No start DODGE NEON 2000 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 54 of 1285

CAUTION: The strut-to-knuckle attaching bolts are

serrated and must not be turned during removal.

Hold the bolts stationary in the steering knuckle

while removing the nuts, then tap the bolts out

using a pin punch.

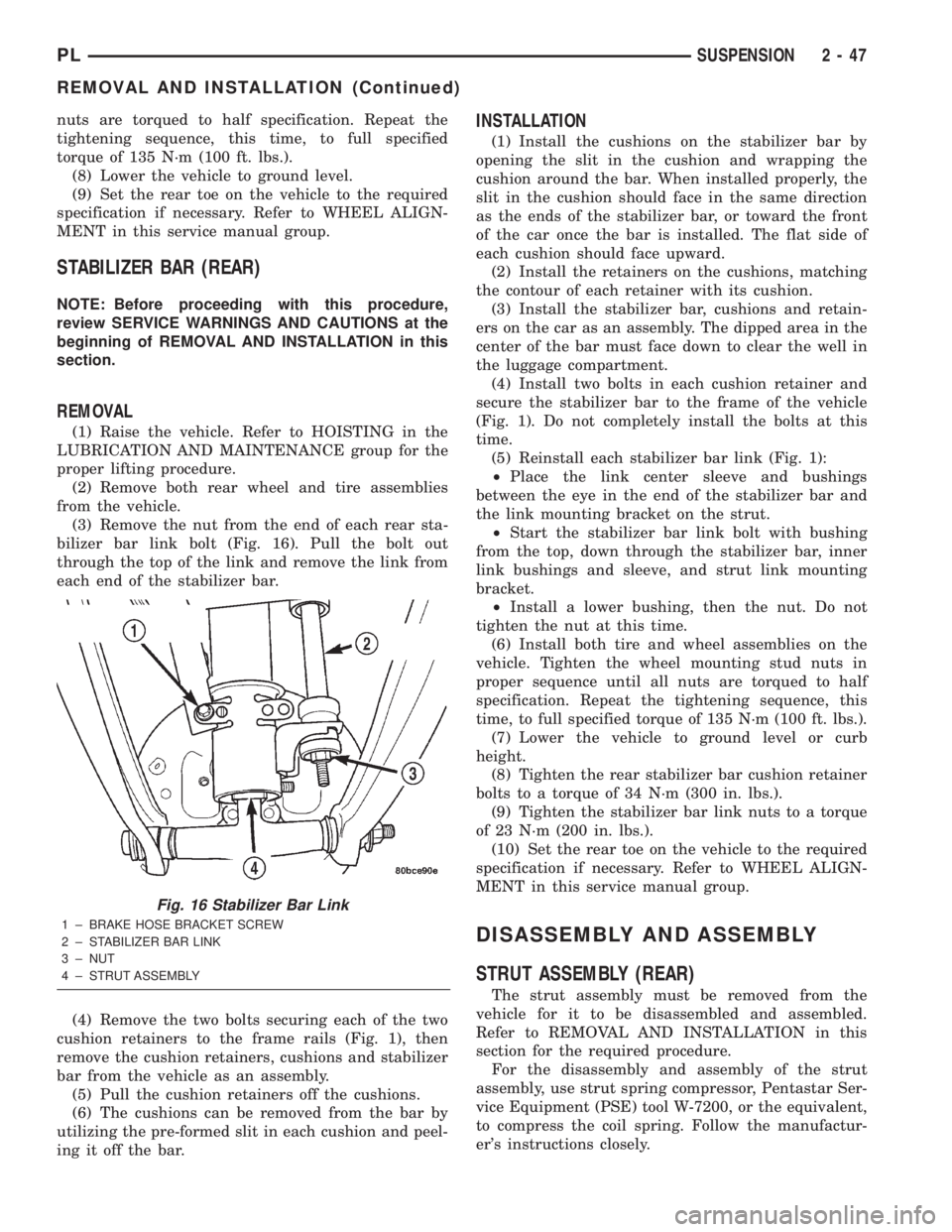

(11) Loosen, but do not completely remove the two

nuts and bolts attaching the rear knuckle to the

strut (Fig. 11).

(12) Remove the nuts and bolt attaching the rear

knuckle to the lateral arms (Fig. 11).(13) Disconnect the tension strut from the knuckle.

To do this, first hold the tension strut from turning

by using a wrench on the flat on the tension strut

and then remove the nut from the rear of the tension

strut (Fig. 12). Next, remove the tension strut

retainer, then the rear tension strut bayonet bushing

from the tension strut.

(14) Remove the two nuts and bolts attaching the

rear knuckle to the strut (Fig. 11). Tap the bolts from

the knuckle using a pin punch.

(15) Remove the knuckle.

INSTALLATION

(1) To install the knuckle on the vehicle, first align

the hole in the lower end of the rear knuckle with

the forward bayonet bushing on the tension strut. Be

sure the stepped area of the bushing is squarely

seated into the hole in the knuckle. Next, Rotate the

knuckle until the upper mounting holes in the

knuckle is aligned with the holes in the strut's clevis

bracket.

CAUTION: The strut-to-knuckle attaching bolts are

serrated and must not be turned during installation.

Once installed, hold the bolts stationary in the

steering knuckle while installing and tightening the

nuts.

(2) Install the two bolts attaching the strut to the

rear knuckle from the front side. Install the nuts on

the bolts (Fig. 11). Tighten the two nuts to a torque

of 88 N´m (65 ft. lbs.).

