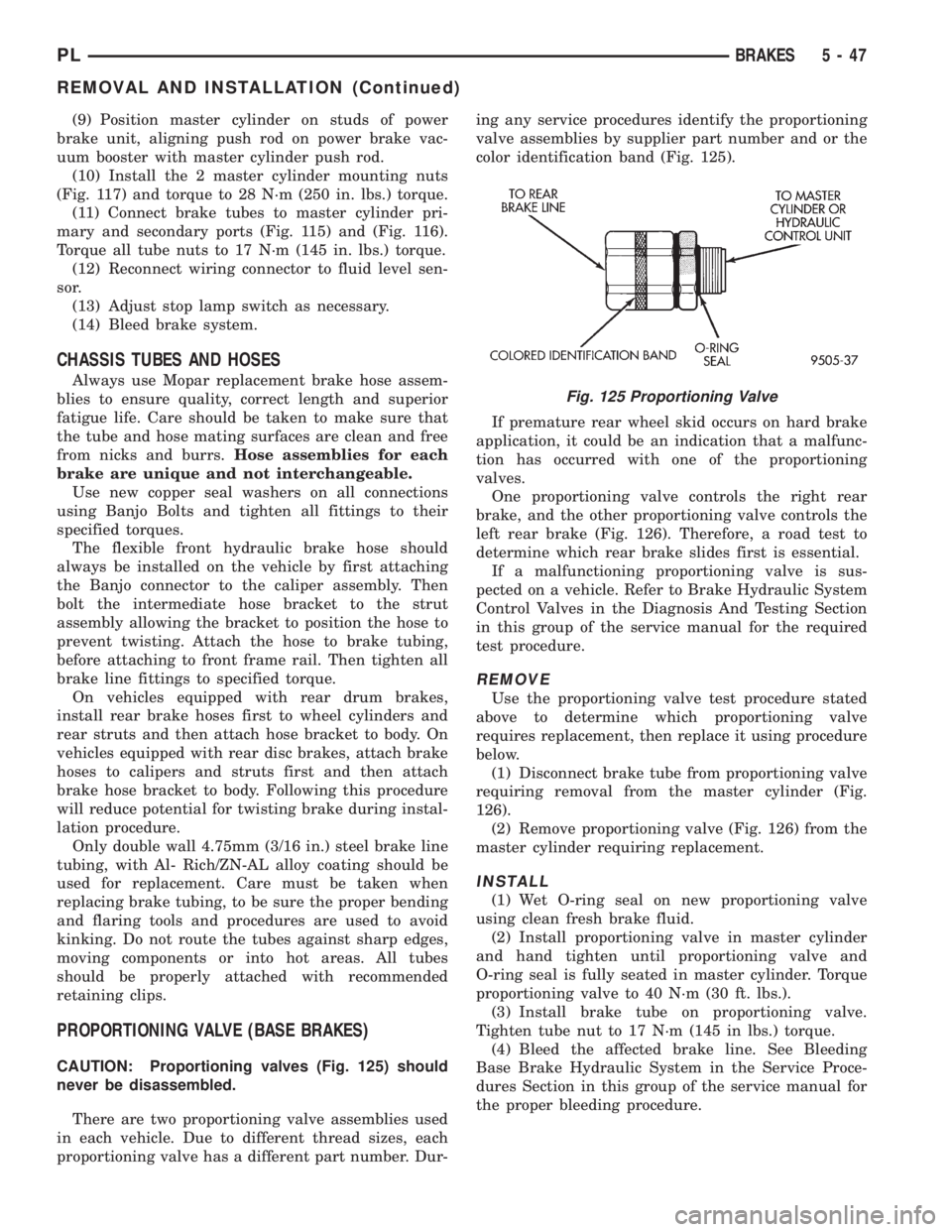

PROPORTIONING VALVE (BASE BRAKES)

CAUTION: Proportioning valves (Fig. 125) should

never be disassembled.

There are two proportioning valve assemblies used

in each vehicle. Due to different thread sizes, each

proportioning valve has a different part number. Dur-ing any service procedures identify the proportioning

valve assemblies by supplier part number and or the

color identification band (Fig. 125).

If premature rear wheel skid occurs on hard brake

application, it could be an indication that a malfunc-

tion has occurred with one of the proportioning

valves.

One proportioning valve controls the right rear

brake, and the other proportioning valve controls the

left rear brake (Fig. 126). Therefore, a road test to

determine which rear brake slides first is essential.

If a malfunctioning proportioning valve is sus-

pected on a vehicle. Refer to Brake Hydraulic System

Control Valves in the Diagnosis And Testing Section

in this group of the service manual for the required

test procedure.

REMOVE

Use the proportioning valve test procedure stated

above to determine which proportioning valve

requires replacement, then replace it using procedure

below.

(1) Disconnect brake tube from proportioning valve

requiring removal from the master cylinder (Fig.

126).

(2) Remove proportioning valve (Fig. 126) from the

master cylinder requiring replacement.

INSTALL

(1) Wet O-ring seal on new proportioning valve

using clean fresh brake fluid.

(2) Install proportioning valve in master cylinder

and hand tighten until proportioning valve and

O-ring seal is fully seated in master cylinder. Torque

proportioning valve to 40 N´m (30 ft. lbs.).

