warning DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 832 of 1285

being serviced. The plastic retainer will remain on

component being serviced after fitting is discon-

nected. The O-rings and spacer will remain in quick-

connect fitting connector body.

(5) Inspect quick-connect fitting body and compo-

nent for damage. Replace as necessary.

CAUTION:

When the quick-connect fitting was dis-

connected, the plastic retainer will remain on the com-

ponent being serviced. If this retainer must be

removed, very carefully release the retainer from the

component with two small screwdrivers. After removal,

inspect the retainer for cracks or any damage.

(6) Prior to connecting quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean parts with a lint-free cloth.

Lubricate with clean engine oil.

(7) Insert quick-connect fitting to component being

serviced and into plastic retainer. When a connection

is made, a click will be heard.

(8) Verify a locked condition by firmly pulling on

fuel tube and fitting (15-30 lbs.).

(9) Connect negative cable to battery or auxiliary

jumper terminal.

(10) Start engine and check for leaks.

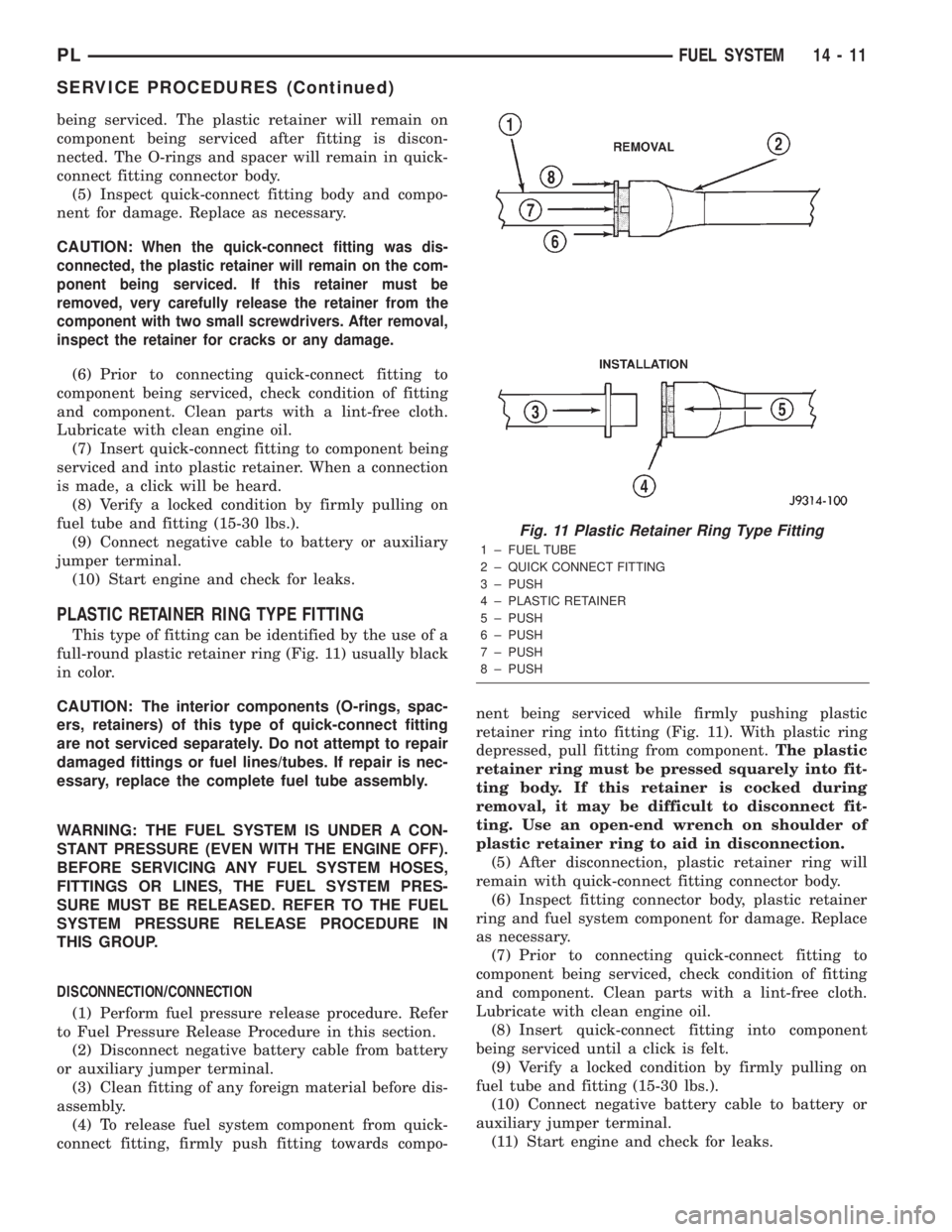

PLASTIC RETAINER RING TYPE FITTING

This type of fitting can be identified by the use of a

full-round plastic retainer ring (Fig. 11) usually black

in color.

CAUTION: The interior components (O-rings, spac-

ers, retainers) of this type of quick-connect fitting

are not serviced separately. Do not attempt to repair

damaged fittings or fuel lines/tubes. If repair is nec-

essary, replace the complete fuel tube assembly.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

SYSTEM PRESSURE RELEASE PROCEDURE IN

THIS GROUP.

DISCONNECTION/CONNECTION

(1) Perform fuel pressure release procedure. Refer

to Fuel Pressure Release Procedure in this section.

(2) Disconnect negative battery cable from battery

or auxiliary jumper terminal.

(3) Clean fitting of any foreign material before dis-

assembly.

(4) To release fuel system component from quick-

connect fitting, firmly push fitting towards compo-nent being serviced while firmly pushing plastic

retainer ring into fitting (Fig. 11). With plastic ring

depressed, pull fitting from component.The plastic

retainer ring must be pressed squarely into fit-

ting body. If this retainer is cocked during

removal, it may be difficult to disconnect fit-

ting. Use an open-end wrench on shoulder of

plastic retainer ring to aid in disconnection.

(5) After disconnection, plastic retainer ring will

remain with quick-connect fitting connector body.

(6) Inspect fitting connector body, plastic retainer

ring and fuel system component for damage. Replace

as necessary.

(7) Prior to connecting quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean parts with a lint-free cloth.

Lubricate with clean engine oil.

(8) Insert quick-connect fitting into component

being serviced until a click is felt.

(9) Verify a locked condition by firmly pulling on

fuel tube and fitting (15-30 lbs.).

(10) Connect negative battery cable to battery or

auxiliary jumper terminal.

(11) Start engine and check for leaks.

