electrical DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 907 of 1285

(g) Install the ignition key cylinder in the steer-

ing column. To do this, first position the key cylin-

der in the ON position (with the key in it) so the

retaining tab can be depressed. Push key cylinder

into the column ignition cylinder housing until the

retaining tab locks into place (Fig. 16).

NOTE: When installing a tilt column, do not release

the tilt lever from the locked position until after the

column is installed on the instrument panel.

(2) Install the steering column into steering col-

umn access opening in the lower instrument panel.

(3) If the vehicle is equipped with a SKIM, Con-

nect its wiring harness electrical connector (Fig. 15).(4) Connect the wiring harness electrical connec-

tors to the multi-function switch, windshield wiper

switch, and ignition switch (Fig. 14).

(5) Connect the wiring harness electrical connector

to the clockspring (Fig. 13).

(6) Align the slots in the mounting brackets on the

steering column with the studs in the instrument

panel (Fig. 12) Attach the column to the instrument

panel by first installing the two upper mounting nuts

(Do not completely tighten the two upper mounting

nuts at this time). Next, install the two lower mount-

ing nuts. Tighten all four mounting nuts to a torque

of 17 N´m (150 in. lbs.).

(7) If the vehicle is equipped with an automatic

transaxle, connect the automatic transaxle ignition

interlock cable to the steering column by pushing the

end of the cable into the back side of the ignition cyl-

inder housing until it snaps into place (Fig. 11).

(8) Position the steering column shaft in the cor-

rect position for mounting to the lower coupling. To

do this, turn the steering wheel end of the shaft until

the missing spline area on that end of the shaft faces

straight up.

(9) Verify the front wheels of vehicle are in the

STRAIGHT-AHEAD position.

NOTE: Do not tighten the coupling pinch bolt any-

time the vehicle is not at curb riding height. It may

cause unwanted conditions within the steering col-

umn if the vehicle is suspended in any manner

when the pinch bolt is tightened.

(10) Reconnect the steering column lower coupling

to the steering column upper coupling (Fig. 10).

