electrical DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1107 of 1285

NOTE: Comprehensive component monitors are

continuous. Therefore, enabling conditions do not

apply.

Input RationalityÐWhile input signals to the

PCM are constantly being monitored for electrical

opens and shorts, they are also tested for rationality.

This means that the input signal is compared against

other inputs and information to see if it makes sense

under the current conditions.

PCM sensor inputs that are checked for rationality

include:

²Manifold Absolute Pressure (MAP) Sensor

²Oxygen Sensor (O2S)

²Engine Coolant Temperature (ECT) Sensor

²Camshaft Position (CMP) Sensor

²Vehicle Speed Sensor

²Crankshaft Position (CKP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Ambient/Battery Temperature Sensors

²Power Steering Switch

²Oxygen Sensor Heater

²Engine Controller

²Brake Switch

²Leak Detection Pump Switch

²P/N Switch

²Trans Controls

Output FunctionalityÐPCM outputs are tested

for functionality in addition to testing for opens and

shorts. When the PCM provides a voltage to an out-

put component, it can verify that the command was

carried out by monitoring specific input signals for

expected changes. For example, when the PCM com-

mands the Idle Air Control (IAC) Motor to a specific

position under certain operating conditions, it expects

to see a specific (target) idle speed (RPM). If it does

not, it stores a DTC.

PCM outputs monitored for functionality include:

²Fuel Injectors

²Ignition Coils

²Torque Converter Clutch Solenoid

²Idle Air Control

²Purge Solenoid

²EGR Solenoid

²LDP Solenoid

²Radiator Fan Control

²Trans Controls

OXYGEN SENSOR (O2S) MONITOR

DESCRIPTIONÐEffective control of exhaust

emissions is achieved by an oxygen feedback system.

The most important element of the feedback system

is the O2S. The O2S is located in the exhaust path.

Once it reaches operating temperature 300É to 350ÉC

(572É to 662ÉF), the sensor generates a voltage that

is inversely proportional to the amount of oxygen inthe exhaust. When there is a large amount of oxygen

in the exhaust caused by a lean condition, the sensor

produces a low voltage, below 450 mV. When the oxy-

gen content is lower, caused by a rich condition, the

sensor produces a higher voltage, above 450mV.

The information obtained by the sensor is used to

calculate the fuel injector pulse width. This main-

tains a 14.7 to 1 air fuel (A/F) ratio. At this mixture

ratio, the catalyst works best to remove hydrocarbons

(HC), carbon monoxide (CO) and nitrous oxide (NOx)

from the exhaust.

The O2S is also the main sensing element for the

EGR, Catalyst and Fuel Monitors.

The O2S may fail in any or all of the following

manners:

²Slow response rate (Big Slope)

²Reduced output voltage (Half Cycle)

²Heater Performance

Slow Response Rate (Big Slope)ÐResponse

rate is the time required for the sensor to switch

from lean to rich signal output once it is exposed to a

richer than optimum A/F mixture or vice versa. As

the PCM adjusts the air/fuel ratio, the sensor must

be able to rapidly detect the change. As the sensor

ages, it could take longer to detect the changes in the

oxygen content of the exhaust gas. The rate of

change that an oxygen sensor experiences is called

'Big Slope'. The PCM checks the oxygen sensor volt-

age in increments of a few milliseconds.

Reduced Output Voltage (Half Cycle)ÐThe

output voltage of the O2S ranges from 0 to 1 volt. A

good sensor can easily generate any output voltage in

this range as it is exposed to different concentrations

of oxygen. To detect a shift in the A/F mixture (lean

or rich), the output voltage has to change beyond a

threshold value. A malfunctioning sensor could have

difficulty changing beyond the threshold value. Each

time the voltage signal surpasses the threshold, a

counter is incremented by one. This is called the Half

Cycle Counter.

Heater PerformanceÐThe heater is tested by a

separate monitor. Refer to the Oxygen Sensor Heater

Monitor.

OPERATIONÐAs the Oxygen Sensor signal

switches, the PCM monitors the half cycle and big

slope signals from the oxygen sensor. If during the

test neither counter reaches a predetermined value, a

malfunction is entered and a Freeze Frame is stored.

Only one counter reaching its predetermined value is

needed for the monitor to pass.

The Oxygen Sensor Monitor is a two trip monitor

that is tested only once per trip. When the Oxygen

Sensor fails the test in two consecutive trips, the

MIL is illuminated and a DTC is set. The MIL is

extinguished when the Oxygen Sensor monitor

passes in three consecutive trips. The DTC is erased

25 - 20 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1108 of 1285

from memory after 40 consecutive warm-up cycles

without test failure.

Enabling ConditionsÐThe following conditions

must typically be met for the PCM to run the oxygen

sensor monitor:

²Battery voltage

²Engine temperature

²Engine run time

²Engine run time at a predetermined speed

²Engine run time at a predetermined speed and

throttle opening

²Transmission in gear (automatic only)

²Fuel system in Closed Loop

²Long Term Adaptive (within parameters)

²Power Steering Switch in low PSI (no load)

²Engine at idle

²Fuel level above 15%

²Ambient air temperature

²Barometric pressure

²Engine RPM within acceptable range of desired

idle

²Closed throttle speed

Pending ConditionsÐThe Task Manager typi-

cally does not run the Oxygen Sensor Monitor if over-

lapping monitors are running or the MIL is

illuminated for any of the following:

²Misfire Monitor

²Front Oxygen Sensor and Heater Monitor

²MAP Sensor

²Vehicle Speed Sensor

²Engine Coolant Temperature Sensor

²Throttle Position Sensor

²Engine Controller Self Test Faults

²Cam or Crank Sensor

²Injector and Coil

²Idle Air Control Motor

²EVAP Electrical

²EGR Solenoid Electrical

²Intake Air Temperature

²5 Volt Feed

ConflictÐThe Task Manager does not run the

Oxygen Sensor Monitor if any of the following condi-

tions are present:

²A/C ON (A/C clutch cycling temporarily sus-

pends monitor)

²Purge flow in progress

SuspendÐThe Task Manager suspends maturing

a fault for the Oxygen Sensor Monitor if an of the fol-

lowing are present:

²Oxygen Sensor Heater Monitor, Priority 1

²Misfire Monitor, Priority 2

OXYGEN SENSOR HEATER MONITOR

DESCRIPTIONÐIf there is an oxygen sensor

(O2S) DTC as well as a O2S heater DTC, the O2S

fault MUST be repaired first. After the O2S fault isrepaired, verify that the heater circuit is operating

correctly.

The voltage readings taken from the O2S are very

temperature sensitive. The readings are not accurate

below 300ÉC. Heating of the O2S is done to allow the

engine controller to shift to closed loop control as

soon as possible. The heating element used to heat

the O2S must be tested to ensure that it is heating

the sensor properly.

