No start DODGE NEON 2000 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 245 of 1285

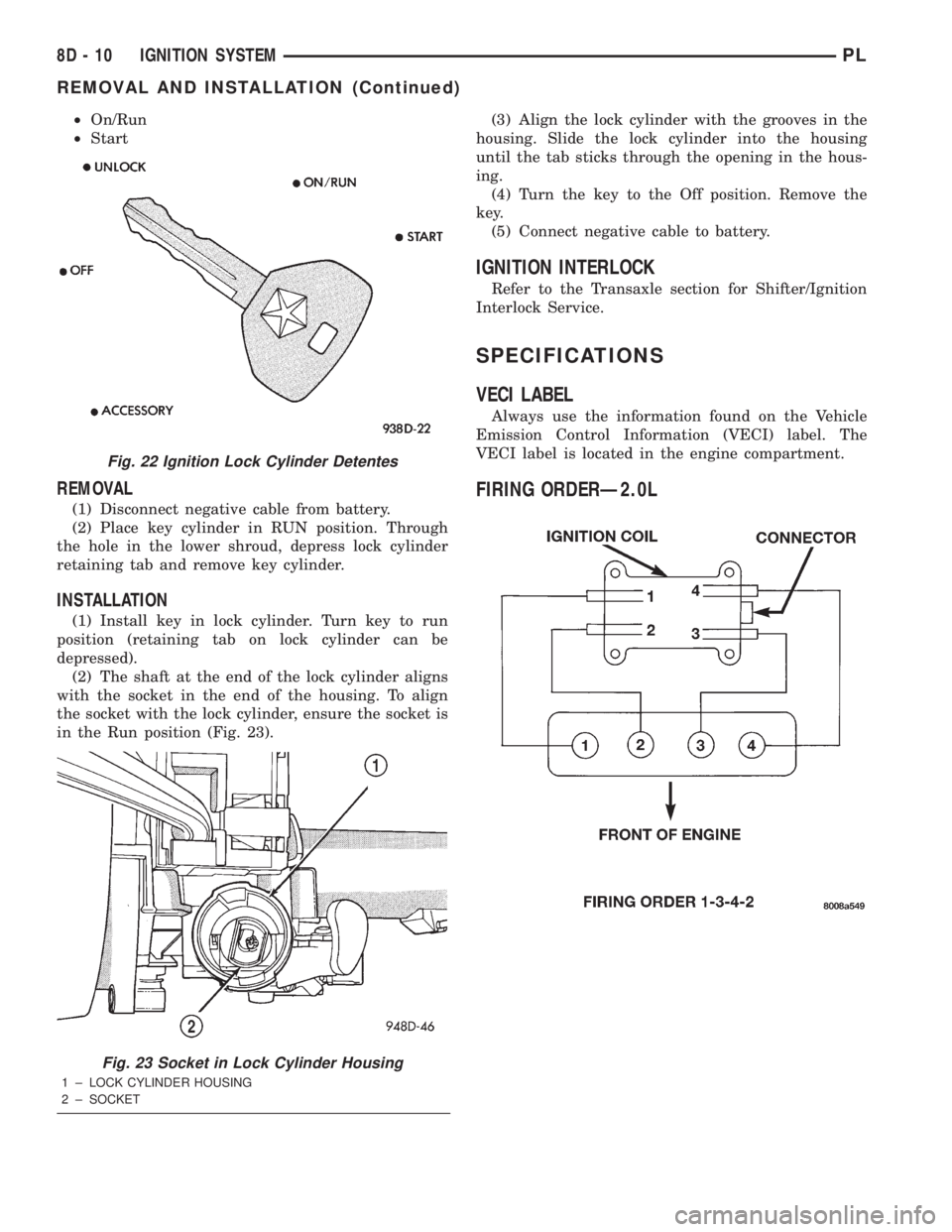

²On/Run

²Start

REMOVAL

(1) Disconnect negative cable from battery.

(2) Place key cylinder in RUN position. Through

the hole in the lower shroud, depress lock cylinder

retaining tab and remove key cylinder.

INSTALLATION

(1) Install key in lock cylinder. Turn key to run

position (retaining tab on lock cylinder can be

depressed).

(2) The shaft at the end of the lock cylinder aligns

with the socket in the end of the housing. To align

the socket with the lock cylinder, ensure the socket is

in the Run position (Fig. 23).(3) Align the lock cylinder with the grooves in the

housing. Slide the lock cylinder into the housing

until the tab sticks through the opening in the hous-

ing.

(4) Turn the key to the Off position. Remove the

key.

(5) Connect negative cable to battery.

IGNITION INTERLOCK

Refer to the Transaxle section for Shifter/Ignition

Interlock Service.

SPECIFICATIONS

VECI LABEL

Always use the information found on the Vehicle

Emission Control Information (VECI) label. The

VECI label is located in the engine compartment.

