check oil DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 2 of 1285

LUBRICATION AND MAINTENANCE

TABLE OF CONTENTS

page page

LUBRICANTS............................. 1

MAINTENANCE SCHEDULES................. 3JUMP STARTING, TOWING, AND HOISTING..... 7

LUBRICANTS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

PARTS AND LUBRICANT

RECOMMENDATIONS....................1

CLASSIFICATION OF LUBRICANTS............1

INTERNATIONAL SYMBOLS.................2FLUID CHECK/FILL POINTS AND

LUBRICATION LOCATIONS.................2

LUBRICATION POINT LOCATIONS............2

SPECIFICATIONS

FLUID CAPACITIES........................2

DESCRIPTION AND OPERATION

PARTS AND LUBRICANT RECOMMENDATIONS

When service is required, DaimlerChrysler Corpo-

ration recommends that only Mopartbrand parts,

lubricants and chemicals be used. Mopar provides

the best engineered products for servicing

DaimlerChrysler Corporation vehicles.

CLASSIFICATION OF LUBRICANTS

DESCRIPTION

Only lubricants bearing designations defined by

the following organization should be used to service a

DaimlerChrysler Corporation vehicle.

²Society of Automotive Engineers (SAE)

²American Petroleum Institute (API) (Fig. 1)

²National Lubricating Grease Institute (NLGI)

(Fig. 2)

SAE VISCOSITY RATING

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. These are specified with a dual

SAE viscosity grade which indicates the cold-to-hot

temperature viscosity range. Example SAE 5W-30 =

multiple grade engine oil.DaimlerChrysler Corporation only recommends

multiple grade engine oils.

API QUALITY CLASSIFICATION

This symbol (Fig. 1) on the front of an oil container

means that the oil has been certified by the Ameri-

can Petroleum Institute (API) to meet all the lubri-

cation requirements specified by DaimlerChrysler

Corporation.

Refer to Group 9, Engine for gasoline engine oil

specification.

GEAR LUBRICANTS

SAE ratings also apply to multiple grade gear

lubricants. In addition, API classification defines the

lubricants usage. Such as API GL-5 and SAE 80W-90.

Fig. 1 API Symbol

PLLUBRICATION AND MAINTENANCE 0 - 1

Page 3 of 1285

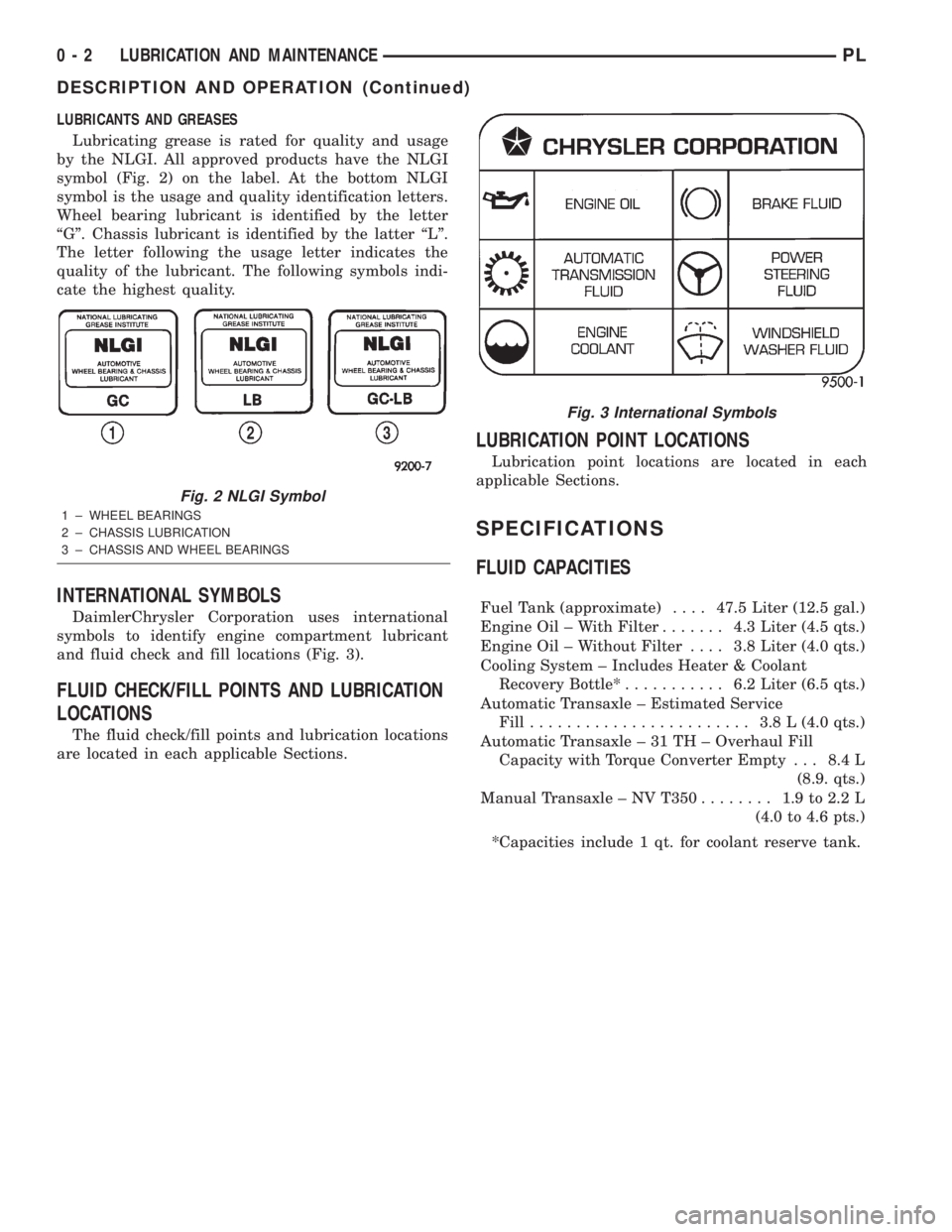

LUBRICANTS AND GREASES

Lubricating grease is rated for quality and usage

by the NLGI. All approved products have the NLGI

symbol (Fig. 2) on the label. At the bottom NLGI

symbol is the usage and quality identification letters.

Wheel bearing lubricant is identified by the letter

ªGº. Chassis lubricant is identified by the latter ªLº.

The letter following the usage letter indicates the

quality of the lubricant. The following symbols indi-

cate the highest quality.