The heater element itself is not tested. The sensor

output is used to test the heater by isolating the

effect of the heater element on the O2S output volt-

age from the other effects. The resistance is normally

between 100 ohms and 4.5 megaohms. When oxygen

sensor temperature increases, the resistance in the

internal circuit decreases. The PCM sends a 5 volts

biased signal through the oxygen sensors to ground

this monitoring circuit. As the temperature increases,

resistance decreases and the PCM detects a lower

voltage at the reference signal. Inversely, as the tem-

perature decreases, the resistance increases and the

PCM detects a higher voltage at the reference signal.

an The O2S circuit is monitored for a drop in voltage.

OPERATIONÐThe Oxygen Sensor Heater Moni-

tor begins after the ignition has been turned OFF

and the O2 sensors have cooled. The PCM sends a 5

volt bias to the oxygen sensor every 1.6 seconds. The

PCM keeps it biased for 35 ms each time. As the sen-

sor cools down, the resistance increases and the PCM

reads the increase in voltage. Once voltage has

increased to a predetermined amount, higher than

when the test started, the oxygen sensor is cool

enough to test heater operation.

When the oxygen sensor is cool enough, the PCM

energizes the ASD relay. Voltage to the O2 sensor

begins to increase the temperature. As the sensor

temperature increases, the internal resistance

decreases. The PCM continues biasing the 5 volt sig-

nal to the sensor. Each time the signal is biased, the

PCM reads a voltage decrease. When the PCM

detects a voltage decrease of a predetermined value

for several biased pulses, the test passes.

The heater elements are tested each time the

engine is turned OFF if all the enabling conditions

are met. If the monitor fails, the PCM stores a

maturing fault and a Freeze Frame is entered. If two

consecutive tests fail, a DTC is stored. Because the

ignition is OFF, the MIL is illuminated at the begin-

ning of the next key cycle.

Enabling ConditionsÐThe following conditions

must be met for the PCM to run the oxygen sensor

heater test:

²Engine run time of at least 5.1 minutes

²Key OFF power down

²Battery voltage of at least 10 volts

²Sufficient Oxygen Sensor cool down

PLEMISSION CONTROL SYSTEMS 25 - 21

DESCRIPTION AND OPERATION (Continued)

Page 1110 of 1285

Pending ConditionsÐ

²Misfire DTC

²Front Oxygen Sensor Response

²Front Oxygen Sensor Heater Monitor

²Front Oxygen Sensor Electrical

²Rear Oxygen Sensor Rationality (middle check)

²Rear Oxygen Sensor Heater Monitor

²Rear Oxygen Sensor Electrical

²Fuel System Monitor

²All TPS faults

²All MAP faults

²All ECT sensor faults

²Purge flow solenoid functionality

²Purge flow solenoid electrical

²All PCM self test faults

²All CMP and CKP sensor faults

²All injector and ignition electrical faults

²Idle Air Control (IAC) motor functionality

²Vehicle Speed Sensor

²Brake switch

²Intake air temperature

ConflictÐThe catalyst monitor does not run if

any of the following are conditions are present:

²EGR Monitor in progress

²Fuel system rich intrusive test in progress

²EVAP Monitor in progress

²Time since start is less than 60 seconds

²Low fuel level

²Low ambient air temperature

SuspendÐThe Task Manager does not mature a

catalyst fault if any of the following are present:

²Oxygen Sensor Monitor, Priority 1

²Upstream Oxygen Sensor Heater, Priority 1

²EGR Monitor, Priority 1

²EVAP Monitor, Priority 1

²Fuel System Monitor, Priority 2

²Misfire Monitor, Priority 2

NON-MONITORED CIRCUITS

OPERATION

The PCM does not monitor all circuits, systems

and conditions that could have malfunctions causing

driveability problems. However, problems with these

systems may cause the PCM to store diagnostic trou-

ble codes for other systems or components. For exam-

ple, a fuel pressure problem will not register a fault

directly, but could cause a rich/lean condition or mis-

fire. This could cause the PCM to store an oxygen

sensor or misfire diagnostic trouble code.

The major non-monitored circuits are listed below

along with examples of failures modes that do not

directly cause the PCM to set a DTC, but for a sys-

tem that is monitored.FUEL PRESSURE

The fuel pressure regulator controls fuel system

pressure. The PCM cannot detect a clogged fuel

pump inlet filter, clogged in-line fuel filter, or a

pinched fuel supply or return line. However, these

could result in a rich or lean condition causing the

PCM to store an oxygen sensor or fuel system diag-

nostic trouble code.

SECONDARY IGNITION CIRCUIT

The PCM cannot detect an inoperative ignition coil,

fouled or worn spark plugs, ignition cross firing, or

open spark plug cables.

CYLINDER COMPRESSION

The PCM cannot detect uneven, low, or high engine

cylinder compression.

EXHAUST SYSTEM

The PCM cannot detect a plugged, restricted or

leaking exhaust system. It may set a EGR or Fuel

system fault or O2S.

FUEL INJECTOR MECHANICAL MALFUNCTIONS

The PCM cannot determine if a fuel injector is

clogged, the needle is sticking or if the wrong injector

is installed. However, these could result in a rich or

lean condition causing the PCM to store a diagnostic

trouble code for either misfire, an oxygen sensor, or

the fuel system.

EXCESSIVE OIL CONSUMPTION

Although the PCM monitors engine exhaust oxygen

content when the system is in closed loop, it cannot

determine excessive oil consumption.

THROTTLE BODY AIR FLOW

The PCM cannot detect a clogged or restricted air

cleaner inlet or filter element.

VACUUM ASSIST

The PCM cannot detect leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices. However, these could cause the PCM

to store a MAP sensor diagnostic trouble code and

cause a high idle condition.

PCM SYSTEM GROUND

The PCM cannot determine a poor system ground.

However, one or more diagnostic trouble codes may

be generated as a result of this condition. The mod-

ule should be mounted to the body at all times, also

during diagnostic.

PLEMISSION CONTROL SYSTEMS 25 - 23

DESCRIPTION AND OPERATION (Continued)

Page 1117 of 1285

INSTALLATION

(1) Install EVAP canister to Bracket (Fig. 8).

(2) Install 2 nuts to EVAP canister and bracket

and tighten nuts to 6.7 N´m (60 in. lbs.).

(3) Connect hoses.

(4) Install EVAP canister and bracket to vehicle

and tighten nut 22.4 N´m (250 in. lbs.).

(5) Lower vehicle.

(6) Connect negative battery cable.

LEAK DETECTION PUMP

REMOVAL

(1) Raise and support vehicle on a hoist.

(2) Push locking tab on electrical connector to

unlock and remove connector.

(3) loosen the sway bar bracket to remove the

pump bracket.

(4) Remove pump and bracket as an assembly.

(5) Disconnect lines from LDP.

