recommended oil DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 4 of 1200

MAINTENANCE SCHEDULES

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 3

SCHEDULE ± A.......................... 3SCHEDULE ± B.......................... 4

UNSCHEDULED INSPECTION............... 3

GENERAL INFORMATION

INTRODUCTION

Service and maintenance procedures for compo-

nents and systems listed in Schedule ± A or B can be

found by using the Group Tab Locator index at the

front of this manual. If it is not clear which group

contains the information needed, refer to the index at

the back of this manual.

There are two maintenance schedules that show

proper service based on the conditions that the vehi-

cle is subjected to. Use the schedule that best

describes these conditions.

Schedule ±A, lists maintenance recommended for

vehicles used for general transportation.

Schedule ±B, lists maintenance recommended for

vehicles used under the following conditions:

²Frequent short trip driving less than 5 miles (8

km)

²Frequent driving in dusty conditions

²Frequent trailer towing

²Extensive idling

²More than 50% of your driving is at sustained

high speeds during hot weather, above 90ÉF (32ÉC)

Where time and mileage are listed, follow the

interval that occurs first.

EMISSION CONTROL SYSTEM MAINTENANCE

The scheduled emission maintenance listed inbold

typeon the Maintenance Schedules, must be done at

the mileage specified to assure the continued proper

functioning of the emission control system. These,

and all other maintenance services included in this

manual, should be done to provide the best vehicle

performance and reliability. More frequent mainte-

nance may be needed for vehicles in severe operating

conditions such as dusty areas and very short trip

driving.

UNSCHEDULED INSPECTION

At Each Stop For Fuel

²Check engine oil level, add as required.

²Check windshield washer solvent and add if

required.

Once A Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect battery, clean, and tighten terminals as

required.

²Check fluid levels of coolant reservoir, power

steering and automatic transmission and add as

required.

²Check all lights and all other electrical items for

correct operation.

At Each Oil Change

²Inspect exhaust system.

²Inspect brake hoses.

²Inspect the CV joints and front suspension com-

ponents.

²Rotate the tires at each oil change interval

shown on Schedule ± A (7,500 miles) or every other

interval shown on schedule ± B (6,000 miles).

²Check coolant level, hoses and clamps.

²Check the manual transaxle fluid level.

²If the mileage is less than 7,500 miles (12 000

km) yearly, replace the engine oil filter at each oil

change.

SCHEDULE ± A

7,500 Miles (12 000 km) or at 6 months

²Change engine oil.

15,000 Miles (24 000 km) or at 12 months

²Change engine oil.

²Replace engine oil filter.

²Adjust drive belt tension.

22,500 Miles (36 000 km) or at 18 months

²Change engine oil.

²Inspect the front brake pads and rear brake lin-

ings.

30,000 Miles (48 000 km) or at 24 months

²Change engine oil.

²Replace engine oil filter.

²Lubricate front suspension ball joints.

²Adjust drive belt tension.

PLLUBRICATION AND MAINTENANCE 0 - 3

Page 7 of 1200

90,000 Miles (144 000 km)

²Change engine oil.

²Replace engine oil filter.

²Inspect front brake pads and rear brake linings.

²Check and replace, if necessary***, the PCV

valve.**

²Lubricate front suspension upper ball joints.

²Adjust drive belt tension.

²Replace air cleaner element.

²Replace spark plugs.

²Change automatic transaxle fluid and filter.

Adjust the bands.*

93,000 Miles (149 000 km)

²Change engine oil.

96,000 Miles (154 000 km)

²Change engine oil.

²Replace engine oil filter.

99,000 Miles (158 000 km)

²Change engine oil.

²Inspect front brake pads and rear brake linings.

102,000 Miles (163 000km)

²Change engine oil.

²Replace engine oil filter.

105,000 Miles (168 000km)

²Replace the engine timing belt

²Change engine oil.

²Replace engine oil filter.

²Adjust drive belt tension.

²Inspect and replace, if necessary, the air

cleaner element.

NOTE: **This maintenance is recommended by

Chrysler to the owner but is not required to main-

tain the warranty on the PCV valve.

NOTE: ***This maintenance is not required if the

PCV valve was previously replaced.

0 - 6 LUBRICATION AND MAINTENANCEPL

GENERAL INFORMATION (Continued)

Page 9 of 1200

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

TOWING RECOMMENDATIONS

WARNING: DO NOT ALLOW TOWING ATTACH-

MENT DEVICES TO CONTACT THE FUEL TANK OR

LINES, FUEL LEAK CAN RESULT. DO NOT LIFT OR

TOW VEHICLE BY FRONT OR REAR BUMPER, OR

BUMPER ENERGY ABSORBER UNITS. DO NOT

VENTURE UNDER A LIFTED VEHICLE IF NOT SUP-

PORTED PROPERLY ON SAFETY STANDS. DO NOT

ALLOW PASSENGERS TO RIDE IN A TOWED VEHI-

CLE. USE A SAFETY CHAIN THAT IS INDEPENDENT

FROM THE TOWING ATTACHMENT DEVICE.

CAUTION: Do not damage brake lines, exhaust

system, shock absorbers, sway bars, or any other

under vehicle components when attaching towing

device to vehicle. Do not attach towing device to

front or rear suspension components. Do not

secure vehicle to towing device by the use of front

or rear suspension or steering components.

Remove or secure loose or protruding objects from

a damaged vehicle before towing. Refer to state and

local rules and regulations before towing a vehicle.

Do not allow weight of towed vehicle to bear on

lower fascia, air dams, or spoilers.