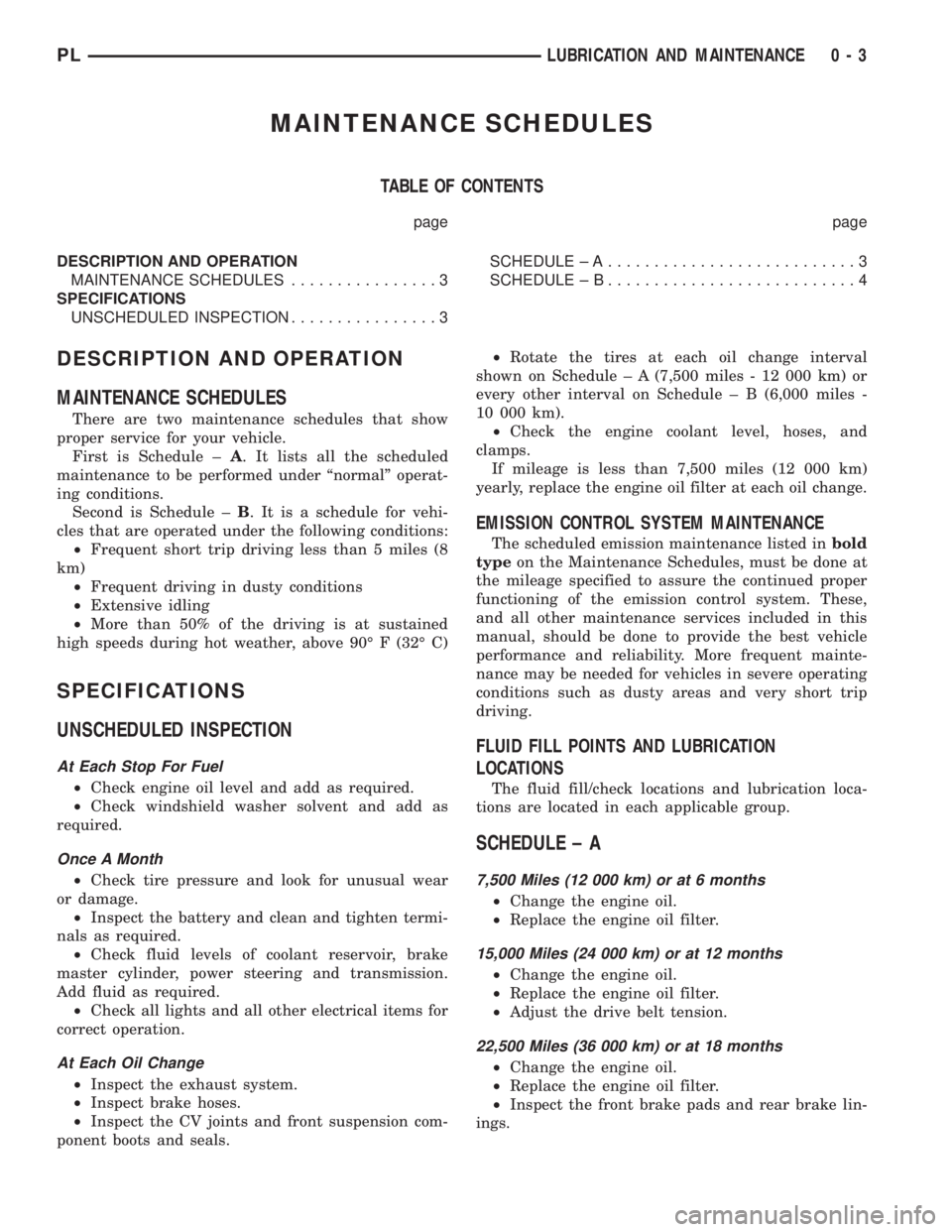

INTERNATIONAL SYMBOLS

DaimlerChrysler Corporation uses international

symbols to identify engine compartment lubricant

and fluid check and fill locations (Fig. 3).

FLUID CHECK/FILL POINTS AND LUBRICATION

LOCATIONS

The fluid check/fill points and lubrication locations

are located in each applicable Sections.

LUBRICATION POINT LOCATIONS

Lubrication point locations are located in each

applicable Sections.

SPECIFICATIONS

FLUID CAPACITIES

Fuel Tank (approximate)....47.5 Liter (12.5 gal.)

Engine Oil ± With Filter....... 4.3Liter (4.5 qts.)

Engine Oil ± Without Filter.... 3.8Liter (4.0 qts.)

Cooling System ± Includes Heater & Coolant

Recovery Bottle*........... 6.2Liter (6.5 qts.)

Automatic Transaxle ± Estimated Service

Fill........................ 3.8L(4.0 qts.)

Automatic Transaxle ± 31 TH ± Overhaul Fill

Capacity with Torque Converter Empty . . . 8.4 L

(8.9. qts.)

Manual Transaxle ± NV T350........ 1.9to2.2L

(4.0 to 4.6 pts.)

*Capacities include 1 qt. for coolant reserve tank.

Fig. 2 NLGI Symbol

1 ± WHEEL BEARINGS

2 ± CHASSIS LUBRICATION

3 ± CHASSIS AND WHEEL BEARINGS

Fig. 3 International Symbols

0 - 2 LUBRICATION AND MAINTENANCEPL

DESCRIPTION AND OPERATION (Continued)

Page 4 of 1285

MAINTENANCE SCHEDULES

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

MAINTENANCE SCHEDULES................3

SPECIFICATIONS

UNSCHEDULED INSPECTION................3SCHEDULE ± A...........................3

SCHEDULE ± B...........................4

DESCRIPTION AND OPERATION

MAINTENANCE SCHEDULES

There are two maintenance schedules that show

proper service for your vehicle.

First is Schedule ±A. It lists all the scheduled

maintenance to be performed under ªnormalº operat-

ing conditions.

Second is Schedule ±B. It is a schedule for vehi-

cles that are operated under the following conditions:

²Frequent short trip driving less than 5 miles (8

km)

²Frequent driving in dusty conditions

²Extensive idling

²More than 50% of the driving is at sustained

high speeds during hot weather, above 90É F (32É C)

SPECIFICATIONS

UNSCHEDULED INSPECTION

At Each Stop For Fuel

²Check engine oil level and add as required.

²Check windshield washer solvent and add as

required.

Once A Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect the battery and clean and tighten termi-

nals as required.