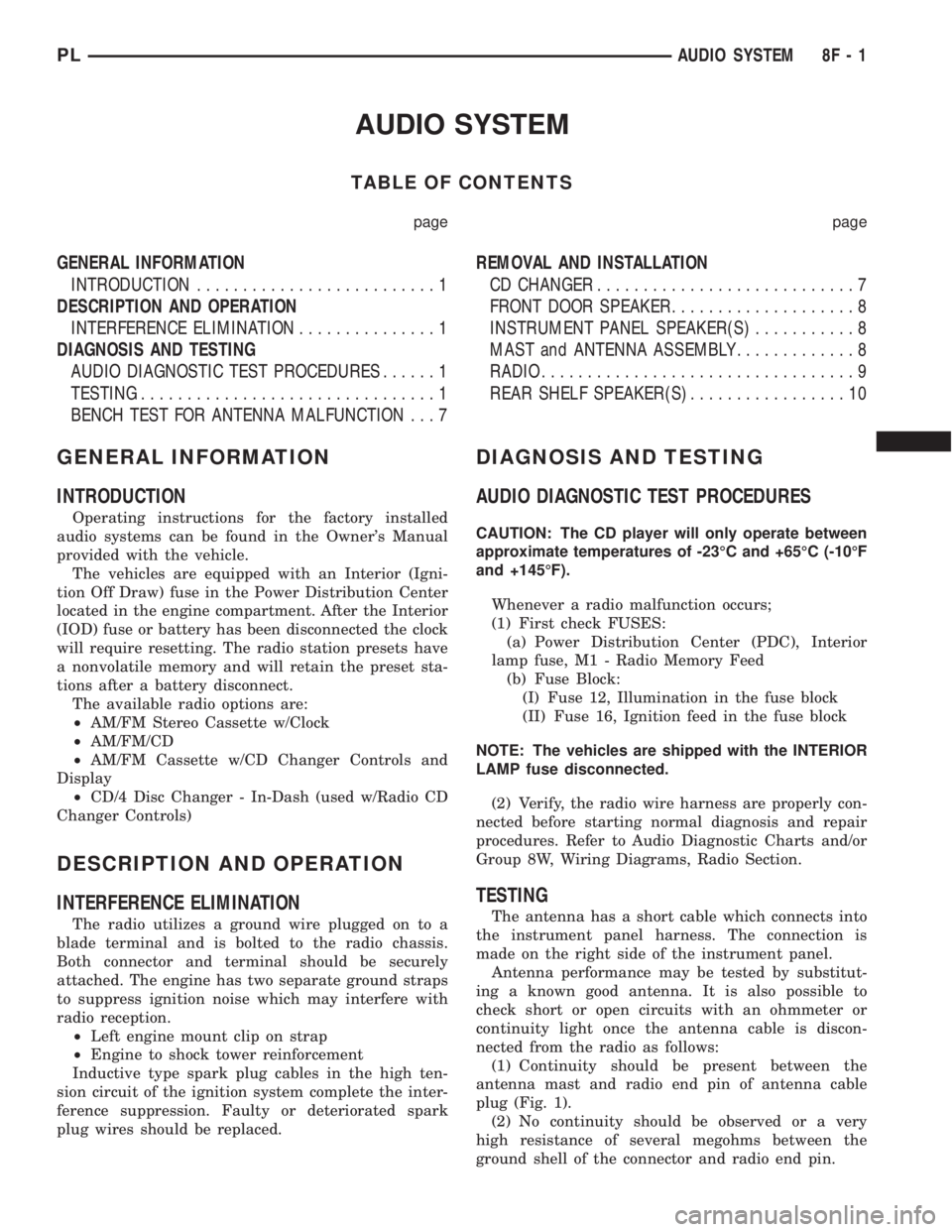

FIRING ORDERÐ2.0L

Fig. 22 Ignition Lock Cylinder Detentes

Fig. 23 Socket in Lock Cylinder Housing

1 ± LOCK CYLINDER HOUSING

2 ± SOCKET

8D - 10 IGNITION SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 249 of 1285

DESCRIPTION AND OPERATION

HEADLAMP SWITCH

The headlamp switch is part of the Multi-Function

Switch. Refer to Group 8J, Turn Signal and Flasher

for the Multi-Function Switch Test, Removal and

Installation procedures.

INSTRUMENT CLUSTER

There are two conventional instrument cluster

assemblies available. The clusters electronically drive

the speedometer, odometer, gauges, and tachometer

(if equipped). Refer to (Fig. 2) and (Fig. 3).

The instrument cluster controls the courtesy

lamps, it receives and sends messages to other mod-

ules via the PCI bus circuit, it controls all the instru-

ment illumination and the chime is also an integral

part of the cluster. The front turn signals are wired

through the cluster and then go to the front lamps.

The reason being that the DRL module is built into

the cluster (if equipped).

All gauges in the electronic clusters are the analog

type gauges. When the ignition switch is moved to

the OFF position, the cluster drives each gauge to its

lowest position. The individual gauges are not servi-

cable and require complete replacement of the cluster

if one or more gauges are inoperable.

One button is used to switch the display from trip

to total mileage. Holding the button when the display

is in the trip mode will reset the trip mileage. This

button is also used to put the cluster in self-diagnos-

tic mode. Refer to Service Procedures, Cluster Self-

Diagnostics in this section. Most of the indicators will

come on briefly for a bulb heck when the ignition is

turned from OFF to ON. All of the LED's are replace-

able.

In the event that the instrument cluster looses

communication with all other modules on the PCI

bus, the cluster will display ªnobusº in the VF dis-

play. The VF display also displays ªDoorº, ªCruiseº,

ªTracº, and odometer trip or total.

If the cluster does not detect voltage on the cour-

tesy lamp circuit, the message ªFUSEº will alternate

with the odometer/trip odometer for 30 seconds after

the ignition is turned on and for 15 seconds after the

vehicle is first moved. The lack of voltage can be due

to the M1 Fused B(+) (IOD) fuse being open, a bad or

missing courtesy lamp bulb, or a circuit problem.

WARNING AND INDICATOR LAMPS

The instrument cluster has warning lamps and

indicators for the following systems:

²Airbag

²Anti-lock Brakes (ABS) if equipped

²Brake warning

²Charging System²Front fog lamps (if equipped)

²High beam indicator

²Low fuel (premium cluster only)

²Low oil pressure

²Malfunction indicator (service engine soon) lamp

²Right and left turn signals

²Seat belt warning

²Security system

²Trac-Off (ABS equipped vehicles only)

The instrument cluster has a Vacuum Fluorescent

(VF) display for the following systems:

²Cruise

²Door (ajar)

²Odometer

²Set (cruise)

²Trac

²Trip

DIAGNOSIS AND TESTING

AIRBAG WARNING SYSTEM

For testing of this system refer to Group 8M, Pas-

sive Restraint Systems.

BRAKE SYSTEM WARNING LAMP TEST

The brake warning lamp illuminates when the

parking brake is applied with ignition switch turned

to the ON position. The same lamp will also illumi-

nate if one of the two service brake systems fail the

when brake pedal is applied.

To test the system:

²As the ignition switch is turned to the start posi-

tion the lamp should light.

²Turn ignition switch to the ON position and

apply the parking brake. The lamp should light.

If lamp fails to light inspect for:

²A burned out lamp

²Loose, corroded or damaged socket

²A damaged circuit board

²A broken or disconnected wire at the switch

²Defective switch

To test the service brake warning system, refer to

Group 5, Brakes, Hydraulic System Control Valves.

INSTRUMENT CLUSTER LAMPS

Every time the vehicle is switched to the START/

RUN position, the cluster goes through a BULB

CHECK. This tests most of the indicator lamps and

Vacuum Fluorescent (VF) displays. If only one lamp

is out, remove the instrument cluster and replace the

defective bulb or Light Emitting Diode (LED). If

some or all of the lamps fail to light, refer to the

proper Body Diagnostics Procedures Manual.