(3) Install brake tube on proportioning valve.

Tighten tube nut to 17 N´m (145 in lbs.) torque.

(4) Bleed the affected brake line. See Bleeding

Base Brake Hydraulic System in the Service Proce-

dures Section in this group of the service manual for

the proper bleeding procedure.

Fig. 125 Proportioning Valve

PLBRAKES 5 - 47

REMOVAL AND INSTALLATION (Continued)

Page 136 of 1200

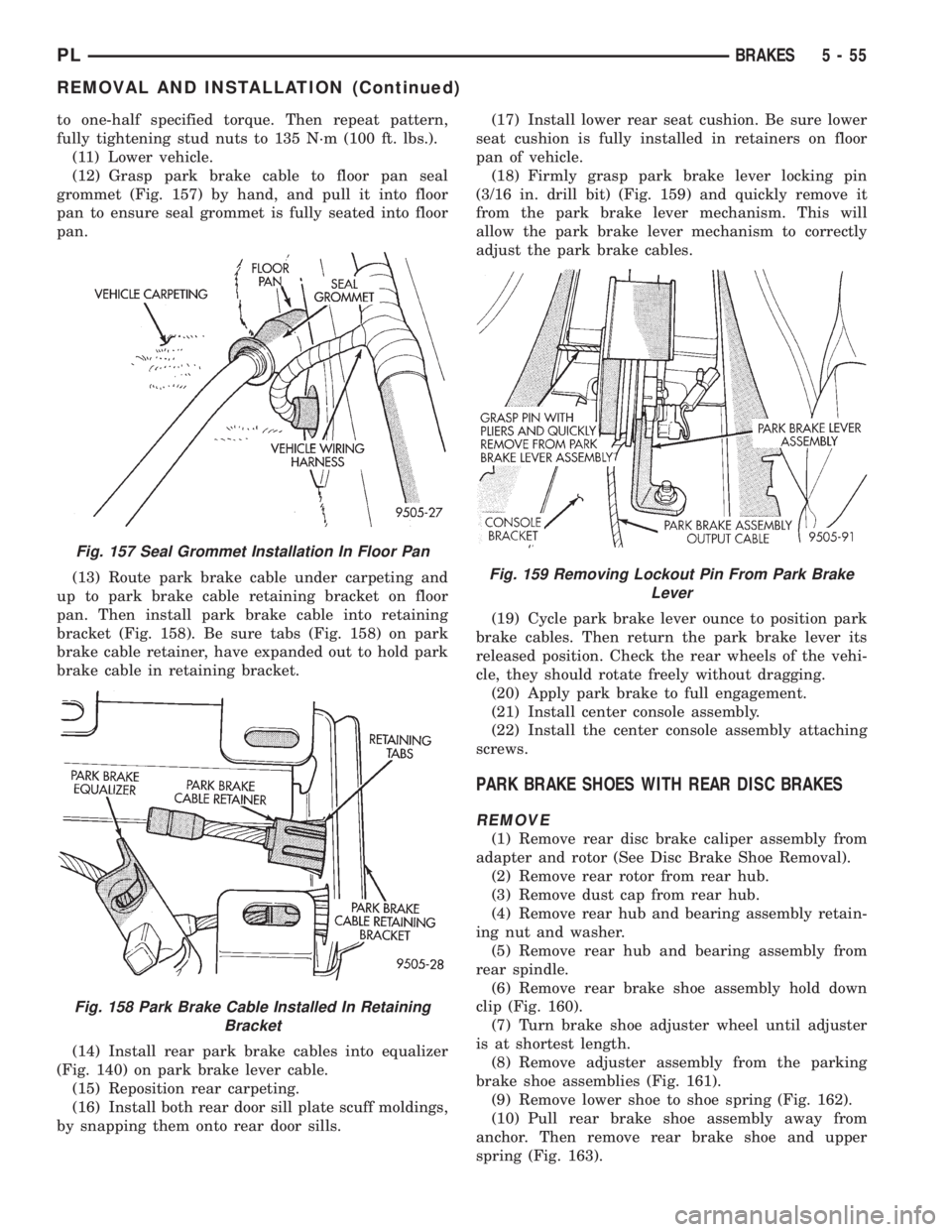

to one-half specified torque. Then repeat pattern,

fully tightening stud nuts to 135 N´m (100 ft. lbs.).

(11) Lower vehicle.

(12) Grasp park brake cable to floor pan seal

grommet (Fig. 157) by hand, and pull it into floor

pan to ensure seal grommet is fully seated into floor

pan.