Install the coupling pinch bolt an tighten the pinch

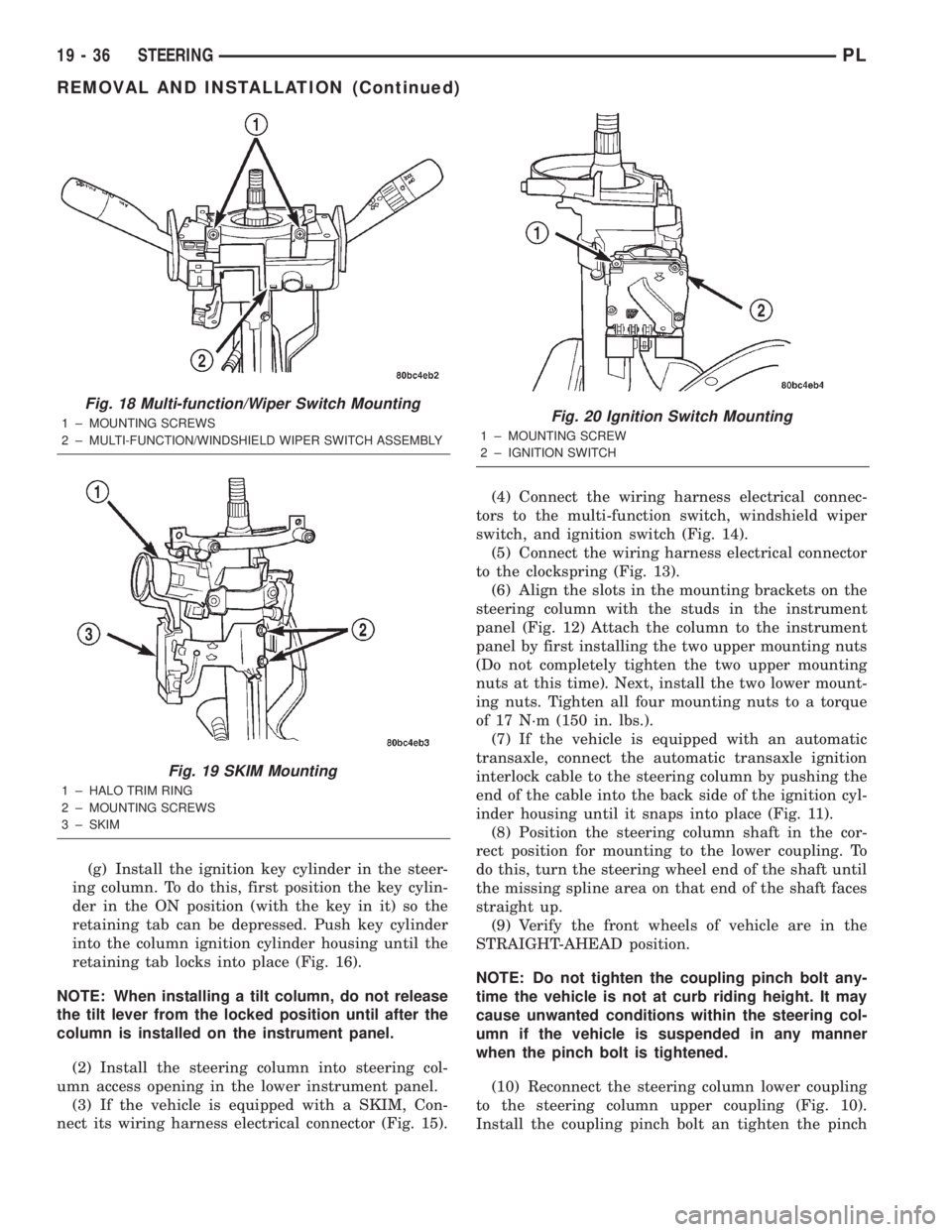

Fig. 18 Multi-function/Wiper Switch Mounting

1 ± MOUNTING SCREWS

2 ± MULTI-FUNCTION/WINDSHIELD WIPER SWITCH ASSEMBLY

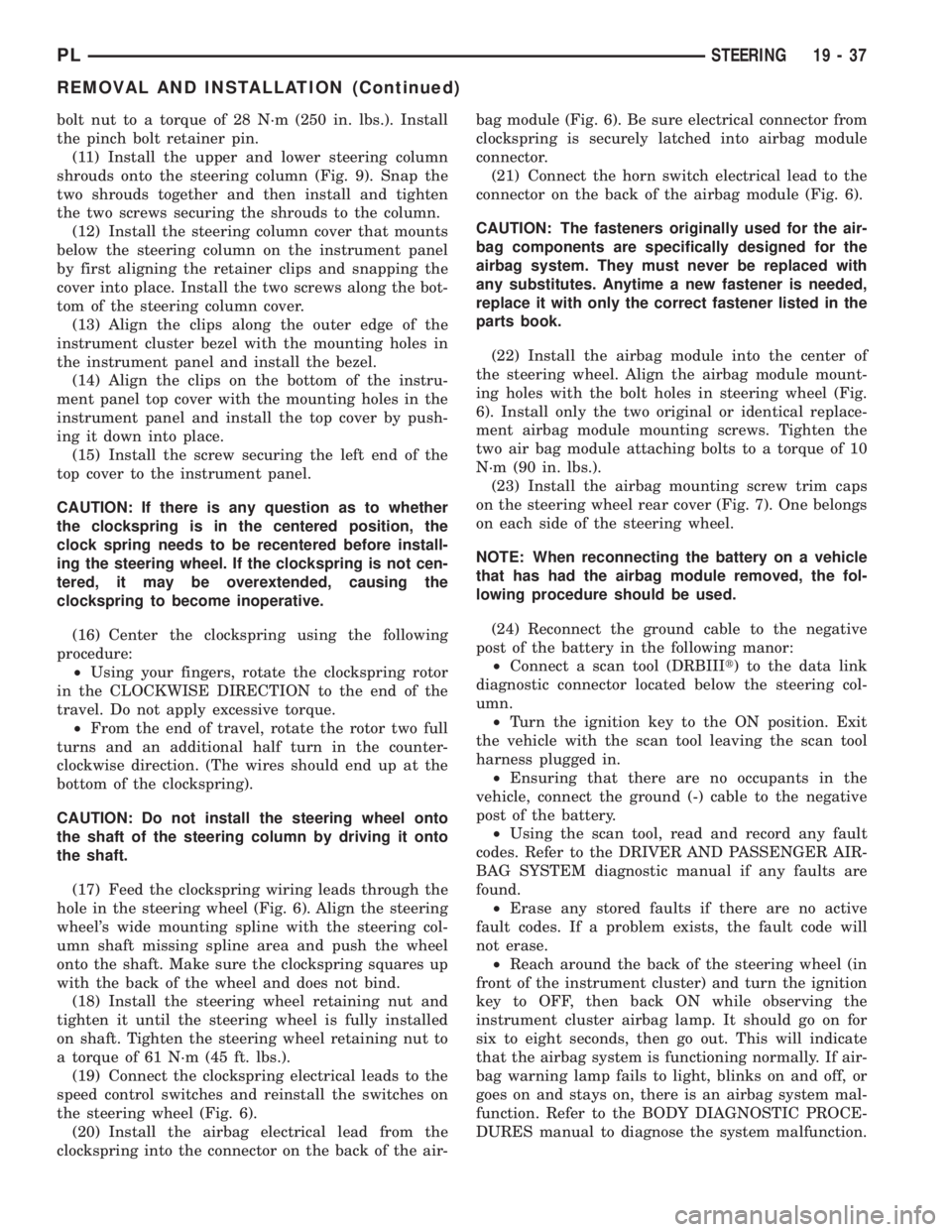

Fig. 19 SKIM Mounting

1 ± HALO TRIM RING

2 ± MOUNTING SCREWS

3 ± SKIM

Fig. 20 Ignition Switch Mounting

1 ± MOUNTING SCREW

2 ± IGNITION SWITCH

19 - 36 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 908 of 1285

bolt nut to a torque of 28 N´m (250 in. lbs.). Install

the pinch bolt retainer pin.

(11) Install the upper and lower steering column

shrouds onto the steering column (Fig. 9). Snap the

two shrouds together and then install and tighten

the two screws securing the shrouds to the column.

(12) Install the steering column cover that mounts

below the steering column on the instrument panel

by first aligning the retainer clips and snapping the

cover into place. Install the two screws along the bot-

tom of the steering column cover.

(13) Align the clips along the outer edge of the

instrument cluster bezel with the mounting holes in

the instrument panel and install the bezel.

(14) Align the clips on the bottom of the instru-

ment panel top cover with the mounting holes in the

instrument panel and install the top cover by push-

ing it down into place.

(15) Install the screw securing the left end of the

top cover to the instrument panel.

CAUTION: If there is any question as to whether

the clockspring is in the centered position, the

clock spring needs to be recentered before install-

ing the steering wheel. If the clockspring is not cen-

tered, it may be overextended, causing the

clockspring to become inoperative.

(16) Center the clockspring using the following

procedure:

²Using your fingers, rotate the clockspring rotor

in the CLOCKWISE DIRECTION to the end of the

travel. Do not apply excessive torque.

²From the end of travel, rotate the rotor two full

turns and an additional half turn in the counter-

clockwise direction. (The wires should end up at the

bottom of the clockspring).

CAUTION: Do not install the steering wheel onto

the shaft of the steering column by driving it onto

the shaft.

(17) Feed the clockspring wiring leads through the

hole in the steering wheel (Fig. 6). Align the steering

wheel's wide mounting spline with the steering col-

umn shaft missing spline area and push the wheel

onto the shaft. Make sure the clockspring squares up

with the back of the wheel and does not bind.

(18) Install the steering wheel retaining nut and

tighten it until the steering wheel is fully installed

on shaft. Tighten the steering wheel retaining nut to

a torque of 61 N´m (45 ft. lbs.).

(19) Connect the clockspring electrical leads to the

speed control switches and reinstall the switches on

the steering wheel (Fig. 6).

(20) Install the airbag electrical lead from the

clockspring into the connector on the back of the air-bag module (Fig. 6). Be sure electrical connector from

clockspring is securely latched into airbag module

connector.

(21) Connect the horn switch electrical lead to the

connector on the back of the airbag module (Fig. 6).

CAUTION: The fasteners originally used for the air-

bag components are specifically designed for the

airbag system. They must never be replaced with

any substitutes. Anytime a new fastener is needed,

replace it with only the correct fastener listed in the

parts book.

(22) Install the airbag module into the center of

the steering wheel. Align the airbag module mount-

ing holes with the bolt holes in steering wheel (Fig.

6). Install only the two original or identical replace-

ment airbag module mounting screws. Tighten the

two air bag module attaching bolts to a torque of 10

N´m (90 in. lbs.).

(23) Install the airbag mounting screw trim caps

on the steering wheel rear cover (Fig. 7). One belongs

on each side of the steering wheel.

NOTE: When reconnecting the battery on a vehicle

that has had the airbag module removed, the fol-

lowing procedure should be used.

(24) Reconnect the ground cable to the negative

post of the battery in the following manor:

²Connect a scan tool (DRBIIIt) to the data link

diagnostic connector located below the steering col-

umn.

²Turn the ignition key to the ON position. Exit

the vehicle with the scan tool leaving the scan tool

harness plugged in.

²Ensuring that there are no occupants in the

vehicle, connect the ground (-) cable to the negative

post of the battery.

²Using the scan tool, read and record any fault

codes. Refer to the DRIVER AND PASSENGER AIR-

BAG SYSTEM diagnostic manual if any faults are

found.

²Erase any stored faults if there are no active

fault codes. If a problem exists, the fault code will

not erase.

²Reach around the back of the steering wheel (in

front of the instrument cluster) and turn the ignition

key to OFF, then back ON while observing the

instrument cluster airbag lamp. It should go on for

six to eight seconds, then go out. This will indicate

that the airbag system is functioning normally. If air-

bag warning lamp fails to light, blinks on and off, or

goes on and stays on, there is an airbag system mal-

function. Refer to the BODY DIAGNOSTIC PROCE-

DURES manual to diagnose the system malfunction.

PLSTEERING 19 - 37

REMOVAL AND INSTALLATION (Continued)

Page 929 of 1285

(23) Carefully lower engine and transaxle on screw

jack until proper removal clearance is obtained.

(24) Obtain a helper to assist in holding transaxle

while removing transaxle-to-engine mounting bolts

(Fig. 44).(25) Remove transaxle from vehicle (Fig. 44).

(26) If installing a new or replacement transaxle,

remove the upper mount as shown in (Fig. 45), trans-

fer to the replacement unit and torque all bolts to 68

N´m (50 ft. lbs.) torque.

INSTALLATION

(1) Install clutch module onto input shaft. Install

transaxle into position.

(2) Install transaxle-to-engine mounting bolts (Fig.

44) and tighten to 95 N´m (70 ft. lbs.) torque.

(3) Raise engine and transaxle with screw jack

until through hole in upper mount aligns with hole

in mount bracket. Install mount bolt and tighten to

108 N´m (80 ft. lbs.) torque (Fig. 43).

(4) Remove screwjack.

(5) Install drive plate-to-clutch module bolts and

torque to 88 N´m (65 ft. lbs.) torque.

