electrical DODGE NEON 2000 Service Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 864 of 1285

(5) Install the air cleaner element, make sure that

the element is past the lip on the air cleaner box.

(6) Install the air cleaner box cover and tighten

the screws.

(7) Connect the negative battery cable.

THROTTLE POSITION SENSOR

REMOVAL

(1) Disconnect the negative battery cable.

(2) Loosen the clamp for the air duct at the throt-

tle body.

(3) Remove the mounting bolt and nut for the air

cleaner box.

(4) Pull the air cleaner box and throttle body up to

access the throttle position sensor.

(5) Remove the throttle position sensor.

INSTALLATION

(1) Install the throttle position sensor.

(2) Locate the air cleaner box and throttle body

and tighten the mounting bolt and nut.

(3) Install the air duct hose and tighten the clamp.

(4) Connect the negative battery cable.

IDLE AIR CONTROL MOTOR

When servicing throttle body components, always

reassemble components with new O-rings and seals

where applicable. Never use lubricants on O-rings or

seals, damage may result. If assembly of component

is difficult, use water to aid assembly. Use care when

removing hoses to prevent damage to hose or hose

nipple.

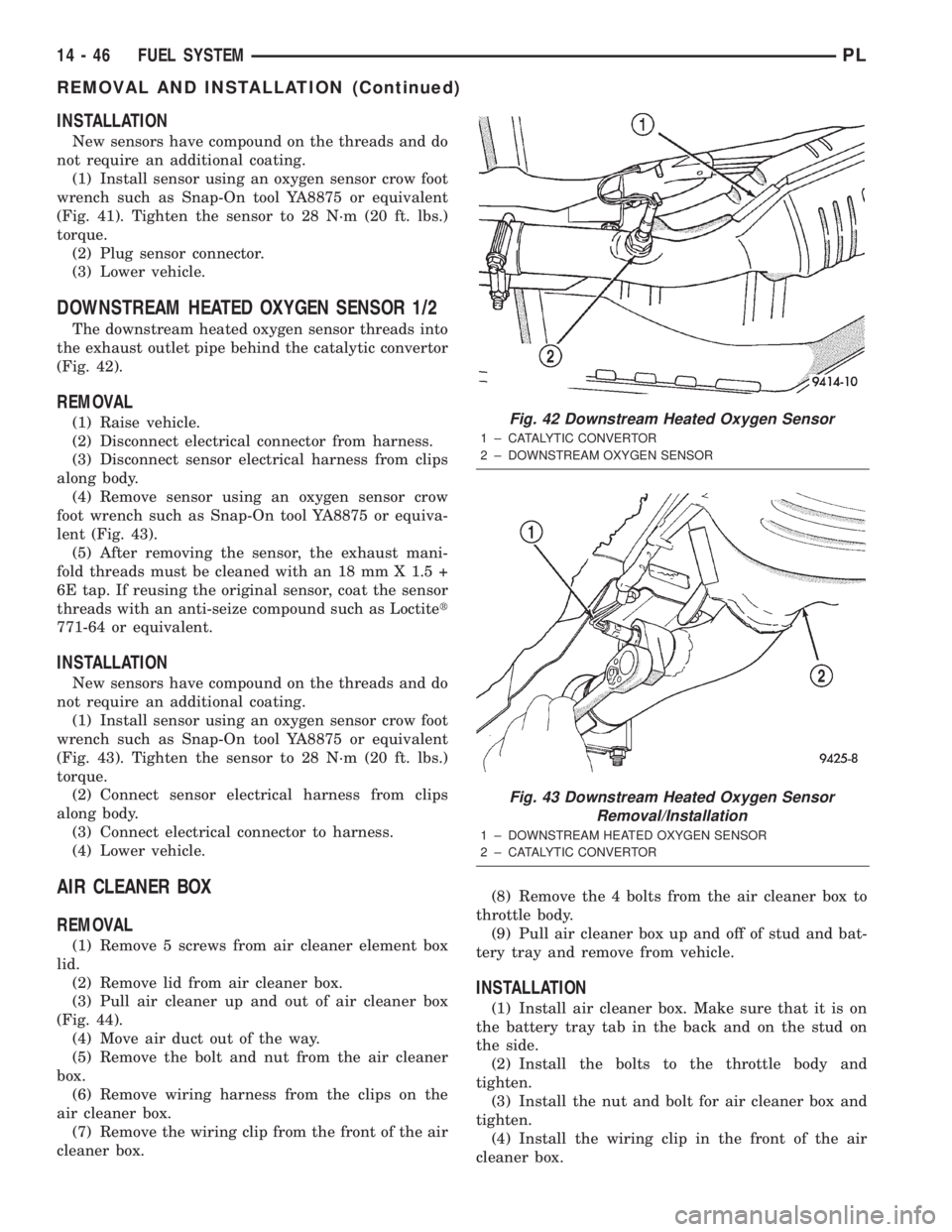

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove electrical connector from idle air con-

trol motor.

(3) Remove idle air control motor mounting screws

(Fig. 34).

(4) Remove motor from throttle body. Ensure the

O-ring is removed with the motor.

INSTALLATION

(1) The new idle air control motor has a new

O-ring installed on it. If pintle measures more than 1

inch (25 mm) it must be retracted. Use the DRB Idle

Air Control Motor Open/Close Test to retract the

pintle (battery must be connected.)

(2) Carefully place idle air control motor into

throttle body.

(3) Install mounting screws. Tighten screws to 4.5

N´m (40 in. lbs.) torque.

