warning DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1256 of 1285

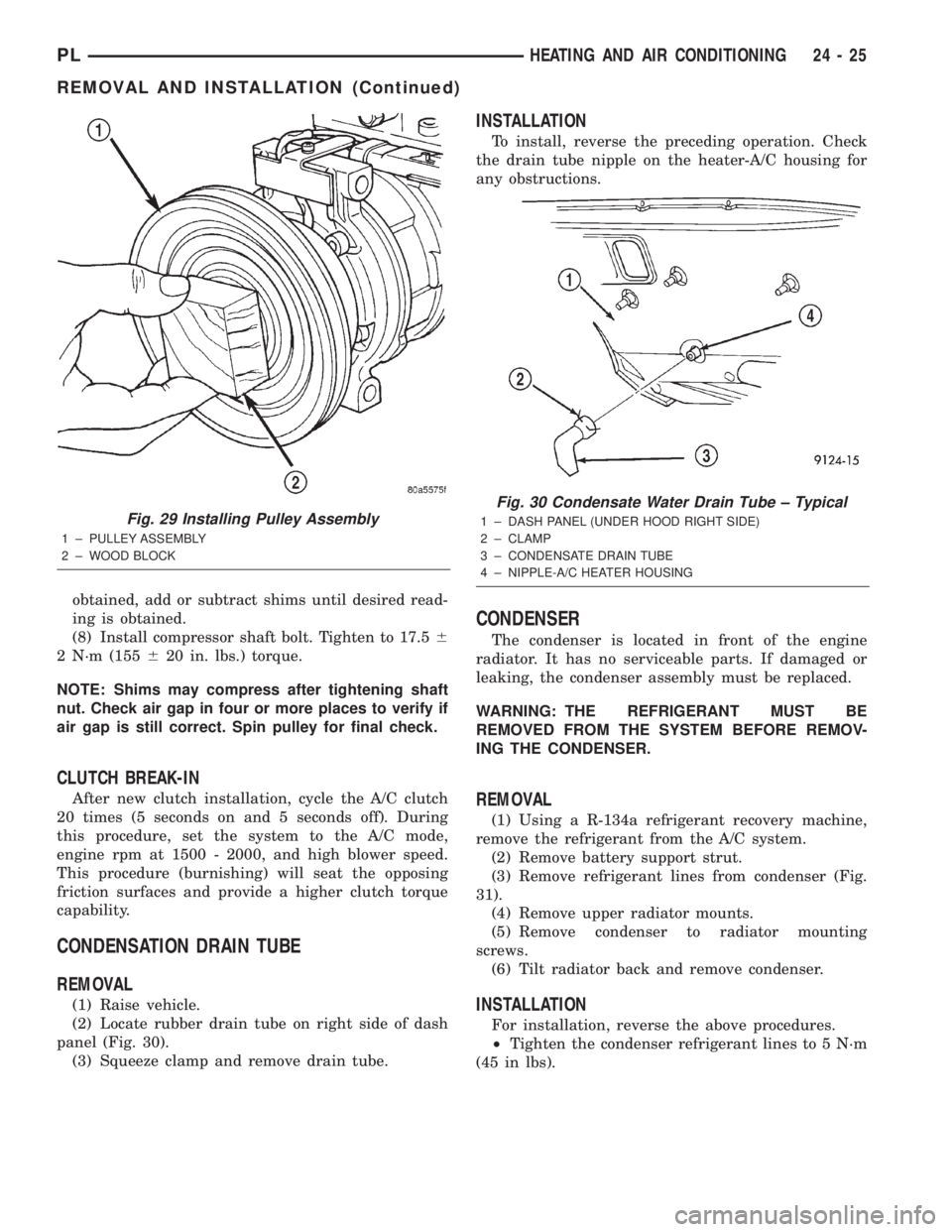

obtained, add or subtract shims until desired read-

ing is obtained.

(8) Install compressor shaft bolt. Tighten to 17.56

2 N´m (155620 in. lbs.) torque.

NOTE: Shims may compress after tightening shaft

nut. Check air gap in four or more places to verify if

air gap is still correct. Spin pulley for final check.

CLUTCH BREAK-IN

After new clutch installation, cycle the A/C clutch

20 times (5 seconds on and 5 seconds off). During

this procedure, set the system to the A/C mode,

engine rpm at 1500 - 2000, and high blower speed.

This procedure (burnishing) will seat the opposing

friction surfaces and provide a higher clutch torque

capability.

