motor DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 682 of 1285

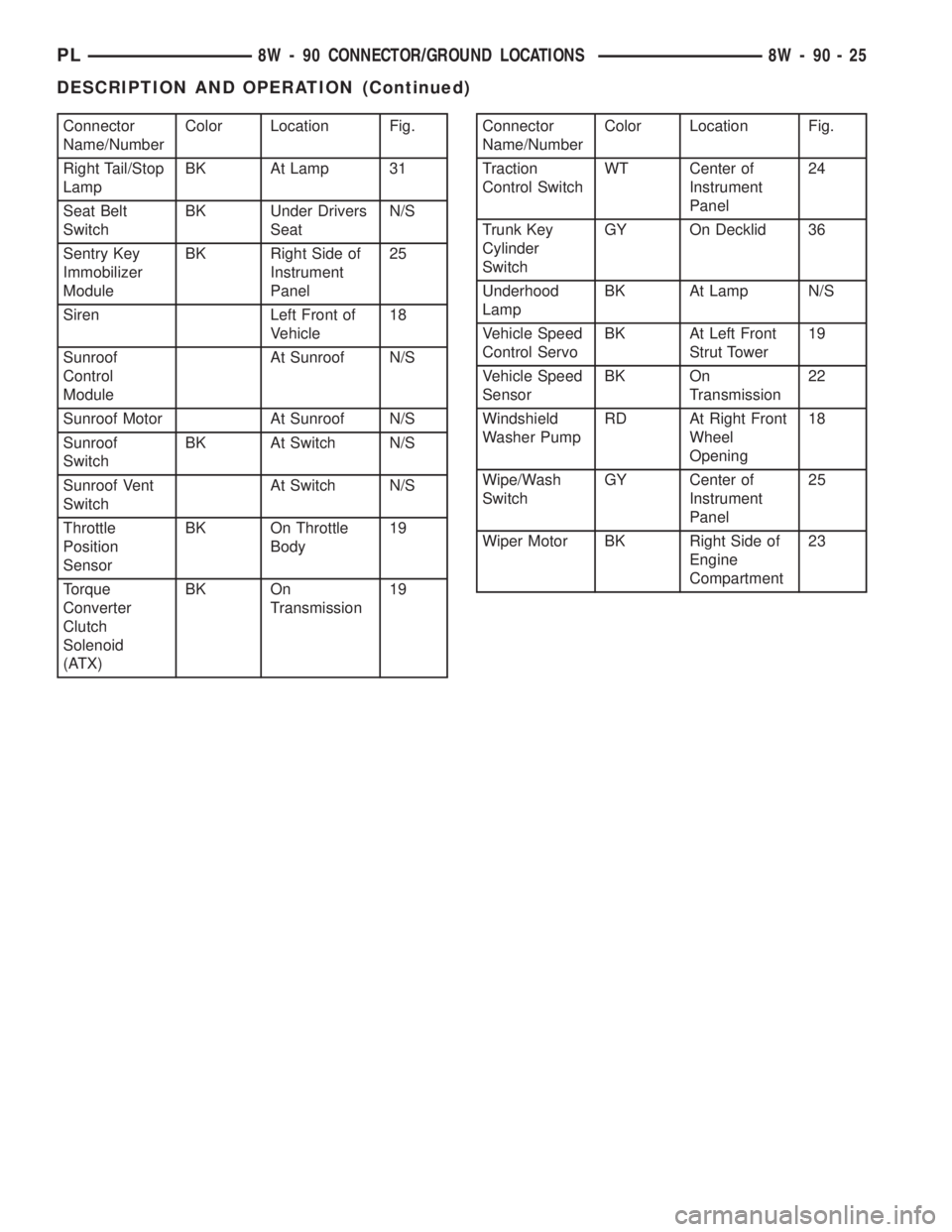

Connector

Name/NumberColor Location Fig.

Right Tail/Stop

LampBK At Lamp 31

Seat Belt

SwitchBK Under Drivers

SeatN/S

Sentry Key

Immobilizer

ModuleBK Right Side of

Instrument

Panel25

Siren Left Front of

Vehicle18

Sunroof

Control

ModuleAt Sunroof N/S

Sunroof Motor At Sunroof N/S

Sunroof

SwitchBK At Switch N/S

Sunroof Vent

SwitchAt Switch N/S

Throttle

Position

SensorBK On Throttle

Body19

Torque

Converter

Clutch

Solenoid

(ATX)BK On

Transmission19Connector

Name/NumberColor Location Fig.

Traction

Control SwitchWT Center of

Instrument

Panel24

Trunk Key

Cylinder

SwitchGY On Decklid 36

Underhood

LampBK At Lamp N/S

Vehicle Speed

Control ServoBK At Left Front

Strut Tower19

Vehicle Speed

SensorBK On

Transmission22

Windshield

Washer PumpRD At Right Front

Wheel

Opening18

Wipe/Wash

SwitchGY Center of

Instrument

Panel25

Wiper Motor BK Right Side of

Engine

Compartment23

PL8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 25

DESCRIPTION AND OPERATION (Continued)

