hose DODGE NEON 2000 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 89 of 1285

OTHER BRAKE CONDITIONS

CONDITION POSSIBLE CAUSES CORRECTION

BRAKES CHATTER 1. Rear brake drum out of round or

disc brake rotor has excessive

thickness variation.1. Isolate condition as rear or front.

Reface or replace brake drums or rotors

as necessary.

BRAKES DRAG (FRONT OR

ALL)1. Contaminated brake fluid. 1. Check for swollen seals. Replace all

system components containing rubber.

2. Binding caliper pins or bushings. 2. Replace pins and bushings

3. Binding master cylinder. 3. Replace master cylinder.

4. Binding brake pedal. 4. Replace brake pedal.

BRAKES DRAG (REAR

ONLY)1. Parking brake cables binding or

froze up.1. Check cable routing. Replace cables as

necessary.

2. Parking brake cable return spring

not returning shoes.2. Replace cables as necessary.

3. Service brakes not adjusted properly

(rear drum brakes only).3. Follow the procedure listed in the

adjustment section.

4. Obstruction inside the center

console preventing full return of the

parking brake cables.4. Remove console and remove

obstruction.

BRAKES GRAB 1. Contaminated brake shoe linings. 1. Inspect and clean, or replace shoes.

Repair source of contamination.

2. Improper power brake booster

assist.2. Refer to power brake booster in the

diagnosis and testing section.

EXCESSIVE PEDAL

EFFORT1. Obstruction of brake pedal. 1. Inspect, remove or move obstruction.

2. Low power brake booster assist. 2. Refer to power brake booster in the

diagnosis and testing section.

3. Glazed brake linings. 3. Reface or replace brake rotors as

necessary. Replace brake shoes.

4. Brake shoe lining transfer to brake

rotor.4. Reface or replace brake rotors as

necessary. Replace brake shoes.

EXCESSIVE PEDAL

TRAVEL (VEHICLE STOPS

OK)1. Air in brake lines. 1. Bleed brakes.

2. Rear drum brake auto-adjuster

malfunctioning.2. Inspect and replace drum brake

components as necessary. Adjust rear

brakes.

EXCESSIVE PEDAL

TRAVEL (PEDAL GOES TO

FLOOR - CAN'T SKID

WHEELS)1. Power brake booster runout

(vacuum assist).1. Check booster vacuum hose and

engine tune for adequate vacuum supply.

Refer to power brake booster in the

diagnosis and testing section.

EXCESSIVE PEDAL

TRAVEL (ONE FRONT

WHEEL LOCKS UP DURING

HARD BRAKING)1. One of the two hydraulic circuits to

the front brakes is malfunctioning.1. Inspect system for leaks. Check master

cylinder for internal malfunction.

5 - 10 BRAKESPL

DIAGNOSIS AND TESTING (Continued)

Page 90 of 1285

CONDITION POSSIBLE CAUSES CORRECTION

PEDAL PULSATES/SURGES

DURING BRAKING1. Rear brake drum out of round or

disc brake rotor has excessive

thickness variation.1. Isolate condition as rear or front.

Reface or replace brake drums or rotors

as necessary.

PEDAL IS SPONGY 1. Air in brake lines. 1. Bleed brakes.

2. Power brake booster runout

(vacuum assist).2. Check booster vacuum hose and

engine tune for adequate vacuum supply.

Refer to power brake booster in the

diagnosis and testing section.

PREMATURE REAR WHEEL

LOCKUP1. Contaminated brake shoe linings. 1. Inspect and clean, or replace shoes.

Repair source of contamination.

2. Inoperative proportioning valve

(non-ABS vehicles only).2. Test proportioning valves folowing

procedure listed in diagnosis and testing

section. Replace valves as necessary.

3. ABS EBD not functioning. 3. Refer to the ABS section and Chassis

Diagnostic Procedures manual.

4. Improper power brake booster

assist.4. Refer to power brake booster in the

diagnosis and testing section.

STOP LAMPS STAY ON 1. Brake lamp switch out of

adjustment.1. Adjust brake lamp switch.

2. Brake pedal binding. 2. Inspect and replace as necessary.

3. Obstruction in pedal linkage. 3. Remove obstruction.

4. Power Brake Booster not allowing

pedal to return completely.4. Replace power brake booster.

VEHICLE PULLS TO RIGHT

OR LEFT ON BRAKING1. Frozen brake caliper piston. 1. Replace frozen piston or caliper. Bleed

brakes.

2. Contaminated brake shoe lining. 2. Inspect and clean, or replace shoes.

Repair source of contamination.

3. Pinched brake lines. 3. Replace pinched line.

4. Leaking piston seal. 4. Replace piston seal or brake caliper.

5. Suspension problem. 5. Refer to the Suspension group.

PARKING BRAKE -

EXCESSIVE HANDLE

TRAVEL1. Rear brakes out of adjustment. 1. Adjust rear drum brake shoes, or rear

parking brake shoes on vehicles with rear

disc brakes.

POWER BRAKE BOOSTER

BASIC TEST

(1) With engine off, depress and release the brake

pedal several times to purge all vacuum from the

power brake booster.

(2) Depress and hold the pedal with light effort (15

to 25 lbs. pressure), then start the engine.

The pedal should fall slightly, then hold. Less effort

should be needed to apply the pedal at this time. If

the pedal fell as indicated, perform the VACUUM

LEAK TEST listed after the BASIC TEST. If thepedal did not fall, continue on with this BASIC

TEST.

(3) Disconnect the vacuum hose on the side of the

vacuum check valve that leads to the speed control,

then connect a vacuum gauge to the open vacuum

port on the valve.

(4) Start the engine.

(5) When the engine is at warm operating temper-

ature, allow it to idle and check the vacuum at the

gauge.

PLBRAKES 5 - 11

DIAGNOSIS AND TESTING (Continued)

Page 91 of 1285

If the vacuum supply is 12 inches Hg (40.5 kPa) or

more, the power brake booster is defective and must

be replaced. If the vacuum supply is below 12 inches,

continue on with this BASIC TEST.

(6) Shut off the engine.

(7) Connect the vacuum gauge to the vacuum ref-

erence port on the engine intake manifold.

(8)

Start the engine and observe the vacuum gauge.

If the vacuum is still low, check the engine tune

and repair as necessary. If the vacuum is above 12

inches, the hose or check to the booster has a restric-

tion or leak.

Once an adequate vacuum supply is obtained,

repeat the BASIC TEST.

VACUUM LEAK TEST

(1) Disconnect the vacuum hose on the side of the

power brake booster vacuum check valve that leads

to the speed control, then connect a vacuum gauge to

the open vacuum port on the valve.

(2) Remove the remaining hose on the vacuum

check valve that is not the vacuum supply hose com-

ing from the intake manifold. Cap off the open port

on the check valve.

(3) Start the engine.

(4) Allow the engine to warm up to normal operat-

ing temperature and engine idle.

(5) Using vacuum line pliers, close off the vacuum

supply hose near the booster and observe the vacuum

gauge.

If the vacuum drop exceeds 1.0 inch Hg (3.3 kPa)

in one minute, repeat the above steps to confirm the

reading. The vacuum loss should be less than 1.0

inch Hg in one minute time span. If the loss is more

than 1.0 inch Hg, replace the power brake booster. If

it is not, continue on with this test.

(6) Remove the pliers from the hose temporarily.

(7) Apply light effort (approximately 15 lbs. of

force) to the brake pedal and hold the pedal steady.

Do not move the pedal once the pressure is applied

or the test results may vary.

(8) Have an assistant reattach the pliers to the

vacuum supply hose.