(3) Align the lateral arms with the hole in the cen-

ter of the knuckle. Install the bolt attaching the arms

to the knuckle. When installing the bolt, start it from

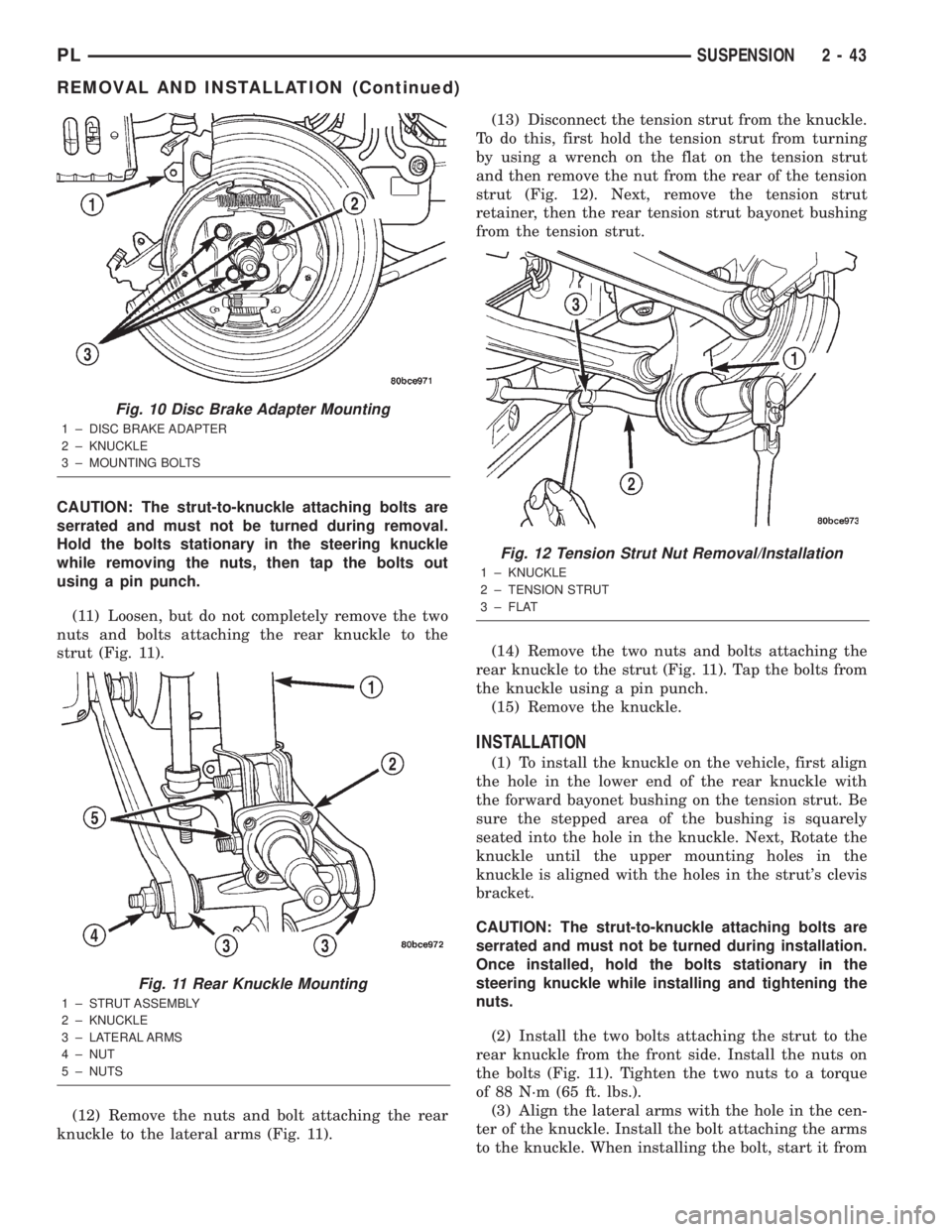

Fig. 10 Disc Brake Adapter Mounting

1 ± DISC BRAKE ADAPTER

2 ± KNUCKLE

3 ± MOUNTING BOLTS

Fig. 11 Rear Knuckle Mounting

1 ± STRUT ASSEMBLY

2 ± KNUCKLE

3 ± LATERAL ARMS

4 ± NUT

5 ± NUTS

Fig. 12 Tension Strut Nut Removal/Installation

1 ± KNUCKLE

2 ± TENSION STRUT

3 ± FLAT

PLSUSPENSION 2 - 43

REMOVAL AND INSTALLATION (Continued)

Page 58 of 1285

nuts are torqued to half specification. Repeat the

tightening sequence, this time, to full specified

torque of 135 N´m (100 ft. lbs.).

(8) Lower the vehicle to ground level.

(9) Set the rear toe on the vehicle to the required

specification if necessary. Refer to WHEEL ALIGN-

MENT in this service manual group.

STABILIZER BAR (REAR)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove both rear wheel and tire assemblies

from the vehicle.

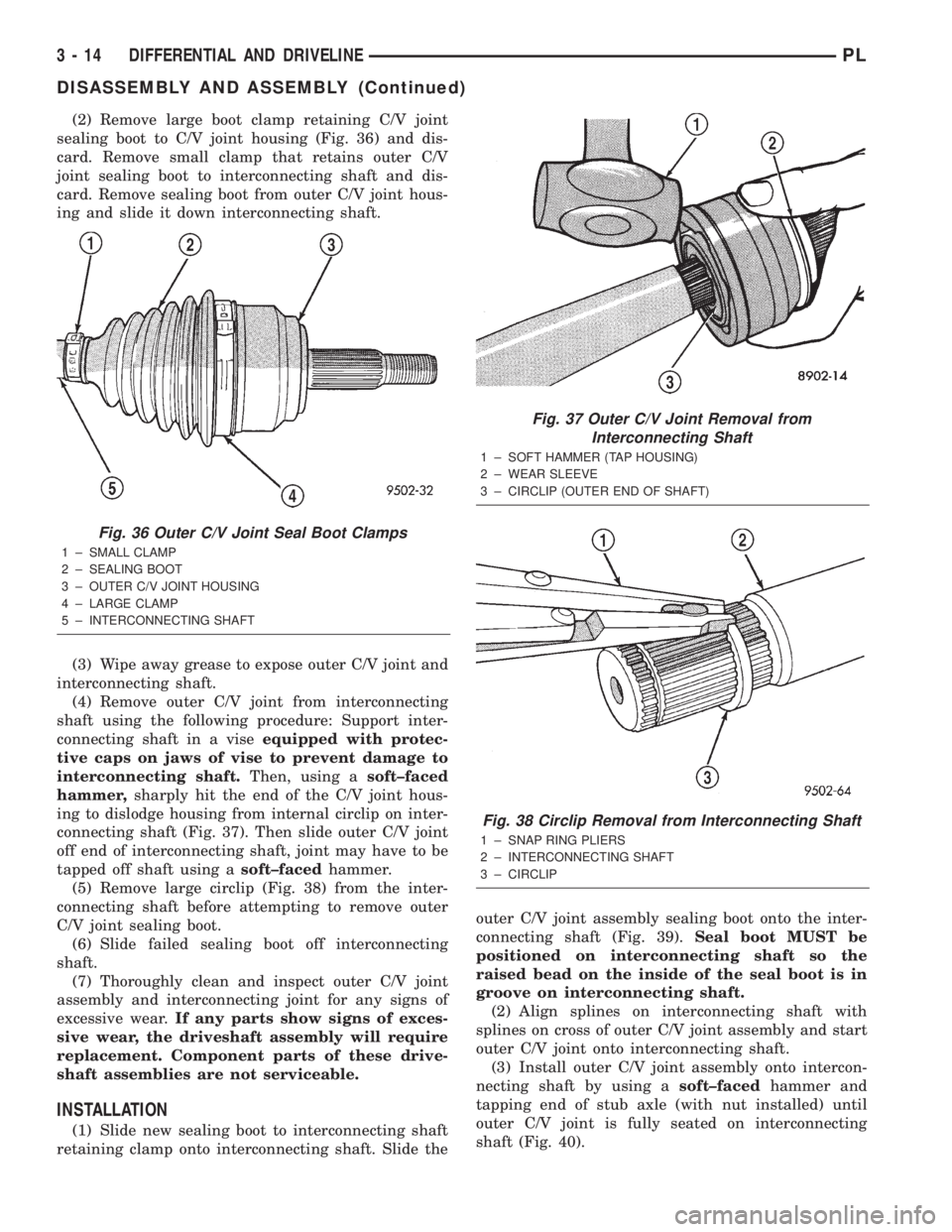

(3) Remove the nut from the end of each rear sta-

bilizer bar link bolt (Fig. 16). Pull the bolt out

through the top of the link and remove the link from

each end of the stabilizer bar.

(4) Remove the two bolts securing each of the two

cushion retainers to the frame rails (Fig. 1), then

remove the cushion retainers, cushions and stabilizer

bar from the vehicle as an assembly.

(5) Pull the cushion retainers off the cushions.

(6) The cushions can be removed from the bar by

utilizing the pre-formed slit in each cushion and peel-

ing it off the bar.

INSTALLATION

(1) Install the cushions on the stabilizer bar by

opening the slit in the cushion and wrapping the

cushion around the bar. When installed properly, the

slit in the cushion should face in the same direction

as the ends of the stabilizer bar, or toward the front

of the car once the bar is installed. The flat side of

each cushion should face upward.

(2) Install the retainers on the cushions, matching

the contour of each retainer with its cushion.

(3) Install the stabilizer bar, cushions and retain-

ers on the car as an assembly. The dipped area in the

center of the bar must face down to clear the well in

the luggage compartment.

(4) Install two bolts in each cushion retainer and

secure the stabilizer bar to the frame of the vehicle

(Fig. 1). Do not completely install the bolts at this

time.

(5) Reinstall each stabilizer bar link (Fig. 1):

²Place the link center sleeve and bushings

between the eye in the end of the stabilizer bar and

the link mounting bracket on the strut.

²Start the stabilizer bar link bolt with bushing

from the top, down through the stabilizer bar, inner

link bushings and sleeve, and strut link mounting

bracket.

²Install a lower bushing, then the nut. Do not

tighten the nut at this time.

(6) Install both tire and wheel assemblies on the

vehicle. Tighten the wheel mounting stud nuts in

proper sequence until all nuts are torqued to half

specification. Repeat the tightening sequence, this

time, to full specified torque of 135 N´m (100 ft. lbs.).

(7) Lower the vehicle to ground level or curb

height.

(8) Tighten the rear stabilizer bar cushion retainer

bolts to a torque of 34 N´m (300 in. lbs.).

(9) Tighten the stabilizer bar link nuts to a torque

of 23 N´m (200 in. lbs.).

(10) Set the rear toe on the vehicle to the required

specification if necessary. Refer to WHEEL ALIGN-

MENT in this service manual group.