(6) Remove filter.

(7) Remove pump from bracket.

INSTALLATION

(1) Install pump to bracket and tighten bolts to 1.2

N´m (10.6 in. lbs.).

(2) Install filter and tighten to 2.8 N´m (25 in.

lbs.).

(3)Before installing hoses to LDP, make sure

they are not cracked or split. If a hose leaks, it

will cause the Check Engine Lamp to illumi-

nate.Connect lines to the LDP.

NOTE: The LDP bracket must be between the rail

and sway bar bracket.

(4) Install pump and bracket assembly to body and

tighten bolts to 5.0 N´m (45 in. lbs.).

(5) Install sway bar bracket bolt and tighten bolts

to 33.8 N´m (25 ft. lbs.).

(6) Install electrical connector to pump and push

locking tab to lock.

(7) Lower vehicle(8) Use the DRB scan tool, verify proper operation

of LDP.

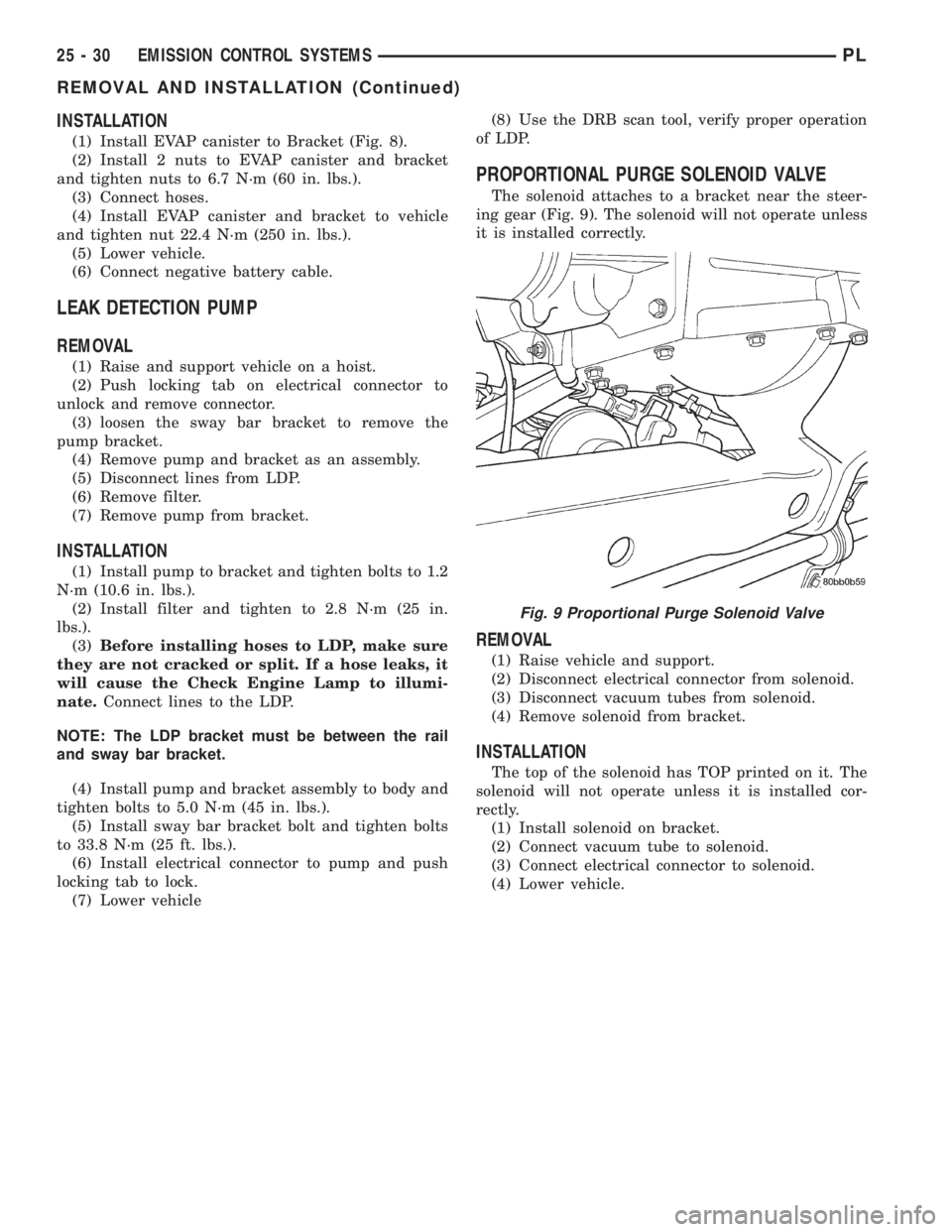

PROPORTIONAL PURGE SOLENOID VALVE

The solenoid attaches to a bracket near the steer-

ing gear (Fig. 9). The solenoid will not operate unless

it is installed correctly.

REMOVAL

(1) Raise vehicle and support.

(2) Disconnect electrical connector from solenoid.

(3) Disconnect vacuum tubes from solenoid.

(4) Remove solenoid from bracket.

INSTALLATION

The top of the solenoid has TOP printed on it. The

solenoid will not operate unless it is installed cor-

rectly.

(1) Install solenoid on bracket.

(2) Connect vacuum tube to solenoid.

(3) Connect electrical connector to solenoid.

(4) Lower vehicle.

Fig. 9 Proportional Purge Solenoid Valve

25 - 30 EMISSION CONTROL SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 1125 of 1285

