airbag disable DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 352 of 1200

RESTRAINT SYSTEM

CONTENTS

page page

GENERAL INFORMATION

WARNINGS AND PRECAUTIONS............ 1

DESCRIPTION AND OPERATION

AIRBAG CONTROL MODULE............... 1

CLOCKSPRING.......................... 2

DRIVER AND PASSENGER AIRBAG MODULE . . 2

DIAGNOSIS AND TESTING

AIRBAG SYSTEM TEST................... 3

SERVICE PROCEDURES

CLEANUP PROCEDURE................... 3HANDLING AIRBAG MODULE.............. 3

MAINTENANCE INSPECTION............... 4

REMOVAL AND INSTALLATION

AIRBAG CONTROL MODULE (ACM)......... 4

CLOCKSPRING.......................... 8

DRIVER AIRBAG MODULE................. 9

PASSENGER AIRBAG MODULE............. 9

STEERING WHEEL...................... 10

ADJUSTMENTS

CLOCKSPRING CENTERING PROCEDURE.... 11

GENERAL INFORMATION

WARNINGS AND PRECAUTIONS

WARNING: THIS SYSTEM IS A SENSITIVE, COM-

PLEX ELECTRO±MECHANICAL UNIT. DISCONNECT

AND ISOLATE THE BATTERY NEGATIVE CABLE

BEFORE BEGINNING AIRBAG SYSTEM COMPO-

NENT REMOVAL OR INSTALLATION PROCEDURES.

THIS WILL DISABLE THE AIRBAG SYSTEM. FAIL-

URE TO DISCONNECT THE BATTERY COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

ALLOW SYSTEM CAPACITOR TO DISCHARGE

FOR TWO MINUTES BEFORE REMOVING AIRBAG

COMPONENTS.

DO NOT PLACE AN INTACT UNDEPLOYED AIR-

BAG FACE DOWN ON A SOLID SURFACE, THE AIR-

BAG WILL PROPEL INTO THE AIR IF

ACCIDENTALLY DEPLOYED AND COULD RESULT

IN PERSONAL INJURY. WHEN CARRYING OR HAN-

DLING AN UNDEPLOYED AIRBAG MODULE, THE

TRIM SIDE OF THE AIRBAG SHOULD BE POINTING

AWAY FROM THE BODY TO MINIMIZE POSSIBILITY

OF INJURY IF ACCIDENTAL DEPLOYMENT

OCCURS.

REPLACE AIRBAG SYSTEM COMPONENTS WITH

MOPARTREPLACEMENT PARTS. SUBSTITUTE

PARTS MAY APPEAR INTERCHANGEABLE, BUT

INTERNAL DIFFERENCES MAY RESULT IN INFE-

RIOR OCCUPANT PROTECTION.

WEAR SAFETY GLASSES, RUBBER GLOVES,

AND LONG SLEEVES CLOTHING WHEN CLEANING

POWDER RESIDUE FROM VEHICLE AFTER AIRBAG

DEPLOYMENT. SODIUM HYDROXIDE POWDER

RESIDUE EMITTED FROM A DEPLOYED AIRBAGCAN CAUSE SKIN IRRITATION. FLUSH AFFECTED

AREA WITH COOL WATER IF IRRITATION IS EXPE-

RIENCED. IF NASAL OR THROAT IRRITATION IS

EXPERIENCED, EXIT THE VEHICLE FOR FRESH AIR

UNTIL THE IRRITATION CEASES. IF IRRITATION

CONTINUES, SEE A PHYSICIAN.

DO NOT USE A REPLACEMENT AIRBAG THAT IS

NOT IN THE ORIGINAL PACKAGING, IMPROPER

DEPLOYMENT AND PERSONAL INJURY CAN

RESULT.

THE FACTORY INSTALLED FASTENERS,

SCREWS AND BOLTS USED TO FASTEN AIRBAG

COMPONENTS, ARE SPECIFICALLY DESIGNED

FOR THE AIRBAG SYSTEM. DO NOT USE SUBSTI-

TUTE FASTENERS, USE ONLY ORIGINAL EQUIP-

MENT FASTENERS LISTED IN THE PARTS

CATALOG WHEN FASTENER REPLACEMENT IS

REQUIRED.

NOTE: Airbags should be stored in a cool dry loca-

tion away from excessive heat and static electrical

activity with the fabric airbag facing UP, or a prema-

ture deployment can result.

If the Driver/Passenger Airbag Module is defective

and not deployed, refer to Chrysler Corporation cur-

rent return list for proper handling procedures.

DESCRIPTION AND OPERATION

AIRBAG CONTROL MODULE

The Airbag Control Module (ACM) contains the

safing sensor and energy reserve capacitor. The saf-

ing sensor is located inside the ACM. The module is

mounted on the tunnel/floor pan between the gear

PLRESTRAINT SYSTEM 8M - 1

Page 355 of 1200

tal deployment occurs. Do not place undeployed air-

bag face down on a solid surface, the airbag will

propel into the air if accidental deployment occurs.

MAINTENANCE INSPECTION

(1) Check the airbag warning lamp for proper

operation as follows:

(a) Turn ignition switch to the ON position, the

airbag warning lamp should light. If not, test the

system using a scan tool and Passive Restraint

System Diagnostic Procedures Manual. Repair as

required.

