check oil DODGE NEON 2000 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 188 of 1285

CONDITION POSSIBLE CAUSE CORRECTION

16. Electric cooling fan not

operating properly.16. Check electric fan operation and

repair as necessary.

17. Cylinder head gasket leaking. 17. Check cylinder head gasket for

leaks. Refer to testing cooling

system for leaks. For repairs, refer

to Group 9, Engine.

18. Heater core leaking. 18. Check heater core for leaks.

Refer to Group 24, Heating and Air

Conditioning and repair as

necessary.

TEMPERATURE GAUGE READING

IS INCONSISTENT (FLUCTUATES,

CYCLES OR IS ERRATIC)1. The gauge may cycle up and

down. This is due to the cycling of

the electric radiator fan.1. A normal condition. No correction

is necessary. If gauge cycling is

going into the hot zone, check

electric fan operation and repair as

necessary. Refer to procedure in

this section.

2. During cold weather operation

with the heater blower in the high

position, the gauge reading may

drop slightly.2. A normal condition. No correction

is necessary.

3, Temperature gauge or engine

mounted gauge sensor is defective

or shorted.3. Check operation of gauge and

repair as necessary. Refer to Group

8E, Instrument Panel and Gauges.

4. Gauge reading rises when

vehicle is brought to a stop after

heavy use (engine still running).4. A normal condition. No correction

is necessary. The gauge should

return to normal range after vehicle

is driven.

5. Gauge reading high after

restarting a warmed-up (hot)

engine.5. A normal condition. No correction

is necessary. The gauge should

return to normal range after a few

minutes of engine operation.

6. Coolant level low in radiator (air

will build up in the cooling system

causing the thermostat to open

late).6. Check and correct coolant leaks.

Refer to Testing Cooling System For

Leaks in the section.

7. Cylinder head gasket leaking

allowing exhaust gas to enter

cooling system. This will cause

thermostat to open late.7. (a) Check for cylinder head

gasket leaks with a commercially

available Block Leak Tester. Repair

as necessary.

(b) Check for coolant in the engine

oil. Inspect for white steam emitting

from exhaust system. Repair as

necessary.

8. Water pump impeller loose on

shaft.8. Check water pump and replace

as necessary. Refer to Water Pump

in this section.

9. Loose drive belt (water pump

slipping).9. Check drive belt and correct as

necessary.

PLCOOLING SYSTEM 7 - 9

DIAGNOSIS AND TESTING (Continued)

Page 191 of 1285

CONDITION POSSIBLE CAUSE CORRECTION

INADEQUATE HEATER

PERFORMANCE.1. Has a diagnostic trouble code

(DTC) been set?1. Refer to On-Board Diagnostic in

Group 25, Emission Control

Systems.

2. Coolant level low. 2. Refer to testing cooling system

for leaks in this section. Repair as

necessary.

3. Obstructions in heater hose

fittings at engine.3. Remove heater hoses at both

ends and check for obstructions.

Repair as necessary.

4. Heater hose kinked. 4. Locate kinked area and repair as

necessary.

5. Water pump is not pumping

coolant to heater core. When the

engine is fully warmed up, both

heater hoses should be hot to the

touch. The water pump drive belt

may be slipping causing poor water

pump operation.5. Refer to water pump in this

section. Repair as necessary.

HEAT ODOR 1. Various heat shields are used at

certain driveline components. One

or more of these shields may be

missing.1. Locate missing shields and

replace or repair as necessary.

2. Is temperature gauge reading

above the normal range?2. Refer to the previous

Temperature Gauge Reads High in

these Diagnostic Charts. Repair as

necessary.

3. Is cooling fan operating

correctly?3. Refer to Cooling System Fan in

this section for diagnosis. Repair as

necessary.

4. Has undercoating been applied

to any unnecessary component.4. Clean undercoating as necessary.

5. Engine may be running rich

causing the catalytic converter to

overheat.5. Refer to appropriate Powertrain

Diagnostic Procedures manual for

operation of the DRB scan tool.

Repair as necessary.

POOR DRIVEABILITY

(THERMOSTAT POSSIBLY STUCK

OPEN). GAUGE MAY BE READING

LOW1. For proper driveability, good

vehicle emissions and for

preventing build-up of engine oil

sludge, the thermostat must be

operating properly. Has a diagnostic

trouble code (DTC ) been set?1. Refer to On-Board Diagnostics in

Group 25, Emission Control

Systems. DTC's may also be check

using the DRB scan tool. Refer to

the proper Powertrain Diagnostic

Procedure manual for checking the

thermostat if necessary.

7 - 12 COOLING SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 193 of 1285

ENGINE THERMOSTAT TESTING

The thermostat is operated by a wax filled con-

tainer (pellet) which is sealed. When heated coolant

reaches a predetermined temperature the wax pellet

expands enough to overcome the closing spring and

water pump pressure, which forces the valve to open.

Coolant leakage into the pellet will cause a thermo-

stat to fail open. Do not attempt to free up a thermo-

stat with a screwdriver.

The thermostat that opens too soon type failure

mode is included in the on-board diagnosis. Thecheck engine light will not be lit by an open too soon

condition. If it has failed open, a diagnostic trouble

code (DTC) will be set. Do not change a thermostat

for lack of heater performance or temperature gauge

position, unless a DTC is present. See Diagnosis for

other probable causes. Thermostat failing shut is the

normal long term mode of failure, and normally, only

on high mileage vehicles. The temperature gauge will

indicate this. Refer to Diagnosis in this section.

ACCESSORY DRIVE BELT DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

BELT SLIPPAGE 1. Belt slipping because of

insufficient tension.1. Retension generator belt.

Replace the power steering belt's

automatic belt tensioner.

2. Belt excessively glazed or

hardened from heat and excessive

slippage.2. Replace belt.

3. Incorrect belt. 3. Replace belt.

4. Driven component bearing

failure.4. Replace faulty component.

5. Belt or pulley subjected to

substance (belt dressing, oil,

ethylene glycol) that has reduced

friction.5. Replace belt and clean pulleys.

BELT NOISE (OBJECTIONABLE

SQUEAL, SQUEAK, OR RUMBLE)1. Belt slippage. 1. Retension generator belt, replace

belt, or automatic belt tensioner.