SEATS

TABLE OF CONTENTS

page page

REMOVAL AND INSTALLATION

FRONT SEAT.............................8

FRONT SEAT BACK........................8

FRONT SEAT BACK COVER.................9FRONT SEAT CUSHION COVER..............9

FRONT SEAT CUSHION....................9

REAR SEAT BACK........................10

REAR SEAT CUSHION.....................11

REMOVAL AND INSTALLATION

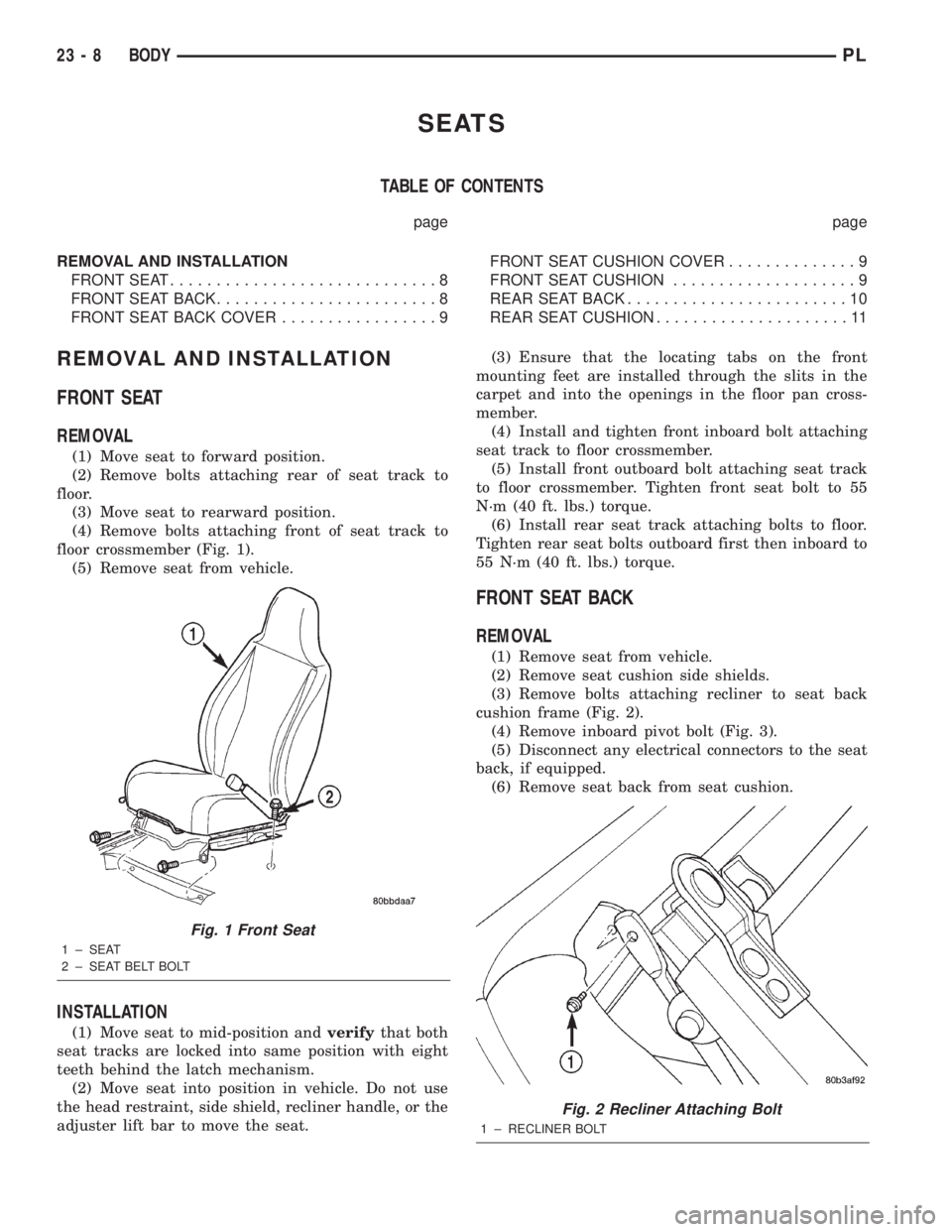

FRONT SEAT

REMOVAL

(1) Move seat to forward position.

(2) Remove bolts attaching rear of seat track to

floor.

(3) Move seat to rearward position.

(4) Remove bolts attaching front of seat track to

floor crossmember (Fig. 1).

(5) Remove seat from vehicle.

INSTALLATION

(1) Move seat to mid-position andverifythat both

seat tracks are locked into same position with eight

teeth behind the latch mechanism.

(2) Move seat into position in vehicle. Do not use

the head restraint, side shield, recliner handle, or the

adjuster lift bar to move the seat.(3) Ensure that the locating tabs on the front

mounting feet are installed through the slits in the

carpet and into the openings in the floor pan cross-

member.

(4) Install and tighten front inboard bolt attaching

seat track to floor crossmember.

(5) Install front outboard bolt attaching seat track

to floor crossmember. Tighten front seat bolt to 55

N´m (40 ft. lbs.) torque.

(6) Install rear seat track attaching bolts to floor.

Tighten rear seat bolts outboard first then inboard to

55 N´m (40 ft. lbs.) torque.

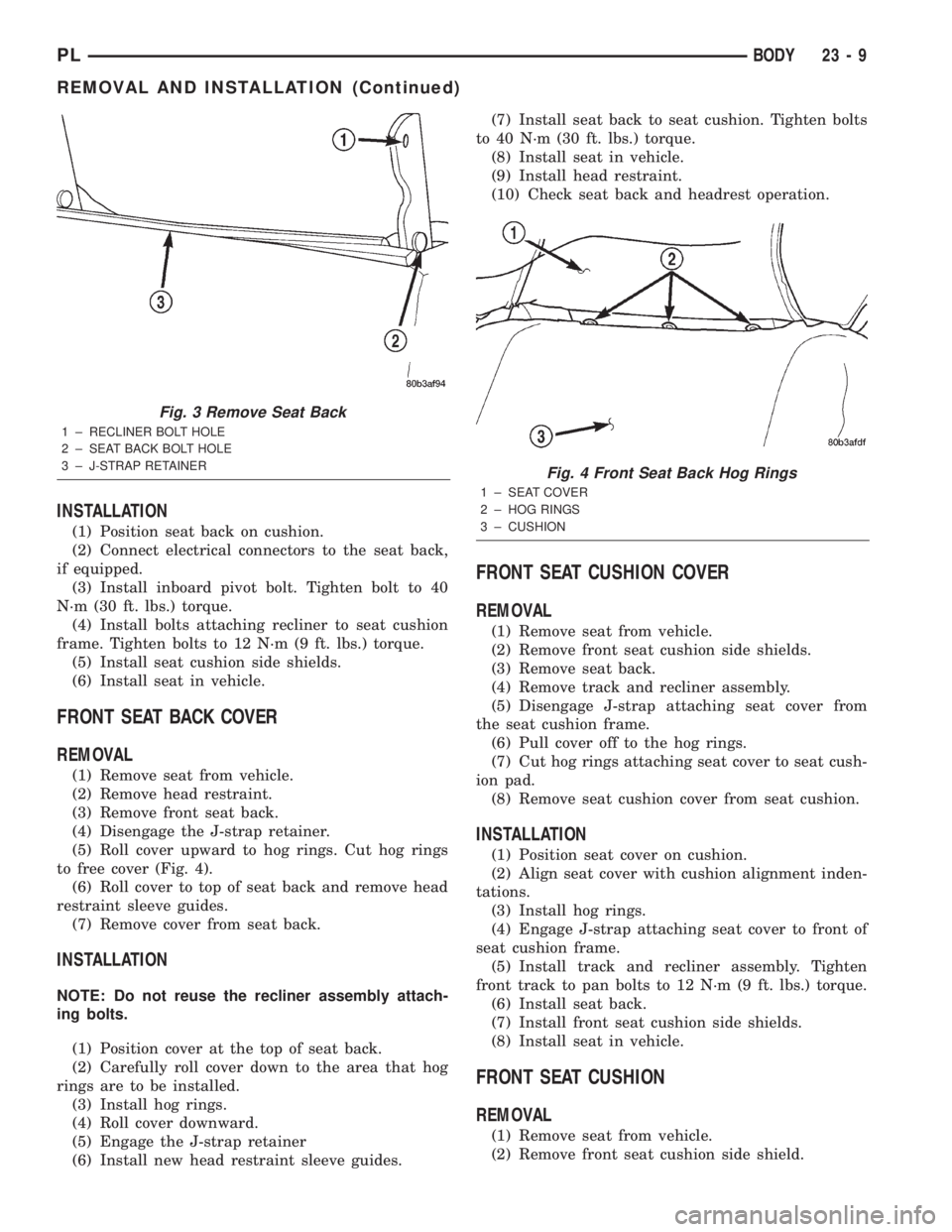

FRONT SEAT BACK

REMOVAL

(1) Remove seat from vehicle.

