hose DODGE NEON 2000 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 136 of 1285

CALIPER PISTON AND SEALS

CALIPER PISTON REMOVAL

WARNING: UNDER NO CONDITION SHOULD HIGH

PRESSURE AIR EVER BE USED TO REMOVE A PIS-

TON FROM A CALIPER BORE. PERSONAL INJURY

COULD RESULT FROM SUCH A PRACTICE.

NOTE: The safest way to remove the piston from

the caliper bore is to use the hydraulic pressure of

the vehicle's brake system.

(1) Following the removal procedure in DISC

BRAKE SHOES found in this section, remove the

caliper from the brake rotor and hang the assembly

on a wire hook away from rotor and body of the vehi-

cle so brake fluid cannot get on these components.

Remove the brake shoes, and place a small piece of

wood between the piston and caliper fingers.

(2) Carefully depress the brake pedal to hydrauli-

cally push piston out of its bore. Once completed,

apply and hold down the brake pedal to any position

beyond the first inch of pedal travel using a brake

pedal holding tool. This will prevent the fluid in the

master cylinder reservoir from completely draining

out.(3) Disconnect the brake fluid flex hose from the

caliper assembly and remove it from the vehicle.

CALIPER SEAL REMOVAL

CAUTION: Do not use excessive force when clamp-

ing caliper in vise. Excessive vise pressure will

cause bore distortion.

(1) To disassemble the caliper, mount it in a vise

equipped with protective jaws.

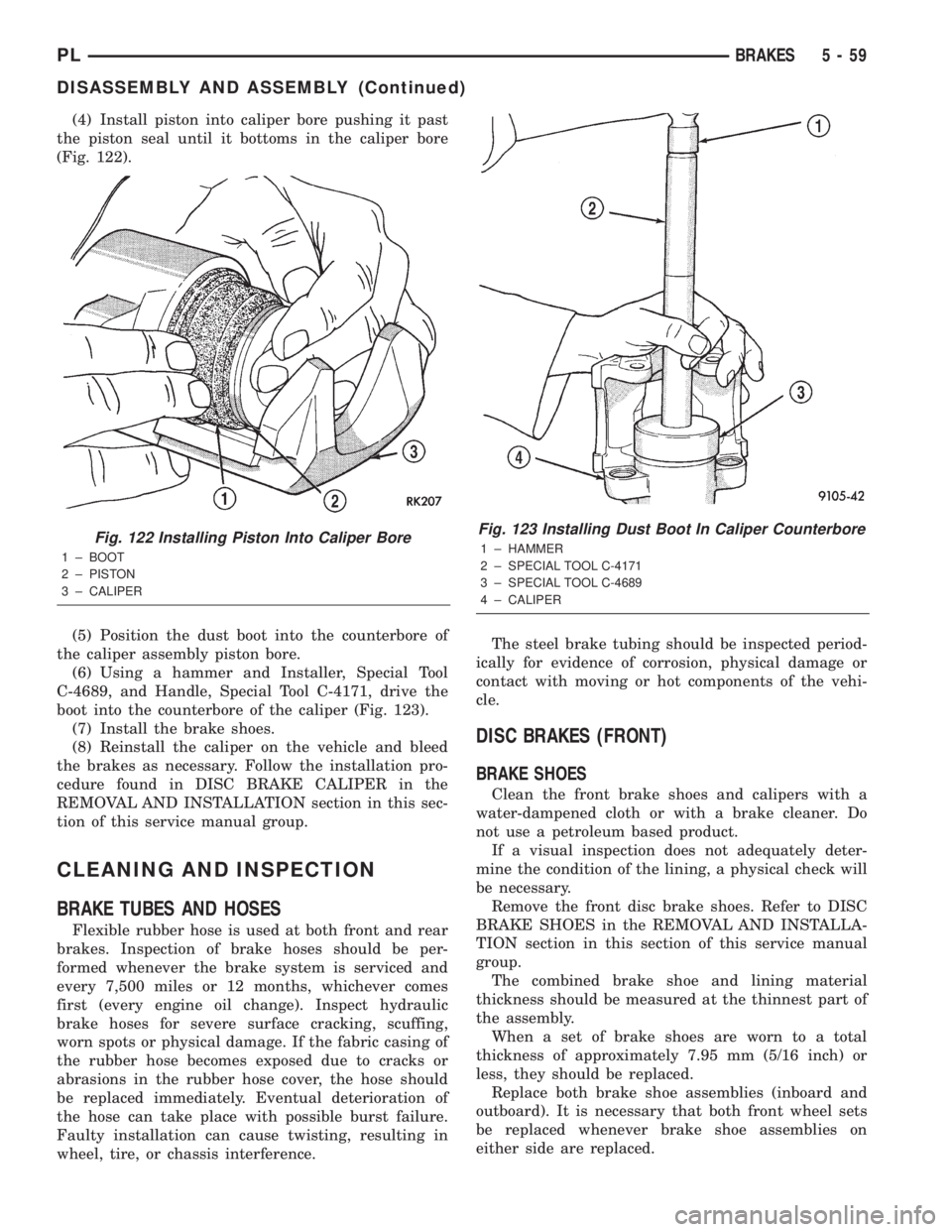

(2) Remove the piston dust boot from the caliper

and discard (Fig. 118).

NOTE: Do not use a screw driver or other metal

tool for seal removal. Using such tools can scratch

the bore or leave burrs on the seal groove edges.

(3) Using a soft tool such as a plastic trim stick,

work the piston seal out of its groove in caliper pis-

ton bore (Fig. 119). Discard the old seal.

(4) Clean the piston bore and drilled passage ways

using alcohol or a suitable solvent. Wipe it dry using

only a lint-free cloth.

(5) Inspect the piston bore for scoring or pitting.