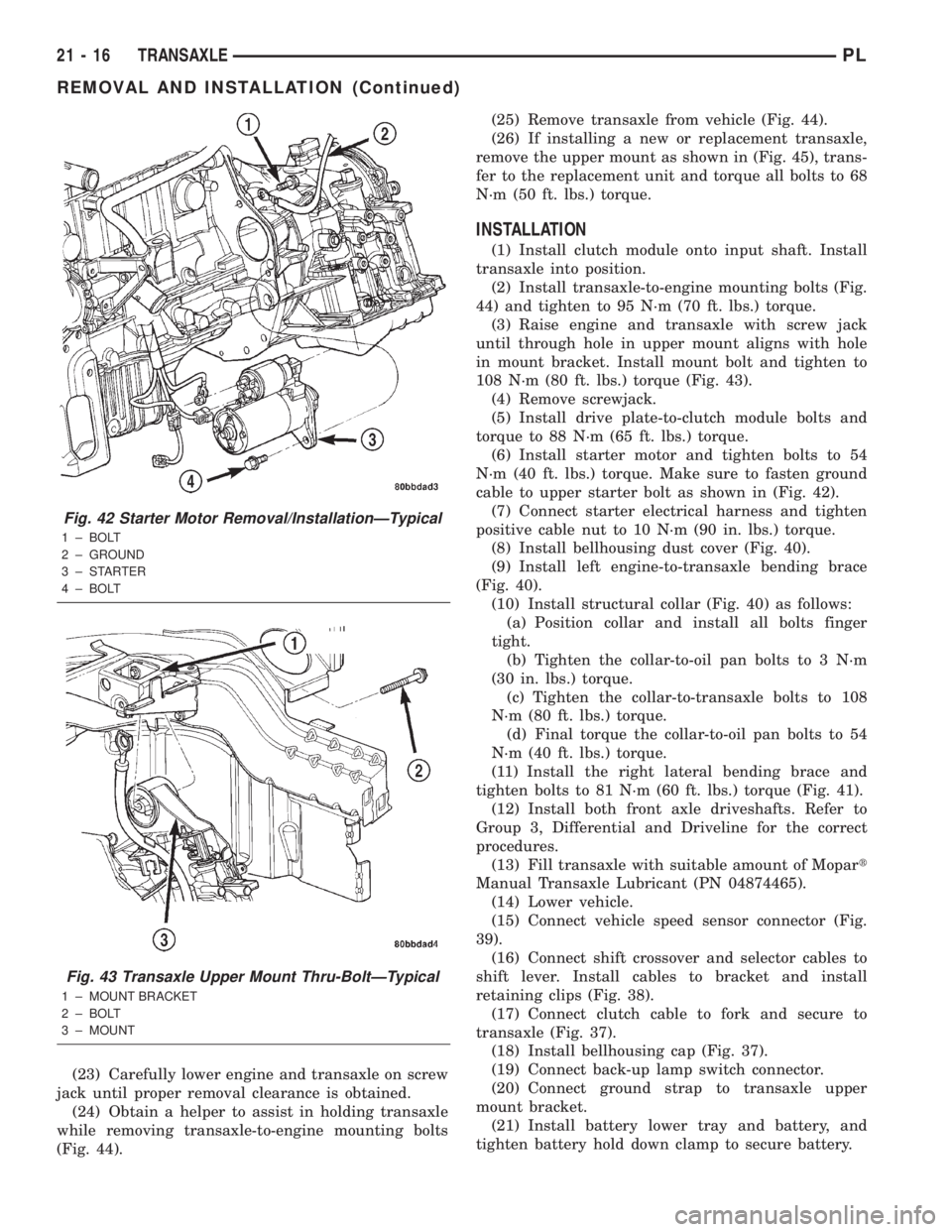

(6) Install starter motor and tighten bolts to 54

N´m (40 ft. lbs.) torque. Make sure to fasten ground

cable to upper starter bolt as shown in (Fig. 42).

(7) Connect starter electrical harness and tighten

positive cable nut to 10 N´m (90 in. lbs.) torque.

(8) Install bellhousing dust cover (Fig. 40).

(9) Install left engine-to-transaxle bending brace

(Fig. 40).

(10) Install structural collar (Fig. 40) as follows:

(a) Position collar and install all bolts finger

tight.

(b) Tighten the collar-to-oil pan bolts to 3 N´m

(30 in. lbs.) torque.

(c) Tighten the collar-to-transaxle bolts to 108

N´m (80 ft. lbs.) torque.

(d) Final torque the collar-to-oil pan bolts to 54

N´m (40 ft. lbs.) torque.

(11) Install the right lateral bending brace and

tighten bolts to 81 N´m (60 ft. lbs.) torque (Fig. 41).

(12) Install both front axle driveshafts. Refer to

Group 3, Differential and Driveline for the correct

procedures.

(13) Fill transaxle with suitable amount of Mopart

Manual Transaxle Lubricant (PN 04874465).

(14) Lower vehicle.

(15) Connect vehicle speed sensor connector (Fig.

39).

(16) Connect shift crossover and selector cables to

shift lever. Install cables to bracket and install

retaining clips (Fig. 38).

(17) Connect clutch cable to fork and secure to

transaxle (Fig. 37).

(18) Install bellhousing cap (Fig. 37).

(19) Connect back-up lamp switch connector.

(20) Connect ground strap to transaxle upper

mount bracket.

(21) Install battery lower tray and battery, and

tighten battery hold down clamp to secure battery.

Fig. 42 Starter Motor Removal/InstallationÐTypical

1 ± BOLT

2 ± GROUND

3±STARTER

4 ± BOLT

Fig. 43 Transaxle Upper Mount Thru-BoltÐTypical

1 ± MOUNT BRACKET

2 ± BOLT

3 ± MOUNT

21 - 16 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 970 of 1285

The kickdown valve makes possible a forced down-

shift from third to second, second to first, or third to

first (depending on vehicle speed). This can be done

by depressing the accelerator pedal past the detent

feel near wide open throttle.

The shuttle valve has two separate functions and

performs each independently of the other. The first is

providing fast release of the kickdown band, and

smooth front clutch engagement when a lift-foot

upshift from second to third is made. The second

function is to regulate the application of the kick-

down servo and band when making third±to±second

kickdown.

The bypass valve provides for smooth application

of the kickdown band on 1-2 upshifts.

The torque converter clutch solenoid allows for the

electronic control of the torque converter clutch. It

also disengages the torque converter at closed throt-

tle. This is done during engine warm-up and part-

throttle acceleration.

The switch valve directs oil to apply the torque

converter clutch in one position. The switch valve

releases the torque converter clutch in the other posi-

tion.

CLUTCHES, BAND SERVOS, AND

ACCUMULATOR

The front and rear clutch pistons, and both servo

pistons, are moved hydraulically to engage the

clutches and apply the bands. The pistons are

released by spring tension when hydraulic pressure

is released. On the 2-3 upshift, the kickdown servo

piston is released by spring tension and hydraulic

pressure.

The accumulator controls the hydraulic pressure

on the apply±side of the kickdown servo during the

1-2 upshift; thereby cushioning the kickdown band

application at any throttle position.