DISASSEMBLY AND ASSEMBLY

STRUT ASSEMBLY (REAR)

The strut assembly must be removed from the

vehicle for it to be disassembled and assembled.

Refer to REMOVAL AND INSTALLATION in this

section for the required procedure.

For the disassembly and assembly of the strut

assembly, use strut spring compressor, Pentastar Ser-

vice Equipment (PSE) tool W-7200, or the equivalent,

to compress the coil spring. Follow the manufactur-

er's instructions closely.

Fig. 16 Stabilizer Bar Link

1 ± BRAKE HOSE BRACKET SCREW

2 ± STABILIZER BAR LINK

3 ± NUT

4 ± STRUT ASSEMBLY

PLSUSPENSION 2 - 47

REMOVAL AND INSTALLATION (Continued)

Page 75 of 1285

(2) Remove large boot clamp retaining C/V joint

sealing boot to C/V joint housing (Fig. 36) and dis-

card. Remove small clamp that retains outer C/V

joint sealing boot to interconnecting shaft and dis-

card. Remove sealing boot from outer C/V joint hous-

ing and slide it down interconnecting shaft.

(3) Wipe away grease to expose outer C/V joint and

interconnecting shaft.

(4) Remove outer C/V joint from interconnecting

shaft using the following procedure: Support inter-

connecting shaft in a viseequipped with protec-

tive caps on jaws of vise to prevent damage to

interconnecting shaft.Then, using asoft±faced

hammer,sharply hit the end of the C/V joint hous-

ing to dislodge housing from internal circlip on inter-

connecting shaft (Fig. 37). Then slide outer C/V joint

off end of interconnecting shaft, joint may have to be

tapped off shaft using asoft±facedhammer.

(5) Remove large circlip (Fig. 38) from the inter-

connecting shaft before attempting to remove outer

C/V joint sealing boot.

(6) Slide failed sealing boot off interconnecting

shaft.

(7) Thoroughly clean and inspect outer C/V joint

assembly and interconnecting joint for any signs of

excessive wear.If any parts show signs of exces-

sive wear, the driveshaft assembly will require

replacement. Component parts of these drive-

shaft assemblies are not serviceable.

INSTALLATION

(1) Slide new sealing boot to interconnecting shaft

retaining clamp onto interconnecting shaft. Slide theouter C/V joint assembly sealing boot onto the inter-

connecting shaft (Fig. 39).Seal boot MUST be

positioned on interconnecting shaft so the

raised bead on the inside of the seal boot is in

groove on interconnecting shaft.

(2) Align splines on interconnecting shaft with

splines on cross of outer C/V joint assembly and start

outer C/V joint onto interconnecting shaft.

(3) Install outer C/V joint assembly onto intercon-

necting shaft by using asoft±facedhammer and

tapping end of stub axle (with nut installed) until

outer C/V joint is fully seated on interconnecting

shaft (Fig. 40).

Fig. 36 Outer C/V Joint Seal Boot Clamps

1 ± SMALL CLAMP

2 ± SEALING BOOT

3 ± OUTER C/V JOINT HOUSING

4 ± LARGE CLAMP

5 ± INTERCONNECTING SHAFT

Fig. 37 Outer C/V Joint Removal from

Interconnecting Shaft

1 ± SOFT HAMMER (TAP HOUSING)

2 ± WEAR SLEEVE

3 ± CIRCLIP (OUTER END OF SHAFT)

Fig. 38 Circlip Removal from Interconnecting Shaft

1 ± SNAP RING PLIERS

2 ± INTERCONNECTING SHAFT

3 ± CIRCLIP

3 - 14 DIFFERENTIAL AND DRIVELINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 90 of 1285

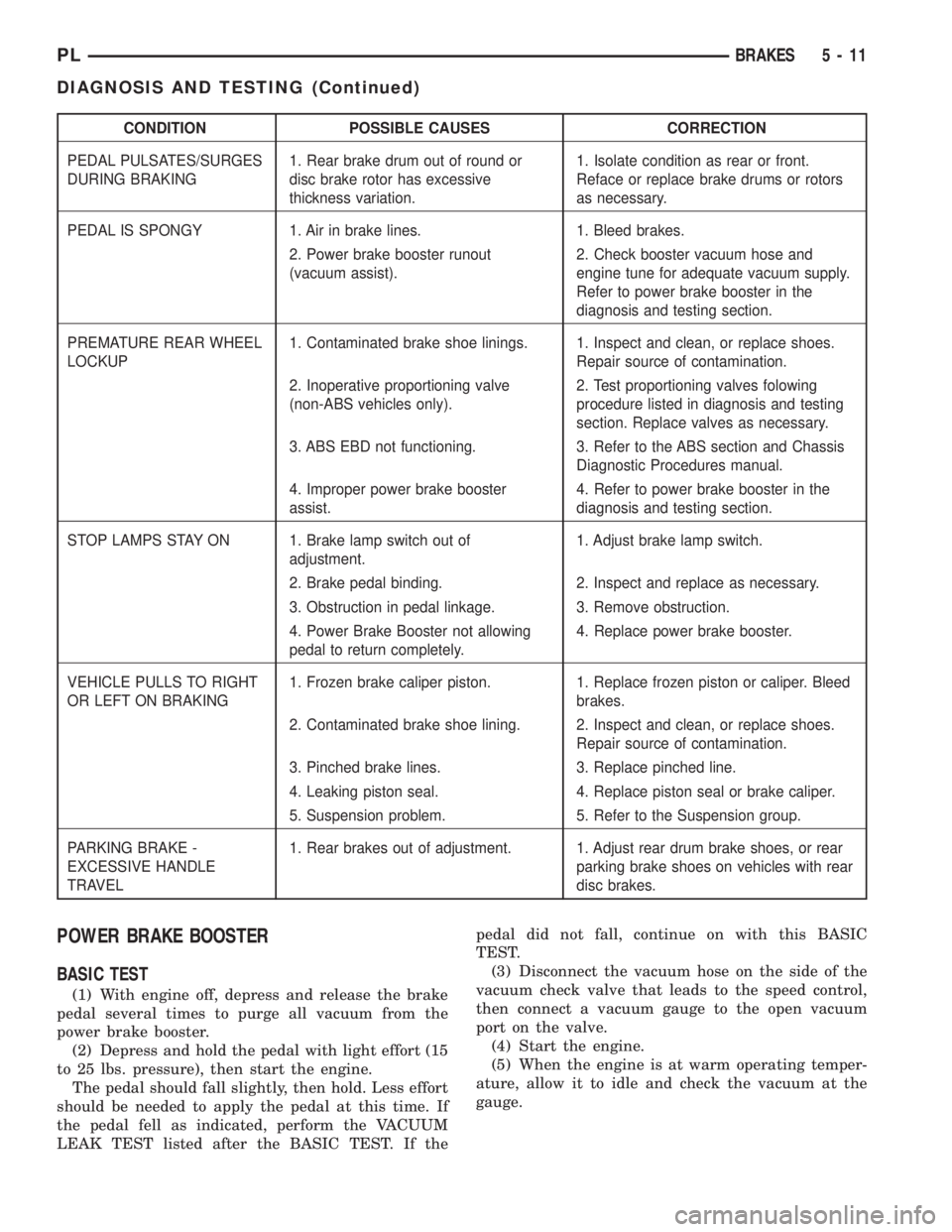

CONDITION POSSIBLE CAUSES CORRECTION

PEDAL PULSATES/SURGES

DURING BRAKING1. Rear brake drum out of round or

disc brake rotor has excessive

thickness variation.1. Isolate condition as rear or front.

Reface or replace brake drums or rotors

as necessary.

PEDAL IS SPONGY 1. Air in brake lines. 1. Bleed brakes.

2. Power brake booster runout

(vacuum assist).2. Check booster vacuum hose and

engine tune for adequate vacuum supply.

Refer to power brake booster in the

diagnosis and testing section.

PREMATURE REAR WHEEL

LOCKUP1. Contaminated brake shoe linings. 1. Inspect and clean, or replace shoes.

Repair source of contamination.

2. Inoperative proportioning valve

(non-ABS vehicles only).2. Test proportioning valves folowing

procedure listed in diagnosis and testing

section. Replace valves as necessary.