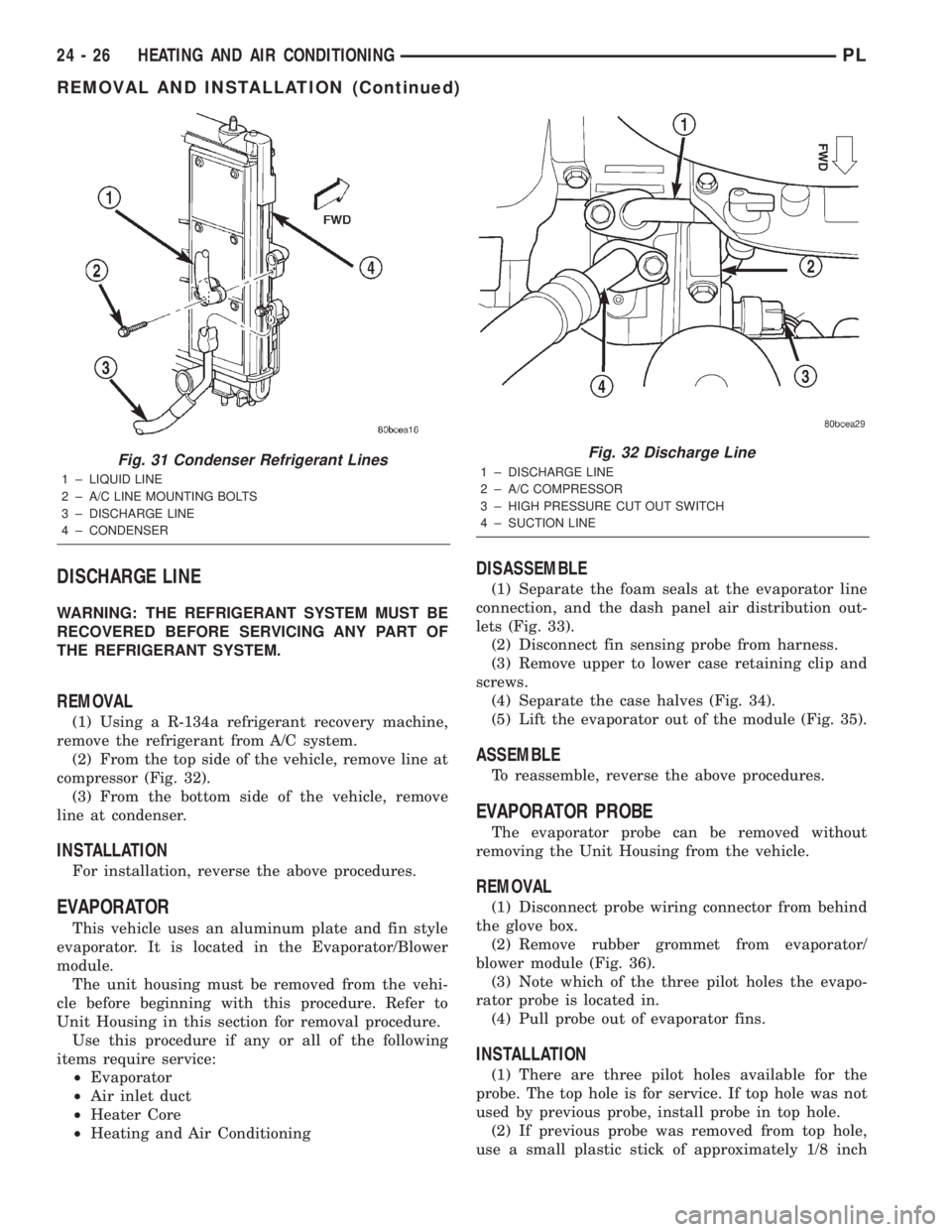

CONDENSATION DRAIN TUBE

REMOVAL

(1) Raise vehicle.

(2) Locate rubber drain tube on right side of dash

panel (Fig. 30).

(3) Squeeze clamp and remove drain tube.

INSTALLATION

To install, reverse the preceding operation. Check

the drain tube nipple on the heater-A/C housing for

any obstructions.

CONDENSER

The condenser is located in front of the engine

radiator. It has no serviceable parts. If damaged or

leaking, the condenser assembly must be replaced.

WARNING: THE REFRIGERANT MUST BE

REMOVED FROM THE SYSTEM BEFORE REMOV-

ING THE CONDENSER.

REMOVAL

(1) Using a R-134a refrigerant recovery machine,

remove the refrigerant from the A/C system.

(2) Remove battery support strut.

(3) Remove refrigerant lines from condenser (Fig.

31).

(4) Remove upper radiator mounts.

(5) Remove condenser to radiator mounting

screws.

(6) Tilt radiator back and remove condenser.

INSTALLATION

For installation, reverse the above procedures.

²Tighten the condenser refrigerant lines to 5 N´m

(45 in lbs).

Fig. 29 Installing Pulley Assembly

1 ± PULLEY ASSEMBLY

2 ± WOOD BLOCK

Fig. 30 Condensate Water Drain Tube ± Typical

1 ± DASH PANEL (UNDER HOOD RIGHT SIDE)

2 ± CLAMP

3 ± CONDENSATE DRAIN TUBE

4 ± NIPPLE-A/C HEATER HOUSING

PLHEATING AND AIR CONDITIONING 24 - 25

REMOVAL AND INSTALLATION (Continued)

Page 1257 of 1285

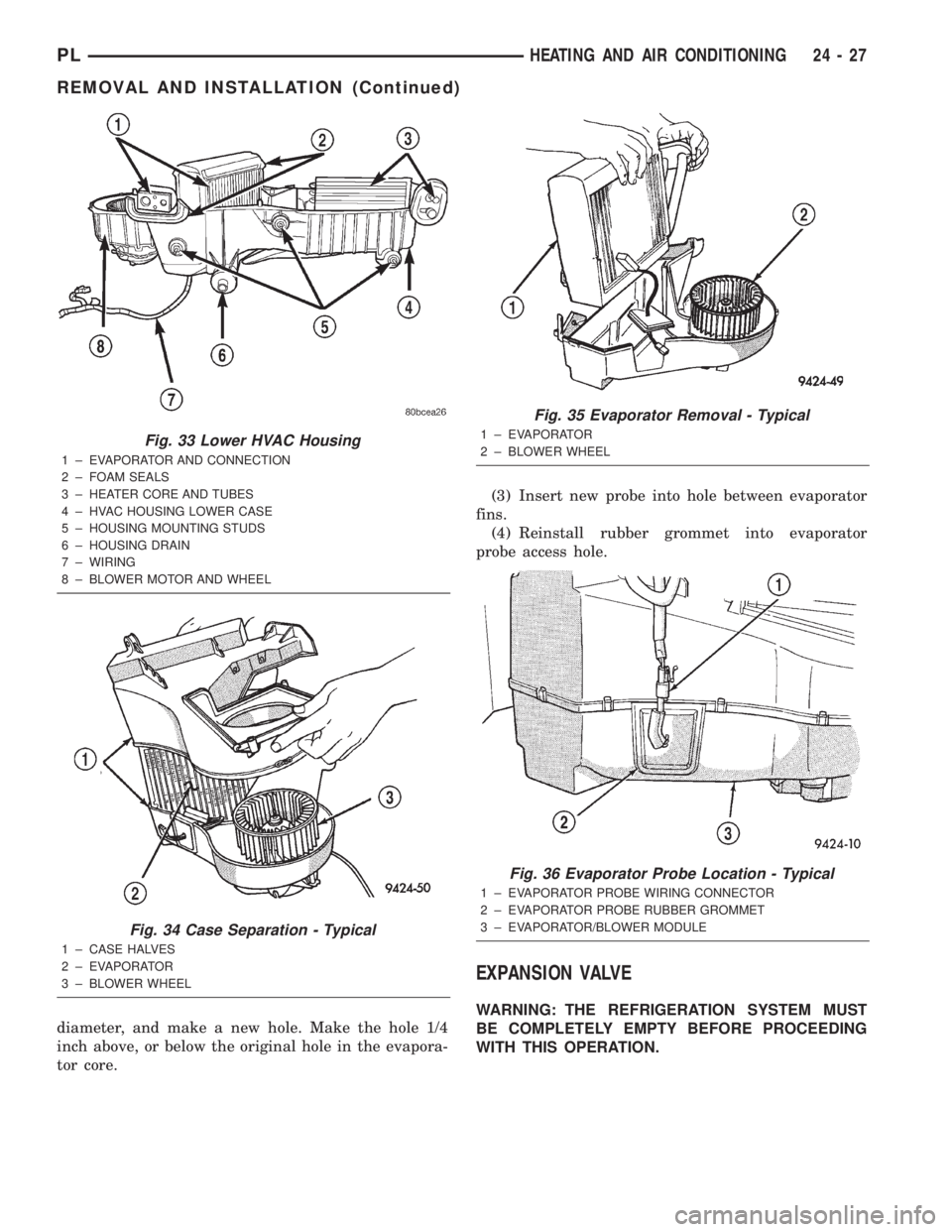

DISCHARGE LINE

WARNING: THE REFRIGERANT SYSTEM MUST BE

RECOVERED BEFORE SERVICING ANY PART OF

THE REFRIGERANT SYSTEM.