8E - 2 INSTRUMENT PANEL SYSTEMSPL

Page 251 of 1285

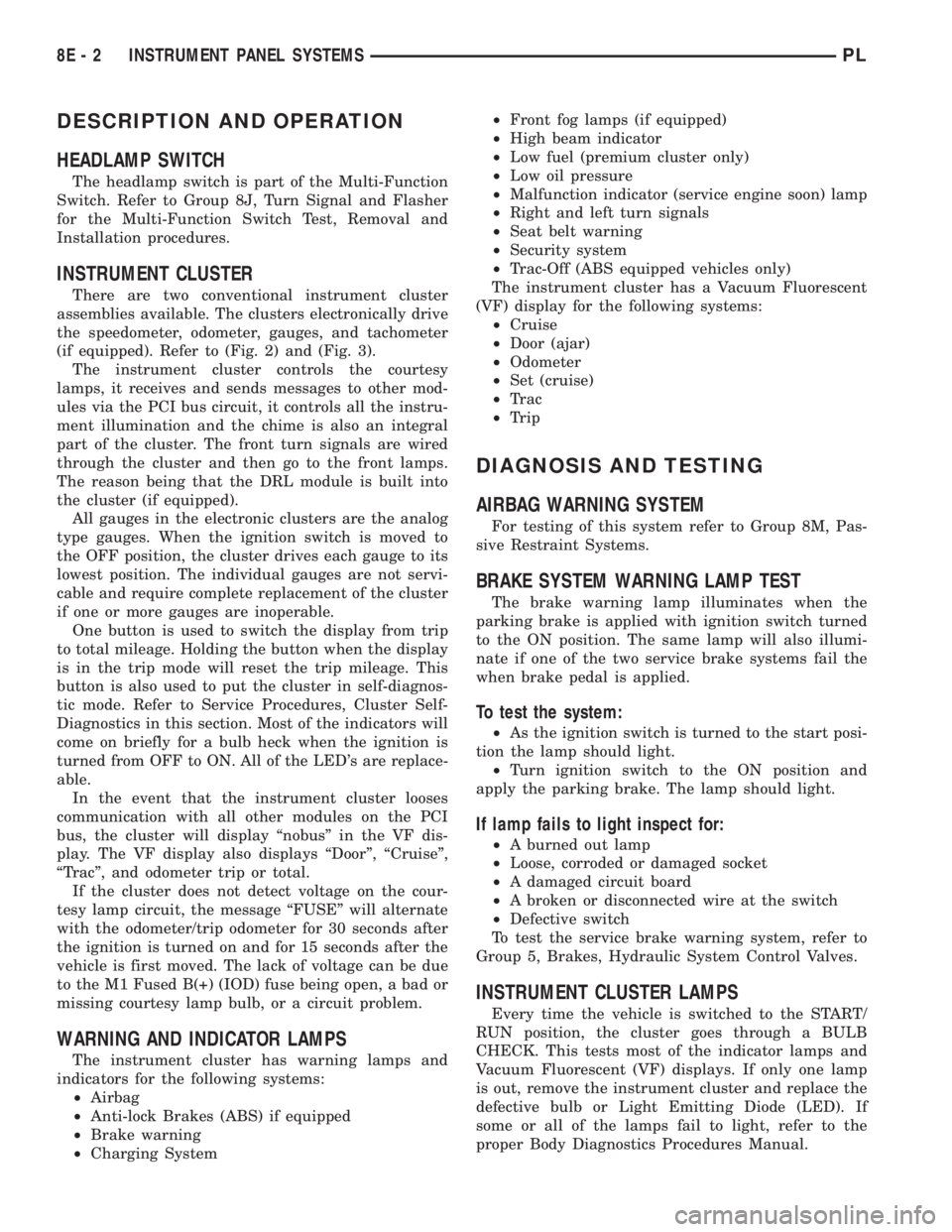

MULTIPLE/INDIVIDUAL GAUGES INOPERATIVE

Test speedometer, tachometer and other gauges for

malfunction:

(1) Remove the cluster. Refer to Cluster Removal

and Installation.

(2) Check for ignition voltage at Pin 15 of the clus-

ter wire harness connector (Fig. 5). Check for battery

voltage at Pin 21 of the connector. If no voltage,

repair as necessary.

(3) Check Pin 10 of the connector for continuity to

ground. If no ground, repair as necessary.

(4) If the voltage and ground are OK, and the pins

or the connectors are not distorted, replace the

instrument cluster.

(5) Install cluster. Refer to Instrument Cluster

Removal and Installation in this section.

SERVICE PROCEDURES

INSTRUMENT CLUSTER SELF-DIAGNOSTICS

To put the cluster in self-diagnostics mode press

the trip reset button down and then turn the ignition

to the RUN position simultaneously, then release the

button. The gauges will increment to selected stoops

and all indicators will light with the exception of the

turn signals, high beam, and fog lamp indicators.

The oil lamp will come on when the ignition is

turned ON and the engine is OFF.

REMOVAL AND INSTALLATION

ACCESSORY SWITCH/POWER OUTLET BEZEL

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 6).

(2) Remove the instrument panel center bezel.

Refer to Instrument Panel Center Bezel Removal and

Installation in this section.

(3) Remove four screws retaining accessory switch/

power outlet bezel (Fig. 7).(4) Disconnect the harness connectors to the fol-

lowing:

²Rear Window Defogger Switch (if equipped)

²Traction Control Switch (if equipped)

²Cigar Lighter/Power Outlet

Fig. 5 Cluster Wire Harness Connector

INSTRUMENT CLUSTER CONNECTOR PIN

CALL-OUT

PIN DESCRIPTION PIN DESCRIPTION

1 REAR FOG

LAMP FEED14 PARK LAMP

SWITCH

OUTPUT

2 PCI BUS 15 FUSED IGNITION

SWITCH

OUTPUT

(RUN-START)

3 COURTESY

LAMPS DRIVER16 DAYTIME

RUNNING

LAMPS

4 FOG LAMP

SWITCH

OUTPUT17 DAYTIME

RUNNING

LAMPS

5 VTSS

INDICATOR

DRIVER18 LEFT TURN

SIGNAL

6 PANEL LAMPS

DIMMER

SIGNAL19 RIGHT TURN

SIGNAL

7 FUEL LEVEL

SENSOR

SIGNAL20 DIMMER

SWITCH LOW

BEAM OUTPUT

8 NOT USED 21 FUSED B+

9 NOT USED 22 RED BRAKE

WARNING

INDICATOR

DRIVER

10 GROUND 23 KEY-IN IGNITION

SWITCH SENSE

11 NOT USED 24 DRIVER DOOR

AJAR SWITCH

SENSE

12 PANEL LAMPS

DRIVER25 SEAT BELT

SWITCH SENSE

13 KEYLESS

ENTRY SIGNAL26 DIMMER

SWITCH HIGH

BEAM OUTPUT

Fig. 4 Oil Pressure Switch

8E - 4 INSTRUMENT PANEL SYSTEMSPL

DIAGNOSIS AND TESTING (Continued)

Page 270 of 1285

AUDIO SYSTEM

TABLE OF CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION..........................1

DESCRIPTION AND OPERATION

INTERFERENCE ELIMINATION...............1

DIAGNOSIS AND TESTING

AUDIO DIAGNOSTIC TEST PROCEDURES......1

TESTING................................1

BENCH TEST FOR ANTENNA MALFUNCTION...7REMOVAL AND INSTALLATION

CD CHANGER............................7

FRONT DOOR SPEAKER....................8

INSTRUMENT PANEL SPEAKER(S)...........8

MAST and ANTENNA ASSEMBLY.............8

RADIO..................................9

REAR SHELF SPEAKER(S).................10

GENERAL INFORMATION

INTRODUCTION

Operating instructions for the factory installed

audio systems can be found in the Owner's Manual

provided with the vehicle.

The vehicles are equipped with an Interior (Igni-

tion Off Draw) fuse in the Power Distribution Center

located in the engine compartment. After the Interior

(IOD) fuse or battery has been disconnected the clock

will require resetting. The radio station presets have

a nonvolatile memory and will retain the preset sta-

tions after a battery disconnect.

The available radio options are:

²AM/FM Stereo Cassette w/Clock

²AM/FM/CD

²AM/FM Cassette w/CD Changer Controls and

Display

²CD/4 Disc Changer - In-Dash (used w/Radio CD

Changer Controls)

DESCRIPTION AND OPERATION

INTERFERENCE ELIMINATION

The radio utilizes a ground wire plugged on to a

blade terminal and is bolted to the radio chassis.

Both connector and terminal should be securely

attached. The engine has two separate ground straps

to suppress ignition noise which may interfere with

radio reception.