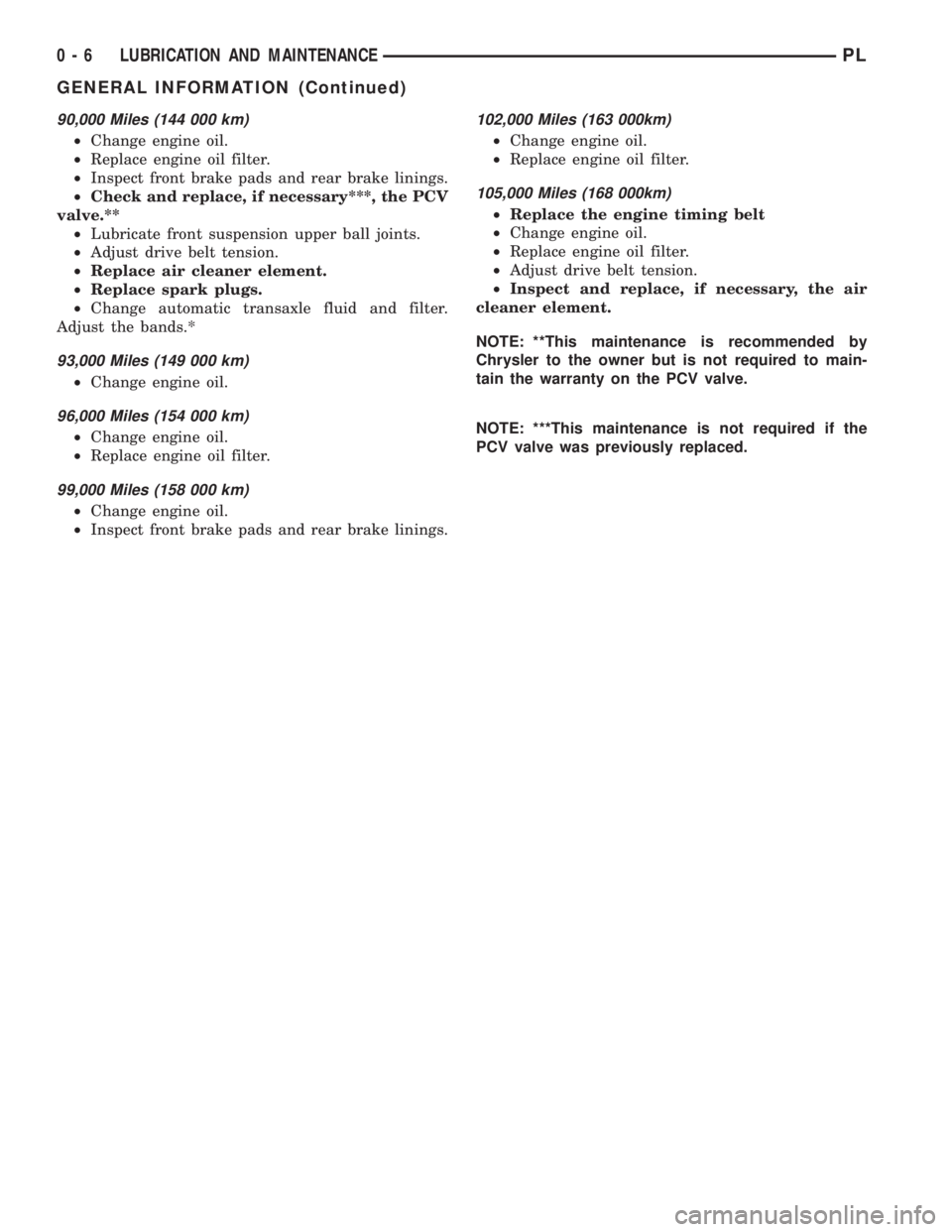

RECOMMENDED TOWING EQUIPMENT

To avoid damage to bumper fascia and air dams

use of a wheel lift or flat bed towing device (Fig. 2) is

recommended. When using a wheel lift towing device,

be sure the unlifted end of disabled vehicle has at

least 100 mm (4 in.) ground clearance. If minimum

ground clearance cannot be reached, use a towing

dolly. If a flat bed device is used, the approach angle

should not exceed 15 degrees.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels

removed, install lug nuts to retain brake drums or

rotors.

A towed vehicle should be raised until lifted wheels

are a minimum 100 mm (4 in) from the ground. Be

sure there is adequate ground clearance at the oppo-

site end of the vehicle, especially when towing overrough terrain or steep rises in the road. If necessary,

remove the wheels from the lifted end of the vehicle

and lower the vehicle closer to the ground, to

increase the ground clearance at the opposite end of

the vehicle. Install lug nuts on wheel attaching studs

to retain brake drums or rotors.

LOCKED VEHICLE TOWING

When a locked vehicle must be towed with the

front wheels on the ground, use a towing dolly or flat

bed hauler.

FLAT TOWING WITH TOW BAR

²3-speed automatic transaxle vehicles can be flat

towed at speeds not to exceed 40 km/h (25 mph) for

not more than 25 km (15 miles). The steering column

must be unlocked and gear selector in neutral.

²5-speed manual transaxle vehicles can be flat

towed at any legal highway speed for extended dis-

tances. The gear selector must be in the neutral posi-

tion.

TOWINGÐFRONT WHEEL LIFT

Chrysler Corporation recommends that a vehicle be

towed with the front end lifted, whenever possible.

TOWINGÐREAR WHEEL LIFT

If a vehicle cannot be towed with the front wheels

lifted, the rear wheels can be lifted provided the fol-

lowing guide lines are observed.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

²Unlock steering column and secure steering

wheel in straight ahead position with a clamp device

designed for towing.

²Verify that front drive line and steering compo-

nents are in good condition.

²5-speed manual transaxle vehicles can be towed

at any legal highway speed for extended distances.

The gear selector must be in the neutral position.

²3-speed automatic transaxle vehicles can be

towed at speeds not to exceed 40 km/h (25 mph) for

Fig. 2 Recommended Towing Devices

0 - 8 LUBRICATION AND MAINTENANCEPL

SERVICE PROCEDURES (Continued)

Page 148 of 1200

(3) Remove the rubber plug from the adjusting

hole in the brake shoe backing plate on both sides of

the vehicle.

(4)Driver (left) side park brake shoe adjust-

ment procedure.Insert a medium size screwdriver

through adjustment hole in backing plate. Position

the srewdriver against the starwheel on the park

brake shoe adjuster mechanism. Using the screw-

driver rotate the starwheeldownwarduntil a slight

drag is felt when turning the rear tire and wheel.

Then, using the screwdriver rotate the starwheel

upwardjust until the rear tire and wheel can be

rotated with no park brake shoe drag. From the

point where there is no more park brake drag rotate

the starwheelupwarda maximum of two additional

clicks. The park brake shoe to drum clearance is

know properly adjusted.

(5)Passenger (right) side park brake shoe

adjustment procedure.Insert a medium size

screwdriver through adjustment hole in backing

plate. Position the srewdriver against the starwheel

on the park brake shoe adjuster mechanism. Using

the screwdriver rotate the starwheelupwarduntil a

slight drag is felt when turning the rear tire and

wheel. Then, using the screwdriver rotate the star-

wheeldownwardjust until the rear tire and wheel

can be rotated with no park brake shoe drag. From

the point where there is no more park brake drag

rotate the starwheeldownwarda maximum of two

additional clicks. The park brake shoe to drum clear-

ance is know properly adjusted.

(6) Install the rubber plug in the adjusting hole on

the brake shoe backing plate on both sides of the

vehicle.

(7) Lower vehicle far enough to allow access the

park brake lever. The rear tires must not be on the

ground.

(8) Fully apply and release the park brakes two

times after adjusting the park brake shoes. Then

rotate both rear wheels to ensure that the park

brake shoes do not drag on the brake drum following

the application and release of the park brakes.