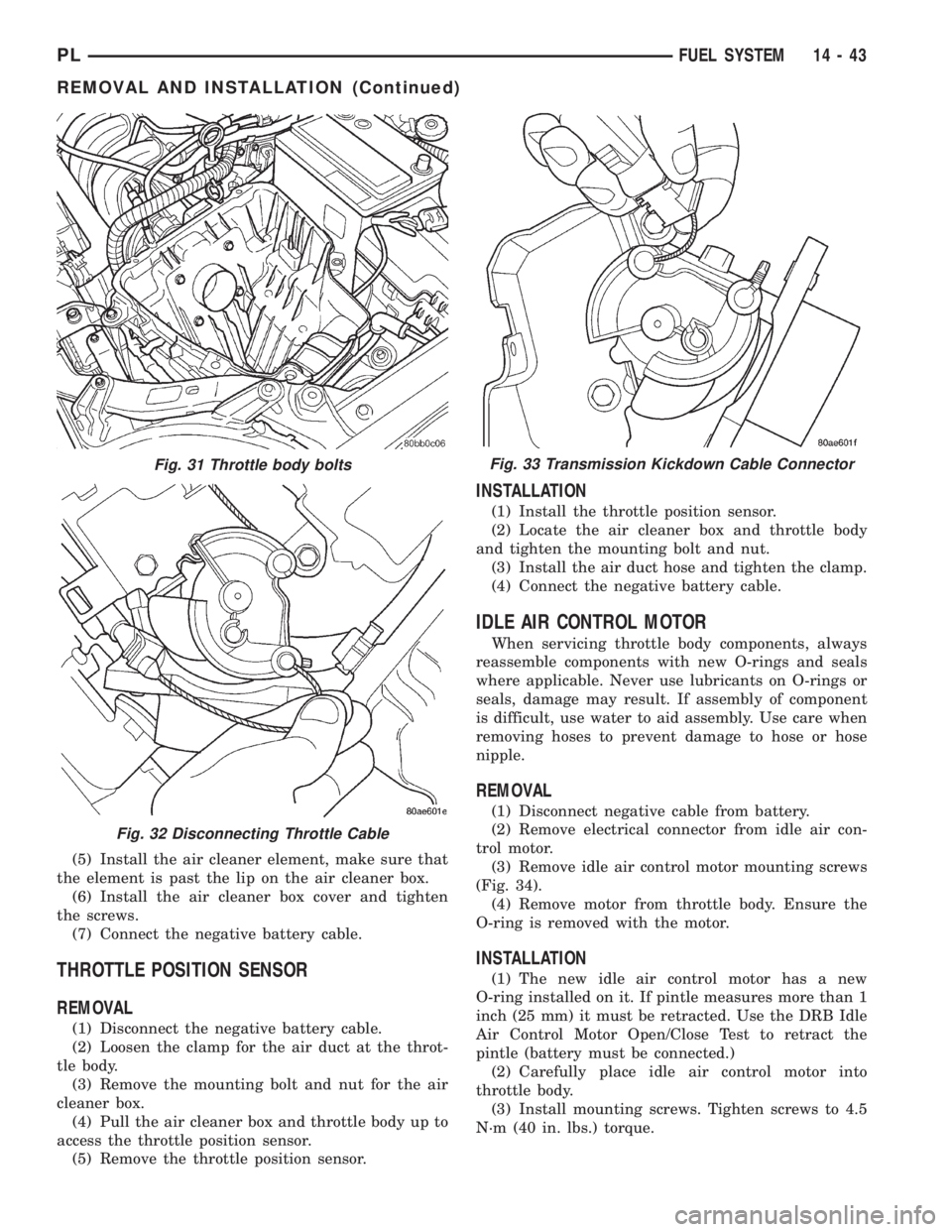

Fig. 31 Throttle body bolts

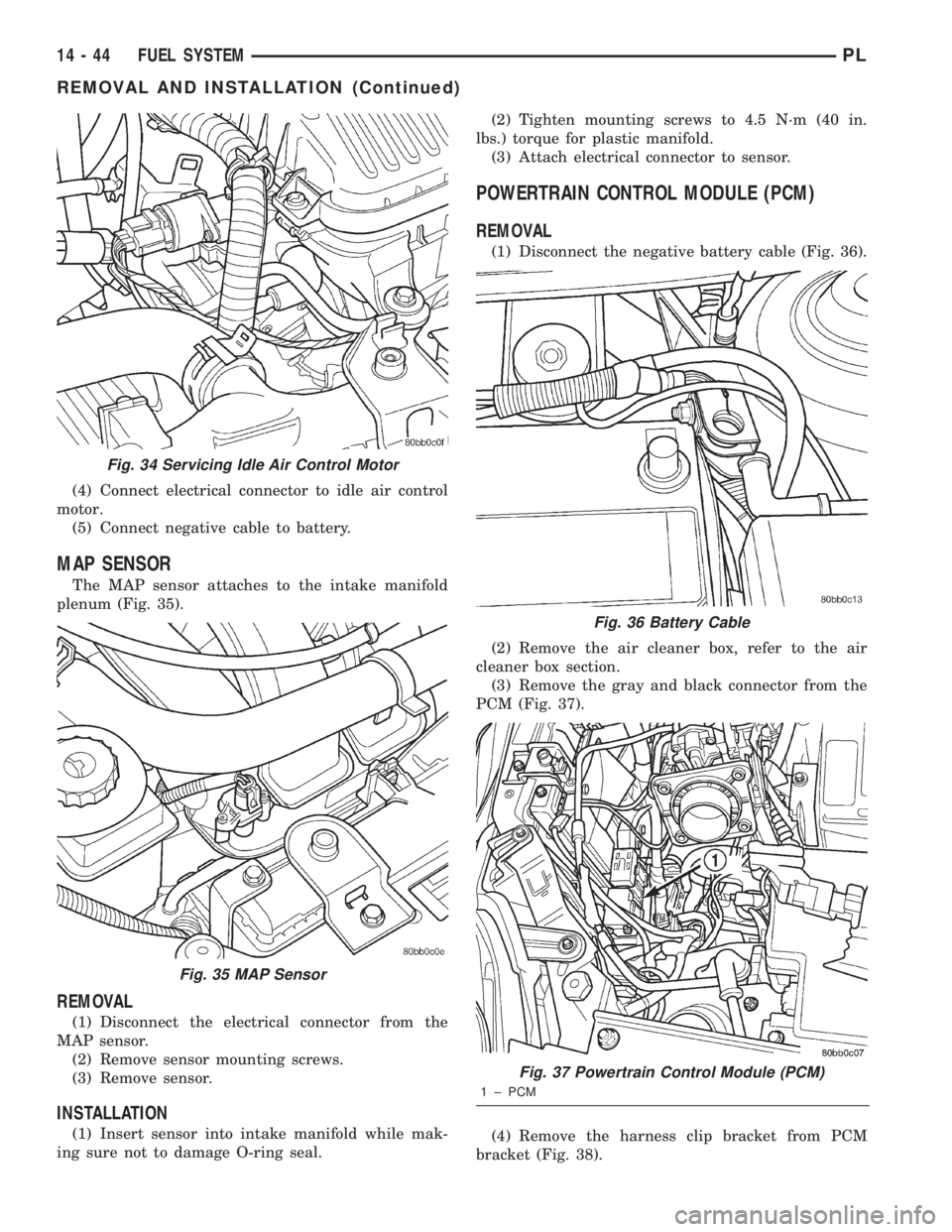

Fig. 32 Disconnecting Throttle Cable

Fig. 33 Transmission Kickdown Cable Connector

PLFUEL SYSTEM 14 - 43

REMOVAL AND INSTALLATION (Continued)

Page 865 of 1285

(4) Connect electrical connector to idle air control

motor.

(5) Connect negative cable to battery.