Bores that show light scratches or corrosion can usu-

ally be cleared of the light scratches or corrosion

using crocus cloth. Bores that have deep scratches or

scoring should be honed. Use Caliper Hone, Special

Tool C-4095, or the equivalent to hone the bore. Do

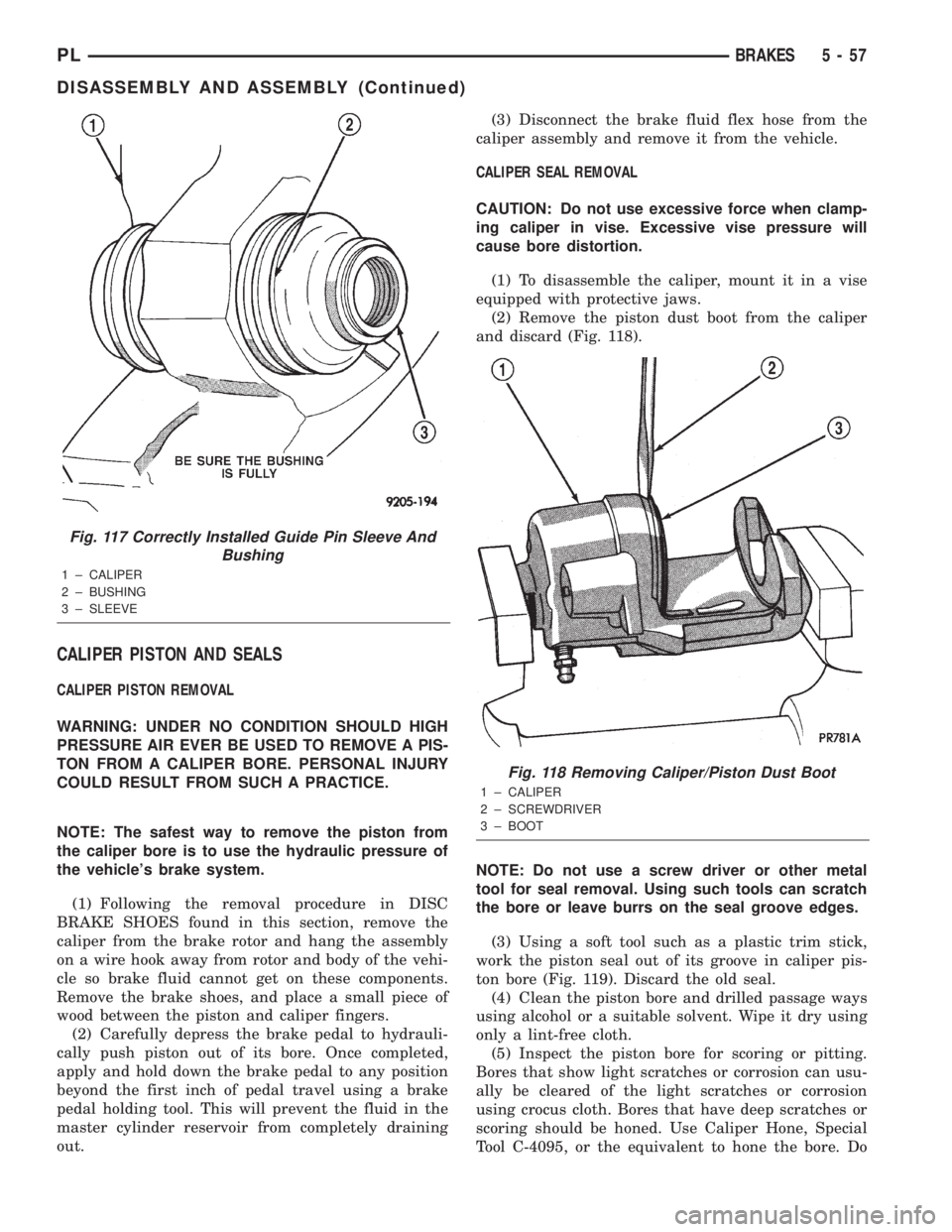

Fig. 117 Correctly Installed Guide Pin Sleeve And

Bushing

1 ± CALIPER

2 ± BUSHING

3 ± SLEEVE

Fig. 118 Removing Caliper/Piston Dust Boot

1 ± CALIPER

2 ± SCREWDRIVER

3 ± BOOT

PLBRAKES 5 - 57

DISASSEMBLY AND ASSEMBLY (Continued)

Page 138 of 1285

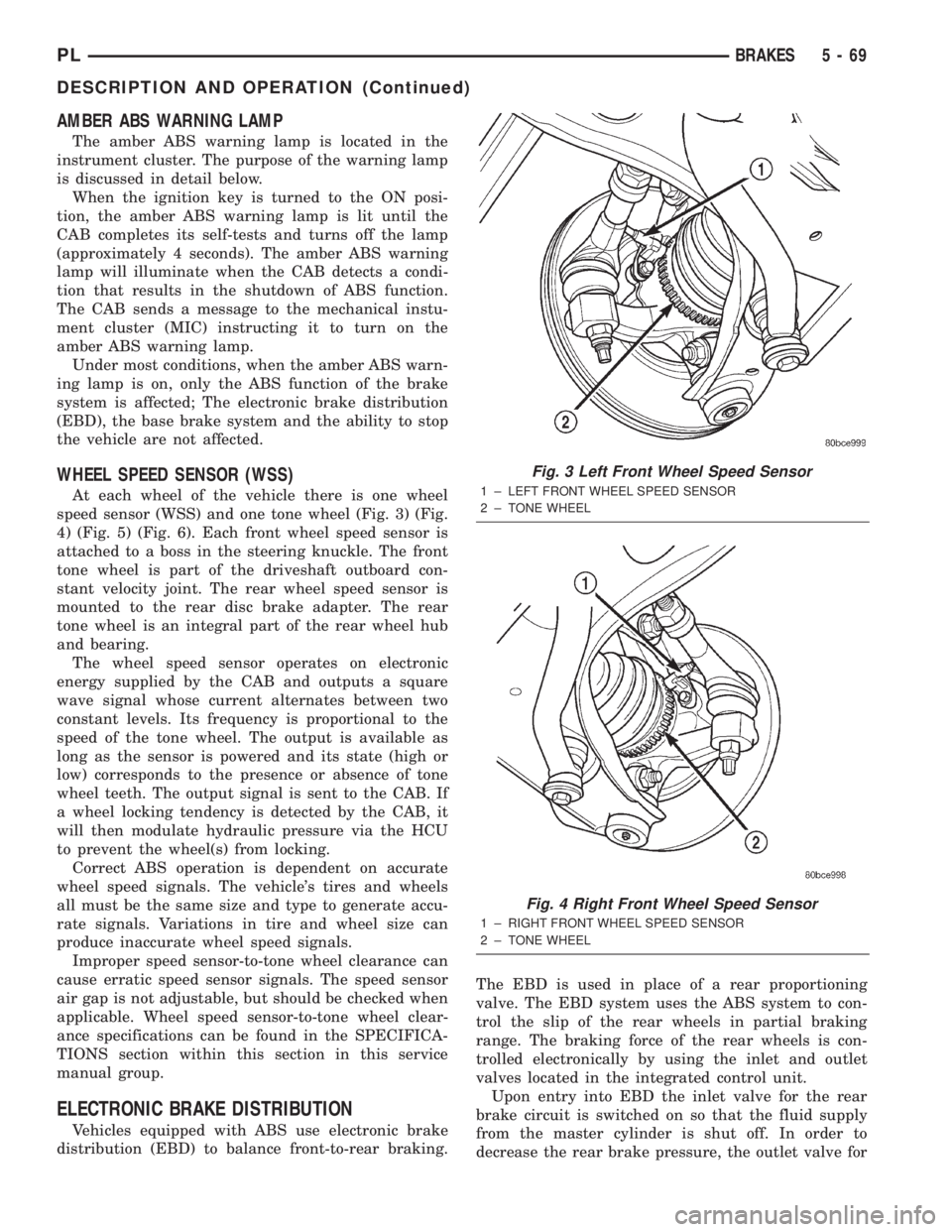

(4) Install piston into caliper bore pushing it past

the piston seal until it bottoms in the caliper bore

(Fig. 122).

(5) Position the dust boot into the counterbore of

the caliper assembly piston bore.

(6) Using a hammer and Installer, Special Tool

C-4689, and Handle, Special Tool C-4171, drive the

boot into the counterbore of the caliper (Fig. 123).

(7) Install the brake shoes.

(8) Reinstall the caliper on the vehicle and bleed

the brakes as necessary. Follow the installation pro-

cedure found in DISC BRAKE CALIPER in the

REMOVAL AND INSTALLATION section in this sec-

tion of this service manual group.

CLEANING AND INSPECTION

BRAKE TUBES AND HOSES

Flexible rubber hose is used at both front and rear

brakes. Inspection of brake hoses should be per-

formed whenever the brake system is serviced and

every 7,500 miles or 12 months, whichever comes

first (every engine oil change). Inspect hydraulic

brake hoses for severe surface cracking, scuffing,

worn spots or physical damage. If the fabric casing of

the rubber hose becomes exposed due to cracks or

abrasions in the rubber hose cover, the hose should

be replaced immediately. Eventual deterioration of

the hose can take place with possible burst failure.

Faulty installation can cause twisting, resulting in

wheel, tire, or chassis interference.The steel brake tubing should be inspected period-

ically for evidence of corrosion, physical damage or

contact with moving or hot components of the vehi-

cle.

DISC BRAKES (FRONT)

BRAKE SHOES

Clean the front brake shoes and calipers with a

water-dampened cloth or with a brake cleaner. Do

not use a petroleum based product.

If a visual inspection does not adequately deter-

mine the condition of the lining, a physical check will

be necessary.

Remove the front disc brake shoes. Refer to DISC

BRAKE SHOES in the REMOVAL AND INSTALLA-

TION section in this section of this service manual

group.

The combined brake shoe and lining material

thickness should be measured at the thinnest part of

the assembly.

When a set of brake shoes are worn to a total

thickness of approximately 7.95 mm (5/16 inch) or

less, they should be replaced.

Replace both brake shoe assemblies (inboard and

outboard). It is necessary that both front wheel sets

be replaced whenever brake shoe assemblies on

either side are replaced.

Fig. 122 Installing Piston Into Caliper Bore

1 ± BOOT

2 ± PISTON

3 ± CALIPER

Fig. 123 Installing Dust Boot In Caliper Counterbore

1 ± HAMMER

2 ± SPECIAL TOOL C-4171

3 ± SPECIAL TOOL C-4689

4 ± CALIPER

PLBRAKES 5 - 59

DISASSEMBLY AND ASSEMBLY (Continued)

Page 148 of 1285

AMBER ABS WARNING LAMP

The amber ABS warning lamp is located in the

instrument cluster. The purpose of the warning lamp

is discussed in detail below.