²Left engine mount clip on strap

²Engine to shock tower reinforcement

Inductive type spark plug cables in the high ten-

sion circuit of the ignition system complete the inter-

ference suppression. Faulty or deteriorated spark

plug wires should be replaced.

DIAGNOSIS AND TESTING

AUDIO DIAGNOSTIC TEST PROCEDURES

CAUTION: The CD player will only operate between

approximate temperatures of -23ÉC and +65ÉC (-10ÉF

and +145ÉF).

Whenever a radio malfunction occurs;

(1) First check FUSES:

(a) Power Distribution Center (PDC), Interior

lamp fuse, M1 - Radio Memory Feed

(b) Fuse Block:

(I) Fuse 12, Illumination in the fuse block

(II) Fuse 16, Ignition feed in the fuse block

NOTE: The vehicles are shipped with the INTERIOR

LAMP fuse disconnected.

(2) Verify, the radio wire harness are properly con-

nected before starting normal diagnosis and repair

procedures. Refer to Audio Diagnostic Charts and/or

Group 8W, Wiring Diagrams, Radio Section.

TESTING

The antenna has a short cable which connects into

the instrument panel harness. The connection is

made on the right side of the instrument panel.

Antenna performance may be tested by substitut-

ing a known good antenna. It is also possible to

check short or open circuits with an ohmmeter or

continuity light once the antenna cable is discon-

nected from the radio as follows:

(1) Continuity should be present between the

antenna mast and radio end pin of antenna cable

plug (Fig. 1).

(2) No continuity should be observed or a very

high resistance of several megohms between the

ground shell of the connector and radio end pin.

PLAUDIO SYSTEM 8F - 1

Page 300 of 1285

(a) If no voltage, repair wiring as necessary. If

OK, go to Step b.

(b) Check wiper switch low speed. Connect volt-

meter positive lead to terminal 6 of the wiper

switch connector. Move wiper stalk to LOW posi-

tion. If no voltage, replace switch.

(c) Check wiper switch high speed, connect volt-

meter positive lead to terminal 5 of the wiper

switch connector. Move wiper stalk to HIGH posi-

tion. If no voltage, replace switch.

(7) Disconnect motor connector and replace fuse 1

in fuse block.

(a) If fuse does not blow, replace motor.

(b) If fuse blows, disconnect wiper switch and

replace fuse.

(c) If fuse does not blow, replace switch.

(d) If fuse blows, repair wiring as necessary.

MOTOR OPERATES SLOWLY AT ALL SPEEDS

(1) Remove wiper arms and cowl screen. Discon-

nect motor linkage from motor. Connect an ammeter

between battery positive terminal and terminal 4 of

the motor connector. Turn wiper motor on and check

ampere reading.

If motor runs and ammeter reading is more than 6

amps, go to Step 2. If less than 6 amps, go to Step 3.

When replacing drive link nut tighten to 11 to 12

N´m (98 to 106 in. lbs.) torque.

(2) Using an ohmmeter, check the high and low

circuits for a short to ground. Refer to Group 8W,

Wiring Diagrams.

(3) Check to see if wiper linkage or pivots are

binding or caught.

WIPERS RUN AT HIGH SPEED WITH SWITCH IN

LOW SPEED POSITION OR WIPERS RUN AT LOW

SPEED WITH SWITCH IN HIGH SPEED POSITION.

(1) Check for crossed wires in the motor pigtail

wire connector. Refer to Group 8W, Wiring Diagrams.

(2) Check for crossed wires in harness connector

from wiper switch to motor.

(3) If OK, replace wiper switch.

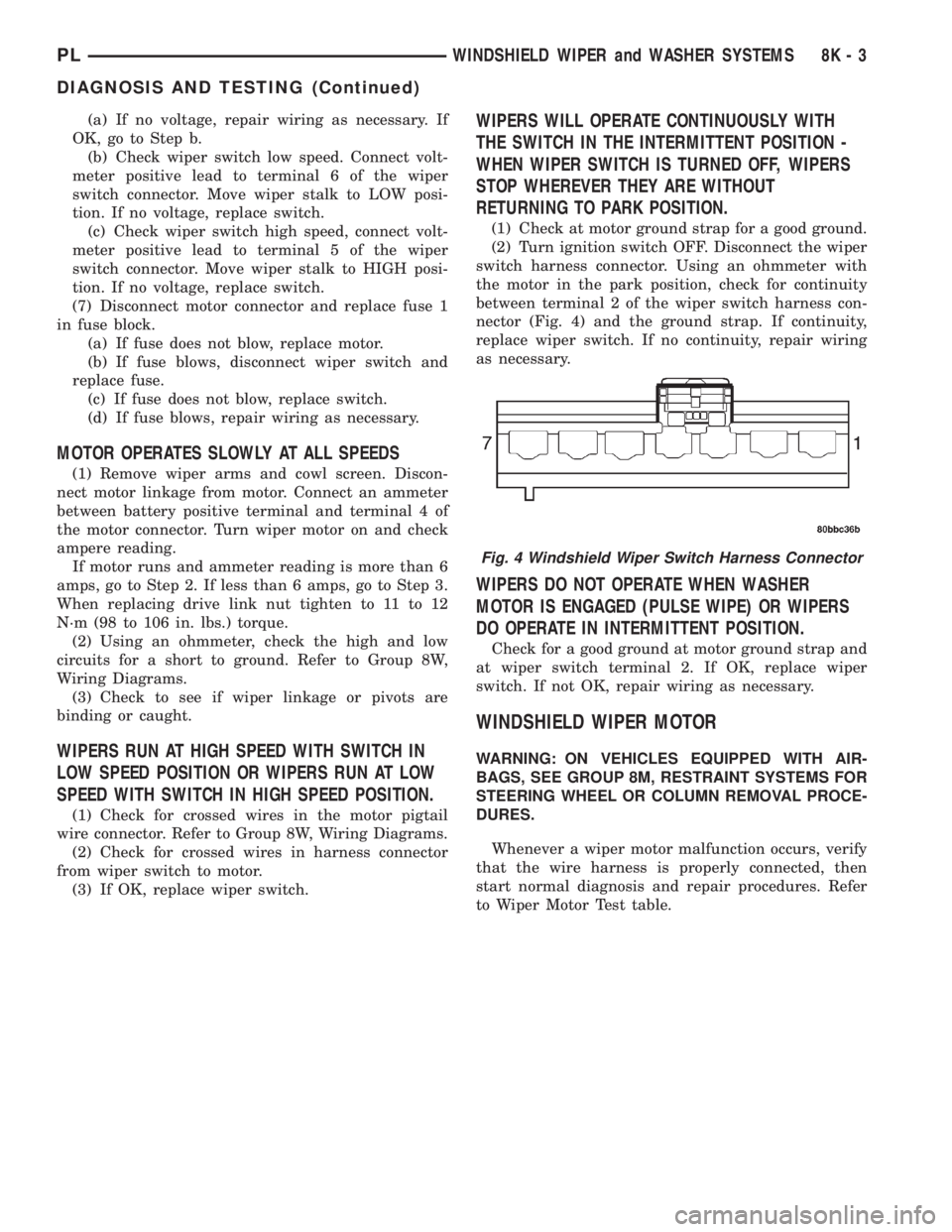

WIPERS WILL OPERATE CONTINUOUSLY WITH

THE SWITCH IN THE INTERMITTENT POSITION -

WHEN WIPER SWITCH IS TURNED OFF, WIPERS

STOP WHEREVER THEY ARE WITHOUT

RETURNING TO PARK POSITION.