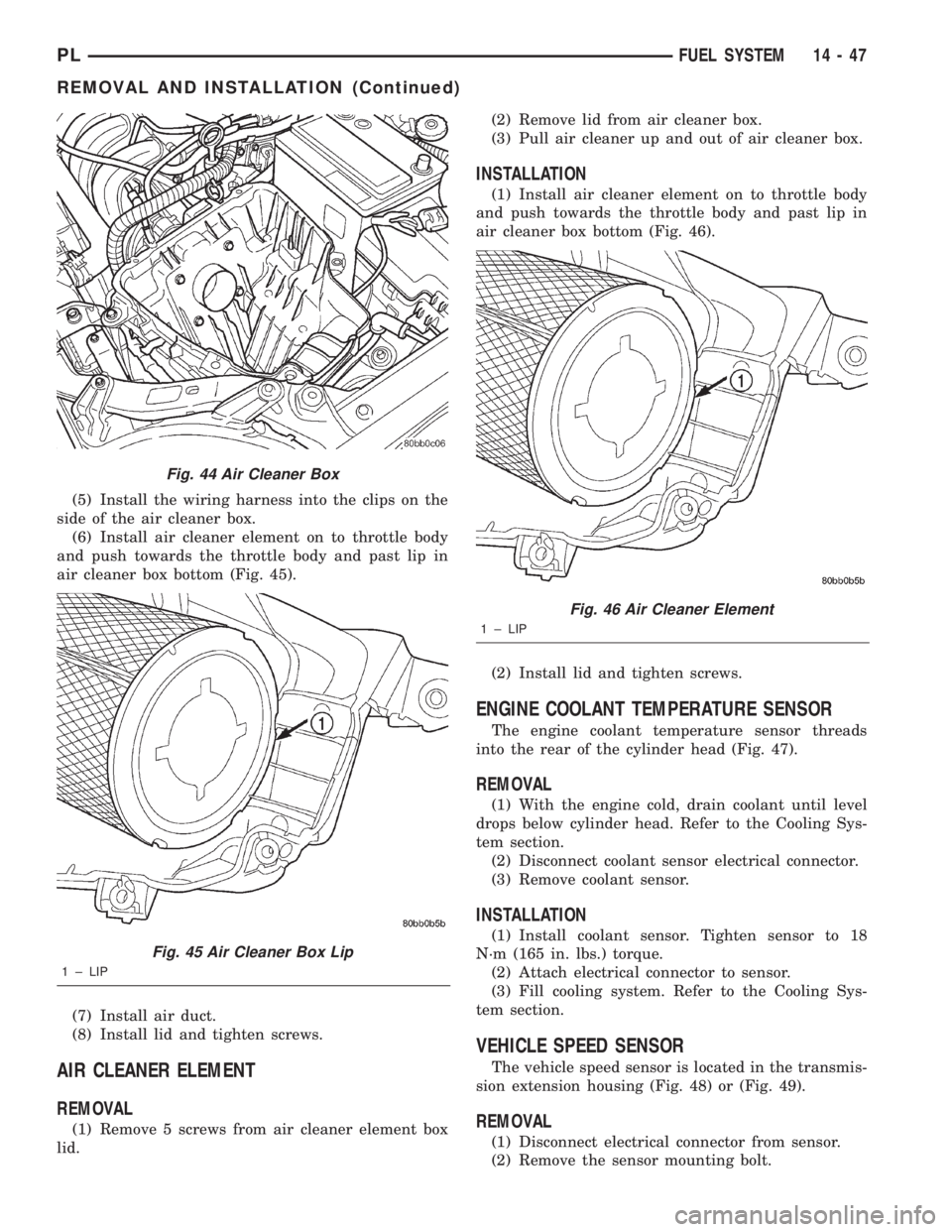

MAP SENSOR

The MAP sensor attaches to the intake manifold

plenum (Fig. 35).

REMOVAL

(1) Disconnect the electrical connector from the

MAP sensor.

(2) Remove sensor mounting screws.

(3) Remove sensor.

INSTALLATION

(1) Insert sensor into intake manifold while mak-

ing sure not to damage O-ring seal.(2) Tighten mounting screws to 4.5 N´m (40 in.

lbs.) torque for plastic manifold.

(3) Attach electrical connector to sensor.

POWERTRAIN CONTROL MODULE (PCM)

REMOVAL

(1) Disconnect the negative battery cable (Fig. 36).

(2) Remove the air cleaner box, refer to the air

cleaner box section.

(3) Remove the gray and black connector from the

PCM (Fig. 37).

(4) Remove the harness clip bracket from PCM

bracket (Fig. 38).

Fig. 34 Servicing Idle Air Control Motor

Fig. 35 MAP Sensor

Fig. 36 Battery Cable

Fig. 37 Powertrain Control Module (PCM)

1 ± PCM

14 - 44 FUEL SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 867 of 1285

INSTALLATION

New sensors have compound on the threads and do

not require an additional coating.

(1) Install sensor using an oxygen sensor crow foot

wrench such as Snap-On tool YA8875 or equivalent

(Fig. 41). Tighten the sensor to 28 N´m (20 ft. lbs.)

torque.

(2) Plug sensor connector.

(3) Lower vehicle.

DOWNSTREAM HEATED OXYGEN SENSOR 1/2

The downstream heated oxygen sensor threads into

the exhaust outlet pipe behind the catalytic convertor

(Fig. 42).

REMOVAL

(1) Raise vehicle.

(2) Disconnect electrical connector from harness.

(3) Disconnect sensor electrical harness from clips

along body.

(4) Remove sensor using an oxygen sensor crow

foot wrench such as Snap-On tool YA8875 or equiva-

lent (Fig. 43).

(5) After removing the sensor, the exhaust mani-

fold threads must be cleaned with an 18 mm X 1.5 +

6E tap. If reusing the original sensor, coat the sensor

threads with an anti-seize compound such as Loctitet

771-64 or equivalent.

INSTALLATION

New sensors have compound on the threads and do

not require an additional coating.

(1) Install sensor using an oxygen sensor crow foot

wrench such as Snap-On tool YA8875 or equivalent

(Fig. 43). Tighten the sensor to 28 N´m (20 ft. lbs.)

torque.

(2) Connect sensor electrical harness from clips

along body.

(3) Connect electrical connector to harness.

(4) Lower vehicle.

AIR CLEANER BOX

REMOVAL

(1) Remove 5 screws from air cleaner element box

lid.

(2) Remove lid from air cleaner box.

(3) Pull air cleaner up and out of air cleaner box

(Fig. 44).

(4) Move air duct out of the way.

(5) Remove the bolt and nut from the air cleaner

box.

(6) Remove wiring harness from the clips on the

air cleaner box.

(7) Remove the wiring clip from the front of the air

cleaner box.(8) Remove the 4 bolts from the air cleaner box to

throttle body.

(9) Pull air cleaner box up and off of stud and bat-

tery tray and remove from vehicle.

INSTALLATION

(1) Install air cleaner box. Make sure that it is on

the battery tray tab in the back and on the stud on

the side.

(2) Install the bolts to the throttle body and

tighten.

(3) Install the nut and bolt for air cleaner box and

tighten.

(4) Install the wiring clip in the front of the air

cleaner box.

Fig. 42 Downstream Heated Oxygen Sensor

1 ± CATALYTIC CONVERTOR

2 ± DOWNSTREAM OXYGEN SENSOR

Fig. 43 Downstream Heated Oxygen Sensor

Removal/Installation

1 ± DOWNSTREAM HEATED OXYGEN SENSOR

2 ± CATALYTIC CONVERTOR

14 - 46 FUEL SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 868 of 1285

(5) Install the wiring harness into the clips on the

side of the air cleaner box.

(6) Install air cleaner element on to throttle body

and push towards the throttle body and past lip in

air cleaner box bottom (Fig. 45).

(7) Install air duct.

(8) Install lid and tighten screws.

AIR CLEANER ELEMENT

REMOVAL

(1) Remove 5 screws from air cleaner element box

lid.(2) Remove lid from air cleaner box.

(3) Pull air cleaner up and out of air cleaner box.

INSTALLATION

(1) Install air cleaner element on to throttle body

and push towards the throttle body and past lip in

air cleaner box bottom (Fig. 46).

(2) Install lid and tighten screws.