Page 698 of 1285

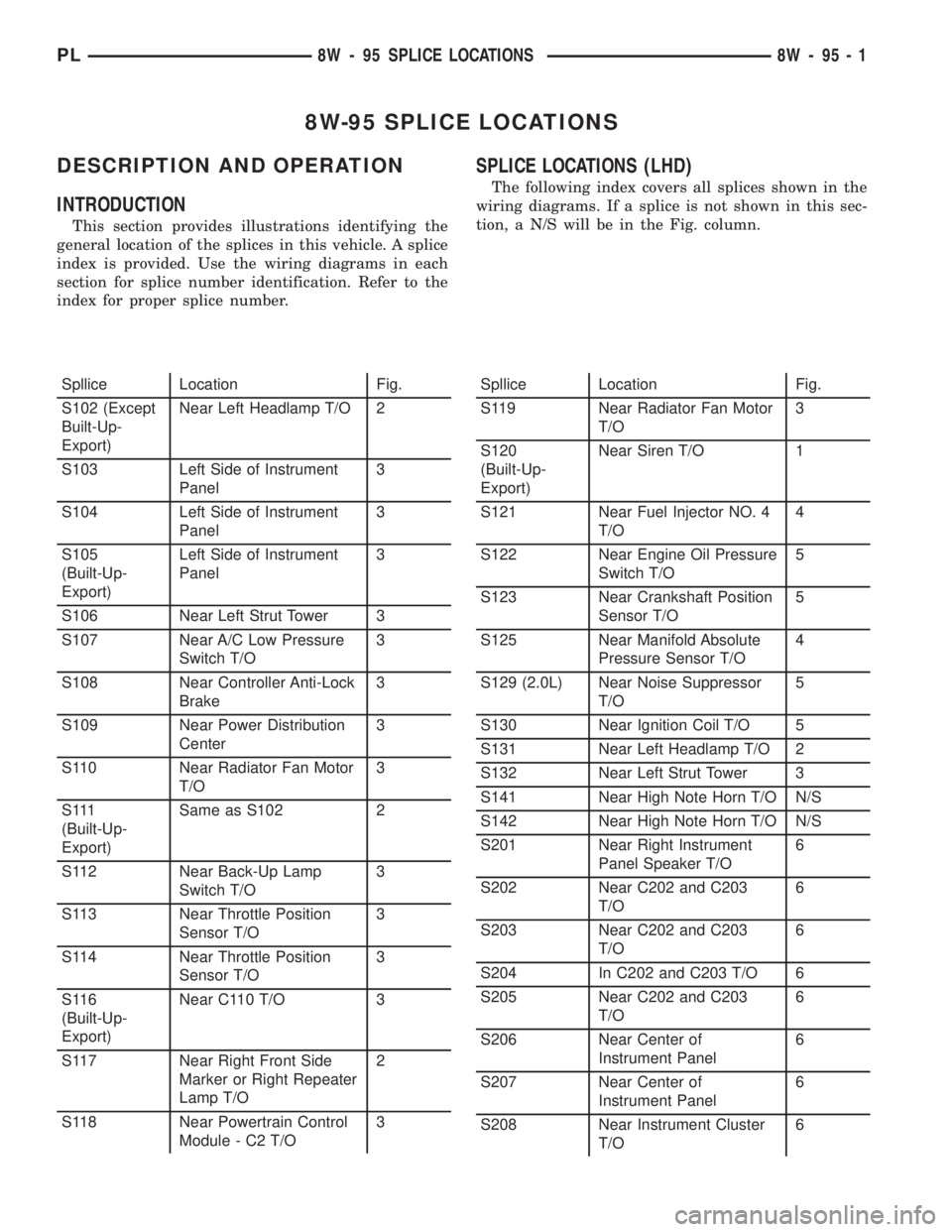

8W-95 SPLICE LOCATIONS

DESCRIPTION AND OPERATION

INTRODUCTION

This section provides illustrations identifying the

general location of the splices in this vehicle. A splice

index is provided. Use the wiring diagrams in each

section for splice number identification. Refer to the

index for proper splice number.

SPLICE LOCATIONS (LHD)

The following index covers all splices shown in the

wiring diagrams. If a splice is not shown in this sec-

tion, a N/S will be in the Fig. column.

Spllice Location Fig.

S102 (Except

Built-Up-

Export)Near Left Headlamp T/O 2

S103 Left Side of Instrument

Panel3

S104 Left Side of Instrument

Panel3

S105

(Built-Up-

Export)Left Side of Instrument

Panel3

S106 Near Left Strut Tower 3

S107 Near A/C Low Pressure

Switch T/O3

S108 Near Controller Anti-Lock

Brake3

S109 Near Power Distribution

Center3

S110 Near Radiator Fan Motor

T/O3

S 111

(Built-Up-

Export)Same as S102 2

S112 Near Back-Up Lamp

Switch T/O3

S113 Near Throttle Position

Sensor T/O3

S114 Near Throttle Position

Sensor T/O3

S116

(Built-Up-

Export)Near C110 T/O 3

S117 Near Right Front Side

Marker or Right Repeater

Lamp T/O2

S118 Near Powertrain Control

Module - C2 T/O3Spllice Location Fig.