(1) Check at motor ground strap for a good ground.

(2) Turn ignition switch OFF. Disconnect the wiper

switch harness connector. Using an ohmmeter with

the motor in the park position, check for continuity

between terminal 2 of the wiper switch harness con-

nector (Fig. 4) and the ground strap. If continuity,

replace wiper switch. If no continuity, repair wiring

as necessary.

WIPERS DO NOT OPERATE WHEN WASHER

MOTOR IS ENGAGED (PULSE WIPE) OR WIPERS

DO OPERATE IN INTERMITTENT POSITION.

Check for a good ground at motor ground strap and

at wiper switch terminal 2. If OK, replace wiper

switch. If not OK, repair wiring as necessary.

WINDSHIELD WIPER MOTOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

Whenever a wiper motor malfunction occurs, verify

that the wire harness is properly connected, then

start normal diagnosis and repair procedures. Refer

to Wiper Motor Test table.

Fig. 4 Windshield Wiper Switch Harness Connector

PLWINDSHIELD WIPER and WASHER SYSTEMS 8K - 3

DIAGNOSIS AND TESTING (Continued)

Page 306 of 1285

DIAGNOSIS AND TESTING

WINDSHIELD WASHER SYSTEM

Whenever a windshield washer malfunction occurs,

first verify that the windshield washer wire harnessis properly connected to all connectors before starting

normal diagnosis and repair procedures. Refer to

Windshield Washer System Test table.

WINDSHIELD WASHER SYSTEM TEST

CONDITION POSSIBLE CAUSE CORRECTION

PUMP RUNS NO FLUID

FLOWING.1. NO FLUID IN THE

RESERVOIR.

2. NOZZLE PLUGGED

OR FROZEN.

3. BROKEN, LOOSE OR

PINCHED HOSE.

4. FAULTY PUMP.1. FILL RESERVOIR.

2. THAW AND CHECK FLOW IF BLOCKED

3. CHECK FLOW THROUGH HOSE CONNECTIONS.

4. APPLY BATTERY VOLTAGE TO MOTOR

TERMINALS, REPLACE IF PUMP DOES NOT RUN.

SYSTEM OPERATES

INTERMITTENTLY.1. LOOSE WIRE

CONNECTION.

2. FAULTY SWITCH.1. CHECK WIRE CONNECTIONS.

2. DISCONNECT WIRE HARNESS USE

VOLTMETER TO CHECK SWITCH.

SYSTEM OUTPUT IS

LOW.1. PINCHED HOSE.

2. HOSE BLOCKED.1. CHECK FLOW THROUGH HOSE CONNECTION.

2. DISCONNECT HOSE AT NOZZLE AND Y

CONNECTOR CHECK FOR FLOW. REPLACE ASS

NECESSARY.

REMOVAL AND INSTALLATION

WINDSHIELD WASHER HOSE

REMOVAL

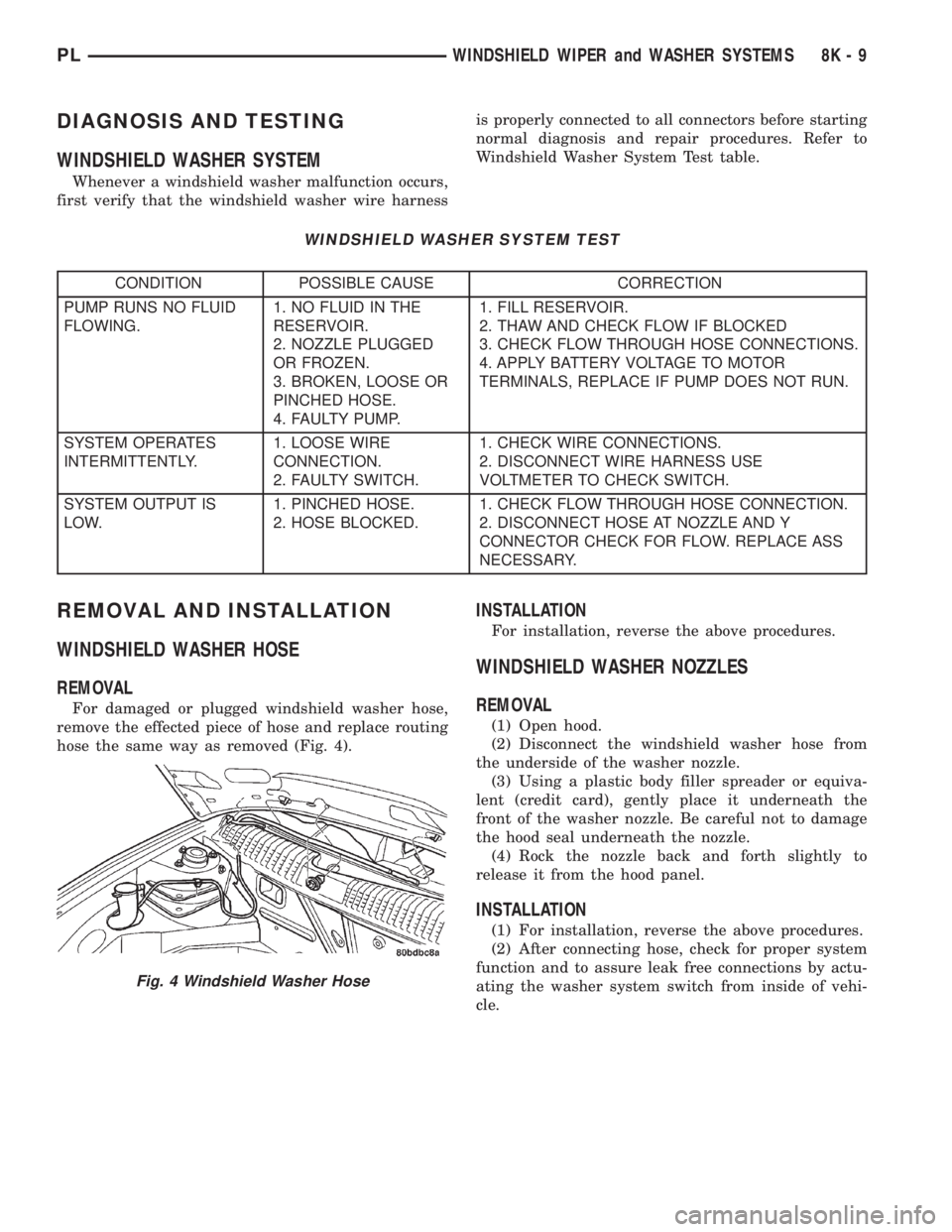

For damaged or plugged windshield washer hose,

remove the effected piece of hose and replace routing

hose the same way as removed (Fig. 4).

INSTALLATION

For installation, reverse the above procedures.

WINDSHIELD WASHER NOZZLES

REMOVAL

(1) Open hood.