Fig. 11 Plastic Retainer Ring Type Fitting

1 ± FUEL TUBE

2 ± QUICK CONNECT FITTING

3 ± PUSH

4 ± PLASTIC RETAINER

5 ± PUSH

6 ± PUSH

7 ± PUSH

8 ± PUSH

PLFUEL SYSTEM 14 - 11

SERVICE PROCEDURES (Continued)

Page 833 of 1285

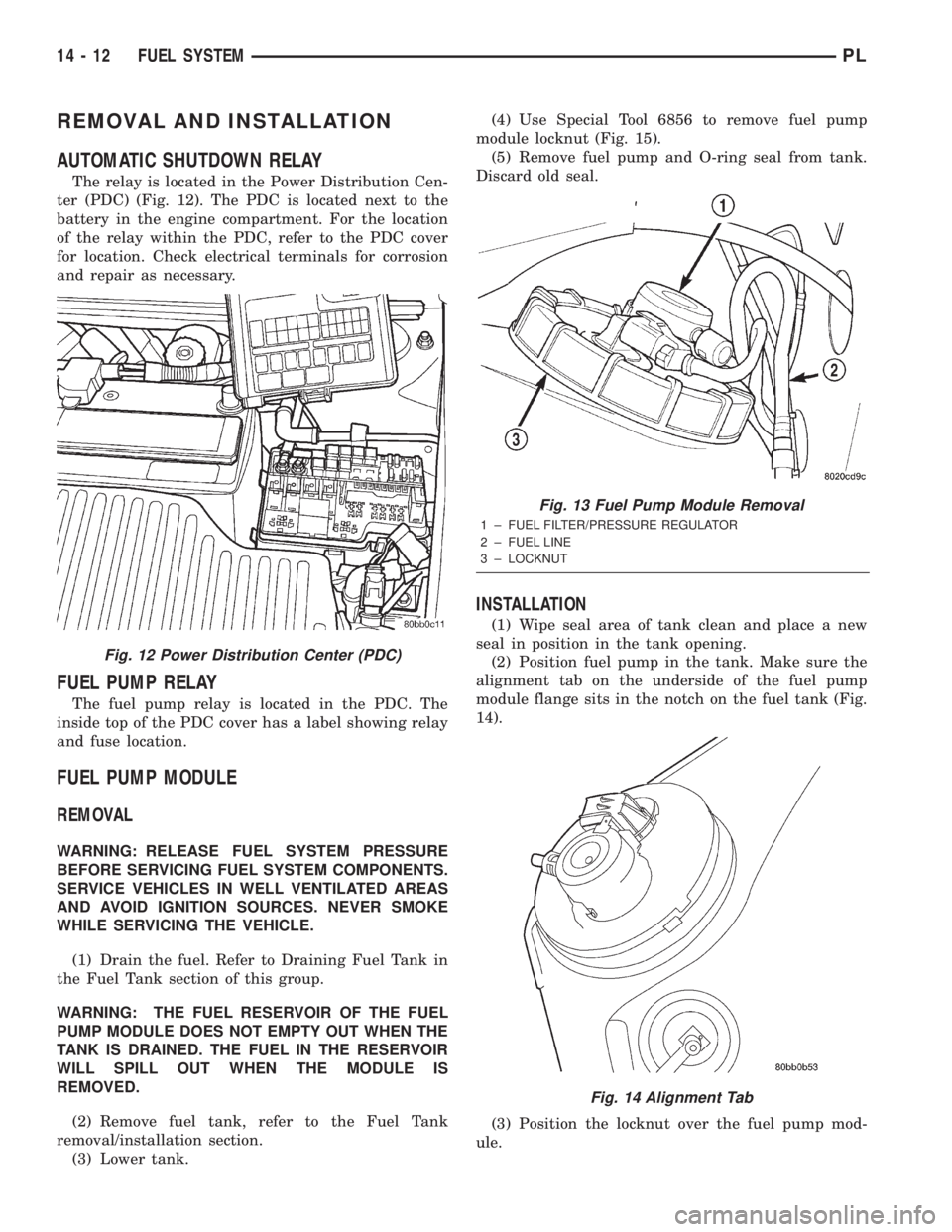

REMOVAL AND INSTALLATION

AUTOMATIC SHUTDOWN RELAY

The relay is located in the Power Distribution Cen-

ter (PDC) (Fig. 12). The PDC is located next to the

battery in the engine compartment. For the location

of the relay within the PDC, refer to the PDC cover

for location. Check electrical terminals for corrosion

and repair as necessary.

FUEL PUMP RELAY

The fuel pump relay is located in the PDC. The

inside top of the PDC cover has a label showing relay

and fuse location.

FUEL PUMP MODULE

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Drain the fuel. Refer to Draining Fuel Tank in

the Fuel Tank section of this group.

WARNING: THE FUEL RESERVOIR OF THE FUEL

PUMP MODULE DOES NOT EMPTY OUT WHEN THE

TANK IS DRAINED. THE FUEL IN THE RESERVOIR

WILL SPILL OUT WHEN THE MODULE IS

REMOVED.

(2) Remove fuel tank, refer to the Fuel Tank

removal/installation section.

(3) Lower tank.(4) Use Special Tool 6856 to remove fuel pump

module locknut (Fig. 15).

(5) Remove fuel pump and O-ring seal from tank.

Discard old seal.

INSTALLATION

(1) Wipe seal area of tank clean and place a new

seal in position in the tank opening.

(2) Position fuel pump in the tank. Make sure the

alignment tab on the underside of the fuel pump

module flange sits in the notch on the fuel tank (Fig.

14).

(3) Position the locknut over the fuel pump mod-

ule.

Fig. 12 Power Distribution Center (PDC)