When the ignition key is turned to the ON posi-

tion, the amber ABS warning lamp is lit until the

CAB completes its self-tests and turns off the lamp

(approximately 4 seconds). The amber ABS warning

lamp will illuminate when the CAB detects a condi-

tion that results in the shutdown of ABS function.

The CAB sends a message to the mechanical instu-

ment cluster (MIC) instructing it to turn on the

amber ABS warning lamp.

Under most conditions, when the amber ABS warn-

ing lamp is on, only the ABS function of the brake

system is affected; The electronic brake distribution

(EBD), the base brake system and the ability to stop

the vehicle are not affected.

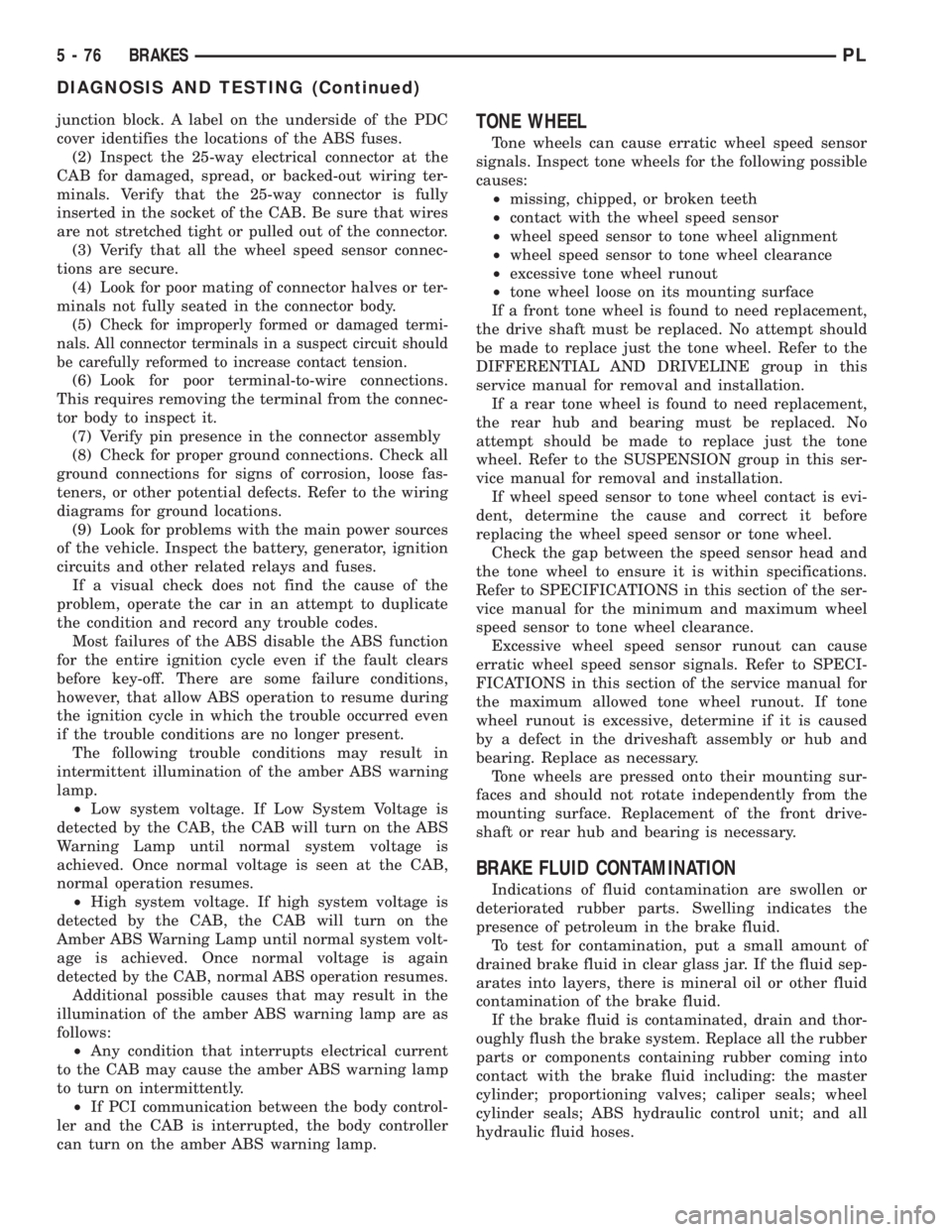

WHEEL SPEED SENSOR (WSS)

At each wheel of the vehicle there is one wheel

speed sensor (WSS) and one tone wheel (Fig. 3) (Fig.

4) (Fig. 5) (Fig. 6). Each front wheel speed sensor is

attached to a boss in the steering knuckle. The front

tone wheel is part of the driveshaft outboard con-

stant velocity joint. The rear wheel speed sensor is

mounted to the rear disc brake adapter. The rear

tone wheel is an integral part of the rear wheel hub

and bearing.

The wheel speed sensor operates on electronic

energy supplied by the CAB and outputs a square

wave signal whose current alternates between two

constant levels. Its frequency is proportional to the

speed of the tone wheel. The output is available as

long as the sensor is powered and its state (high or

low) corresponds to the presence or absence of tone

wheel teeth. The output signal is sent to the CAB. If

a wheel locking tendency is detected by the CAB, it

will then modulate hydraulic pressure via the HCU

to prevent the wheel(s) from locking.

Correct ABS operation is dependent on accurate

wheel speed signals. The vehicle's tires and wheels

all must be the same size and type to generate accu-

rate signals. Variations in tire and wheel size can

produce inaccurate wheel speed signals.

Improper speed sensor-to-tone wheel clearance can

cause erratic speed sensor signals. The speed sensor

air gap is not adjustable, but should be checked when

applicable. Wheel speed sensor-to-tone wheel clear-

ance specifications can be found in the SPECIFICA-

TIONS section within this section in this service

manual group.

ELECTRONIC BRAKE DISTRIBUTION

Vehicles equipped with ABS use electronic brake

distribution (EBD) to balance front-to-rear braking.The EBD is used in place of a rear proportioning

valve. The EBD system uses the ABS system to con-

trol the slip of the rear wheels in partial braking

range. The braking force of the rear wheels is con-

trolled electronically by using the inlet and outlet

valves located in the integrated control unit.

Upon entry into EBD the inlet valve for the rear

brake circuit is switched on so that the fluid supply

from the master cylinder is shut off. In order to

decrease the rear brake pressure, the outlet valve for

Fig. 3 Left Front Wheel Speed Sensor

1 ± LEFT FRONT WHEEL SPEED SENSOR

2 ± TONE WHEEL

Fig. 4 Right Front Wheel Speed Sensor

1 ± RIGHT FRONT WHEEL SPEED SENSOR

2 ± TONE WHEEL

PLBRAKES 5 - 69

DESCRIPTION AND OPERATION (Continued)

Page 155 of 1285

junction block. A label on the underside of the PDC

cover identifies the locations of the ABS fuses.

(2) Inspect the 25-way electrical connector at the

CAB for damaged, spread, or backed-out wiring ter-

minals. Verify that the 25-way connector is fully

inserted in the socket of the CAB. Be sure that wires

are not stretched tight or pulled out of the connector.

(3) Verify that all the wheel speed sensor connec-

tions are secure.

(4) Look for poor mating of connector halves or ter-

minals not fully seated in the connector body.

(5)

Check for improperly formed or damaged termi-

nals. All connector terminals in a suspect circuit should

be carefully reformed to increase contact tension.

(6) Look for poor terminal-to-wire connections.

This requires removing the terminal from the connec-

tor body to inspect it.

(7) Verify pin presence in the connector assembly

(8) Check for proper ground connections. Check all

ground connections for signs of corrosion, loose fas-

teners, or other potential defects. Refer to the wiring

diagrams for ground locations.

(9) Look for problems with the main power sources

of the vehicle. Inspect the battery, generator, ignition

circuits and other related relays and fuses.

If a visual check does not find the cause of the

problem, operate the car in an attempt to duplicate

the condition and record any trouble codes.

Most failures of the ABS disable the ABS function

for the entire ignition cycle even if the fault clears

before key-off. There are some failure conditions,

however, that allow ABS operation to resume during

the ignition cycle in which the trouble occurred even

if the trouble conditions are no longer present.