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications and SAE J1703 standards.

No other type of brake fluid is recommended or

approved for usage in the vehicle brake system. Use

only Mopar brake fluid or an equivalent from a

tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. Anopen container will absorb moisture from the air

and contaminate the fluid.

CAUTION: Never use any type of a petroleum-

based fluid in the brake hydraulic system. Use of

such type fluids will result in seal damage of the

vehicle brake hydraulic system causing a failure of

the vehicle brake system. Petroleum based fluids

would be items such as engine oil, transmission

fluid, power steering fluid ect.

BRAKE ACTUATION SYSTEM

ACTUATION:

Vacuum Operated Power Brakes.........Standard

Hydraulic System...........Dual-Diagonally Split

MASTER CYLINDER ASSEMBLY:

Type ...........................Dual Tandem

Body Material...............Anodized Aluminum

Reservoir Material................Polypropelene

MASTER CYLINDER BORE / STROKE

AND SPLIT:

NonABS ....21mmx32.6 mm (.875 in. x 1.28 in.)

ABS........21mmx32.7 mm (.874 in. x 1.29 in.)

Displacement Split.....................50/50

MASTER CYLINDER FLUID OUTLET PORTS:

ABS ..........Primary 3/8±24 Secondary 7/16±24

Non ABS . . .Primary Inboard And Outboard 7/16±24

Non ABS . . .Secondary Inboard And Outboard 3/8±23

Outlet Fitting Type.......SAE 45 É Inverted Flare

ABS HYDRAULIC CONTROL UNIT:

Hydraulic Tube Fitting Type.SAE 45 É Inverted Flare

BOOSTER:

Make/Type.........Bendix Vacuum W/&W/O ABS

Mounting Studs.....................M8x1.25

Type ..........................230 mm Single

Boost At 20 inches Of Manifold Vacuum. . . .4690 All

PROPORTIONING VALVE:

Material...........................Aluminum

Function........Hydraulic Pressure Proportioning

BRAKE PEDAL

Pedal Ratio.............................3.28

BRAKE FASTENER TORQUE SPECIFICATIONS

DESCRIPTION TORQUE

BRAKE TUBES:

Tube Nuts To Fittings And

Components Except HCU. . . . 17 N´m (145 in. lbs.)

From Master Cylinder To

HCU At HCU Ports........21N´m(185 in. lbs.)

BRAKE HOSE:

To Caliper Banjo Bolt..........48N´m(35ft.lbs.)

Intermediate Bracket.........12N´m(105 in. lbs.)

PLBRAKES 5 - 67

ADJUSTMENTS (Continued)

Page 196 of 1200

ENGINE THERMOSTAT

The engine thermostat is located on the front of

the engine (radiator side) in the thermostat housing/

engine outlet connector. The thermostat has an air

bleed (vent) located in the flange and a O-ring for

sealing incorporate on it. There is a relief in the ther-

mostat housing/outlet connector for the O-ring.

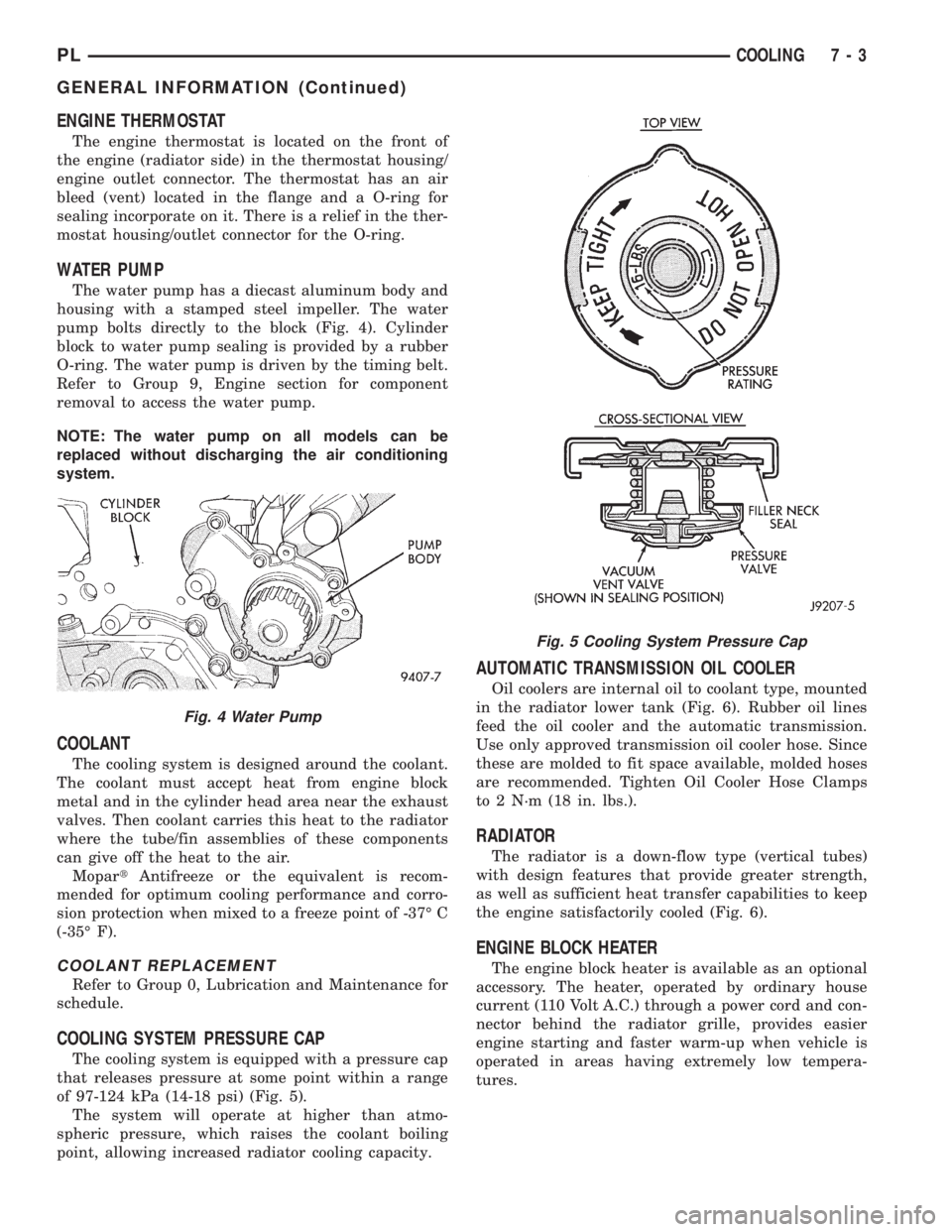

WATER PUMP

The water pump has a diecast aluminum body and

housing with a stamped steel impeller. The water

pump bolts directly to the block (Fig. 4). Cylinder

block to water pump sealing is provided by a rubber

O-ring. The water pump is driven by the timing belt.