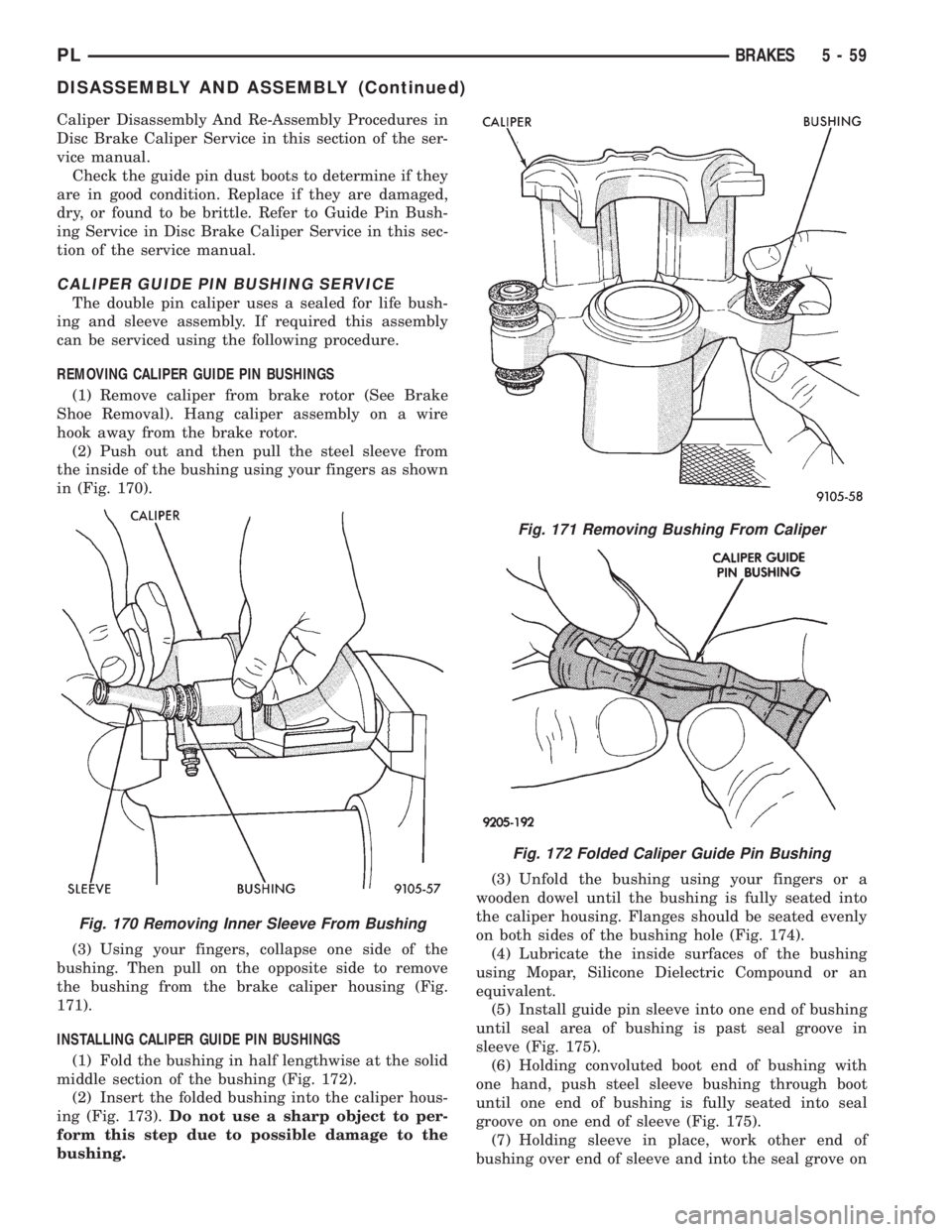

(13) Route park brake cable under carpeting and

up to park brake cable retaining bracket on floor

pan. Then install park brake cable into retaining

bracket (Fig. 158). Be sure tabs (Fig. 158) on park

brake cable retainer, have expanded out to hold park

brake cable in retaining bracket.

(14) Install rear park brake cables into equalizer

(Fig. 140) on park brake lever cable.

(15) Reposition rear carpeting.

(16) Install both rear door sill plate scuff moldings,

by snapping them onto rear door sills.(17) Install lower rear seat cushion. Be sure lower

seat cushion is fully installed in retainers on floor

pan of vehicle.