3. ABS EBD not functioning. 3. Refer to the ABS section and Chassis

Diagnostic Procedures manual.

4. Improper power brake booster

assist.4. Refer to power brake booster in the

diagnosis and testing section.

STOP LAMPS STAY ON 1. Brake lamp switch out of

adjustment.1. Adjust brake lamp switch.

2. Brake pedal binding. 2. Inspect and replace as necessary.

3. Obstruction in pedal linkage. 3. Remove obstruction.

4. Power Brake Booster not allowing

pedal to return completely.4. Replace power brake booster.

VEHICLE PULLS TO RIGHT

OR LEFT ON BRAKING1. Frozen brake caliper piston. 1. Replace frozen piston or caliper. Bleed

brakes.

2. Contaminated brake shoe lining. 2. Inspect and clean, or replace shoes.

Repair source of contamination.

3. Pinched brake lines. 3. Replace pinched line.

4. Leaking piston seal. 4. Replace piston seal or brake caliper.

5. Suspension problem. 5. Refer to the Suspension group.

PARKING BRAKE -

EXCESSIVE HANDLE

TRAVEL1. Rear brakes out of adjustment. 1. Adjust rear drum brake shoes, or rear

parking brake shoes on vehicles with rear

disc brakes.

POWER BRAKE BOOSTER

BASIC TEST

(1) With engine off, depress and release the brake

pedal several times to purge all vacuum from the

power brake booster.

(2) Depress and hold the pedal with light effort (15

to 25 lbs. pressure), then start the engine.

The pedal should fall slightly, then hold. Less effort

should be needed to apply the pedal at this time. If

the pedal fell as indicated, perform the VACUUM

LEAK TEST listed after the BASIC TEST. If thepedal did not fall, continue on with this BASIC

TEST.

(3) Disconnect the vacuum hose on the side of the

vacuum check valve that leads to the speed control,

then connect a vacuum gauge to the open vacuum

port on the valve.

(4) Start the engine.

(5) When the engine is at warm operating temper-

ature, allow it to idle and check the vacuum at the

gauge.

PLBRAKES 5 - 11

DIAGNOSIS AND TESTING (Continued)

Page 91 of 1285

If the vacuum supply is 12 inches Hg (40.5 kPa) or

more, the power brake booster is defective and must

be replaced. If the vacuum supply is below 12 inches,

continue on with this BASIC TEST.

(6) Shut off the engine.

(7) Connect the vacuum gauge to the vacuum ref-

erence port on the engine intake manifold.

(8)

Start the engine and observe the vacuum gauge.

If the vacuum is still low, check the engine tune

and repair as necessary. If the vacuum is above 12

inches, the hose or check to the booster has a restric-

tion or leak.

Once an adequate vacuum supply is obtained,

repeat the BASIC TEST.

VACUUM LEAK TEST

(1) Disconnect the vacuum hose on the side of the

power brake booster vacuum check valve that leads

to the speed control, then connect a vacuum gauge to

the open vacuum port on the valve.

(2) Remove the remaining hose on the vacuum

check valve that is not the vacuum supply hose com-

ing from the intake manifold. Cap off the open port

on the check valve.

(3) Start the engine.

(4) Allow the engine to warm up to normal operat-

ing temperature and engine idle.

(5) Using vacuum line pliers, close off the vacuum

supply hose near the booster and observe the vacuum

gauge.

If the vacuum drop exceeds 1.0 inch Hg (3.3 kPa)

in one minute, repeat the above steps to confirm the

reading. The vacuum loss should be less than 1.0

inch Hg in one minute time span. If the loss is more

than 1.0 inch Hg, replace the power brake booster. If

it is not, continue on with this test.

(6) Remove the pliers from the hose temporarily.

(7) Apply light effort (approximately 15 lbs. of

force) to the brake pedal and hold the pedal steady.

Do not move the pedal once the pressure is applied

or the test results may vary.

(8) Have an assistant reattach the pliers to the

vacuum supply hose.

(9) Allow 5 seconds for stabilization, then observe

the vacuum gauge.

If the vacuum drop exceeds 3.0 inches Hg (10 kPa)

in 15 seconds, repeat the above steps to confirm the

reading. The vacuum loss should be less than 3.0

inches Hg in 15 seconds time span. If the loss is

more than 3.0 inches Hg, replace the power brake

booster. If it is not, the booster is not defective.

DRUM BRAKE AUTOMATIC ADJUSTER

To properly test the drum brake automatic

adjuster, the aide of a helper inside the vehicle to

apply the brakes will be necessary.(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove the access plug from the rear adjust-

ment slot in each brake support plate.

(3) Insert a thin screwdriver in the adjustment

slot and push back the adjustment lever. With the

lever in this position, back the star wheel adjustment

off approximately 10 notches. This will eliminate the

possibility that the brake is at full adjustment, and

can be adjusted no further.

(4)

Remove the screwdriver from the adjustment slot.

(5) Watch the star wheel through the adjustment

slot, while a helper applies the brake pedal. As the

brake shoes apply, the adjustment lever should move

downward, turning the star wheel. A definite rotation

of the adjuster star wheel can be observed if the

automatic adjuster is working properly.

If the star wheel does not move as indicated, the

brake drum needs to be removed and further inspec-

tion of the rear brakes is necessary.

(6) If the star wheel is operating properly, readjust

the brakes. Refer to ADJUSTMENTS in this section

of this service manual group.

(7) Reinstall the adjustment slot access plug.

(8) Lower the vehicle.

BRAKE ROTOR

Any servicing of the rotor requires extreme care to

maintain the rotor within service tolerances to

ensure proper brake action.

Excessive runout or wobble in a rotor can increase

pedal travel due to piston knock-back. This increases

guide pin sleeve wear due to the tendency of the cal-

iper to follow the rotor wobble.

When diagnosing a brake noise or pulsation, the

machined disc braking surface should be checked and

inspected.

BRAKING SURFACE INSPECTION

Light braking surface scoring and wear is accept-

able. If heavy scoring or warping is evident, the rotor

must be refaced or replaced. Refer to SERVICE PRO-

CEDURES in this section of this group for informa-

tion on brake rotor machining.

Excessive wear and scoring of the rotor can cause

improper lining contact on the rotor's braking sur-

face. If the ridges on the rotor are not removed before

new brake shoes are installed, improper wear of the

shoes will result.

If a vehicle has not been driven for a period of

time, the rotor's braking surface will rust in the

areas not covered by the brake shoes at that time.

Once the vehicle is driven, noise and chatter from

the disc brakes can result when the brakes are

applied.

5 - 12 BRAKESPL

DIAGNOSIS AND TESTING (Continued)