Fig. 13 Fuel Pump Module Removal

1 ± FUEL FILTER/PRESSURE REGULATOR

2 ± FUEL LINE

3 ± LOCKNUT

Fig. 14 Alignment Tab

14 - 12 FUEL SYSTEMPL

Page 834 of 1285

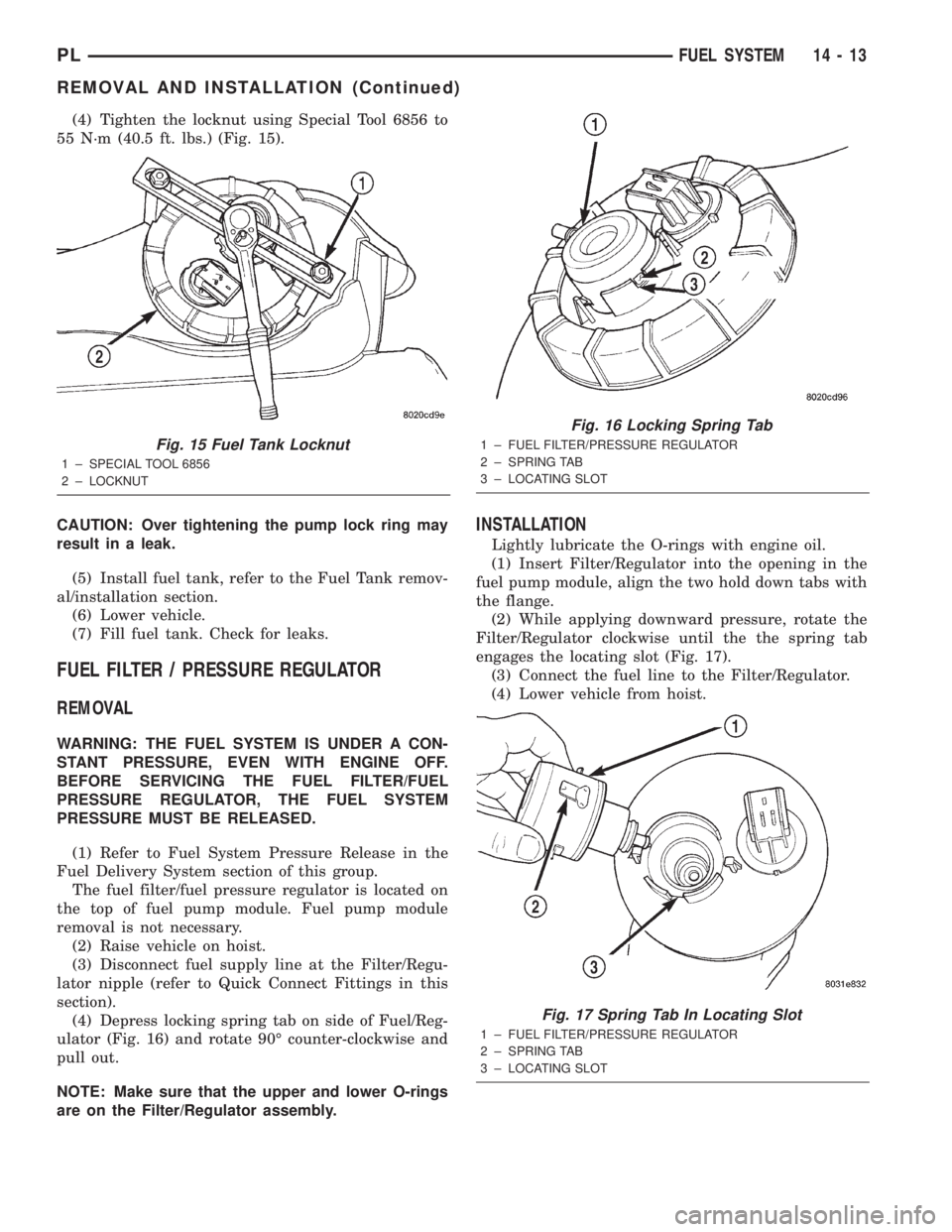

(4) Tighten the locknut using Special Tool 6856 to

55 N´m (40.5 ft. lbs.) (Fig. 15).

CAUTION: Over tightening the pump lock ring may

result in a leak.

(5) Install fuel tank, refer to the Fuel Tank remov-

al/installation section.

(6) Lower vehicle.

(7) Fill fuel tank. Check for leaks.

FUEL FILTER / PRESSURE REGULATOR

REMOVAL

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE, EVEN WITH ENGINE OFF.

BEFORE SERVICING THE FUEL FILTER/FUEL

PRESSURE REGULATOR, THE FUEL SYSTEM

PRESSURE MUST BE RELEASED.

(1) Refer to Fuel System Pressure Release in the

Fuel Delivery System section of this group.

The fuel filter/fuel pressure regulator is located on

the top of fuel pump module. Fuel pump module

removal is not necessary.

(2) Raise vehicle on hoist.

(3) Disconnect fuel supply line at the Filter/Regu-

lator nipple (refer to Quick Connect Fittings in this

section).

(4) Depress locking spring tab on side of Fuel/Reg-

ulator (Fig. 16) and rotate 90É counter-clockwise and

pull out.

NOTE: Make sure that the upper and lower O-rings

are on the Filter/Regulator assembly.

INSTALLATION

Lightly lubricate the O-rings with engine oil.

(1) Insert Filter/Regulator into the opening in the

fuel pump module, align the two hold down tabs with

the flange.

(2) While applying downward pressure, rotate the

Filter/Regulator clockwise until the the spring tab

engages the locating slot (Fig. 17).

(3) Connect the fuel line to the Filter/Regulator.

(4) Lower vehicle from hoist.

Fig. 15 Fuel Tank Locknut

1 ± SPECIAL TOOL 6856

2 ± LOCKNUT

Fig. 16 Locking Spring Tab

1 ± FUEL FILTER/PRESSURE REGULATOR

2 ± SPRING TAB

3 ± LOCATING SLOT

Fig. 17 Spring Tab In Locating Slot

1 ± FUEL FILTER/PRESSURE REGULATOR

2 ± SPRING TAB

3 ± LOCATING SLOT

PLFUEL SYSTEM 14 - 13

REMOVAL AND INSTALLATION (Continued)

Page 872 of 1285

STEERING

TABLE OF CONTENTS

page page

POWER STEERING......................... 1

POWER STEERING PUMP.................. 16STEERING GEAR.......................... 21

STEERING COLUMN....................... 29

POWER STEERING

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

POWER STEERING SYSTEM................1

POWER STEERING FLUID HOSES............2

POWER STEERING FLUID COOLER...........2

POWER STEERING FLUID PRESSURE

SWITCH...............................3

DIAGNOSIS AND TESTING

STEERING SYSTEM DIAGNOSIS CHARTS......4

POWER STEERING SYSTEM FLOW AND

PRESSURE TEST........................9

SERVICE PROCEDURES

POWER STEERING SYSTEM FLUID LEVEL

CHECK...............................11REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS........11

POWER STEERING FLUID PRESSURE HOSE . . . 11

POWER STEERING FLUID RETURN HOSE.....12

POWER STEERING FLUID COOLER..........13

POWER STEERING FLUID PRESSURE

SWITCH..............................14

SPECIFICATIONS

POWER STEERING FASTENER TORQUE

SPECIFICATIONS.......................15

SPECIAL TOOLS

POWER STEERING.......................15

DESCRIPTION AND OPERATION

POWER STEERING SYSTEM

Turning of the steering wheel is converted into lin-

ear travel through the meshing of the helical pinion

teeth with the rack teeth within the steering gear.

Power assist steering is provided by an open-cen-

ter, rotary-type control valve. It is used to direct

power steering fluid from the power steering pump to

either side of the integral steering rack piston. Road

feel is controlled by the diameter of a torsion bar

which initially steers the vehicle. As steering effort

increases as in a turn, the torsion bar twists, causing

relative rotary motion between the rotary valve body

and valve spool. This movement directs fluid behind

the integral rack piston, which in turn builds up

hydraulic pressure and assists in the turning effort.

This vehicle comes with power steering as stan-

dard equipment and it is the only steering systemavailable. The power steering system consists of

these major components:

²POWER STEERING PUMP

²POWER STEERING GEAR

²POWER STEERING FLUID RESERVOIR

(mounted on the pump)

²POWER STEERING FLUID PRESSURE HOSE

²POWER STEERING FLUID RETURN HOSE

²POWER STEERING FLUID COOLER (on some

models)

For information on the first two components, refer

to their respective sections within this service man-

ual group. Information on the third component can

be found in POWER STEERING PUMP. Information

on all other components can be found in this section

of this service manual group.

PLSTEERING 19 - 1

Page 882 of 1285

CAUTION: Do not force the pump to operate

against the stops for more than 5 seconds at a time

as pump damage may result.

(6) Completely open the valve on the Power Steer-

ing Analyzer flow meter. Turn the steering wheel to

the extreme left until the stop in the steering gear is

met, then turn the steering wheel to the right until

the right stop is met. Record the highest indicated

pressure at each position. Compare the recorded

readings to the specifications. If the highest output

pressure reading against one stop is within 50 psi of

the highest reading at the other stop, the steering

gear is leaking internally and must be replaced.