²Check fluid levels of coolant reservoir, brake

master cylinder, power steering and transmission.

Add fluid as required.

²Check all lights and all other electrical items for

correct operation.

At Each Oil Change

²Inspect the exhaust system.

²Inspect brake hoses.

²Inspect the CV joints and front suspension com-

ponent boots and seals.²Rotate the tires at each oil change interval

shown on Schedule ± A (7,500 miles - 12 000 km) or

every other interval on Schedule ± B (6,000 miles -

10 000 km).

²Check the engine coolant level, hoses, and

clamps.

If mileage is less than 7,500 miles (12 000 km)

yearly, replace the engine oil filter at each oil change.

EMISSION CONTROL SYSTEM MAINTENANCE

The scheduled emission maintenance listed inbold

typeon the Maintenance Schedules, must be done at

the mileage specified to assure the continued proper

functioning of the emission control system. These,

and all other maintenance services included in this

manual, should be done to provide the best vehicle

performance and reliability. More frequent mainte-

nance may be needed for vehicles in severe operating

conditions such as dusty areas and very short trip

driving.

FLUID FILL POINTS AND LUBRICATION

LOCATIONS

The fluid fill/check locations and lubrication loca-

tions are located in each applicable group.

SCHEDULE ± A

7,500 Miles (12 000 km) or at 6 months

²Change the engine oil.

²Replace the engine oil filter.

15,000 Miles (24 000 km) or at 12 months

²Change the engine oil.

²Replace the engine oil filter.

²Adjust the drive belt tension.

22,500 Miles (36 000 km) or at 18 months

²Change the engine oil.

²Replace the engine oil filter.

²Inspect the front brake pads and rear brake lin-

ings.

PLLUBRICATION AND MAINTENANCE 0 - 3

Page 5 of 1285

30,000 Miles (48 000 km) or at 24 months

²Change the engine oil.

²Replace the engine oil filter.

²Lubricate the front suspension lower ball joint.

²Inspect the tie rod ends and boot seals.

²Adjust the drive belt tension.

²Replace the engine air cleaner element (fil-

ter).

²Replace the engine spark plugs

²Change the automatic transaxle fluid.

37,500 Miles (60 000 km) or at 30 months

²Change the engine oil.

²Replace the engine oil filter.

45,000 Miles (72 000 km) or at 36 months

²Change the engine oil.

²Replace the engine oil filter.

²Inspect the front brake pads and rear brake lin-

ings.

²Adjust the drive belt tension.

²Flush and replace the engine coolant at 36

months, regardless of mileage.

52,500 Miles (84 000 km) or at 42 months

²Change the engine oil.

²Replace the engine oil filter.

²Flush and replace the engine coolant if not done

at 36 months.

60,000 Miles (96 000 km) or at 48 months

²Change the engine oil.

²Replace the engine oil filter.

²Check the PCV valve and replace, if neces-

sary. Not required if previously changed.*

²Lubricate the front suspension lower ball joints.

²Replace the drive belts.

²Replace the engine air cleaner element (fil-

ter).

²Replace the ignition cables.

²Replace the spark plugs.

²Change the automatic transaxle fluid.

67,500 Miles (108 000 km) or at 54 months

²Change the engine oil.

²Replace the engine oil filter.

²Inspect the front brake pads and rear brake lin-

ings.

75,000 Miles (120 000 km) or at 60 months

²Change the engine oil.

²Replace the engine oil filter.

²Adjust the drive belt tension.

²Flush and replace engine coolant if has been

30,000 miles (48 000 km) or 24 months since last

change.

82,500 Miles (132 000 km) or at 66 months

²Change the engine oil.

²Replace the engine oil filter.

²Flush and replace engine coolant if it has been

30,000 miles (48 000 km) or 24 months since last

change.

90,000 Miles (144 000 km) or at 72 months

²Change the engine oil.

²Replace the engine oil filter.

²Check the PCV valve and replace, if neces-

sary. Not required if previously changed.*

²Lubricate the front suspension lower ball joints.

²Inspect the front brake pads and rear brake lin-

ings.

²Adjust the drive belt tension.

²Replace the engine air cleaner element (fil-

ter).

²Replace the spark plugs.

²Inspect the serpentine drive belt, replace if nec-

essary. This maintenance is not required if the belt

was previously replaced.

²Change the automatic transaxle fluid.

97,500 Miles (156 000 km) or at 78 months

²Change the engine oil.

²Replace the engine oil filter.

105,000 Miles (168 000 km) or at 84 months

²Change the engine oil.

²Replace the engine oil filter.

²Replace the engine timing belt.

²Adjust the drive belt tension.

*This maintenance is recommended by Daimler-

Chrysler Corporation to the owner but is not

required to maintain the emissions warranty.

NOTE: Inspection and service should also be per-

formed anytime a malfunction is observed or sus-

pected. Retain all receipts.

SCHEDULE ± B

3,000 Miles (5 000 km)

²Change the engine oil.

6,000 Miles (10 000 km)

²Change the engine oil.

²Replace the engine oil filter.

9,000 Miles (14 000 km)

²Change the engine oil.

²Inspect the front brake pads and rear brake lin-

ings.

0 - 4 LUBRICATION AND MAINTENANCEPL

SPECIFICATIONS (Continued)

Page 6 of 1285

12,000 Miles (19 000 km)

²Change the engine oil.

²Replace the engine oil filter.

15,000 Miles (24 000 km)

²Change the engine oil.

²Adjust the drive belt tension.

²Inspect theengine air cleaner element (fil-

ter).Replace as necessary.*

²Change the automatic transaxle fluid/filter and

adjust the bands.

18,000 Miles (29 000 km)

²Change the engine oil.

²Replace the engine oil filter.

²Inspect the front brake pads and rear brake lin-

ings.

21,000 Miles (34 000 km)

²Change the engine oil.

24,000 Miles (38 000 km)

²Change the engine oil.

²Replace the engine oil filter.

27,000 Miles (43 000 km)

²Change the engine oil.

²Inspect the front brake pads and rear brake lin-

ings.

30,000 Miles (48 000 km)

²Change the engine oil.

²Replace the engine oil filter.

²Inspect thePCV valveand replace as neces-

sary.*

²Lubricate the front suspension lower ball joints.

²Adjust the drive belt tension.

²Replace theengine air cleaner element (fil-

ter).

²Replace thespark plugs

²Change the automatic transaxle fluid/filter and

adjust bands.