(2) Disconnect the windshield washer hose from

the underside of the washer nozzle.

(3) Using a plastic body filler spreader or equiva-

lent (credit card), gently place it underneath the

front of the washer nozzle. Be careful not to damage

the hood seal underneath the nozzle.

(4) Rock the nozzle back and forth slightly to

release it from the hood panel.

INSTALLATION

(1) For installation, reverse the above procedures.

(2) After connecting hose, check for proper system

function and to assure leak free connections by actu-

ating the washer system switch from inside of vehi-

cle.

Fig. 4 Windshield Washer Hose

PLWINDSHIELD WIPER and WASHER SYSTEMS 8K - 9

Page 333 of 1285

(2) Remove the lamp through the opening in the

rear bumper cover.

(3) Remove the lamp socket from the lamp assem-

bly. Rotate and pull the socket straight from the

lamp assembly.

(4) Pull the bulb straight from the lamp socket.

INSTALLATION

(1) Align and install the bulb in the lamp socket.

(2) Verify lamp operation.

(3) Install the lamp socket in the lamp assembly.

(4) Install the lamp through the opening in the

rear bumper cover.

(5) Hold the lamp assembly in position with your

hand until both retaining screws are started.

(6) Tighten the lamp retaining screws (Fig. 9).

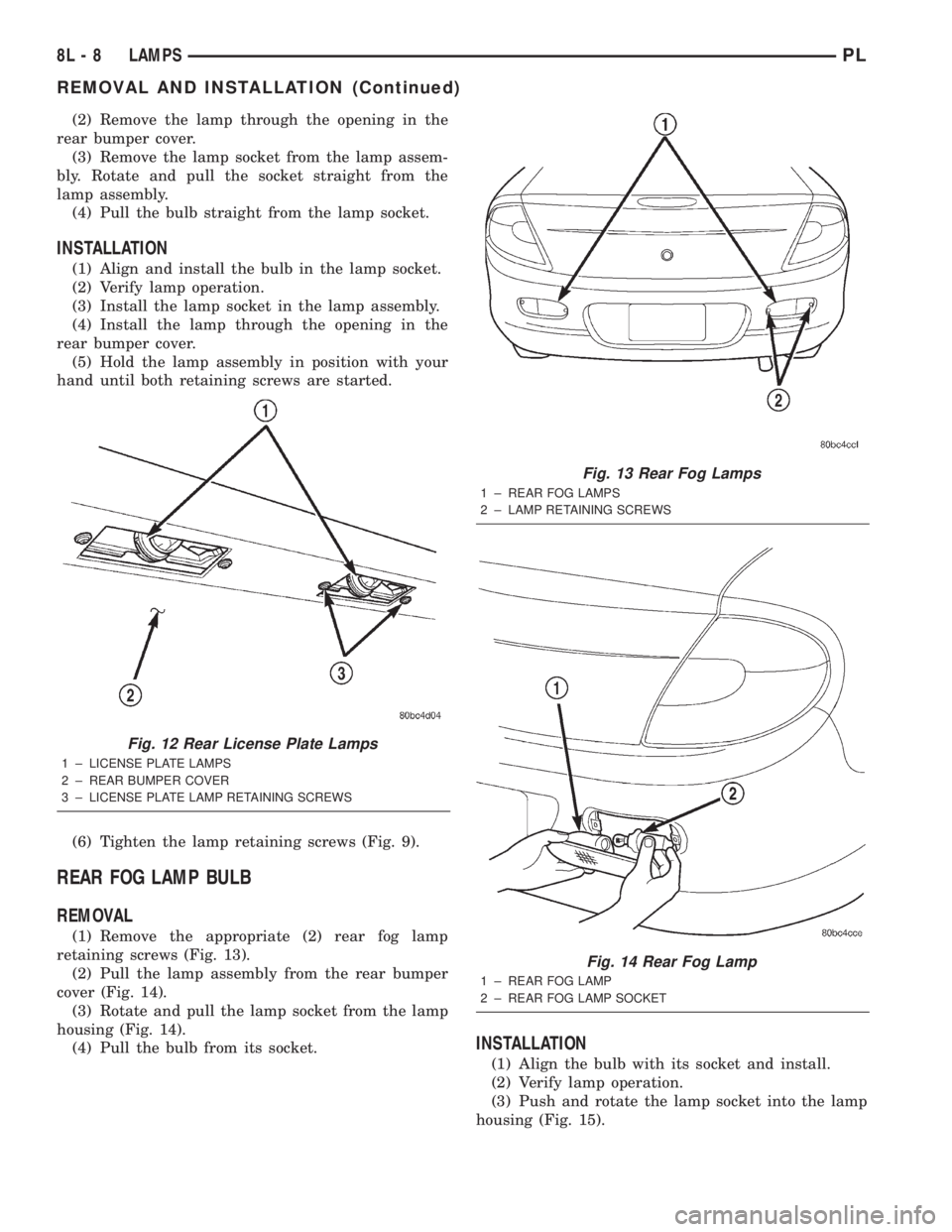

REAR FOG LAMP BULB

REMOVAL

(1) Remove the appropriate (2) rear fog lamp

retaining screws (Fig. 13).

(2) Pull the lamp assembly from the rear bumper

cover (Fig. 14).

(3) Rotate and pull the lamp socket from the lamp

housing (Fig. 14).

(4) Pull the bulb from its socket.

INSTALLATION

(1) Align the bulb with its socket and install.

(2) Verify lamp operation.

(3) Push and rotate the lamp socket into the lamp

housing (Fig. 15).

Fig. 12 Rear License Plate Lamps

1 ± LICENSE PLATE LAMPS

2 ± REAR BUMPER COVER

3 ± LICENSE PLATE LAMP RETAINING SCREWS

Fig. 13 Rear Fog Lamps

1 ± REAR FOG LAMPS

2 ± LAMP RETAINING SCREWS

Fig. 14 Rear Fog Lamp

1 ± REAR FOG LAMP

2 ± REAR FOG LAMP SOCKET

8L - 8 LAMPSPL

REMOVAL AND INSTALLATION (Continued)

Page 340 of 1285

FRONT FOG LAMP

REMOVAL

(1) Raise the vehicle on a hoist or position a

creeper under the front of the vehicle.

(2) Remove the front air dam retaining fasteners

and remove the air dam from the vehicle.

(3) Disconnect the fog lamp electrical connector by

reaching between the front fascia and the lower clo-

sure panel.

(4) Remove the (3) fog lamp retaining nuts from

the lamp mounting studs.

(5) Remove the fog lamp from the front fascia.

INSTALLATION

(1) Position the fog lamp in the front fascia and

install the retaining nuts. Torque the nuts to 4.5 N´m

(40 in. lbs.).

(2) Connect the fog lamp electrical connector.

(3) Install the front air dam and retaining fasten-

ers.