REMOVAL

(1) Using a R-134a refrigerant recovery machine,

remove the refrigerant from A/C system.

(2) From the top side of the vehicle, remove line at

compressor (Fig. 32).

(3) From the bottom side of the vehicle, remove

line at condenser.

INSTALLATION

For installation, reverse the above procedures.

EVAPORATOR

This vehicle uses an aluminum plate and fin style

evaporator. It is located in the Evaporator/Blower

module.

The unit housing must be removed from the vehi-

cle before beginning with this procedure. Refer to

Unit Housing in this section for removal procedure.

Use this procedure if any or all of the following

items require service:

²Evaporator

²Air inlet duct

²Heater Core

²Heating and Air Conditioning

DISASSEMBLE

(1) Separate the foam seals at the evaporator line

connection, and the dash panel air distribution out-

lets (Fig. 33).

(2) Disconnect fin sensing probe from harness.

(3) Remove upper to lower case retaining clip and

screws.

(4) Separate the case halves (Fig. 34).

(5) Lift the evaporator out of the module (Fig. 35).

ASSEMBLE

To reassemble, reverse the above procedures.

EVAPORATOR PROBE

The evaporator probe can be removed without

removing the Unit Housing from the vehicle.

REMOVAL

(1) Disconnect probe wiring connector from behind

the glove box.

(2) Remove rubber grommet from evaporator/

blower module (Fig. 36).

(3) Note which of the three pilot holes the evapo-

rator probe is located in.

(4) Pull probe out of evaporator fins.

INSTALLATION

(1) There are three pilot holes available for the

probe. The top hole is for service. If top hole was not

used by previous probe, install probe in top hole.

(2) If previous probe was removed from top hole,

use a small plastic stick of approximately 1/8 inch

Fig. 31 Condenser Refrigerant Lines

1 ± LIQUID LINE

2 ± A/C LINE MOUNTING BOLTS

3 ± DISCHARGE LINE

4 ± CONDENSER

Fig. 32 Discharge Line

1 ± DISCHARGE LINE

2 ± A/C COMPRESSOR

3 ± HIGH PRESSURE CUT OUT SWITCH

4 ± SUCTION LINE

24 - 26 HEATING AND AIR CONDITIONINGPL

REMOVAL AND INSTALLATION (Continued)

Page 1258 of 1285

diameter, and make a new hole. Make the hole 1/4

inch above, or below the original hole in the evapora-

tor core.(3) Insert new probe into hole between evaporator

fins.

(4) Reinstall rubber grommet into evaporator

probe access hole.

EXPANSION VALVE

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION.

Fig. 33 Lower HVAC Housing

1 ± EVAPORATOR AND CONNECTION

2 ± FOAM SEALS

3 ± HEATER CORE AND TUBES

4 ± HVAC HOUSING LOWER CASE

5 ± HOUSING MOUNTING STUDS

6 ± HOUSING DRAIN

7 ± WIRING

8 ± BLOWER MOTOR AND WHEEL

Fig. 34 Case Separation - Typical

1 ± CASE HALVES

2 ± EVAPORATOR

3 ± BLOWER WHEEL

Fig. 35 Evaporator Removal - Typical

1 ± EVAPORATOR

2 ± BLOWER WHEEL

Fig. 36 Evaporator Probe Location - Typical

1 ± EVAPORATOR PROBE WIRING CONNECTOR

2 ± EVAPORATOR PROBE RUBBER GROMMET

3 ± EVAPORATOR/BLOWER MODULE

PLHEATING AND AIR CONDITIONING 24 - 27

REMOVAL AND INSTALLATION (Continued)