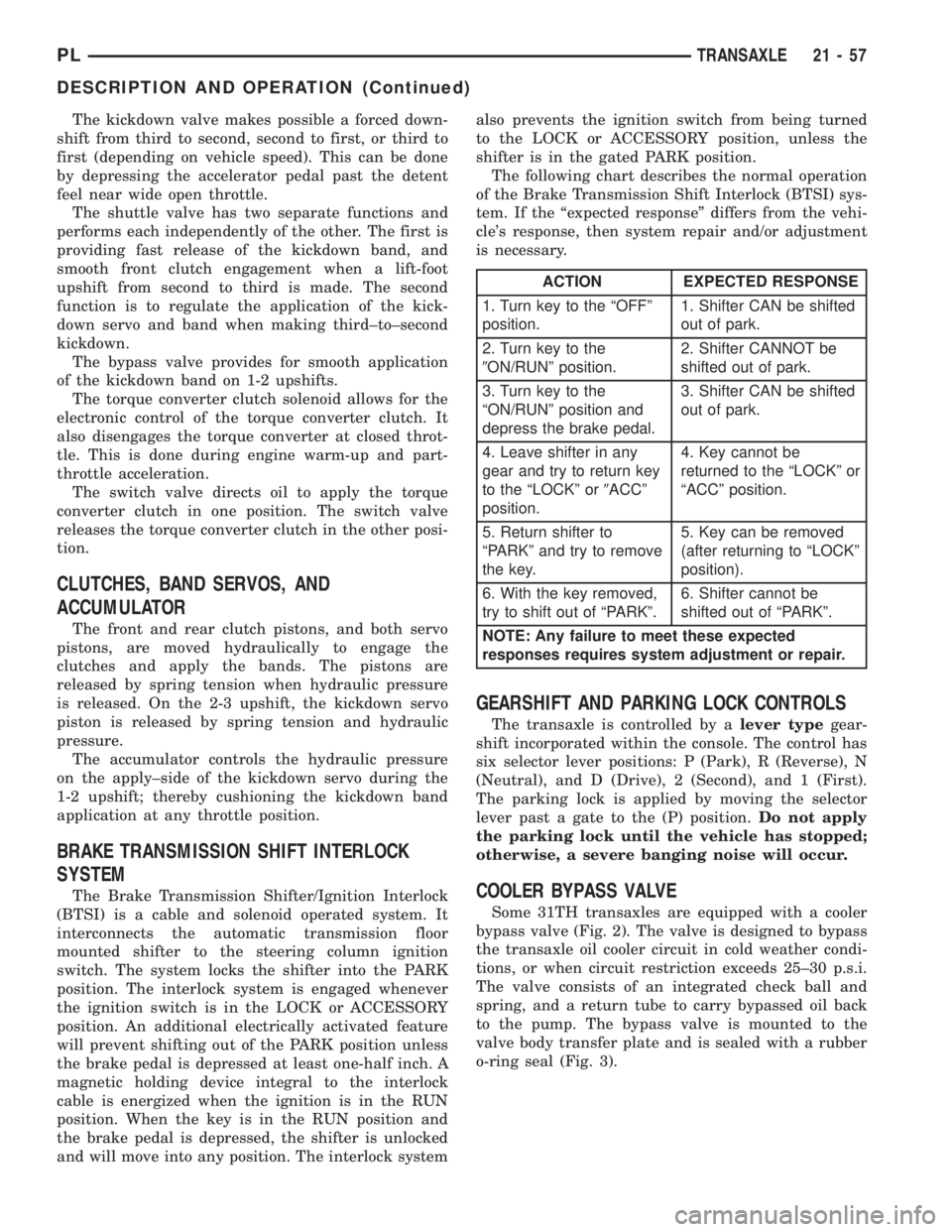

BRAKE TRANSMISSION SHIFT INTERLOCK

SYSTEM

The Brake Transmission Shifter/Ignition Interlock

(BTSI) is a cable and solenoid operated system. It

interconnects the automatic transmission floor

mounted shifter to the steering column ignition

switch. The system locks the shifter into the PARK

position. The interlock system is engaged whenever

the ignition switch is in the LOCK or ACCESSORY

position. An additional electrically activated feature

will prevent shifting out of the PARK position unless

the brake pedal is depressed at least one-half inch. A

magnetic holding device integral to the interlock

cable is energized when the ignition is in the RUN

position. When the key is in the RUN position and

the brake pedal is depressed, the shifter is unlocked

and will move into any position. The interlock systemalso prevents the ignition switch from being turned

to the LOCK or ACCESSORY position, unless the

shifter is in the gated PARK position.

The following chart describes the normal operation

of the Brake Transmission Shift Interlock (BTSI) sys-

tem. If the ªexpected responseº differs from the vehi-

cle's response, then system repair and/or adjustment

is necessary.

GEARSHIFT AND PARKING LOCK CONTROLS

The transaxle is controlled by alever typegear-

shift incorporated within the console. The control has

six selector lever positions: P (Park), R (Reverse), N

(Neutral), and D (Drive), 2 (Second), and 1 (First).

The parking lock is applied by moving the selector

lever past a gate to the (P) position.Do not apply

the parking lock until the vehicle has stopped;

otherwise, a severe banging noise will occur.

COOLER BYPASS VALVE

Some 31TH transaxles are equipped with a cooler

bypass valve (Fig. 2). The valve is designed to bypass

the transaxle oil cooler circuit in cold weather condi-

tions, or when circuit restriction exceeds 25±30 p.s.i.

The valve consists of an integrated check ball and

spring, and a return tube to carry bypassed oil back

to the pump. The bypass valve is mounted to the

valve body transfer plate and is sealed with a rubber

o-ring seal (Fig. 3).

ACTION EXPECTED RESPONSE

1. Turn key to the ªOFFº

position.1. Shifter CAN be shifted

out of park.

2. Turn key to the

9ON/RUNº position.2. Shifter CANNOT be

shifted out of park.

3. Turn key to the

ªON/RUNº position and

depress the brake pedal.3. Shifter CAN be shifted

out of park.

4. Leave shifter in any

gear and try to return key

to the ªLOCKº or9ACCº

position.4. Key cannot be

returned to the ªLOCKº or

ªACCº position.

5. Return shifter to

ªPARKº and try to remove

the key.5. Key can be removed

(after returning to ªLOCKº

position).

6. With the key removed,

try to shift out of ªPARKº.6. Shifter cannot be

shifted out of ªPARKº.

NOTE: Any failure to meet these expected

responses requires system adjustment or repair.

PLTRANSAXLE 21 - 57

DESCRIPTION AND OPERATION (Continued)

