battery DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 985 of 1285

FLUSHING COOLERS AND TUBES

When a transaxle failure has contaminated the

fluid, the transaxle oil cooler(s) must be flushed (both

radiator and remote). The cooler bypass valve in the

transaxle must be replaced also. The torque con-

verter must also be replaced with an exchange unit.

This will ensure that metal particles or sludged oil

are not later transferred back into the reconditioned

(or replaced) transaxle.

The recommended procedure for flushing the cool-

ers and tubes is to use Tool 6906A Cooler Flusher.

WARNING: WEAR PROTECTIVE EYEWEAR THAT

MEETS THE REQUIREMENTS OF OSHA AND ANSI

Z87.1±1968. WEAR STANDARD INDUSTRIAL RUB-

BER GLOVES.

KEEP LIT CIGARETTES, SPARKS, FLAMES, AND

OTHER IGNITION SOURCES AWAY FROM THE

AREA TO PREVENT THE IGNITION OF COMBUSTI-

BLE LIQUIDS AND GASES. KEEP A CLASS (B) FIRE

EXTINGUISHER IN THE AREA WHERE THE

FLUSHER WILL BE USED.

KEEP THE AREA WELL VENTILATED.

DO NOT LET FLUSHING SOLVENT COME IN CON-

TACT WITH YOUR EYES OR SKIN: IF EYE CONTAM-

INATION OCCURS, FLUSH EYES WITH WATER FOR

15 TO 20 SECONDS. REMOVE CONTAMINATED

CLOTHING AND WASH AFFECTED SKIN WITH

SOAP AND WATER. SEEK MEDICAL ATTENTION.

COOLER FLUSH USING TOOL 6906A

(1) Remove cover plate filler plug on Tool 6906A.

Fill reservoir 1/2 to 3/4 full of fresh flushing solution.

Flushing solvents are petroleum based solutions gen-

erally used to clean automatic transmission compo-

nents.DO NOTuse solvents containing acids, water,

gasoline, or any other corrosive liquids.

(2) Reinstall filler plug on Tool 6906A.

(3) Verify pump power switch is turned OFF. Con-

nect red alligator clip to positive (+) battery post.

Connect black (-) alligator clip to a good ground.

(4) Disconnect the cooler lines at the transmission.

NOTE: When flushing transmission cooler and

lines, ALWAYS reverse flush.

(5) Connect the BLUE pressure line to the OUT-

LET (From) cooler line.

(6) Connect the CLEAR return line to the INLET

(To) cooler line

(7) Turn pump ON for two to three minutes to

flush cooler(s) and lines. Monitor pressure readingsand clear return lines. Pressure readings should sta-

bilize below 20 psi. for vehicles equipped with a sin-

gle cooler and 30 psi. for vehicles equipped with dual

coolers. If flow is intermittent or exceeds these pres-

sures, replace cooler.

(8) Turn pump OFF.

(9) Disconnect CLEAR suction line from reservoir

at cover plate. Disconnect CLEAR return line at

cover plate, and place it in a drain pan.

(10) Turn pump ON for 30 seconds to purge flush-

ing solution from cooler and lines. Turn pump OFF.

(11) Place CLEAR suction line into a one quart

container of MopartATF+4 (Automatic Transmission

Fluid) Type 9602.

(12) Turn pump ON until all transmission fluid is

removed from the one quart container and lines. This

purges any residual cleaning solvent from the trans-

mission cooler and lines. Turn pump OFF.

(13) Disconnect alligator clips from battery. Recon-

nect flusher lines to cover plate, and remove flushing

adapters from cooler lines.

OIL PUMP VOLUME CHECK

After the new or repaired transmission has been

installed, fill to the proper level with MopartATF+4

(Automatic Transmission Fluid) Type 9602. The vol-

ume should be checked using the following proce-

dure:

(1) Disconnect theFrom coolerline at the trans-

mission and place a collecting container under the

disconnected line.