(9) Allow 5 seconds for stabilization, then observe

the vacuum gauge.

If the vacuum drop exceeds 3.0 inches Hg (10 kPa)

in 15 seconds, repeat the above steps to confirm the

reading. The vacuum loss should be less than 3.0

inches Hg in 15 seconds time span. If the loss is

more than 3.0 inches Hg, replace the power brake

booster. If it is not, the booster is not defective.

DRUM BRAKE AUTOMATIC ADJUSTER

To properly test the drum brake automatic

adjuster, the aide of a helper inside the vehicle to

apply the brakes will be necessary.(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove the access plug from the rear adjust-

ment slot in each brake support plate.

(3) Insert a thin screwdriver in the adjustment

slot and push back the adjustment lever. With the

lever in this position, back the star wheel adjustment

off approximately 10 notches. This will eliminate the

possibility that the brake is at full adjustment, and

can be adjusted no further.

(4)

Remove the screwdriver from the adjustment slot.

(5) Watch the star wheel through the adjustment

slot, while a helper applies the brake pedal. As the

brake shoes apply, the adjustment lever should move

downward, turning the star wheel. A definite rotation

of the adjuster star wheel can be observed if the

automatic adjuster is working properly.

If the star wheel does not move as indicated, the

brake drum needs to be removed and further inspec-

tion of the rear brakes is necessary.

(6) If the star wheel is operating properly, readjust

the brakes. Refer to ADJUSTMENTS in this section

of this service manual group.

(7) Reinstall the adjustment slot access plug.

(8) Lower the vehicle.

BRAKE ROTOR

Any servicing of the rotor requires extreme care to

maintain the rotor within service tolerances to

ensure proper brake action.

Excessive runout or wobble in a rotor can increase

pedal travel due to piston knock-back. This increases

guide pin sleeve wear due to the tendency of the cal-

iper to follow the rotor wobble.

When diagnosing a brake noise or pulsation, the

machined disc braking surface should be checked and

inspected.

BRAKING SURFACE INSPECTION

Light braking surface scoring and wear is accept-

able. If heavy scoring or warping is evident, the rotor

must be refaced or replaced. Refer to SERVICE PRO-

CEDURES in this section of this group for informa-

tion on brake rotor machining.

Excessive wear and scoring of the rotor can cause

improper lining contact on the rotor's braking sur-

face. If the ridges on the rotor are not removed before

new brake shoes are installed, improper wear of the

shoes will result.

If a vehicle has not been driven for a period of

time, the rotor's braking surface will rust in the

areas not covered by the brake shoes at that time.

Once the vehicle is driven, noise and chatter from

the disc brakes can result when the brakes are

applied.

5 - 12 BRAKESPL

DIAGNOSIS AND TESTING (Continued)

Page 95 of 1285

The in-line proportioning valves used on this vehi-

cle require special pressure fittings to test the pro-

portioning valves for proper proportioning valve

function. The pressure fittings are installed before

and after the proportioning valve being tested to ver-

ify proportioning valve is maintaining the required

hydraulic pressure to the rear wheel brake which it

controls.

The testing of proportioning valves for this vehicle,

if equipped with ABS, can be found in the

ANTILOCK BRAKE SYSTEM section.

PROPORTIONING VALVE TEST

The test procedure is the same for either rear pro-

portioning valve. After road testing the vehicle to

determine which wheel skids first, follow the proce-

dure below for testing the suspect proportioning

valve.

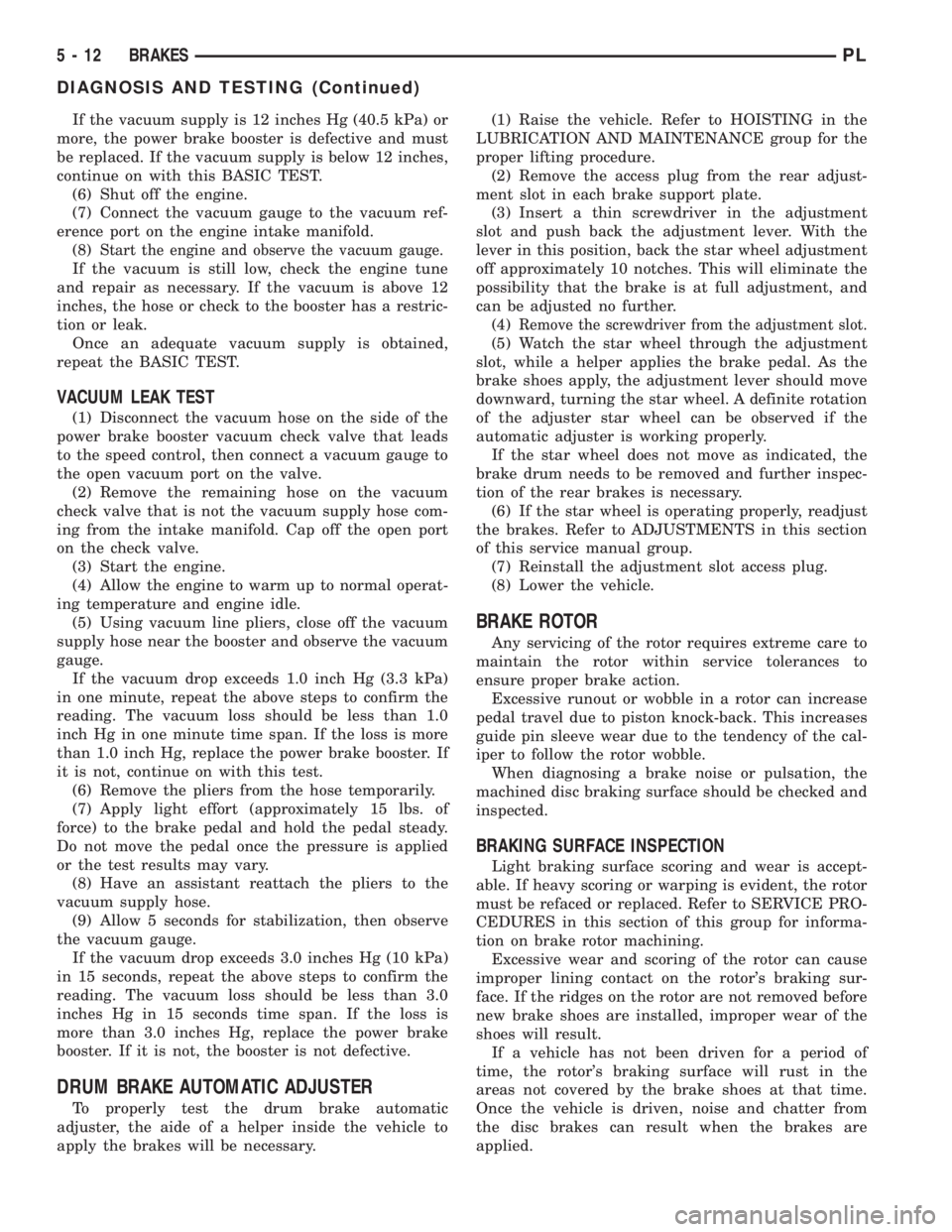

(1) Using a brake pedal holding tool as shown (Fig.

22), depress the brake pedal past its first one inch of

travel and hold it in this position. This will isolate

the master cylinder from the brake hydraulic system

and will not allow the brake fluid to drain out of the

master cylinder reservoir.

(2) Use the figure shown to determine which pro-

portioning valve needs to be tested (Fig. 21).

(3) Remove the hydraulic brake tube from the pro-

portioning valve controlling the rear wheel of the

vehicle that has premature wheel skid.