S119 Near Radiator Fan Motor

T/O3

S120

(Built-Up-

Export)Near Siren T/O 1

S121 Near Fuel Injector NO. 4

T/O4

S122 Near Engine Oil Pressure

Switch T/O5

S123 Near Crankshaft Position

Sensor T/O5

S125 Near Manifold Absolute

Pressure Sensor T/O4

S129 (2.0L) Near Noise Suppressor

T/O5

S130 Near Ignition Coil T/O 5

S131 Near Left Headlamp T/O 2

S132 Near Left Strut Tower 3

S141 Near High Note Horn T/O N/S

S142 Near High Note Horn T/O N/S

S201 Near Right Instrument

Panel Speaker T/O6

S202 Near C202 and C203

T/O6

S203 Near C202 and C203

T/O6

S204 In C202 and C203 T/O 6

S205 Near C202 and C203

T/O6

S206 Near Center of

Instrument Panel6

S207 Near Center of

Instrument Panel6

S208 Near Instrument Cluster

T/O6

PL8W - 95 SPLICE LOCATIONS 8W - 95 - 1

Page 699 of 1285

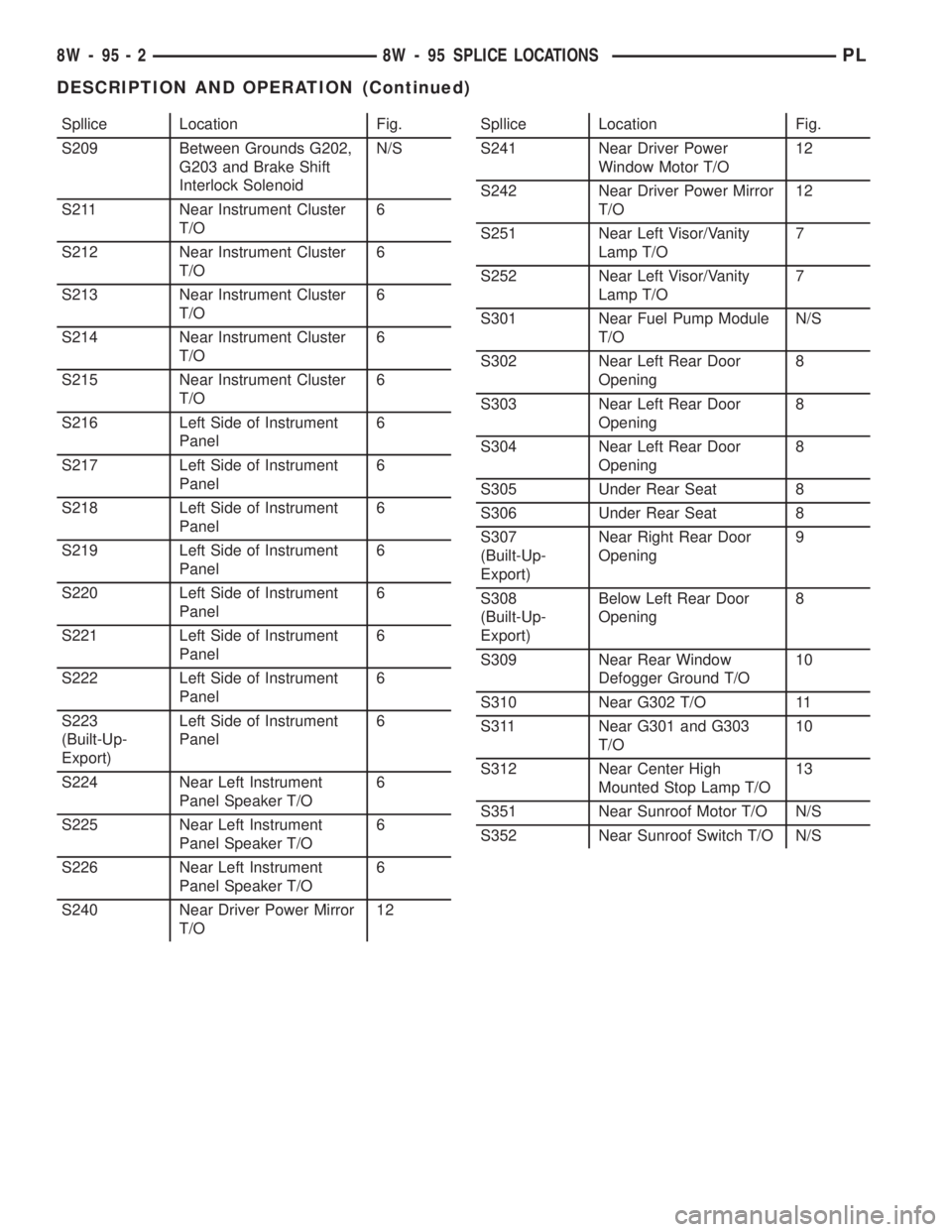

Spllice Location Fig.

S209 Between Grounds G202,

G203 and Brake Shift

Interlock SolenoidN/S

S211 Near Instrument Cluster

T/O6

S212 Near Instrument Cluster

T/O6

S213 Near Instrument Cluster

T/O6

S214 Near Instrument Cluster

T/O6

S215 Near Instrument Cluster

T/O6

S216 Left Side of Instrument

Panel6

S217 Left Side of Instrument

Panel6

S218 Left Side of Instrument

Panel6

S219 Left Side of Instrument

Panel6

S220 Left Side of Instrument

Panel6

S221 Left Side of Instrument

Panel6

S222 Left Side of Instrument

Panel6

S223

(Built-Up-

Export)Left Side of Instrument

Panel6

S224 Near Left Instrument

Panel Speaker T/O6

S225 Near Left Instrument

Panel Speaker T/O6

S226 Near Left Instrument

Panel Speaker T/O6

S240 Near Driver Power Mirror

T/O12Spllice Location Fig.

S241 Near Driver Power

Window Motor T/O12

S242 Near Driver Power Mirror

T/O12

S251 Near Left Visor/Vanity

Lamp T/O7

S252 Near Left Visor/Vanity

Lamp T/O7

S301 Near Fuel Pump Module

T/ON/S

S302 Near Left Rear Door

Opening8

S303 Near Left Rear Door

Opening8

S304 Near Left Rear Door

Opening8

S305 Under Rear Seat 8

S306 Under Rear Seat 8

S307

(Built-Up-

Export)Near Right Rear Door

Opening9

S308

(Built-Up-

Export)Below Left Rear Door

Opening8

S309 Near Rear Window

Defogger Ground T/O10

S310 Near G302 T/O 11

S311 Near G301 and G303

T/O10

S312 Near Center High

Mounted Stop Lamp T/O13

S351 Near Sunroof Motor T/O N/S

S352 Near Sunroof Switch T/O N/S

8W - 95 - 2 8W - 95 SPLICE LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