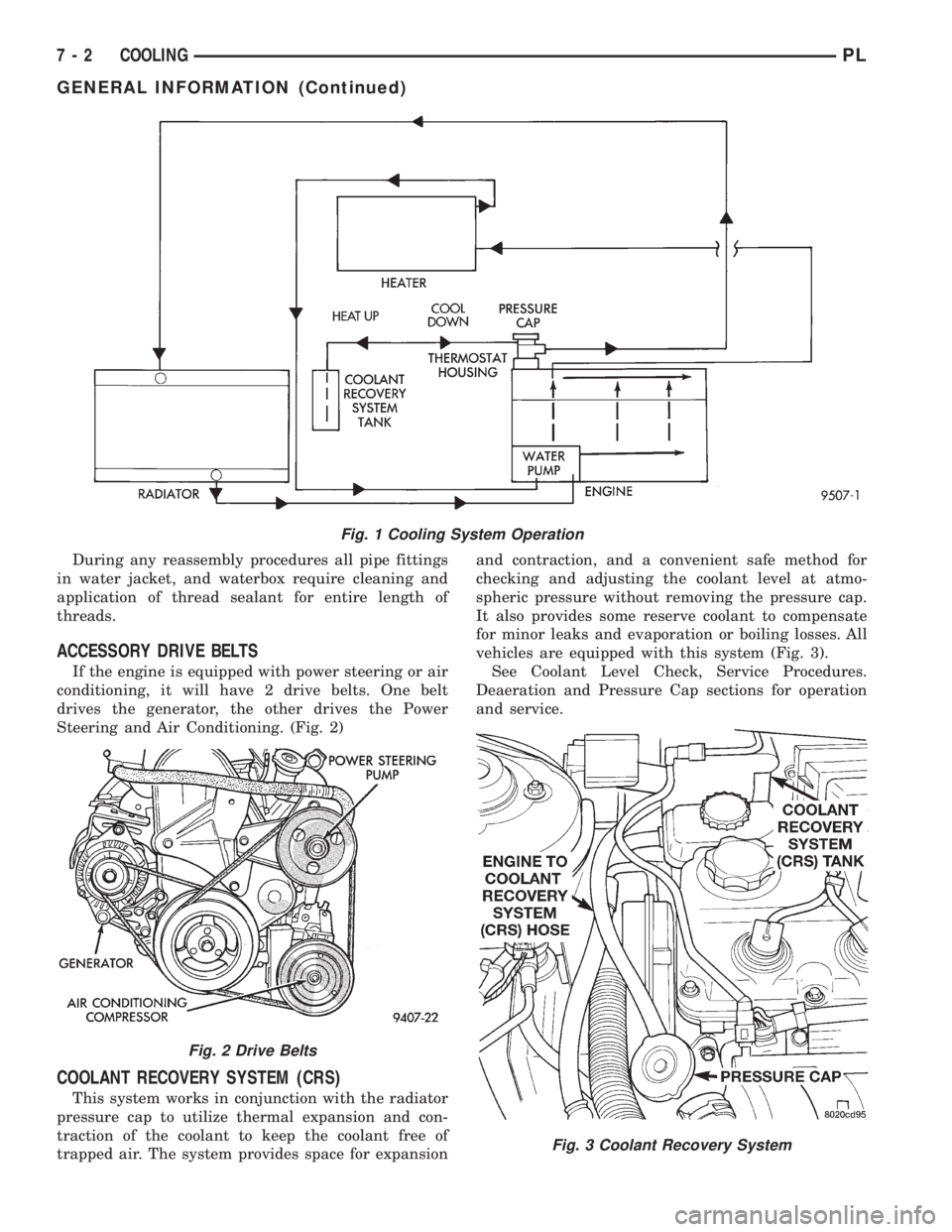

(18) Firmly grasp park brake lever locking pin

(3/16 in. drill bit) (Fig. 159) and quickly remove it

from the park brake lever mechanism. This will

allow the park brake lever mechanism to correctly

adjust the park brake cables.

(19) Cycle park brake lever ounce to position park

brake cables. Then return the park brake lever its

released position. Check the rear wheels of the vehi-

cle, they should rotate freely without dragging.

(20) Apply park brake to full engagement.

(21) Install center console assembly.

(22) Install the center console assembly attaching

screws.

PARK BRAKE SHOES WITH REAR DISC BRAKES

REMOVE

(1) Remove rear disc brake caliper assembly from

adapter and rotor (See Disc Brake Shoe Removal).

(2) Remove rear rotor from rear hub.

(3) Remove dust cap from rear hub.

(4) Remove rear hub and bearing assembly retain-

ing nut and washer.

(5) Remove rear hub and bearing assembly from

rear spindle.

(6) Remove rear brake shoe assembly hold down

clip (Fig. 160).

(7) Turn brake shoe adjuster wheel until adjuster

is at shortest length.

(8) Remove adjuster assembly from the parking

brake shoe assemblies (Fig. 161).

(9) Remove lower shoe to shoe spring (Fig. 162).

(10) Pull rear brake shoe assembly away from

anchor. Then remove rear brake shoe and upper

spring (Fig. 163).

Fig. 157 Seal Grommet Installation In Floor Pan

Fig. 158 Park Brake Cable Installed In Retaining

Bracket

Fig. 159 Removing Lockout Pin From Park Brake

Lever

PLBRAKES 5 - 55

REMOVAL AND INSTALLATION (Continued)

Page 140 of 1200

Caliper Disassembly And Re-Assembly Procedures in

Disc Brake Caliper Service in this section of the ser-

vice manual.

Check the guide pin dust boots to determine if they

are in good condition. Replace if they are damaged,

dry, or found to be brittle. Refer to Guide Pin Bush-

ing Service in Disc Brake Caliper Service in this sec-

tion of the service manual.

CALIPER GUIDE PIN BUSHING SERVICE

The double pin caliper uses a sealed for life bush-

ing and sleeve assembly. If required this assembly

can be serviced using the following procedure.

REMOVING CALIPER GUIDE PIN BUSHINGS

(1) Remove caliper from brake rotor (See Brake

Shoe Removal). Hang caliper assembly on a wire

hook away from the brake rotor.

(2) Push out and then pull the steel sleeve from

the inside of the bushing using your fingers as shown

in (Fig. 170).

(3) Using your fingers, collapse one side of the

bushing. Then pull on the opposite side to remove

the bushing from the brake caliper housing (Fig.

171).

INSTALLING CALIPER GUIDE PIN BUSHINGS

(1) Fold the bushing in half lengthwise at the solid

middle section of the bushing (Fig. 172).