(2) Remove seat cushion side shields.

(3) Remove bolts attaching recliner to seat back

cushion frame (Fig. 2).

(4) Remove inboard pivot bolt (Fig. 3).

(5) Disconnect any electrical connectors to the seat

back, if equipped.

(6) Remove seat back from seat cushion.

Fig. 1 Front Seat

1 ± SEAT

2 ± SEAT BELT BOLT

Fig. 2 Recliner Attaching Bolt

1 ± RECLINER BOLT

23 - 8 BODYPL

Page 1126 of 1285

INSTALLATION

(1) Position seat back on cushion.

(2) Connect electrical connectors to the seat back,

if equipped.

(3) Install inboard pivot bolt. Tighten bolt to 40

N´m (30 ft. lbs.) torque.

(4) Install bolts attaching recliner to seat cushion

frame. Tighten bolts to 12 N´m (9 ft. lbs.) torque.

(5) Install seat cushion side shields.

(6) Install seat in vehicle.

FRONT SEAT BACK COVER

REMOVAL

(1) Remove seat from vehicle.

(2) Remove head restraint.

(3) Remove front seat back.

(4) Disengage the J-strap retainer.

(5) Roll cover upward to hog rings. Cut hog rings

to free cover (Fig. 4).

(6) Roll cover to top of seat back and remove head

restraint sleeve guides.

(7) Remove cover from seat back.

INSTALLATION

NOTE: Do not reuse the recliner assembly attach-

ing bolts.

(1) Position cover at the top of seat back.

(2) Carefully roll cover down to the area that hog

rings are to be installed.

(3) Install hog rings.

(4) Roll cover downward.

(5) Engage the J-strap retainer

(6) Install new head restraint sleeve guides.(7) Install seat back to seat cushion. Tighten bolts

to 40 N´m (30 ft. lbs.) torque.

(8) Install seat in vehicle.

(9) Install head restraint.

(10) Check seat back and headrest operation.

FRONT SEAT CUSHION COVER

REMOVAL

(1) Remove seat from vehicle.

(2) Remove front seat cushion side shields.

(3) Remove seat back.

(4) Remove track and recliner assembly.

(5) Disengage J-strap attaching seat cover from

the seat cushion frame.

(6) Pull cover off to the hog rings.

(7) Cut hog rings attaching seat cover to seat cush-

ion pad.

(8) Remove seat cushion cover from seat cushion.

INSTALLATION

(1) Position seat cover on cushion.

(2) Align seat cover with cushion alignment inden-

tations.

(3) Install hog rings.

(4) Engage J-strap attaching seat cover to front of

seat cushion frame.

(5) Install track and recliner assembly. Tighten

front track to pan bolts to 12 N´m (9 ft. lbs.) torque.

(6) Install seat back.

(7) Install front seat cushion side shields.

(8) Install seat in vehicle.

FRONT SEAT CUSHION

REMOVAL

(1) Remove seat from vehicle.

(2) Remove front seat cushion side shield.

Fig. 3 Remove Seat Back

1 ± RECLINER BOLT HOLE

2 ± SEAT BACK BOLT HOLE

3 ± J-STRAP RETAINER

Fig. 4 Front Seat Back Hog Rings

1 ± SEAT COVER

2 ± HOG RINGS

3 ± CUSHION

PLBODY 23 - 9

REMOVAL AND INSTALLATION (Continued)

Page 1137 of 1285

SAFETY PRECAUTION AND WARNINGS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING RTM AND SMC COMPONENTS.

PERSONAL INJURE CAN RESULT.

USE AN OSHA APPROVED BREATHING DEVICE

WHEN MIXING EPOXY, GRINDING RTM AND SMC,

AND SPRAYING PAINT OR SOLVENTS IN A CON-

FINED AREA. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH

EPOXY RESIN, PETROLEUM, OR ALCOHOL BASED

SOLVENTS. PERSONAL INJURY CAN RESULT.

DO NOT VENTURE UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

²When holes must be drilled or cut in body pan-

els, verify locations of internal body components and

electrical wiring. Damage to vehicle can result.

²Do not use abrasive chemicals or compounds on

undamaged painted surfaces around repair areas.

Damage to finish can result.

PANEL SECTIONING

If it is required to section a large panel for an SMC

or RTM repair, it will be necessary to reinforce the

panel with epoxy structural adhesive (rigid repair

adhesive) (Fig. 2). To bond two plastic panels

together, a reinforcement must overlap both panels.

The panels must be ªV'dº at a 20 degree angle. The

area to be reinforced should be washed, then sanded.

Be sure to wipe off any excess soap and water when

finished. Lightly sand or abrade the plastic with an

abrasive pad or sandpaper. Blow off any dust with

compressed air or wipe with a clean dry rag.When bonding SMC or RTM panels, use a two-part

epoxy adhesive. Properly mix parts A and B, and

apply it to the panels being repaired. Be sure that

enough adhesive has been applied to allow squeeze

out and to fill the full bond line. Once the pieces

have been brought together, do not move them until

the adhesive is cured. The assembly can be held

together with clamps, rivets, etc. A faster cure can be

obtained by heating with a heat lamp or heat gun.

After the parts have been bonded and have had

time to cure, rough sand the seam and apply the

final adhesive filler to the area being repaired.

Smooth the filler with a spatula, wooden tongue

depressor, or squeegee. For fine texturing, a small

amount of water can be applied to the filler surface

while smoothing. The cured filler can be sanded as

necessary and, as a final step, cleanup can be done

withy soapy water. Wipe the surface clean with a dry

cloth allowing time for the panel to dry before mov-

ing on with the repair.

PANEL REINFORCEMENT

Structural repair procedures for rigid panels such

as Sheet Molded compound (SMC) or Resin Transfer

Molded (RTM) with large cracks and holes will

require a reinforcement backing. Reinforcements can

be made with several applications of glass cloth sat-

urated with epoxy structural adhesive, semirigid or

flexible repair materials should be used for semirigid

or flexible part repairs (Fig. 3) and (Fig. 4). Open

meshed fiberglass dry wall tape can be used to form

a reinforcement. The dry wall tape allows the resin

to penetrate through and make a good bond between

the panel and the epoxy adhesive. Structurally, the

more dry wall tape used, the stronger the repair.