(b) The airbag warning lamp lights, but fails to

go out after eight seconds. Test the system using a

scan tool and Passive Restraint System Diagnostic

Procedures Manual. Repair as required.

(c) After correcting active malfunction erase

stored diagnostic codes.

REMOVAL AND INSTALLATION

AIRBAG CONTROL MODULE (ACM)

REMOVAL

WARNING: THE ACM CONTAINS A SAFING SEN-

SOR WHICH ENABLES THE SYSTEM TO DEPLOY

THE AIRBAGS. TO AVOID ACCIDENTAL DEPLOY-

MENT, NEVER CONNECT THE ACM ELECTRICALLY

TO THE SYSTEM WHILE VEHICLE BATTERY IS

CONNECTED.

DISCONNECT AND ISOLATE THE BATTERY NEG-

ATIVE (GROUND) CABLE BEFORE BEGINNING ANY

AIRBAG SYSTEM COMPONENT REMOVAL OR

INSTALLATION PROCEDURE. THIS WILL DISABLE

THE AIRBAG SYSTEM. FAILURE TO DISCONNECT

BATTERY COULD RESULT IN ACCIDENTAL AIRBAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY.

ALLOW SYSTEM CAPACITOR TO DISCHARGE

FOR 2 MINUTES BEFORE REMOVING ANY AIRBAG

COMPONENTS.

CAUTION: Failure to follow the parking brake ser-

vice procedures can result in damage to the park-

ing brake mechanism.

(1) Disconnect and isolate the battery negative

cable.

(2) Manual transaxle only, remove shifter knob

fastener and remove shifter knob.

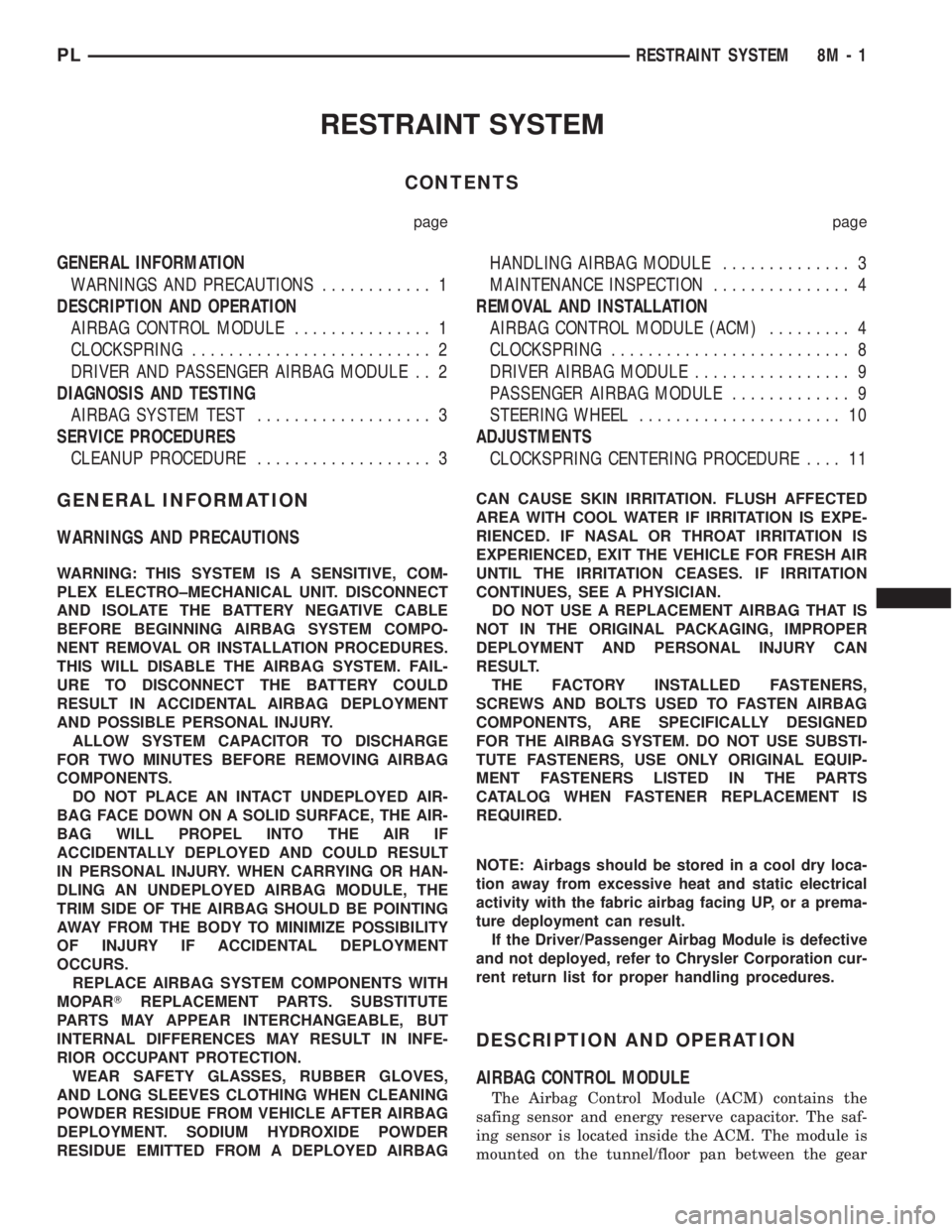

(3) Remove screws attaching rear of center console

assembly to console bracket (Fig. 5) or (Fig. 6).