(4) Remove the proportioning valve from its outlet

port on the master cylinder.CAUTION: Be sure the pressure test fittings being

installed into master cylinder and proportioning

valve, have the correct thread sizes needed.

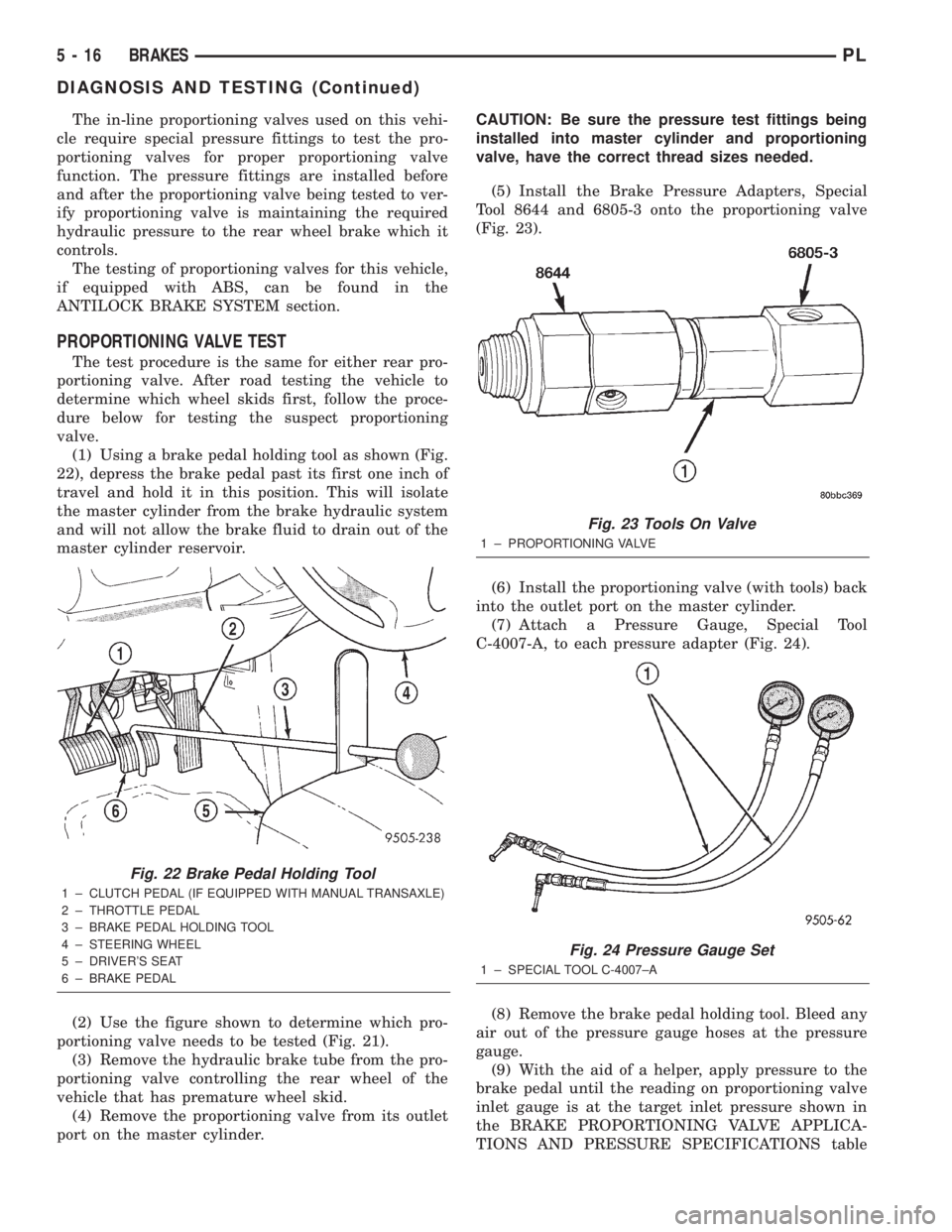

(5) Install the Brake Pressure Adapters, Special

Tool 8644 and 6805-3 onto the proportioning valve

(Fig. 23).

(6) Install the proportioning valve (with tools) back

into the outlet port on the master cylinder.

(7) Attach a Pressure Gauge, Special Tool

C-4007-A, to each pressure adapter (Fig. 24).

(8) Remove the brake pedal holding tool. Bleed any

air out of the pressure gauge hoses at the pressure

gauge.

(9) With the aid of a helper, apply pressure to the

brake pedal until the reading on proportioning valve

inlet gauge is at the target inlet pressure shown in

the BRAKE PROPORTIONING VALVE APPLICA-

TIONS AND PRESSURE SPECIFICATIONS table

Fig. 22 Brake Pedal Holding Tool

1 ± CLUTCH PEDAL (IF EQUIPPED WITH MANUAL TRANSAXLE)

2 ± THROTTLE PEDAL

3 ± BRAKE PEDAL HOLDING TOOL

4 ± STEERING WHEEL

5 ± DRIVER'S SEAT

6 ± BRAKE PEDAL

Fig. 23 Tools On Valve

1 ± PROPORTIONING VALVE

Fig. 24 Pressure Gauge Set

1 ± SPECIAL TOOL C-4007±A

5 - 16 BRAKESPL

DIAGNOSIS AND TESTING (Continued)

Page 96 of 1285

following this procedure. If the inlet gauge pressure

overshoots its target pressure when the pedal is

depressed, release the brake pedal, relieving the

pressure in the system, before reapplying the pedal

to reach the target pressure at the inlet gauge. This

is necessary to get an accurate reading of the outlet

pressure.

(10) Once inlet pressure has been achieved, check

the pressure reading on the proportioning valve out-

let gauge. If the proportioning valve outlet pressure

does not agree with value shown in the table, replace

the proportioning valve. If proportioning valve is

within pressure specifications, the valve is good and

does not require replacement.(11)Reinstall the brake holding tool on the brake

pedal and remove the test equipment from the vehicle.

(12) Remove the tools from the proportioning

valve.

(13) Install the proportioning valve in the master

cylinder and hand tighten until the proportioning

valve is fully installed and its O-ring seal is seated

into the master cylinder. Torque the proportioning

valve to 40 N´m (30 ft. lbs.).

(14) Install the brake tube on the proportioning

valve. Torque the tube nut to 17 N´m (145 in. lbs.).

(15) Bleed the affected brake line. See BASE

BRAKE BLEEDING in this section of this service

manual group.

BRAKE PROPORTIONING VALVE APPLICATIONS AND PRESSURE SPECIFICATIONS

Sales

CodeBrake System Type Split Point Slope IdentificationInlet

PressureOutlet Pressure

BRA 14º Disc/Drum 300 psi 0.34 Black Band 1000 psi 550-650 psi

BRD 14º Disc/Disc 400 psi 0.43 Bar Code Band 1000 psi 600-700 psi

BRAKE FLUID CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts. Swelling indicates the

presence of petroleum in the brake fluid.

To test for contamination, put a small amount of

drained brake fluid in clear glass jar. If the fluid sep-

arates into layers, there is mineral oil or other fluid

contamination of the brake fluid.

If the brake fluid is contaminated, drain and thor-

oughly flush the brake system. Replace all the rubber

parts or components containing rubber coming into

contact with the brake fluid including: the master

cylinder; proportioning valves; caliper seals; wheel

cylinder seals; ABS hydraulic control unit; and all

hydraulic fluid hoses.