Page 710 of 1285

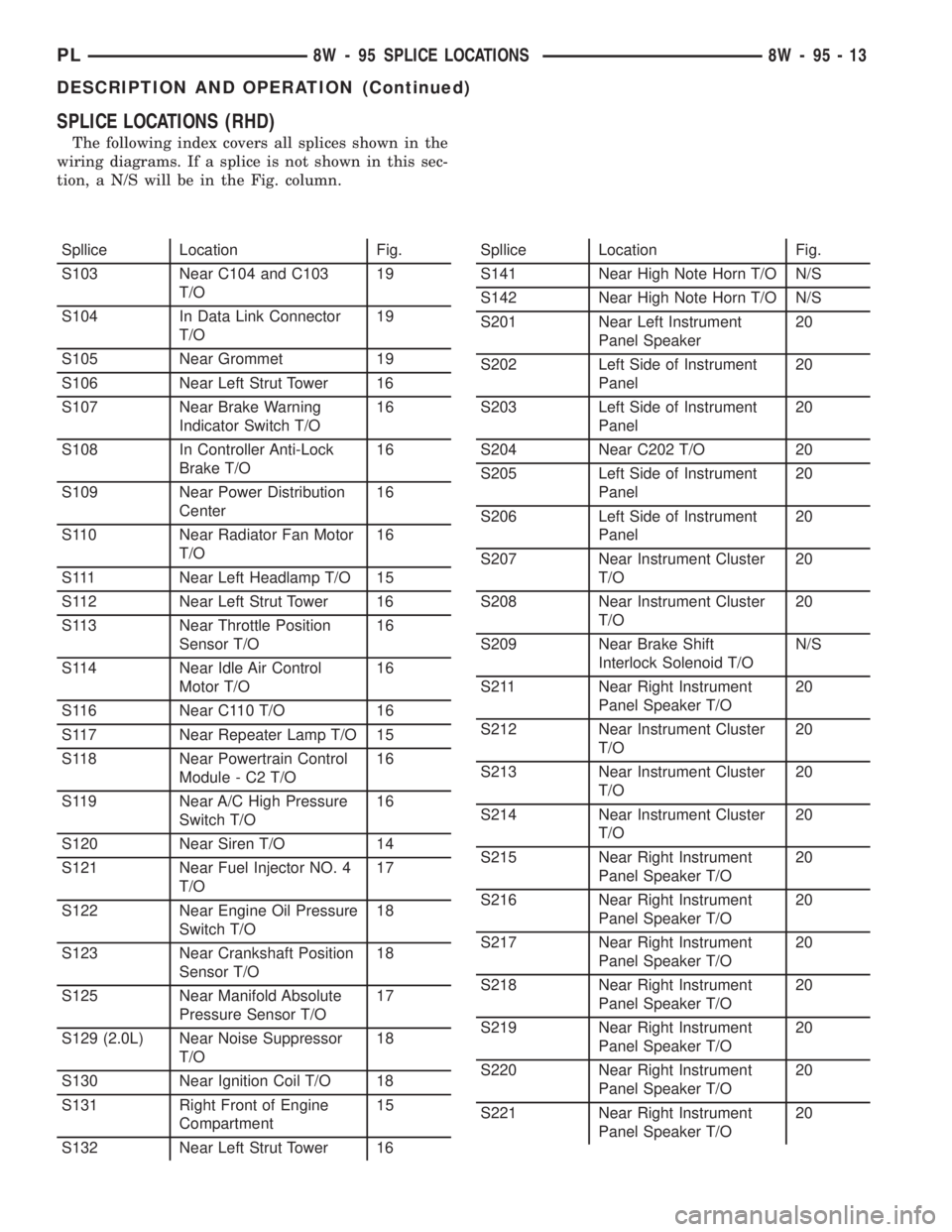

SPLICE LOCATIONS (RHD)

The following index covers all splices shown in the

wiring diagrams. If a splice is not shown in this sec-

tion, a N/S will be in the Fig. column.

Spllice Location Fig.

S103 Near C104 and C103

T/O19

S104 In Data Link Connector

T/O19

S105 Near Grommet 19

S106 Near Left Strut Tower 16

S107 Near Brake Warning

Indicator Switch T/O16

S108 In Controller Anti-Lock

Brake T/O16

S109 Near Power Distribution

Center16

S110 Near Radiator Fan Motor

T/O16

S111 Near Left Headlamp T/O 15

S112 Near Left Strut Tower 16

S113 Near Throttle Position

Sensor T/O16

S114 Near Idle Air Control

Motor T/O16

S116 Near C110 T/O 16

S117 Near Repeater Lamp T/O 15

S118 Near Powertrain Control

Module - C2 T/O16

S119 Near A/C High Pressure

Switch T/O16

S120 Near Siren T/O 14

S121 Near Fuel Injector NO. 4

T/O17

S122 Near Engine Oil Pressure

Switch T/O18

S123 Near Crankshaft Position

Sensor T/O18

S125 Near Manifold Absolute

Pressure Sensor T/O17

S129 (2.0L) Near Noise Suppressor

T/O18

S130 Near Ignition Coil T/O 18

S131 Right Front of Engine

Compartment15

S132 Near Left Strut Tower 16Spllice Location Fig.

S141 Near High Note Horn T/O N/S

S142 Near High Note Horn T/O N/S

S201 Near Left Instrument

Panel Speaker20

S202 Left Side of Instrument

Panel20

S203 Left Side of Instrument

Panel20

S204 Near C202 T/O 20

S205 Left Side of Instrument

Panel20

S206 Left Side of Instrument

Panel20

S207 Near Instrument Cluster

T/O20

S208 Near Instrument Cluster

T/O20

S209 Near Brake Shift

Interlock Solenoid T/ON/S

S211 Near Right Instrument

Panel Speaker T/O20

S212 Near Instrument Cluster

T/O20

S213 Near Instrument Cluster

T/O20

S214 Near Instrument Cluster

T/O20

S215 Near Right Instrument

Panel Speaker T/O20

S216 Near Right Instrument

Panel Speaker T/O20

S217 Near Right Instrument

Panel Speaker T/O20

S218 Near Right Instrument

Panel Speaker T/O20

S219 Near Right Instrument

Panel Speaker T/O20

S220 Near Right Instrument

Panel Speaker T/O20

S221 Near Right Instrument

Panel Speaker T/O20

PL8W - 95 SPLICE LOCATIONS 8W - 95 - 13

DESCRIPTION AND OPERATION (Continued)

Page 711 of 1285

Spllice Location Fig.

S222 Near Right Instrument

Panel Speaker T/O20

S223 Near Right Instrument

Panel Speaker T/O20

S224 Near Right Instrument

Panel Speaker T/O20

S225 Near Instrument Cluster

T/O20

S226 In C103, C104 and C305

T/O20

S240 Near Driver Power

Window Motor T/O26

S241 Near Driver Power

Window Motor T/O26

S242 Near Driver Power Mirror

T/O26

S251 Near Left Visor/Vanity

Lamp T/O21

S252 Near Left Visor/Vanity

Lamp T/O21

S301 Near Fuel Pump Module

T/ON/SSpllice Location Fig.

S302 Near Right Door Opening 23

S303 Near Right Door Opening 23

S304 Near Right Door Opening 23

S305 Under Rear Seat 22

S306 Under Rear Seat 23

S307 Near Right Rear Door

Opening23

S308 Near Left Rear Door

Opening22

S309 Near Rear Window

Defogger Ground T/O24

S310 Near G302 T/O 25

S311 Near G301 and G303

T/O24

S312 Near Center High

Mounted Stop Lamp T/O27

S351 Near Sunroof Motor T/O N/S

S352 Near Sunroof Switch T/O N/S

8W - 95 - 14 8W - 95 SPLICE LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

Page 725 of 1285

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4 oz./16 oz. can w/applicator.