(4) Remove the two screws located in cup holders

(Fig. 7), attaching front of center console assembly to

console bracket.

Fig. 5 Attaching Screws At Rear Of Center Console

With/Without Arm Rest

Fig. 6 Attaching Screws At Rear Of Center Console

With Arm Rest

Fig. 7 Attaching Screws At Front Of Center Console

8M - 4 RESTRAINT SYSTEMPL

SERVICE PROCEDURES (Continued)

Page 359 of 1200

CLOCKSPRING

REMOVAL

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE BEFORE

BEGINNING ANY AIRBAG SYSTEM COMPONENT

REMOVAL OR INSTALLATION PROCEDURE. THIS

WILL DISABLE THE AIRBAG SYSTEM. FAILURE TO

DISCONNECT BATTERY COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY. ALLOW SYSTEM CAPACITOR

TO DISCHARGE FOR 2 MINUTES BEFORE REMOV-

ING ANY AIRBAG COMPONENTS.

(1) Place the front road wheels in the straight

ahead position then:

²Rotate the steering wheel half turn (180

degrees) to the right (clockwise)

²Lock column with ignition lock cylinder.

(2) Disconnect and isolate the battery negative

cable.

(3) Wait two minutes for the reserve capacitor to

discharge before removing non-deployed module.

(4) Remove speed control switch mounting screws,

switches and disconnect the wire connectors or

remove covers.

(5) Remove the Driver Airbag Module attaching

bolts from under the speed control switches or covers.

(6) Lift module and disconnect the airbag and horn

wire connectors.

(7) Remove the steering wheel, refer to Steering

Wheel removal procedures.

(8) Remove upper and lower steering column

shrouds to gain access to clockspring wiring.