2. Foreign material imbedded in

belt.2. Replace belt.

3. Non-uniform belt. 3. Replace belt.

4. Misaligned pulley(s). 4. Align accessories.

5. Non-uniform groove or eccentric

pulley.5. Replace pulley(s).

6. Bearing noise. 6. Locate and repair.

BELT ROLLED OVER IN GROOVE

OR BELT JUMPS OFF1. Broken cord in belt. 1. Replace belt.

2. Belt tension too loose, or too

tight.2. Retension generator belt.

Replace the power steering belt's

automatic belt tensioner.

3. Misaligned pulleys. 3. Align accessories.

4. Non-uniform grooves or eccentric

pulley.4. Replace pulley(s).

5. Foreign object(s) in grooves. 5. Remove foreign objects in

groove.

7 - 14 COOLING SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 195 of 1285

the coolant to expand. Reattach the tester. If the nee-

dle on the dial fluctuates it indicates a combustion

leak, usually a head gasket leak.

WARNING: WITH THE PRESSURE TESTER IN

PLACE PRESSURE BUILDS UP QUICKLY. ANY

EXCESSIVE PRESSURE BUILD-UP DUE TO CON-

TINUOUS ENGINE OPERATION MUST BE

RELEASED TO A SAFE PRESSURE POINT. NEVER

PERMIT PRESSURE TO EXCEED 138 kPa (20 psi).

If the needle on the dial does not fluctuate, race

the engine a few times. If an abnormal amount of

coolant or steam is emitted from the tail pipe, it may

indicate a faulty head gasket, cracked engine block,

or cracked cylinder head.

There may be internal leaks, which can be deter-

mined by removing the oil dipstick. If water globules

appear intermixed with the oil, it indicates an inter-

nal leak in the engine. If there is an internal leak,

the engine must be disassembled for repair.

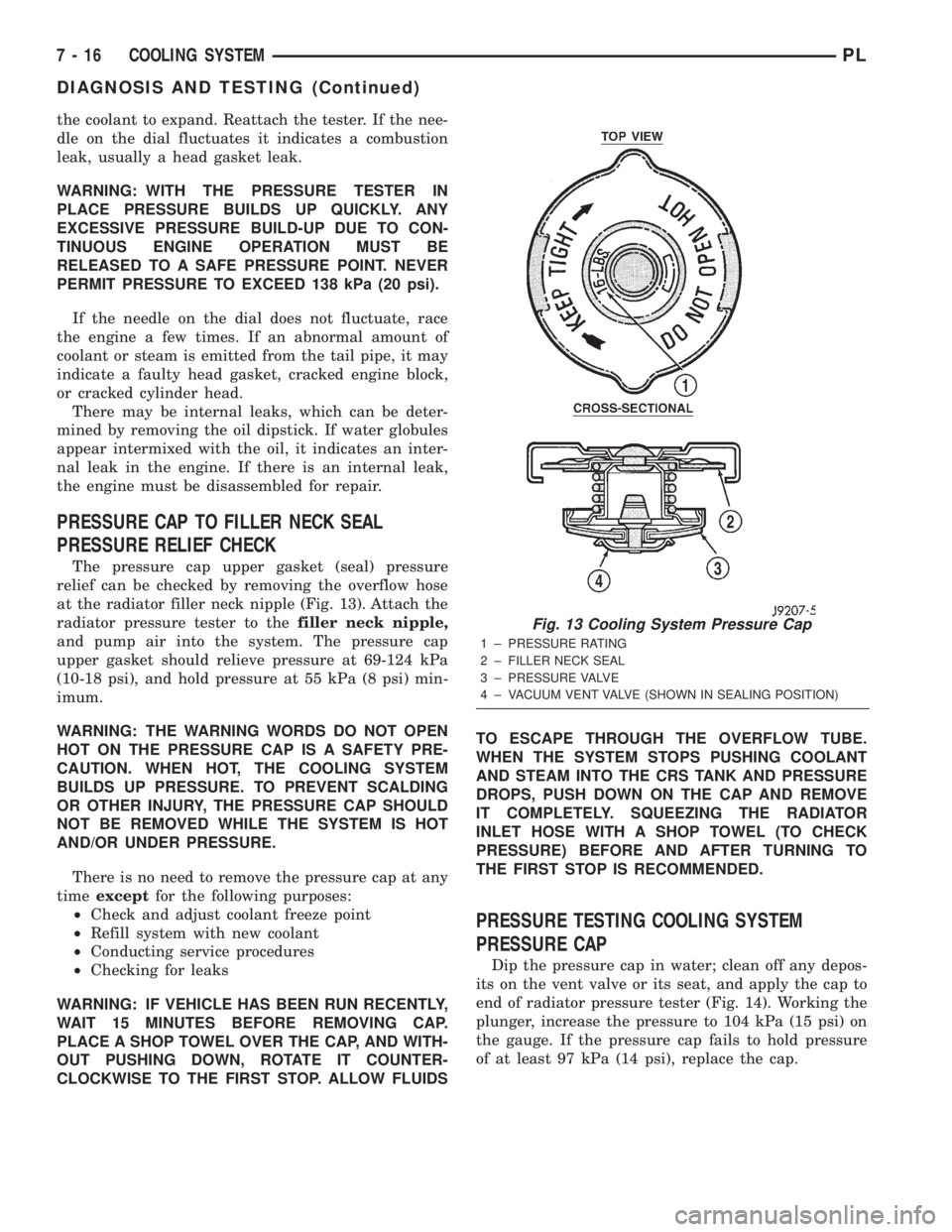

PRESSURE CAP TO FILLER NECK SEAL

PRESSURE RELIEF CHECK

The pressure cap upper gasket (seal) pressure

relief can be checked by removing the overflow hose

at the radiator filler neck nipple (Fig. 13). Attach the

radiator pressure tester to thefiller neck nipple,

and pump air into the system. The pressure cap

upper gasket should relieve pressure at 69-124 kPa

(10-18 psi), and hold pressure at 55 kPa (8 psi) min-

imum.

WARNING: THE WARNING WORDS DO NOT OPEN

HOT ON THE PRESSURE CAP IS A SAFETY PRE-

CAUTION. WHEN HOT, THE COOLING SYSTEM

BUILDS UP PRESSURE. TO PREVENT SCALDING

OR OTHER INJURY, THE PRESSURE CAP SHOULD

NOT BE REMOVED WHILE THE SYSTEM IS HOT

AND/OR UNDER PRESSURE.