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

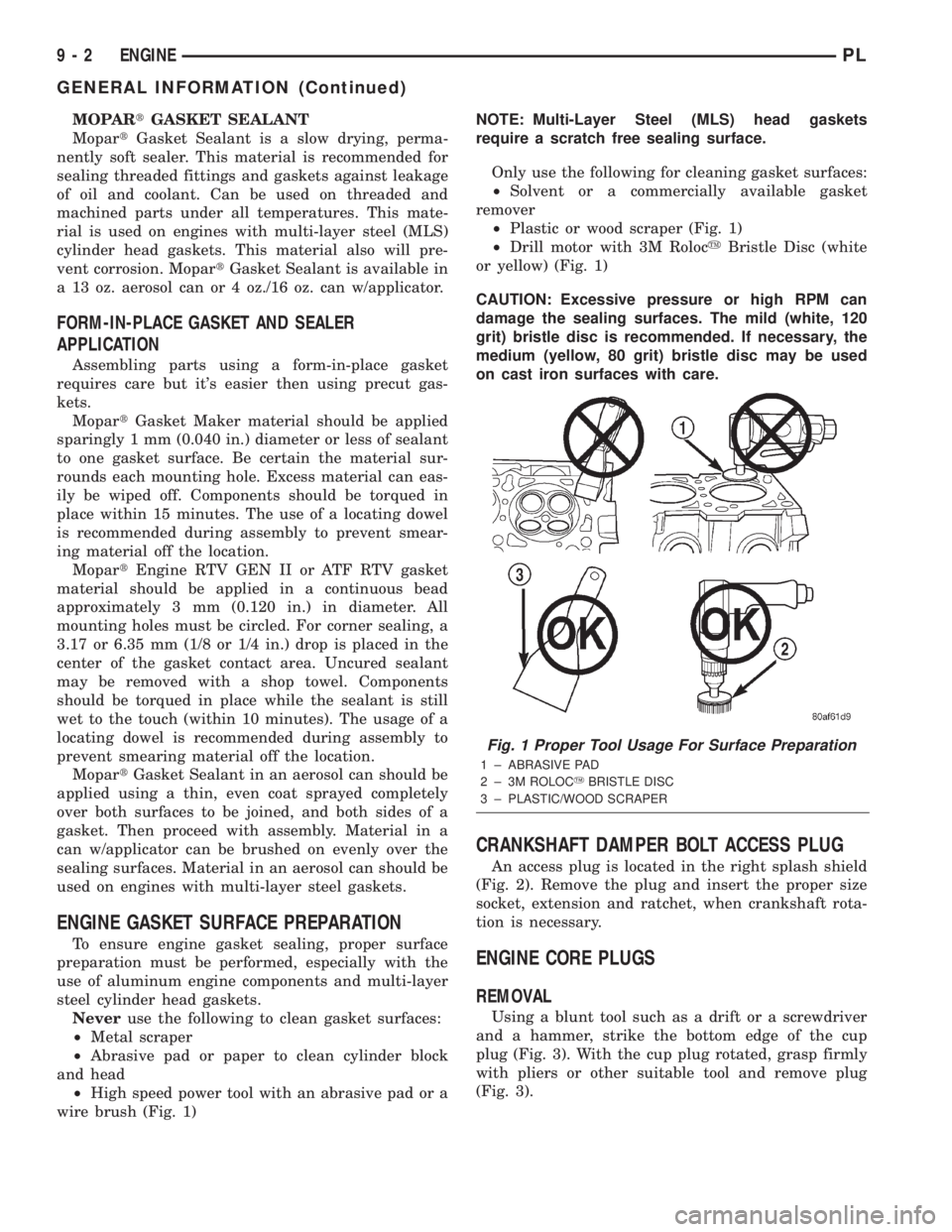

ENGINE GASKET SURFACE PREPARATION

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

Neveruse the following to clean gasket surfaces:

²Metal scraper

²Abrasive pad or paper to clean cylinder block

and head

²High speed power tool with an abrasive pad or a

wire brush (Fig. 1)NOTE: Multi-Layer Steel (MLS) head gaskets

require a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:

²Solvent or a commercially available gasket

remover

²Plastic or wood scraper (Fig. 1)

²Drill motor with 3M RolocyBristle Disc (white

or yellow) (Fig. 1)

CAUTION: Excessive pressure or high RPM can

damage the sealing surfaces. The mild (white, 120

grit) bristle disc is recommended. If necessary, the

medium (yellow, 80 grit) bristle disc may be used

on cast iron surfaces with care.

CRANKSHAFT DAMPER BOLT ACCESS PLUG

An access plug is located in the right splash shield

(Fig. 2). Remove the plug and insert the proper size

socket, extension and ratchet, when crankshaft rota-

tion is necessary.

ENGINE CORE PLUGS

REMOVAL

Using a blunt tool such as a drift or a screwdriver

and a hammer, strike the bottom edge of the cup

plug (Fig. 3). With the cup plug rotated, grasp firmly

with pliers or other suitable tool and remove plug

(Fig. 3).

Fig. 1 Proper Tool Usage For Surface Preparation

1 ± ABRASIVE PAD

2 ± 3M ROLOCYBRISTLE DISC

3 ± PLASTIC/WOOD SCRAPER

9 - 2 ENGINEPL

GENERAL INFORMATION (Continued)