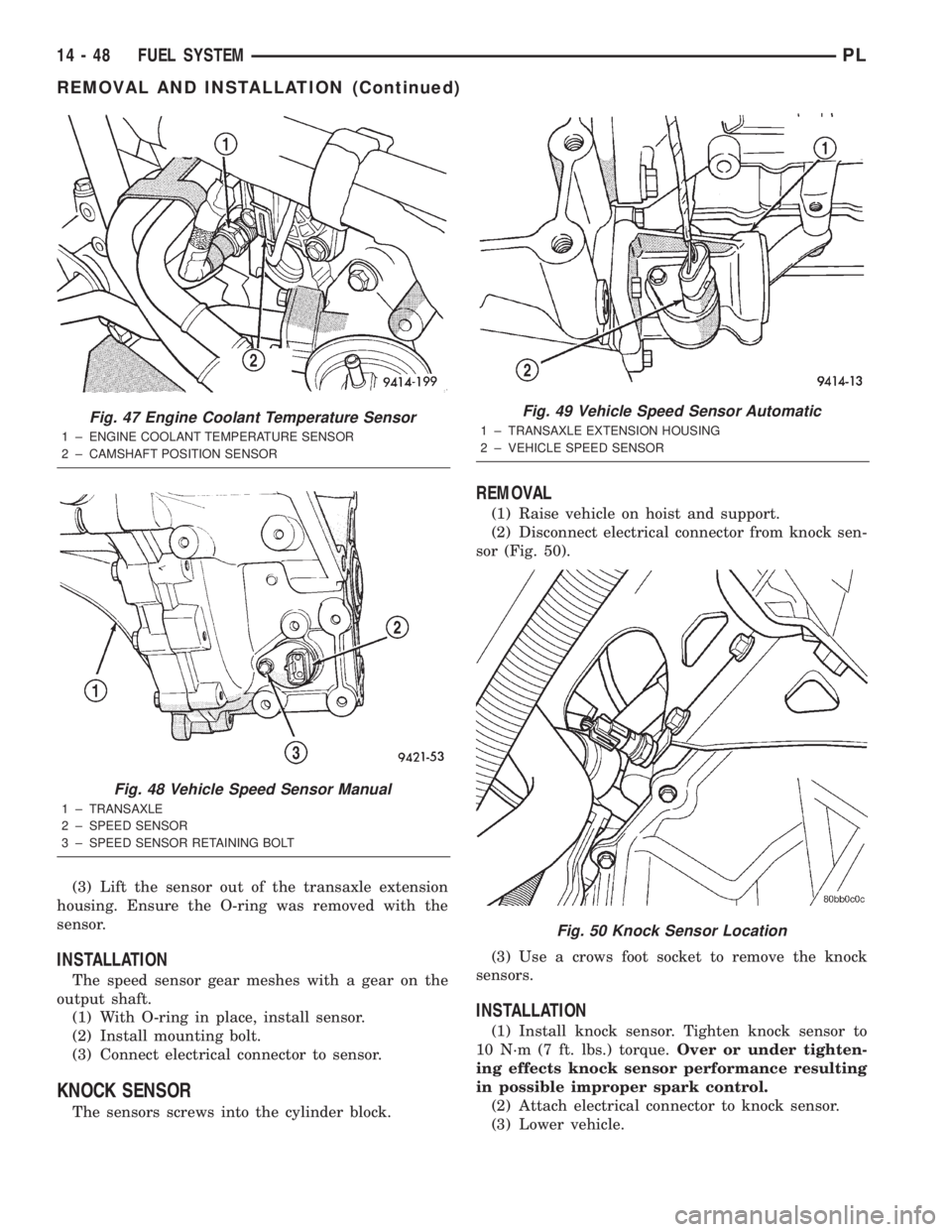

ENGINE COOLANT TEMPERATURE SENSOR

The engine coolant temperature sensor threads

into the rear of the cylinder head (Fig. 47).

REMOVAL

(1) With the engine cold, drain coolant until level

drops below cylinder head. Refer to the Cooling Sys-

tem section.

(2) Disconnect coolant sensor electrical connector.

(3) Remove coolant sensor.

INSTALLATION

(1) Install coolant sensor. Tighten sensor to 18

N´m (165 in. lbs.) torque.

(2) Attach electrical connector to sensor.

(3) Fill cooling system. Refer to the Cooling Sys-

tem section.

VEHICLE SPEED SENSOR

The vehicle speed sensor is located in the transmis-

sion extension housing (Fig. 48) or (Fig. 49).

REMOVAL

(1) Disconnect electrical connector from sensor.

(2) Remove the sensor mounting bolt.

Fig. 44 Air Cleaner Box

Fig. 45 Air Cleaner Box Lip

1 ± LIP

Fig. 46 Air Cleaner Element

1 ± LIP

PLFUEL SYSTEM 14 - 47

REMOVAL AND INSTALLATION (Continued)

Page 869 of 1285

(3) Lift the sensor out of the transaxle extension

housing. Ensure the O-ring was removed with the

sensor.

INSTALLATION

The speed sensor gear meshes with a gear on the

output shaft.

(1) With O-ring in place, install sensor.

(2) Install mounting bolt.

(3) Connect electrical connector to sensor.

KNOCK SENSOR

The sensors screws into the cylinder block.

REMOVAL

(1) Raise vehicle on hoist and support.

(2) Disconnect electrical connector from knock sen-

sor (Fig. 50).

(3) Use a crows foot socket to remove the knock

sensors.

INSTALLATION

(1) Install knock sensor. Tighten knock sensor to

10 N´m (7 ft. lbs.) torque.Over or under tighten-

ing effects knock sensor performance resulting

in possible improper spark control.

(2) Attach electrical connector to knock sensor.

(3) Lower vehicle.

Fig. 47 Engine Coolant Temperature Sensor

1 ± ENGINE COOLANT TEMPERATURE SENSOR

2 ± CAMSHAFT POSITION SENSOR

Fig. 48 Vehicle Speed Sensor Manual

1 ± TRANSAXLE

2 ± SPEED SENSOR

3 ± SPEED SENSOR RETAINING BOLT

Fig. 49 Vehicle Speed Sensor Automatic

1 ± TRANSAXLE EXTENSION HOUSING

2 ± VEHICLE SPEED SENSOR

Fig. 50 Knock Sensor Location

14 - 48 FUEL SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 885 of 1285

(3) Install the hose clamp on the power steering

cooler fluid hose past the bead formed into the steel

fitting and secure in place.

(4) Install the two screws attaching the cooler to

the front suspension crossmember. Tighten the cooler

attaching screws to a torque of 10 N´m (90 in. lbs.).

(5) Install the power steering fluid return hose on

the power steering fluid cooler tube. Install the hose

clamp on the power steering return hose securing it

to the power steering cooler. Be sure the hose clamp

is installed on the return hose past the bead on the

end of the cooler tube.

(6) Lower the vehicle.

(7) Perform the POWER STEERING PUMP INI-

TIAL OPERATION service procedure which can be

found in the POWER STEERING PUMP section of

this group to properly fill and bleed the power steer-

ing system.

(8) Check for leaks at all connections.