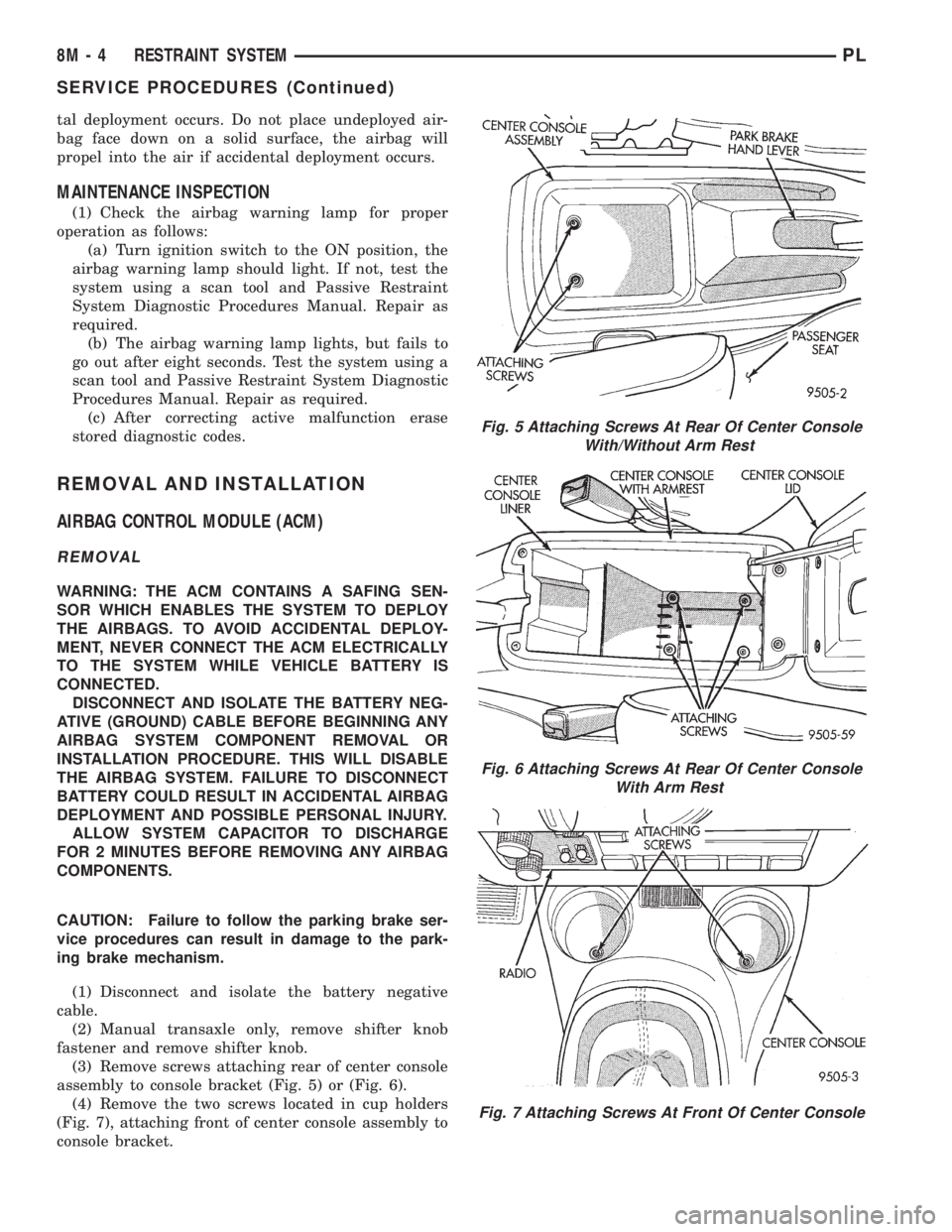

(9) Disconnect the 2-way and 4-way connectors

between the clockspring and the instrument panel

wiring harness at the base of the clockspring (Fig.

21).

(10) Unlatch and remove clockspring assembly

from steering shaft. The clockspring cannot be

repaired, and must be replaced if faulty.

(11) Rotate clockspring rotor a half turn (180

degrees) to the left (counter clockwise).

(12) Lock the clockspring rotor in the center posi-

tion as follows: Insert a paper clip wire through the

hole in the rotor at the 10 O'clock position and bend

to prevent it from falling out.

INSTALLATION

(1) Confirm that:

²The steering wheel position is a half turn (180

degrees) to the right (clockwise)

²The column is locked with the ignition cylinder

lock.

²Check that the turn signal stalk is in the neu-

tral position²When reusing the clockspring, remove locking

wire and rotate clockspring rotor one half turn (180

degrees) to the right (clockwise). Locate the clock-

spring on the steering shaft and push down on the

rotor until the clockspring is fully seated on the

steering column.

²When installing a new clockspring remove gre-

nade pin and rotate clockspring rotor one half turn

(180 degrees) to the right (clockwise). Locate clock-

spring on the steering shaft and push down on the

rotor until the clockspring is fullly seated on the

steering wheel.

(2) Connect the clockspring to the instrument

panel harness, ensure wiring is properly routed.

Then check that the connectors, locking tabs are

properly engaged and the halo lamp wire is in posi-

tion.

(3) Install steering column shrouds. Be sure all

wires are inside of shrouds.

(4) Install steering wheel ensuring the flats on hub

align with the clockspring. Pull the horn, airbag and

speed control leads through the larger slot. Ensure

leads do not get pinched under the steering wheel.

(5) Route speed control wires under and behind

the airbag module mounting tabs.

(6) Connect the horn lead wire and the airbag lead

wire to the airbag module.

(7) Install the airbag module and tighten bolts to

12 to 14 N´m (105 to 125 in. lbs.) torque.

(8) Connect the speed control wires to the switches

and install switches. Tighten screws to 2 N´m (20 in.

lbs.) torque.

(9) Do not connect the battery negative cable.

Refer to Diagnosis and Testing for Airbag System

Test procedures.

Fig. 21 Clockspring

8M - 8 RESTRAINT SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 360 of 1200