There is no need to remove the pressure cap at any

timeexceptfor the following purposes:

²Check and adjust coolant freeze point

²Refill system with new coolant

²Conducting service procedures

²Checking for leaks

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT 15 MINUTES BEFORE REMOVING CAP.

PLACE A SHOP TOWEL OVER THE CAP, AND WITH-

OUT PUSHING DOWN, ROTATE IT COUNTER-

CLOCKWISE TO THE FIRST STOP. ALLOW FLUIDSTO ESCAPE THROUGH THE OVERFLOW TUBE.

WHEN THE SYSTEM STOPS PUSHING COOLANT

AND STEAM INTO THE CRS TANK AND PRESSURE

DROPS, PUSH DOWN ON THE CAP AND REMOVE

IT COMPLETELY. SQUEEZING THE RADIATOR

INLET HOSE WITH A SHOP TOWEL (TO CHECK

PRESSURE) BEFORE AND AFTER TURNING TO

THE FIRST STOP IS RECOMMENDED.

PRESSURE TESTING COOLING SYSTEM

PRESSURE CAP

Dip the pressure cap in water; clean off any depos-

its on the vent valve or its seat, and apply the cap to

end of radiator pressure tester (Fig. 14). Working the

plunger, increase the pressure to 104 kPa (15 psi) on

the gauge. If the pressure cap fails to hold pressure

of at least 97 kPa (14 psi), replace the cap.

Fig. 13 Cooling System Pressure Cap

1 ± PRESSURE RATING

2 ± FILLER NECK SEAL

3 ± PRESSURE VALVE

4 ± VACUUM VENT VALVE (SHOWN IN SEALING POSITION)

7 - 16 COOLING SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 197 of 1285

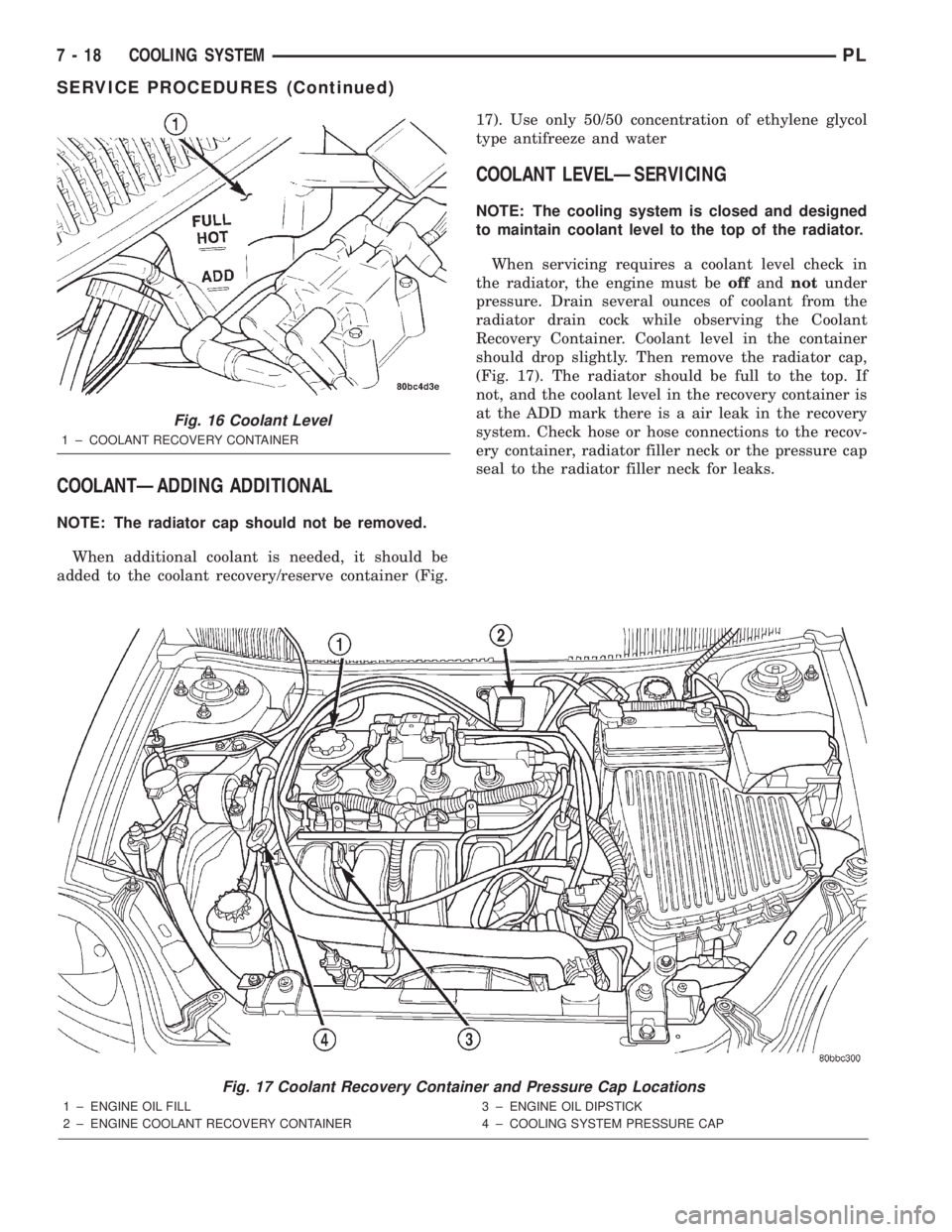

COOLANTÐADDING ADDITIONAL

NOTE: The radiator cap should not be removed.

When additional coolant is needed, it should be

added to the coolant recovery/reserve container (Fig.17). Use only 50/50 concentration of ethylene glycol

type antifreeze and water

COOLANT LEVELÐSERVICING

NOTE: The cooling system is closed and designed

to maintain coolant level to the top of the radiator.

When servicing requires a coolant level check in

the radiator, the engine must beoffandnotunder

pressure. Drain several ounces of coolant from the

radiator drain cock while observing the Coolant

Recovery Container. Coolant level in the container

should drop slightly. Then remove the radiator cap,

(Fig. 17). The radiator should be full to the top. If

not, and the coolant level in the recovery container is

at the ADD mark there is a air leak in the recovery

system. Check hose or hose connections to the recov-

ery container, radiator filler neck or the pressure cap

seal to the radiator filler neck for leaks.