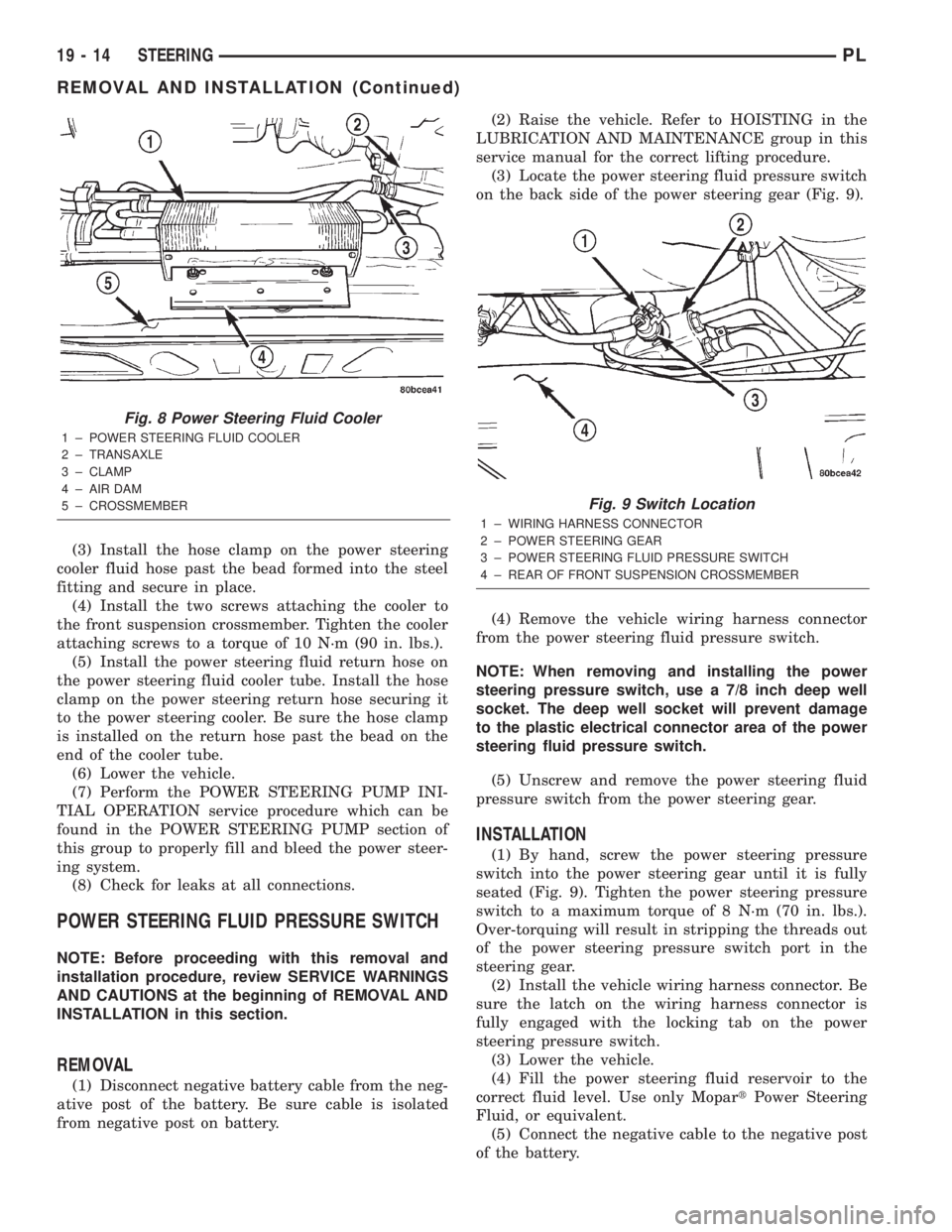

POWER STEERING FLUID PRESSURE SWITCH

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

REMOVAL

(1) Disconnect negative battery cable from the neg-

ative post of the battery. Be sure cable is isolated

from negative post on battery.(2) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.

(3) Locate the power steering fluid pressure switch

on the back side of the power steering gear (Fig. 9).

(4) Remove the vehicle wiring harness connector

from the power steering fluid pressure switch.

NOTE: When removing and installing the power

steering pressure switch, use a 7/8 inch deep well

socket. The deep well socket will prevent damage

to the plastic electrical connector area of the power

steering fluid pressure switch.

(5) Unscrew and remove the power steering fluid

pressure switch from the power steering gear.

INSTALLATION

(1) By hand, screw the power steering pressure

switch into the power steering gear until it is fully

seated (Fig. 9). Tighten the power steering pressure

switch to a maximum torque of 8 N´m (70 in. lbs.).

Over-torquing will result in stripping the threads out

of the power steering pressure switch port in the

steering gear.

(2) Install the vehicle wiring harness connector. Be

sure the latch on the wiring harness connector is

fully engaged with the locking tab on the power

steering pressure switch.

(3) Lower the vehicle.

(4) Fill the power steering fluid reservoir to the

correct fluid level. Use only MopartPower Steering

Fluid, or equivalent.

(5) Connect the negative cable to the negative post

of the battery.

Fig. 8 Power Steering Fluid Cooler

1 ± POWER STEERING FLUID COOLER

2 ± TRANSAXLE

3 ± CLAMP

4 ± AIR DAM

5 ± CROSSMEMBER

Fig. 9 Switch Location

1 ± WIRING HARNESS CONNECTOR

2 ± POWER STEERING GEAR

3 ± POWER STEERING FLUID PRESSURE SWITCH

4 ± REAR OF FRONT SUSPENSION CROSSMEMBER

19 - 14 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 902 of 1285

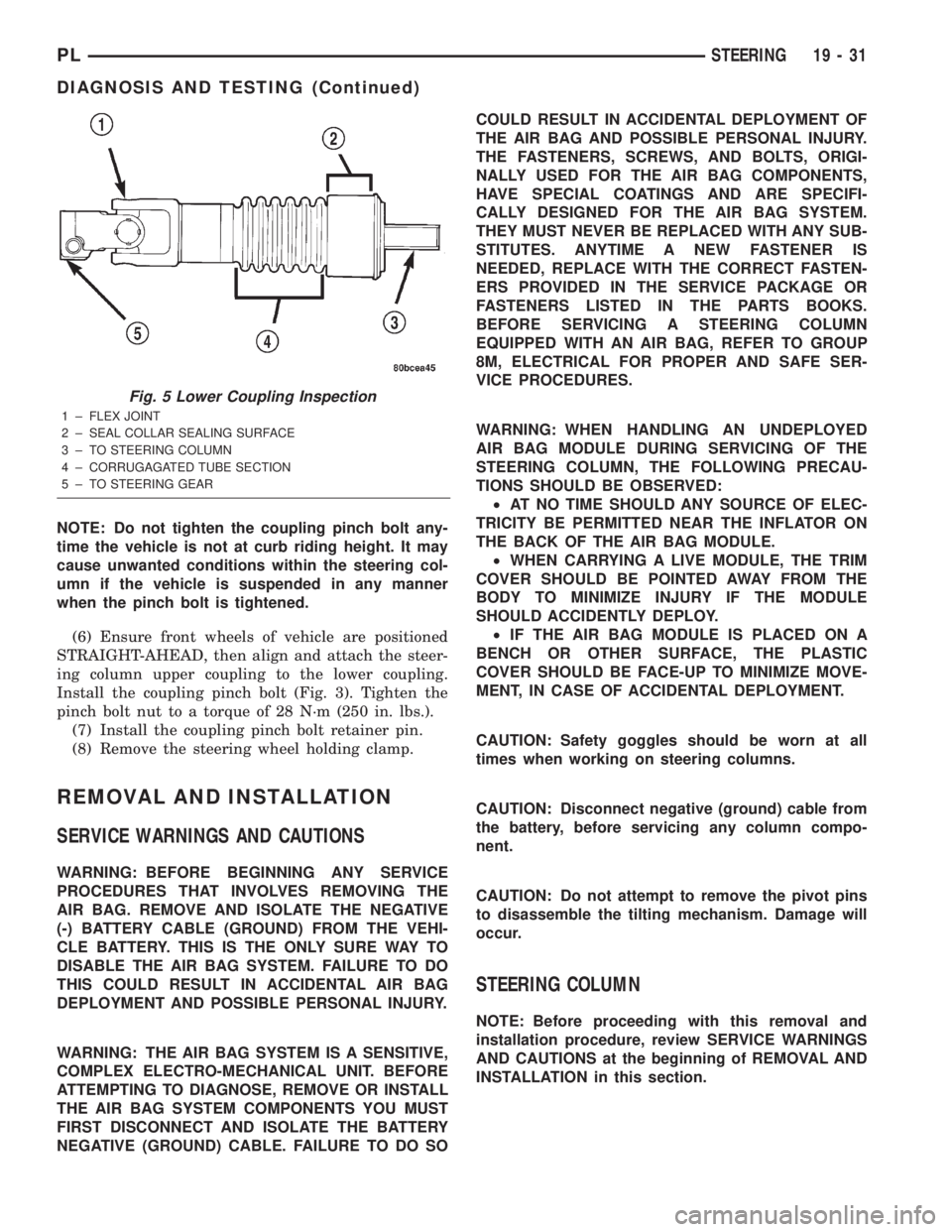

NOTE: Do not tighten the coupling pinch bolt any-

time the vehicle is not at curb riding height. It may

cause unwanted conditions within the steering col-

umn if the vehicle is suspended in any manner

when the pinch bolt is tightened.