SERVICE PROCEDURES

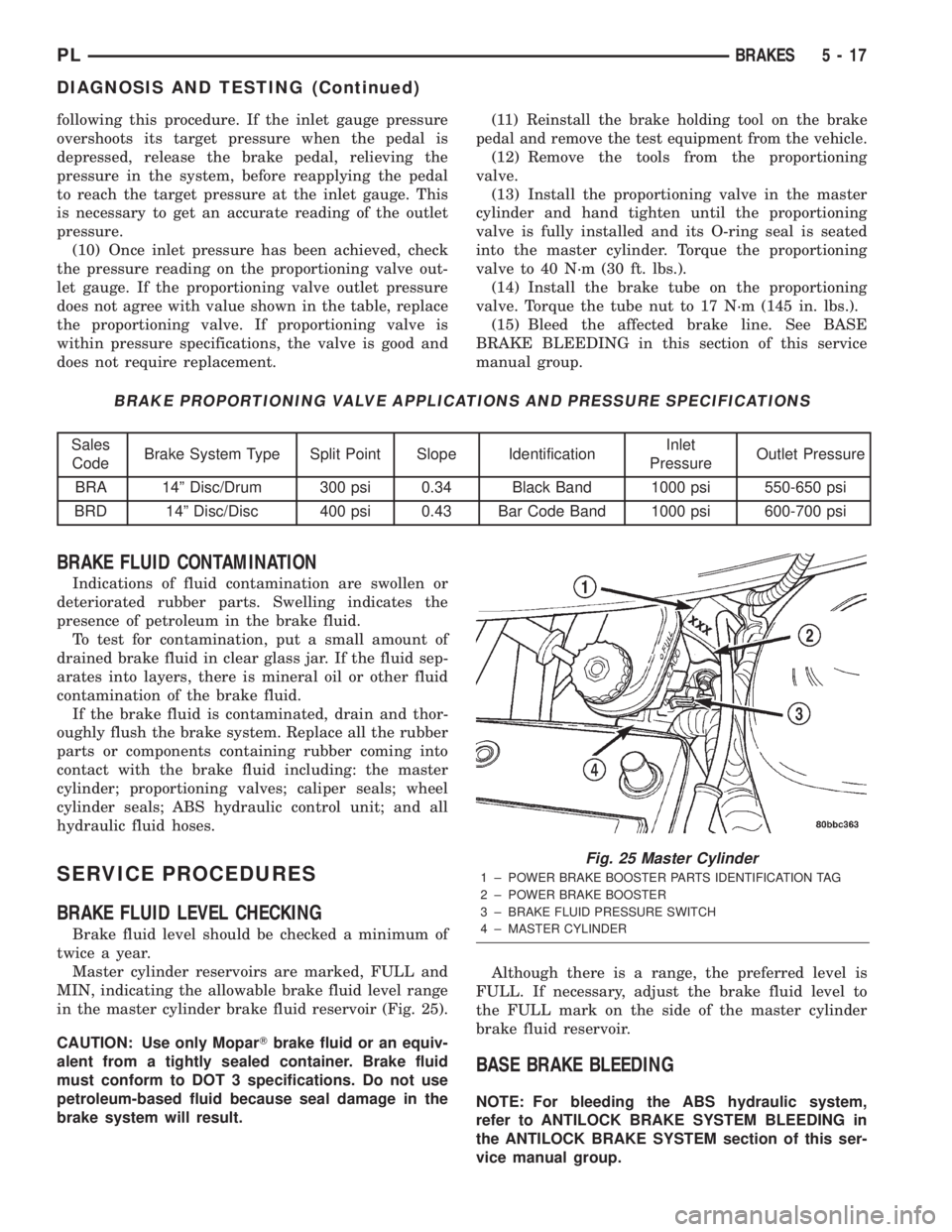

BRAKE FLUID LEVEL CHECKING

Brake fluid level should be checked a minimum of

twice a year.

Master cylinder reservoirs are marked, FULL and

MIN, indicating the allowable brake fluid level range

in the master cylinder brake fluid reservoir (Fig. 25).

CAUTION: Use only MoparTbrake fluid or an equiv-

alent from a tightly sealed container. Brake fluid

must conform to DOT 3 specifications. Do not use

petroleum-based fluid because seal damage in the

brake system will result.Although there is a range, the preferred level is

FULL. If necessary, adjust the brake fluid level to

the FULL mark on the side of the master cylinder

brake fluid reservoir.

BASE BRAKE BLEEDING

NOTE: For bleeding the ABS hydraulic system,

refer to ANTILOCK BRAKE SYSTEM BLEEDING in

the ANTILOCK BRAKE SYSTEM section of this ser-

vice manual group.

Fig. 25 Master Cylinder

1 ± POWER BRAKE BOOSTER PARTS IDENTIFICATION TAG

2 ± POWER BRAKE BOOSTER

3 ± BRAKE FLUID PRESSURE SWITCH

4 ± MASTER CYLINDER

PLBRAKES 5 - 17

DIAGNOSIS AND TESTING (Continued)

Page 97 of 1285

CAUTION: Before removing the master cylinder

cap, wipe it clean to prevent dirt and other foreign

matter from dropping into the master cylinder res-

ervoir.

CAUTION: Use only MoparTbrake fluid or an equiv-

alent from a fresh, tightly sealed container. Brake

fluid must conform to DOT 3 specifications.

Do not pump the brake pedal at any time while

having a bleeder screw open during the bleeding pro-

cess. This will only increase the amount of air in the

system and make additional bleeding necessary.

Do not allow the master cylinder reservoir to run

out of brake fluid while bleeding the system. An

empty reservoir will allow additional air into the

brake system. Check the fluid level frequently and

add fluid as needed.

The following wheel circuit sequence for bleeding

the brake hydraulic system should be used to ensure

adequate removal of all trapped air from the hydrau-

lic system.

²Left rear wheel

²Right front wheel

²Right rear wheel

²Left front wheel

MANUAL BLEEDING

NOTE: To bleed the brakes manually, the aid of a

helper will be required.