Page 118 of 1285

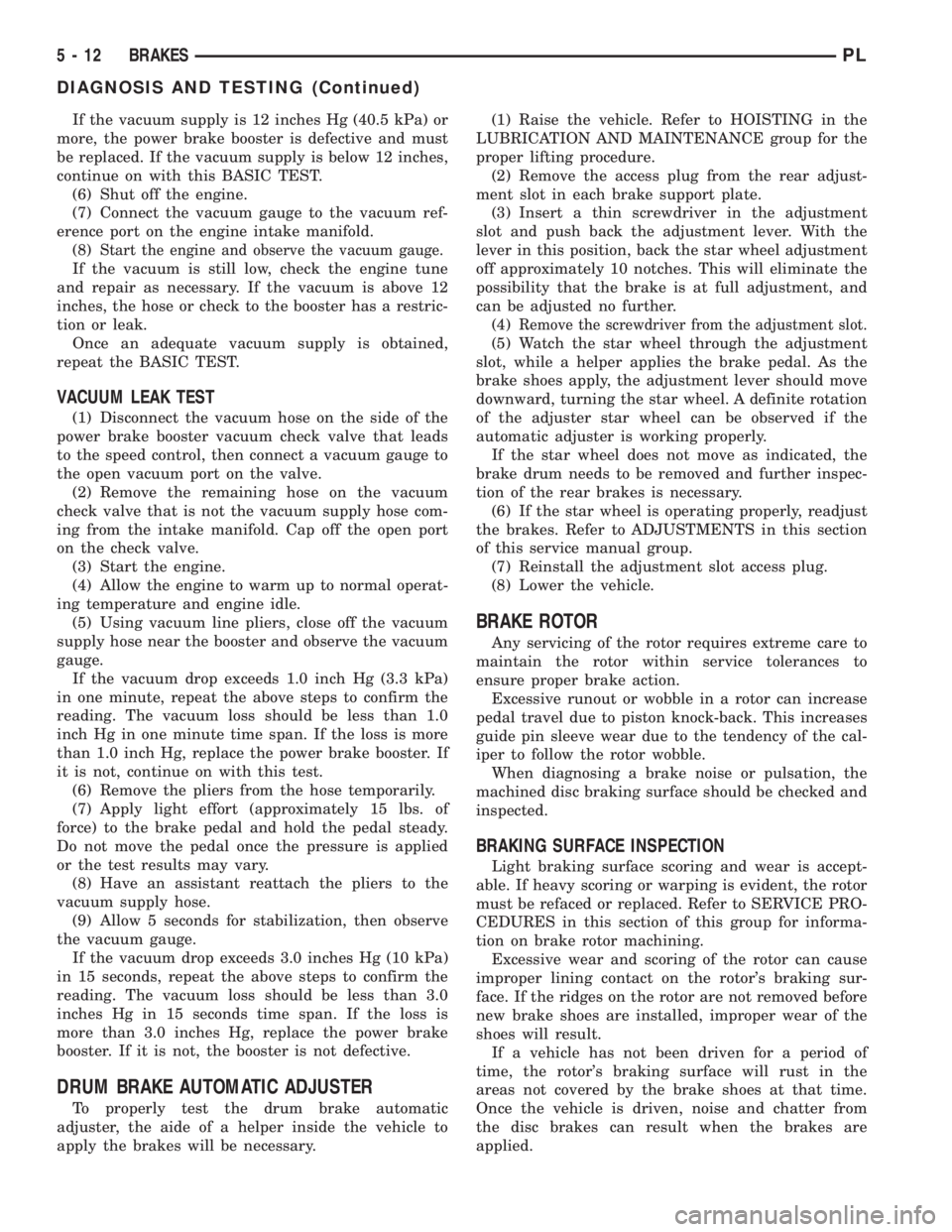

(1) Completely retract the caliper piston back into

piston bore of the caliper.

(2) Lubricate both adapter caliper slide abutments

with a liberal amount of MopartMultipurpose Lubri-

cant, or an equivalent.

CAUTION: Use care when installing the caliper

assembly onto adapter so the guide pin bushings

and sleeves do not get damaged by the mounting

bosses on adapter.

(3) Starting with the lower end, carefully lower the

caliper and brake shoes over the brake rotor and

catch the caliper's bottom edge behind the caliper

slide abutment (Fig. 69). Rotate the top of the caliper

into mounting position on the adapter.

CAUTION: Extreme caution should be taken not to

cross thread the caliper guide pin bolts when they

are installed.

(4) Carefully install the caliper guide pin bolts

(Fig. 68), then tighten them to a torque of 22 N´m

(192 in. lbs.).

(5) Install the banjo bolt connecting the brake hose

to the brake caliper (Fig. 67). Place one fitting

washer on each side of the hose fitting as the banjo

bolt is guided through the fitting. Install new wash-

ers if they are worn or damaged at all. Thread the

banjo bolt into the caliper and tighten it to a torque

of 48 N´m (35 ft. lbs.).(6) Install the tire and wheel assembly. Tighten

the wheel mounting nuts to a torque of 135 N´m (100

ft. lbs.).

(7) Lower the vehicle.

(8) Remove the brake pedal holding tool.

(9) Bleed the caliper as necessary. Refer to BASE

BRAKE BLEEDING in the SERVICE PROCE-

DURES section in this service manual group.

(10) Road test the vehicle and make several stops

to wear off any foreign material on the brakes and to

seat the brake shoes.

DISC BRAKE SHOES (REAR)

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove both rear tire and wheel assemblies

from vehicle.

(3) Begin on one side of the vehicle.

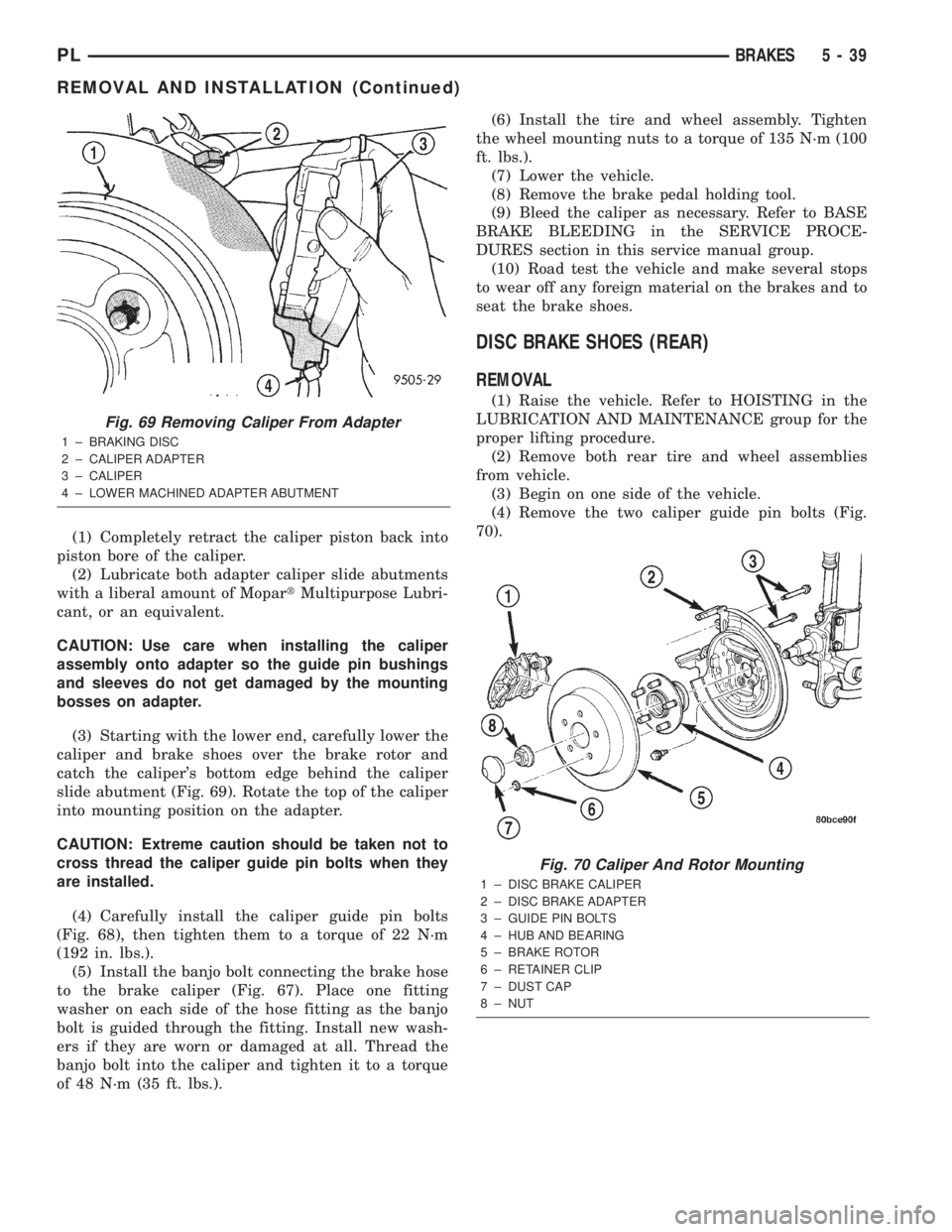

(4) Remove the two caliper guide pin bolts (Fig.

70).

Fig. 69 Removing Caliper From Adapter

1 ± BRAKING DISC

2 ± CALIPER ADAPTER

3 ± CALIPER

4 ± LOWER MACHINED ADAPTER ABUTMENT

Fig. 70 Caliper And Rotor Mounting

1 ± DISC BRAKE CALIPER

2 ± DISC BRAKE ADAPTER

3 ± GUIDE PIN BOLTS

4 ± HUB AND BEARING

5 ± BRAKE ROTOR

6 ± RETAINER CLIP

7 ± DUST CAP

8 ± NUT

PLBRAKES 5 - 39

REMOVAL AND INSTALLATION (Continued)

Page 120 of 1285

(6) Lubricate both adapter caliper slide abutments

with a liberal amount of MopartMultipurpose Lubri-

cant, or an equivalent.