The following trouble conditions may result in

intermittent illumination of the amber ABS warning

lamp.

²Low system voltage. If Low System Voltage is

detected by the CAB, the CAB will turn on the ABS

Warning Lamp until normal system voltage is

achieved. Once normal voltage is seen at the CAB,

normal operation resumes.

²High system voltage. If high system voltage is

detected by the CAB, the CAB will turn on the

Amber ABS Warning Lamp until normal system volt-

age is achieved. Once normal voltage is again

detected by the CAB, normal ABS operation resumes.

Additional possible causes that may result in the

illumination of the amber ABS warning lamp are as

follows:

²Any condition that interrupts electrical current

to the CAB may cause the amber ABS warning lamp

to turn on intermittently.

²If PCI communication between the body control-

ler and the CAB is interrupted, the body controller

can turn on the amber ABS warning lamp.

TONE WHEEL

Tone wheels can cause erratic wheel speed sensor

signals. Inspect tone wheels for the following possible

causes:

²missing, chipped, or broken teeth

²contact with the wheel speed sensor

²wheel speed sensor to tone wheel alignment

²wheel speed sensor to tone wheel clearance

²excessive tone wheel runout

²tone wheel loose on its mounting surface

If a front tone wheel is found to need replacement,

the drive shaft must be replaced. No attempt should

be made to replace just the tone wheel. Refer to the

DIFFERENTIAL AND DRIVELINE group in this

service manual for removal and installation.

If a rear tone wheel is found to need replacement,

the rear hub and bearing must be replaced. No

attempt should be made to replace just the tone

wheel. Refer to the SUSPENSION group in this ser-

vice manual for removal and installation.

If wheel speed sensor to tone wheel contact is evi-

dent, determine the cause and correct it before

replacing the wheel speed sensor or tone wheel.

Check the gap between the speed sensor head and

the tone wheel to ensure it is within specifications.

Refer to SPECIFICATIONS in this section of the ser-

vice manual for the minimum and maximum wheel

speed sensor to tone wheel clearance.

Excessive wheel speed sensor runout can cause

erratic wheel speed sensor signals. Refer to SPECI-

FICATIONS in this section of the service manual for

the maximum allowed tone wheel runout. If tone

wheel runout is excessive, determine if it is caused

by a defect in the driveshaft assembly or hub and

bearing. Replace as necessary.

Tone wheels are pressed onto their mounting sur-

faces and should not rotate independently from the

mounting surface. Replacement of the front drive-

shaft or rear hub and bearing is necessary.

BRAKE FLUID CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts. Swelling indicates the

presence of petroleum in the brake fluid.

To test for contamination, put a small amount of

drained brake fluid in clear glass jar. If the fluid sep-

arates into layers, there is mineral oil or other fluid

contamination of the brake fluid.

If the brake fluid is contaminated, drain and thor-

oughly flush the brake system. Replace all the rubber

parts or components containing rubber coming into

contact with the brake fluid including: the master

cylinder; proportioning valves; caliper seals; wheel

cylinder seals; ABS hydraulic control unit; and all

hydraulic fluid hoses.

5 - 76 BRAKESPL

DIAGNOSIS AND TESTING (Continued)

Page 157 of 1285

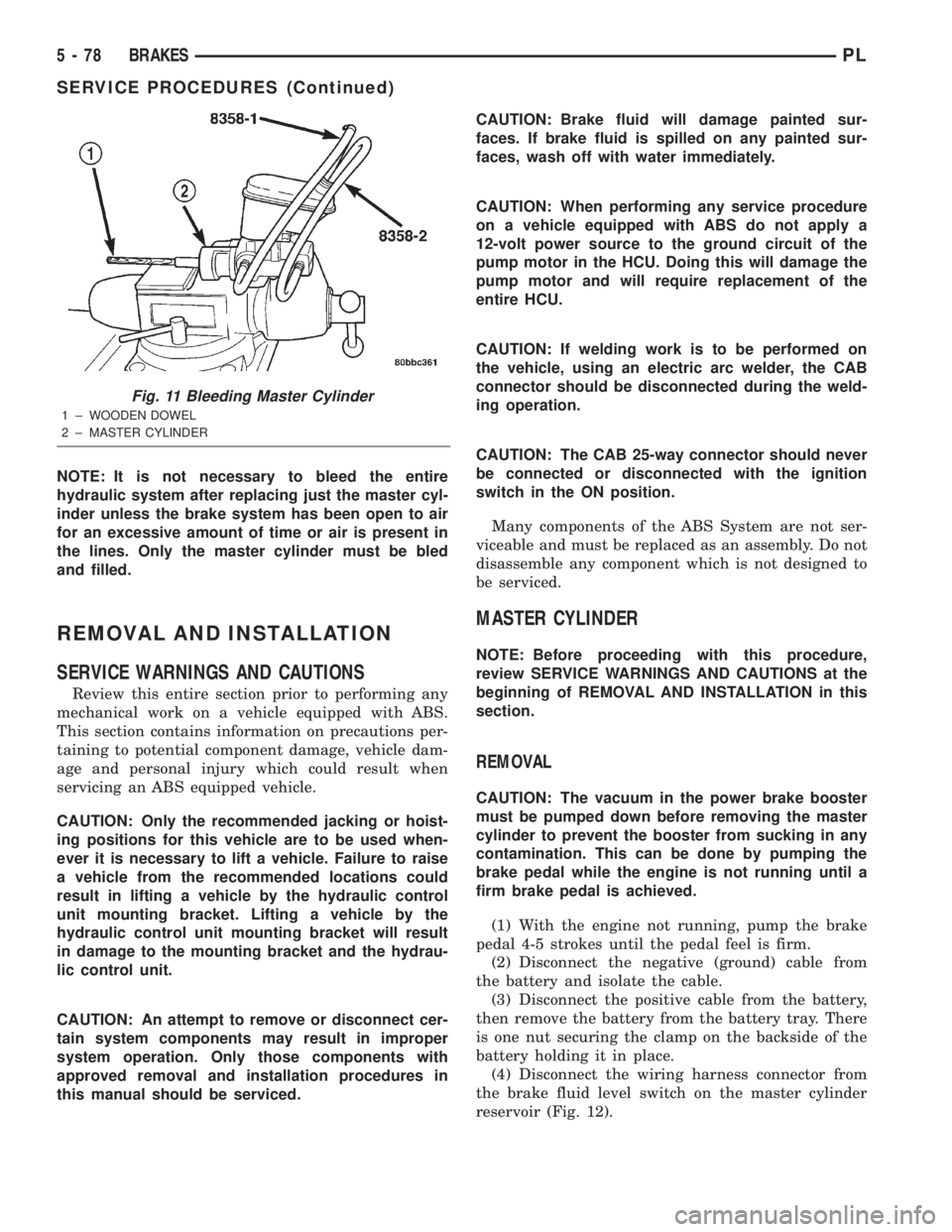

NOTE: It is not necessary to bleed the entire

hydraulic system after replacing just the master cyl-

inder unless the brake system has been open to air

for an excessive amount of time or air is present in

the lines. Only the master cylinder must be bled

and filled.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

Review this entire section prior to performing any

mechanical work on a vehicle equipped with ABS.

This section contains information on precautions per-

taining to potential component damage, vehicle dam-

age and personal injury which could result when

servicing an ABS equipped vehicle.

CAUTION: Only the recommended jacking or hoist-

ing positions for this vehicle are to be used when-

ever it is necessary to lift a vehicle. Failure to raise

a vehicle from the recommended locations could

result in lifting a vehicle by the hydraulic control

unit mounting bracket. Lifting a vehicle by the

hydraulic control unit mounting bracket will result

in damage to the mounting bracket and the hydrau-

lic control unit.

CAUTION: An attempt to remove or disconnect cer-

tain system components may result in improper

system operation. Only those components with

approved removal and installation procedures in

this manual should be serviced.CAUTION: Brake fluid will damage painted sur-

faces. If brake fluid is spilled on any painted sur-

faces, wash off with water immediately.

CAUTION: When performing any service procedure

on a vehicle equipped with ABS do not apply a

12-volt power source to the ground circuit of the

pump motor in the HCU. Doing this will damage the

pump motor and will require replacement of the

entire HCU.