Refer to Group 9, Engine section for component

removal to access the water pump.

NOTE: The water pump on all models can be

replaced without discharging the air conditioning

system.

COOLANT

The cooling system is designed around the coolant.

The coolant must accept heat from engine block

metal and in the cylinder head area near the exhaust

valves. Then coolant carries this heat to the radiator

where the tube/fin assemblies of these components

can give off the heat to the air.

MopartAntifreeze or the equivalent is recom-

mended for optimum cooling performance and corro-

sion protection when mixed to a freeze point of -37É C

(-35É F).

COOLANT REPLACEMENT

Refer to Group 0, Lubrication and Maintenance for

schedule.

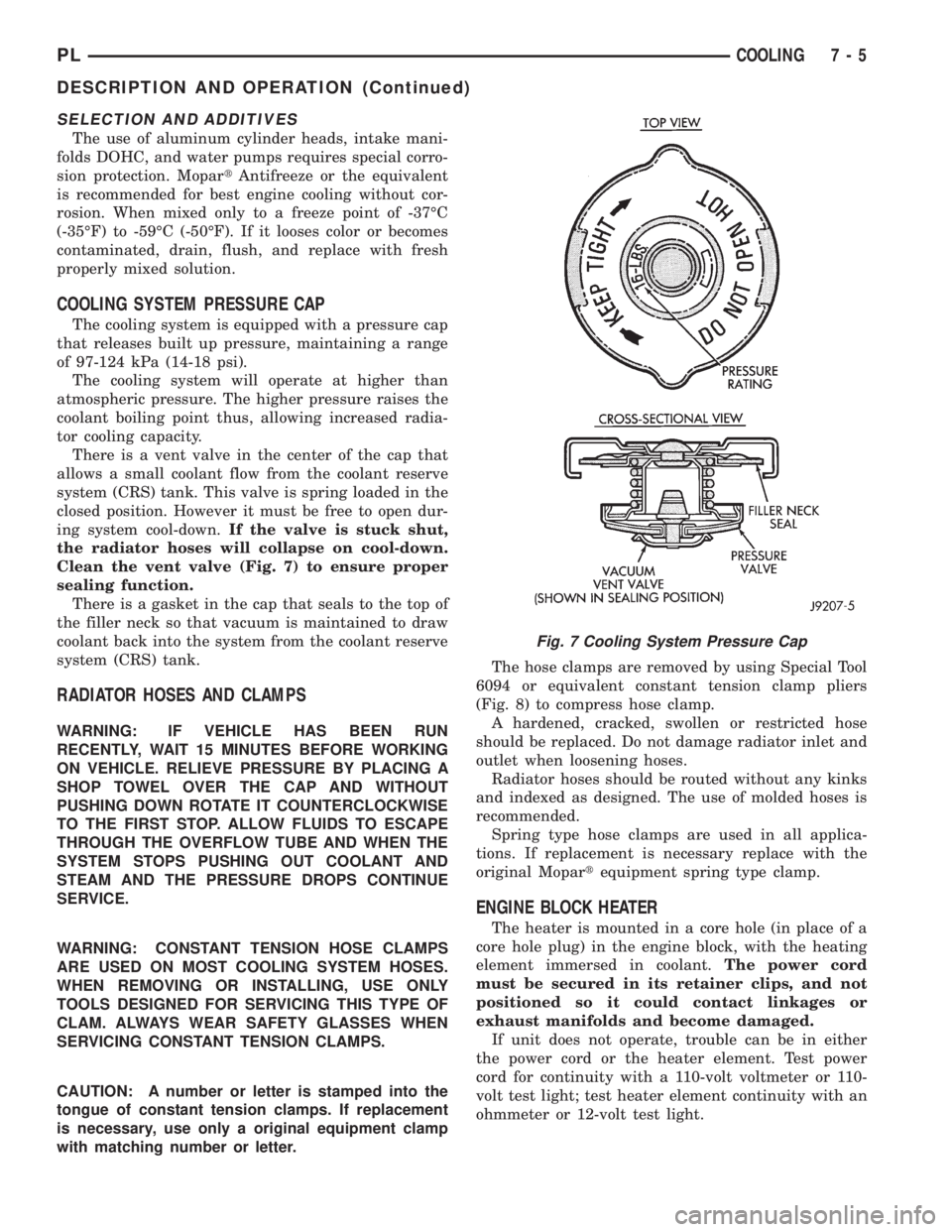

COOLING SYSTEM PRESSURE CAP

The cooling system is equipped with a pressure cap

that releases pressure at some point within a range

of 97-124 kPa (14-18 psi) (Fig. 5).

The system will operate at higher than atmo-

spheric pressure, which raises the coolant boiling

point, allowing increased radiator cooling capacity.

AUTOMATIC TRANSMISSION OIL COOLER

Oil coolers are internal oil to coolant type, mounted

in the radiator lower tank (Fig. 6). Rubber oil lines

feed the oil cooler and the automatic transmission.

Use only approved transmission oil cooler hose. Since

these are molded to fit space available, molded hoses

are recommended. Tighten Oil Cooler Hose Clamps

to 2 N´m (18 in. lbs.).

RADIATOR

The radiator is a down-flow type (vertical tubes)

with design features that provide greater strength,

as well as sufficient heat transfer capabilities to keep

the engine satisfactorily cooled (Fig. 6).

ENGINE BLOCK HEATER

The engine block heater is available as an optional

accessory. The heater, operated by ordinary house

current (110 Volt A.C.) through a power cord and con-

nector behind the radiator grille, provides easier

engine starting and faster warm-up when vehicle is

operated in areas having extremely low tempera-

tures.

Fig. 4 Water Pump

Fig. 5 Cooling System Pressure Cap

PLCOOLING 7 - 3

GENERAL INFORMATION (Continued)

Page 198 of 1200

SELECTION AND ADDITIVES

The use of aluminum cylinder heads, intake mani-

folds DOHC, and water pumps requires special corro-

sion protection. MopartAntifreeze or the equivalent

is recommended for best engine cooling without cor-

rosion. When mixed only to a freeze point of -37ÉC

(-35ÉF) to -59ÉC (-50ÉF). If it looses color or becomes

contaminated, drain, flush, and replace with fresh

properly mixed solution.