Page 1000 of 1285

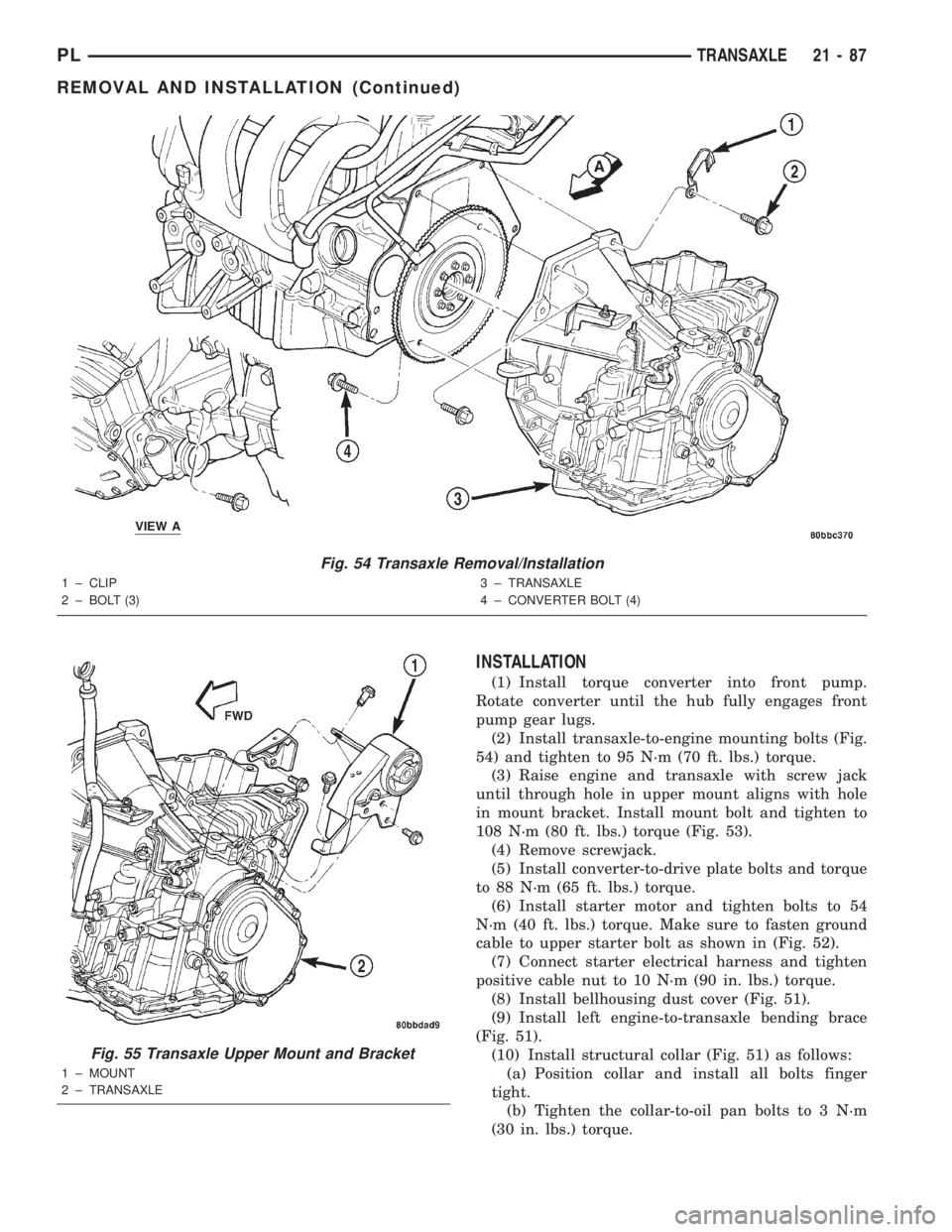

INSTALLATION

(1) Install torque converter into front pump.

Rotate converter until the hub fully engages front

pump gear lugs.

(2) Install transaxle-to-engine mounting bolts (Fig.

54) and tighten to 95 N´m (70 ft. lbs.) torque.

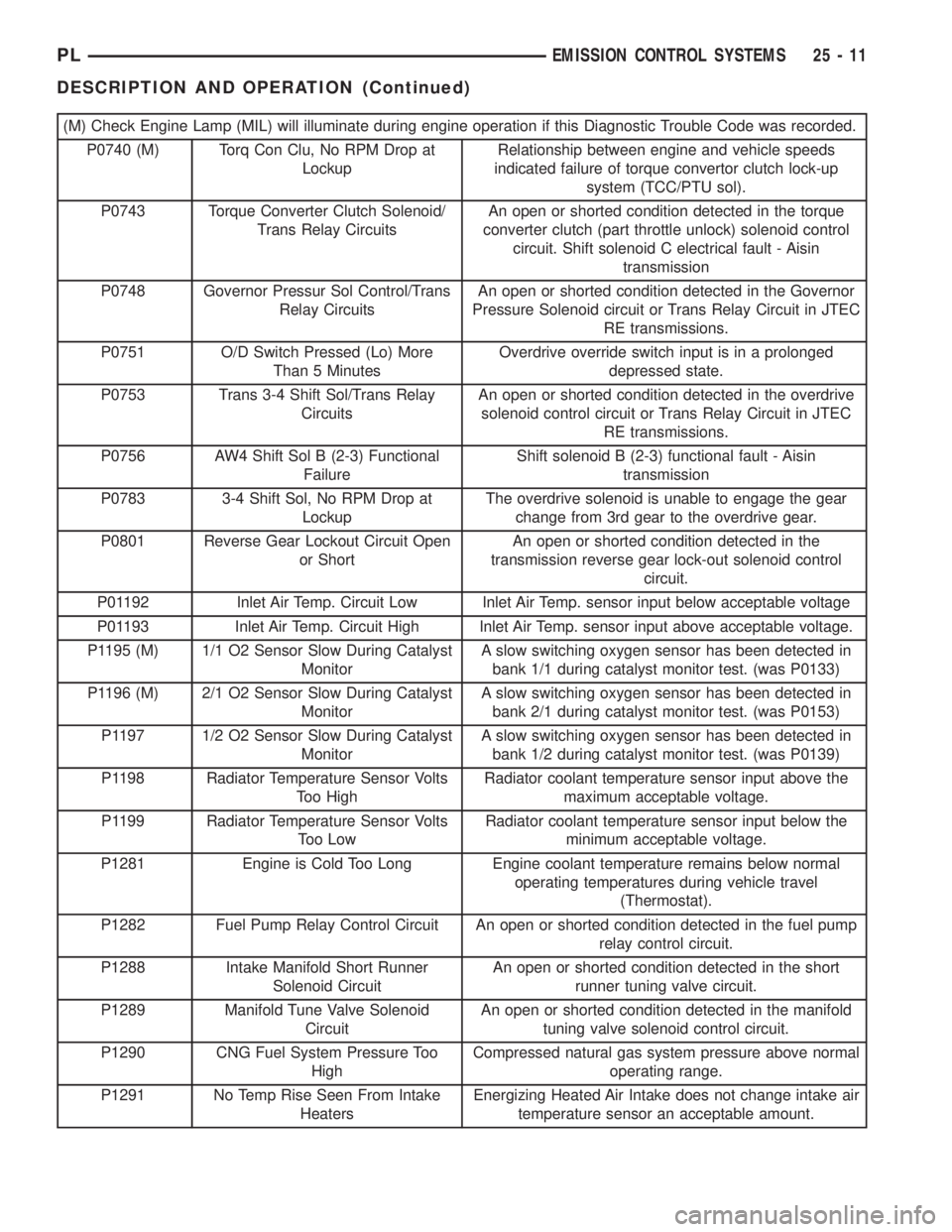

(3) Raise engine and transaxle with screw jack

until through hole in upper mount aligns with hole

in mount bracket. Install mount bolt and tighten to

108 N´m (80 ft. lbs.) torque (Fig. 53).

(4) Remove screwjack.

(5) Install converter-to-drive plate bolts and torque

to 88 N´m (65 ft. lbs.) torque.

(6) Install starter motor and tighten bolts to 54

N´m (40 ft. lbs.) torque. Make sure to fasten ground

cable to upper starter bolt as shown in (Fig. 52).

(7) Connect starter electrical harness and tighten

positive cable nut to 10 N´m (90 in. lbs.) torque.

(8) Install bellhousing dust cover (Fig. 51).

(9) Install left engine-to-transaxle bending brace

(Fig. 51).

(10) Install structural collar (Fig. 51) as follows:

(a) Position collar and install all bolts finger

tight.

(b) Tighten the collar-to-oil pan bolts to 3 N´m

(30 in. lbs.) torque.