Another kind of repair that can be done to repair

large cracks and holes is to use a scrap piece of sim-

ilar plastic and bond with structural adhesive. The

reinforcement should cover the entire break and

should have a generous amount of overlap on either

side of the cracked or broken area.

When repairing plastic, the damaged area is first

ªV'dº out, or beveled. Large bonding areas are desir-

able when repairing plastic because small repairs are

less likely to hold permanently. Beveling the area

around a crack at a 20 degree angle will increase the

bonding surface for a repair (Fig. 5). It is recom-

mended that sharp edges be avoided because the

joint may show through after the panel is refinished.

²Panel repair for both flexible and rigid panels

are basically the same. The primary difference

between flexible panel repair and rigid panel repair

is in the adhesive materials used (Fig. 6).

²The technician should first decide what needs to

be done when working on any type of body panel.

One should determine if it is possible to return the

Fig. 2 Panel Sectioning

1 ± EXISTING PANEL

2 ± NEW PANEL

3 ± PANEL ADHESIVE

4 ± BONDING STRIP

23 - 20 BODYPL

SERVICE PROCEDURES (Continued)

Page 1156 of 1285

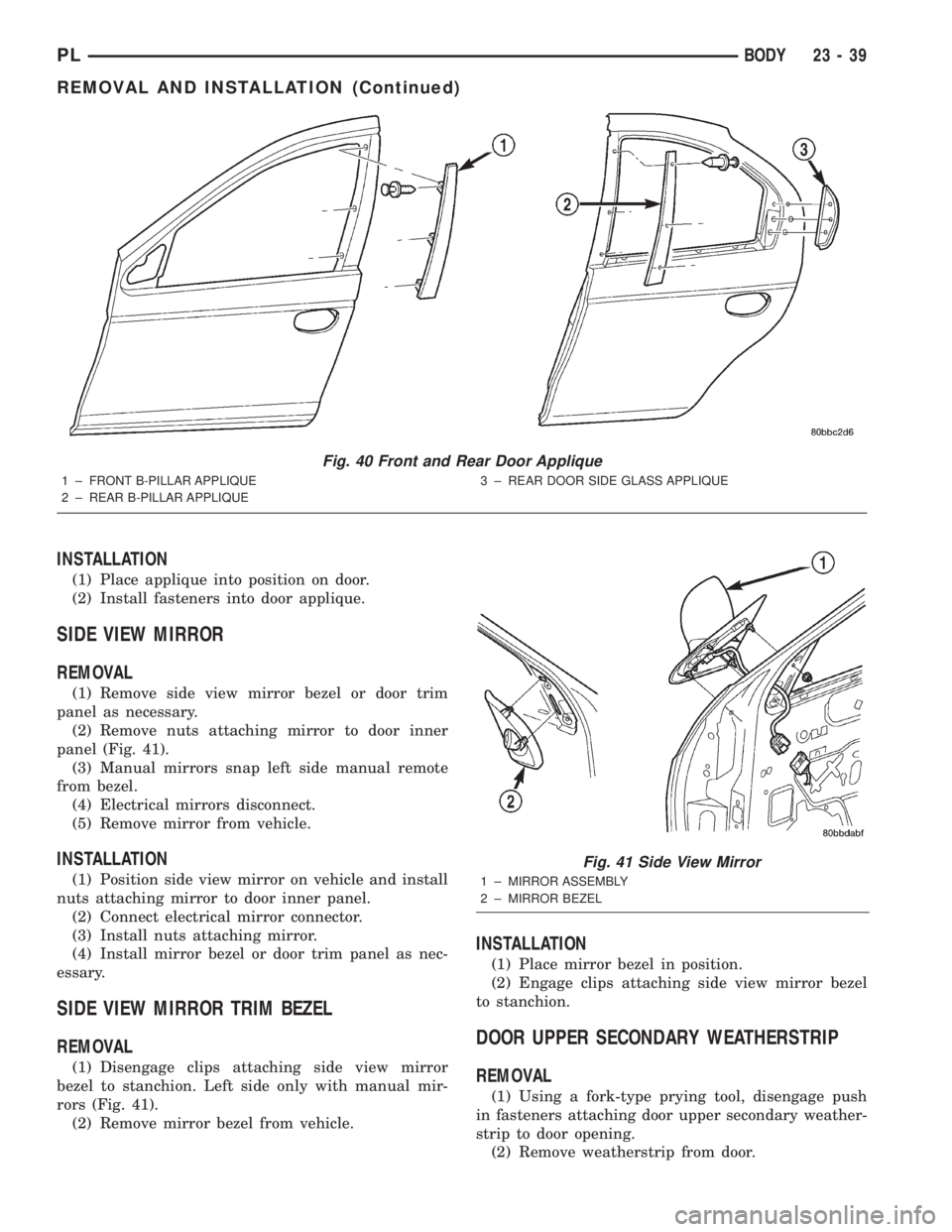

INSTALLATION

(1) Place applique into position on door.

(2) Install fasteners into door applique.

SIDE VIEW MIRROR

REMOVAL

(1) Remove side view mirror bezel or door trim

panel as necessary.

(2) Remove nuts attaching mirror to door inner

panel (Fig. 41).

(3) Manual mirrors snap left side manual remote

from bezel.

(4) Electrical mirrors disconnect.

(5) Remove mirror from vehicle.

INSTALLATION

(1) Position side view mirror on vehicle and install

nuts attaching mirror to door inner panel.

(2) Connect electrical mirror connector.

(3) Install nuts attaching mirror.

(4) Install mirror bezel or door trim panel as nec-

essary.

SIDE VIEW MIRROR TRIM BEZEL

REMOVAL

(1) Disengage clips attaching side view mirror

bezel to stanchion. Left side only with manual mir-

rors (Fig. 41).

(2) Remove mirror bezel from vehicle.

INSTALLATION

(1) Place mirror bezel in position.

(2) Engage clips attaching side view mirror bezel

to stanchion.

DOOR UPPER SECONDARY WEATHERSTRIP

REMOVAL

(1) Using a fork-type prying tool, disengage push

in fasteners attaching door upper secondary weather-

strip to door opening.

(2) Remove weatherstrip from door.