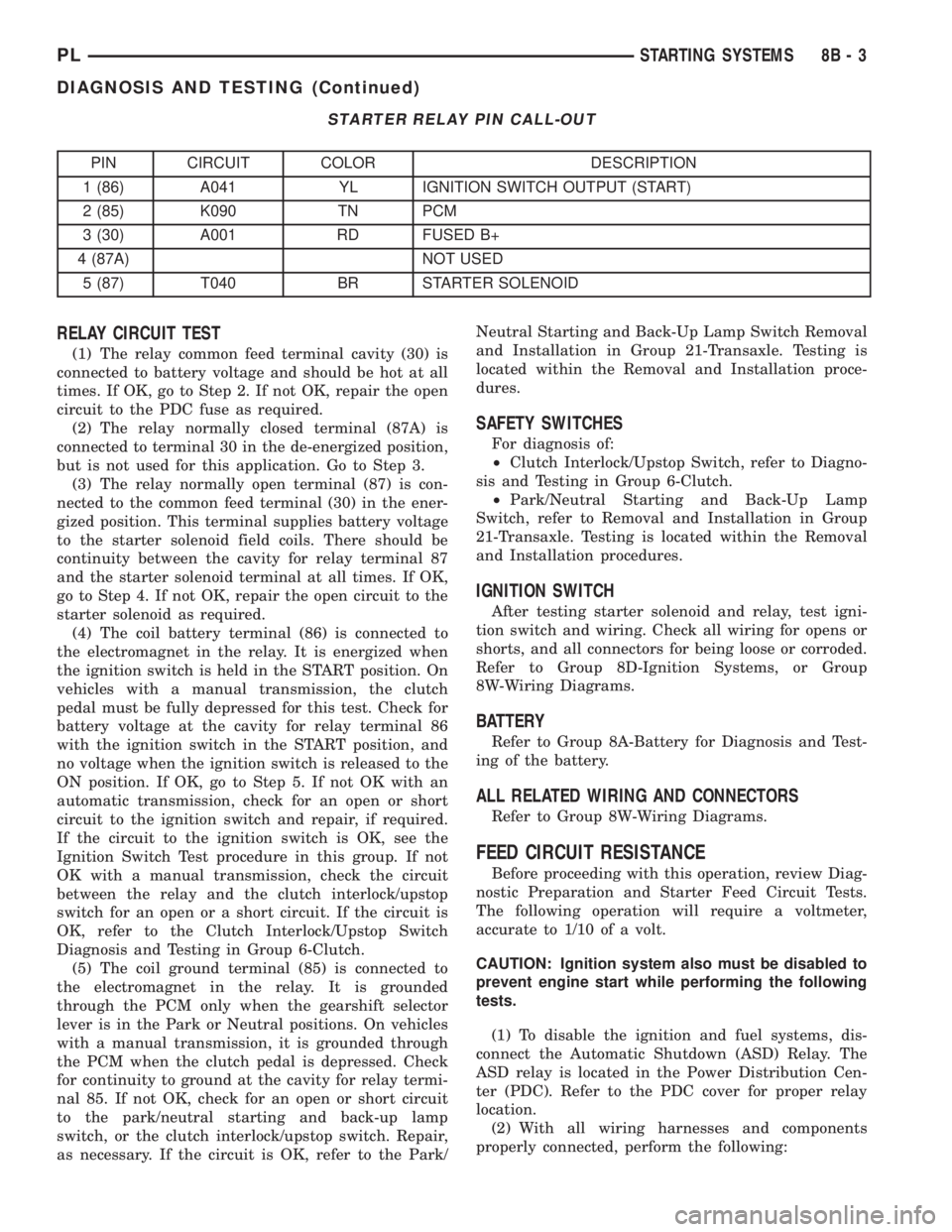

Fig. 17 Coolant Recovery Container and Pressure Cap Locations

1 ± ENGINE OIL FILL

2 ± ENGINE COOLANT RECOVERY CONTAINER3 ± ENGINE OIL DIPSTICK

4 ± COOLING SYSTEM PRESSURE CAP

Fig. 16 Coolant Level

1 ± COOLANT RECOVERY CONTAINER

7 - 18 COOLING SYSTEMPL

SERVICE PROCEDURES (Continued)