(6) Ensure front wheels of vehicle are positioned

STRAIGHT-AHEAD, then align and attach the steer-

ing column upper coupling to the lower coupling.

Install the coupling pinch bolt (Fig. 3). Tighten the

pinch bolt nut to a torque of 28 N´m (250 in. lbs.).

(7) Install the coupling pinch bolt retainer pin.

(8) Remove the steering wheel holding clamp.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

WARNING: BEFORE BEGINNING ANY SERVICE

PROCEDURES THAT INVOLVES REMOVING THE

AIR BAG. REMOVE AND ISOLATE THE NEGATIVE

(-) BATTERY CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY.

WARNING: THE AIR BAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIR BAG SYSTEM COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. FAILURE TO DO SOCOULD RESULT IN ACCIDENTAL DEPLOYMENT OF

THE AIR BAG AND POSSIBLE PERSONAL INJURY.

THE FASTENERS, SCREWS, AND BOLTS, ORIGI-

NALLY USED FOR THE AIR BAG COMPONENTS,

HAVE SPECIAL COATINGS AND ARE SPECIFI-

CALLY DESIGNED FOR THE AIR BAG SYSTEM.

THEY MUST NEVER BE REPLACED WITH ANY SUB-

STITUTES. ANYTIME A NEW FASTENER IS

NEEDED, REPLACE WITH THE CORRECT FASTEN-

ERS PROVIDED IN THE SERVICE PACKAGE OR

FASTENERS LISTED IN THE PARTS BOOKS.

BEFORE SERVICING A STEERING COLUMN

EQUIPPED WITH AN AIR BAG, REFER TO GROUP

8M, ELECTRICAL FOR PROPER AND SAFE SER-

VICE PROCEDURES.

WARNING: WHEN HANDLING AN UNDEPLOYED

AIR BAG MODULE DURING SERVICING OF THE

STEERING COLUMN, THE FOLLOWING PRECAU-

TIONS SHOULD BE OBSERVED:

²AT NO TIME SHOULD ANY SOURCE OF ELEC-

TRICITY BE PERMITTED NEAR THE INFLATOR ON

THE BACK OF THE AIR BAG MODULE.

²WHEN CARRYING A LIVE MODULE, THE TRIM

COVER SHOULD BE POINTED AWAY FROM THE

BODY TO MINIMIZE INJURY IF THE MODULE

SHOULD ACCIDENTLY DEPLOY.

²IF THE AIR BAG MODULE IS PLACED ON A

BENCH OR OTHER SURFACE, THE PLASTIC

COVER SHOULD BE FACE-UP TO MINIMIZE MOVE-

MENT, IN CASE OF ACCIDENTAL DEPLOYMENT.

CAUTION: Safety goggles should be worn at all

times when working on steering columns.

CAUTION: Disconnect negative (ground) cable from

the battery, before servicing any column compo-

nent.

CAUTION: Do not attempt to remove the pivot pins

to disassemble the tilting mechanism. Damage will

occur.

STEERING COLUMN

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

Fig. 5 Lower Coupling Inspection

1 ± FLEX JOINT

2 ± SEAL COLLAR SEALING SURFACE

3 ± TO STEERING COLUMN

4 ± CORRUGAGATED TUBE SECTION

5 ± TO STEERING GEAR

PLSTEERING 19 - 31

DIAGNOSIS AND TESTING (Continued)

Page 903 of 1285

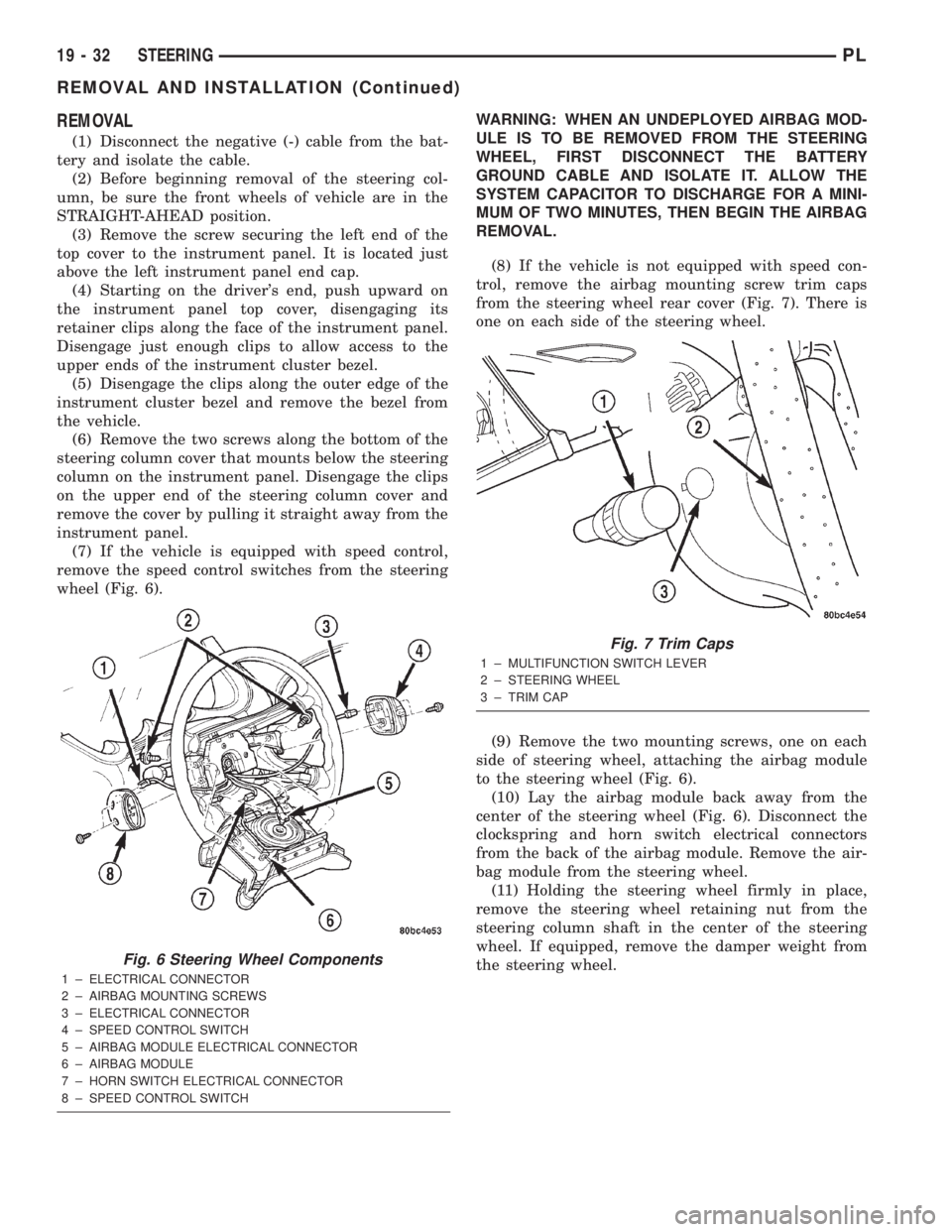

REMOVAL

(1) Disconnect the negative (-) cable from the bat-

tery and isolate the cable.