33,000 Miles (53 000 km)

²Change the engine oil.

36,000 Miles (58 000 km)

²Change the engine oil.

²Replace the engine oil filter.

²Inspect the front brake pads and rear brake lin-

ings.

²Flush and replace the engine coolant.

39,000 Miles (62 000 km)

²Change the engine oil.

42,000 Miles (67 000 km)

²Change the engine oil.

²Replace the engine oil filter.

45,000 Miles (72 000 km)

²Change the engine oil.

²Inspect the front brake pads and rear brake lin-

ings.

²Inspect theengine air cleaner element (fil-

ter).Replace as necessary.*

²Adjust the drive belt tension.

²Change the automatic transaxle fluid/filter and

adjust bands.

48,000 Miles (77 000 km)

²Change the engine oil.

²Replace the engine oil filter.

51,000 Miles (82 000 km)

²Change the engine oil.

²Flush and replace the engine coolant.

54,000 Miles (86 000 km)

²Change the engine oil.

²Replace the engine oil filter.

²Inspect the front brake pads and rear brake lin-

ings.

57,000 Miles (91 000 km)

²Change the engine oil.

60,000 Miles (96 000 km)

²Change the engine oil.

²Replace the engine oil filter.

²Inspect thePCV valveand replace if neces-

sary.*

²Lubricate the front suspension lower ball joints.

²Replace the drive belts.

²Replace theengine air cleaner element (fil-

ter).

²Replace theignition cables

²Replace thespark plugs

²Check and replace, if necessary, theengine tim-

ing belton 3.0 liter engines.

²Change the automatic transaxle fluid/filter and

adjust bands.

63,000 Miles (101 000 km)

²Change the engine oil.

²Inspect the front brake pads and rear brake lin-

ings.

66,000 Miles (106 000 km)

²Change the engine oil.

²Replace the engine oil filter.

PLLUBRICATION AND MAINTENANCE 0 - 5

SPECIFICATIONS (Continued)

Page 7 of 1285

69,000 Miles (110 000 km)

²Change the engine oil.

72,000 Miles (115 000 km)

²Change the engine oil.

²Replace the engine oil filter.

²Inspect the front brake pads and rear brake lin-

ings.

75,000 Miles (120 000 km)

²Change the engine oil.

²Adjust the drive belt tension.

²Inspect theengine air cleaner element (fil-

ter)and replace as necessary.*

²Change the automatic transaxle fluid/filter and

adjust bands.

78,000 Miles (125 000 km)

²Change the engine oil.

²Replace the engine oil filter.

81,000 Miles (130 000 km)

²Change the engine oil.

²Flush and replace the engine coolant.

²Inspect the front brake pads and rear brake lin-

ings.

84,000 Miles (134 000 km)

²Change the engine oil.

²Replace the engine oil filter.

87,000 Miles (139 000 km)

²Change the engine oil.

90,000 Miles (144 000 km)

²Change the engine oil.

²Replace the engine oil filter.

²Inspect front brake pads and rear brake linings

²Check thePCV valveand replace if necessary.

Not required if previously changed.*

²Lubricate the front suspension lower ball joint.

²Replace theengine air cleaner element (fil-

ter).²Replace thespark plugs

²Change the automatic transaxle fluid/filter and

adjust the bands.

93,000 Miles (149 000 km)

²Change the engine oil.

96,000 Miles (154 000 km)

²Change the engine oil.

²Replace the engine oil filter.

99,000 Miles (158 000 km)

²Change the engine oil.

²Inspect the front brake pads and rear brake lin-

ings.

102,000 Miles (163 000 km)

²Change the engine oil.

²Replace the engine oil filter.

105,000 Miles (168 000 km)

²Replace theengine timing belt.

²Change the engine oil.

²Adjust the drive belt tension.

²Inspect theengine air cleaner element (fil-

ter)and replace as necessary.*

²Change the automatic transaxle fluid/filter and

adjust the bands.

²Flush and replace the engine coolant.

* This maintenance is recommended by Daimler-

Chrysler Corporation to the owner but is not

required to maintain the emissions warranty.

NOTE: Operating the vehicle more than 50% in

heavy traffic during hot weather, above 90É F (32É

C), using vehicle for police, taxi, limousine type

operation or trailer towing require the more fre-

quent transaxle service noted in Schedule ± B. Per-

form these services if vehicle usually operate under

these conditions.

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

0 - 6 LUBRICATION AND MAINTENANCEPL

SPECIFICATIONS (Continued)

Page 16 of 1285

SERVICE PROCEDURES

CURB HEIGHT MEASUREMENT

The wheel alignment is to be checked and all align-

ment adjustments made with the vehicle at its

required curb height specification.

Vehicle height is to be checked with the vehicle on

a flat, level surface, preferably a vehicle alignment

rack. The tires are to be inflated to the recommended

pressure. All tires are to be the same size as stan-

dard equipment. Vehicle height is checked with the

fuel tank full of fuel, and no passenger or luggage

compartment load.

Vehicle height is not adjustable. If the measure-

ment is not within specifications, inspect the vehicle

for bent or weak suspension components. Compare

the parts tag on the suspect coil spring(s) to the

parts book and the vehicle sales code, checking for a

match. Once removed from the vehicle, compare thecoil spring height to a correct new or known good coil

spring. The heights should vary if the suspect spring

is weak.

NOTE: Prior to reading the curb height measure-

ment, the front an rear of the vehicle should be

jounced. Induce jounce by grasping the center of

the rear, then front bumper (or fascia) and jouncing

the vehicle an equal number of times. Release the

bumper at the bottom of the jounce cycle.

(1) Measure from the inboard edge of the wheel

opening fender lip directly above the wheel center

(spindle), to the floor or alignment rack surface.

(2) When measuring, maximum left-to-right differ-

ential is not to exceed 10 mm (0.39 in.).

(3) Compare the measurements to specifications

listed in the following CURB HEIGHT SPECIFICA-

TIONS chart.

CURB HEIGHT SPECIFICATIONS

VEHICLE FRONT REAR

ALL NEON672 mm68 mm 679 mm68mm

26.46 in.60.32 in. 26.73 in.60.32 in.

WHEEL ALIGNMENT

PRE-WHEEL ALIGNMENT VEHICLE INSPECTION

CAUTION: If during the inspection the front sus-

pension crossmember shows any sign of impact

damage, the steering column lower coupling must

be inspected. Refer to DIAGNOSIS AND TESTING in

the STEERING group in this service manual.