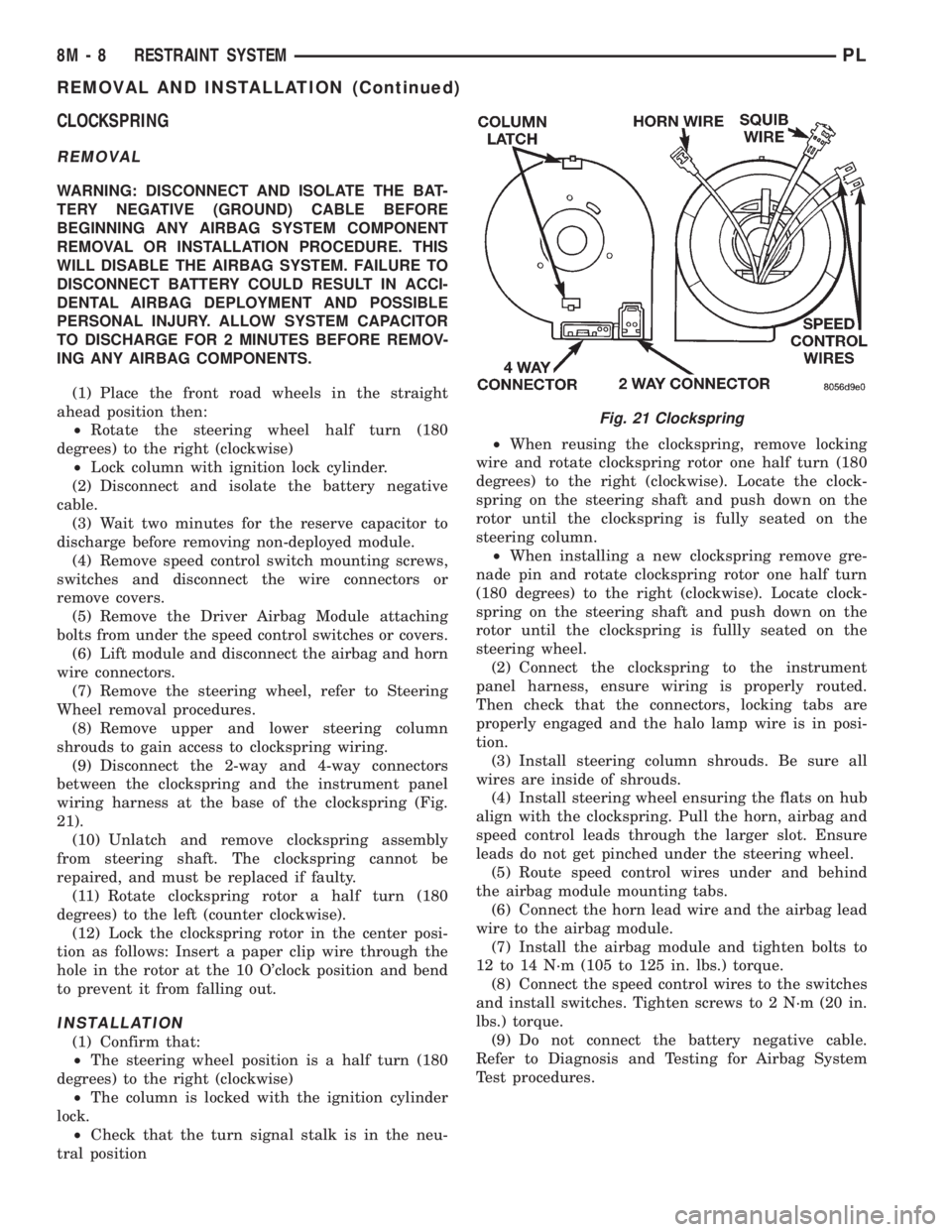

DRIVER AIRBAG MODULE

REMOVAL

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE BEFORE

BEGINNING ANY AIRBAG SYSTEM COMPONENT

REMOVAL OR INSTALLATION PROCEDURE. THIS

WILL DISABLE THE AIRBAG SYSTEM. FAILURE TO

DISCONNECT BATTERY COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY. ALLOW SYSTEM CAPACITOR

TO DISCHARGE FOR 2 MINUTES BEFORE REMOV-

ING ANY AIRBAG COMPONENTS.

When removing a deployed module, rubber gloves,

eye protection and long sleeved shirt should be worn,

as there may be deposits on the surface which could

irritate the skin and eyes.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove speed control switches or covers from

steering wheel armature and disconnect the wires.

(3) Remove two bolts attaching Driver Airbag Mod-

ule from the sides of steering wheel (Fig. 22).

(4) Lift module and disconnect airbag squib wire

connector and horn wire.

(5) Remove Driver Airbag Module.

(6) When replacing a deployed driver airbag mod-

ule, the clockspring must also be replaced. Refer to

Clockspring Removal and Installation for proper pro-

cedure.

INSTALLATION

For installation, reverse the above procedures.

(1) Connect the squib wire to the module. Make

airbag connection by pressing straight in on the con-

nector. The connector should be fully seated feel for

positive snap to assure positive connection.

(2) Connect the horn wire.

(3) Install two bolts and tighten to 10 to 11 N´m

(90 to 100 in. lbs.) torque.

(4) Install non-speed control covers to the steering

wheel armature or connect the wire connectors to the

speed control switches and install switches. Tighten

fastener to 2 N´m (20 in. lbs.) TORQUE.

(5) Do not connect battery negative cable. Refer to

Diagnosis and Testing for Airbag System Test proce-

dures.