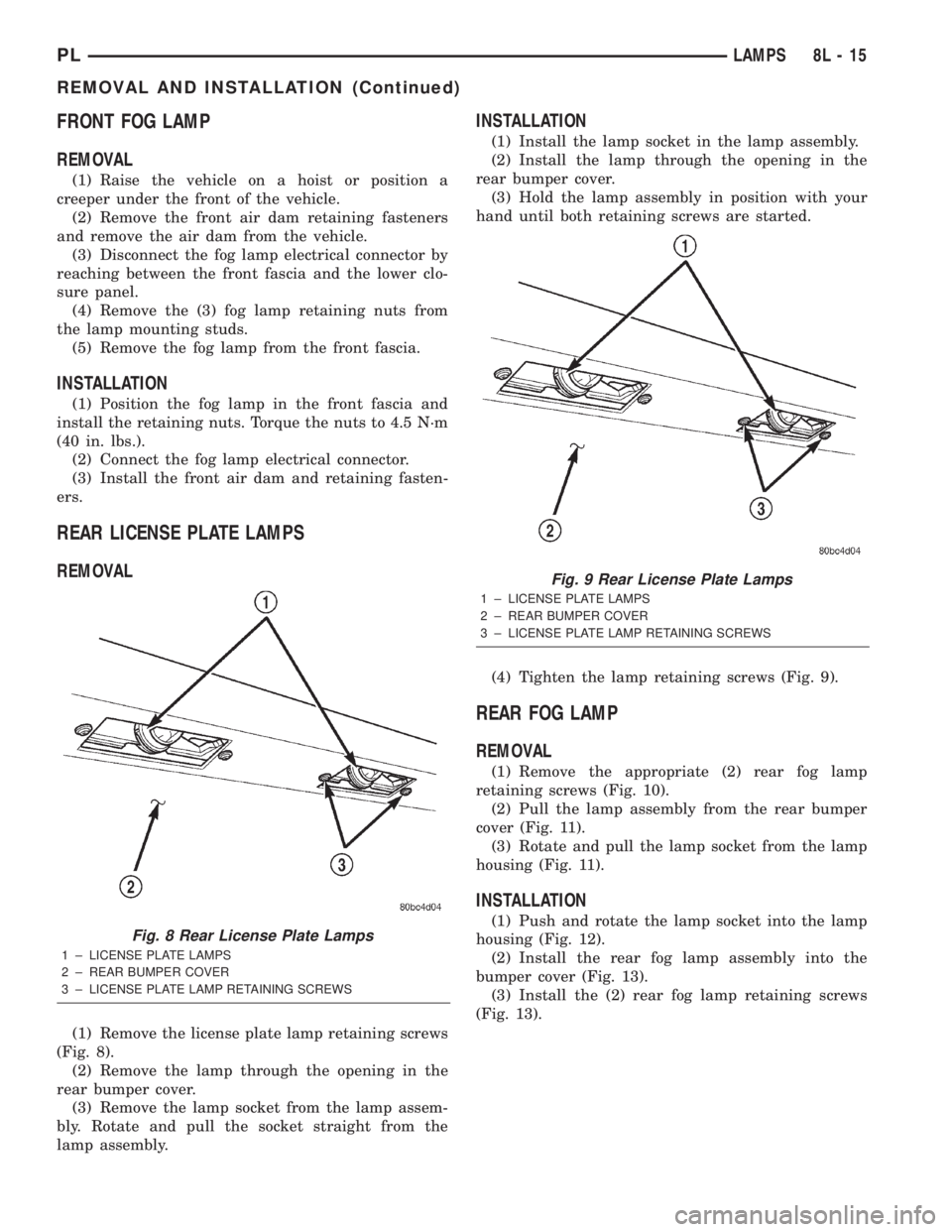

REAR LICENSE PLATE LAMPS

REMOVAL

(1) Remove the license plate lamp retaining screws

(Fig. 8).

(2) Remove the lamp through the opening in the

rear bumper cover.

(3) Remove the lamp socket from the lamp assem-

bly. Rotate and pull the socket straight from the

lamp assembly.

INSTALLATION

(1) Install the lamp socket in the lamp assembly.

(2) Install the lamp through the opening in the

rear bumper cover.

(3) Hold the lamp assembly in position with your

hand until both retaining screws are started.

(4) Tighten the lamp retaining screws (Fig. 9).

REAR FOG LAMP

REMOVAL

(1) Remove the appropriate (2) rear fog lamp

retaining screws (Fig. 10).

(2) Pull the lamp assembly from the rear bumper

cover (Fig. 11).

(3) Rotate and pull the lamp socket from the lamp

housing (Fig. 11).

INSTALLATION

(1) Push and rotate the lamp socket into the lamp

housing (Fig. 12).

(2) Install the rear fog lamp assembly into the

bumper cover (Fig. 13).

(3) Install the (2) rear fog lamp retaining screws

(Fig. 13).Fig. 8 Rear License Plate Lamps

1 ± LICENSE PLATE LAMPS

2 ± REAR BUMPER COVER

3 ± LICENSE PLATE LAMP RETAINING SCREWS

Fig. 9 Rear License Plate Lamps

1 ± LICENSE PLATE LAMPS

2 ± REAR BUMPER COVER

3 ± LICENSE PLATE LAMP RETAINING SCREWS

PLLAMPS 8L - 15

REMOVAL AND INSTALLATION (Continued)