CAUTION: With the fluid set at the proper level,

fluid collection should not exceed (1) quart or inter-

nal damage to the transmission may occur.

(2) Run the engineat curb idle speed, with the

shift selector in neutral.

(3) If fluid flow is intermittent or it takes more

than 20 seconds to collect one quart of ATF, discon-

nect theTo Coolerline at the transaxle.

(4) Refill the transaxle to proper level and recheck

pump volume.

(5) If flow is found to be within acceptable limits,

replace the cooler. Then fill transmission to the

proper level, using MopartATF+4 (Automatic Trans-

mission Fluid) Type 9602.

(6) If fluid flow is still found to be inadequate,

check the line pressure using the Transaxle Hydrau-

lic Pressure Test procedure.

21 - 72 TRANSAXLEPL

SERVICE PROCEDURES (Continued)

Page 987 of 1285

(6) Disconnect both battery cables, remove battery

hold down clamp and bolt, and remove battery.

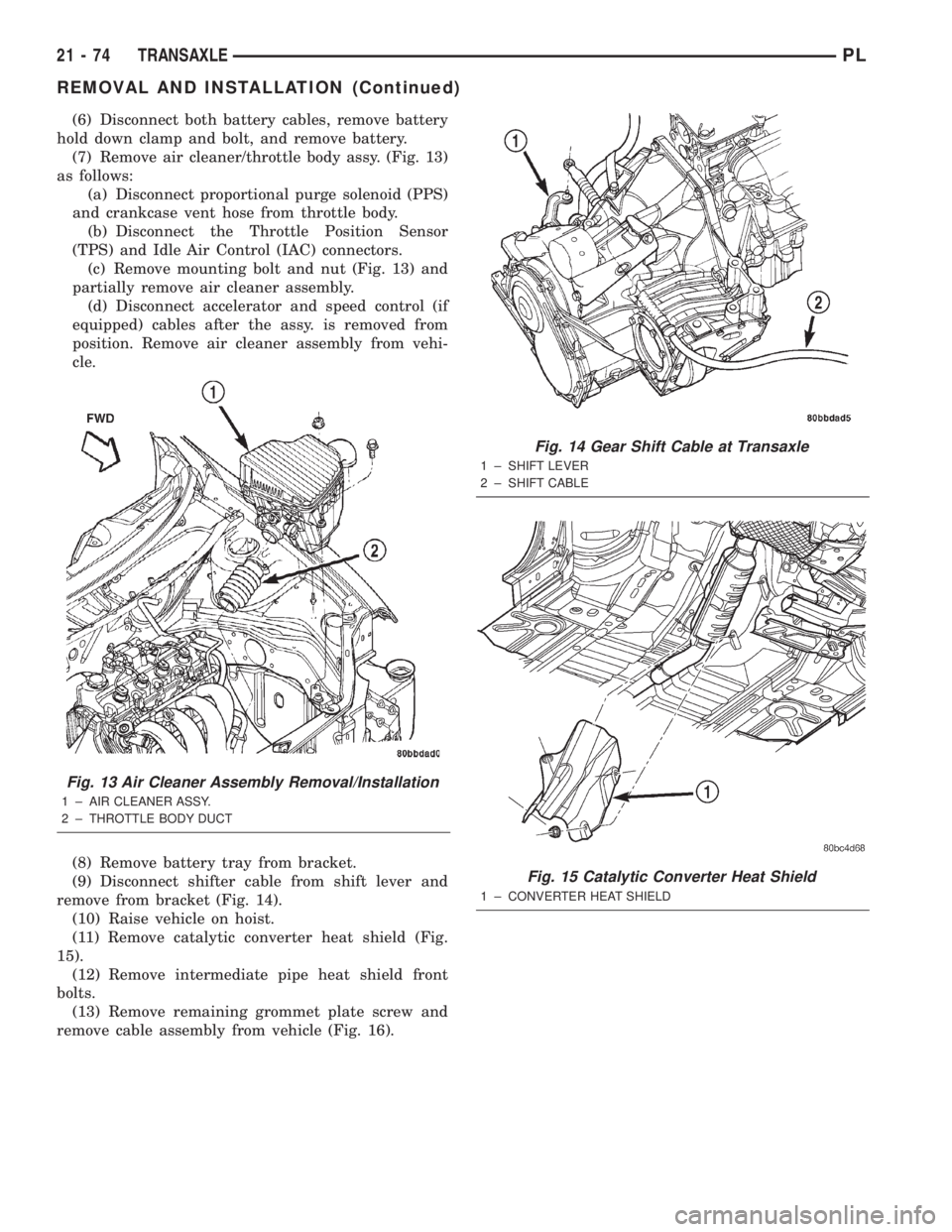

(7) Remove air cleaner/throttle body assy. (Fig. 13)

as follows:

(a) Disconnect proportional purge solenoid (PPS)

and crankcase vent hose from throttle body.

(b) Disconnect the Throttle Position Sensor

(TPS) and Idle Air Control (IAC) connectors.

(c) Remove mounting bolt and nut (Fig. 13) and

partially remove air cleaner assembly.

(d) Disconnect accelerator and speed control (if

equipped) cables after the assy. is removed from

position. Remove air cleaner assembly from vehi-

cle.

(8) Remove battery tray from bracket.

(9) Disconnect shifter cable from shift lever and

remove from bracket (Fig. 14).

(10) Raise vehicle on hoist.

(11) Remove catalytic converter heat shield (Fig.

15).

(12) Remove intermediate pipe heat shield front

bolts.

(13) Remove remaining grommet plate screw and

remove cable assembly from vehicle (Fig. 16).

Fig. 13 Air Cleaner Assembly Removal/Installation

1 ± AIR CLEANER ASSY.