If the power steering gear requires replacement,

refer to the section POWER STEERING GEAR

within this group for the removal and installation

procedure.

SERVICE PROCEDURES

POWER STEERING SYSTEM FLUID LEVEL

CHECK

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

Before opening power steering system, wipe the

reservoir filler cap free of dirt and debris. Remove

the cap and check the fluid level on its dipstick.

When the fluid is at normal ambient temperature,

approximately 21ÉC to 27ÉC (70ÉF to 80ÉF), the dip-

stick level should indicateCOLD. Do not overfill the

power steering system. In all power steering systems,

use only Mopar Power Steering Fluid, or its equiva-

lent.

NOTE: Do not use any type of automatic transmis-

sion fluid in the power steering system.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

WARNING: POWER STEERING FLUID, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

CAUTION: When the system is open, cap all open

ends of the hoses, power steering pump fittings or

power steering gear ports to prevent entry of for-

eign material into the components.

NOTE: Do not use any type of automatic transmis-

sion fluid in the power steering system.

POWER STEERING FLUID PRESSURE HOSE

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

REMOVAL

(1) Siphon as much fluid as possible from the

power steering fluid reservoir.

(2) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.

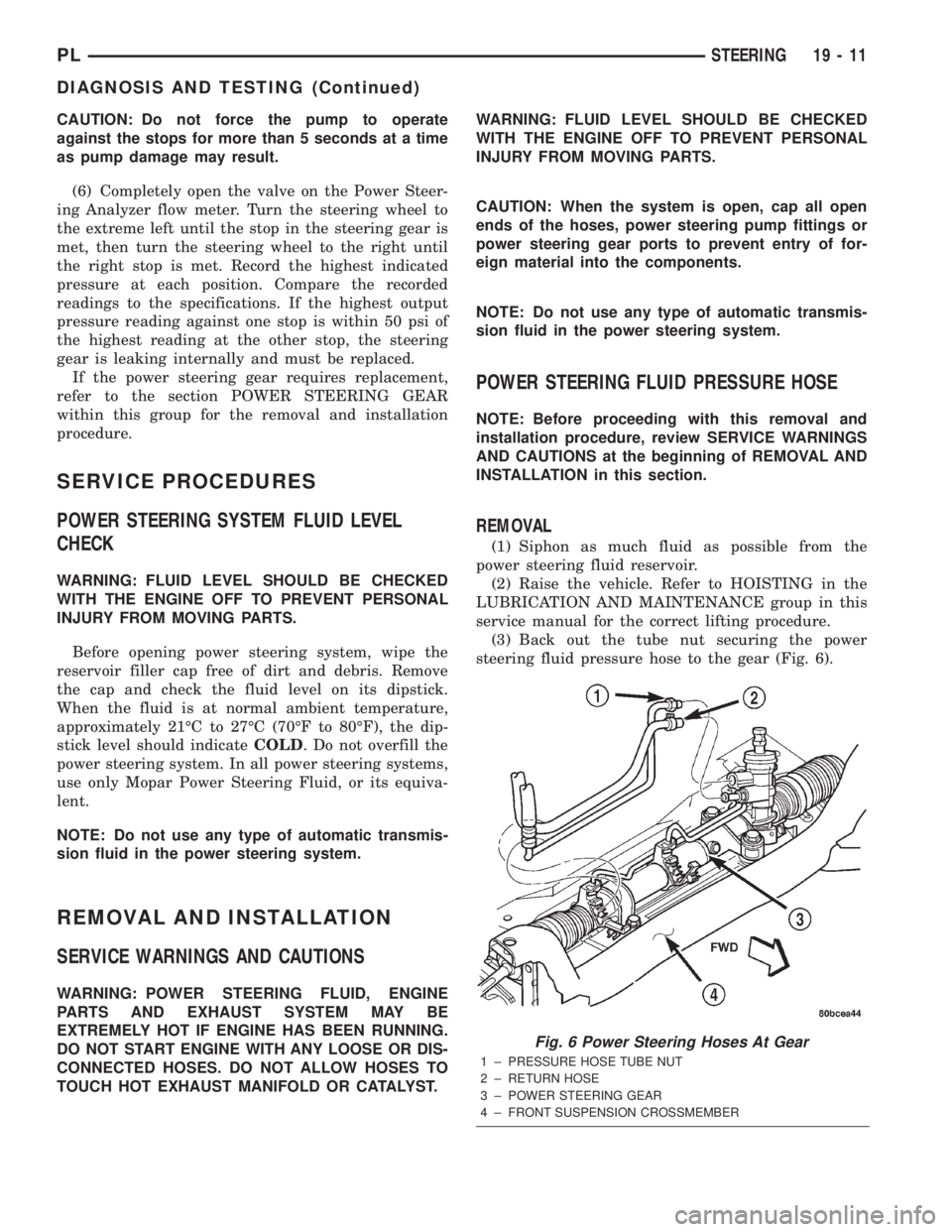

(3) Back out the tube nut securing the power

steering fluid pressure hose to the gear (Fig. 6).

Fig. 6 Power Steering Hoses At Gear

1 ± PRESSURE HOSE TUBE NUT

2 ± RETURN HOSE

3 ± POWER STEERING GEAR

4 ± FRONT SUSPENSION CROSSMEMBER

PLSTEERING 19 - 11

DIAGNOSIS AND TESTING (Continued)