(2) Before beginning removal of the steering col-

umn, be sure the front wheels of vehicle are in the

STRAIGHT-AHEAD position.

(3) Remove the screw securing the left end of the

top cover to the instrument panel. It is located just

above the left instrument panel end cap.

(4) Starting on the driver's end, push upward on

the instrument panel top cover, disengaging its

retainer clips along the face of the instrument panel.

Disengage just enough clips to allow access to the

upper ends of the instrument cluster bezel.

(5) Disengage the clips along the outer edge of the

instrument cluster bezel and remove the bezel from

the vehicle.

(6) Remove the two screws along the bottom of the

steering column cover that mounts below the steering

column on the instrument panel. Disengage the clips

on the upper end of the steering column cover and

remove the cover by pulling it straight away from the

instrument panel.

(7) If the vehicle is equipped with speed control,

remove the speed control switches from the steering

wheel (Fig. 6).WARNING: WHEN AN UNDEPLOYED AIRBAG MOD-

ULE IS TO BE REMOVED FROM THE STEERING

WHEEL, FIRST DISCONNECT THE BATTERY

GROUND CABLE AND ISOLATE IT. ALLOW THE

SYSTEM CAPACITOR TO DISCHARGE FOR A MINI-

MUM OF TWO MINUTES, THEN BEGIN THE AIRBAG

REMOVAL.

(8) If the vehicle is not equipped with speed con-

trol, remove the airbag mounting screw trim caps

from the steering wheel rear cover (Fig. 7). There is

one on each side of the steering wheel.

(9) Remove the two mounting screws, one on each

side of steering wheel, attaching the airbag module

to the steering wheel (Fig. 6).

(10) Lay the airbag module back away from the

center of the steering wheel (Fig. 6). Disconnect the

clockspring and horn switch electrical connectors

from the back of the airbag module. Remove the air-

bag module from the steering wheel.

(11) Holding the steering wheel firmly in place,

remove the steering wheel retaining nut from the

steering column shaft in the center of the steering

wheel. If equipped, remove the damper weight from

the steering wheel.

Fig. 6 Steering Wheel Components

1 ± ELECTRICAL CONNECTOR

2 ± AIRBAG MOUNTING SCREWS

3 ± ELECTRICAL CONNECTOR

4 ± SPEED CONTROL SWITCH

5 ± AIRBAG MODULE ELECTRICAL CONNECTOR

6 ± AIRBAG MODULE

7 ± HORN SWITCH ELECTRICAL CONNECTOR

8 ± SPEED CONTROL SWITCH

Fig. 7 Trim Caps

1 ± MULTIFUNCTION SWITCH LEVER

2 ± STEERING WHEEL

3 ± TRIM CAP

19 - 32 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 905 of 1285

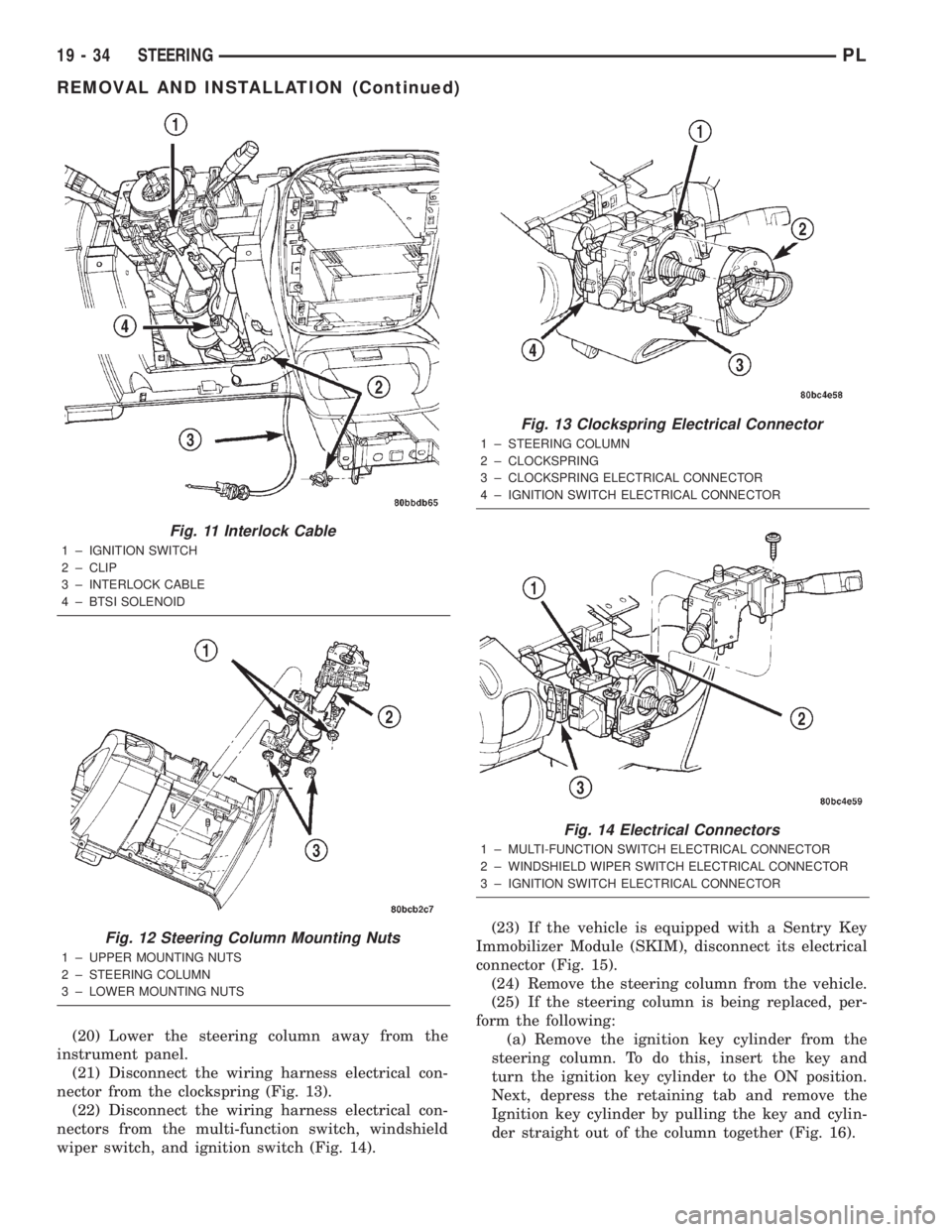

(20) Lower the steering column away from the

instrument panel.

(21) Disconnect the wiring harness electrical con-

nector from the clockspring (Fig. 13).

(22) Disconnect the wiring harness electrical con-

nectors from the multi-function switch, windshield

wiper switch, and ignition switch (Fig. 14).(23) If the vehicle is equipped with a Sentry Key

Immobilizer Module (SKIM), disconnect its electrical

connector (Fig. 15).