2 ± THROTTLE BODY DUCT

Fig. 14 Gear Shift Cable at Transaxle

1 ± SHIFT LEVER

2 ± SHIFT CABLE

Fig. 15 Catalytic Converter Heat Shield

1 ± CONVERTER HEAT SHIELD

21 - 74 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 988 of 1285

INSTALLATION

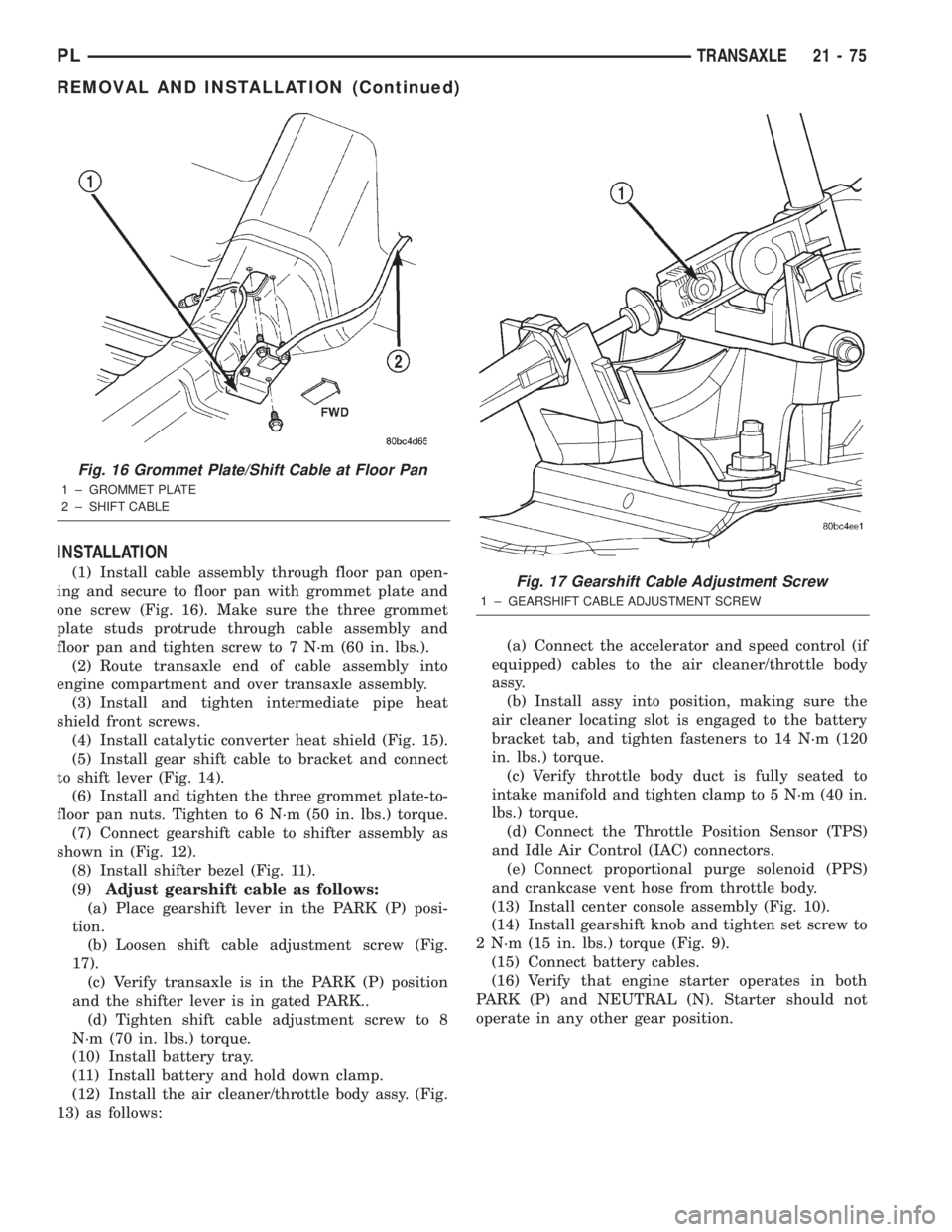

(1) Install cable assembly through floor pan open-

ing and secure to floor pan with grommet plate and

one screw (Fig. 16). Make sure the three grommet

plate studs protrude through cable assembly and

floor pan and tighten screw to 7 N´m (60 in. lbs.).

(2) Route transaxle end of cable assembly into

engine compartment and over transaxle assembly.

(3) Install and tighten intermediate pipe heat

shield front screws.

(4) Install catalytic converter heat shield (Fig. 15).

(5) Install gear shift cable to bracket and connect

to shift lever (Fig. 14).

(6) Install and tighten the three grommet plate-to-

floor pan nuts. Tighten to 6 N´m (50 in. lbs.) torque.

(7) Connect gearshift cable to shifter assembly as

shown in (Fig. 12).

(8) Install shifter bezel (Fig. 11).

(9)Adjust gearshift cable as follows:

(a) Place gearshift lever in the PARK (P) posi-

tion.

(b) Loosen shift cable adjustment screw (Fig.

17).

(c) Verify transaxle is in the PARK (P) position

and the shifter lever is in gated PARK..

(d) Tighten shift cable adjustment screw to 8

N´m (70 in. lbs.) torque.

(10) Install battery tray.

(11) Install battery and hold down clamp.

(12) Install the air cleaner/throttle body assy. (Fig.

13) as follows:(a) Connect the accelerator and speed control (if

equipped) cables to the air cleaner/throttle body

assy.

(b) Install assy into position, making sure the

air cleaner locating slot is engaged to the battery

bracket tab, and tighten fasteners to 14 N´m (120

in. lbs.) torque.

(c) Verify throttle body duct is fully seated to

intake manifold and tighten clamp to 5 N´m (40 in.

lbs.) torque.

(d) Connect the Throttle Position Sensor (TPS)

and Idle Air Control (IAC) connectors.

(e) Connect proportional purge solenoid (PPS)

and crankcase vent hose from throttle body.

(13) Install center console assembly (Fig. 10).