Page 1260 of 1285

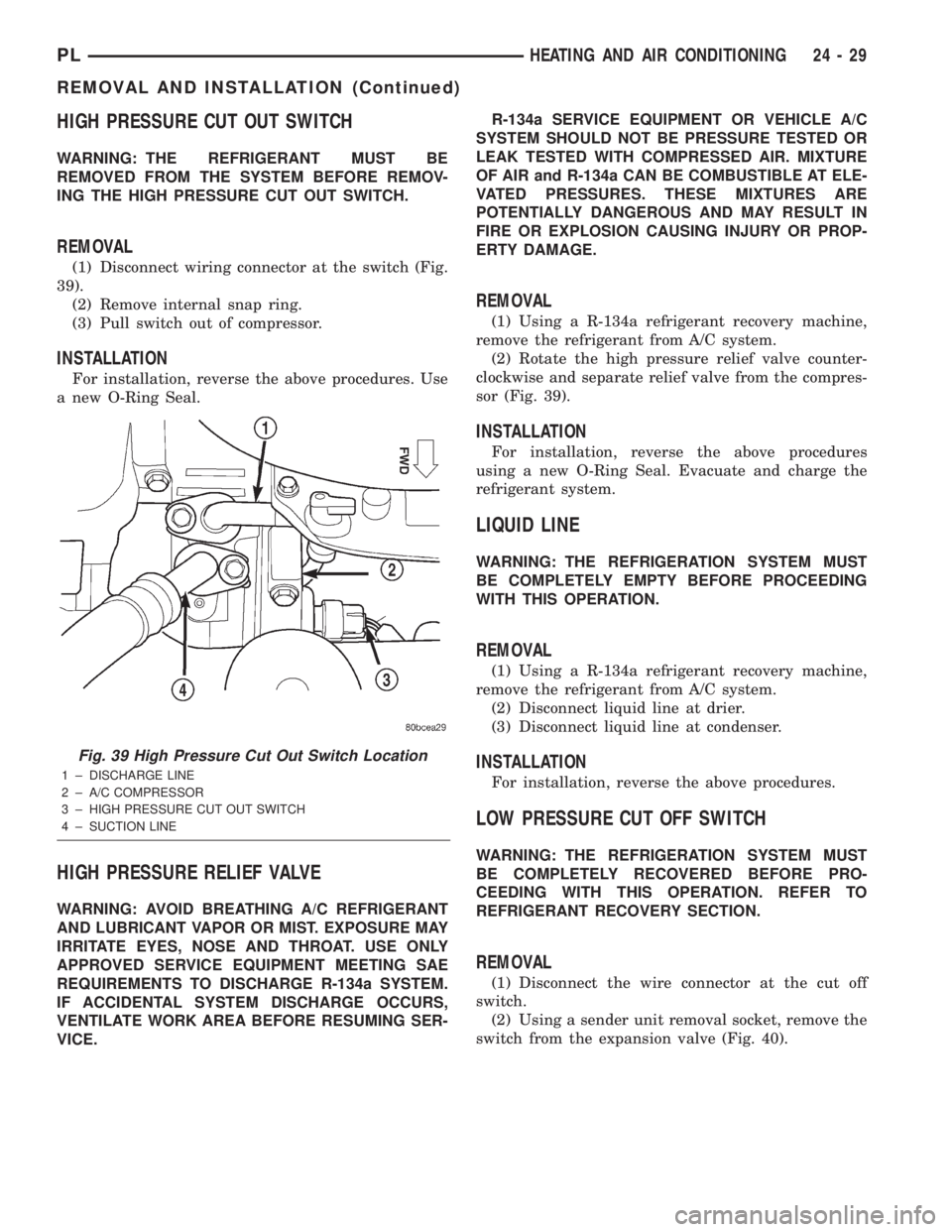

HIGH PRESSURE CUT OUT SWITCH

WARNING: THE REFRIGERANT MUST BE

REMOVED FROM THE SYSTEM BEFORE REMOV-

ING THE HIGH PRESSURE CUT OUT SWITCH.

REMOVAL

(1) Disconnect wiring connector at the switch (Fig.

39).

(2) Remove internal snap ring.

(3) Pull switch out of compressor.

INSTALLATION

For installation, reverse the above procedures. Use

a new O-Ring Seal.

HIGH PRESSURE RELIEF VALVE

WARNING: AVOID BREATHING A/C REFRIGERANT

AND LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND THROAT. USE ONLY

APPROVED SERVICE EQUIPMENT MEETING SAE

REQUIREMENTS TO DISCHARGE R-134a SYSTEM.

IF ACCIDENTAL SYSTEM DISCHARGE OCCURS,

VENTILATE WORK AREA BEFORE RESUMING SER-

VICE.R-134a SERVICE EQUIPMENT OR VEHICLE A/C

SYSTEM SHOULD NOT BE PRESSURE TESTED OR

LEAK TESTED WITH COMPRESSED AIR. MIXTURE

OF AIR and R-134a CAN BE COMBUSTIBLE AT ELE-

VATED PRESSURES. THESE MIXTURES ARE

POTENTIALLY DANGEROUS AND MAY RESULT IN

FIRE OR EXPLOSION CAUSING INJURY OR PROP-

ERTY DAMAGE.

REMOVAL

(1) Using a R-134a refrigerant recovery machine,

remove the refrigerant from A/C system.

(2) Rotate the high pressure relief valve counter-

clockwise and separate relief valve from the compres-

sor (Fig. 39).

INSTALLATION

For installation, reverse the above procedures

using a new O-Ring Seal. Evacuate and charge the

refrigerant system.

LIQUID LINE

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION.

REMOVAL

(1) Using a R-134a refrigerant recovery machine,

remove the refrigerant from A/C system.

(2) Disconnect liquid line at drier.

(3) Disconnect liquid line at condenser.

INSTALLATION

For installation, reverse the above procedures.

LOW PRESSURE CUT OFF SWITCH

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY RECOVERED BEFORE PRO-

CEEDING WITH THIS OPERATION. REFER TO

REFRIGERANT RECOVERY SECTION.

REMOVAL

(1) Disconnect the wire connector at the cut off

switch.

(2) Using a sender unit removal socket, remove the

switch from the expansion valve (Fig. 40).

Fig. 39 High Pressure Cut Out Switch Location

1 ± DISCHARGE LINE

2 ± A/C COMPRESSOR

3 ± HIGH PRESSURE CUT OUT SWITCH

4 ± SUCTION LINE

PLHEATING AND AIR CONDITIONING 24 - 29

REMOVAL AND INSTALLATION (Continued)