Fig. 40 Front and Rear Door Applique

1 ± FRONT B-PILLAR APPLIQUE

2 ± REAR B-PILLAR APPLIQUE3 ± REAR DOOR SIDE GLASS APPLIQUE

Fig. 41 Side View Mirror

1 ± MIRROR ASSEMBLY

2 ± MIRROR BEZEL

PLBODY 23 - 39

REMOVAL AND INSTALLATION (Continued)

Page 1232 of 1285

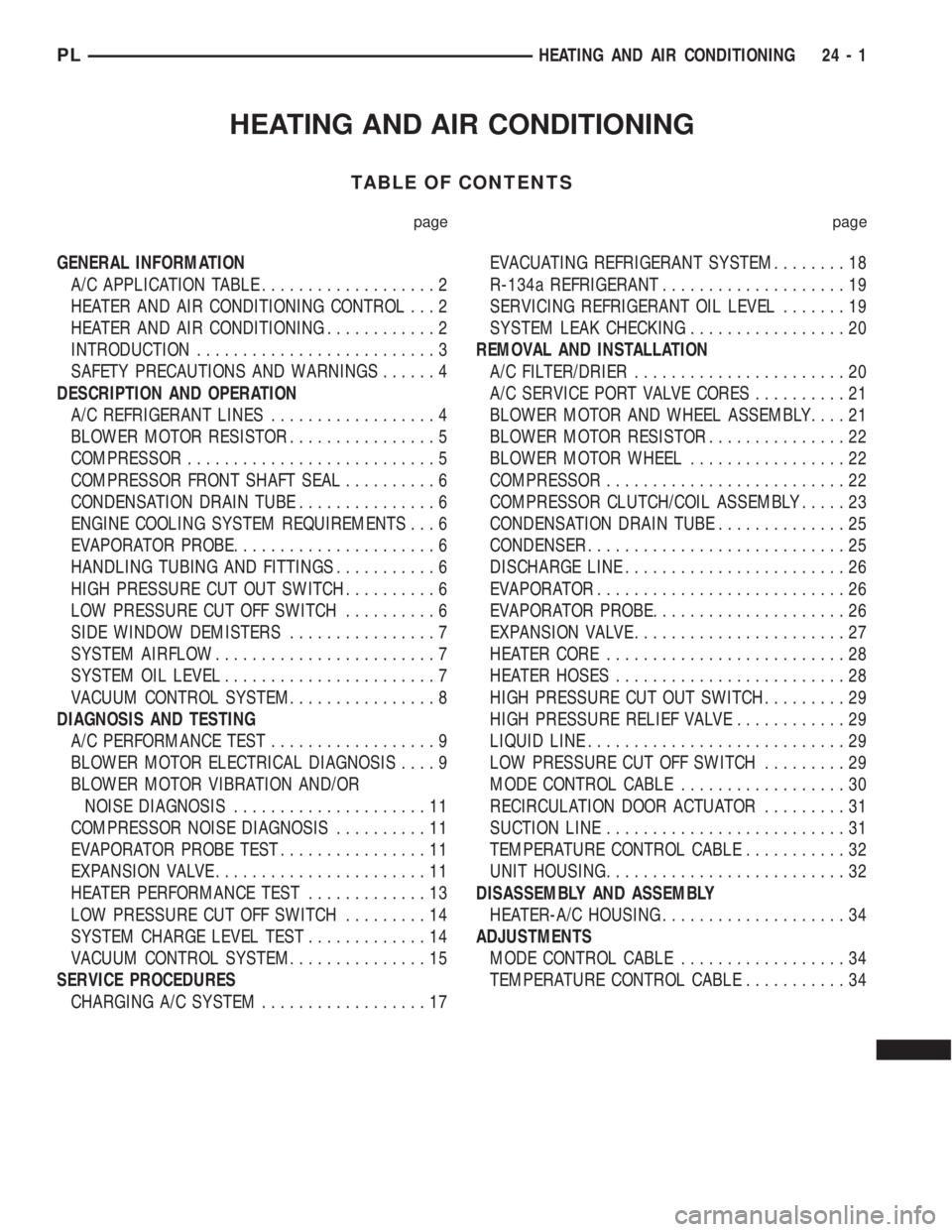

HEATING AND AIR CONDITIONING

TABLE OF CONTENTS

page page

GENERAL INFORMATION

A/C APPLICATION TABLE...................2

HEATER AND AIR CONDITIONING CONTROL...2

HEATER AND AIR CONDITIONING............2

INTRODUCTION..........................3

SAFETY PRECAUTIONS AND WARNINGS......4

DESCRIPTION AND OPERATION

A/C REFRIGERANT LINES..................4

BLOWER MOTOR RESISTOR................5

COMPRESSOR...........................5

COMPRESSOR FRONT SHAFT SEAL..........6

CONDENSATION DRAIN TUBE...............6

ENGINE COOLING SYSTEM REQUIREMENTS...6

EVAPORATOR PROBE......................6

HANDLING TUBING AND FITTINGS...........6

HIGH PRESSURE CUT OUT SWITCH..........6

LOW PRESSURE CUT OFF SWITCH..........6

SIDE WINDOW DEMISTERS................7

SYSTEM AIRFLOW........................7

SYSTEM OIL LEVEL.......................7

VACUUM CONTROL SYSTEM................8

DIAGNOSIS AND TESTING

A/C PERFORMANCE TEST..................9

BLOWER MOTOR ELECTRICAL DIAGNOSIS....9

BLOWER MOTOR VIBRATION AND/OR

NOISE DIAGNOSIS.....................11

COMPRESSOR NOISE DIAGNOSIS..........11

EVAPORATOR PROBE TEST................11

EXPANSION VALVE.......................11

HEATER PERFORMANCE TEST.............13

LOW PRESSURE CUT OFF SWITCH.........14

SYSTEM CHARGE LEVEL TEST.............14

VACUUM CONTROL SYSTEM...............15

SERVICE PROCEDURES

CHARGING A/C SYSTEM..................17EVACUATING REFRIGERANT SYSTEM........18

R-134a REFRIGERANT....................19

SERVICING REFRIGERANT OIL LEVEL.......19

SYSTEM LEAK CHECKING.................20

REMOVAL AND INSTALLATION

A/C FILTER/DRIER.......................20

A/C SERVICE PORT VALVE CORES..........21

BLOWER MOTOR AND WHEEL ASSEMBLY....21

BLOWER MOTOR RESISTOR...............22

BLOWER MOTOR WHEEL.................22

COMPRESSOR..........................22

COMPRESSOR CLUTCH/COIL ASSEMBLY.....23

CONDENSATION DRAIN TUBE..............25

CONDENSER............................25

DISCHARGE LINE........................26

EVAPORATOR...........................26

EVAPORATOR PROBE.....................26

EXPANSION VALVE.......................27

HEATER CORE..........................28

HEATER HOSES.........................28

HIGH PRESSURE CUT OUT SWITCH.........29

HIGH PRESSURE RELIEF VALVE............29

LIQUID LINE............................29

LOW PRESSURE CUT OFF SWITCH.........29

MODE CONTROL CABLE..................30

RECIRCULATION DOOR ACTUATOR.........31

SUCTION LINE..........................31

TEMPERATURE CONTROL CABLE...........32

UNIT HOUSING..........................32

DISASSEMBLY AND ASSEMBLY