Page 224 of 1285

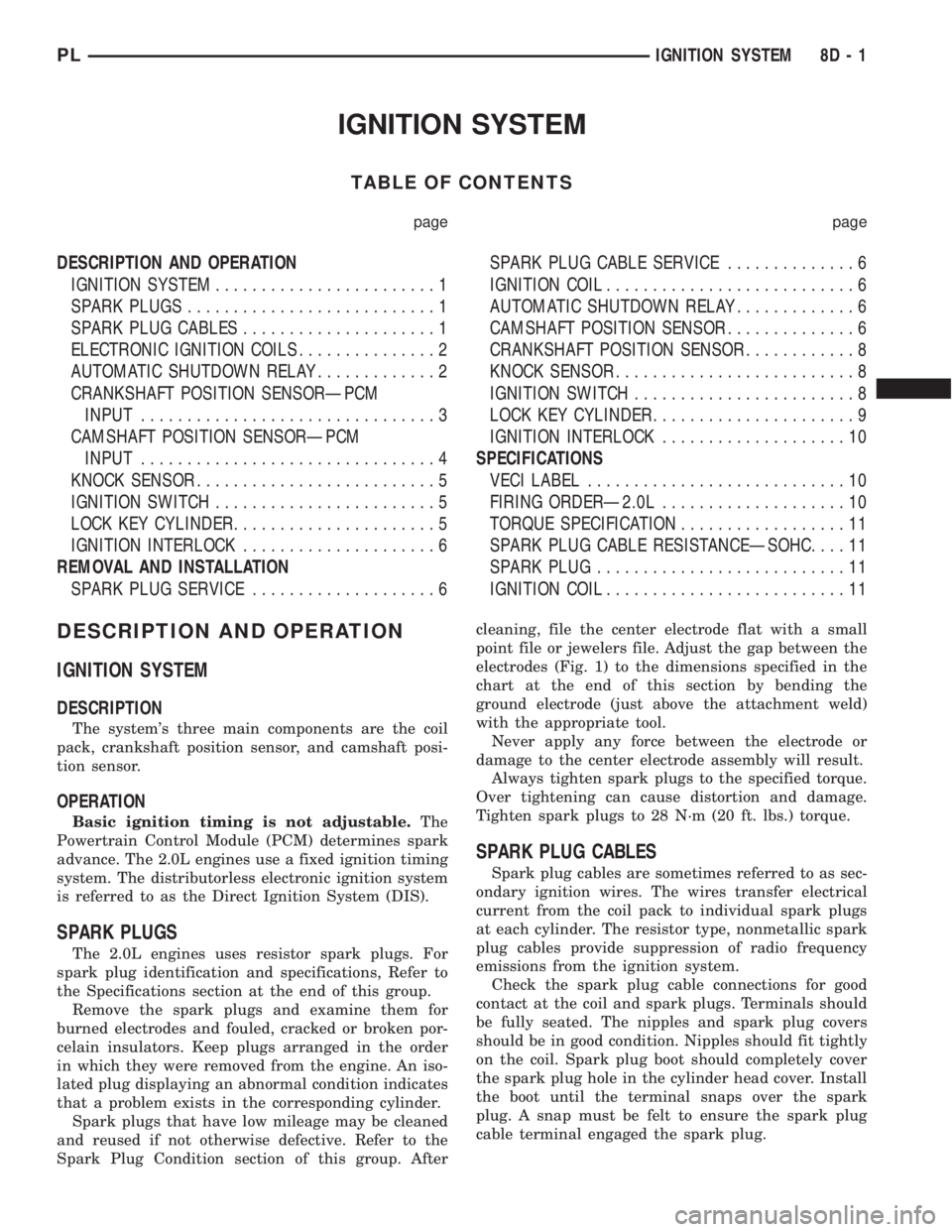

STARTER RELAY PIN CALL-OUT

PIN CIRCUIT COLOR DESCRIPTION

1 (86) A041 YL IGNITION SWITCH OUTPUT (START)

2 (85) K090 TN PCM

3 (30) A001 RD FUSED B+

4 (87A) NOT USED

5 (87) T040 BR STARTER SOLENOID

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the PDC fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the starter solenoid field coils. There should be

continuity between the cavity for relay terminal 87

and the starter solenoid terminal at all times. If OK,

go to Step 4. If not OK, repair the open circuit to the

starter solenoid as required.

(4) The coil battery terminal (86) is connected to

the electromagnet in the relay. It is energized when

the ignition switch is held in the START position. On

vehicles with a manual transmission, the clutch

pedal must be fully depressed for this test. Check for

battery voltage at the cavity for relay terminal 86

with the ignition switch in the START position, and

no voltage when the ignition switch is released to the

ON position. If OK, go to Step 5. If not OK with an

automatic transmission, check for an open or short

circuit to the ignition switch and repair, if required.

If the circuit to the ignition switch is OK, see the

Ignition Switch Test procedure in this group. If not

OK with a manual transmission, check the circuit

between the relay and the clutch interlock/upstop

switch for an open or a short circuit. If the circuit is

OK, refer to the Clutch Interlock/Upstop Switch

Diagnosis and Testing in Group 6-Clutch.

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. It is grounded

through the PCM only when the gearshift selector

lever is in the Park or Neutral positions. On vehicles

with a manual transmission, it is grounded through

the PCM when the clutch pedal is depressed. Check

for continuity to ground at the cavity for relay termi-

nal 85. If not OK, check for an open or short circuit

to the park/neutral starting and back-up lamp

switch, or the clutch interlock/upstop switch. Repair,

as necessary. If the circuit is OK, refer to the Park/Neutral Starting and Back-Up Lamp Switch Removal

and Installation in Group 21-Transaxle. Testing is

located within the Removal and Installation proce-

dures.

SAFETY SWITCHES

For diagnosis of:

²Clutch Interlock/Upstop Switch, refer to Diagno-

sis and Testing in Group 6-Clutch.

²Park/Neutral Starting and Back-Up Lamp

Switch, refer to Removal and Installation in Group

21-Transaxle. Testing is located within the Removal

and Installation procedures.

IGNITION SWITCH

After testing starter solenoid and relay, test igni-

tion switch and wiring. Check all wiring for opens or

shorts, and all connectors for being loose or corroded.

Refer to Group 8D-Ignition Systems, or Group

8W-Wiring Diagrams.

BATTERY

Refer to Group 8A-Battery for Diagnosis and Test-

ing of the battery.

ALL RELATED WIRING AND CONNECTORS

Refer to Group 8W-Wiring Diagrams.

FEED CIRCUIT RESISTANCE

Before proceeding with this operation, review Diag-

nostic Preparation and Starter Feed Circuit Tests.

The following operation will require a voltmeter,

accurate to 1/10 of a volt.

CAUTION: Ignition system also must be disabled to

prevent engine start while performing the following

tests.

(1) To disable the ignition and fuel systems, dis-

connect the Automatic Shutdown (ASD) Relay. The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(2) With all wiring harnesses and components

properly connected, perform the following:

PLSTARTING SYSTEMS 8B - 3

DIAGNOSIS AND TESTING (Continued)