CAUTION: If welding work is to be performed on

the vehicle, using an electric arc welder, the CAB

connector should be disconnected during the weld-

ing operation.

CAUTION: The CAB 25-way connector should never

be connected or disconnected with the ignition

switch in the ON position.

Many components of the ABS System are not ser-

viceable and must be replaced as an assembly. Do not

disassemble any component which is not designed to

be serviced.

MASTER CYLINDER

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

CAUTION: The vacuum in the power brake booster

must be pumped down before removing the master

cylinder to prevent the booster from sucking in any

contamination. This can be done by pumping the

brake pedal while the engine is not running until a

firm brake pedal is achieved.

(1) With the engine not running, pump the brake

pedal 4-5 strokes until the pedal feel is firm.

(2) Disconnect the negative (ground) cable from

the battery and isolate the cable.

(3) Disconnect the positive cable from the battery,

then remove the battery from the battery tray. There

is one nut securing the clamp on the backside of the

battery holding it in place.

(4) Disconnect the wiring harness connector from

the brake fluid level switch on the master cylinder

reservoir (Fig. 12).

Fig. 11 Bleeding Master Cylinder

1 ± WOODEN DOWEL

2 ± MASTER CYLINDER

5 - 78 BRAKESPL

SERVICE PROCEDURES (Continued)

Page 160 of 1285

(14) Refer to DISASSEMBLY AND ASSEMBLY in

this section of this group for the procedure on sepa-

rating and reattaching the CAB to the HCU.

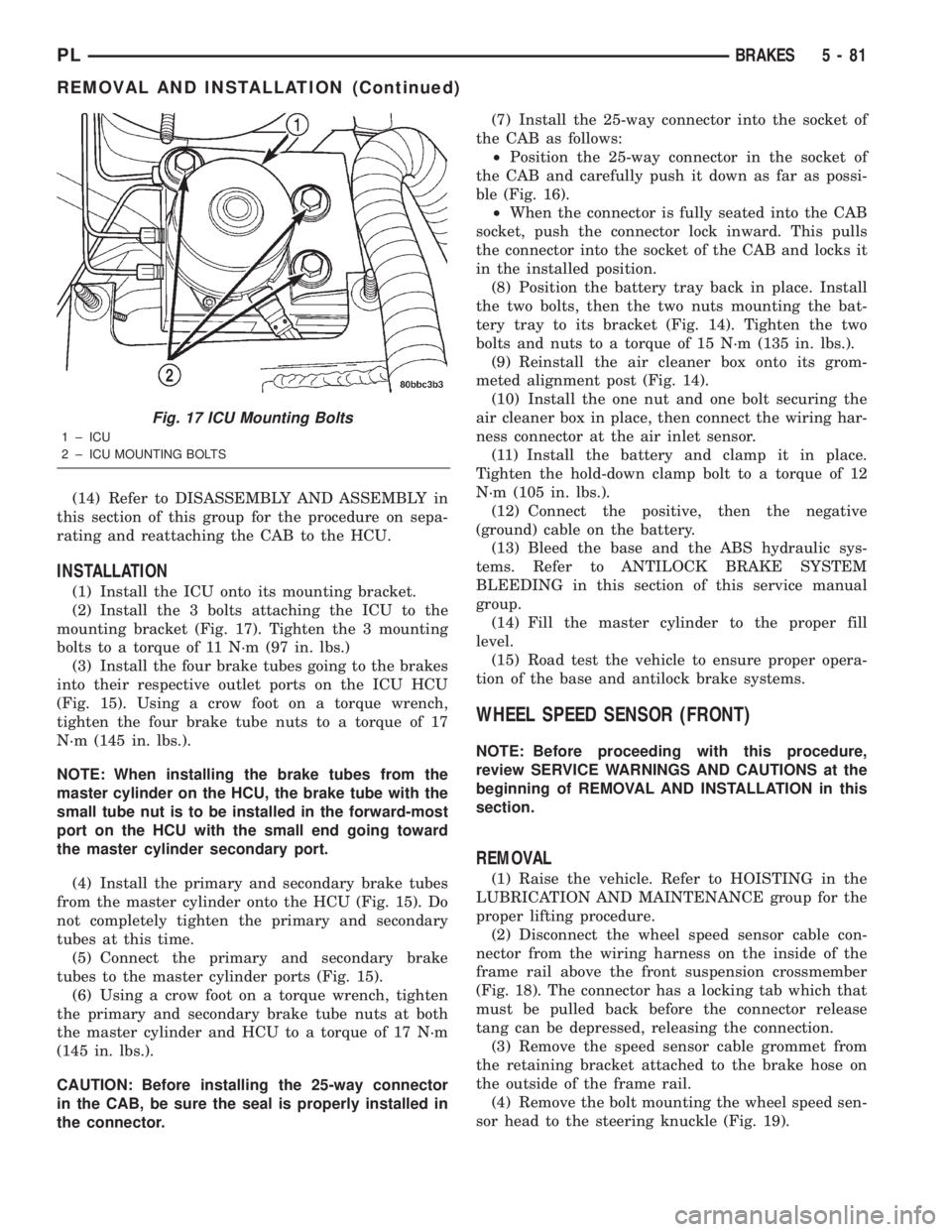

INSTALLATION

(1) Install the ICU onto its mounting bracket.

(2) Install the 3 bolts attaching the ICU to the

mounting bracket (Fig. 17). Tighten the 3 mounting

bolts to a torque of 11 N´m (97 in. lbs.)

(3) Install the four brake tubes going to the brakes

into their respective outlet ports on the ICU HCU

(Fig. 15). Using a crow foot on a torque wrench,

tighten the four brake tube nuts to a torque of 17

N´m (145 in. lbs.).

NOTE: When installing the brake tubes from the

master cylinder on the HCU, the brake tube with the

small tube nut is to be installed in the forward-most

port on the HCU with the small end going toward

the master cylinder secondary port.

(4) Install the primary and secondary brake tubes

from the master cylinder onto the HCU (Fig. 15). Do

not completely tighten the primary and secondary

tubes at this time.

(5) Connect the primary and secondary brake

tubes to the master cylinder ports (Fig. 15).

(6) Using a crow foot on a torque wrench, tighten

the primary and secondary brake tube nuts at both

the master cylinder and HCU to a torque of 17 N´m

(145 in. lbs.).

CAUTION: Before installing the 25-way connector

in the CAB, be sure the seal is properly installed in

the connector.(7) Install the 25-way connector into the socket of

the CAB as follows:

²Position the 25-way connector in the socket of

the CAB and carefully push it down as far as possi-

ble (Fig. 16).

²When the connector is fully seated into the CAB

socket, push the connector lock inward. This pulls

the connector into the socket of the CAB and locks it

in the installed position.

(8) Position the battery tray back in place. Install

the two bolts, then the two nuts mounting the bat-

tery tray to its bracket (Fig. 14). Tighten the two

bolts and nuts to a torque of 15 N´m (135 in. lbs.).

(9) Reinstall the air cleaner box onto its grom-

meted alignment post (Fig. 14).

(10) Install the one nut and one bolt securing the

air cleaner box in place, then connect the wiring har-

ness connector at the air inlet sensor.

(11) Install the battery and clamp it in place.

Tighten the hold-down clamp bolt to a torque of 12

N´m (105 in. lbs.).

(12) Connect the positive, then the negative

(ground) cable on the battery.

(13) Bleed the base and the ABS hydraulic sys-

tems. Refer to ANTILOCK BRAKE SYSTEM

BLEEDING in this section of this service manual

group.

(14) Fill the master cylinder to the proper fill

level.

(15) Road test the vehicle to ensure proper opera-

tion of the base and antilock brake systems.