(2) Insert the folded bushing into the caliper hous-

ing (Fig. 173).Do not use a sharp object to per-

form this step due to possible damage to the

bushing.(3) Unfold the bushing using your fingers or a

wooden dowel until the bushing is fully seated into

the caliper housing. Flanges should be seated evenly

on both sides of the bushing hole (Fig. 174).

(4) Lubricate the inside surfaces of the bushing

using Mopar, Silicone Dielectric Compound or an

equivalent.

(5) Install guide pin sleeve into one end of bushing

until seal area of bushing is past seal groove in

sleeve (Fig. 175).

(6) Holding convoluted boot end of bushing with

one hand, push steel sleeve bushing through boot

until one end of bushing is fully seated into seal

groove on one end of sleeve (Fig. 175).

(7) Holding sleeve in place, work other end of

bushing over end of sleeve and into the seal grove on

Fig. 170 Removing Inner Sleeve From Bushing

Fig. 171 Removing Bushing From Caliper

Fig. 172 Folded Caliper Guide Pin Bushing

PLBRAKES 5 - 59

DISASSEMBLY AND ASSEMBLY (Continued)

Page 195 of 1200

During any reassembly procedures all pipe fittings

in water jacket, and waterbox require cleaning and

application of thread sealant for entire length of

threads.

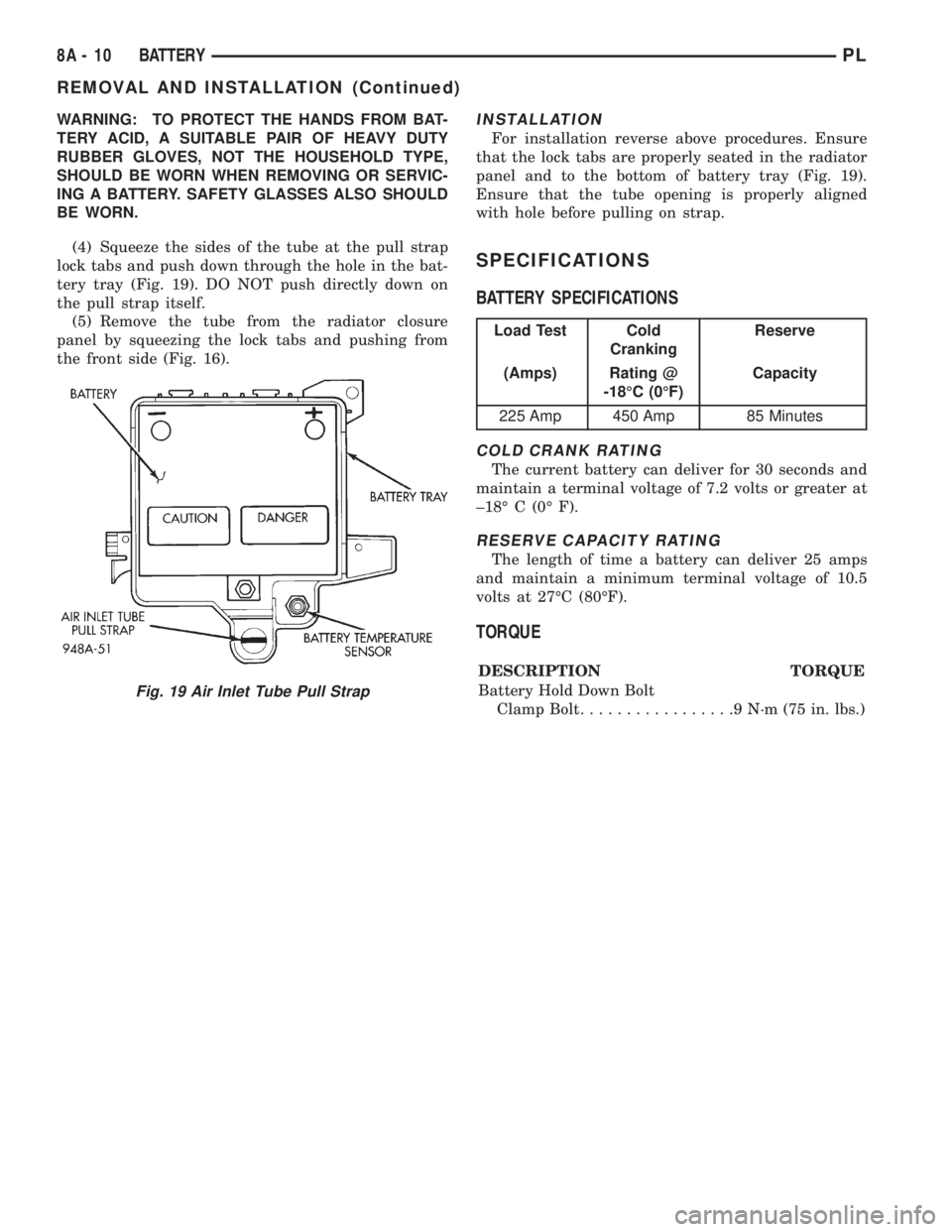

ACCESSORY DRIVE BELTS

If the engine is equipped with power steering or air

conditioning, it will have 2 drive belts. One belt

drives the generator, the other drives the Power

Steering and Air Conditioning. (Fig. 2)

COOLANT RECOVERY SYSTEM (CRS)

This system works in conjunction with the radiator

pressure cap to utilize thermal expansion and con-

traction of the coolant to keep the coolant free of

trapped air. The system provides space for expansionand contraction, and a convenient safe method for

checking and adjusting the coolant level at atmo-

spheric pressure without removing the pressure cap.