Fig. 54 Transaxle Removal/Installation

1 ± CLIP

2 ± BOLT (3)3 ± TRANSAXLE

4 ± CONVERTER BOLT (4)

Fig. 55 Transaxle Upper Mount and Bracket

1 ± MOUNT

2 ± TRANSAXLE

PLTRANSAXLE 21 - 87

REMOVAL AND INSTALLATION (Continued)

Page 1098 of 1285

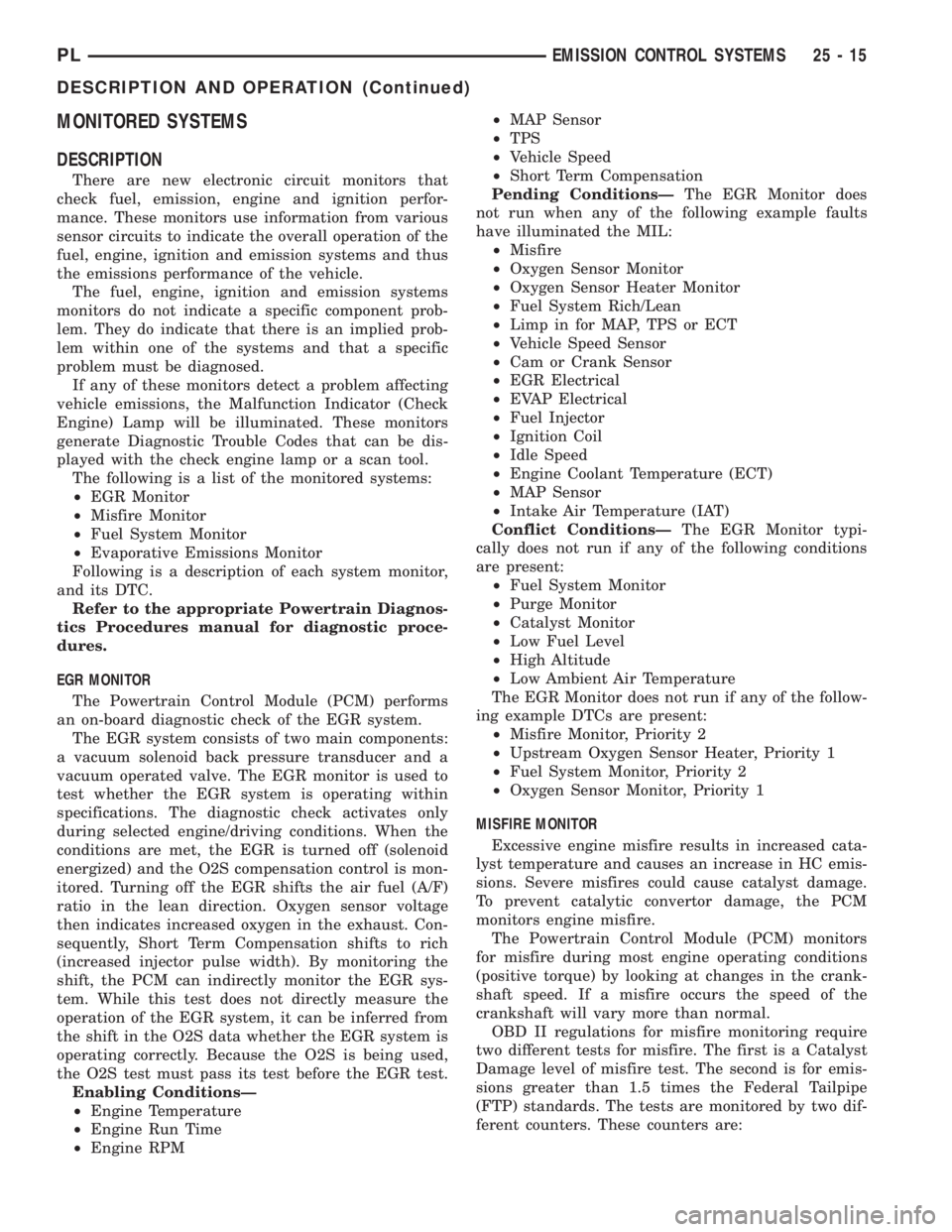

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

P0740 (M) Torq Con Clu, No RPM Drop at

LockupRelationship between engine and vehicle speeds

indicated failure of torque convertor clutch lock-up

system (TCC/PTU sol).

P0743 Torque Converter Clutch Solenoid/

Trans Relay CircuitsAn open or shorted condition detected in the torque

converter clutch (part throttle unlock) solenoid control

circuit. Shift solenoid C electrical fault - Aisin

transmission

P0748 Governor Pressur Sol Control/Trans

Relay CircuitsAn open or shorted condition detected in the Governor

Pressure Solenoid circuit or Trans Relay Circuit in JTEC

RE transmissions.

P0751 O/D Switch Pressed (Lo) More

Than 5 MinutesOverdrive override switch input is in a prolonged

depressed state.

P0753 Trans 3-4 Shift Sol/Trans Relay

CircuitsAn open or shorted condition detected in the overdrive

solenoid control circuit or Trans Relay Circuit in JTEC

RE transmissions.

P0756 AW4 Shift Sol B (2-3) Functional

FailureShift solenoid B (2-3) functional fault - Aisin

transmission

P0783 3-4 Shift Sol, No RPM Drop at

LockupThe overdrive solenoid is unable to engage the gear

change from 3rd gear to the overdrive gear.

P0801 Reverse Gear Lockout Circuit Open

or ShortAn open or shorted condition detected in the

transmission reverse gear lock-out solenoid control

circuit.

P01192 Inlet Air Temp. Circuit Low Inlet Air Temp. sensor input below acceptable voltage

P01193 Inlet Air Temp. Circuit High Inlet Air Temp. sensor input above acceptable voltage.

P1195 (M) 1/1 O2 Sensor Slow During Catalyst

MonitorA slow switching oxygen sensor has been detected in

bank 1/1 during catalyst monitor test. (was P0133)

P1196 (M) 2/1 O2 Sensor Slow During Catalyst

MonitorA slow switching oxygen sensor has been detected in

bank 2/1 during catalyst monitor test. (was P0153)

P1197 1/2 O2 Sensor Slow During Catalyst

MonitorA slow switching oxygen sensor has been detected in

bank 1/2 during catalyst monitor test. (was P0139)

P1198 Radiator Temperature Sensor Volts

Too HighRadiator coolant temperature sensor input above the

maximum acceptable voltage.

P1199 Radiator Temperature Sensor Volts

Too LowRadiator coolant temperature sensor input below the

minimum acceptable voltage.

P1281 Engine is Cold Too Long Engine coolant temperature remains below normal

operating temperatures during vehicle travel

(Thermostat).

P1282 Fuel Pump Relay Control Circuit An open or shorted condition detected in the fuel pump

relay control circuit.

P1288 Intake Manifold Short Runner

Solenoid CircuitAn open or shorted condition detected in the short

runner tuning valve circuit.

P1289 Manifold Tune Valve Solenoid

CircuitAn open or shorted condition detected in the manifold

tuning valve solenoid control circuit.

P1290 CNG Fuel System Pressure Too

HighCompressed natural gas system pressure above normal

operating range.

P1291 No Temp Rise Seen From Intake

HeatersEnergizing Heated Air Intake does not change intake air

temperature sensor an acceptable amount.

PLEMISSION CONTROL SYSTEMS 25 - 11

DESCRIPTION AND OPERATION (Continued)

Page 1102 of 1285

MONITORED SYSTEMS

DESCRIPTION

There are new electronic circuit monitors that

check fuel, emission, engine and ignition perfor-

mance. These monitors use information from various

sensor circuits to indicate the overall operation of the

fuel, engine, ignition and emission systems and thus

the emissions performance of the vehicle.

The fuel, engine, ignition and emission systems

monitors do not indicate a specific component prob-

lem. They do indicate that there is an implied prob-

lem within one of the systems and that a specific

problem must be diagnosed.

If any of these monitors detect a problem affecting

vehicle emissions, the Malfunction Indicator (Check

Engine) Lamp will be illuminated. These monitors

generate Diagnostic Trouble Codes that can be dis-

played with the check engine lamp or a scan tool.

The following is a list of the monitored systems:

²EGR Monitor

²Misfire Monitor

²Fuel System Monitor

²Evaporative Emissions Monitor

Following is a description of each system monitor,

and its DTC.