WHEEL SPEED SENSOR (FRONT)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

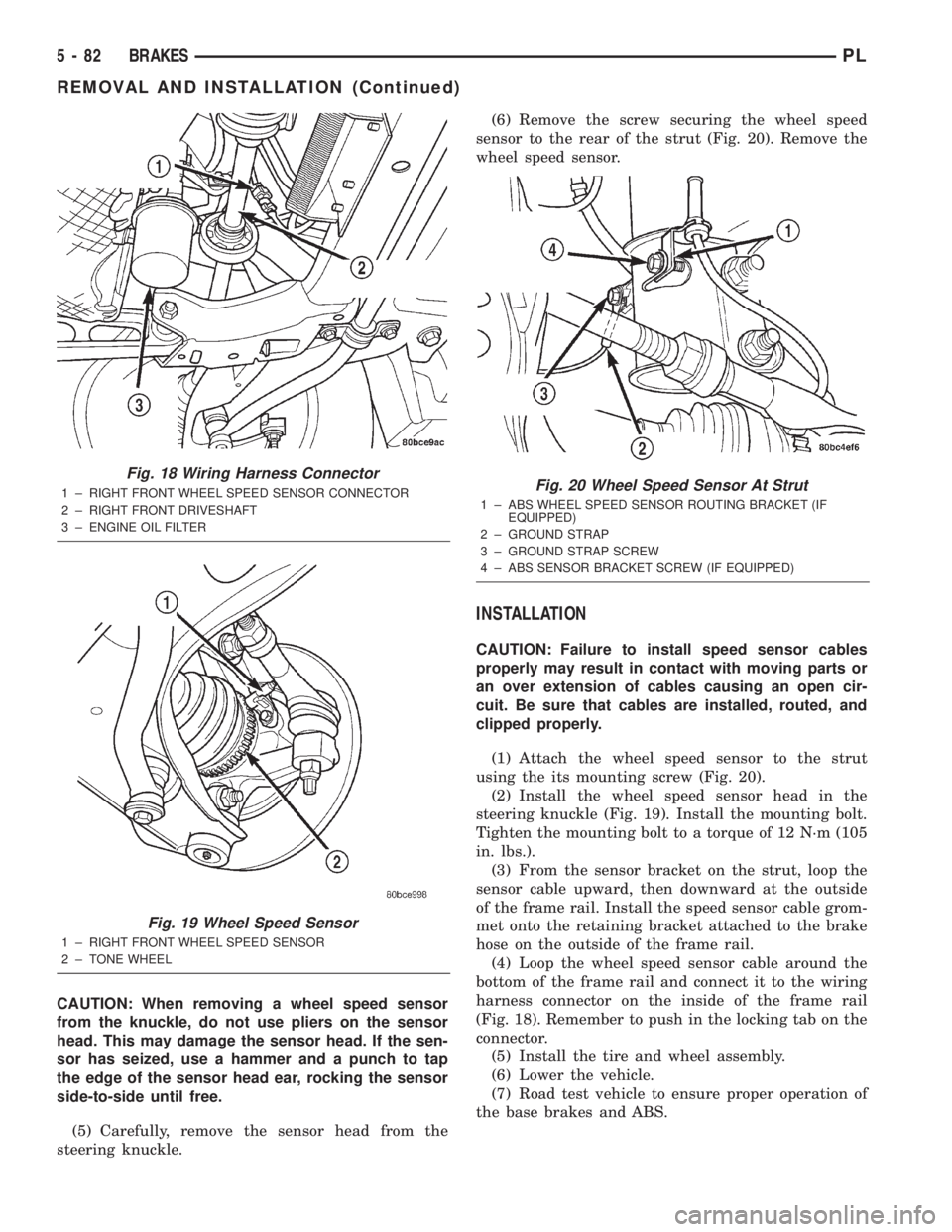

(2) Disconnect the wheel speed sensor cable con-

nector from the wiring harness on the inside of the

frame rail above the front suspension crossmember

(Fig. 18). The connector has a locking tab which that

must be pulled back before the connector release

tang can be depressed, releasing the connection.

(3) Remove the speed sensor cable grommet from

the retaining bracket attached to the brake hose on

the outside of the frame rail.

(4) Remove the bolt mounting the wheel speed sen-

sor head to the steering knuckle (Fig. 19).

Fig. 17 ICU Mounting Bolts

1 ± ICU

2 ± ICU MOUNTING BOLTS

PLBRAKES 5 - 81

REMOVAL AND INSTALLATION (Continued)

Page 161 of 1285

CAUTION: When removing a wheel speed sensor

from the knuckle, do not use pliers on the sensor

head. This may damage the sensor head. If the sen-

sor has seized, use a hammer and a punch to tap

the edge of the sensor head ear, rocking the sensor

side-to-side until free.

(5) Carefully, remove the sensor head from the

steering knuckle.(6) Remove the screw securing the wheel speed

sensor to the rear of the strut (Fig. 20). Remove the

wheel speed sensor.

INSTALLATION

CAUTION: Failure to install speed sensor cables

properly may result in contact with moving parts or

an over extension of cables causing an open cir-

cuit. Be sure that cables are installed, routed, and

clipped properly.

(1) Attach the wheel speed sensor to the strut

using the its mounting screw (Fig. 20).

(2) Install the wheel speed sensor head in the

steering knuckle (Fig. 19). Install the mounting bolt.

Tighten the mounting bolt to a torque of 12 N´m (105

in. lbs.).

(3) From the sensor bracket on the strut, loop the

sensor cable upward, then downward at the outside

of the frame rail. Install the speed sensor cable grom-

met onto the retaining bracket attached to the brake

hose on the outside of the frame rail.

(4) Loop the wheel speed sensor cable around the

bottom of the frame rail and connect it to the wiring

harness connector on the inside of the frame rail

(Fig. 18). Remember to push in the locking tab on the

connector.

(5) Install the tire and wheel assembly.

(6) Lower the vehicle.

(7) Road test vehicle to ensure proper operation of

the base brakes and ABS.

Fig. 18 Wiring Harness Connector

1 ± RIGHT FRONT WHEEL SPEED SENSOR CONNECTOR

2 ± RIGHT FRONT DRIVESHAFT

3 ± ENGINE OIL FILTER

Fig. 19 Wheel Speed Sensor

1 ± RIGHT FRONT WHEEL SPEED SENSOR

2 ± TONE WHEEL

Fig. 20 Wheel Speed Sensor At Strut

1 ± ABS WHEEL SPEED SENSOR ROUTING BRACKET (IF

EQUIPPED)

2 ± GROUND STRAP

3 ± GROUND STRAP SCREW

4 ± ABS SENSOR BRACKET SCREW (IF EQUIPPED)

5 - 82 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 162 of 1285

WHEEL SPEED SENSOR (REAR)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove the tire and wheel assembly from the

vehicle.