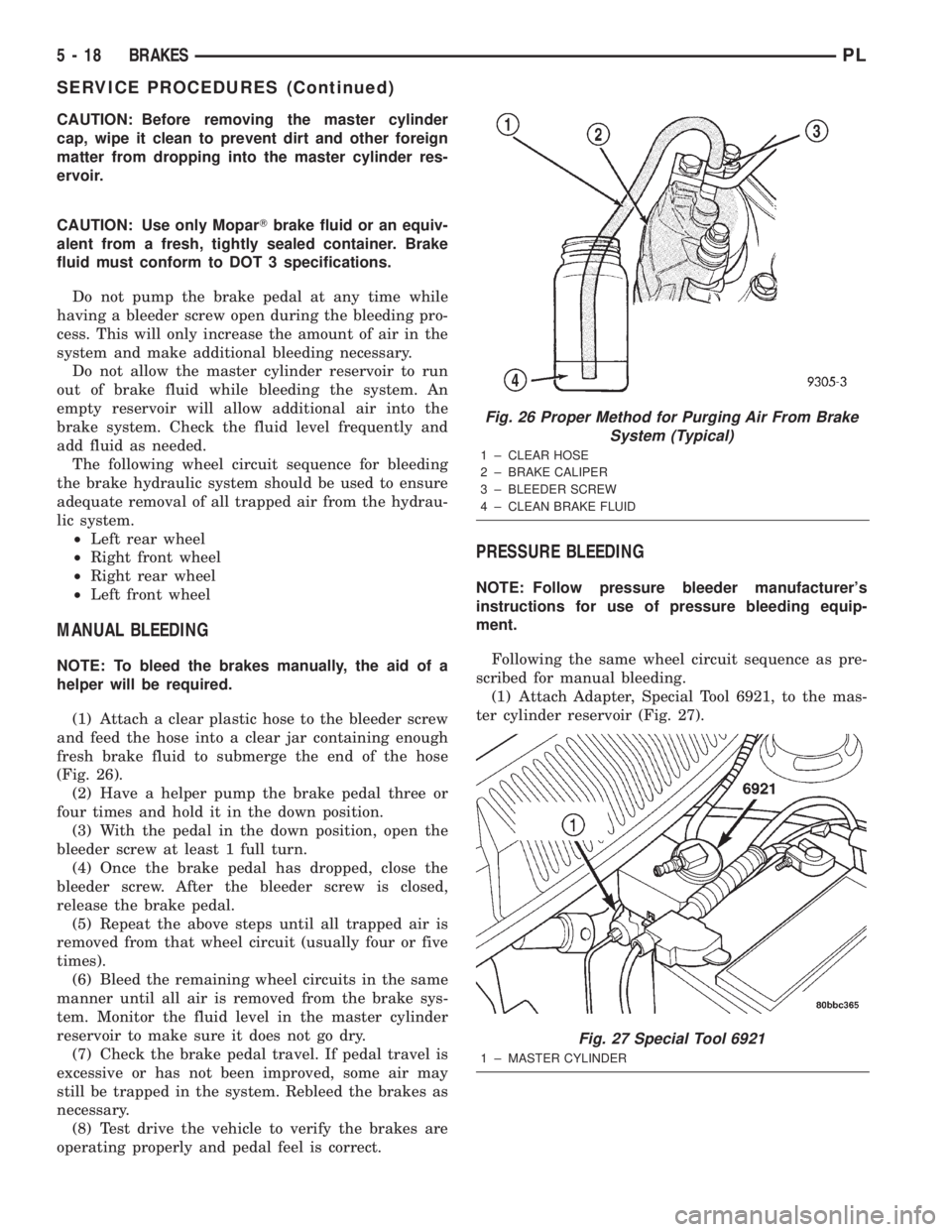

(1) Attach a clear plastic hose to the bleeder screw

and feed the hose into a clear jar containing enough

fresh brake fluid to submerge the end of the hose

(Fig. 26).

(2) Have a helper pump the brake pedal three or

four times and hold it in the down position.

(3) With the pedal in the down position, open the

bleeder screw at least 1 full turn.

(4) Once the brake pedal has dropped, close the

bleeder screw. After the bleeder screw is closed,

release the brake pedal.

(5) Repeat the above steps until all trapped air is

removed from that wheel circuit (usually four or five

times).

(6) Bleed the remaining wheel circuits in the same

manner until all air is removed from the brake sys-

tem. Monitor the fluid level in the master cylinder

reservoir to make sure it does not go dry.

(7) Check the brake pedal travel. If pedal travel is

excessive or has not been improved, some air may

still be trapped in the system. Rebleed the brakes as

necessary.

(8) Test drive the vehicle to verify the brakes are

operating properly and pedal feel is correct.

PRESSURE BLEEDING

NOTE: Follow pressure bleeder manufacturer's

instructions for use of pressure bleeding equip-

ment.

Following the same wheel circuit sequence as pre-

scribed for manual bleeding.

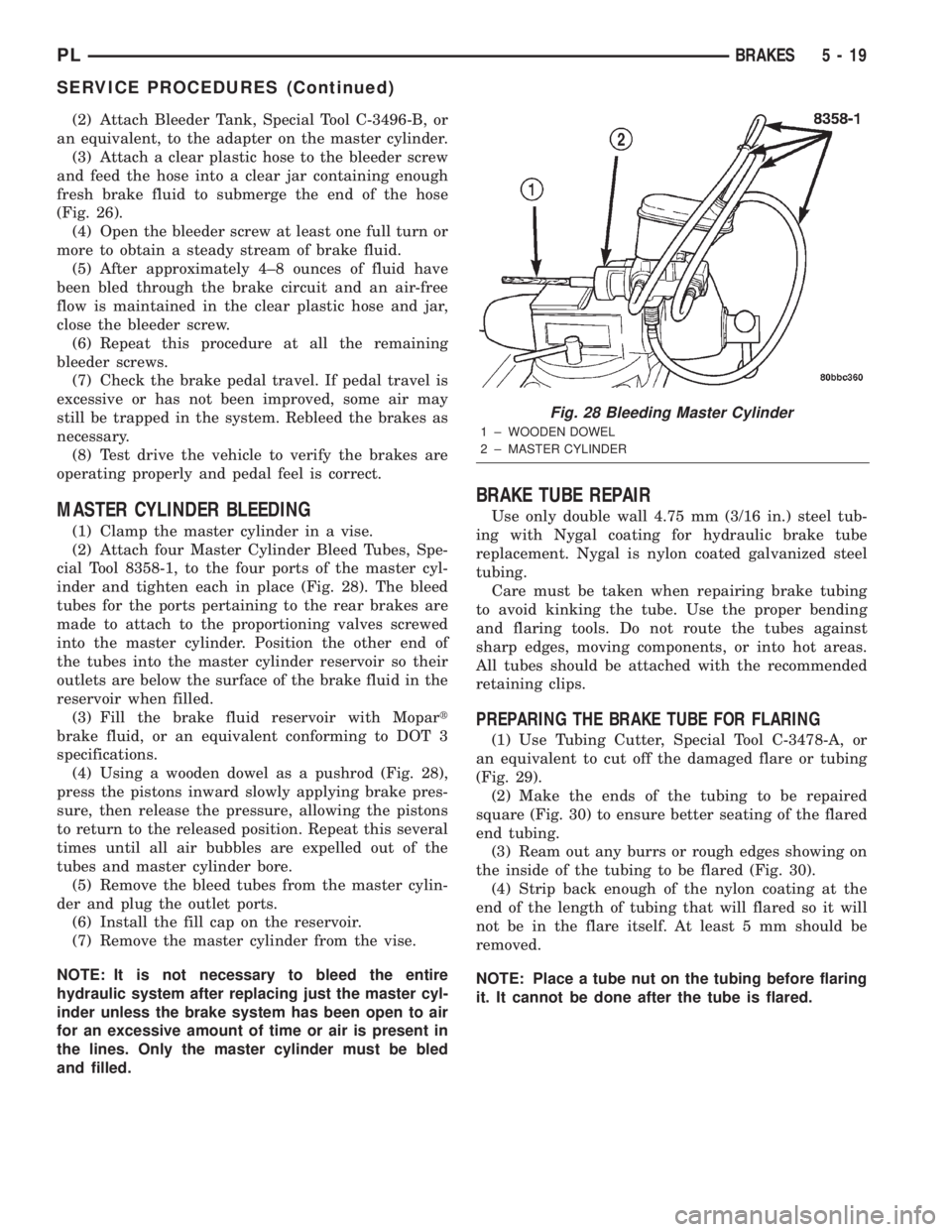

(1) Attach Adapter, Special Tool 6921, to the mas-

ter cylinder reservoir (Fig. 27).

Fig. 26 Proper Method for Purging Air From Brake

System (Typical)

1 ± CLEAR HOSE

2 ± BRAKE CALIPER

3 ± BLEEDER SCREW

4 ± CLEAN BRAKE FLUID

Fig. 27 Special Tool 6921

1 ± MASTER CYLINDER

5 - 18 BRAKESPL

SERVICE PROCEDURES (Continued)

Page 98 of 1285

(2) Attach Bleeder Tank, Special Tool C-3496-B, or

an equivalent, to the adapter on the master cylinder.