Refer to the appropriate Powertrain Diagnos-

tics Procedures manual for diagnostic proce-

dures.

EGR MONITOR

The Powertrain Control Module (PCM) performs

an on-board diagnostic check of the EGR system.

The EGR system consists of two main components:

a vacuum solenoid back pressure transducer and a

vacuum operated valve. The EGR monitor is used to

test whether the EGR system is operating within

specifications. The diagnostic check activates only

during selected engine/driving conditions. When the

conditions are met, the EGR is turned off (solenoid

energized) and the O2S compensation control is mon-

itored. Turning off the EGR shifts the air fuel (A/F)

ratio in the lean direction. Oxygen sensor voltage

then indicates increased oxygen in the exhaust. Con-

sequently, Short Term Compensation shifts to rich

(increased injector pulse width). By monitoring the

shift, the PCM can indirectly monitor the EGR sys-

tem. While this test does not directly measure the

operation of the EGR system, it can be inferred from

the shift in the O2S data whether the EGR system is

operating correctly. Because the O2S is being used,

the O2S test must pass its test before the EGR test.

Enabling ConditionsÐ

²Engine Temperature

²Engine Run Time

²Engine RPM²MAP Sensor

²TPS

²Vehicle Speed

²Short Term Compensation

Pending ConditionsÐThe EGR Monitor does

not run when any of the following example faults

have illuminated the MIL:

²Misfire

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Fuel System Rich/Lean

²Limp in for MAP, TPS or ECT

²Vehicle Speed Sensor

²Cam or Crank Sensor

²EGR Electrical

²EVAP Electrical

²Fuel Injector

²Ignition Coil

²Idle Speed

²Engine Coolant Temperature (ECT)

²MAP Sensor

²Intake Air Temperature (IAT)

Conflict ConditionsÐThe EGR Monitor typi-

cally does not run if any of the following conditions

are present:

²Fuel System Monitor

²Purge Monitor

²Catalyst Monitor

²Low Fuel Level

²High Altitude

²Low Ambient Air Temperature

The EGR Monitor does not run if any of the follow-

ing example DTCs are present:

²Misfire Monitor, Priority 2

²Upstream Oxygen Sensor Heater, Priority 1

²Fuel System Monitor, Priority 2

²Oxygen Sensor Monitor, Priority 1

MISFIRE MONITOR

Excessive engine misfire results in increased cata-

lyst temperature and causes an increase in HC emis-

sions. Severe misfires could cause catalyst damage.

To prevent catalytic convertor damage, the PCM

monitors engine misfire.

The Powertrain Control Module (PCM) monitors

for misfire during most engine operating conditions

(positive torque) by looking at changes in the crank-

shaft speed. If a misfire occurs the speed of the

crankshaft will vary more than normal.

OBD II regulations for misfire monitoring require

two different tests for misfire. The first is a Catalyst

Damage level of misfire test. The second is for emis-

sions greater than 1.5 times the Federal Tailpipe

(FTP) standards. The tests are monitored by two dif-

ferent counters. These counters are:

PLEMISSION CONTROL SYSTEMS 25 - 15

DESCRIPTION AND OPERATION (Continued)

Page 1103 of 1285

²200 revolution increments for immediate cata-

lyst damage

²1000 revolution increments for emissions viola-

tion and Inspection/Maintenance (I/M) test failure

NOTE: The percent of misfire for malfunction crite-

ria varies due to RPM and load. As the engine

speed increases or load decreases, the effects of a

misfire diminishes due to crankshaft momentum.

Failure percentages also vary from engine to

engine.

Monitor OperationÐThe PCM utilizes the

Crankshaft Speed Fluctuation method to monitor for

misfire. The misfire monitor utilizes a crankshaft

position sensor to determine engine RPM. The sensor

can detect slight variations in engine speed due to

misfire. Misfire is continuously monitored once the

enabling conditions are met.

Once enabling conditions are met, the PCM counts

the number of misfires in every 200 revolutions of

the crankshaft. If, duringfive200 counters, the mis-

fire percentage exceeds a predetermined value, a

maturing code is set and a Freeze Frame is entered.

Freeze Frame data is recorded during the last 200

revolutions of the 1000 revolution period. A failure on

the second consecutive trip matures the code and a

DTC is set.

If misfire continues during the initial trip, the MIL

is not illuminated. However, the MIL flashes when

the misfire percentage exceeds the malfunction per-

centage, in any 200 revolution period, that would

cause permanent catalyst damage. This is a one trip

monitor. If misfire reaches a point in which catalyst

damage is likely to occur, the MIL flashes and a DTC

is stored in a Freeze Frame. The engine defaults to

open loop operation to prevent increased fuel flow to

the cylinders. Once misfire is below the predeter-

mined percentage, the MIL stops flashing but

remains illuminated.

The 1000 revolution counters are two trip moni-

tors. As with the fuel system monitor, Freeze Frame

data is from the original fault, and MIL extinguish-

ing requires the monitor to pass under similar condi-

tions.

The Adaptive NumeratorÐThe Misfire Monitor

takes into account component wear, sensor fatigue

and machining tolerances. The PCM compares the

crankshaft in the vehicle to data on an ideal crank

and uses this as a basis to determine variance. To do

this, the crankshaft sensor monitors the reference

notches in the crank. The PCM uses the first signal

set as a point of reference. It then measures where

the second set of signals is, compared to where engi-

neering data has determined it should be. This vari-

ance is the Adaptive Numerator. The monitor will not

run if the numerator is not set.If the Adaptive Numerator is equal to the default

value, the adaptive Numerator has not been learned

and the Misfire Monitor does not run. If the Adaptive

Numerator exceeds its limits, the PCM sets a DTC

for Adaptive Numerator and illuminates the MIL.

RPM ErrorÐThe PCM also checks the machining

tolerances for each group of slots. By monitoring the

speed of the crank from the first slot to the last slot

in a group, the PCM can calculate engine RPM. The

variance between groups of slots is know as the RPM

error. In order for the PCM to run the Misfire Mon-

itor, RPM error must be less than approximately 5%.

Enabling ConditionsÐThe following conditions

must be met before the PCM runs the Misfire Moni-

tor:

²RPM

²Engine Coolant Temperature (ECT)

²Barometric Pressure (MAP)

²Fuel level

²Ambient air Temperature

Pending ConditionsÐThe Misfire Monitor does

not run when the MIL is illuminated for any of the

following:

²Limp in mode for

Ð MAP

Ð TPS

Ð Crankshaft Sensor

Ð Engine Coolant Temperature Sensor

²Speed Sensor DTC

²EGR Electrical

²EVAP Electrical

²Idle Speed Faults

²Intake Air Temperature

²Oxygen Sensor Monitor

²Oxygen Sensor Electrical

Conflict ConditionsÐIf any of the following con-

ditions conflict with the Misfire Monitor, the monitor

will not run:

²Low fuel level

²MAP voltage rapidly changing

²Severe engine decel

²TPS toggling OPEN/CLOSED

²Engine RPM too low (RPM levels by vehicle)

²Engine RPM too high (RPM levels vary by vehi-

cle)

²Full Lean or Decel Fuel Shut-off

²Cold start

FUEL SYSTEM MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide. The catalyst works best

when the air fuel (A/F) ratio is at or near the opti-

mum of 14.7 to 1.

25 - 16 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1104 of 1285

The PCM is programmed to maintain the optimum

air/fuel ratio of 14.7 to 1. This is done by making

short term corrections in the fuel injector pulse width

based on the O2S output. The programmed memory

acts as a self calibration tool that the engine control-

ler uses to compensate for variations in engine spec-

ifications, sensor tolerances and engine fatigue over

the life span of the engine. By monitoring the actual

air-fuel ratio with the O2S (short term) and multiply-

ing that with the program long-term (adaptive) mem-

ory and comparing that to the limit, it can be

determined whether it will pass an emissions test. If

a malfunction occurs such that the PCM cannot

maintain the optimum A/F ratio, then the MIL will

be illuminated.