Page 236 of 1285

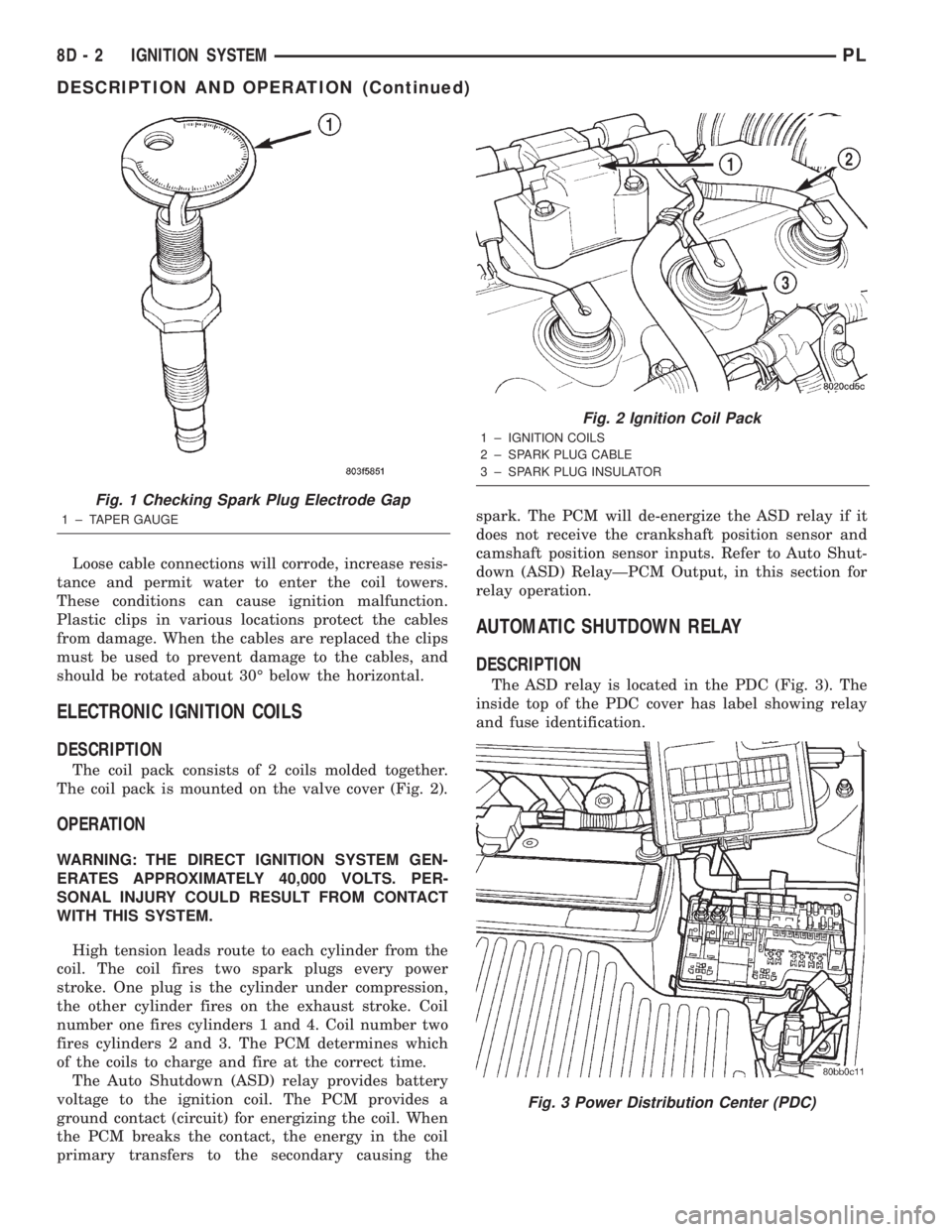

IGNITION SYSTEM

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

IGNITION SYSTEM........................1

SPARK PLUGS...........................1

SPARK PLUG CABLES.....................1

ELECTRONIC IGNITION COILS...............2

AUTOMATIC SHUTDOWN RELAY.............2

CRANKSHAFT POSITION SENSORÐPCM

INPUT................................3

CAMSHAFT POSITION SENSORÐPCM

INPUT................................4

KNOCK SENSOR..........................5

IGNITION SWITCH........................5

LOCK KEY CYLINDER......................5

IGNITION INTERLOCK.....................6

REMOVAL AND INSTALLATION

SPARK PLUG SERVICE....................6SPARK PLUG CABLE SERVICE..............6

IGNITION COIL...........................6

AUTOMATIC SHUTDOWN RELAY.............6

CAMSHAFT POSITION SENSOR..............6

CRANKSHAFT POSITION SENSOR............8

KNOCK SENSOR..........................8

IGNITION SWITCH........................8

LOCK KEY CYLINDER......................9

IGNITION INTERLOCK....................10

SPECIFICATIONS

VECI LABEL............................10

FIRING ORDERÐ2.0L....................10

TORQUE SPECIFICATION..................11

SPARK PLUG CABLE RESISTANCEÐSOHC....11

SPARK PLUG...........................11

IGNITION COIL..........................11

DESCRIPTION AND OPERATION

IGNITION SYSTEM

DESCRIPTION

The system's three main components are the coil

pack, crankshaft position sensor, and camshaft posi-

tion sensor.

OPERATION

Basic ignition timing is not adjustable.The

Powertrain Control Module (PCM) determines spark

advance. The 2.0L engines use a fixed ignition timing

system. The distributorless electronic ignition system

is referred to as the Direct Ignition System (DIS).

SPARK PLUGS

The 2.0L engines uses resistor spark plugs. For

spark plug identification and specifications, Refer to

the Specifications section at the end of this group.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indicates

that a problem exists in the corresponding cylinder.

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective. Refer to the

Spark Plug Condition section of this group. Aftercleaning, file the center electrode flat with a small

point file or jewelers file. Adjust the gap between the

electrodes (Fig. 1) to the dimensions specified in the

chart at the end of this section by bending the

ground electrode (just above the attachment weld)

with the appropriate tool.

Never apply any force between the electrode or

damage to the center electrode assembly will result.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion and damage.

Tighten spark plugs to 28 N´m (20 ft. lbs.) torque.

SPARK PLUG CABLES

Spark plug cables are sometimes referred to as sec-

ondary ignition wires. The wires transfer electrical

current from the coil pack to individual spark plugs

at each cylinder. The resistor type, nonmetallic spark

plug cables provide suppression of radio frequency

emissions from the ignition system.

Check the spark plug cable connections for good

contact at the coil and spark plugs. Terminals should

be fully seated. The nipples and spark plug covers

should be in good condition. Nipples should fit tightly

on the coil. Spark plug boot should completely cover

the spark plug hole in the cylinder head cover. Install

the boot until the terminal snaps over the spark

plug. A snap must be felt to ensure the spark plug

cable terminal engaged the spark plug.

PLIGNITION SYSTEM 8D - 1

Page 237 of 1285

Loose cable connections will corrode, increase resis-

tance and permit water to enter the coil towers.

These conditions can cause ignition malfunction.

Plastic clips in various locations protect the cables

from damage. When the cables are replaced the clips

must be used to prevent damage to the cables, and

should be rotated about 30É below the horizontal.