Page 1262 of 1285

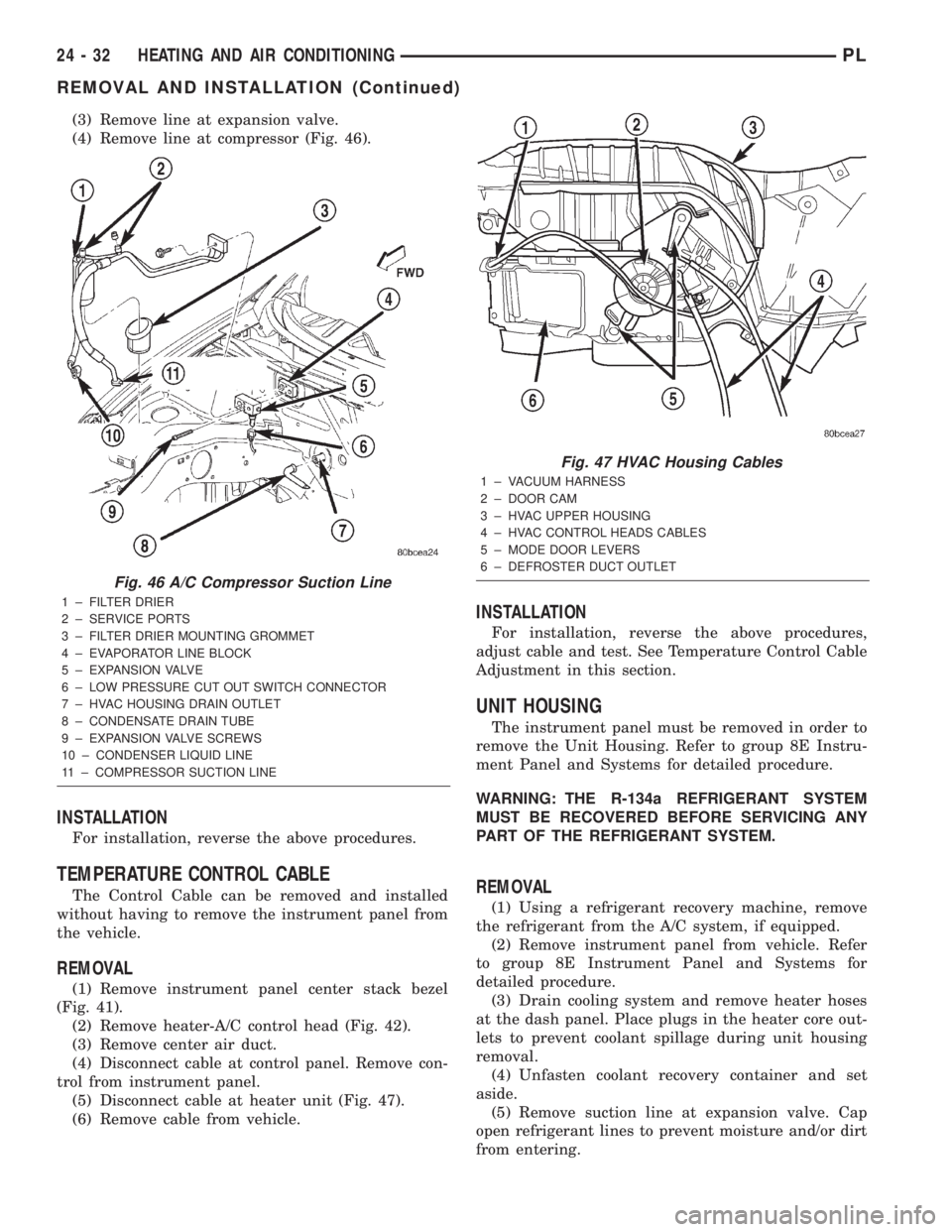

RECIRCULATION DOOR ACTUATOR

The recirculation door actuator is a vacuum con-

trolled actuator used to control movement of the

recirculation door in air conditioned equipped vehi-

cles.

The instrument panel must be removed from the

vehicle to gain access to the recirculation door actua-

tor.

REMOVAL

(1) Remove instrument panel from vehicle. Refer

to Group 8E, Instrument Panel And Systems for

removal procedures.

(2) Disconnect vacuum line from actuator.

(3) Disconnect actuator from recirculation door

link (Fig. 44).

(4) Release tension on latch, and slide recircula-

tion door actuator off housing.

INSTALLATION

For installation, reverse the above procedures.

SUCTION LINE

WARNING: THE REFRIGERANT MUST BE RECOV-

ERED BEFORE SERVICING ANY PART OF THE

REFRIGERANT SYSTEMS.

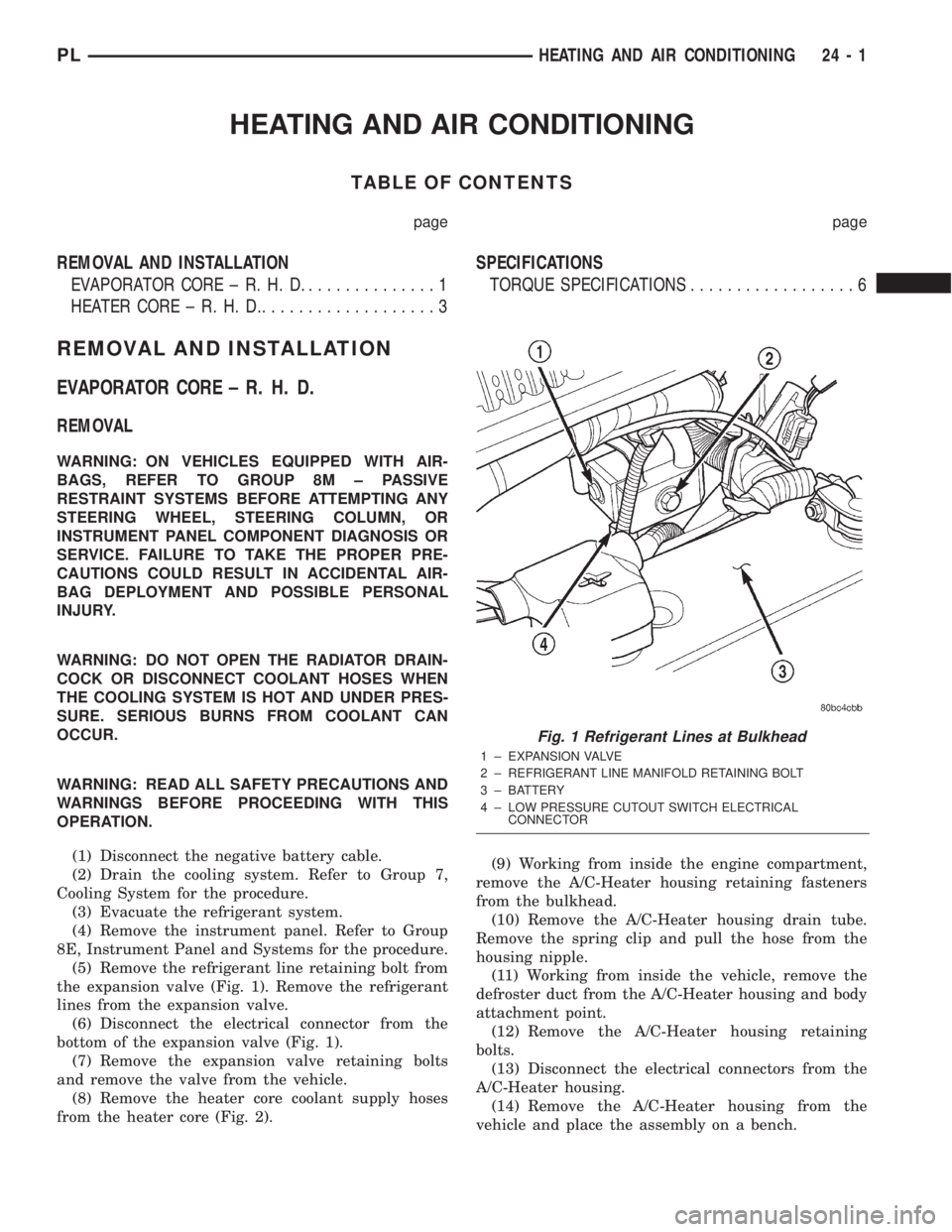

REMOVAL

(1) Using a R-134a refrigerant recovery machine,

remove the refrigerant from A/C system.

(2) Remove retaining bolt at expansion valve (Fig.

45).