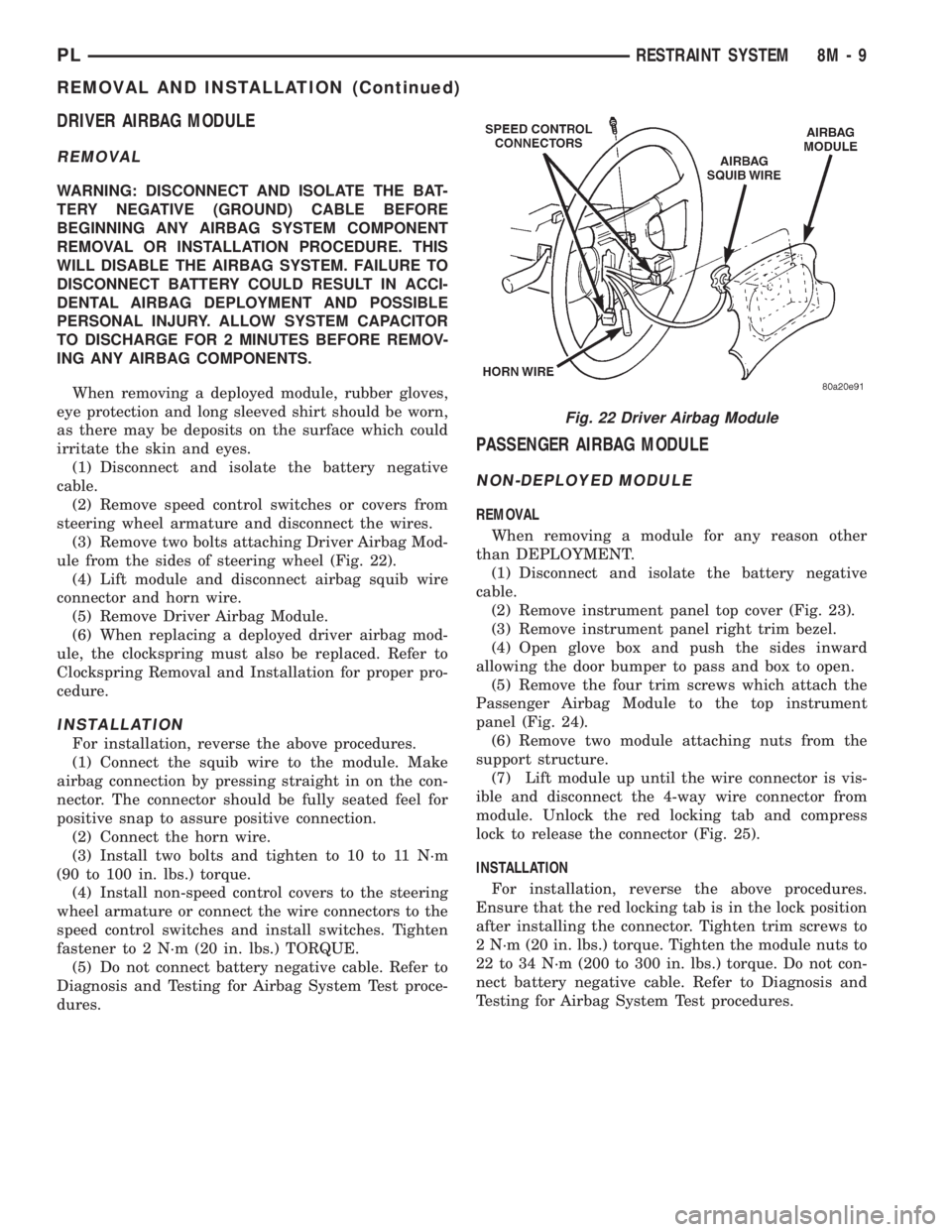

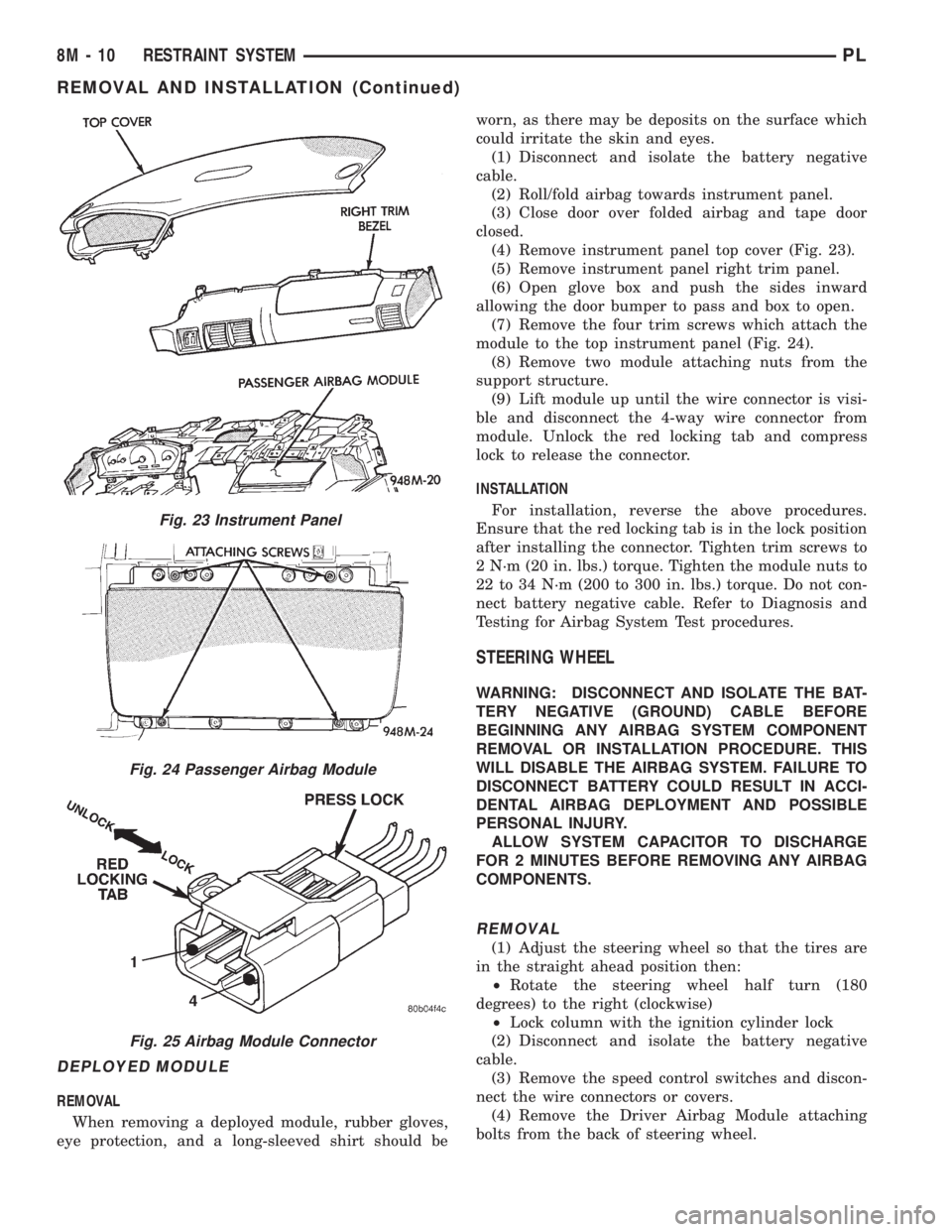

PASSENGER AIRBAG MODULE

NON-DEPLOYED MODULE

REMOVAL

When removing a module for any reason other

than DEPLOYMENT.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove instrument panel top cover (Fig. 23).