ELECTRONIC IGNITION COILS

DESCRIPTION

The coil pack consists of 2 coils molded together.

The coil pack is mounted on the valve cover (Fig. 2).

OPERATION

WARNING: THE DIRECT IGNITION SYSTEM GEN-

ERATES APPROXIMATELY 40,000 VOLTS. PER-

SONAL INJURY COULD RESULT FROM CONTACT

WITH THIS SYSTEM.

High tension leads route to each cylinder from the

coil. The coil fires two spark plugs every power

stroke. One plug is the cylinder under compression,

the other cylinder fires on the exhaust stroke. Coil

number one fires cylinders 1 and 4. Coil number two

fires cylinders 2 and 3. The PCM determines which

of the coils to charge and fire at the correct time.

The Auto Shutdown (ASD) relay provides battery

voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil. When

the PCM breaks the contact, the energy in the coil

primary transfers to the secondary causing thespark. The PCM will de-energize the ASD relay if it

does not receive the crankshaft position sensor and

camshaft position sensor inputs. Refer to Auto Shut-

down (ASD) RelayÐPCM Output, in this section for

relay operation.

AUTOMATIC SHUTDOWN RELAY

DESCRIPTION

The ASD relay is located in the PDC (Fig. 3). The

inside top of the PDC cover has label showing relay

and fuse identification.

Fig. 1 Checking Spark Plug Electrode Gap

1 ± TAPER GAUGE

Fig. 2 Ignition Coil Pack

1 ± IGNITION COILS

2 ± SPARK PLUG CABLE

3 ± SPARK PLUG INSULATOR

Fig. 3 Power Distribution Center (PDC)

8D - 2 IGNITION SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 241 of 1285

IGNITION INTERLOCK

OPERATION

All vehicles equipped with automatic transaxles

have an interlock system. The system prevents shift-

ing the vehicle out of Park unless the ignition lock

cylinder is in the Off, Run or Start position. In addi-

tion, the operator cannot rotate the key to the lock

position unless the shifter is in the park position. On

vehicles equipped with floor shift refer to the - Tran-

saxle for Automatic Transmission Shifter/Ignition

Interlock.

REMOVAL AND INSTALLATION

SPARK PLUG SERVICE

Failure to route the cables properly could cause the

radio to reproduce ignition noise, cross ignition of the

spark plugs or short circuit the cables to ground.

REMOVAL

REMOVE CABLES FROM COIL FIRST.

Always remove the spark plug cable by grasping

the top of the spark plug insulator, turning the boot

1/2 turn and pulling straight up in a steady motion.

(1) Remove the spark plug using a quality socket

with a rubber or foam insert.

(2) Inspect the spark plug condition.

INSTALLATION

(1) To avoid cross threading, start the spark plug

into the cylinder head by hand.

(2) Tighten spark plugs to 28 N´m (20 ft. lbs.)

torque.

(3) Install spark plug insulators over spark plugs.

Ensure the top of the spark plug insulator covers the

upper end of the spark plug tube.

Reconnect to coil.

SPARK PLUG CABLE SERVICE

Failure to route the cables properly could cause the

radio to reproduce ignition noise, cross ignition of the

spark plugs or short circuit the cables to ground.

REMOVAL

Remove spark plug cable from coil first.

Always remove the spark plug cable by grasping

the top of the spark plug insulator, turning the boot

1/2 turn and pulling straight up in a steady motion.

INSTALLATION

Install spark plug insulators over spark plugs.

Ensure the top of the spark plug insulator covers the

upper end of the spark plug tube. The connect theother end to coil pack. Be sure that dual plastic clip

holds the cables off of the valve cover.

IGNITION COIL

The electronic ignition coil pack attaches directly

to the valve cover (Fig. 11).