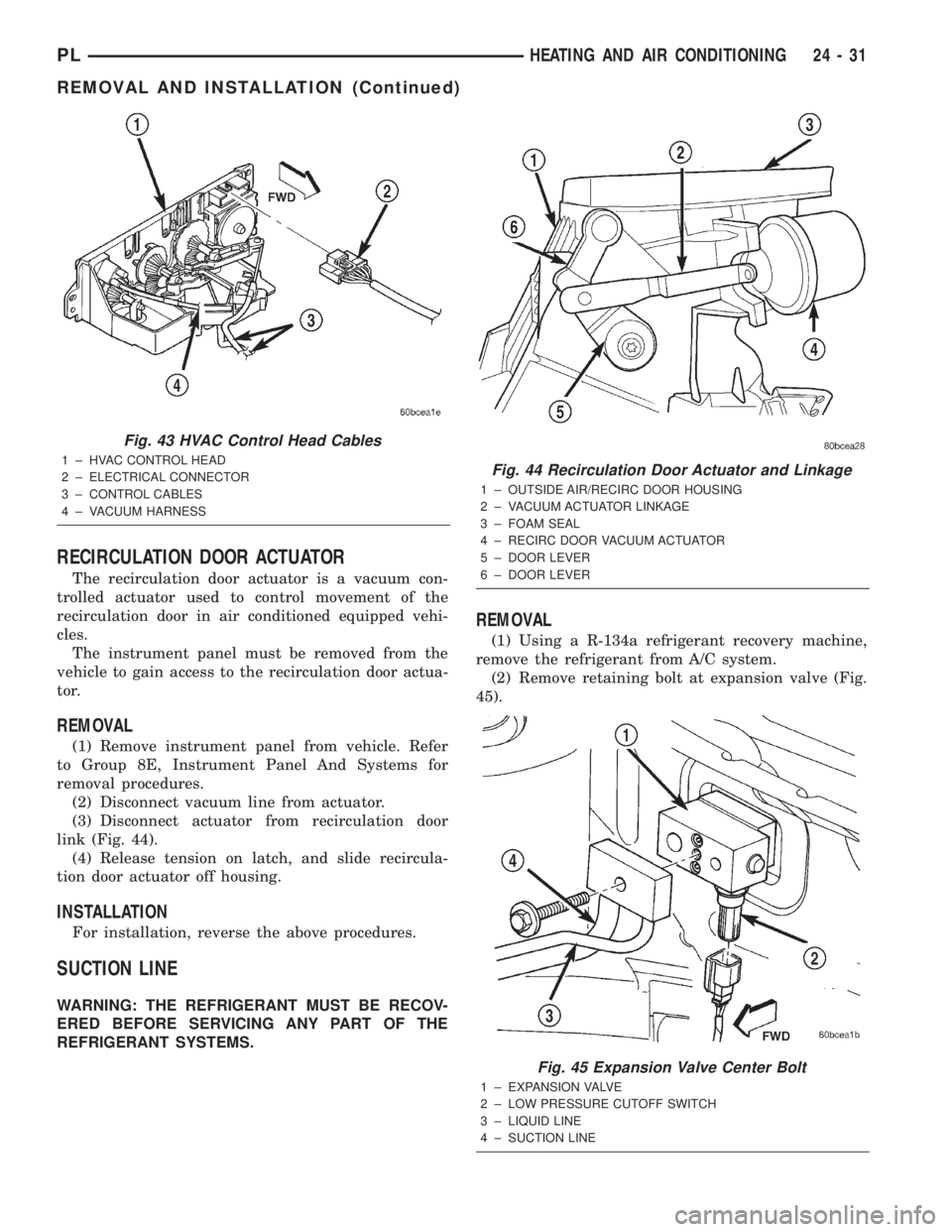

Fig. 43 HVAC Control Head Cables

1 ± HVAC CONTROL HEAD

2 ± ELECTRICAL CONNECTOR

3 ± CONTROL CABLES

4 ± VACUUM HARNESSFig. 44 Recirculation Door Actuator and Linkage

1 ± OUTSIDE AIR/RECIRC DOOR HOUSING

2 ± VACUUM ACTUATOR LINKAGE

3 ± FOAM SEAL

4 ± RECIRC DOOR VACUUM ACTUATOR

5 ± DOOR LEVER

6 ± DOOR LEVER

Fig. 45 Expansion Valve Center Bolt

1 ± EXPANSION VALVE

2 ± LOW PRESSURE CUTOFF SWITCH

3 ± LIQUID LINE

4 ± SUCTION LINE

PLHEATING AND AIR CONDITIONING 24 - 31

REMOVAL AND INSTALLATION (Continued)