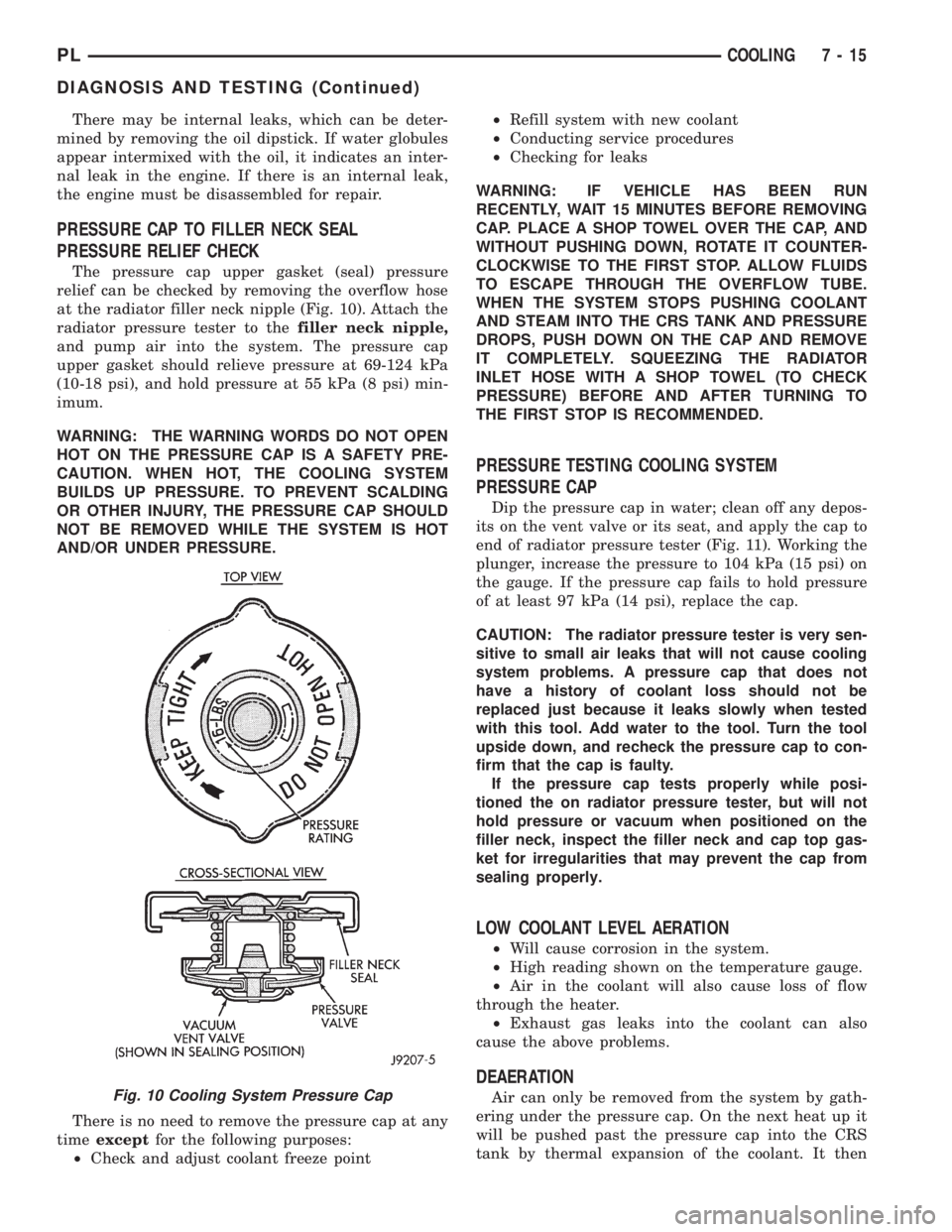

COOLING SYSTEM PRESSURE CAP

The cooling system is equipped with a pressure cap

that releases built up pressure, maintaining a range

of 97-124 kPa (14-18 psi).

The cooling system will operate at higher than

atmospheric pressure. The higher pressure raises the

coolant boiling point thus, allowing increased radia-

tor cooling capacity.

There is a vent valve in the center of the cap that

allows a small coolant flow from the coolant reserve

system (CRS) tank. This valve is spring loaded in the

closed position. However it must be free to open dur-

ing system cool-down.If the valve is stuck shut,

the radiator hoses will collapse on cool-down.

Clean the vent valve (Fig. 7) to ensure proper

sealing function.

There is a gasket in the cap that seals to the top of

the filler neck so that vacuum is maintained to draw

coolant back into the system from the coolant reserve

system (CRS) tank.

RADIATOR HOSES AND CLAMPS

WARNING: IF VEHICLE HAS BEEN RUN

RECENTLY, WAIT 15 MINUTES BEFORE WORKING

ON VEHICLE. RELIEVE PRESSURE BY PLACING A

SHOP TOWEL OVER THE CAP AND WITHOUT

PUSHING DOWN ROTATE IT COUNTERCLOCKWISE

TO THE FIRST STOP. ALLOW FLUIDS TO ESCAPE

THROUGH THE OVERFLOW TUBE AND WHEN THE

SYSTEM STOPS PUSHING OUT COOLANT AND

STEAM AND THE PRESSURE DROPS CONTINUE

SERVICE.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAM. ALWAYS WEAR SAFETY GLASSES WHEN

SERVICING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter.The hose clamps are removed by using Special Tool

6094 or equivalent constant tension clamp pliers

(Fig. 8) to compress hose clamp.

A hardened, cracked, swollen or restricted hose

should be replaced. Do not damage radiator inlet and

outlet when loosening hoses.

Radiator hoses should be routed without any kinks

and indexed as designed. The use of molded hoses is

recommended.

Spring type hose clamps are used in all applica-

tions. If replacement is necessary replace with the

original Mopartequipment spring type clamp.

ENGINE BLOCK HEATER

The heater is mounted in a core hole (in place of a

core hole plug) in the engine block, with the heating

element immersed in coolant.The power cord

must be secured in its retainer clips, and not

positioned so it could contact linkages or

exhaust manifolds and become damaged.

If unit does not operate, trouble can be in either

the power cord or the heater element. Test power

cord for continuity with a 110-volt voltmeter or 110-

volt test light; test heater element continuity with an

ohmmeter or 12-volt test light.

Fig. 7 Cooling System Pressure Cap

PLCOOLING 7 - 5

DESCRIPTION AND OPERATION (Continued)

Page 208 of 1200

There may be internal leaks, which can be deter-

mined by removing the oil dipstick. If water globules

appear intermixed with the oil, it indicates an inter-

nal leak in the engine. If there is an internal leak,

the engine must be disassembled for repair.

PRESSURE CAP TO FILLER NECK SEAL

PRESSURE RELIEF CHECK

The pressure cap upper gasket (seal) pressure

relief can be checked by removing the overflow hose

at the radiator filler neck nipple (Fig. 10). Attach the

radiator pressure tester to thefiller neck nipple,

and pump air into the system. The pressure cap

upper gasket should relieve pressure at 69-124 kPa

(10-18 psi), and hold pressure at 55 kPa (8 psi) min-

imum.