Page 883 of 1285

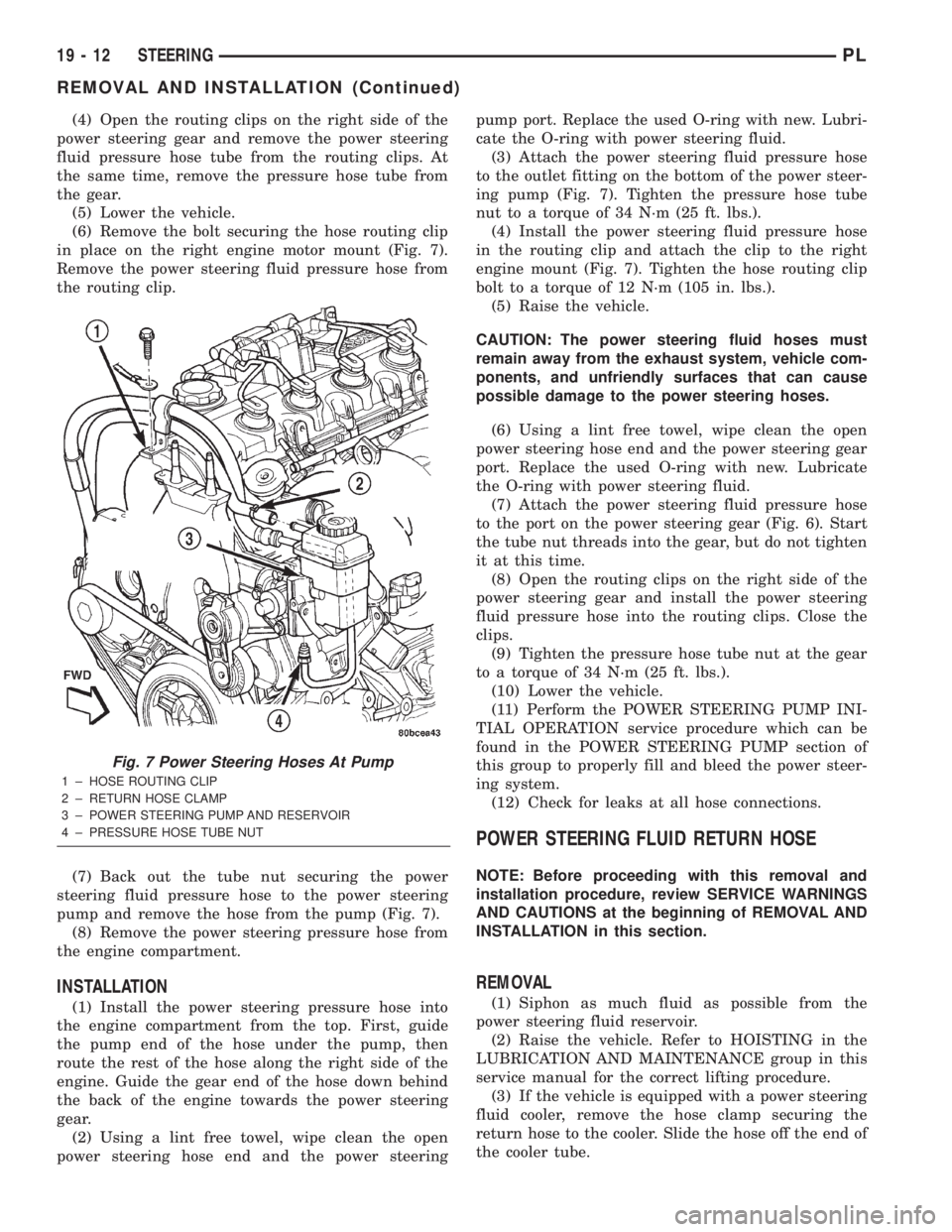

(4) Open the routing clips on the right side of the

power steering gear and remove the power steering

fluid pressure hose tube from the routing clips. At

the same time, remove the pressure hose tube from

the gear.

(5) Lower the vehicle.

(6) Remove the bolt securing the hose routing clip

in place on the right engine motor mount (Fig. 7).

Remove the power steering fluid pressure hose from

the routing clip.

(7) Back out the tube nut securing the power

steering fluid pressure hose to the power steering

pump and remove the hose from the pump (Fig. 7).

(8) Remove the power steering pressure hose from

the engine compartment.

INSTALLATION

(1) Install the power steering pressure hose into

the engine compartment from the top. First, guide

the pump end of the hose under the pump, then

route the rest of the hose along the right side of the

engine. Guide the gear end of the hose down behind

the back of the engine towards the power steering

gear.

(2) Using a lint free towel, wipe clean the open

power steering hose end and the power steeringpump port. Replace the used O-ring with new. Lubri-

cate the O-ring with power steering fluid.

(3) Attach the power steering fluid pressure hose

to the outlet fitting on the bottom of the power steer-

ing pump (Fig. 7). Tighten the pressure hose tube

nut to a torque of 34 N´m (25 ft. lbs.).

(4) Install the power steering fluid pressure hose

in the routing clip and attach the clip to the right

engine mount (Fig. 7). Tighten the hose routing clip

bolt to a torque of 12 N´m (105 in. lbs.).

(5) Raise the vehicle.

CAUTION: The power steering fluid hoses must

remain away from the exhaust system, vehicle com-

ponents, and unfriendly surfaces that can cause

possible damage to the power steering hoses.

(6) Using a lint free towel, wipe clean the open

power steering hose end and the power steering gear

port. Replace the used O-ring with new. Lubricate

the O-ring with power steering fluid.

(7) Attach the power steering fluid pressure hose

to the port on the power steering gear (Fig. 6). Start

the tube nut threads into the gear, but do not tighten

it at this time.

(8) Open the routing clips on the right side of the

power steering gear and install the power steering

fluid pressure hose into the routing clips. Close the

clips.

(9) Tighten the pressure hose tube nut at the gear

to a torque of 34 N´m (25 ft. lbs.).

(10) Lower the vehicle.

(11) Perform the POWER STEERING PUMP INI-

TIAL OPERATION service procedure which can be

found in the POWER STEERING PUMP section of

this group to properly fill and bleed the power steer-

ing system.

(12) Check for leaks at all hose connections.

POWER STEERING FLUID RETURN HOSE

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

REMOVAL

(1) Siphon as much fluid as possible from the

power steering fluid reservoir.

(2) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.

(3) If the vehicle is equipped with a power steering

fluid cooler, remove the hose clamp securing the

return hose to the cooler. Slide the hose off the end of

the cooler tube.

Fig. 7 Power Steering Hoses At Pump

1 ± HOSE ROUTING CLIP

2 ± RETURN HOSE CLAMP

3 ± POWER STEERING PUMP AND RESERVOIR

4 ± PRESSURE HOSE TUBE NUT

19 - 12 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 884 of 1285

(4) If the vehicle is not equipped with a power

steering fluid cooler:

²Remove the hose clamp securing the return hose

to the steel fitting in the outlet port on the power

steering gear (Fig. 6).

²Slide the hose off the end of the steel fitting.

²Pull the hose loose from the C-clamps on the two

routing clips located on the front of the steering gear

(Fig. 6).

(5) Lower the vehicle.

(6) Remove the bolt securing the hose routing clip

in place on the right engine mount (Fig. 7). Remove

the power steering fluid return hose from the routing

clip.

(7) Remove the hose clamp securing the return

hose to the power steering fluid reservoir (Fig. 7).

Slide the hose off the end of the reservoir fitting.

(8) Remove the power steering return hose from

the engine compartment.

INSTALLATION

(1) Slide a hose clamp onto the power steering

pump end of the hose far enough to clear the fitting

on the power steering fluid reservoir once the hose is

installed.

(2) Install the power steering return hose into the

engine compartment from the top. First, guide the

pump end of the hose onto the fitting on the power

steering fluid reservoir, then route the rest of the

hose along the right side of the engine (Fig. 7). Guide

the gear end of the hose down behind the back of the

engine towards the power steering gear.

(3) Expand the hose clamp and slide it onto the

fluid reservoir fitting. Secure the clamp once it is

past the bead formed into the fluid reservoir fitting.

(4) Install the power steering fluid return hose in

the hose routing clip and attach the clip to the right

engine mount (Fig. 7). Tighten the hose routing clip

bolt to a torque of 12 N´m (105 in. lbs.).

(5) Raise the vehicle.

CAUTION: The power steering fluid hoses must

remain away from the exhaust system, vehicle com-

ponents, and unfriendly surfaces that can cause

possible damage to the power steering hoses.

(6) Using a lint free towel, wipe clean the open

power steering hose end and the power steering gear

port fitting or power steering fluid cooler port.

(7) Install a hose clamp onto the end of the hose

far enough to clear the fitting on the steering gear or

cooler once the hose is installed.

(8) If the vehicle is equipped with a power steering

fluid cooler, slide the hose onto the end of the cooler

tube. Install the hose clamp past the bead formed

into the cooler tube and secure in place.(9) If the vehicle is not equipped with a power

steering fluid cooler:

²Slide the hose onto the end of the steel fitting in

the steering gear outlet port (Fig. 6).