Page 1263 of 1285

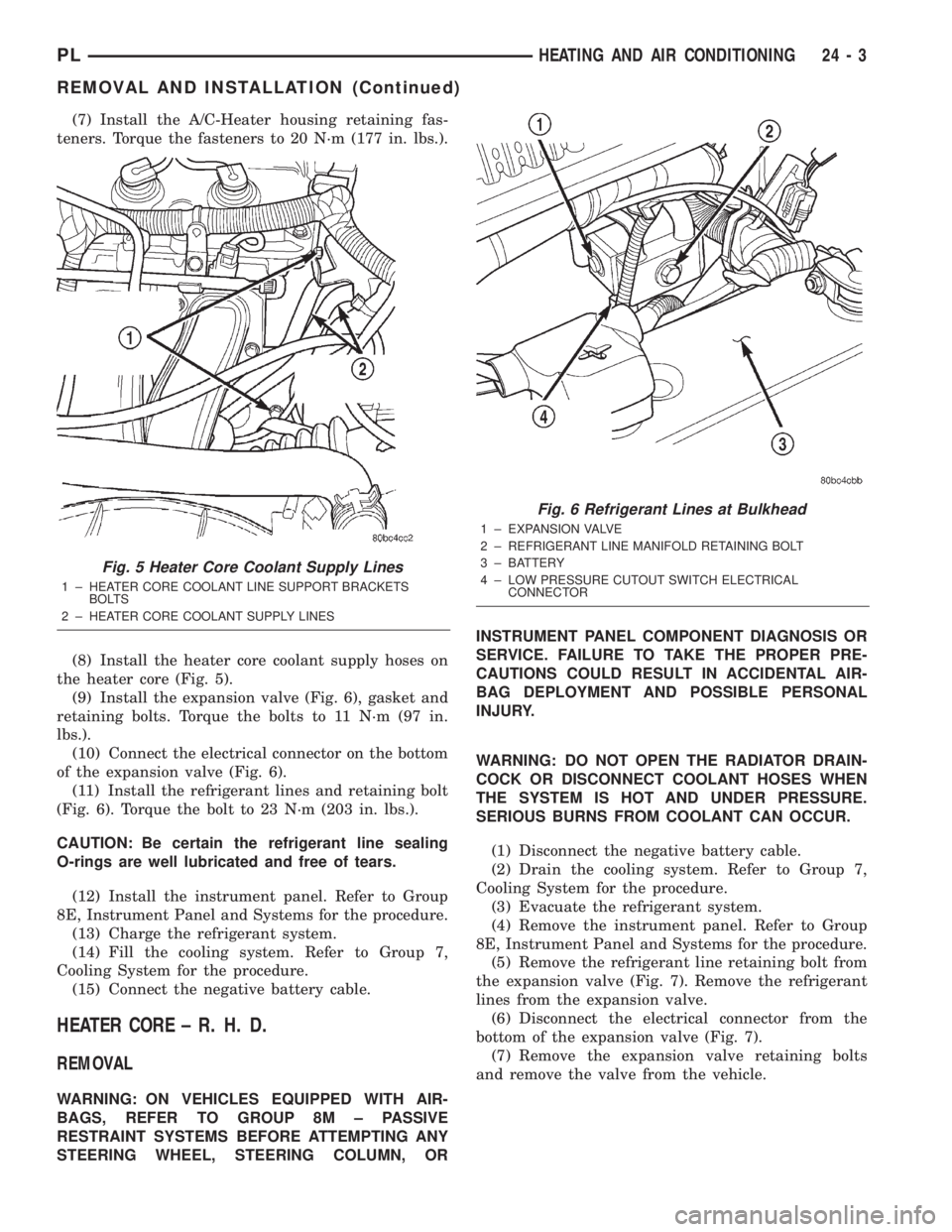

(3) Remove line at expansion valve.

(4) Remove line at compressor (Fig. 46).

INSTALLATION

For installation, reverse the above procedures.

TEMPERATURE CONTROL CABLE

The Control Cable can be removed and installed

without having to remove the instrument panel from

the vehicle.

REMOVAL

(1) Remove instrument panel center stack bezel

(Fig. 41).

(2) Remove heater-A/C control head (Fig. 42).

(3) Remove center air duct.

(4) Disconnect cable at control panel. Remove con-

trol from instrument panel.

(5) Disconnect cable at heater unit (Fig. 47).

(6) Remove cable from vehicle.

INSTALLATION

For installation, reverse the above procedures,

adjust cable and test. See Temperature Control Cable

Adjustment in this section.

UNIT HOUSING

The instrument panel must be removed in order to

remove the Unit Housing. Refer to group 8E Instru-

ment Panel and Systems for detailed procedure.

WARNING: THE R-134a REFRIGERANT SYSTEM

MUST BE RECOVERED BEFORE SERVICING ANY

PART OF THE REFRIGERANT SYSTEM.

REMOVAL

(1) Using a refrigerant recovery machine, remove

the refrigerant from the A/C system, if equipped.

(2) Remove instrument panel from vehicle. Refer

to group 8E Instrument Panel and Systems for

detailed procedure.

(3) Drain cooling system and remove heater hoses

at the dash panel. Place plugs in the heater core out-

lets to prevent coolant spillage during unit housing

removal.

(4) Unfasten coolant recovery container and set

aside.

(5) Remove suction line at expansion valve. Cap

open refrigerant lines to prevent moisture and/or dirt

from entering.

Fig. 46 A/C Compressor Suction Line

1 ± FILTER DRIER

2 ± SERVICE PORTS

3 ± FILTER DRIER MOUNTING GROMMET

4 ± EVAPORATOR LINE BLOCK

5 ± EXPANSION VALVE

6 ± LOW PRESSURE CUT OUT SWITCH CONNECTOR

7 ± HVAC HOUSING DRAIN OUTLET

8 ± CONDENSATE DRAIN TUBE

9 ± EXPANSION VALVE SCREWS

10 ± CONDENSER LIQUID LINE

11 ± COMPRESSOR SUCTION LINE

Fig. 47 HVAC Housing Cables

1 ± VACUUM HARNESS

2 ± DOOR CAM

3 ± HVAC UPPER HOUSING

4 ± HVAC CONTROL HEADS CABLES

5 ± MODE DOOR LEVERS

6 ± DEFROSTER DUCT OUTLET

24 - 32 HEATING AND AIR CONDITIONINGPL

REMOVAL AND INSTALLATION (Continued)

Page 1268 of 1285

HEATING AND AIR CONDITIONING

TABLE OF CONTENTS

page page

REMOVAL AND INSTALLATION

EVAPORATOR CORE ± R. H. D...............1

HEATER CORE ± R. H. D....................3SPECIFICATIONS

TORQUE SPECIFICATIONS..................6

REMOVAL AND INSTALLATION

EVAPORATOR CORE ± R. H. D.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M ± PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: DO NOT OPEN THE RADIATOR DRAIN-

COCK OR DISCONNECT COOLANT HOSES WHEN

THE COOLING SYSTEM IS HOT AND UNDER PRES-

SURE. SERIOUS BURNS FROM COOLANT CAN

OCCUR.

WARNING: READ ALL SAFETY PRECAUTIONS AND

WARNINGS BEFORE PROCEEDING WITH THIS

OPERATION.

(1) Disconnect the negative battery cable.

(2) Drain the cooling system. Refer to Group 7,

Cooling System for the procedure.

(3) Evacuate the refrigerant system.

(4) Remove the instrument panel. Refer to Group

8E, Instrument Panel and Systems for the procedure.

(5) Remove the refrigerant line retaining bolt from

the expansion valve (Fig. 1). Remove the refrigerant

lines from the expansion valve.

(6) Disconnect the electrical connector from the

bottom of the expansion valve (Fig. 1).

(7) Remove the expansion valve retaining bolts

and remove the valve from the vehicle.

(8) Remove the heater core coolant supply hoses

from the heater core (Fig. 2).(9) Working from inside the engine compartment,

remove the A/C-Heater housing retaining fasteners

from the bulkhead.

(10) Remove the A/C-Heater housing drain tube.

Remove the spring clip and pull the hose from the

housing nipple.

(11) Working from inside the vehicle, remove the

defroster duct from the A/C-Heater housing and body

attachment point.

(12) Remove the A/C-Heater housing retaining

bolts.

(13) Disconnect the electrical connectors from the

A/C-Heater housing.

(14) Remove the A/C-Heater housing from the

vehicle and place the assembly on a bench.

Fig. 1 Refrigerant Lines at Bulkhead

1 ± EXPANSION VALVE

2 ± REFRIGERANT LINE MANIFOLD RETAINING BOLT

3 ± BATTERY

4 ± LOW PRESSURE CUTOUT SWITCH ELECTRICAL

CONNECTOR

PLHEATING AND AIR CONDITIONING 24 - 1

Page 1270 of 1285

(7) Install the A/C-Heater housing retaining fas-

teners. Torque the fasteners to 20 N´m (177 in. lbs.).