WARNING: THE WARNING WORDS DO NOT OPEN

HOT ON THE PRESSURE CAP IS A SAFETY PRE-

CAUTION. WHEN HOT, THE COOLING SYSTEM

BUILDS UP PRESSURE. TO PREVENT SCALDING

OR OTHER INJURY, THE PRESSURE CAP SHOULD

NOT BE REMOVED WHILE THE SYSTEM IS HOT

AND/OR UNDER PRESSURE.

There is no need to remove the pressure cap at any

timeexceptfor the following purposes:

²Check and adjust coolant freeze point²Refill system with new coolant

²Conducting service procedures

²Checking for leaks

WARNING: IF VEHICLE HAS BEEN RUN

RECENTLY, WAIT 15 MINUTES BEFORE REMOVING

CAP. PLACE A SHOP TOWEL OVER THE CAP, AND

WITHOUT PUSHING DOWN, ROTATE IT COUNTER-

CLOCKWISE TO THE FIRST STOP. ALLOW FLUIDS

TO ESCAPE THROUGH THE OVERFLOW TUBE.

WHEN THE SYSTEM STOPS PUSHING COOLANT

AND STEAM INTO THE CRS TANK AND PRESSURE

DROPS, PUSH DOWN ON THE CAP AND REMOVE

IT COMPLETELY. SQUEEZING THE RADIATOR

INLET HOSE WITH A SHOP TOWEL (TO CHECK

PRESSURE) BEFORE AND AFTER TURNING TO

THE FIRST STOP IS RECOMMENDED.

PRESSURE TESTING COOLING SYSTEM

PRESSURE CAP

Dip the pressure cap in water; clean off any depos-

its on the vent valve or its seat, and apply the cap to

end of radiator pressure tester (Fig. 11). Working the

plunger, increase the pressure to 104 kPa (15 psi) on

the gauge. If the pressure cap fails to hold pressure

of at least 97 kPa (14 psi), replace the cap.

CAUTION: The radiator pressure tester is very sen-

sitive to small air leaks that will not cause cooling

system problems. A pressure cap that does not

have a history of coolant loss should not be

replaced just because it leaks slowly when tested

with this tool. Add water to the tool. Turn the tool

upside down, and recheck the pressure cap to con-

firm that the cap is faulty.

If the pressure cap tests properly while posi-

tioned the on radiator pressure tester, but will not

hold pressure or vacuum when positioned on the

filler neck, inspect the filler neck and cap top gas-

ket for irregularities that may prevent the cap from

sealing properly.

LOW COOLANT LEVEL AERATION

²Will cause corrosion in the system.

²High reading shown on the temperature gauge.

²Air in the coolant will also cause loss of flow

through the heater.

²Exhaust gas leaks into the coolant can also

cause the above problems.

DEAERATION

Air can only be removed from the system by gath-

ering under the pressure cap. On the next heat up it

will be pushed past the pressure cap into the CRS

tank by thermal expansion of the coolant. It thenFig. 10 Cooling System Pressure Cap

PLCOOLING 7 - 15

DIAGNOSIS AND TESTING (Continued)

Page 251 of 1200

The major difference between the two engines is

component location which affects the ignition system

service procedures. There are various sensors that

are in different locations due to a different cylinder

head and intake manifold.

The 2.0L engines use a fixed ignition timing sys-

tem. The distributorless electronic ignition system is

referred to as the Direct Ignition System (DIS).

Basic ignition timing is not adjustable.The

Powertrain Control Module (PCM) determines spark

advance. The system's three main components are

the coil pack, crankshaft position sensor, and cam-

shaft position sensor.

POWERTRAIN CONTROL MODULE

The Powertrain Control Module (PCM) controls the

ignition system (Fig. 1). The PCM supplies battery

voltage to the ignition coil through the Auto Shut-

down (ASD) Relay. The PCM also controls the ground

circuit for the ignition coil. By switching the ground

path for the coil on and off, the PCM adjusts ignition

timing to meet changing engine operating conditions.

During the crank-start period the PCM maintains

spark advance at 9É BTDC. During engine operation

the following inputs determine the amount of spark

advance provided by the PCM.

²Intake air temperature

²Coolant temperature

²Engine RPM

²Intake manifold vacuum

²Knock sensor

The PCM also regulates the fuel injection system.

Refer to the Fuel Injection sections of Group 14.