Page 347 of 1285

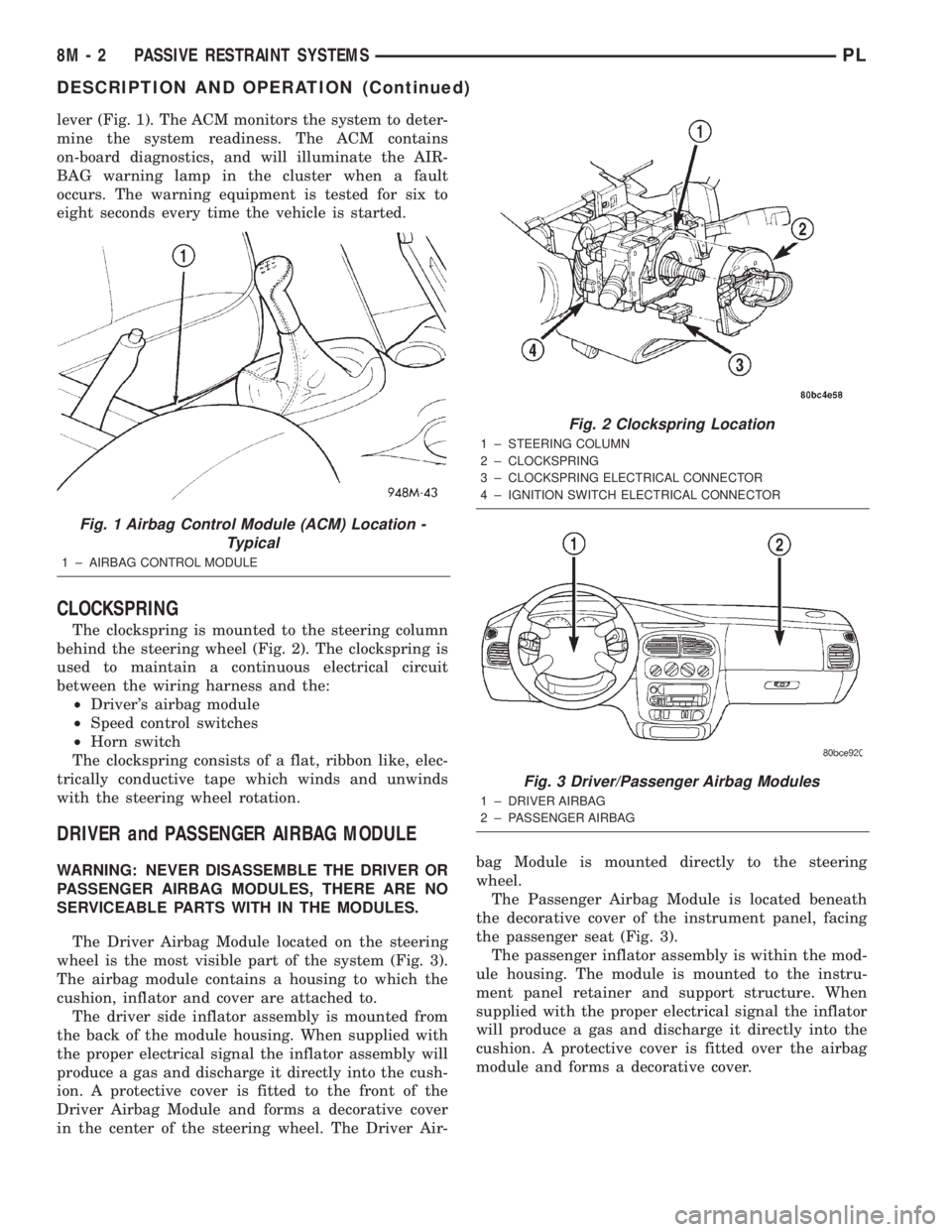

lever (Fig. 1). The ACM monitors the system to deter-

mine the system readiness. The ACM contains

on-board diagnostics, and will illuminate the AIR-

BAG warning lamp in the cluster when a fault

occurs. The warning equipment is tested for six to

eight seconds every time the vehicle is started.

CLOCKSPRING

The clockspring is mounted to the steering column

behind the steering wheel (Fig. 2). The clockspring is

used to maintain a continuous electrical circuit

between the wiring harness and the:

²Driver's airbag module

²Speed control switches

²Horn switch

The clockspring consists of a flat, ribbon like, elec-

trically conductive tape which winds and unwinds

with the steering wheel rotation.

DRIVER and PASSENGER AIRBAG MODULE

WARNING: NEVER DISASSEMBLE THE DRIVER OR

PASSENGER AIRBAG MODULES, THERE ARE NO

SERVICEABLE PARTS WITH IN THE MODULES.

The Driver Airbag Module located on the steering

wheel is the most visible part of the system (Fig. 3).

The airbag module contains a housing to which the

cushion, inflator and cover are attached to.

The driver side inflator assembly is mounted from

the back of the module housing. When supplied with

the proper electrical signal the inflator assembly will

produce a gas and discharge it directly into the cush-

ion. A protective cover is fitted to the front of the

Driver Airbag Module and forms a decorative cover

in the center of the steering wheel. The Driver Air-bag Module is mounted directly to the steering

wheel.

The Passenger Airbag Module is located beneath

the decorative cover of the instrument panel, facing

the passenger seat (Fig. 3).

The passenger inflator assembly is within the mod-

ule housing. The module is mounted to the instru-

ment panel retainer and support structure. When

supplied with the proper electrical signal the inflator

will produce a gas and discharge it directly into the

cushion. A protective cover is fitted over the airbag

module and forms a decorative cover.

Fig. 1 Airbag Control Module (ACM) Location -

Typical

1 ± AIRBAG CONTROL MODULE

Fig. 2 Clockspring Location

1 ± STEERING COLUMN

2 ± CLOCKSPRING

3 ± CLOCKSPRING ELECTRICAL CONNECTOR

4 ± IGNITION SWITCH ELECTRICAL CONNECTOR

Fig. 3 Driver/Passenger Airbag Modules

1 ± DRIVER AIRBAG

2 ± PASSENGER AIRBAG

8M - 2 PASSIVE RESTRAINT SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 366 of 1285

SERVICE PROCEDURES

DOUBLE ACTIVATION UNLOCK

The toggling of the double activation unlock fea-

ture (between enabled and disabled) can be per-

formed with the use of the DRB IIItscan tool, or by

the customer.

DRB lllTPROGRAMMING

When using the DRB IIItscan tool, select:

(1) ªTheft Alarmº

(2) ªVTSSº

(3) ªMiscellaneousº

and then the desired function.

CUSTOMER PROGRAMMING

(1) Open the driver door, sit in the driver seat, and

close the driver door.

(2) Turn the ignition switch to the RUN position

(without starting the vehicle) and then back to OFF.

Repeat this step three additional times (for a total of

four key ON/OFF cycles).

(3) Within ten seconds of switching the ignition

switch to the OFF position for the last time (at the

end of the fourth cycle in the above step), press the

driver interior door lock switch to UNLOCK.

(4) A single chime will be heard to verify that the

customer programmable toggle of the double activa-

tion unlock was successfully completed.

NOTE: When toggling the double activation unlock

feature (customer programmable), the toggle that

happens will be from the last state of the double

activation unlock. If the double activation unlock

feature was enabled, after the toggle process, it will

now be disabled and vice versa. There is no telltale

to inform you of which state the double activation

unlock feature is in.

ROLLING DOOR LOCKS

The toggling of the rolling door lock feature

(between enabled and disabled) can be performed

with the use of the DRB IIItscan tool or by the cus-

tomer.

DRB lllTPROGRAMMING

When using the DRB IIItscan tool, select:

(1) ªTheft Alarmº

(2) ªVTSSº(3) ªMiscellaneousº

and then the desired function.

CUSTOMER PROGRAMMING

(1) Open the driver door, sit in the driver seat, and

close the driver door.

(2) Turn the ignition switch to the RUN position

(without starting the vehicle) and then back to OFF.

Repeat this step three additional times (for a total of

four key ON/OFF cycles).

(3) Within ten seconds of switching the ignition

switch to the OFF position for the last time (at the

end of the fourth cycle in the above step), press the

driver interior door lock switch to LOCK.

(4) A single chime will be heard to verify that the

customer programmable toggle of the rolling door

locks was successfully completed.

NOTE: When toggling the rolling door locks (cus-

tomer programmable), the toggle that happens will

be from the last state of the rolling door locks. If

the rolling door locks were enabled, after the toggle

process, they will now be disabled and vice versa.

There is no telltale to inform you of which state the

rolling door locks are in.

REMOVAL AND INSTALLATION

DOOR LOCK MOTOR/LATCH

Refer to Group 23-Body, Front Door Latch Removal

and Installation.

DOOR LOCK SWITCH

REMOVAL

(1) Remove front door trim panel, refer to Group

23-Body, for Front Door Trim Panel Removal and

Installation.

(2) Disconnect wire connector.

(3) Remove two attaching screws.

(4) Remove the switch.

INSTALLATION

For installation, reverse the above procedures.

REMOTE KEYLESS ENTRY (RKE) MODULE

Refer to RKE Module Removal and Installation

under Remote Keyless Entry in this section.

PLPOWER LOCK SYSTEMS 8P - 3