(14) Install gearshift knob and tighten set screw to

2 N´m (15 in. lbs.) torque (Fig. 9).

(15) Connect battery cables.

(16) Verify that engine starter operates in both

PARK (P) and NEUTRAL (N). Starter should not

operate in any other gear position.

Fig. 16 Grommet Plate/Shift Cable at Floor Pan

1 ± GROMMET PLATE

2 ± SHIFT CABLE

Fig. 17 Gearshift Cable Adjustment Screw

1 ± GEARSHIFT CABLE ADJUSTMENT SCREW

PLTRANSAXLE 21 - 75

REMOVAL AND INSTALLATION (Continued)

Page 989 of 1285

GEARSHIFT MECHANISM

REMOVAL

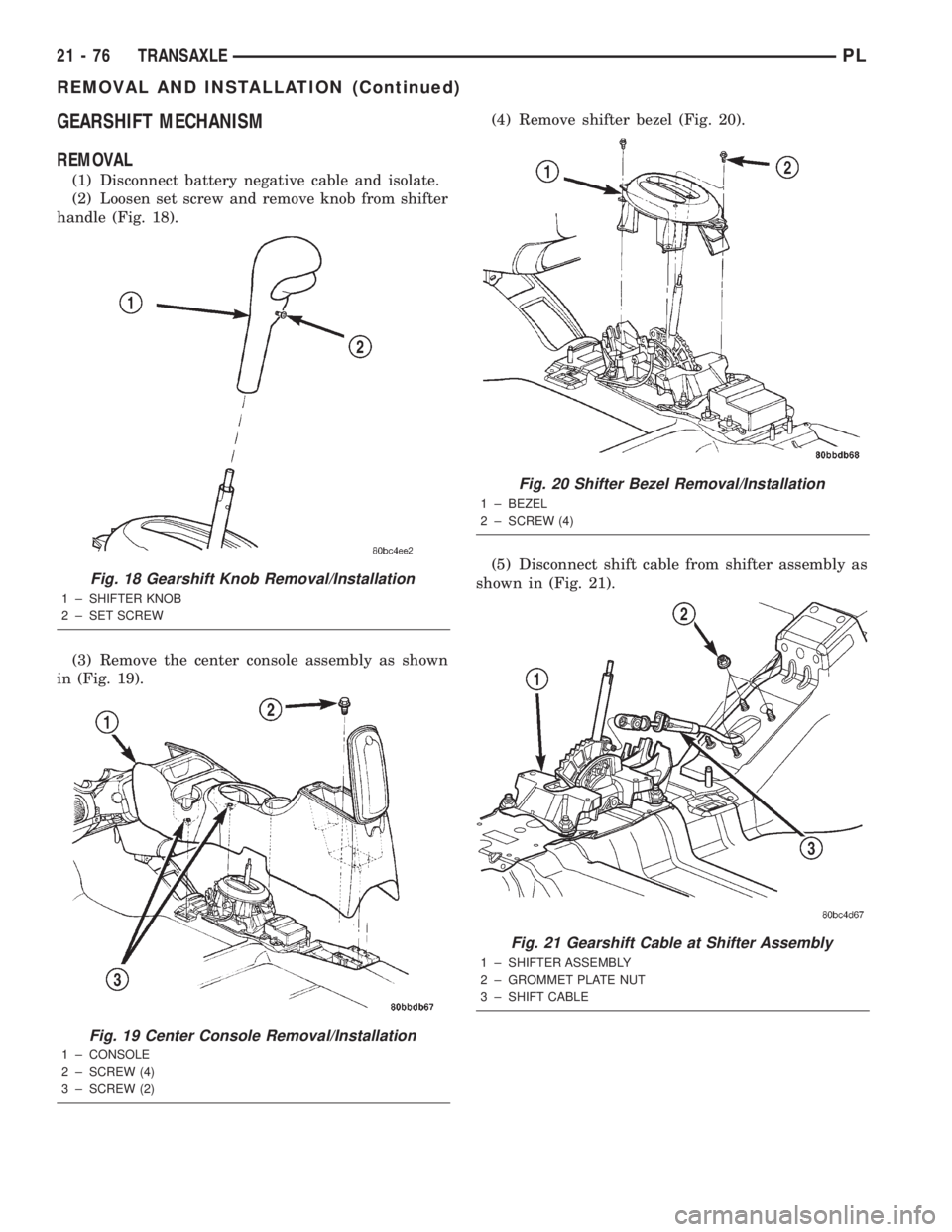

(1) Disconnect battery negative cable and isolate.

(2) Loosen set screw and remove knob from shifter

handle (Fig. 18).

(3) Remove the center console assembly as shown

in (Fig. 19).(4) Remove shifter bezel (Fig. 20).

(5) Disconnect shift cable from shifter assembly as

shown in (Fig. 21).

Fig. 18 Gearshift Knob Removal/Installation

1 ± SHIFTER KNOB

2 ± SET SCREW

Fig. 19 Center Console Removal/Installation

1 ± CONSOLE

2 ± SCREW (4)

3 ± SCREW (2)

Fig. 20 Shifter Bezel Removal/Installation

1 ± BEZEL

2 ± SCREW (4)