CAUTION: Use care when installing the caliper

assembly onto adapter so the guide pin bushings

and sleeves do not get damaged by the mounting

bosses on adapter.

(7) Starting with the lower end, carefully lower the

caliper and brake shoes over the brake rotor and

catch the caliper's bottom edge behind the caliper

slide abutment (Fig. 71). Rotate the top of the caliper

into mounting position on the adapter.

CAUTION: Extreme caution should be taken not to

cross thread the caliper guide pin bolts when they

are installed.

(8) Carefully install the caliper guide pin bolts

(Fig. 70), then tighten them to a torque of 22 N´m

(192 in. lbs.).

(9) Install the tire and wheel assembly. Tighten

the wheel mounting nuts to a torque of 135 N´m (100

ft. lbs.).

(10) Repeat the above procedure to the rear brakes

on the other side of the vehicle.

(11) Lower the vehicle.

(12) Pump the brake pedal several times to ensure

the vehicle has a firm brake pedal before moving the

vehicle.(13) Road test the vehicle and make several stops

to wear off any foreign material on the brakes and to

seat the brake shoes.

BRAKE ROTOR (REAR)

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove the rear tire and wheel assembly.

(3) Remove the rear disc brake caliper assembly

from the brake rotor and store it out of the way.

Refer to DISC BRAKE SHOES (REAR) in this

REMOVAL AND INSTALLATION section of this ser-

vice manual group.

(4) Remove any clips retaining the brake rotor

(Fig. 70).

(5) Remove the brake rotor by pulling it straight

off the wheel mounting studs.

INSTALLATION

NOTE: Inspect the disc brake shoes and parking

brake shoes before brake rotor installation.

(1) Install the rear brake rotor over the wheel

mounting studs and onto the hub (Fig. 70).

(2) Install rear disc brake caliper. Refer to DISC

BRAKE SHOES (REAR) in this REMOVAL AND

INSTALLATION section of this service manual

group.

(3) Install the tire and wheel assembly. Tighten

the wheel mounting nuts to a torque of 135 N´m (100

ft. lbs.).

(4) Adjust the parking brake shoes as necessary.

Refer to ADJUSTMENTS in this section of this ser-

vice manual group.

(5) Lower the vehicle.

(6) Pump the brake pedal before moving the vehi-

cle to set the brake shoes to the brake rotor.

DRUM BRAKE WHEEL CYLINDER (REAR)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

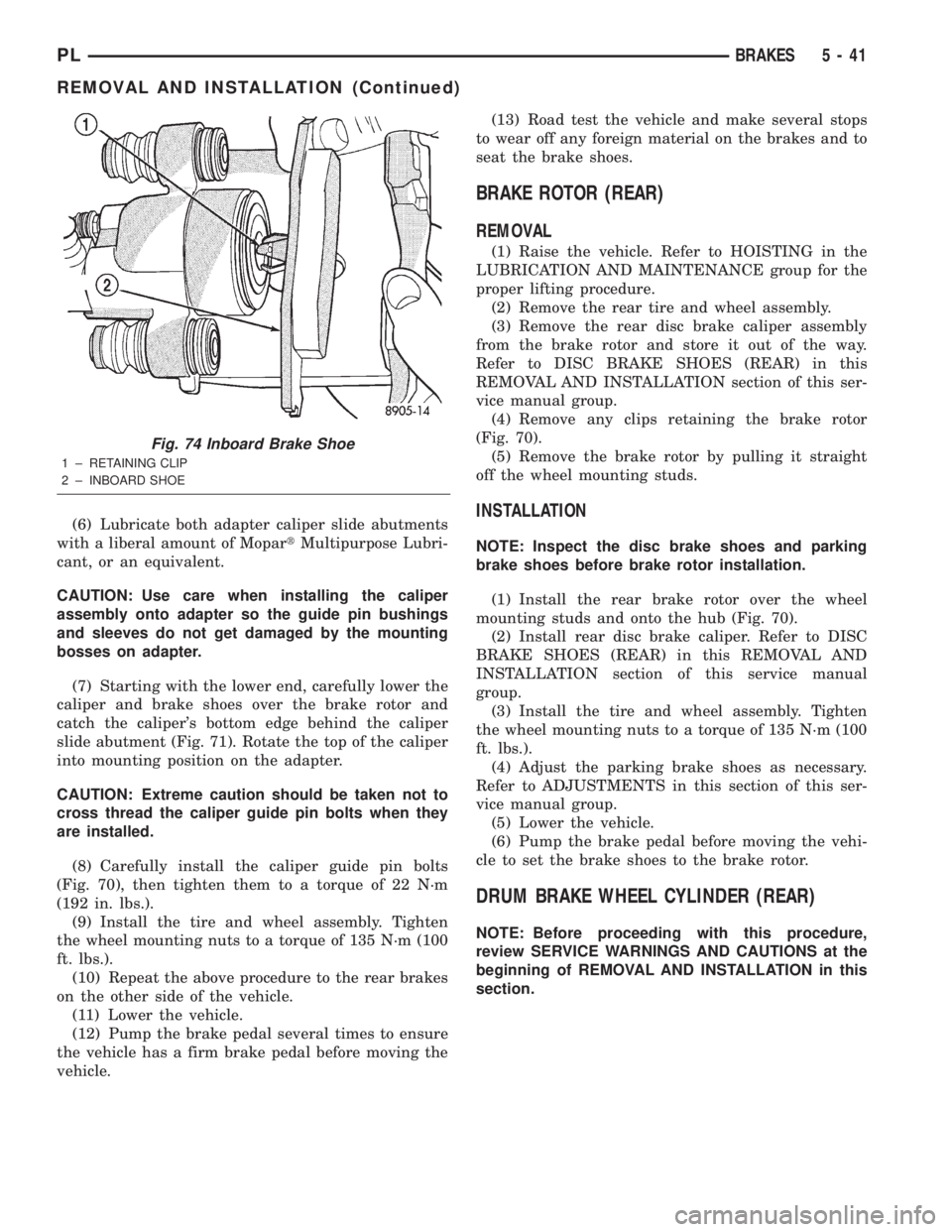

Fig. 74 Inboard Brake Shoe

1 ± RETAINING CLIP

2 ± INBOARD SHOE

PLBRAKES 5 - 41

REMOVAL AND INSTALLATION (Continued)