(3) Attach a clear plastic hose to the bleeder screw

and feed the hose into a clear jar containing enough

fresh brake fluid to submerge the end of the hose

(Fig. 26).

(4) Open the bleeder screw at least one full turn or

more to obtain a steady stream of brake fluid.

(5) After approximately 4±8 ounces of fluid have

been bled through the brake circuit and an air-free

flow is maintained in the clear plastic hose and jar,

close the bleeder screw.

(6) Repeat this procedure at all the remaining

bleeder screws.

(7) Check the brake pedal travel. If pedal travel is

excessive or has not been improved, some air may

still be trapped in the system. Rebleed the brakes as

necessary.

(8) Test drive the vehicle to verify the brakes are

operating properly and pedal feel is correct.

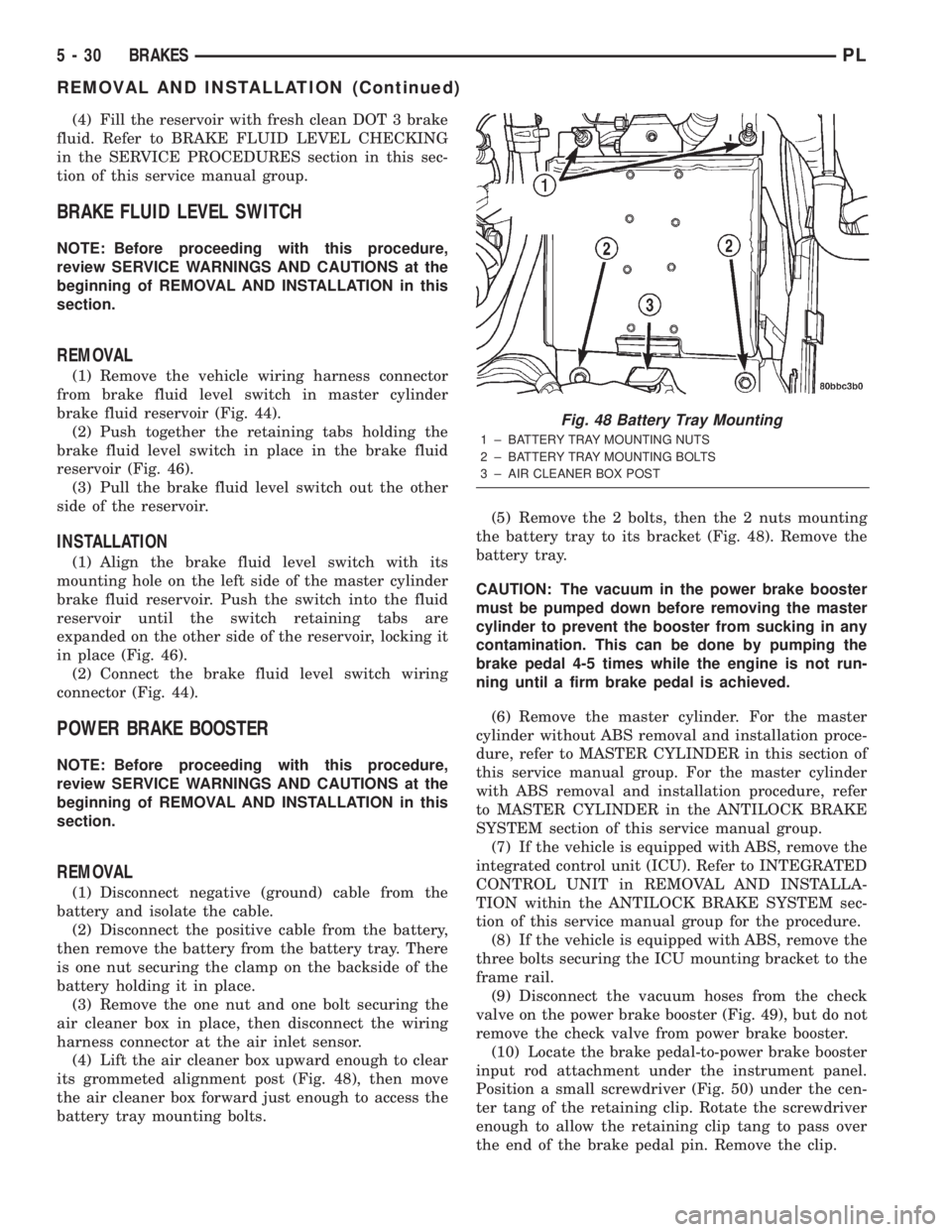

MASTER CYLINDER BLEEDING

(1) Clamp the master cylinder in a vise.

(2) Attach four Master Cylinder Bleed Tubes, Spe-

cial Tool 8358-1, to the four ports of the master cyl-

inder and tighten each in place (Fig. 28). The bleed

tubes for the ports pertaining to the rear brakes are

made to attach to the proportioning valves screwed

into the master cylinder. Position the other end of

the tubes into the master cylinder reservoir so their

outlets are below the surface of the brake fluid in the

reservoir when filled.

(3) Fill the brake fluid reservoir with Mopart

brake fluid, or an equivalent conforming to DOT 3

specifications.

(4) Using a wooden dowel as a pushrod (Fig. 28),

press the pistons inward slowly applying brake pres-

sure, then release the pressure, allowing the pistons

to return to the released position. Repeat this several

times until all air bubbles are expelled out of the

tubes and master cylinder bore.

(5) Remove the bleed tubes from the master cylin-

der and plug the outlet ports.

(6) Install the fill cap on the reservoir.

(7) Remove the master cylinder from the vise.

NOTE: It is not necessary to bleed the entire

hydraulic system after replacing just the master cyl-

inder unless the brake system has been open to air

for an excessive amount of time or air is present in

the lines. Only the master cylinder must be bled

and filled.

BRAKE TUBE REPAIR

Use only double wall 4.75 mm (3/16 in.) steel tub-

ing with Nygal coating for hydraulic brake tube

replacement. Nygal is nylon coated galvanized steel

tubing.

Care must be taken when repairing brake tubing

to avoid kinking the tube. Use the proper bending

and flaring tools. Do not route the tubes against

sharp edges, moving components, or into hot areas.

All tubes should be attached with the recommended

retaining clips.

PREPARING THE BRAKE TUBE FOR FLARING

(1) Use Tubing Cutter, Special Tool C-3478-A, or

an equivalent to cut off the damaged flare or tubing

(Fig. 29).

(2) Make the ends of the tubing to be repaired

square (Fig. 30) to ensure better seating of the flared

end tubing.

(3) Ream out any burrs or rough edges showing on

the inside of the tubing to be flared (Fig. 30).

(4) Strip back enough of the nylon coating at the

end of the length of tubing that will flared so it will

not be in the flare itself. At least 5 mm should be

removed.

NOTE: Place a tube nut on the tubing before flaring

it. It cannot be done after the tube is flared.

Fig. 28 Bleeding Master Cylinder

1 ± WOODEN DOWEL

2 ± MASTER CYLINDER

PLBRAKES 5 - 19

SERVICE PROCEDURES (Continued)

Page 109 of 1285

(4) Fill the reservoir with fresh clean DOT 3 brake

fluid. Refer to BRAKE FLUID LEVEL CHECKING

in the SERVICE PROCEDURES section in this sec-

tion of this service manual group.

BRAKE FLUID LEVEL SWITCH

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Remove the vehicle wiring harness connector

from brake fluid level switch in master cylinder

brake fluid reservoir (Fig. 44).