It also provides some reserve coolant to compensate

for minor leaks and evaporation or boiling losses. All

vehicles are equipped with this system (Fig. 3).

See Coolant Level Check, Service Procedures.

Deaeration and Pressure Cap sections for operation

and service.

Fig. 1 Cooling System Operation

Fig. 2 Drive Belts

Fig. 3 Coolant Recovery System

7 - 2 COOLINGPL

GENERAL INFORMATION (Continued)

Page 227 of 1200

WARNING: TO PROTECT THE HANDS FROM BAT-

TERY ACID, A SUITABLE PAIR OF HEAVY DUTY

RUBBER GLOVES, NOT THE HOUSEHOLD TYPE,

SHOULD BE WORN WHEN REMOVING OR SERVIC-

ING A BATTERY. SAFETY GLASSES ALSO SHOULD

BE WORN.

(4) Squeeze the sides of the tube at the pull strap

lock tabs and push down through the hole in the bat-

tery tray (Fig. 19). DO NOT push directly down on

the pull strap itself.

(5) Remove the tube from the radiator closure

panel by squeezing the lock tabs and pushing from

the front side (Fig. 16).INSTALLATION

For installation reverse above procedures. Ensure

that the lock tabs are properly seated in the radiator

panel and to the bottom of battery tray (Fig. 19).

Ensure that the tube opening is properly aligned

with hole before pulling on strap.

SPECIFICATIONS

BATTERY SPECIFICATIONS

COLD CRANK RATING

The current battery can deliver for 30 seconds and

maintain a terminal voltage of 7.2 volts or greater at

±18É C (0É F).

RESERVE CAPACITY RATING

The length of time a battery can deliver 25 amps

and maintain a minimum terminal voltage of 10.5

volts at 27ÉC (80ÉF).

TORQUE

DESCRIPTION TORQUE

Battery Hold Down Bolt

Clamp Bolt.................9N´m(75in.lbs.)

Fig. 19 Air Inlet Tube Pull Strap

Load Test Cold

CrankingReserve

(Amps) Rating @

-18ÉC (0ÉF)Capacity

225 Amp 450 Amp 85 Minutes

8A - 10 BATTERYPL

REMOVAL AND INSTALLATION (Continued)