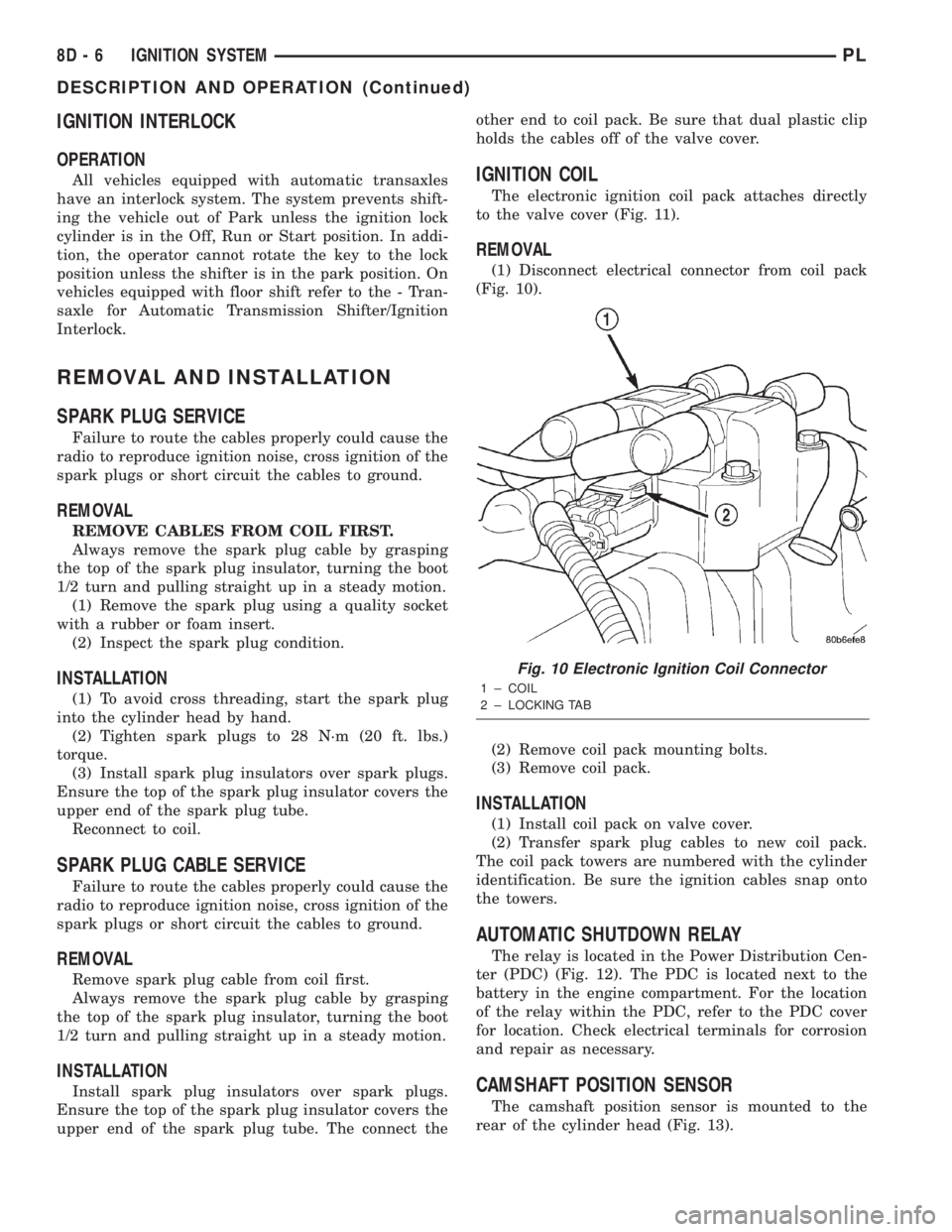

REMOVAL

(1) Disconnect electrical connector from coil pack

(Fig. 10).

(2) Remove coil pack mounting bolts.

(3) Remove coil pack.

INSTALLATION

(1) Install coil pack on valve cover.

(2) Transfer spark plug cables to new coil pack.

The coil pack towers are numbered with the cylinder

identification. Be sure the ignition cables snap onto

the towers.

AUTOMATIC SHUTDOWN RELAY

The relay is located in the Power Distribution Cen-

ter (PDC) (Fig. 12). The PDC is located next to the

battery in the engine compartment. For the location

of the relay within the PDC, refer to the PDC cover

for location. Check electrical terminals for corrosion

and repair as necessary.

CAMSHAFT POSITION SENSOR

The camshaft position sensor is mounted to the

rear of the cylinder head (Fig. 13).

Fig. 10 Electronic Ignition Coil Connector

1 ± COIL

2 ± LOCKING TAB

8D - 6 IGNITION SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 249 of 1285

DESCRIPTION AND OPERATION

HEADLAMP SWITCH

The headlamp switch is part of the Multi-Function

Switch. Refer to Group 8J, Turn Signal and Flasher

for the Multi-Function Switch Test, Removal and

Installation procedures.

INSTRUMENT CLUSTER

There are two conventional instrument cluster

assemblies available. The clusters electronically drive

the speedometer, odometer, gauges, and tachometer

(if equipped). Refer to (Fig. 2) and (Fig. 3).

The instrument cluster controls the courtesy

lamps, it receives and sends messages to other mod-

ules via the PCI bus circuit, it controls all the instru-

ment illumination and the chime is also an integral

part of the cluster. The front turn signals are wired

through the cluster and then go to the front lamps.

The reason being that the DRL module is built into

the cluster (if equipped).

All gauges in the electronic clusters are the analog

type gauges. When the ignition switch is moved to

the OFF position, the cluster drives each gauge to its

lowest position. The individual gauges are not servi-

cable and require complete replacement of the cluster

if one or more gauges are inoperable.

One button is used to switch the display from trip

to total mileage. Holding the button when the display

is in the trip mode will reset the trip mileage. This

button is also used to put the cluster in self-diagnos-

tic mode. Refer to Service Procedures, Cluster Self-

Diagnostics in this section. Most of the indicators will

come on briefly for a bulb heck when the ignition is

turned from OFF to ON. All of the LED's are replace-

able.

In the event that the instrument cluster looses

communication with all other modules on the PCI

bus, the cluster will display ªnobusº in the VF dis-

play. The VF display also displays ªDoorº, ªCruiseº,

ªTracº, and odometer trip or total.

If the cluster does not detect voltage on the cour-

tesy lamp circuit, the message ªFUSEº will alternate

with the odometer/trip odometer for 30 seconds after

the ignition is turned on and for 15 seconds after the

vehicle is first moved. The lack of voltage can be due

to the M1 Fused B(+) (IOD) fuse being open, a bad or

missing courtesy lamp bulb, or a circuit problem.

WARNING AND INDICATOR LAMPS

The instrument cluster has warning lamps and

indicators for the following systems:

²Airbag

²Anti-lock Brakes (ABS) if equipped

²Brake warning

²Charging System²Front fog lamps (if equipped)

²High beam indicator

²Low fuel (premium cluster only)

²Low oil pressure

²Malfunction indicator (service engine soon) lamp

²Right and left turn signals

²Seat belt warning

²Security system

²Trac-Off (ABS equipped vehicles only)

The instrument cluster has a Vacuum Fluorescent

(VF) display for the following systems:

²Cruise

²Door (ajar)

²Odometer

²Set (cruise)

²Trac

²Trip

DIAGNOSIS AND TESTING

AIRBAG WARNING SYSTEM

For testing of this system refer to Group 8M, Pas-

sive Restraint Systems.

BRAKE SYSTEM WARNING LAMP TEST

The brake warning lamp illuminates when the

parking brake is applied with ignition switch turned

to the ON position. The same lamp will also illumi-

nate if one of the two service brake systems fail the

when brake pedal is applied.

To test the system:

²As the ignition switch is turned to the start posi-

tion the lamp should light.

²Turn ignition switch to the ON position and

apply the parking brake. The lamp should light.

If lamp fails to light inspect for:

²A burned out lamp

²Loose, corroded or damaged socket

²A damaged circuit board

²A broken or disconnected wire at the switch

²Defective switch

To test the service brake warning system, refer to

Group 5, Brakes, Hydraulic System Control Valves.

INSTRUMENT CLUSTER LAMPS

Every time the vehicle is switched to the START/

RUN position, the cluster goes through a BULB

CHECK. This tests most of the indicator lamps and

Vacuum Fluorescent (VF) displays. If only one lamp

is out, remove the instrument cluster and replace the

defective bulb or Light Emitting Diode (LED). If

some or all of the lamps fail to light, refer to the

proper Body Diagnostics Procedures Manual.

8E - 2 INSTRUMENT PANEL SYSTEMSPL