(2) Push together the retaining tabs holding the

brake fluid level switch in place in the brake fluid

reservoir (Fig. 46).

(3) Pull the brake fluid level switch out the other

side of the reservoir.

INSTALLATION

(1) Align the brake fluid level switch with its

mounting hole on the left side of the master cylinder

brake fluid reservoir. Push the switch into the fluid

reservoir until the switch retaining tabs are

expanded on the other side of the reservoir, locking it

in place (Fig. 46).

(2) Connect the brake fluid level switch wiring

connector (Fig. 44).

POWER BRAKE BOOSTER

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Disconnect negative (ground) cable from the

battery and isolate the cable.

(2) Disconnect the positive cable from the battery,

then remove the battery from the battery tray. There

is one nut securing the clamp on the backside of the

battery holding it in place.

(3) Remove the one nut and one bolt securing the

air cleaner box in place, then disconnect the wiring

harness connector at the air inlet sensor.

(4) Lift the air cleaner box upward enough to clear

its grommeted alignment post (Fig. 48), then move

the air cleaner box forward just enough to access the

battery tray mounting bolts.(5) Remove the 2 bolts, then the 2 nuts mounting

the battery tray to its bracket (Fig. 48). Remove the

battery tray.

CAUTION: The vacuum in the power brake booster

must be pumped down before removing the master

cylinder to prevent the booster from sucking in any

contamination. This can be done by pumping the

brake pedal 4-5 times while the engine is not run-

ning until a firm brake pedal is achieved.

(6) Remove the master cylinder. For the master

cylinder without ABS removal and installation proce-

dure, refer to MASTER CYLINDER in this section of

this service manual group. For the master cylinder

with ABS removal and installation procedure, refer

to MASTER CYLINDER in the ANTILOCK BRAKE

SYSTEM section of this service manual group.

(7) If the vehicle is equipped with ABS, remove the

integrated control unit (ICU). Refer to INTEGRATED

CONTROL UNIT in REMOVAL AND INSTALLA-

TION within the ANTILOCK BRAKE SYSTEM sec-

tion of this service manual group for the procedure.

(8) If the vehicle is equipped with ABS, remove the

three bolts securing the ICU mounting bracket to the

frame rail.

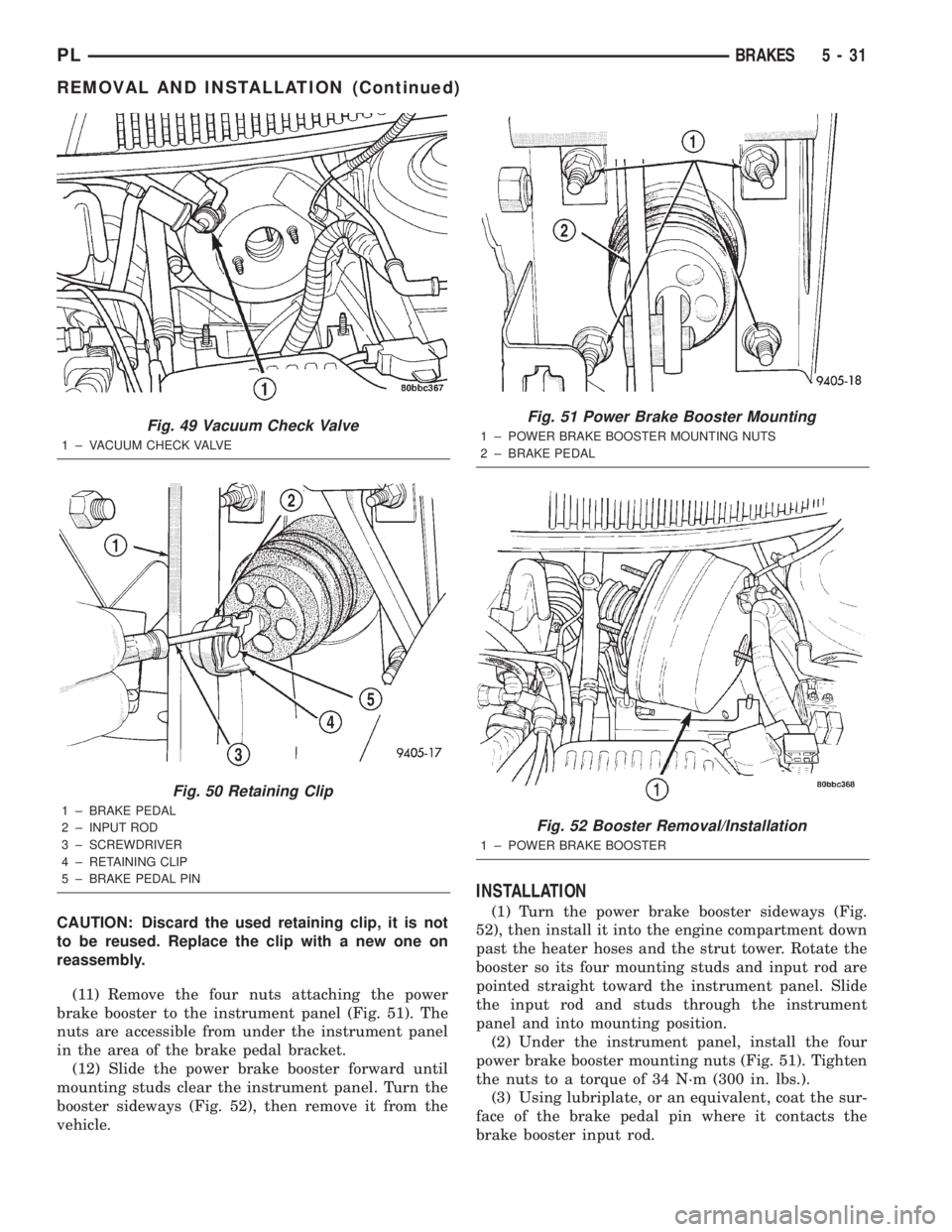

(9) Disconnect the vacuum hoses from the check

valve on the power brake booster (Fig. 49), but do not

remove the check valve from power brake booster.

(10) Locate the brake pedal-to-power brake booster

input rod attachment under the instrument panel.

Position a small screwdriver (Fig. 50) under the cen-

ter tang of the retaining clip. Rotate the screwdriver

enough to allow the retaining clip tang to pass over

the end of the brake pedal pin. Remove the clip.

Fig. 48 Battery Tray Mounting

1 ± BATTERY TRAY MOUNTING NUTS

2 ± BATTERY TRAY MOUNTING BOLTS

3 ± AIR CLEANER BOX POST

5 - 30 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 110 of 1285

CAUTION: Discard the used retaining clip, it is not

to be reused. Replace the clip with a new one on

reassembly.

(11) Remove the four nuts attaching the power

brake booster to the instrument panel (Fig. 51). The

nuts are accessible from under the instrument panel

in the area of the brake pedal bracket.

(12) Slide the power brake booster forward until

mounting studs clear the instrument panel. Turn the

booster sideways (Fig. 52), then remove it from the

vehicle.

INSTALLATION

(1) Turn the power brake booster sideways (Fig.

52), then install it into the engine compartment down

past the heater hoses and the strut tower. Rotate the

booster so its four mounting studs and input rod are

pointed straight toward the instrument panel. Slide

the input rod and studs through the instrument

panel and into mounting position.

(2) Under the instrument panel, install the four

power brake booster mounting nuts (Fig. 51). Tighten

the nuts to a torque of 34 N´m (300 in. lbs.).

(3) Using lubriplate, or an equivalent, coat the sur-

face of the brake pedal pin where it contacts the

brake booster input rod.