Before any attempt is made to change or correct

the wheel alignment, the following inspection and

necessary corrections must be made to the vehicle to

ensure proper alignment.

(1) Be sure the fuel tank is full of fuel. If the fuel

tank is not full, the reduction in weight will affect

the curb height of the vehicle and the alignment

specifications.

(2) The passenger and luggage compartments of

the vehicle should be free of any load that is not fac-

tory equipment.

(3) Check the tires on the vehicle. The tires are to

be inflated to the recommended air pressure. All tires

must be the same size and in good condition with

approximately the same tread wear.

(4) Check the front tire and wheel assemblies for

excessive radial runout.(5) Inspect all suspension component fasteners for

looseness and torque.

(6) Inspect the lower front ball joints and all steer-

ing linkage for looseness and any sign of wear or

damage.

(7) Inspect the rubber bushings on all the suspen-

sion components for signs of wear or deterioration. If

any bushings show signs of wear or deterioration,

they should be replaced prior to aligning the vehicle.

WHEEL ALIGNMENT SETUP

(1) Position the vehicle on an alignment rack.

(2) Install all required alignment equipment on

the vehicle, per the alignment equipment manufac-

turer's instructions. On this vehicle, a four-wheel

alignment is recommended.

NOTE: Prior to reading the vehicle's alignment

readouts, the front and rear of vehicle should be

jounced. Induce jounce (rear first, then front) by

grasping the center of the bumper and jouncing

each end of vehicle an equal number of times. The

bumper should always be released when vehicle is

at the bottom of the jounce cycle.

(3) Read the vehicle's current front and rear align-

ment settings. Compare the vehicle's current align-

ment settings to the vehicle specifications for camber,

caster and toe-in. Refer to WHEEL ALIGNMENT

PLSUSPENSION 2 - 5

Page 24 of 1285

STEERING KNUCKLE

The front suspension steering knuckle is not a

repairable component of the front suspension. It

must be replaced if found to be damaged in any way.

If it is determined that the steering knuckle is bent

when servicing the vehicle, no attempt is to be made

to straighten the steering knuckle.

WHEEL BEARING AND HUB

The wheel bearing is designed for the life of the

vehicle and requires no type of periodic maintenance.

The following procedure may be used for diagnosing

the condition of the wheel bearing and hub.

With the wheel, disc brake caliper, and brake rotor

removed, rotate the wheel hub. Any roughness or

resistance to rotation may indicate dirt intrusion or a

failed hub bearing. If the bearing exhibits any of

these conditions during diagnosis, the hub bearing

will require replacement. The bearing is not service-

able.Damaged bearing seals and the resulting excessive

grease loss may also require bearing replacement.

Moderate grease weapage from the bearing is consid-

ered normal and should not require replacement of

the wheel bearing.

To diagnose a bent hub, refer to BRAKE ROTOR in

the DIAGNOSIS AND TESTING section in the

BRAKES service manual group for the procedure on

measuring hub runout.

LOWER CONTROL ARM

Inspect the lower control arm for signs of damage

from contact with the ground or road debris. If the

lower control arm shows any sign of damage, look for

distortion. Do not attempt to repair or straighten a

broken or bent lower control arm. If damaged, the

lower control arm stamping is serviced only as a

complete component.

The serviceable components of the lower control

arm are: the ball joint, the ball joint grease seal and

the lower control arm rear isolator bushing.

Inspect both lower control arm isolator bushings

for severe deterioration and replace as required.

Inspect the ball joint per the inspection procedure in

this section of the service manual and replace as

required. Refer to BALL JOINT in this section of this

service manual group.