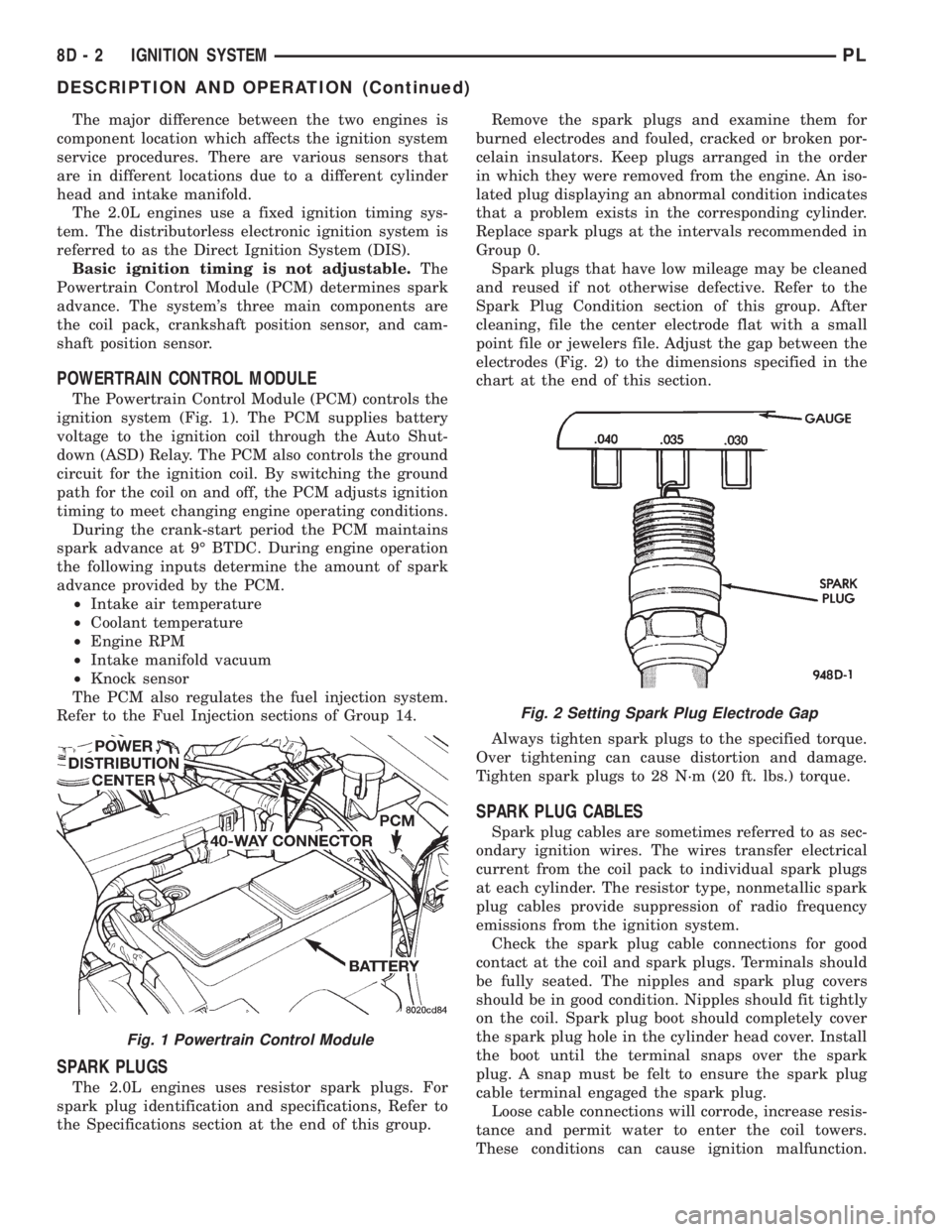

SPARK PLUGS

The 2.0L engines uses resistor spark plugs. For

spark plug identification and specifications, Refer to

the Specifications section at the end of this group.Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indicates

that a problem exists in the corresponding cylinder.

Replace spark plugs at the intervals recommended in

Group 0.

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective. Refer to the

Spark Plug Condition section of this group. After

cleaning, file the center electrode flat with a small

point file or jewelers file. Adjust the gap between the

electrodes (Fig. 2) to the dimensions specified in the

chart at the end of this section.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion and damage.

Tighten spark plugs to 28 N´m (20 ft. lbs.) torque.

SPARK PLUG CABLES

Spark plug cables are sometimes referred to as sec-

ondary ignition wires. The wires transfer electrical

current from the coil pack to individual spark plugs

at each cylinder. The resistor type, nonmetallic spark

plug cables provide suppression of radio frequency

emissions from the ignition system.

Check the spark plug cable connections for good

contact at the coil and spark plugs. Terminals should

be fully seated. The nipples and spark plug covers

should be in good condition. Nipples should fit tightly

on the coil. Spark plug boot should completely cover

the spark plug hole in the cylinder head cover. Install

the boot until the terminal snaps over the spark

plug. A snap must be felt to ensure the spark plug

cable terminal engaged the spark plug.

Loose cable connections will corrode, increase resis-

tance and permit water to enter the coil towers.

These conditions can cause ignition malfunction.

Fig. 1 Powertrain Control Module

Fig. 2 Setting Spark Plug Electrode Gap

8D - 2 IGNITION SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 715 of 1200

assure gasket rails are flat. Flatten rails with a ham-

mer on a heavy steel plate if required. Gasket sur-

faces must be free of oil and dirt. Make sure old

gasket material is removed from blind attaching

holes.

FORM-IN-PLACE GASKET APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 inch.) diameter or less of seal-

ant to one gasket surface. Be certain the material

surrounds each mounting hole. Excess material can

easily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

The MopartSilicone Rubber Adhesive Sealant gas-

ket material or equivalent should be applied in a con-

tinuous bead approximately 3 mm (0.120 inch) in

diameter. All mounting holes must be circled. For

corner sealing, a 3.17 or 6.35 mm (1/8 or 1/4 inch.)

drop is placed in the center of the gasket contact

area. Uncured sealant may be removed with a shop

towel. Components should be torqued in place while

the sealant is still wet to the touch (within 10 min-

utes). The usage of a locating dowel is recommended

during assembly to prevent smearing material off the

location.

CRANKSHAFT SPROCKET BOLT ACCESS PLUG

An Access plug is located in the right inner fender

shield. Remove the plug and insert the proper size

socket, extension and ratchet, when crankshaft rota-

tion is necessary.