Page 121 of 1285

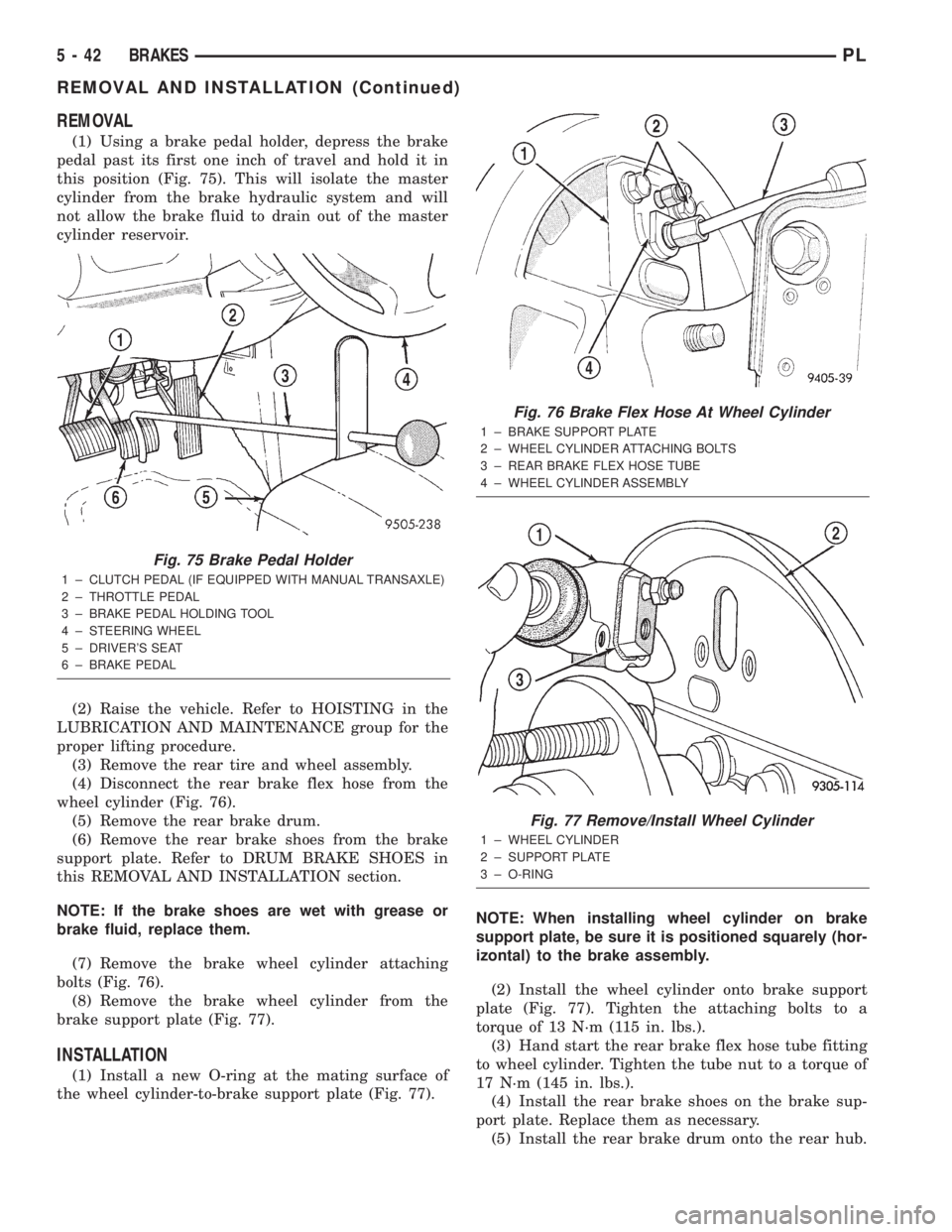

REMOVAL

(1) Using a brake pedal holder, depress the brake

pedal past its first one inch of travel and hold it in

this position (Fig. 75). This will isolate the master

cylinder from the brake hydraulic system and will

not allow the brake fluid to drain out of the master

cylinder reservoir.

(2) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(3) Remove the rear tire and wheel assembly.

(4) Disconnect the rear brake flex hose from the

wheel cylinder (Fig. 76).

(5) Remove the rear brake drum.

(6) Remove the rear brake shoes from the brake

support plate. Refer to DRUM BRAKE SHOES in

this REMOVAL AND INSTALLATION section.

NOTE: If the brake shoes are wet with grease or

brake fluid, replace them.

(7) Remove the brake wheel cylinder attaching

bolts (Fig. 76).

(8) Remove the brake wheel cylinder from the

brake support plate (Fig. 77).

INSTALLATION

(1) Install a new O-ring at the mating surface of

the wheel cylinder-to-brake support plate (Fig. 77).NOTE: When installing wheel cylinder on brake

support plate, be sure it is positioned squarely (hor-

izontal) to the brake assembly.

(2) Install the wheel cylinder onto brake support

plate (Fig. 77). Tighten the attaching bolts to a

torque of 13 N´m (115 in. lbs.).

(3) Hand start the rear brake flex hose tube fitting

to wheel cylinder. Tighten the tube nut to a torque of

17 N´m (145 in. lbs.).

(4) Install the rear brake shoes on the brake sup-

port plate. Replace them as necessary.

(5) Install the rear brake drum onto the rear hub.

Fig. 75 Brake Pedal Holder

1 ± CLUTCH PEDAL (IF EQUIPPED WITH MANUAL TRANSAXLE)

2 ± THROTTLE PEDAL

3 ± BRAKE PEDAL HOLDING TOOL

4 ± STEERING WHEEL

5 ± DRIVER'S SEAT

6 ± BRAKE PEDAL

Fig. 76 Brake Flex Hose At Wheel Cylinder

1 ± BRAKE SUPPORT PLATE

2 ± WHEEL CYLINDER ATTACHING BOLTS

3 ± REAR BRAKE FLEX HOSE TUBE

4 ± WHEEL CYLINDER ASSEMBLY

Fig. 77 Remove/Install Wheel Cylinder

1 ± WHEEL CYLINDER

2 ± SUPPORT PLATE

3 ± O-RING

5 - 42 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 126 of 1285

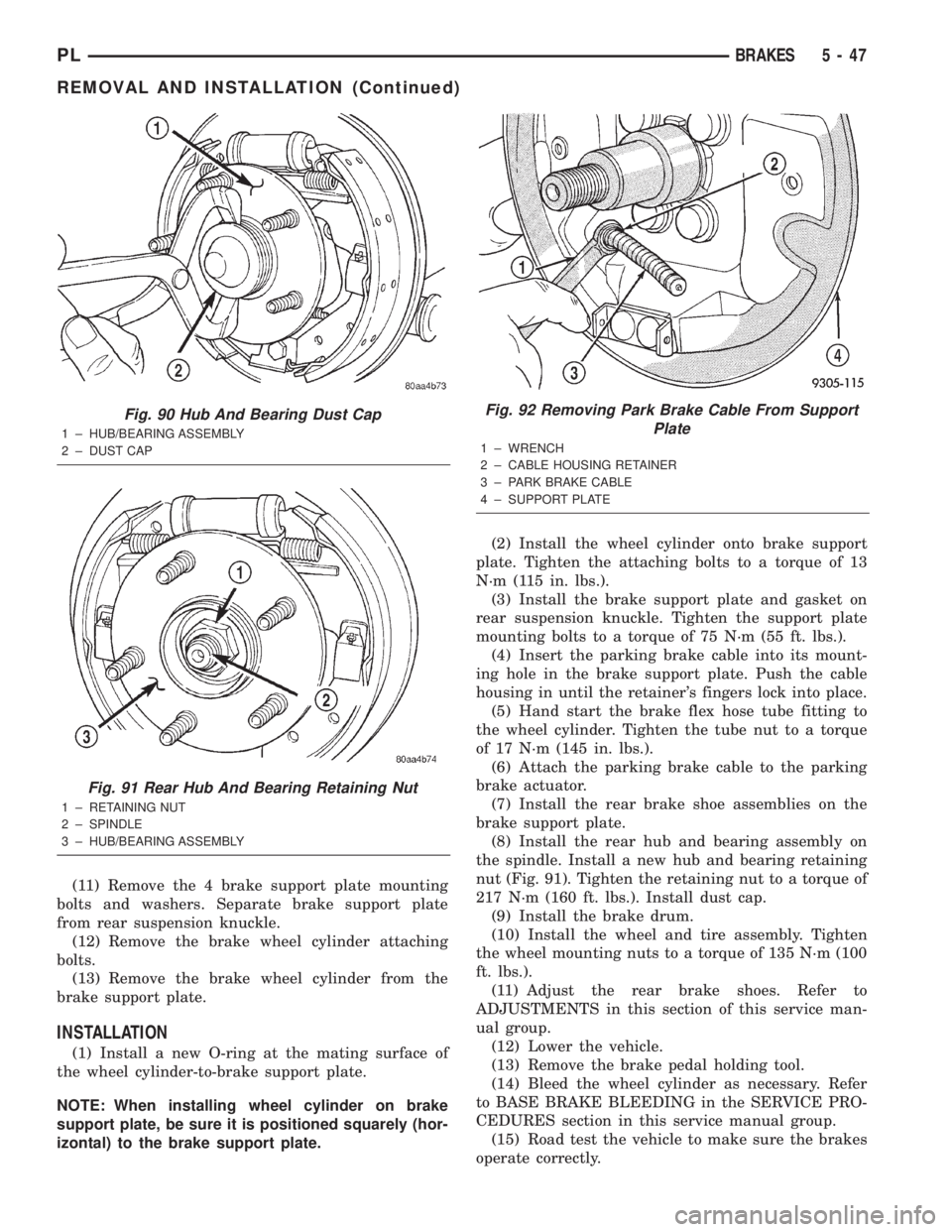

(11) Remove the 4 brake support plate mounting

bolts and washers. Separate brake support plate

from rear suspension knuckle.