(24) Remove the steering column from the vehicle.

(25) If the steering column is being replaced, per-

form the following:

(a) Remove the ignition key cylinder from the

steering column. To do this, insert the key and

turn the ignition key cylinder to the ON position.

Next, depress the retaining tab and remove the

Ignition key cylinder by pulling the key and cylin-

der straight out of the column together (Fig. 16).

Fig. 11 Interlock Cable

1 ± IGNITION SWITCH

2 ± CLIP

3 ± INTERLOCK CABLE

4 ± BTSI SOLENOID

Fig. 12 Steering Column Mounting Nuts

1 ± UPPER MOUNTING NUTS

2 ± STEERING COLUMN

3 ± LOWER MOUNTING NUTS

Fig. 13 Clockspring Electrical Connector

1 ± STEERING COLUMN

2 ± CLOCKSPRING

3 ± CLOCKSPRING ELECTRICAL CONNECTOR

4 ± IGNITION SWITCH ELECTRICAL CONNECTOR

Fig. 14 Electrical Connectors

1 ± MULTI-FUNCTION SWITCH ELECTRICAL CONNECTOR

2 ± WINDSHIELD WIPER SWITCH ELECTRICAL CONNECTOR

3 ± IGNITION SWITCH ELECTRICAL CONNECTOR

19 - 34 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 906 of 1285

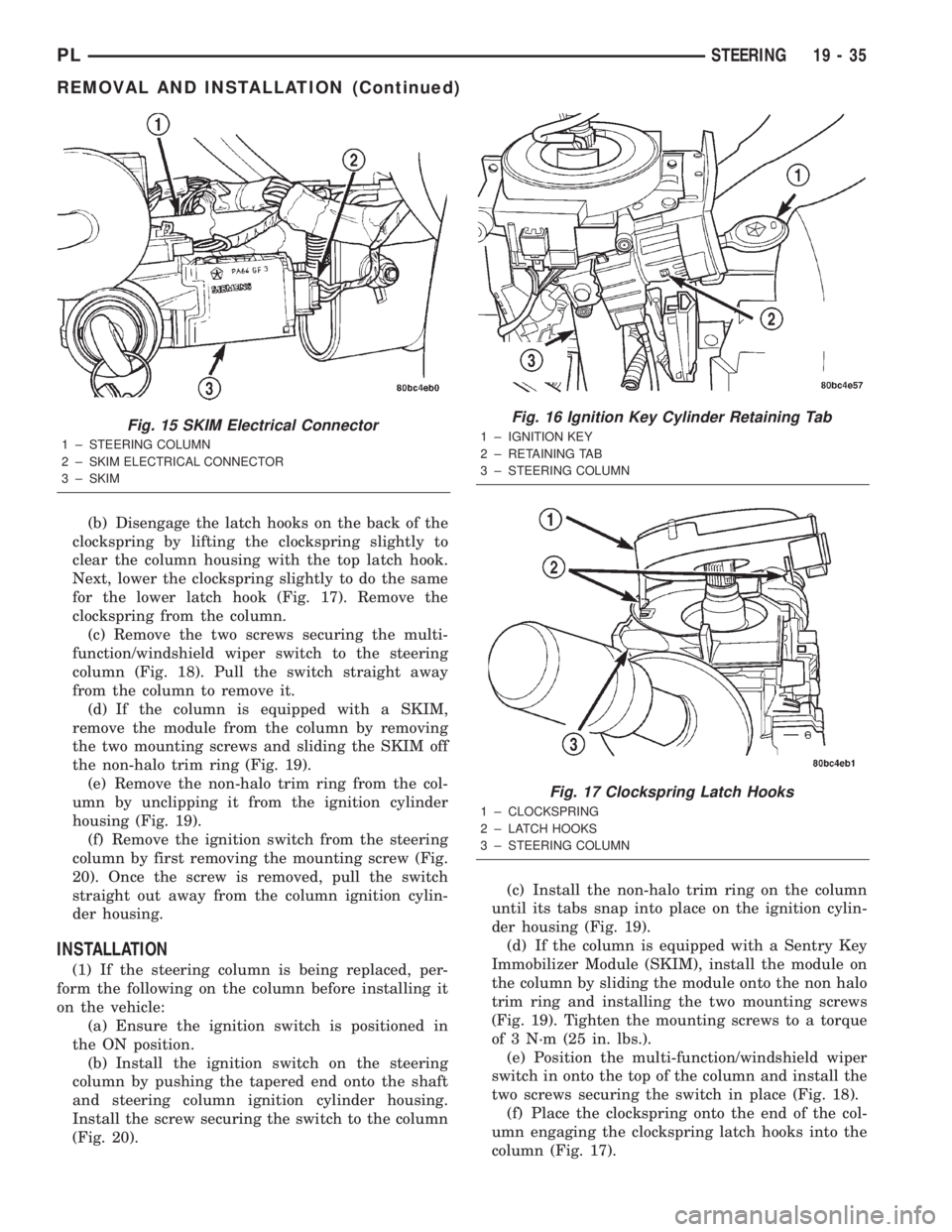

(b) Disengage the latch hooks on the back of the

clockspring by lifting the clockspring slightly to

clear the column housing with the top latch hook.

Next, lower the clockspring slightly to do the same

for the lower latch hook (Fig. 17). Remove the

clockspring from the column.

(c) Remove the two screws securing the multi-

function/windshield wiper switch to the steering

column (Fig. 18). Pull the switch straight away

from the column to remove it.

(d) If the column is equipped with a SKIM,

remove the module from the column by removing

the two mounting screws and sliding the SKIM off

the non-halo trim ring (Fig. 19).

(e) Remove the non-halo trim ring from the col-

umn by unclipping it from the ignition cylinder

housing (Fig. 19).

(f) Remove the ignition switch from the steering

column by first removing the mounting screw (Fig.

20). Once the screw is removed, pull the switch

straight out away from the column ignition cylin-

der housing.

INSTALLATION

(1) If the steering column is being replaced, per-

form the following on the column before installing it

on the vehicle:

(a) Ensure the ignition switch is positioned in

the ON position.

(b) Install the ignition switch on the steering

column by pushing the tapered end onto the shaft

and steering column ignition cylinder housing.

Install the screw securing the switch to the column

(Fig. 20).(c) Install the non-halo trim ring on the column

until its tabs snap into place on the ignition cylin-

der housing (Fig. 19).

(d) If the column is equipped with a Sentry Key

Immobilizer Module (SKIM), install the module on

the column by sliding the module onto the non halo

trim ring and installing the two mounting screws

(Fig. 19). Tighten the mounting screws to a torque

of 3 N´m (25 in. lbs.).

(e) Position the multi-function/windshield wiper

switch in onto the top of the column and install the

two screws securing the switch in place (Fig. 18).

(f) Place the clockspring onto the end of the col-

umn engaging the clockspring latch hooks into the

column (Fig. 17).

Fig. 15 SKIM Electrical Connector

1 ± STEERING COLUMN

2 ± SKIM ELECTRICAL CONNECTOR

3 ± SKIM

Fig. 16 Ignition Key Cylinder Retaining Tab

1 ± IGNITION KEY

2 ± RETAINING TAB

3 ± STEERING COLUMN

Fig. 17 Clockspring Latch Hooks

1 ± CLOCKSPRING

2 ± LATCH HOOKS

3 ± STEERING COLUMN

PLSTEERING 19 - 35

REMOVAL AND INSTALLATION (Continued)