Page 290 of 1200

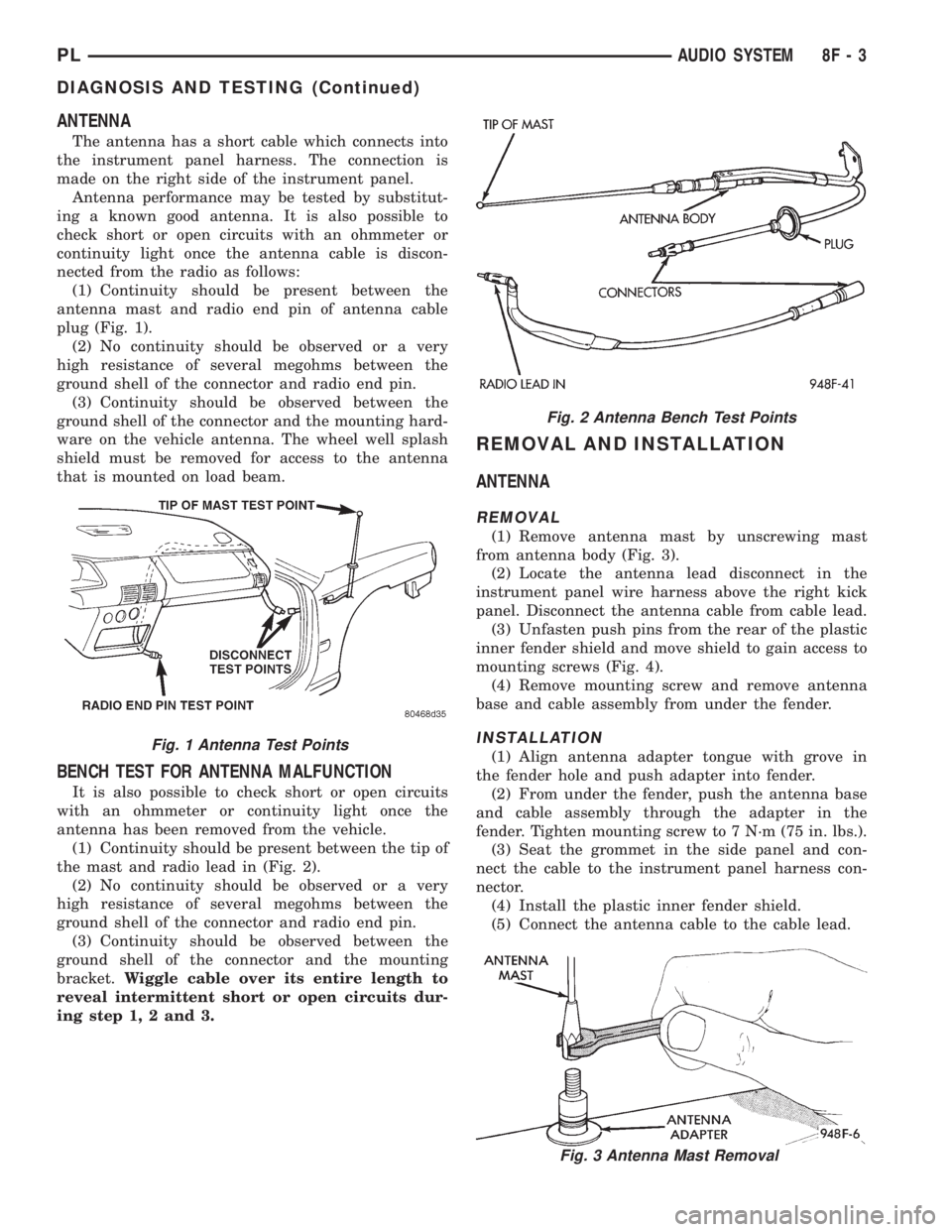

ANTENNA

The antenna has a short cable which connects into

the instrument panel harness. The connection is

made on the right side of the instrument panel.

Antenna performance may be tested by substitut-

ing a known good antenna. It is also possible to

check short or open circuits with an ohmmeter or

continuity light once the antenna cable is discon-

nected from the radio as follows:

(1) Continuity should be present between the

antenna mast and radio end pin of antenna cable

plug (Fig. 1).

(2) No continuity should be observed or a very

high resistance of several megohms between the

ground shell of the connector and radio end pin.

(3) Continuity should be observed between the

ground shell of the connector and the mounting hard-

ware on the vehicle antenna. The wheel well splash

shield must be removed for access to the antenna

that is mounted on load beam.

BENCH TEST FOR ANTENNA MALFUNCTION

It is also possible to check short or open circuits

with an ohmmeter or continuity light once the

antenna has been removed from the vehicle.

(1) Continuity should be present between the tip of

the mast and radio lead in (Fig. 2).

(2) No continuity should be observed or a very

high resistance of several megohms between the

ground shell of the connector and radio end pin.

(3) Continuity should be observed between the

ground shell of the connector and the mounting

bracket.Wiggle cable over its entire length to

reveal intermittent short or open circuits dur-

ing step 1, 2 and 3.

REMOVAL AND INSTALLATION

ANTENNA

REMOVAL

(1) Remove antenna mast by unscrewing mast

from antenna body (Fig. 3).

(2) Locate the antenna lead disconnect in the

instrument panel wire harness above the right kick

panel. Disconnect the antenna cable from cable lead.

(3) Unfasten push pins from the rear of the plastic

inner fender shield and move shield to gain access to

mounting screws (Fig. 4).

(4) Remove mounting screw and remove antenna

base and cable assembly from under the fender.

INSTALLATION

(1) Align antenna adapter tongue with grove in

the fender hole and push adapter into fender.

(2) From under the fender, push the antenna base

and cable assembly through the adapter in the

fender. Tighten mounting screw to 7 N´m (75 in. lbs.).

(3) Seat the grommet in the side panel and con-

nect the cable to the instrument panel harness con-

nector.

(4) Install the plastic inner fender shield.

(5) Connect the antenna cable to the cable lead.

Fig. 2 Antenna Bench Test Points

Fig. 3 Antenna Mast Removal

Fig. 1 Antenna Test Points

PLAUDIO SYSTEM 8F - 3

DIAGNOSIS AND TESTING (Continued)

Page 303 of 1200

OVERSHOOT/UNDERSHOOT FOLLOWING SPEED

CONTROL SET

If the operator repeatedly presses and releases the

set button with their foot off of the accelerator (a ªlift

foot setº to begin speed control operation), the vehicle

may accelerate and exceed the desired set speed by

up to 5 MPH (8 km/h) and then decelerate to less

than the desired set speed before finally achieving

the desired set speed.

The Speed Control has an adaptive strategy that

compensates for vehicle-to-vehicle variations in speed

control cable lengths. When the speed control is set

with the vehicle operators foot off of the accelerator

pedal, the speed control thinks there is excessive

speed control cable slack and adapts. If the lift foot

sets are continually used, the speed control over-

shoot/undershoot condition will develop.

To ªunlearnº the overshoot/undershoot condition,

the vehicle operator has to press and release the set

button while maintaining the desired set speed with

the accelerator pedal (not decelerating or accelerat-

ing), and then turn the cruise control switch to the

OFF position (or press the CANCEL button if

equipped) after waiting 10 seconds. This procedure

must be performed approximately 10±15 times to

completely unlearn the overshoot/undershoot condi-

tion.