Fig. 49 Vacuum Check Valve

1 ± VACUUM CHECK VALVE

Fig. 50 Retaining Clip

1 ± BRAKE PEDAL

2 ± INPUT ROD

3 ± SCREWDRIVER

4 ± RETAINING CLIP

5 ± BRAKE PEDAL PIN

Fig. 51 Power Brake Booster Mounting

1 ± POWER BRAKE BOOSTER MOUNTING NUTS

2 ± BRAKE PEDAL

Fig. 52 Booster Removal/Installation

1 ± POWER BRAKE BOOSTER

PLBRAKES 5 - 31

REMOVAL AND INSTALLATION (Continued)

Page 111 of 1285

CAUTION: Use only a new brake booster input rod-

to-brake pedal retaining clip to ensure proper

retainment.

(4) Connect the power brake booster input rod-to-

brake pedal pin. Install a new retaining clip. Do not

use the old clip.

(5) Connect all previously removed vacuum hoses

to the vacuum check valve (Fig. 49).

(6) If the vehicle is equipped with ABS, install the

ICU mounting bracket on the frame rail using its

three bolts. Tighten the nuts to a torque of 23 N´m

(200 in. lbs.).

(7) If the vehicle is equipped with ABS, reinstall

the ICU. Refer to INTEGRATED CONTROL UNIT in

REMOVAL AND INSTALLATION within the

ANTILOCK BRAKE SYSTEM section of this service

manual group for the procedure.

(8) Install the master cylinder. For the master cyl-

inder without ABS removal and installation proce-

dure, refer to MASTER CYLINDER in this section of

this service manual group. For the master cylinder

with ABS removal and installation procedure, refer

to MASTER CYLINDER in the ANTILOCK BRAKE

SYSTEM section of this service manual group.

(9) Position the battery tray back in place. Install

the two bolts, then the two nuts mounting the bat-

tery tray to its bracket (Fig. 48). Tighten the two

bolts and nuts to a torque of 34 N´m (25 ft. lbs.).

(10) Reinstall the air cleaner box onto its grom-

meted alignment post (Fig. 48).

(11) Install the one nut and one bolt securing the

air cleaner box in place, then connect the wiring har-

ness connector at the air inlet sensor.

(12) Install the battery and clamp it in place.

(13) Connect the positive, then the negative

(ground) cable on the battery.

(14) Adjust the stop lamp switch as necessary.

Refer to STOP LAMP SWITCH in the ADJUST-

MENTS section of this group.

(15) Bleed the base brake system.

(16) Road test the vehicle to ensure proper opera-

tion of the brakes.

PROPORTIONING VALVE

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

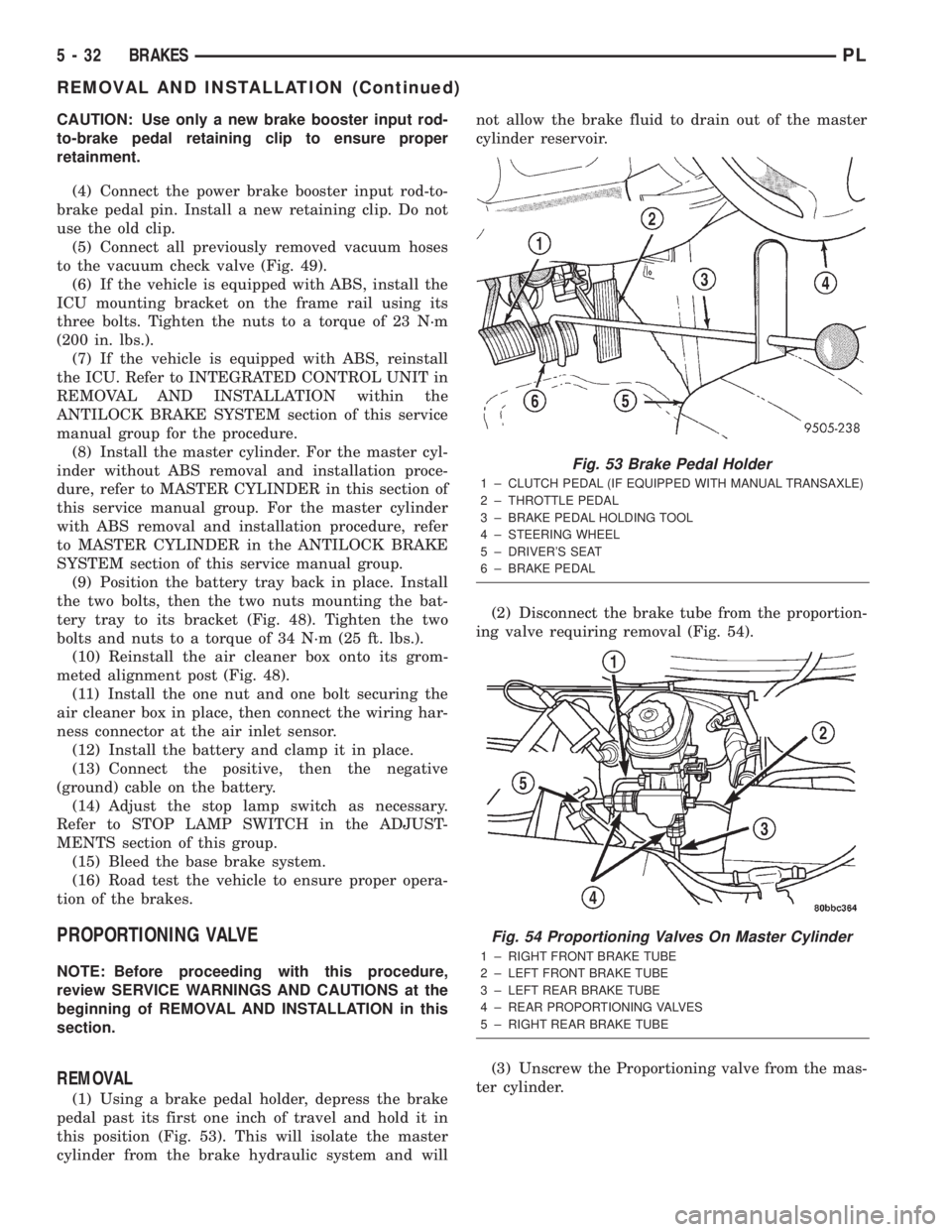

REMOVAL

(1) Using a brake pedal holder, depress the brake

pedal past its first one inch of travel and hold it in

this position (Fig. 53). This will isolate the master

cylinder from the brake hydraulic system and willnot allow the brake fluid to drain out of the master

cylinder reservoir.

(2) Disconnect the brake tube from the proportion-

ing valve requiring removal (Fig. 54).

(3) Unscrew the Proportioning valve from the mas-

ter cylinder.

Fig. 53 Brake Pedal Holder

1 ± CLUTCH PEDAL (IF EQUIPPED WITH MANUAL TRANSAXLE)

2 ± THROTTLE PEDAL

3 ± BRAKE PEDAL HOLDING TOOL

4 ± STEERING WHEEL

5 ± DRIVER'S SEAT

6 ± BRAKE PEDAL

Fig. 54 Proportioning Valves On Master Cylinder

1 ± RIGHT FRONT BRAKE TUBE

2 ± LEFT FRONT BRAKE TUBE

3 ± LEFT REAR BRAKE TUBE

4 ± REAR PROPORTIONING VALVES

5 ± RIGHT REAR BRAKE TUBE

5 - 32 BRAKESPL

REMOVAL AND INSTALLATION (Continued)