Page 727 of 1285

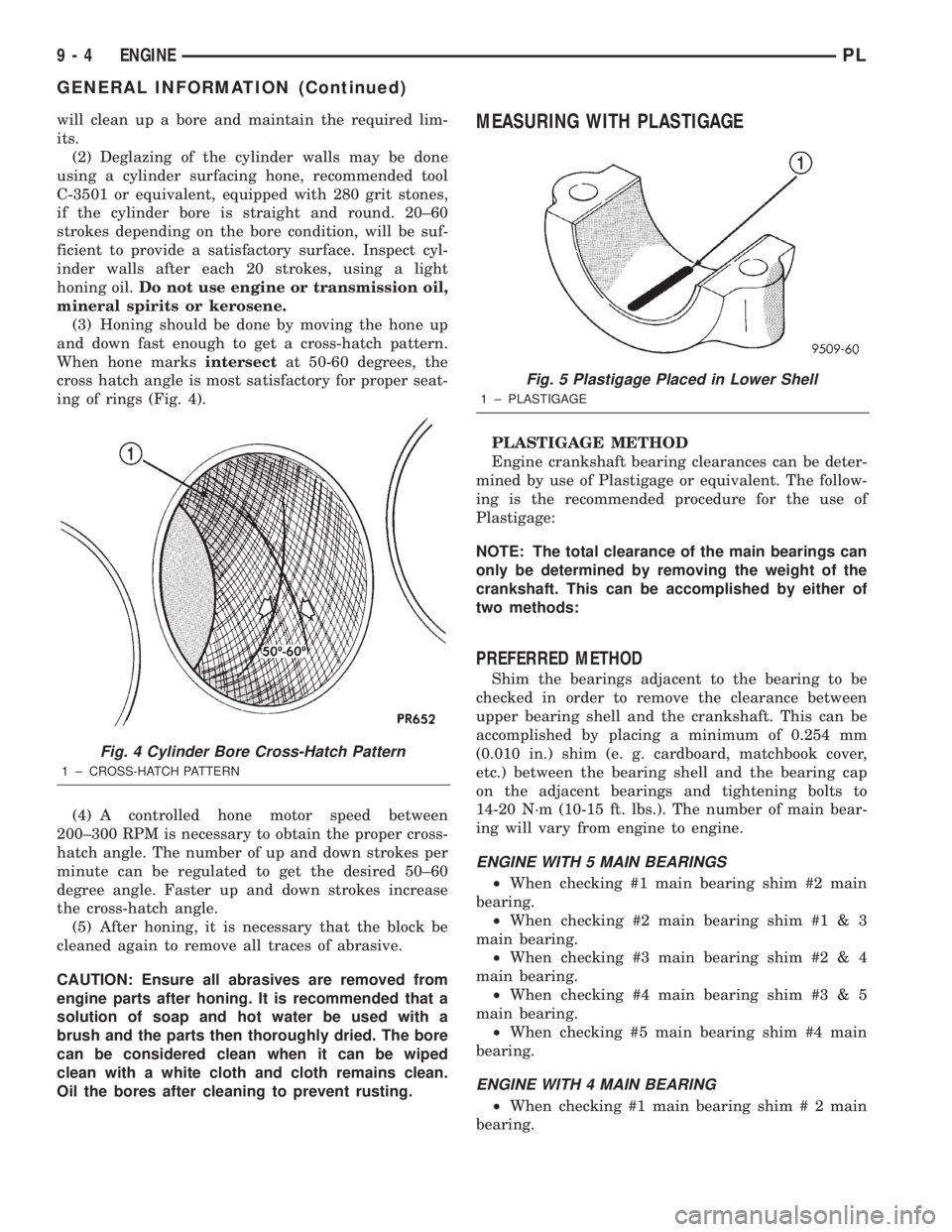

will clean up a bore and maintain the required lim-

its.

(2) Deglazing of the cylinder walls may be done

using a cylinder surfacing hone, recommended tool

C-3501 or equivalent, equipped with 280 grit stones,

if the cylinder bore is straight and round. 20±60

strokes depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Inspect cyl-

inder walls after each 20 strokes, using a light

honing oil.Do not use engine or transmission oil,

mineral spirits or kerosene.

(3) Honing should be done by moving the hone up

and down fast enough to get a cross-hatch pattern.

When hone marksintersectat 50-60 degrees, the

cross hatch angle is most satisfactory for proper seat-

ing of rings (Fig. 4).

(4) A controlled hone motor speed between

200±300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 50±60

degree angle. Faster up and down strokes increase

the cross-hatch angle.

(5) After honing, it is necessary that the block be

cleaned again to remove all traces of abrasive.

CAUTION: Ensure all abrasives are removed from

engine parts after honing. It is recommended that a

solution of soap and hot water be used with a

brush and the parts then thoroughly dried. The bore

can be considered clean when it can be wiped

clean with a white cloth and cloth remains clean.

Oil the bores after cleaning to prevent rusting.MEASURING WITH PLASTIGAGE

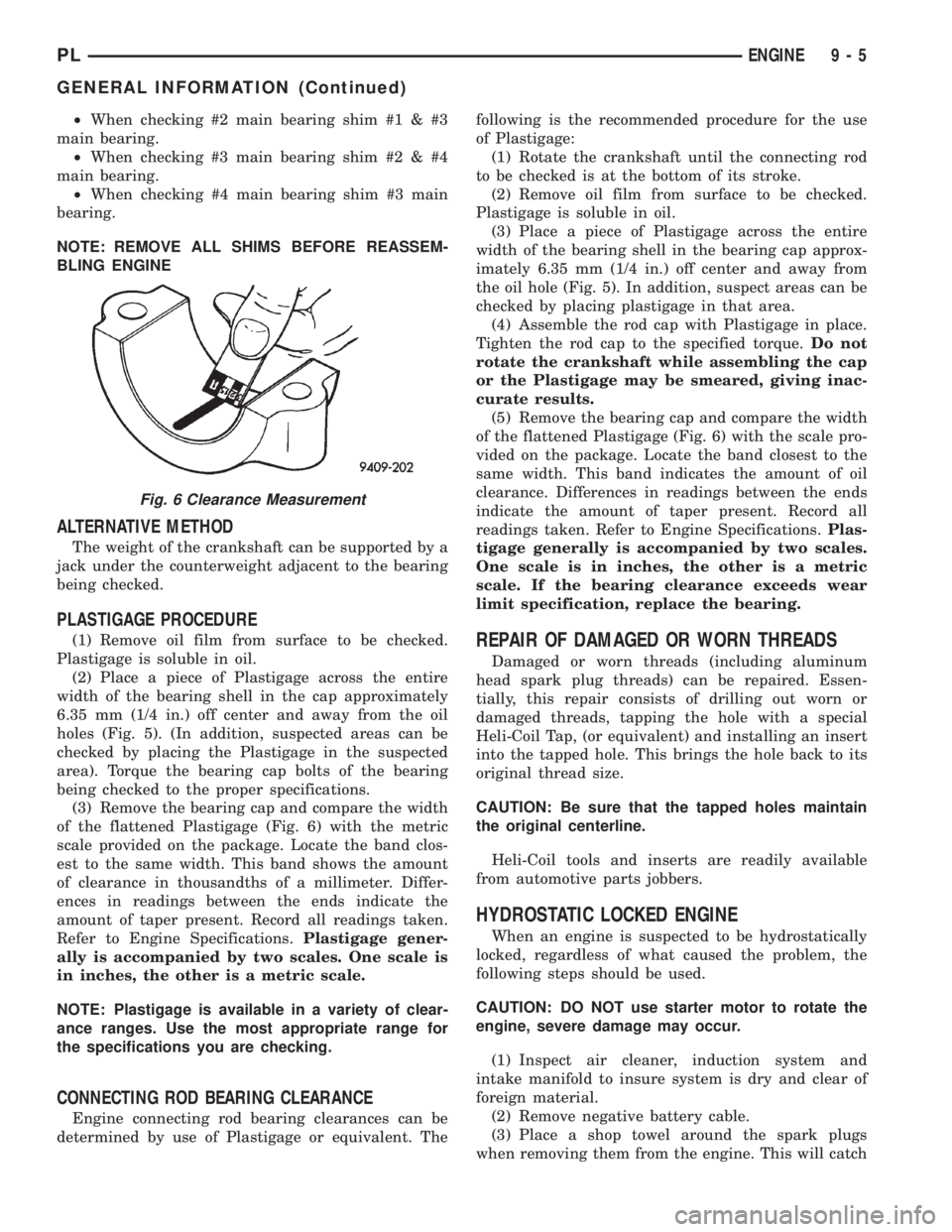

PLASTIGAGE METHOD

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage or equivalent. The follow-

ing is the recommended procedure for the use of

Plastigage:

NOTE: The total clearance of the main bearings can

only be determined by removing the weight of the

crankshaft. This can be accomplished by either of

two methods:

PREFERRED METHOD

Shim the bearings adjacent to the bearing to be

checked in order to remove the clearance between

upper bearing shell and the crankshaft. This can be

accomplished by placing a minimum of 0.254 mm

(0.010 in.) shim (e. g. cardboard, matchbook cover,

etc.) between the bearing shell and the bearing cap

on the adjacent bearings and tightening bolts to

14-20 N´m (10-15 ft. lbs.). The number of main bear-

ing will vary from engine to engine.

ENGINE WITH 5 MAIN BEARINGS

²When checking #1 main bearing shim #2 main

bearing.

²When checking #2 main bearing shim #1 & 3

main bearing.

²When checking #3 main bearing shim #2 & 4

main bearing.

²When checking #4 main bearing shim #3 & 5

main bearing.

²When checking #5 main bearing shim #4 main

bearing.

ENGINE WITH 4 MAIN BEARING

²When checking #1 main bearing shim # 2 main

bearing.

Fig. 4 Cylinder Bore Cross-Hatch Pattern

1 ± CROSS-HATCH PATTERN

Fig. 5 Plastigage Placed in Lower Shell

1 ± PLASTIGAGE

9 - 4 ENGINEPL

GENERAL INFORMATION (Continued)

Page 728 of 1285

²When checking #2 main bearing shim #1 & #3

main bearing.

²When checking #3 main bearing shim #2 & #4

main bearing.

²When checking #4 main bearing shim #3 main

bearing.

NOTE: REMOVE ALL SHIMS BEFORE REASSEM-

BLING ENGINE

ALTERNATIVE METHOD

The weight of the crankshaft can be supported by a

jack under the counterweight adjacent to the bearing

being checked.

PLASTIGAGE PROCEDURE

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(2) Place a piece of Plastigage across the entire

width of the bearing shell in the cap approximately

6.35 mm (1/4 in.) off center and away from the oil

holes (Fig. 5). (In addition, suspected areas can be

checked by placing the Plastigage in the suspected

area). Torque the bearing cap bolts of the bearing

being checked to the proper specifications.

(3) Remove the bearing cap and compare the width

of the flattened Plastigage (Fig. 6) with the metric

scale provided on the package. Locate the band clos-

est to the same width. This band shows the amount

of clearance in thousandths of a millimeter. Differ-

ences in readings between the ends indicate the

amount of taper present. Record all readings taken.

Refer to Engine Specifications.Plastigage gener-

ally is accompanied by two scales. One scale is

in inches, the other is a metric scale.

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.

CONNECTING ROD BEARING CLEARANCE

Engine connecting rod bearing clearances can be

determined by use of Plastigage or equivalent. Thefollowing is the recommended procedure for the use

of Plastigage:

(1) Rotate the crankshaft until the connecting rod

to be checked is at the bottom of its stroke.

(2) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(3) Place a piece of Plastigage across the entire

width of the bearing shell in the bearing cap approx-

imately 6.35 mm (1/4 in.) off center and away from

the oil hole (Fig. 5). In addition, suspect areas can be

checked by placing plastigage in that area.

(4) Assemble the rod cap with Plastigage in place.

Tighten the rod cap to the specified torque.Do not

rotate the crankshaft while assembling the cap

or the Plastigage may be smeared, giving inac-

curate results.

(5) Remove the bearing cap and compare the width

of the flattened Plastigage (Fig. 6) with the scale pro-

vided on the package. Locate the band closest to the

same width. This band indicates the amount of oil

clearance. Differences in readings between the ends

indicate the amount of taper present. Record all

readings taken. Refer to Engine Specifications.Plas-

tigage generally is accompanied by two scales.

One scale is in inches, the other is a metric

scale. If the bearing clearance exceeds wear

limit specification, replace the bearing.

REPAIR OF DAMAGED OR WORN THREADS

Damaged or worn threads (including aluminum

head spark plug threads) can be repaired. Essen-

tially, this repair consists of drilling out worn or

damaged threads, tapping the hole with a special

Heli-Coil Tap, (or equivalent) and installing an insert

into the tapped hole. This brings the hole back to its

original thread size.

CAUTION: Be sure that the tapped holes maintain

the original centerline.

Heli-Coil tools and inserts are readily available

from automotive parts jobbers.

HYDROSTATIC LOCKED ENGINE

When an engine is suspected to be hydrostatically

locked, regardless of what caused the problem, the

following steps should be used.

CAUTION: DO NOT use starter motor to rotate the

engine, severe damage may occur.

(1) Inspect air cleaner, induction system and

intake manifold to insure system is dry and clear of

foreign material.

(2) Remove negative battery cable.

(3) Place a shop towel around the spark plugs

when removing them from the engine. This will catch

Fig. 6 Clearance Measurement

PLENGINE 9 - 5

GENERAL INFORMATION (Continued)

Page 731 of 1285

ENGINE DIAGNOSIS

TABLE OF CONTENTS

page page

DIAGNOSIS AND TESTING

GENERAL INFORMATION...................8

INTAKE MANIFOLD LEAKAGE DIAGNOSIS......8

CYLINDER COMPRESSION PRESSURE TEST . . . 8

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST.........................9LASH ADJUSTER (TAPPET) NOISE

DIAGNOSIS............................9

ENGINE OIL LEAK INSPECTION..............9

ENGINE DIAGNOSISÐPERFORMANCE........11

ENGINE DIAGNOSISÐMECHANICAL.........12

DIAGNOSIS AND TESTING

GENERAL INFORMATION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Service DiagnosisÐMechanical Chart

and the Service DiagnosisÐPerformance Chart, for

possible causes and corrections of malfunctions. Refer

to Group 14, Fuel System, for the fuel system diag-

nosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

INTAKE MANIFOLD LEAKAGE DIAGNOSIS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If engine RPM'S change, the area of the sus-

pected leak has been found.