²Install the hose clamp past the bead formed into

the steel fitting and secure in place.

²Align and attach the hose to the C-clamps on

the two routing clips located on the front of the steer-

ing gear (Fig. 6).

(10) Lower the vehicle.

(11) Perform the POWER STEERING PUMP INI-

TIAL OPERATION service procedure which can be

found in the POWER STEERING PUMP section of

this group to properly fill and bleed the power steer-

ing system.

(12) Check for leaks at all hose connections.

POWER STEERING FLUID COOLER

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

REMOVAL

(1) Siphon as much fluid as possible from the

power steering fluid reservoir.

(2) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.

(3) Remove the hose clamp, attaching the power

steering fluid return hose to the power steering fluid

cooler. Remove the return hose from the cooler.

(4) Remove the hose clamp attaching the power

steering cooler fluid hose to the steel fitting in the

power steering gear outlet port (Fig. 8).

(5) Remove the two screws securing the cooler to

the front suspension crossmember. They are located

behind the cooler. They can be accessed from above.

(6) Open the routing clip on the right front of the

power steering gear housing and remove the cooler

tube from it.

(7) Remove the cooler from the vehicle.

INSTALLATION

(1) Slide a hose clamp onto the end of the power

steering cooler fluid hose far enough to clear the steel

fitting on the power steering gear once the hose is

installed.

(2) Slide the hose (with cooler attached) onto the

fitting on the steering gear, then align the tube on

back of the cooler with the open routing clip on the

right front of the power steering gear housing, and

snap it into place. Close the clip.

PLSTEERING 19 - 13

REMOVAL AND INSTALLATION (Continued)

Page 885 of 1285

(3) Install the hose clamp on the power steering

cooler fluid hose past the bead formed into the steel

fitting and secure in place.

(4) Install the two screws attaching the cooler to

the front suspension crossmember. Tighten the cooler

attaching screws to a torque of 10 N´m (90 in. lbs.).

(5) Install the power steering fluid return hose on

the power steering fluid cooler tube. Install the hose

clamp on the power steering return hose securing it

to the power steering cooler. Be sure the hose clamp

is installed on the return hose past the bead on the

end of the cooler tube.

(6) Lower the vehicle.

(7) Perform the POWER STEERING PUMP INI-

TIAL OPERATION service procedure which can be

found in the POWER STEERING PUMP section of

this group to properly fill and bleed the power steer-

ing system.

(8) Check for leaks at all connections.

POWER STEERING FLUID PRESSURE SWITCH

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

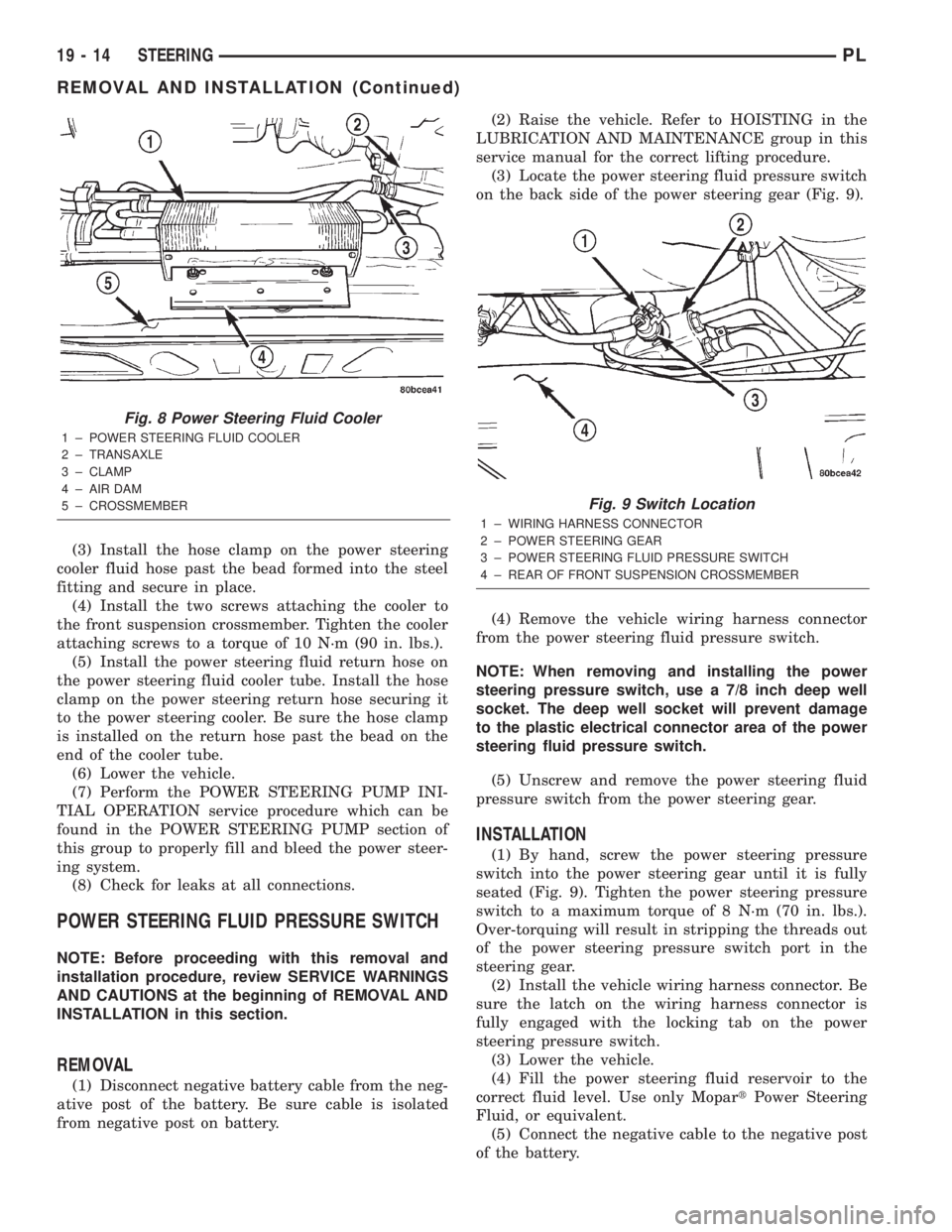

REMOVAL

(1) Disconnect negative battery cable from the neg-

ative post of the battery. Be sure cable is isolated

from negative post on battery.(2) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.

(3) Locate the power steering fluid pressure switch

on the back side of the power steering gear (Fig. 9).

(4) Remove the vehicle wiring harness connector

from the power steering fluid pressure switch.

NOTE: When removing and installing the power

steering pressure switch, use a 7/8 inch deep well

socket. The deep well socket will prevent damage

to the plastic electrical connector area of the power

steering fluid pressure switch.

(5) Unscrew and remove the power steering fluid

pressure switch from the power steering gear.

INSTALLATION

(1) By hand, screw the power steering pressure

switch into the power steering gear until it is fully

seated (Fig. 9). Tighten the power steering pressure

switch to a maximum torque of 8 N´m (70 in. lbs.).