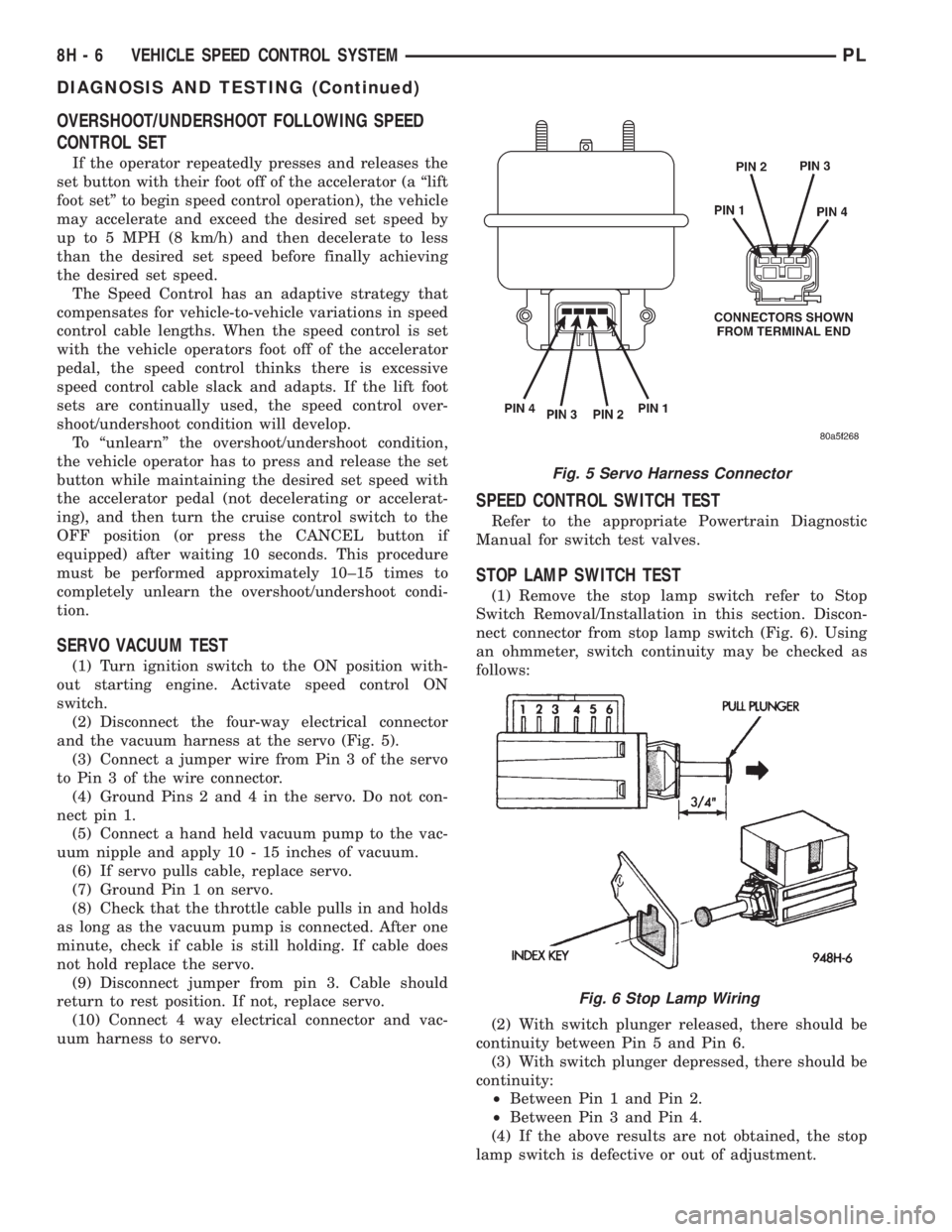

SERVO VACUUM TEST

(1) Turn ignition switch to the ON position with-

out starting engine. Activate speed control ON

switch.

(2) Disconnect the four-way electrical connector

and the vacuum harness at the servo (Fig. 5).

(3) Connect a jumper wire from Pin 3 of the servo

to Pin 3 of the wire connector.

(4) Ground Pins 2 and 4 in the servo. Do not con-

nect pin 1.

(5) Connect a hand held vacuum pump to the vac-

uum nipple and apply 10 - 15 inches of vacuum.

(6) If servo pulls cable, replace servo.

(7) Ground Pin 1 on servo.

(8) Check that the throttle cable pulls in and holds

as long as the vacuum pump is connected. After one

minute, check if cable is still holding. If cable does

not hold replace the servo.

(9) Disconnect jumper from pin 3. Cable should

return to rest position. If not, replace servo.

(10) Connect 4 way electrical connector and vac-

uum harness to servo.

SPEED CONTROL SWITCH TEST

Refer to the appropriate Powertrain Diagnostic

Manual for switch test valves.

STOP LAMP SWITCH TEST

(1) Remove the stop lamp switch refer to Stop

Switch Removal/Installation in this section. Discon-

nect connector from stop lamp switch (Fig. 6). Using

an ohmmeter, switch continuity may be checked as

follows:

(2) With switch plunger released, there should be

continuity between Pin 5 and Pin 6.

(3) With switch plunger depressed, there should be

continuity:

²Between Pin 1 and Pin 2.

²Between Pin 3 and Pin 4.

(4) If the above results are not obtained, the stop

lamp switch is defective or out of adjustment.

Fig. 5 Servo Harness Connector

Fig. 6 Stop Lamp Wiring

8H - 6 VEHICLE SPEED CONTROL SYSTEMPL

DIAGNOSIS AND TESTING (Continued)