Monitor OperationÐFuel systems monitors do

not have a pre-test because they are continuously

running monitors. Therefore, the PCM constantly

monitors Short Term Compensation and Long Term

Adaptive memory.

Lean: If at anytime during a lean engine operation,

short term compensation multiplied by long term

adaptive exceeds a certain percentage for an

extended period, the PCM sets a Fuel System Lean

Fault for that trip and a Freeze Frame is entered.

Rich: If at anytime during a rich operation, Short

Term Compensation multiplied by Long Term Adap-

tive is less than a predetermined value, the PCM

checks the Purge Free Cells.

Purge Free Cells are values placed in Adaptive

Memory cells when the EVAP Purge Solenoid is OFF.

Two, three or four Purge Free cells are used. One cor-

responds to an Adaptive Memory cell at idle, the

other to a cell that is off-idle. For example, if a Purge

Free cell is labeled PFC1, it would hold the value for

Adaptive Memory cell C1 under non-purge condi-

tions.

If all Purge Free Cells are less than a certain per-

centage, and the Adaptive Memory factor is less than

a certain percentage, the PCM sets a Fuel System

Rich fault for that trip and a Freeze Frame is

entered.

The Fuel Monitor is a two trip monitor. The PCM

records engine data in Freeze Frame upon setting of

the first fault, or maturing code. When the fuel mon-

itor fails on a second consecutive trip, the code is

matured and the MIL is illuminated. The stored

Freeze Frame data is still from the first fault.

In order for the PCM to extinguish the MIL, the

Fuel Monitor must pass in a Similar Condition Win-

dow. The similar conditions relate to RPM and load.

The engine must be within a predetermined percent-

age of both RPM and load when the monitor runs to

count a good trip. As with all DTCs, three good tripsare required to extinguish the MIL and 40 warm up

cycles are required to erase the DTC. If the engine

does not run in a Similar Conditions Window, the

Task Manager extinguishes the MIL after 80 good

trips.

Enabling ConditionsÐThe following conditions

must be met to operate the fuel control monitor:

²PCM not in fuel crank mode (engine running)

²PCM in Closed Loop fuel control

²Fuel system updating Long Term Adaptive

²Fuel level above 15% of capacity

²Fuel level below 85% of capacity

Pending ConditionsÐThe Fuel Control Monitor

does not operate if the MIL is illuminated for any of

the following:

²Misfire Monitor

²Upstream O2S

²EVAP Purge Solenoid Electrical PCM Self Test

Fault

²Camshaft or Crankshaft Position Sensor

²Fuel Injectors

²Ignition Coil Primary

²Throttle Position (TPS) Sensor

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure (MAP) Sensor

²Idle Air Control (IAC)

²5V Output Too Low

²EGR Monitor

²EGR Solenoid Circuit

²Vehicle Speed Sensor

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Oxygen Sensor Electrical

²Idle Speed Rationality

²Intake Air Temperature

SuspendÐThe Task Manager will suspend

maturing a Fuel System fault if any of the following

are present:

²Oxygen Sensor Response, Priority 1

²O2 Heater, Priority 1

²Misfire Monitor, Priority 2

EVAPORATIVE EMISSIONS MONITOR

LEAK DETECTION PUMP MONITORÐThe

leak detection assembly incorporates two primary

functions: it must detect a leak in the evaporative

system and seal the evaporative system so the leak

detection test can be run.

The primary components within the assembly are:

A three port solenoid that activates both of the func-

tions listed above; a pump which contains a switch,

two check valves and a spring/diaphragm, a canister

vent valve (CVV) seal which contains a spring loaded

vent seal valve.

PLEMISSION CONTROL SYSTEMS 25 - 17

DESCRIPTION AND OPERATION (Continued)

Page 1106 of 1285

when the MIL is illuminated due to any of the fol-

lowing faults:

²Misfire

²Oxygen Sensor Monitor

²Fuel System Rich

²Fuel System Lean

²EGR Monitor

²MAP

²TPS

²ECT

²DCP Solenoid

Conflict Conditions-With or Without LDPÐ

The EVAP Monitor does not run if any of the follow-

ing tests are in progress:

²Catalyst

²EGR

²Fuel System

²Misfire

TRIP DEFINITION

OPERATION

A ªTripº means vehicle operation (following an

engine-off period) of duration and driving mode such

that all components and systems are monitored at

least once by the diagnostic system. The monitors

must successfully pass before the PCM can verify

that a previously malfunctioning component is meet-

ing the normal operating conditions of that compo-

nent. For misfire or fuel system malfunction, the

MIL may be extinguished if the fault does not recur

when monitored during three subsequent sequential

driving cycles in which conditions are similar to

those under which the malfunction was first deter-

mined.

Anytime the MIL is illuminated, a DTC is stored.

The DTC can self erase only when the MIL has been

extinguished. Once the MIL is extinguished, the

PCM must pass the diagnostic test for the most

recent DTC for 40 warm-up cycles (80 warm-up

cycles for the Fuel System Monitor and the Misfire

Monitor). A warm-up cycle can best be described by

the following:

²The engine must be running

²A rise of 40ÉF in engine temperature must occur

from the time when the engine was started

²Engine coolant temperature must reach at least

160ÉF

²A ªdriving cycleº that consists of engine start up

and engine shut off.

Once the above conditions occur, the PCM is con-

sidered to have passed a warm-up cycle. Due to the

conditions required to extinguish the MIL and erase

the DTC, it is most important that after a repair has

been made, all DTC's be erased and the repair veri-

fied.

MONITORED COMPONENT

DESCRIPTION

There are several components that will affect vehi-

cle emissions if they malfunction. If one of these com-

ponents malfunctions the Malfunction Indicator

Lamp (Check Engine) will illuminate.

Some of the component monitors are checking for

proper operation of the part. Electrically operated

components now have input (rationality) and output

(functionality) checks. Previously, a component like

the Throttle Position sensor (TPS) was checked by

the PCM for an open or shorted circuit. If one of

these conditions occurred, a DTC was set. Now there

is a check to ensure that the component is working.

This is done by watching for a TPS indication of a

greater or lesser throttle opening than MAP and

engine rpm indicate. In the case of the TPS, if engine

vacuum is high and engine rpm is 1600 or greater

and the TPS indicates a large throttle opening, a

DTC will be set. The same applies to low vacuum

and 1600 rpm.

Any component that has an associated limp in will

set a fault after 1 trip with the malfunction present.

Refer to the Diagnostic Trouble Codes Description

Charts in this section and the appropriate Power-

train Diagnostic Procedure Manual for diagnostic

procedures.

The following is a list of the monitored compo-

nents:

²Comprehensive Components

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Catalyst Monitor

COMPREHENSIVE COMPONENTS

Along with the major monitors, OBD II requires

that the diagnostic system monitor any component

that could affect emissions levels. In many cases,

these components were being tested under OBD I.

The OBD I requirements focused mainly on testing

emissions-related components for electrical opens and

shorts.

However, OBD II also requires that inputs from

powertrain components to the PCM be tested for

rationality, and that outputs to powertrain compo-

nents from the PCM be tested forfunctionality.

Methods for monitoring the various Comprehensive

Component monitoring include:

(1) Circuit Continuity

²Open

²Shorted high

²Shorted to ground

(2) Rationality or Proper Functioning

²Inputs tested for rationality

²Outputs tested for functionality

PLEMISSION CONTROL SYSTEMS 25 - 19

DESCRIPTION AND OPERATION (Continued)