Over-torquing will result in stripping the threads out

of the power steering pressure switch port in the

steering gear.

(2) Install the vehicle wiring harness connector. Be

sure the latch on the wiring harness connector is

fully engaged with the locking tab on the power

steering pressure switch.

(3) Lower the vehicle.

(4) Fill the power steering fluid reservoir to the

correct fluid level. Use only MopartPower Steering

Fluid, or equivalent.

(5) Connect the negative cable to the negative post

of the battery.

Fig. 8 Power Steering Fluid Cooler

1 ± POWER STEERING FLUID COOLER

2 ± TRANSAXLE

3 ± CLAMP

4 ± AIR DAM

5 ± CROSSMEMBER

Fig. 9 Switch Location

1 ± WIRING HARNESS CONNECTOR

2 ± POWER STEERING GEAR

3 ± POWER STEERING FLUID PRESSURE SWITCH

4 ± REAR OF FRONT SUSPENSION CROSSMEMBER

19 - 14 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 887 of 1285

POWER STEERING PUMP

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

POWER STEERING PUMP.................16

POWER STEERING FLUID RESERVOIR.......17

SERVICE PROCEDURES

POWER STEERING PUMP INITIAL

OPERATION...........................17

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS........17

POWER STEERING PUMP.................17DISASSEMBLY AND ASSEMBLY

POWER STEERING PUMP (PULLEY).........19

SPECIFICATIONS

POWER STEERING PUMP FLOW

SPECIFICATIONS.......................20

POWER STEERING FASTENER TORQUE

SPECIFICATIONS.......................20

SPECIAL TOOLS

POWER STEERING PUMP.................20

DESCRIPTION AND OPERATION

POWER STEERING PUMP

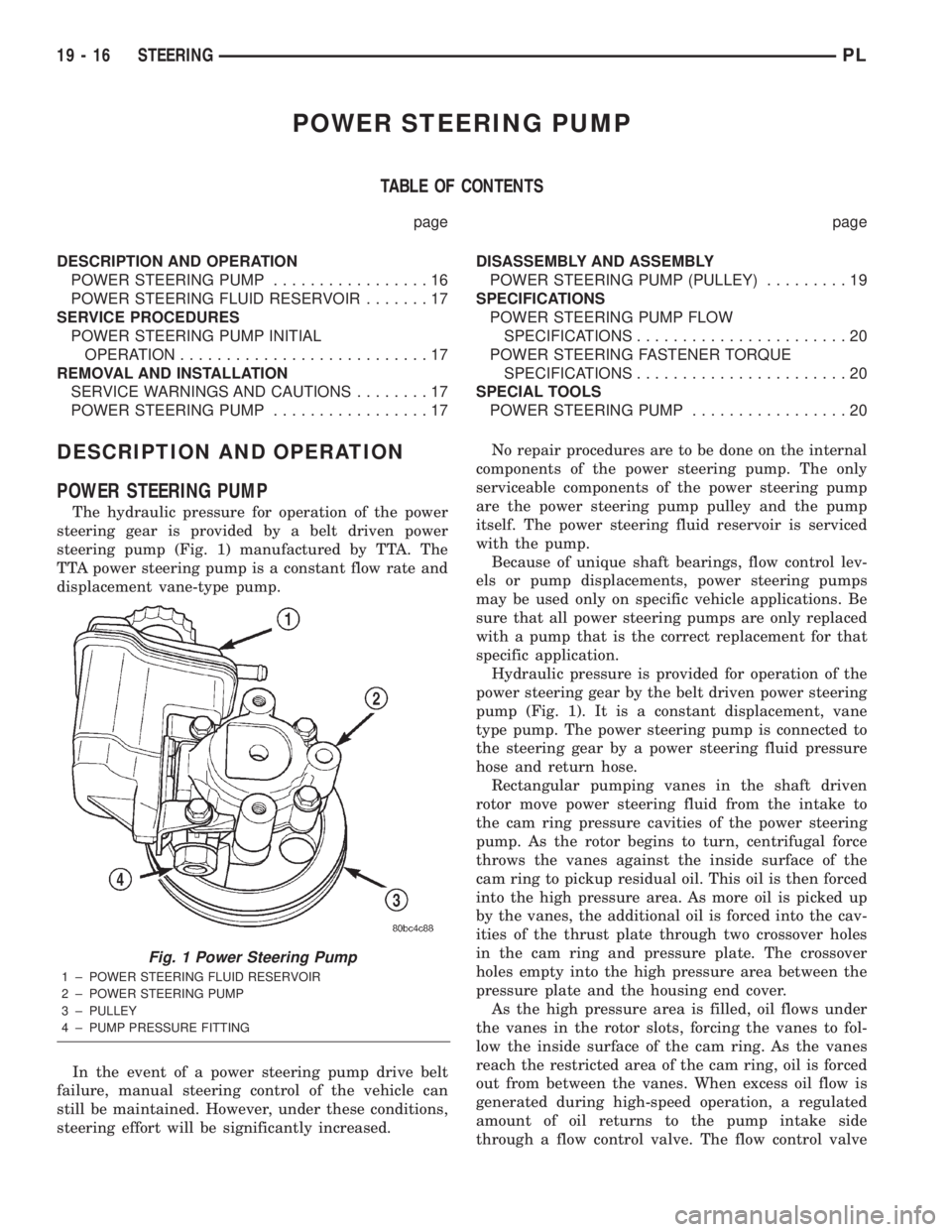

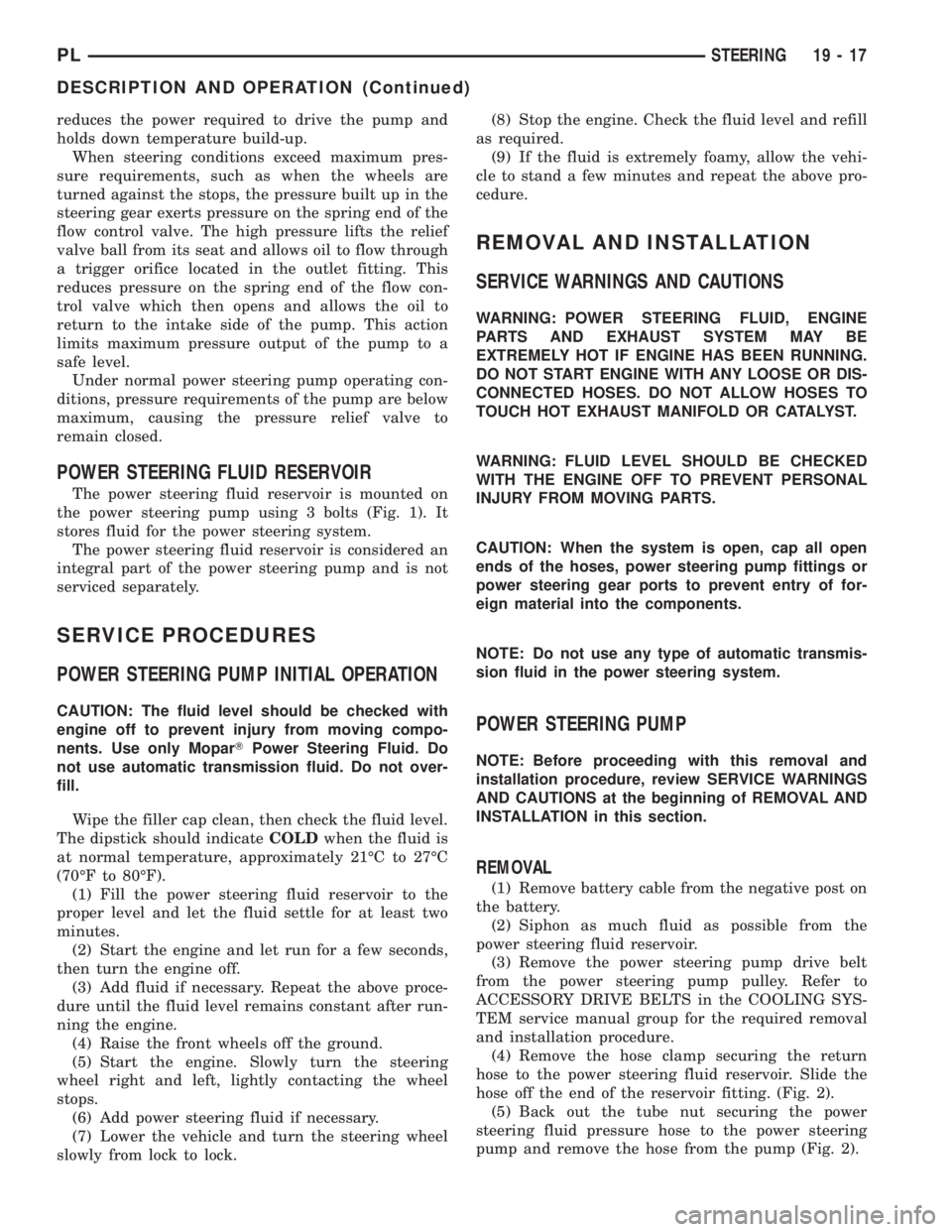

The hydraulic pressure for operation of the power

steering gear is provided by a belt driven power

steering pump (Fig. 1) manufactured by TTA. The

TTA power steering pump is a constant flow rate and

displacement vane-type pump.

In the event of a power steering pump drive belt

failure, manual steering control of the vehicle can

still be maintained. However, under these conditions,

steering effort will be significantly increased.No repair procedures are to be done on the internal

components of the power steering pump. The only

serviceable components of the power steering pump

are the power steering pump pulley and the pump

itself. The power steering fluid reservoir is serviced

with the pump.

Because of unique shaft bearings, flow control lev-

els or pump displacements, power steering pumps

may be used only on specific vehicle applications. Be

sure that all power steering pumps are only replaced

with a pump that is the correct replacement for that

specific application.

Hydraulic pressure is provided for operation of the

power steering gear by the belt driven power steering

pump (Fig. 1). It is a constant displacement, vane

type pump. The power steering pump is connected to

the steering gear by a power steering fluid pressure

hose and return hose.

Rectangular pumping vanes in the shaft driven

rotor move power steering fluid from the intake to

the cam ring pressure cavities of the power steering

pump. As the rotor begins to turn, centrifugal force

throws the vanes against the inside surface of the

cam ring to pickup residual oil. This oil is then forced

into the high pressure area. As more oil is picked up

by the vanes, the additional oil is forced into the cav-

ities of the thrust plate through two crossover holes

in the cam ring and pressure plate. The crossover

holes empty into the high pressure area between the

pressure plate and the housing end cover.

As the high pressure area is filled, oil flows under

the vanes in the rotor slots, forcing the vanes to fol-

low the inside surface of the cam ring. As the vanes

reach the restricted area of the cam ring, oil is forced

out from between the vanes. When excess oil flow is