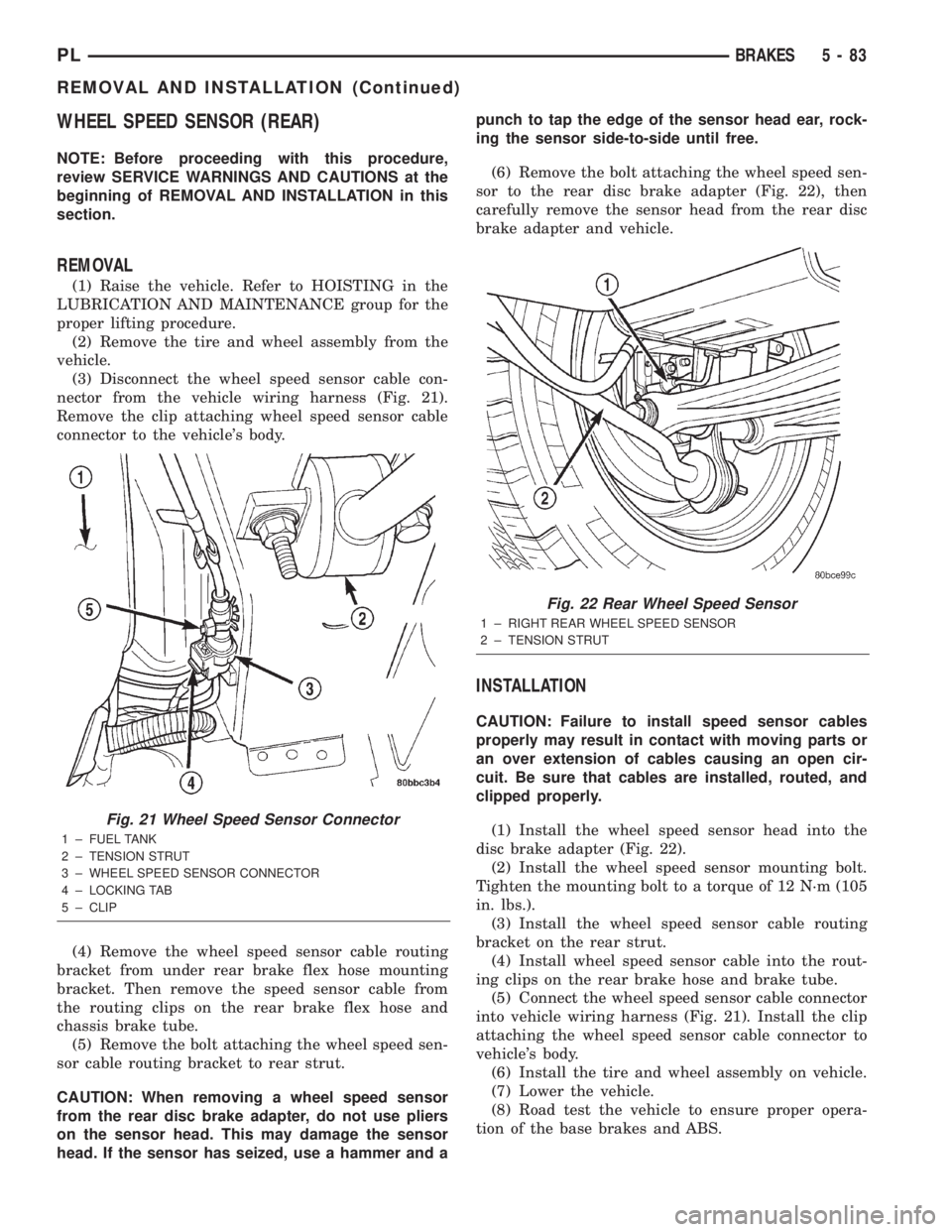

(3) Disconnect the wheel speed sensor cable con-

nector from the vehicle wiring harness (Fig. 21).

Remove the clip attaching wheel speed sensor cable

connector to the vehicle's body.

(4) Remove the wheel speed sensor cable routing

bracket from under rear brake flex hose mounting

bracket. Then remove the speed sensor cable from

the routing clips on the rear brake flex hose and

chassis brake tube.

(5) Remove the bolt attaching the wheel speed sen-

sor cable routing bracket to rear strut.

CAUTION: When removing a wheel speed sensor

from the rear disc brake adapter, do not use pliers

on the sensor head. This may damage the sensor

head. If the sensor has seized, use a hammer and apunch to tap the edge of the sensor head ear, rock-

ing the sensor side-to-side until free.

(6) Remove the bolt attaching the wheel speed sen-

sor to the rear disc brake adapter (Fig. 22), then

carefully remove the sensor head from the rear disc

brake adapter and vehicle.

INSTALLATION

CAUTION: Failure to install speed sensor cables

properly may result in contact with moving parts or

an over extension of cables causing an open cir-

cuit. Be sure that cables are installed, routed, and

clipped properly.

(1) Install the wheel speed sensor head into the

disc brake adapter (Fig. 22).

(2) Install the wheel speed sensor mounting bolt.

Tighten the mounting bolt to a torque of 12 N´m (105

in. lbs.).

(3) Install the wheel speed sensor cable routing

bracket on the rear strut.

(4) Install wheel speed sensor cable into the rout-

ing clips on the rear brake hose and brake tube.

(5) Connect the wheel speed sensor cable connector

into vehicle wiring harness (Fig. 21). Install the clip

attaching the wheel speed sensor cable connector to

vehicle's body.

(6) Install the tire and wheel assembly on vehicle.

(7) Lower the vehicle.

(8) Road test the vehicle to ensure proper opera-

tion of the base brakes and ABS.

Fig. 21 Wheel Speed Sensor Connector

1 ± FUEL TANK

2 ± TENSION STRUT

3 ± WHEEL SPEED SENSOR CONNECTOR

4 ± LOCKING TAB

5 ± CLIP

Fig. 22 Rear Wheel Speed Sensor

1 ± RIGHT REAR WHEEL SPEED SENSOR

2 ± TENSION STRUT

PLBRAKES 5 - 83

REMOVAL AND INSTALLATION (Continued)

Page 173 of 1285

housing does not move, it is improperly installed or

defective.

(3) Route cable to the transaxle and connect cable

end to the clutch release lever and transaxle housing

(Fig. 7).

(4) Install bellhousing cap (Fig. 7).

(5) Install and fasten battery tray.

(6) Install battery and hold-down clamp.

(7) Connect both battery cables.

(8) Verify that the clutch cable is working properly.

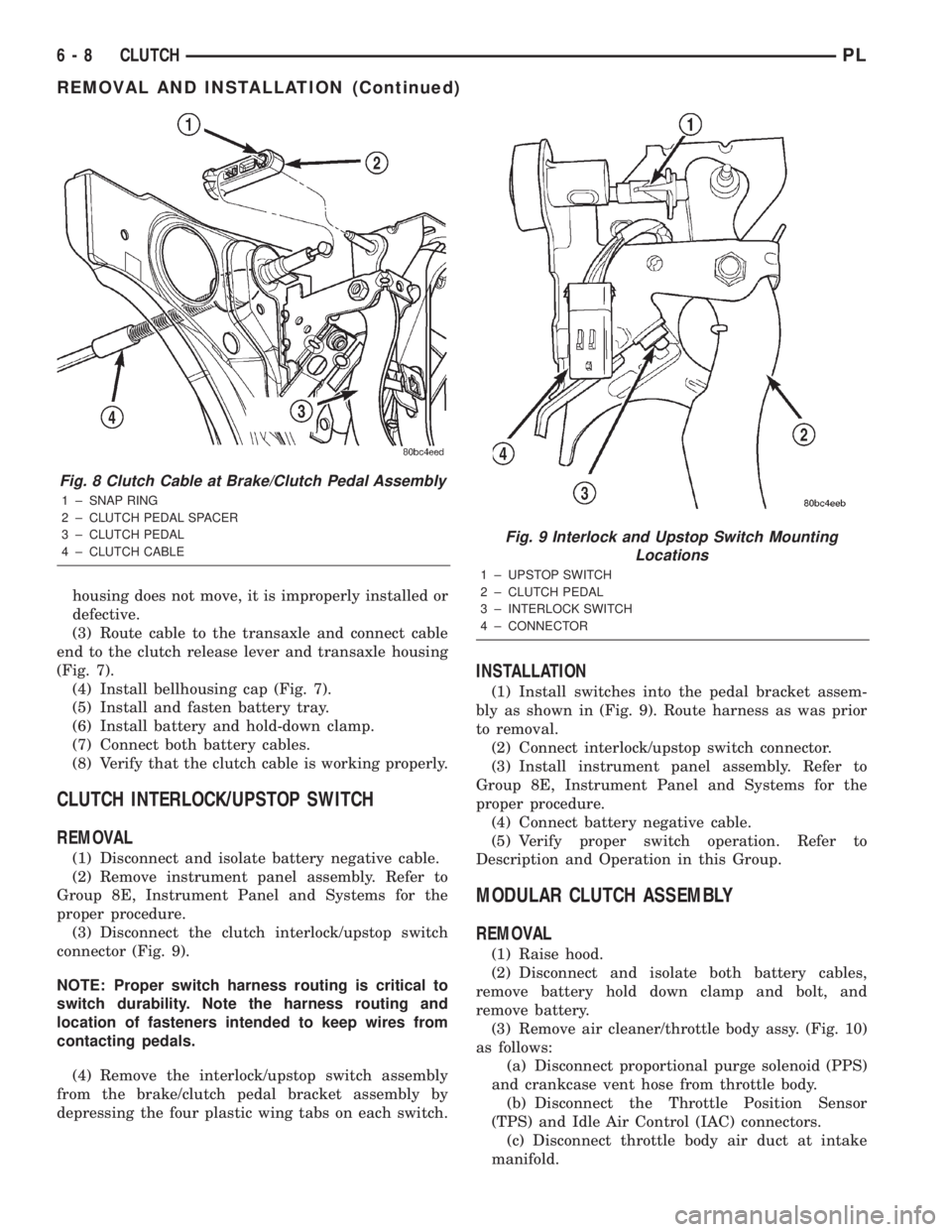

CLUTCH INTERLOCK/UPSTOP SWITCH

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Remove instrument panel assembly. Refer to

Group 8E, Instrument Panel and Systems for the

proper procedure.