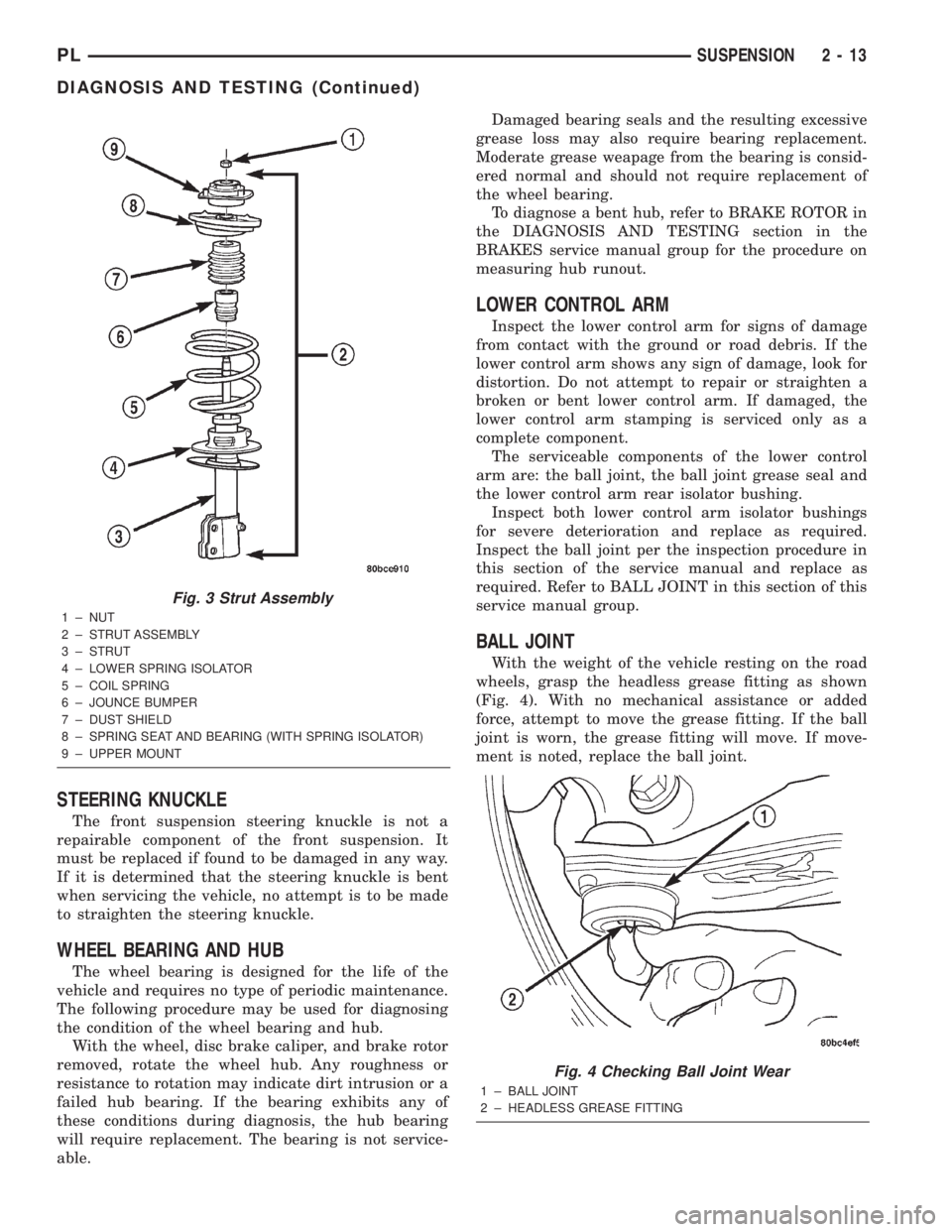

BALL JOINT

With the weight of the vehicle resting on the road

wheels, grasp the headless grease fitting as shown

(Fig. 4). With no mechanical assistance or added

force, attempt to move the grease fitting. If the ball

joint is worn, the grease fitting will move. If move-

ment is noted, replace the ball joint.

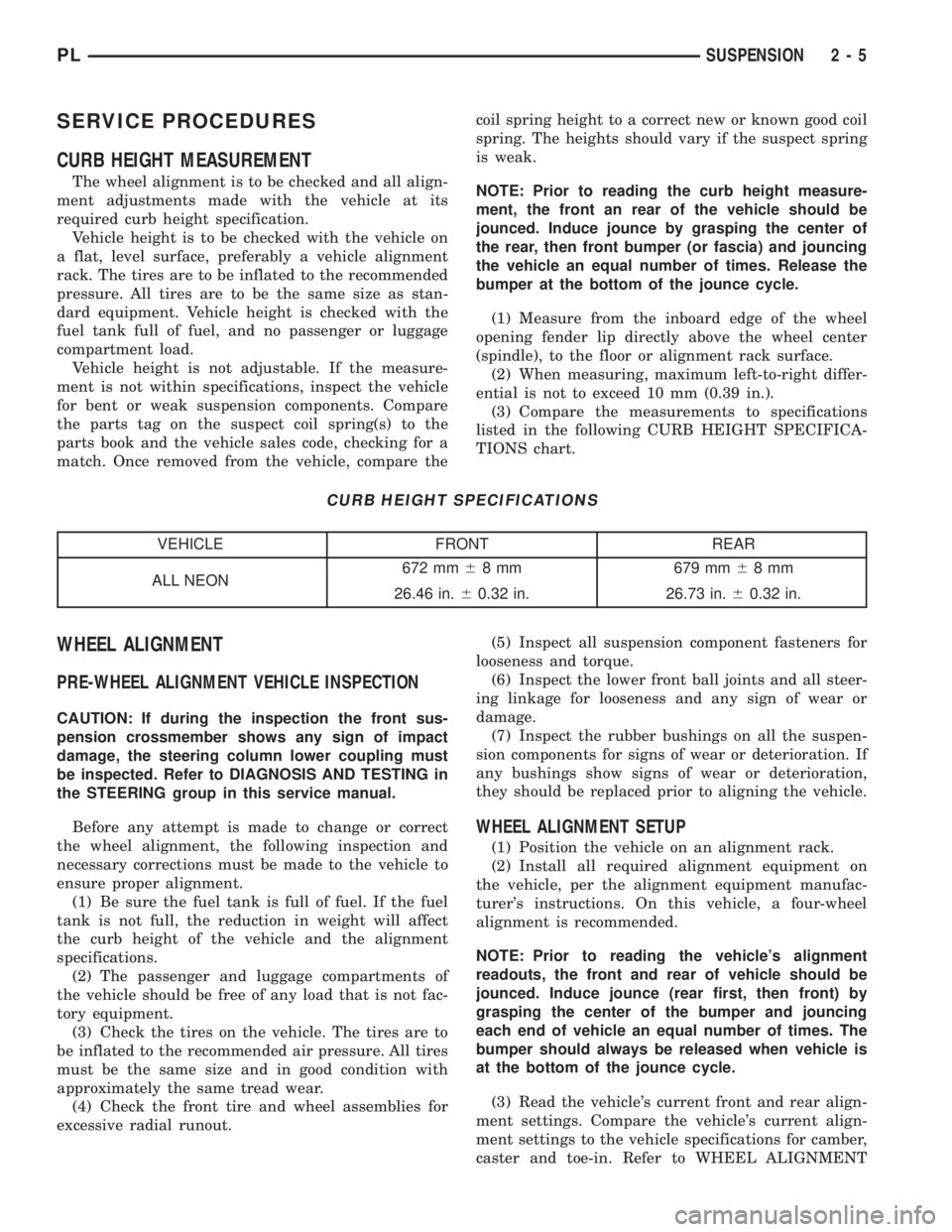

Fig. 3 Strut Assembly

1 ± NUT

2 ± STRUT ASSEMBLY

3 ± STRUT

4 ± LOWER SPRING ISOLATOR

5 ± COIL SPRING

6 ± JOUNCE BUMPER

7 ± DUST SHIELD

8 ± SPRING SEAT AND BEARING (WITH SPRING ISOLATOR)

9 ± UPPER MOUNT

Fig. 4 Checking Ball Joint Wear

1 ± BALL JOINT

2 ± HEADLESS GREASE FITTING

PLSUSPENSION 2 - 13

DIAGNOSIS AND TESTING (Continued)