(12) Remove the brake wheel cylinder attaching

bolts.

(13) Remove the brake wheel cylinder from the

brake support plate.

INSTALLATION

(1) Install a new O-ring at the mating surface of

the wheel cylinder-to-brake support plate.

NOTE: When installing wheel cylinder on brake

support plate, be sure it is positioned squarely (hor-

izontal) to the brake support plate.(2) Install the wheel cylinder onto brake support

plate. Tighten the attaching bolts to a torque of 13

N´m (115 in. lbs.).

(3) Install the brake support plate and gasket on

rear suspension knuckle. Tighten the support plate

mounting bolts to a torque of 75 N´m (55 ft. lbs.).

(4) Insert the parking brake cable into its mount-

ing hole in the brake support plate. Push the cable

housing in until the retainer's fingers lock into place.

(5) Hand start the brake flex hose tube fitting to

the wheel cylinder. Tighten the tube nut to a torque

of 17 N´m (145 in. lbs.).

(6) Attach the parking brake cable to the parking

brake actuator.

(7) Install the rear brake shoe assemblies on the

brake support plate.

(8) Install the rear hub and bearing assembly on

the spindle. Install a new hub and bearing retaining

nut (Fig. 91). Tighten the retaining nut to a torque of

217 N´m (160 ft. lbs.). Install dust cap.

(9) Install the brake drum.

(10) Install the wheel and tire assembly. Tighten

the wheel mounting nuts to a torque of 135 N´m (100

ft. lbs.).

(11) Adjust the rear brake shoes. Refer to

ADJUSTMENTS in this section of this service man-

ual group.

(12) Lower the vehicle.

(13) Remove the brake pedal holding tool.

(14) Bleed the wheel cylinder as necessary. Refer

to BASE BRAKE BLEEDING in the SERVICE PRO-

CEDURES section in this service manual group.

(15) Road test the vehicle to make sure the brakes

operate correctly.

Fig. 90 Hub And Bearing Dust Cap

1 ± HUB/BEARING ASSEMBLY

2 ± DUST CAP

Fig. 91 Rear Hub And Bearing Retaining Nut

1 ± RETAINING NUT

2 ± SPINDLE

3 ± HUB/BEARING ASSEMBLY

Fig. 92 Removing Park Brake Cable From Support

Plate

1 ± WRENCH

2 ± CABLE HOUSING RETAINER

3 ± PARK BRAKE CABLE

4 ± SUPPORT PLATE

PLBRAKES 5 - 47

REMOVAL AND INSTALLATION (Continued)

Page 137 of 1285

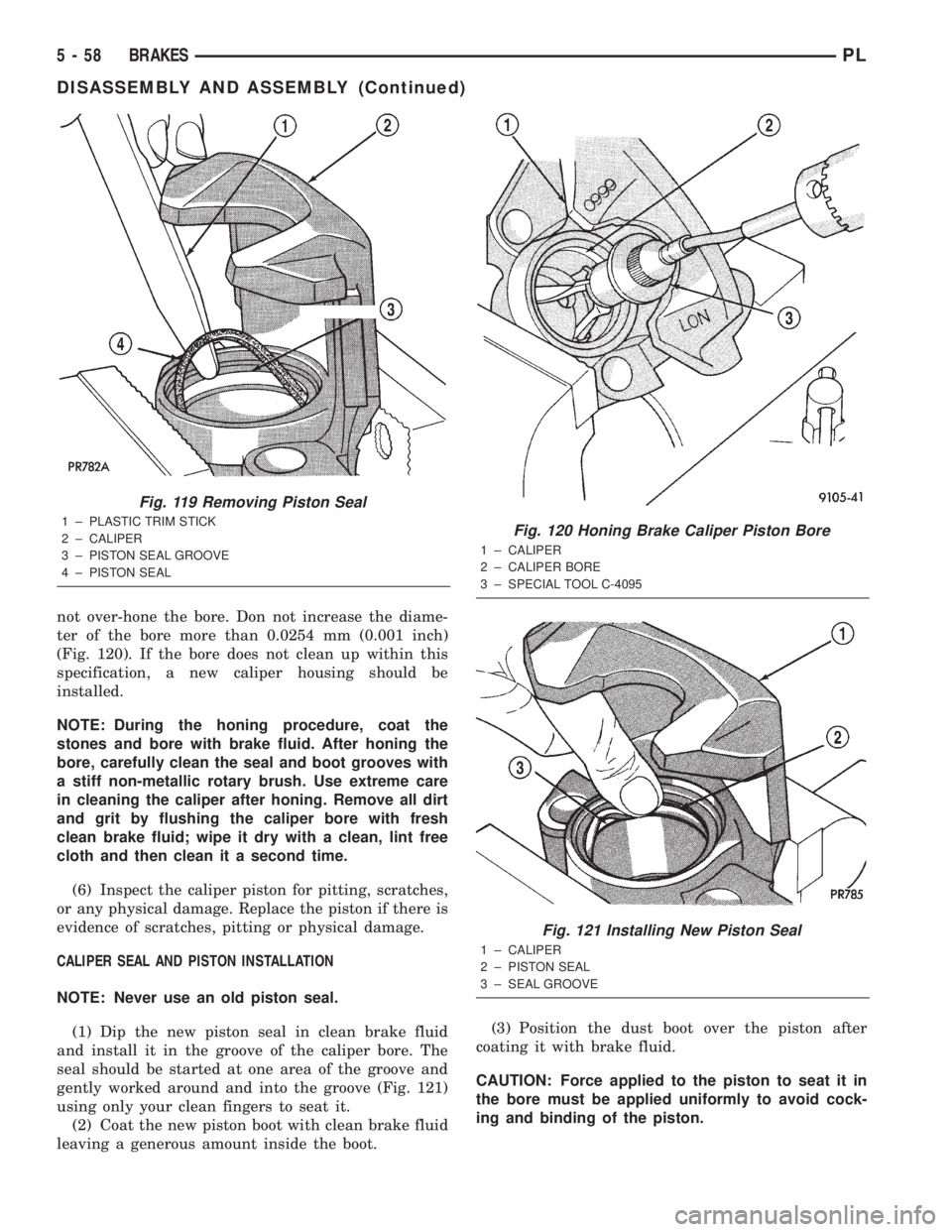

not over-hone the bore. Don not increase the diame-

ter of the bore more than 0.0254 mm (0.001 inch)

(Fig. 120). If the bore does not clean up within this

specification, a new caliper housing should be

installed.

NOTE: During the honing procedure, coat the

stones and bore with brake fluid. After honing the

bore, carefully clean the seal and boot grooves with

a stiff non-metallic rotary brush. Use extreme care

in cleaning the caliper after honing. Remove all dirt

and grit by flushing the caliper bore with fresh

clean brake fluid; wipe it dry with a clean, lint free

cloth and then clean it a second time.

(6) Inspect the caliper piston for pitting, scratches,

or any physical damage. Replace the piston if there is

evidence of scratches, pitting or physical damage.

CALIPER SEAL AND PISTON INSTALLATION

NOTE: Never use an old piston seal.

(1) Dip the new piston seal in clean brake fluid

and install it in the groove of the caliper bore. The

seal should be started at one area of the groove and

gently worked around and into the groove (Fig. 121)

using only your clean fingers to seat it.

(2) Coat the new piston boot with clean brake fluid

leaving a generous amount inside the boot.(3) Position the dust boot over the piston after

coating it with brake fluid.

CAUTION: Force applied to the piston to seat it in

the bore must be applied uniformly to avoid cock-

ing and binding of the piston.

Fig. 119 Removing Piston Seal

1 ± PLASTIC TRIM STICK

2 ± CALIPER

3 ± PISTON SEAL GROOVE

4 ± PISTON SEALFig. 120 Honing Brake Caliper Piston Bore

1 ± CALIPER

2 ± CALIPER BORE

3 ± SPECIAL TOOL C-4095

Fig. 121 Installing New Piston Seal

1 ± CALIPER

2 ± PISTON SEAL

3 ± SEAL GROOVE

5 - 58 BRAKESPL

DISASSEMBLY AND ASSEMBLY (Continued)