(3) Disconnect the clutch interlock/upstop switch

connector (Fig. 9).

NOTE: Proper switch harness routing is critical to

switch durability. Note the harness routing and

location of fasteners intended to keep wires from

contacting pedals.

(4) Remove the interlock/upstop switch assembly

from the brake/clutch pedal bracket assembly by

depressing the four plastic wing tabs on each switch.

INSTALLATION

(1) Install switches into the pedal bracket assem-

bly as shown in (Fig. 9). Route harness as was prior

to removal.

(2) Connect interlock/upstop switch connector.

(3) Install instrument panel assembly. Refer to

Group 8E, Instrument Panel and Systems for the

proper procedure.

(4) Connect battery negative cable.

(5) Verify proper switch operation. Refer to

Description and Operation in this Group.

MODULAR CLUTCH ASSEMBLY

REMOVAL

(1) Raise hood.

(2) Disconnect and isolate both battery cables,

remove battery hold down clamp and bolt, and

remove battery.

(3) Remove air cleaner/throttle body assy. (Fig. 10)

as follows:

(a) Disconnect proportional purge solenoid (PPS)

and crankcase vent hose from throttle body.

(b) Disconnect the Throttle Position Sensor

(TPS) and Idle Air Control (IAC) connectors.

(c) Disconnect throttle body air duct at intake

manifold.

Fig. 8 Clutch Cable at Brake/Clutch Pedal Assembly

1 ± SNAP RING

2 ± CLUTCH PEDAL SPACER

3 ± CLUTCH PEDAL

4 ± CLUTCH CABLE

Fig. 9 Interlock and Upstop Switch Mounting

Locations

1 ± UPSTOP SWITCH

2 ± CLUTCH PEDAL

3 ± INTERLOCK SWITCH

4 ± CONNECTOR

6 - 8 CLUTCHPL

REMOVAL AND INSTALLATION (Continued)

Page 176 of 1285

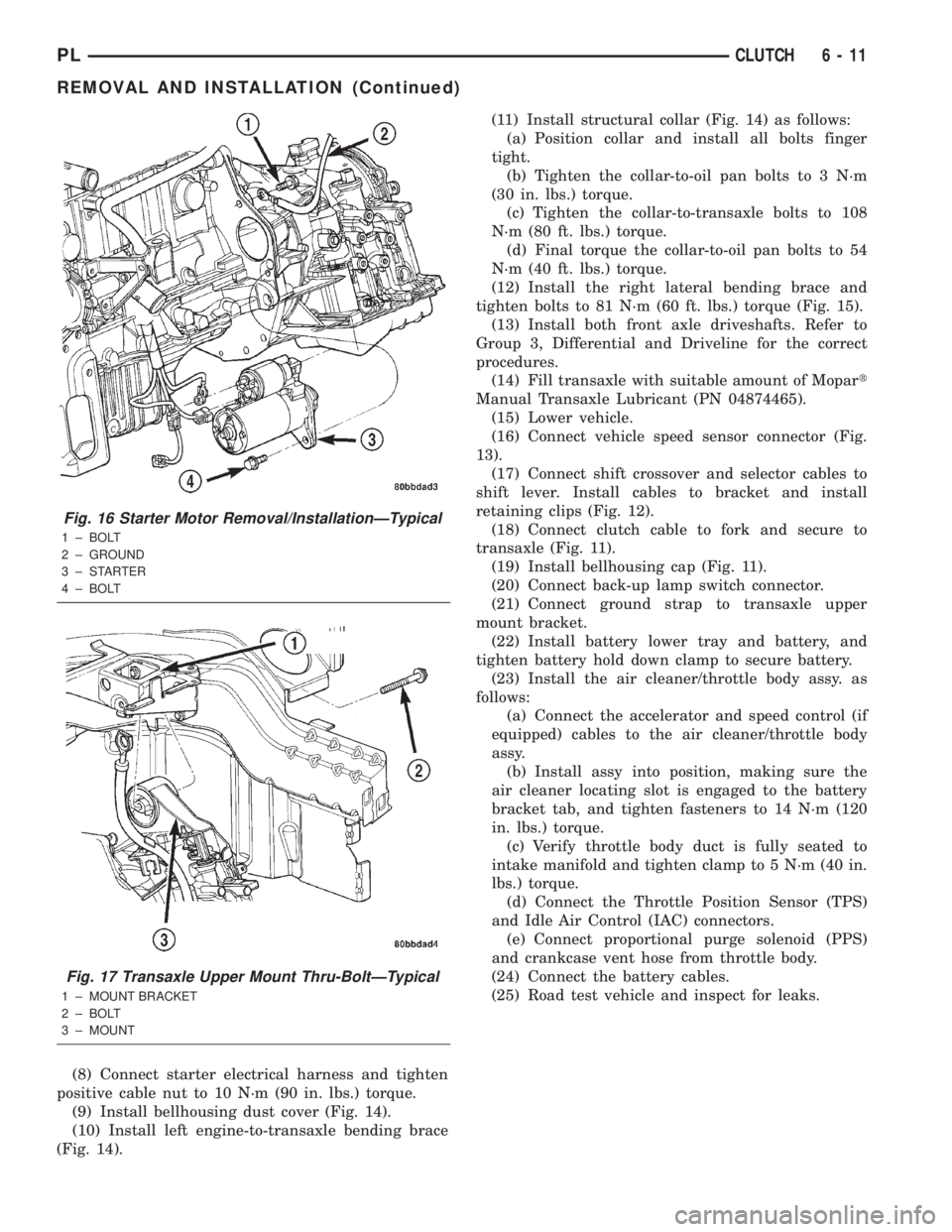

(8) Connect starter electrical harness and tighten

positive cable nut to 10 N´m (90 in. lbs.) torque.

(9) Install bellhousing dust cover (Fig. 14).

(10) Install left engine-to-transaxle bending brace

(Fig. 14).(11) Install structural collar (Fig. 14) as follows:

(a) Position collar and install all bolts finger

tight.

(b) Tighten the collar-to-oil pan bolts to 3 N´m

(30 in. lbs.) torque.

(c) Tighten the collar-to-transaxle bolts to 108

N´m (80 ft. lbs.) torque.

(d) Final torque the collar-to-oil pan bolts to 54

N´m (40 ft. lbs.) torque.

(12) Install the right lateral bending brace and

tighten bolts to 81 N´m (60 ft. lbs.) torque (Fig. 15).

(13) Install both front axle driveshafts. Refer to

Group 3, Differential and Driveline for the correct

procedures.

(14) Fill transaxle with suitable amount of Mopart

Manual Transaxle Lubricant (PN 04874465).

(15) Lower vehicle.

(16) Connect vehicle speed sensor connector (Fig.

13).

(17) Connect shift crossover and selector cables to

shift lever. Install cables to bracket and install

retaining clips (Fig. 12).

(18) Connect clutch cable to fork and secure to

transaxle (Fig. 11).

(19) Install bellhousing cap (Fig. 11).

(20) Connect back-up lamp switch connector.

(21) Connect ground strap to transaxle upper

mount bracket.

(22) Install battery lower tray and battery, and

tighten battery hold down clamp to secure battery.

(23) Install the air cleaner/throttle body assy. as

follows:

(a) Connect the accelerator and speed control (if

equipped) cables to the air cleaner/throttle body

assy.

(b) Install assy into position, making sure the

air cleaner locating slot is engaged to the battery

bracket tab, and tighten fasteners to 14 N´m (120

in. lbs.) torque.

(c) Verify throttle body duct is fully seated to

intake manifold and tighten clamp to 5 N´m (40 in.

lbs.) torque.

(d) Connect the Throttle Position Sensor (TPS)

and Idle Air Control (IAC) connectors.

(e) Connect proportional purge solenoid (PPS)

and crankcase vent hose from throttle body.

(24) Connect the battery cables.

(25) Road test vehicle and inspect for leaks.

Fig. 16 Starter Motor Removal/InstallationÐTypical

1 ± BOLT

2 ± GROUND

3±STARTER

4 ± BOLT

Fig. 17 Transaxle Upper Mount Thru-BoltÐTypical

1 ± MOUNT BRACKET

2 ± BOLT

3 ± MOUNT

PLCLUTCH 6 - 11

REMOVAL AND INSTALLATION (Continued)