Page 35 of 1285

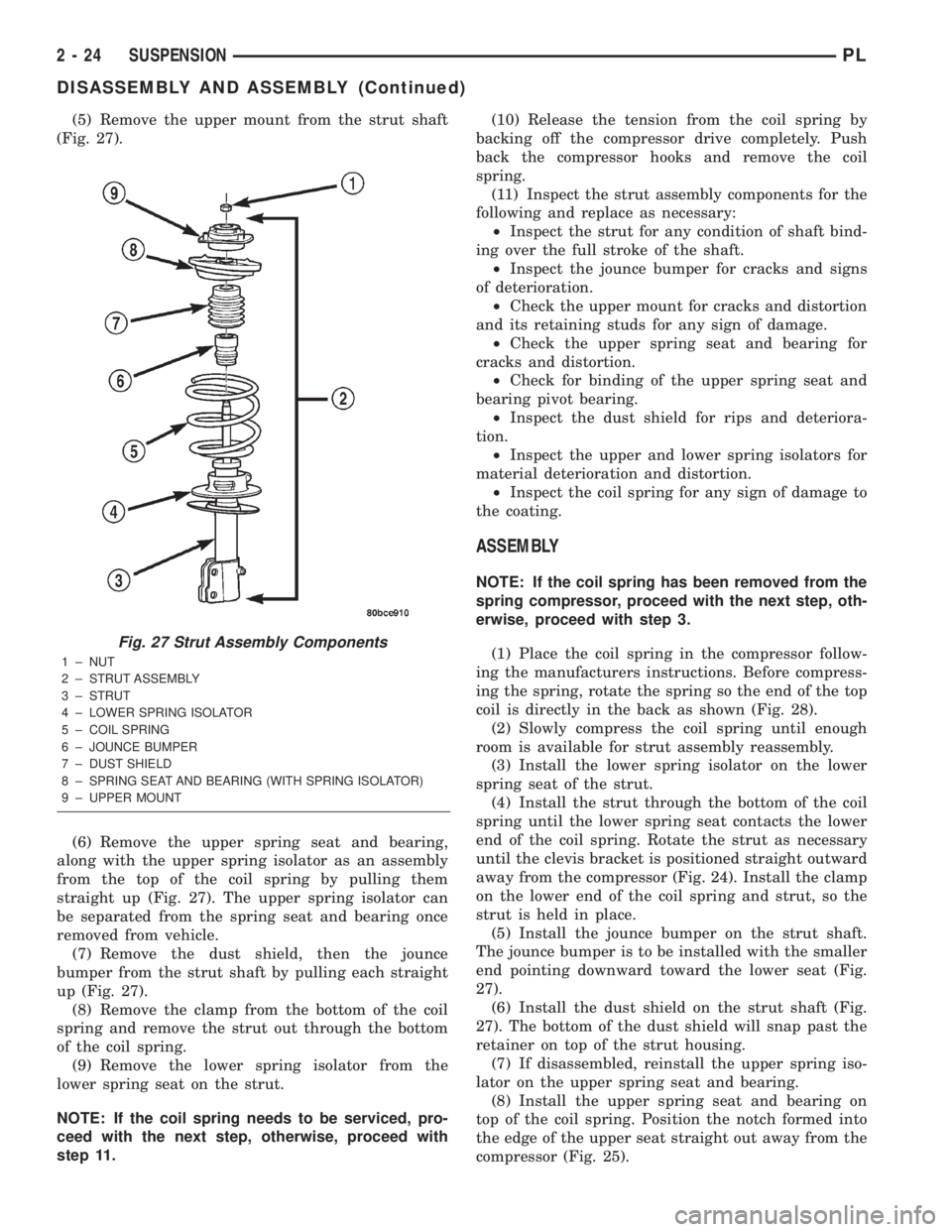

(5) Remove the upper mount from the strut shaft

(Fig. 27).

(6) Remove the upper spring seat and bearing,

along with the upper spring isolator as an assembly

from the top of the coil spring by pulling them

straight up (Fig. 27). The upper spring isolator can

be separated from the spring seat and bearing once

removed from vehicle.

(7) Remove the dust shield, then the jounce

bumper from the strut shaft by pulling each straight

up (Fig. 27).

(8) Remove the clamp from the bottom of the coil

spring and remove the strut out through the bottom

of the coil spring.

(9) Remove the lower spring isolator from the

lower spring seat on the strut.

NOTE: If the coil spring needs to be serviced, pro-

ceed with the next step, otherwise, proceed with

step 11.(10) Release the tension from the coil spring by

backing off the compressor drive completely. Push

back the compressor hooks and remove the coil

spring.

(11) Inspect the strut assembly components for the

following and replace as necessary:

²Inspect the strut for any condition of shaft bind-

ing over the full stroke of the shaft.

²Inspect the jounce bumper for cracks and signs

of deterioration.

²Check the upper mount for cracks and distortion

and its retaining studs for any sign of damage.

²Check the upper spring seat and bearing for

cracks and distortion.

²Check for binding of the upper spring seat and

bearing pivot bearing.

²Inspect the dust shield for rips and deteriora-

tion.

²Inspect the upper and lower spring isolators for

material deterioration and distortion.

²Inspect the coil spring for any sign of damage to

the coating.

ASSEMBLY

NOTE: If the coil spring has been removed from the

spring compressor, proceed with the next step, oth-

erwise, proceed with step 3.

(1) Place the coil spring in the compressor follow-

ing the manufacturers instructions. Before compress-

ing the spring, rotate the spring so the end of the top

coil is directly in the back as shown (Fig. 28).

(2) Slowly compress the coil spring until enough

room is available for strut assembly reassembly.

(3) Install the lower spring isolator on the lower

spring seat of the strut.

(4) Install the strut through the bottom of the coil

spring until the lower spring seat contacts the lower

end of the coil spring. Rotate the strut as necessary

until the clevis bracket is positioned straight outward

away from the compressor (Fig. 24). Install the clamp

on the lower end of the coil spring and strut, so the

strut is held in place.

(5) Install the jounce bumper on the strut shaft.

The jounce bumper is to be installed with the smaller

end pointing downward toward the lower seat (Fig.

27).

(6) Install the dust shield on the strut shaft (Fig.

27). The bottom of the dust shield will snap past the

retainer on top of the strut housing.

(7) If disassembled, reinstall the upper spring iso-

lator on the upper spring seat and bearing.

(8) Install the upper spring seat and bearing on

top of the coil spring. Position the notch formed into

the edge of the upper seat straight out away from the

compressor (Fig. 25).

Fig. 27 Strut Assembly Components

1 ± NUT

2 ± STRUT ASSEMBLY

3 ± STRUT

4 ± LOWER SPRING ISOLATOR

5 ± COIL SPRING

6 ± JOUNCE BUMPER

7 ± DUST SHIELD

8 ± SPRING SEAT AND BEARING (WITH SPRING ISOLATOR)

9 ± UPPER MOUNT

2 - 24 SUSPENSIONPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 60 of 1285

²Check the upper mount for cracks and distortion

and its retaining studs for any sign of damage.

²Inspect the dust shield for rips and deteriora-

tion.