ENGINE CORE PLUGS

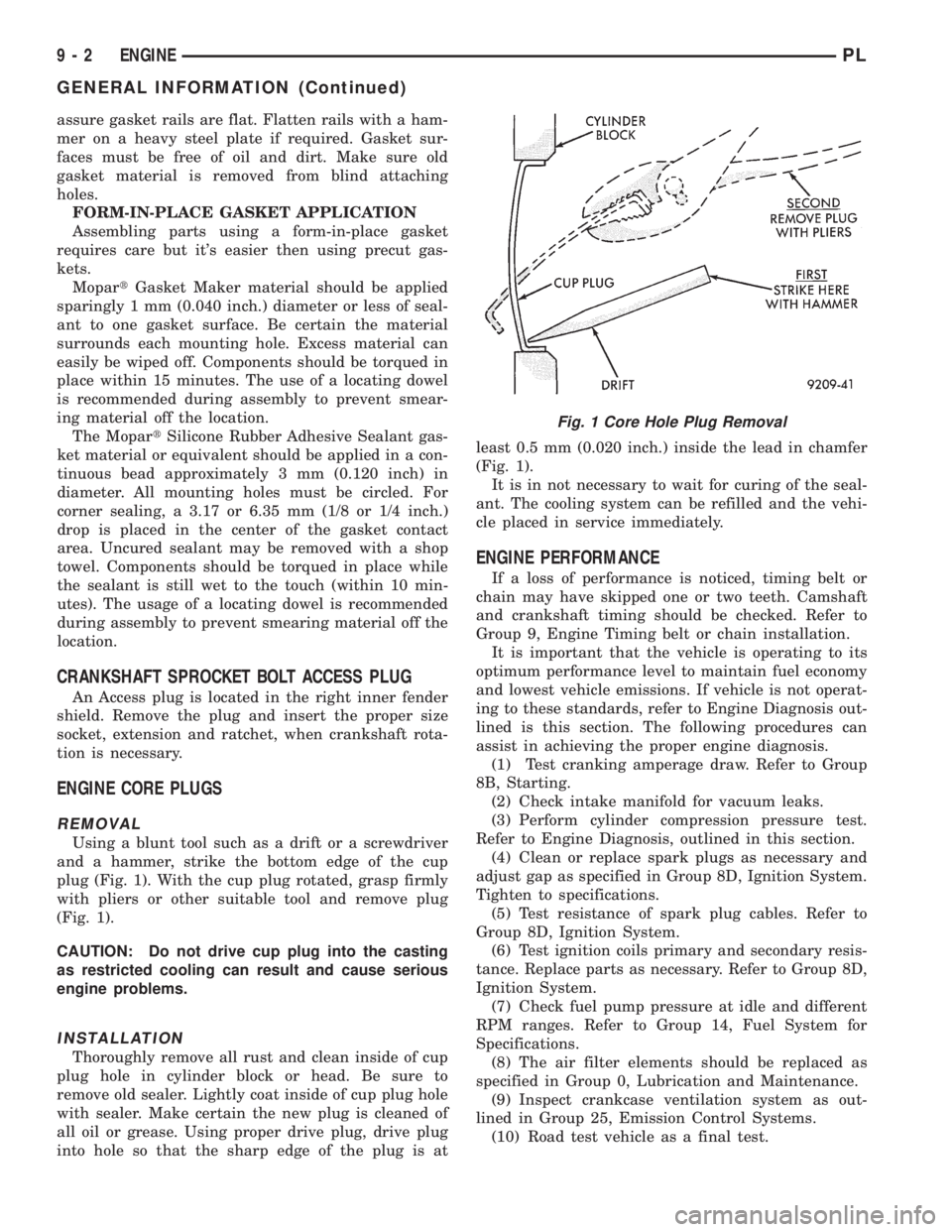

REMOVAL

Using a blunt tool such as a drift or a screwdriver

and a hammer, strike the bottom edge of the cup

plug (Fig. 1). With the cup plug rotated, grasp firmly

with pliers or other suitable tool and remove plug

(Fig. 1).

CAUTION: Do not drive cup plug into the casting

as restricted cooling can result and cause serious

engine problems.

INSTALLATION

Thoroughly remove all rust and clean inside of cup

plug hole in cylinder block or head. Be sure to

remove old sealer. Lightly coat inside of cup plug hole

with sealer. Make certain the new plug is cleaned of

all oil or grease. Using proper drive plug, drive plug

into hole so that the sharp edge of the plug is atleast 0.5 mm (0.020 inch.) inside the lead in chamfer

(Fig. 1).

It is in not necessary to wait for curing of the seal-

ant. The cooling system can be refilled and the vehi-

cle placed in service immediately.

ENGINE PERFORMANCE

If a loss of performance is noticed, timing belt or

chain may have skipped one or two teeth. Camshaft

and crankshaft timing should be checked. Refer to

Group 9, Engine Timing belt or chain installation.

It is important that the vehicle is operating to its

optimum performance level to maintain fuel economy

and lowest vehicle emissions. If vehicle is not operat-

ing to these standards, refer to Engine Diagnosis out-

lined is this section. The following procedures can

assist in achieving the proper engine diagnosis.

(1) Test cranking amperage draw. Refer to Group

8B, Starting.

(2) Check intake manifold for vacuum leaks.

(3) Perform cylinder compression pressure test.

Refer to Engine Diagnosis, outlined in this section.

(4) Clean or replace spark plugs as necessary and

adjust gap as specified in Group 8D, Ignition System.

Tighten to specifications.

(5) Test resistance of spark plug cables. Refer to

Group 8D, Ignition System.

(6) Test ignition coils primary and secondary resis-

tance. Replace parts as necessary. Refer to Group 8D,

Ignition System.

(7) Check fuel pump pressure at idle and different

RPM ranges. Refer to Group 14, Fuel System for

Specifications.

(8) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance.

(9) Inspect crankcase ventilation system as out-

lined in Group 25, Emission Control Systems.

(10) Road test vehicle as a final test.

Fig. 1 Core Hole Plug Removal

9 - 2 ENGINEPL

GENERAL INFORMATION (Continued)

Page 716 of 1200

HONING CYLINDER BORES

(1) Used carefully, the cylinder bore resizing hone

C-823 equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round as well as removing light

scuffing, scoring or scratches. Usually a few strokes

will clean up a bore and maintain the required lim-

its.

(2) Deglazing of the cylinder walls may be done

using a cylinder surfacing hone, Tool C-3501,

equipped with 280 grit stones, if the cylinder bore is

straight and round. 20-60 strokes depending on the

bore condition, will be sufficient to provide a satisfac-

tory surface. Inspect cylinder walls after each 20

strokes, using a light honing oil.Do not use engine

or transmission oil, mineral spirits or kerosene.

(3) Honing should be done by moving the hone up

and down fast enough to get a cross-hatch pattern.

When hone marksintersectat 50-60 degrees, the

cross hatch angle is most satisfactory for proper seat-

ing of rings (Fig. 2).

(4) A controlled hone motor speed between

200-300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 50-60

degree angle. Faster up and down strokes increase

the cross-hatch angle.

(5) After honing, it is necessary that the block be

cleaned again to remove all traces of abrasive.

CAUTION: Ensure all abrasives are removed from

engine parts after honing. It is recommended that a

solution of soap and hot water be used with a

brush and the parts then thoroughly dried. The bore

can be considered clean when it can be wiped

clean with a white cloth and cloth remains clean.

Oil the bores after cleaning to prevent rusting.

MEASURING MAIN BEARING AND CONNECTING

ROD BEARING CLEARANCES

PLASTIGAGE METHOD

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage or equivalent. The follow-

ing is the recommended procedure for the use of

Plastigage:

NOTE: The total clearance of the main bearings

can only be determined by removing the weight of

the crankshaft. This can be accomplished by either

of two methods:

PREFERRED METHOD

Shimming the bearings adjacent to the bearing to

be checked in order to remove the clearance between

upper bearing shell and the crankshaft. This can be

accomplished by placing a minimum of 0.254 mm

(0.010 in.) shim (e. g. cardboard, matchbook cover,

etc.) between the bearing shell and the bearing cap

on the adjacent bearings and tightening bolts to

14-20 N´m (10-15 ft. lbs.). The number of main bear-

ing will vary from engine to engine.

ENGINE WITH 5 MAIN BEARINGS

²When checking #1 main bearing shim #2 main

bearing.

²When checking #2 main bearing shim #1 & 3

main bearing.

²When checking #3 main bearing shim #2 & 4

main bearing.

²When checking #4 main bearing shim #3 & 5

main bearing.

²When checking #5 main bearing shim #4 main

bearing.

ENGINE WITH 4 MAIN BEARING

²When checking #1 main bearing shim # 2 main

bearing.

²When checking #2 main bearing shim #1 & #3

main bearing.

Fig. 2 Cylinder Bore Cross-Hatch Pattern

Fig. 3 Plastigage Placed in Lower Shell

PLENGINE 9 - 3

GENERAL INFORMATION (Continued)