HEATER-A/C HOUSING....................34

ADJUSTMENTS

MODE CONTROL CABLE..................34

TEMPERATURE CONTROL CABLE...........34

PLHEATING AND AIR CONDITIONING 24 - 1

Page 1233 of 1285

GENERAL INFORMATION

A/C APPLICATION TABLE

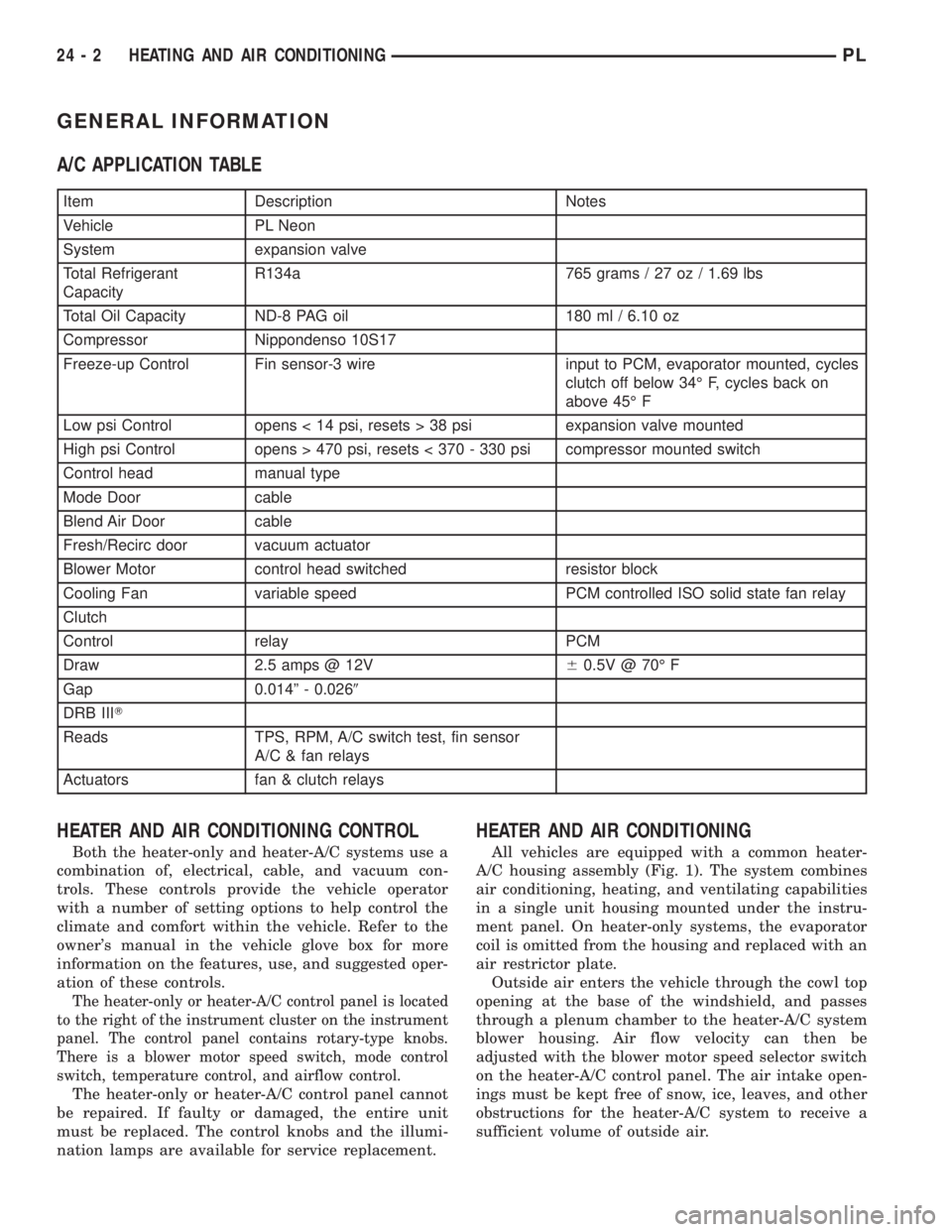

Item Description Notes

Vehicle PL Neon

System expansion valve

Total Refrigerant

CapacityR134a 765 grams / 27 oz / 1.69 lbs

Total Oil Capacity ND-8 PAG oil 180 ml / 6.10 oz

Compressor Nippondenso 10S17

Freeze-up Control Fin sensor-3 wire input to PCM, evaporator mounted, cycles

clutch off below 34É F, cycles back on

above 45É F

Low psi Control opens < 14 psi, resets > 38 psi expansion valve mounted

High psi Control opens > 470 psi, resets < 370 - 330 psi compressor mounted switch

Control head manual type

Mode Door cable

Blend Air Door cable

Fresh/Recirc door vacuum actuator

Blower Motor control head switched resistor block

Cooling Fan variable speed PCM controlled ISO solid state fan relay

Clutch

Control relay PCM

Draw 2.5 amps @ 12V60.5V @ 70É F

Gap 0.014º - 0.0269

DRB IIIT

Reads TPS, RPM, A/C switch test, fin sensor

A/C & fan relays

Actuators fan & clutch relays

HEATER AND AIR CONDITIONING CONTROL

Both the heater-only and heater-A/C systems use a

combination of, electrical, cable, and vacuum con-

trols. These controls provide the vehicle operator

with a number of setting options to help control the

climate and comfort within the vehicle. Refer to the

owner's manual in the vehicle glove box for more

information on the features, use, and suggested oper-

ation of these controls.

The heater-only or heater-A/C control panel is located

to the right of the instrument cluster on the instrument

panel. The control panel contains rotary-type knobs.

There is a blower motor speed switch, mode control

switch, temperature control, and airflow control.

The heater-only or heater-A/C control panel cannot

be repaired. If faulty or damaged, the entire unit

must be replaced. The control knobs and the illumi-

nation lamps are available for service replacement.

HEATER AND AIR CONDITIONING

All vehicles are equipped with a common heater-

A/C housing assembly (Fig. 1). The system combines

air conditioning, heating, and ventilating capabilities

in a single unit housing mounted under the instru-

ment panel. On heater-only systems, the evaporator

coil is omitted from the housing and replaced with an

air restrictor plate.

Outside air enters the vehicle through the cowl top

opening at the base of the windshield, and passes

through a plenum chamber to the heater-A/C system

blower housing. Air flow velocity can then be

adjusted with the blower motor speed selector switch

on the heater-A/C control panel. The air intake open-

ings must be kept free of snow, ice, leaves, and other

obstructions for the heater-A/C system to receive a

sufficient volume of outside air.

24 - 2 HEATING AND AIR CONDITIONINGPL