(3) Remove instrument panel right trim bezel.

(4) Open glove box and push the sides inward

allowing the door bumper to pass and box to open.

(5) Remove the four trim screws which attach the

Passenger Airbag Module to the top instrument

panel (Fig. 24).

(6) Remove two module attaching nuts from the

support structure.

(7) Lift module up until the wire connector is vis-

ible and disconnect the 4-way wire connector from

module. Unlock the red locking tab and compress

lock to release the connector (Fig. 25).

INSTALLATION

For installation, reverse the above procedures.

Ensure that the red locking tab is in the lock position

after installing the connector. Tighten trim screws to

2 N´m (20 in. lbs.) torque. Tighten the module nuts to

22 to 34 N´m (200 to 300 in. lbs.) torque. Do not con-

nect battery negative cable. Refer to Diagnosis and

Testing for Airbag System Test procedures.

Fig. 22 Driver Airbag Module

PLRESTRAINT SYSTEM 8M - 9

REMOVAL AND INSTALLATION (Continued)

Page 361 of 1200

DEPLOYED MODULE

REMOVAL

When removing a deployed module, rubber gloves,

eye protection, and a long-sleeved shirt should beworn, as there may be deposits on the surface which

could irritate the skin and eyes.

(1) Disconnect and isolate the battery negative

cable.

(2) Roll/fold airbag towards instrument panel.

(3) Close door over folded airbag and tape door

closed.

(4) Remove instrument panel top cover (Fig. 23).

(5) Remove instrument panel right trim panel.

(6) Open glove box and push the sides inward

allowing the door bumper to pass and box to open.

(7) Remove the four trim screws which attach the

module to the top instrument panel (Fig. 24).

(8) Remove two module attaching nuts from the

support structure.

(9) Lift module up until the wire connector is visi-

ble and disconnect the 4-way wire connector from

module. Unlock the red locking tab and compress

lock to release the connector.

INSTALLATION

For installation, reverse the above procedures.

Ensure that the red locking tab is in the lock position

after installing the connector. Tighten trim screws to

2 N´m (20 in. lbs.) torque. Tighten the module nuts to

22 to 34 N´m (200 to 300 in. lbs.) torque. Do not con-

nect battery negative cable. Refer to Diagnosis and

Testing for Airbag System Test procedures.