(4) Repair as required.

CYLINDER COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.

(4) Disconnect coil wire from distributor and

secure to good ground to prevent a spark from start-

ing a fire (Conventional Ignition System). For Direct

Ignition System DIS disconnect the coil connector.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gage adaptor into the #1

spark plug hole in cylinder head. Crank engine until

maximum pressure is reached on gage. Record this

pressure as #1 cylinder pressure.

(7) Repeat the previous step for all remaining cyl-

inders.

(8) Compression should not be less than (689 kPa)

100 psi and not vary more than 25 percent from cyl-

inder to cylinder.

(9) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(10) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

9 - 8 ENGINEPL

Page 752 of 1285

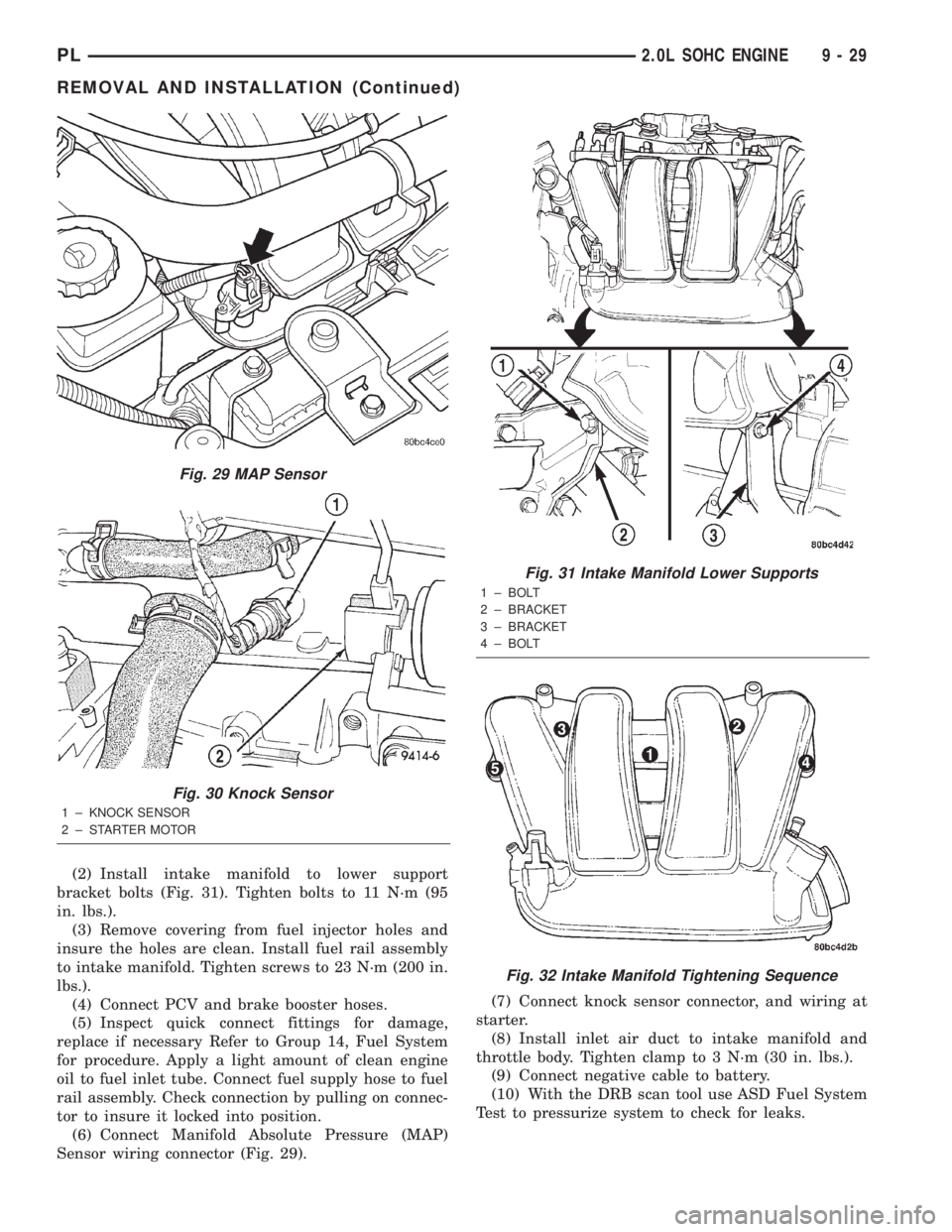

(2) Install intake manifold to lower support

bracket bolts (Fig. 31). Tighten bolts to 11 N´m (95

in. lbs.).

(3) Remove covering from fuel injector holes and

insure the holes are clean. Install fuel rail assembly

to intake manifold. Tighten screws to 23 N´m (200 in.

lbs.).

(4) Connect PCV and brake booster hoses.

(5) Inspect quick connect fittings for damage,

replace if necessary Refer to Group 14, Fuel System

for procedure. Apply a light amount of clean engine

oil to fuel inlet tube. Connect fuel supply hose to fuel

rail assembly. Check connection by pulling on connec-

tor to insure it locked into position.

(6) Connect Manifold Absolute Pressure (MAP)

Sensor wiring connector (Fig. 29).(7) Connect knock sensor connector, and wiring at

starter.

(8) Install inlet air duct to intake manifold and

throttle body. Tighten clamp to 3 N´m (30 in. lbs.).

(9) Connect negative cable to battery.

(10) With the DRB scan tool use ASD Fuel System

Test to pressurize system to check for leaks.

Fig. 29 MAP Sensor

Fig. 30 Knock Sensor

1 ± KNOCK SENSOR

2 ± STARTER MOTOR

Fig. 31 Intake Manifold Lower Supports

1 ± BOLT

2 ± BRACKET

3 ± BRACKET

4 ± BOLT

Fig. 32 Intake Manifold Tightening Sequence

PL2.0L SOHC ENGINE 9 - 29

REMOVAL AND INSTALLATION (Continued)