²Inspect the upper and lower spring isolators for

material deterioration and distortion.

²Inspect the coil spring for any sign of damage to

the coating.

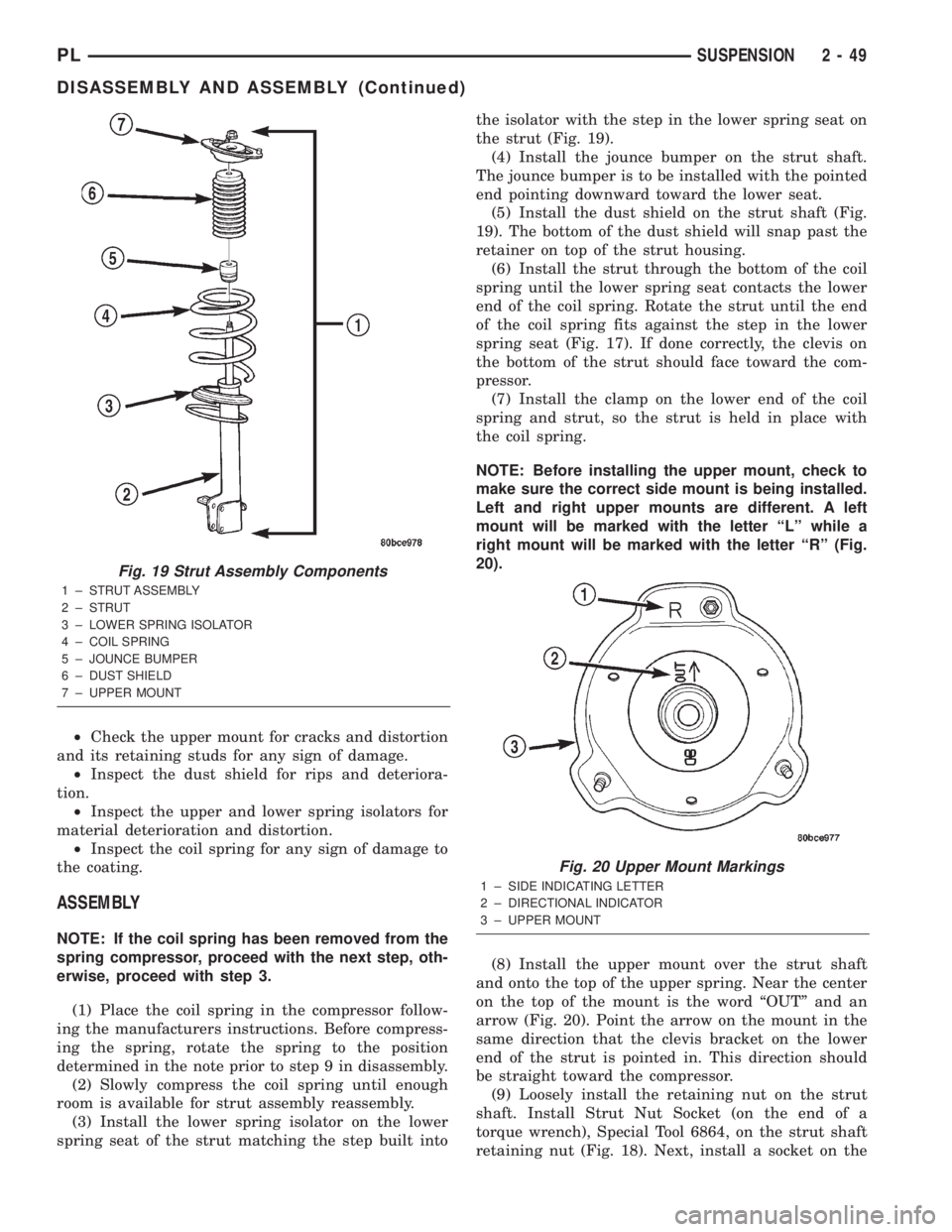

ASSEMBLY

NOTE: If the coil spring has been removed from the

spring compressor, proceed with the next step, oth-

erwise, proceed with step 3.

(1) Place the coil spring in the compressor follow-

ing the manufacturers instructions. Before compress-

ing the spring, rotate the spring to the position

determined in the note prior to step 9 in disassembly.

(2) Slowly compress the coil spring until enough

room is available for strut assembly reassembly.

(3) Install the lower spring isolator on the lower

spring seat of the strut matching the step built intothe isolator with the step in the lower spring seat on

the strut (Fig. 19).

(4) Install the jounce bumper on the strut shaft.

The jounce bumper is to be installed with the pointed

end pointing downward toward the lower seat.

(5) Install the dust shield on the strut shaft (Fig.

19). The bottom of the dust shield will snap past the

retainer on top of the strut housing.

(6) Install the strut through the bottom of the coil

spring until the lower spring seat contacts the lower

end of the coil spring. Rotate the strut until the end

of the coil spring fits against the step in the lower

spring seat (Fig. 17). If done correctly, the clevis on

the bottom of the strut should face toward the com-

pressor.

(7) Install the clamp on the lower end of the coil

spring and strut, so the strut is held in place with

the coil spring.

NOTE: Before installing the upper mount, check to

make sure the correct side mount is being installed.

Left and right upper mounts are different. A left

mount will be marked with the letter ªLº while a

right mount will be marked with the letter ªRº (Fig.

20).

(8) Install the upper mount over the strut shaft

and onto the top of the upper spring. Near the center

on the top of the mount is the word ªOUTº and an

arrow (Fig. 20). Point the arrow on the mount in the

same direction that the clevis bracket on the lower

end of the strut is pointed in. This direction should

be straight toward the compressor.

(9) Loosely install the retaining nut on the strut

shaft. Install Strut Nut Socket (on the end of a

torque wrench), Special Tool 6864, on the strut shaft

retaining nut (Fig. 18). Next, install a socket on the

Fig. 19 Strut Assembly Components

1 ± STRUT ASSEMBLY

2 ± STRUT

3 ± LOWER SPRING ISOLATOR

4 ± COIL SPRING

5 ± JOUNCE BUMPER

6 ± DUST SHIELD

7 ± UPPER MOUNT

Fig. 20 Upper Mount Markings

1 ± SIDE INDICATING LETTER

2 ± DIRECTIONAL INDICATOR

3 ± UPPER MOUNT

PLSUSPENSION 2 - 49

DISASSEMBLY AND ASSEMBLY (Continued)