(8) Install the heater core coolant supply hoses on

the heater core (Fig. 5).

(9) Install the expansion valve (Fig. 6), gasket and

retaining bolts. Torque the bolts to 11 N´m (97 in.

lbs.).

(10) Connect the electrical connector on the bottom

of the expansion valve (Fig. 6).

(11) Install the refrigerant lines and retaining bolt

(Fig. 6). Torque the bolt to 23 N´m (203 in. lbs.).

CAUTION: Be certain the refrigerant line sealing

O-rings are well lubricated and free of tears.

(12) Install the instrument panel. Refer to Group

8E, Instrument Panel and Systems for the procedure.

(13) Charge the refrigerant system.

(14) Fill the cooling system. Refer to Group 7,

Cooling System for the procedure.

(15) Connect the negative battery cable.

HEATER CORE ± R. H. D.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M ± PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, ORINSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: DO NOT OPEN THE RADIATOR DRAIN-

COCK OR DISCONNECT COOLANT HOSES WHEN

THE SYSTEM IS HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

(1) Disconnect the negative battery cable.

(2) Drain the cooling system. Refer to Group 7,

Cooling System for the procedure.

(3) Evacuate the refrigerant system.

(4) Remove the instrument panel. Refer to Group

8E, Instrument Panel and Systems for the procedure.

(5) Remove the refrigerant line retaining bolt from

the expansion valve (Fig. 7). Remove the refrigerant

lines from the expansion valve.

(6) Disconnect the electrical connector from the

bottom of the expansion valve (Fig. 7).

(7) Remove the expansion valve retaining bolts

and remove the valve from the vehicle.

Fig. 5 Heater Core Coolant Supply Lines

1 ± HEATER CORE COOLANT LINE SUPPORT BRACKETS

BOLTS

2 ± HEATER CORE COOLANT SUPPLY LINES

Fig. 6 Refrigerant Lines at Bulkhead

1 ± EXPANSION VALVE

2 ± REFRIGERANT LINE MANIFOLD RETAINING BOLT

3 ± BATTERY

4 ± LOW PRESSURE CUTOUT SWITCH ELECTRICAL

CONNECTOR

PLHEATING AND AIR CONDITIONING 24 - 3

REMOVAL AND INSTALLATION (Continued)

Page 1279 of 1285

FASTENER USAGE

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Figure art, specifications and tightening torque ref-

erences in this manual are identified in metric and

SAE format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be use.

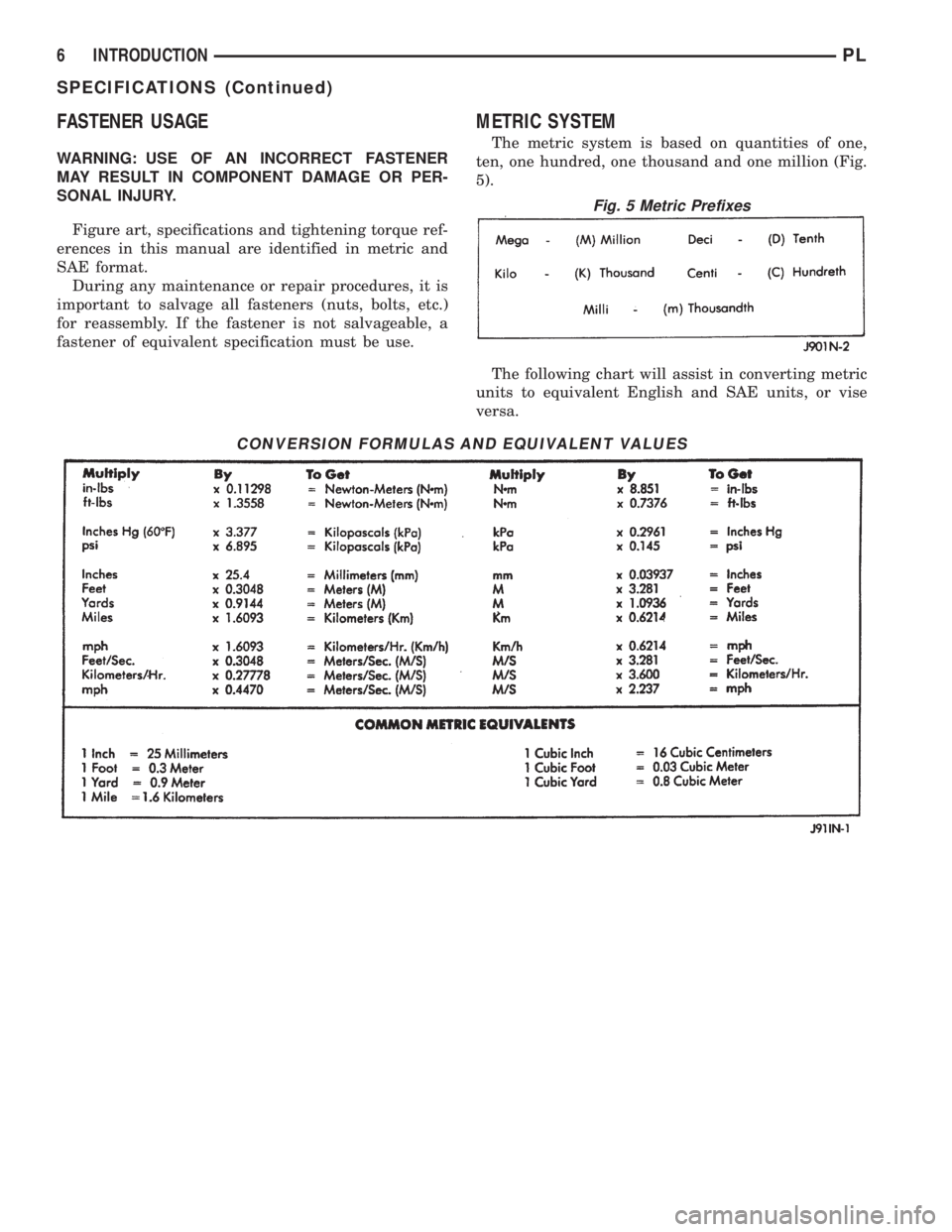

METRIC SYSTEM

The metric system is based on quantities of one,

ten, one hundred, one thousand and one million (Fig.

5).

The following chart will assist in converting metric

units to equivalent English and SAE units, or vise

versa.

CONVERSION FORMULAS AND EQUIVALENT VALUES

Fig. 5 Metric Prefixes

6 INTRODUCTIONPL

SPECIFICATIONS (Continued)