Fig. 21 Gearshift Cable at Shifter Assembly

1 ± SHIFTER ASSEMBLY

2 ± GROMMET PLATE NUT

3 ± SHIFT CABLE

21 - 76 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 991 of 1285

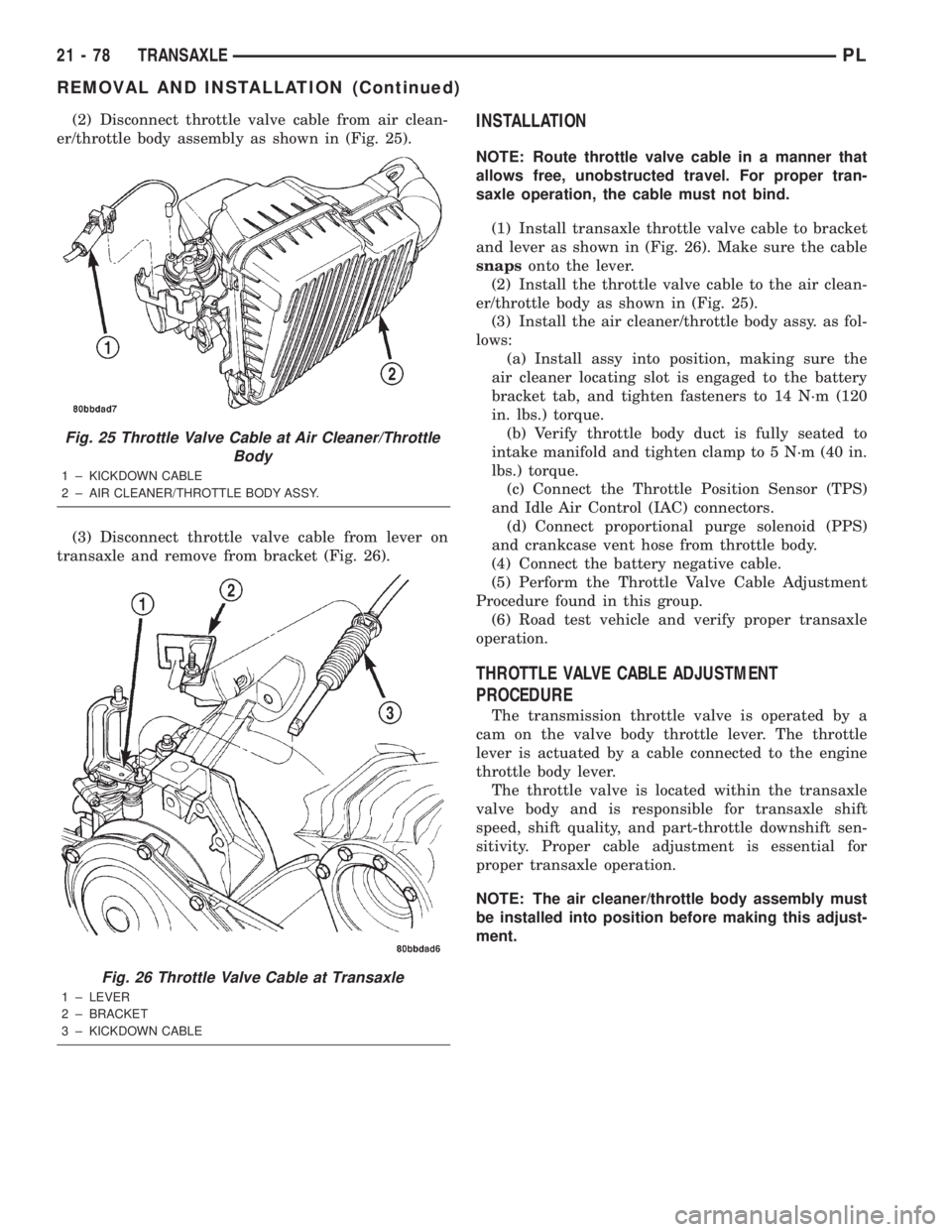

(2) Disconnect throttle valve cable from air clean-

er/throttle body assembly as shown in (Fig. 25).

(3) Disconnect throttle valve cable from lever on

transaxle and remove from bracket (Fig. 26).INSTALLATION

NOTE: Route throttle valve cable in a manner that

allows free, unobstructed travel. For proper tran-

saxle operation, the cable must not bind.

(1) Install transaxle throttle valve cable to bracket

and lever as shown in (Fig. 26). Make sure the cable

snapsonto the lever.

(2) Install the throttle valve cable to the air clean-

er/throttle body as shown in (Fig. 25).

(3) Install the air cleaner/throttle body assy. as fol-

lows:

(a) Install assy into position, making sure the

air cleaner locating slot is engaged to the battery

bracket tab, and tighten fasteners to 14 N´m (120

in. lbs.) torque.

(b) Verify throttle body duct is fully seated to

intake manifold and tighten clamp to 5 N´m (40 in.

lbs.) torque.

(c) Connect the Throttle Position Sensor (TPS)

and Idle Air Control (IAC) connectors.

(d) Connect proportional purge solenoid (PPS)

and crankcase vent hose from throttle body.

(4) Connect the battery negative cable.

(5) Perform the Throttle Valve Cable Adjustment

Procedure found in this group.

(6) Road test vehicle and verify proper transaxle

operation.

THROTTLE VALVE CABLE ADJUSTMENT

PROCEDURE

The transmission throttle valve is operated by a

cam on the valve body throttle lever. The throttle

lever is actuated by a cable connected to the engine

throttle body lever.

The throttle valve is located within the transaxle

valve body and is responsible for transaxle shift

speed, shift quality, and part-throttle downshift sen-

sitivity. Proper cable adjustment is essential for

proper transaxle operation.

NOTE: The air cleaner/throttle body assembly must

be installed into position before making this adjust-

ment.

Fig. 25 Throttle Valve Cable at Air Cleaner/Throttle

Body

1 ± KICKDOWN CABLE

2 ± AIR CLEANER/THROTTLE BODY ASSY.