generated during high-speed operation, a regulated

amount of oil returns to the pump intake side

through a flow control valve. The flow control valve

Fig. 1 Power Steering Pump

1 ± POWER STEERING FLUID RESERVOIR

2 ± POWER STEERING PUMP

3 ± PULLEY

4 ± PUMP PRESSURE FITTING

19 - 16 STEERINGPL

Page 888 of 1285

reduces the power required to drive the pump and

holds down temperature build-up.

When steering conditions exceed maximum pres-

sure requirements, such as when the wheels are

turned against the stops, the pressure built up in the

steering gear exerts pressure on the spring end of the

flow control valve. The high pressure lifts the relief

valve ball from its seat and allows oil to flow through

a trigger orifice located in the outlet fitting. This

reduces pressure on the spring end of the flow con-

trol valve which then opens and allows the oil to

return to the intake side of the pump. This action

limits maximum pressure output of the pump to a

safe level.

Under normal power steering pump operating con-

ditions, pressure requirements of the pump are below

maximum, causing the pressure relief valve to

remain closed.

POWER STEERING FLUID RESERVOIR

The power steering fluid reservoir is mounted on

the power steering pump using 3 bolts (Fig. 1). It

stores fluid for the power steering system.

The power steering fluid reservoir is considered an

integral part of the power steering pump and is not

serviced separately.

SERVICE PROCEDURES

POWER STEERING PUMP INITIAL OPERATION

CAUTION: The fluid level should be checked with

engine off to prevent injury from moving compo-

nents. Use only MoparTPower Steering Fluid. Do

not use automatic transmission fluid. Do not over-

fill.

Wipe the filler cap clean, then check the fluid level.

The dipstick should indicateCOLDwhen the fluid is

at normal temperature, approximately 21ÉC to 27ÉC

(70ÉF to 80ÉF).

(1) Fill the power steering fluid reservoir to the

proper level and let the fluid settle for at least two

minutes.

(2) Start the engine and let run for a few seconds,

then turn the engine off.

(3) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(4) Raise the front wheels off the ground.

(5) Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the wheel

stops.

(6) Add power steering fluid if necessary.

(7) Lower the vehicle and turn the steering wheel

slowly from lock to lock.(8) Stop the engine. Check the fluid level and refill

as required.

(9) If the fluid is extremely foamy, allow the vehi-

cle to stand a few minutes and repeat the above pro-

cedure.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

WARNING: POWER STEERING FLUID, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

CAUTION: When the system is open, cap all open

ends of the hoses, power steering pump fittings or

power steering gear ports to prevent entry of for-

eign material into the components.

NOTE: Do not use any type of automatic transmis-

sion fluid in the power steering system.

POWER STEERING PUMP

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

REMOVAL

(1) Remove battery cable from the negative post on

the battery.

(2) Siphon as much fluid as possible from the

power steering fluid reservoir.

(3) Remove the power steering pump drive belt

from the power steering pump pulley. Refer to

ACCESSORY DRIVE BELTS in the COOLING SYS-

TEM service manual group for the required removal

and installation procedure.

(4) Remove the hose clamp securing the return

hose to the power steering fluid reservoir. Slide the

hose off the end of the reservoir fitting. (Fig. 2).

(5) Back out the tube nut securing the power

steering fluid pressure hose to the power steering

pump and remove the hose from the pump (Fig. 2).

PLSTEERING 19 - 17

DESCRIPTION AND OPERATION (Continued)