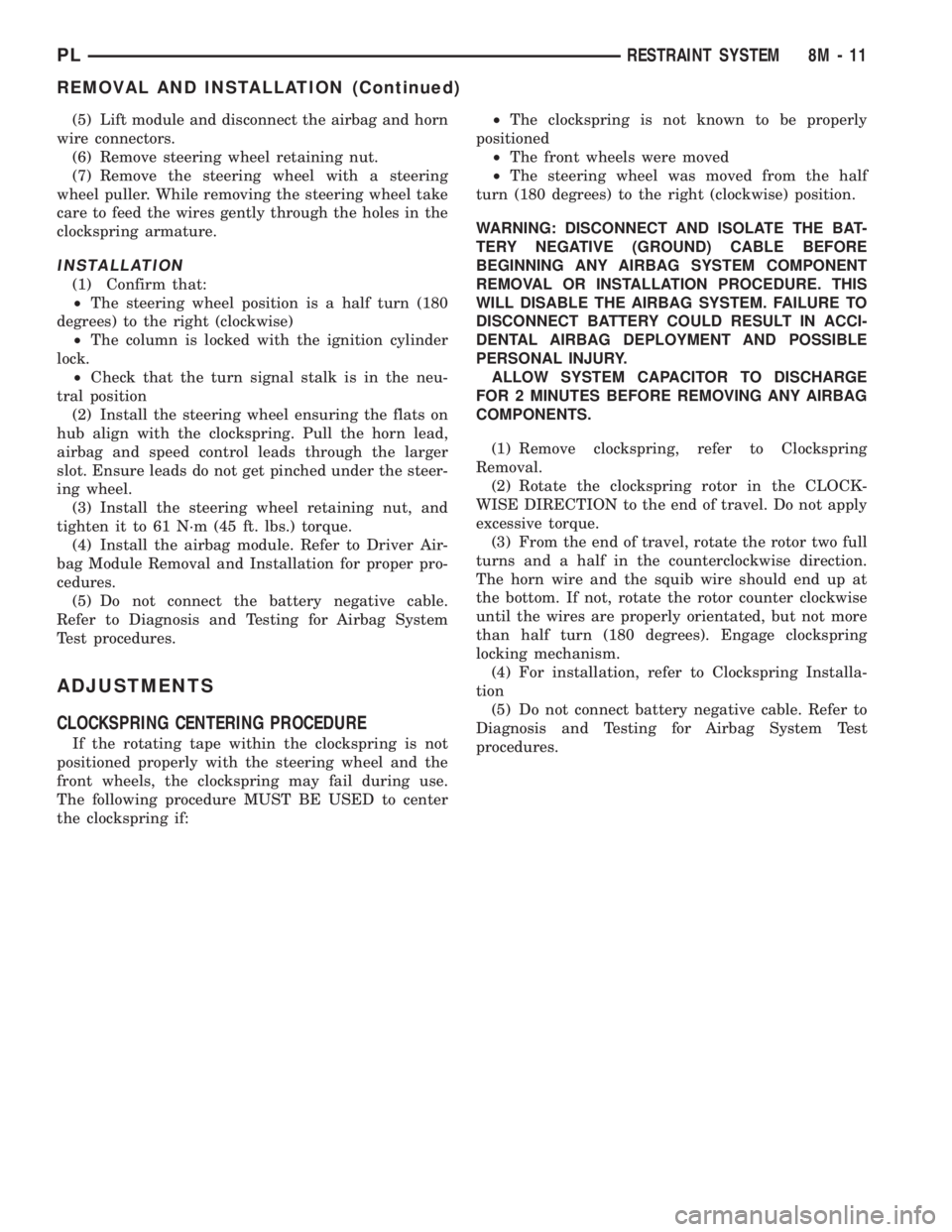

STEERING WHEEL

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE BEFORE

BEGINNING ANY AIRBAG SYSTEM COMPONENT

REMOVAL OR INSTALLATION PROCEDURE. THIS

WILL DISABLE THE AIRBAG SYSTEM. FAILURE TO

DISCONNECT BATTERY COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

ALLOW SYSTEM CAPACITOR TO DISCHARGE

FOR 2 MINUTES BEFORE REMOVING ANY AIRBAG

COMPONENTS.

REMOVAL

(1) Adjust the steering wheel so that the tires are

in the straight ahead position then:

²Rotate the steering wheel half turn (180

degrees) to the right (clockwise)

²Lock column with the ignition cylinder lock

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the speed control switches and discon-

nect the wire connectors or covers.

(4) Remove the Driver Airbag Module attaching

bolts from the back of steering wheel.

Fig. 23 Instrument Panel

Fig. 24 Passenger Airbag Module

Fig. 25 Airbag Module Connector

8M - 10 RESTRAINT SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 362 of 1200

(5) Lift module and disconnect the airbag and horn

wire connectors.

(6) Remove steering wheel retaining nut.

(7) Remove the steering wheel with a steering

wheel puller. While removing the steering wheel take

care to feed the wires gently through the holes in the

clockspring armature.

INSTALLATION

(1) Confirm that:

²The steering wheel position is a half turn (180

degrees) to the right (clockwise)

²The column is locked with the ignition cylinder

lock.

²Check that the turn signal stalk is in the neu-

tral position

(2) Install the steering wheel ensuring the flats on

hub align with the clockspring. Pull the horn lead,

airbag and speed control leads through the larger

slot. Ensure leads do not get pinched under the steer-

ing wheel.

(3) Install the steering wheel retaining nut, and

tighten it to 61 N´m (45 ft. lbs.) torque.

(4) Install the airbag module. Refer to Driver Air-

bag Module Removal and Installation for proper pro-

cedures.

(5) Do not connect the battery negative cable.

Refer to Diagnosis and Testing for Airbag System

Test procedures.

ADJUSTMENTS

CLOCKSPRING CENTERING PROCEDURE

If the rotating tape within the clockspring is not

positioned properly with the steering wheel and the

front wheels, the clockspring may fail during use.

The following procedure MUST BE USED to center

the clockspring if:²The clockspring is not known to be properly

positioned

²The front wheels were moved

²The steering wheel was moved from the half

turn (180 degrees) to the right (clockwise) position.

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE BEFORE

BEGINNING ANY AIRBAG SYSTEM COMPONENT

REMOVAL OR INSTALLATION PROCEDURE. THIS

WILL DISABLE THE AIRBAG SYSTEM. FAILURE TO

DISCONNECT BATTERY COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

ALLOW SYSTEM CAPACITOR TO DISCHARGE

FOR 2 MINUTES BEFORE REMOVING ANY AIRBAG

COMPONENTS.

(1) Remove clockspring, refer to Clockspring

Removal.

(2) Rotate the clockspring rotor in the CLOCK-

WISE DIRECTION to the end of travel. Do not apply

excessive torque.

(3) From the end of travel, rotate the rotor two full

turns and a half in the counterclockwise direction.

The horn wire and the squib wire should end up at

the bottom. If not, rotate the rotor counter clockwise

until the wires are properly orientated, but not more

than half turn (180 degrees). Engage clockspring

locking mechanism.

(4) For installation, refer to Clockspring Installa-

tion

(5) Do not connect battery negative cable. Refer to

Diagnosis and Testing for Airbag System Test

procedures.

PLRESTRAINT SYSTEM 8M - 11

REMOVAL AND INSTALLATION (Continued)