Fig. 26 Throttle Valve Cable at Transaxle

1 ± LEVER

2 ± BRACKET

3 ± KICKDOWN CABLE

21 - 78 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 992 of 1285

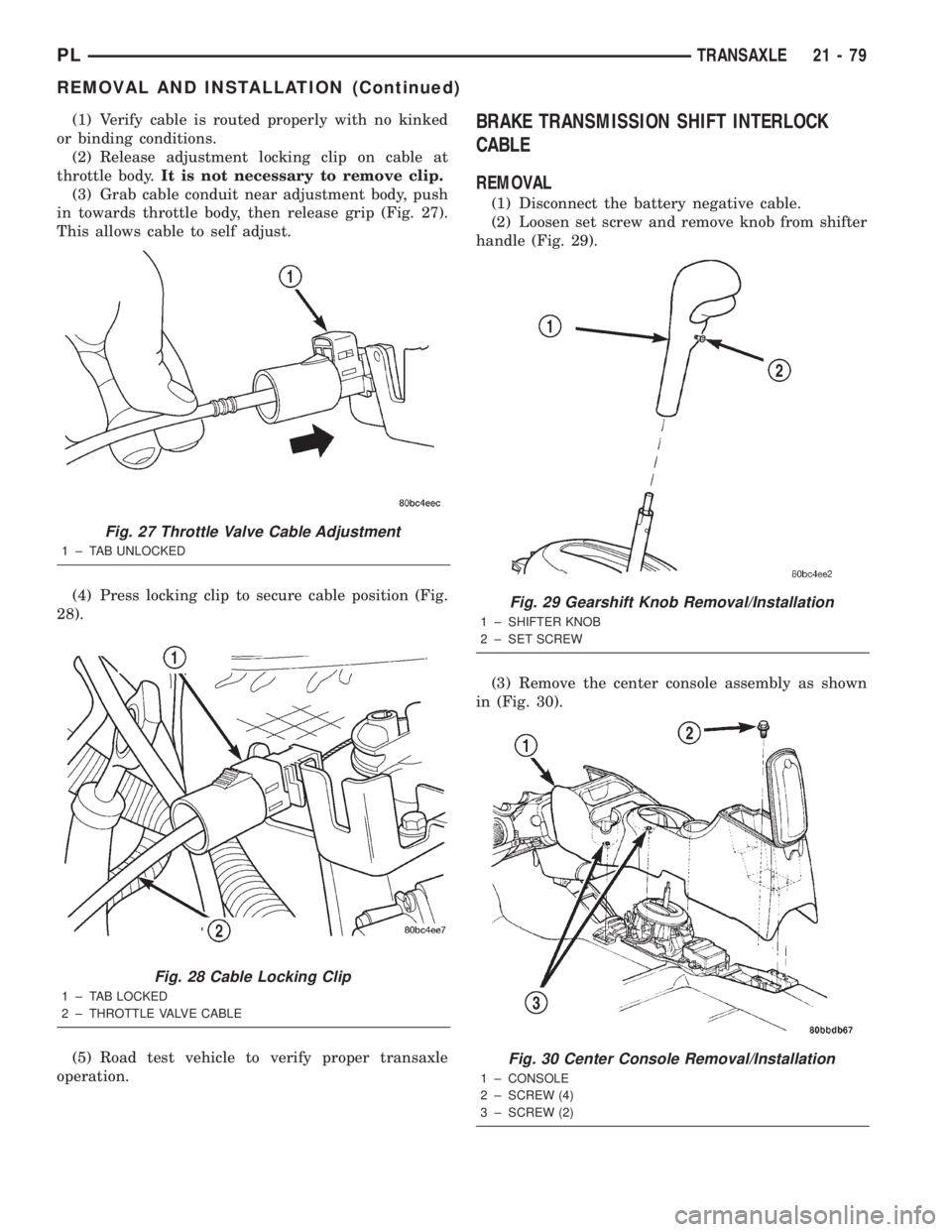

(1) Verify cable is routed properly with no kinked

or binding conditions.

(2) Release adjustment locking clip on cable at

throttle body.It is not necessary to remove clip.

(3) Grab cable conduit near adjustment body, push

in towards throttle body, then release grip (Fig. 27).

This allows cable to self adjust.

(4) Press locking clip to secure cable position (Fig.

28).

(5) Road test vehicle to verify proper transaxle

operation.BRAKE TRANSMISSION SHIFT INTERLOCK

CABLE

REMOVAL

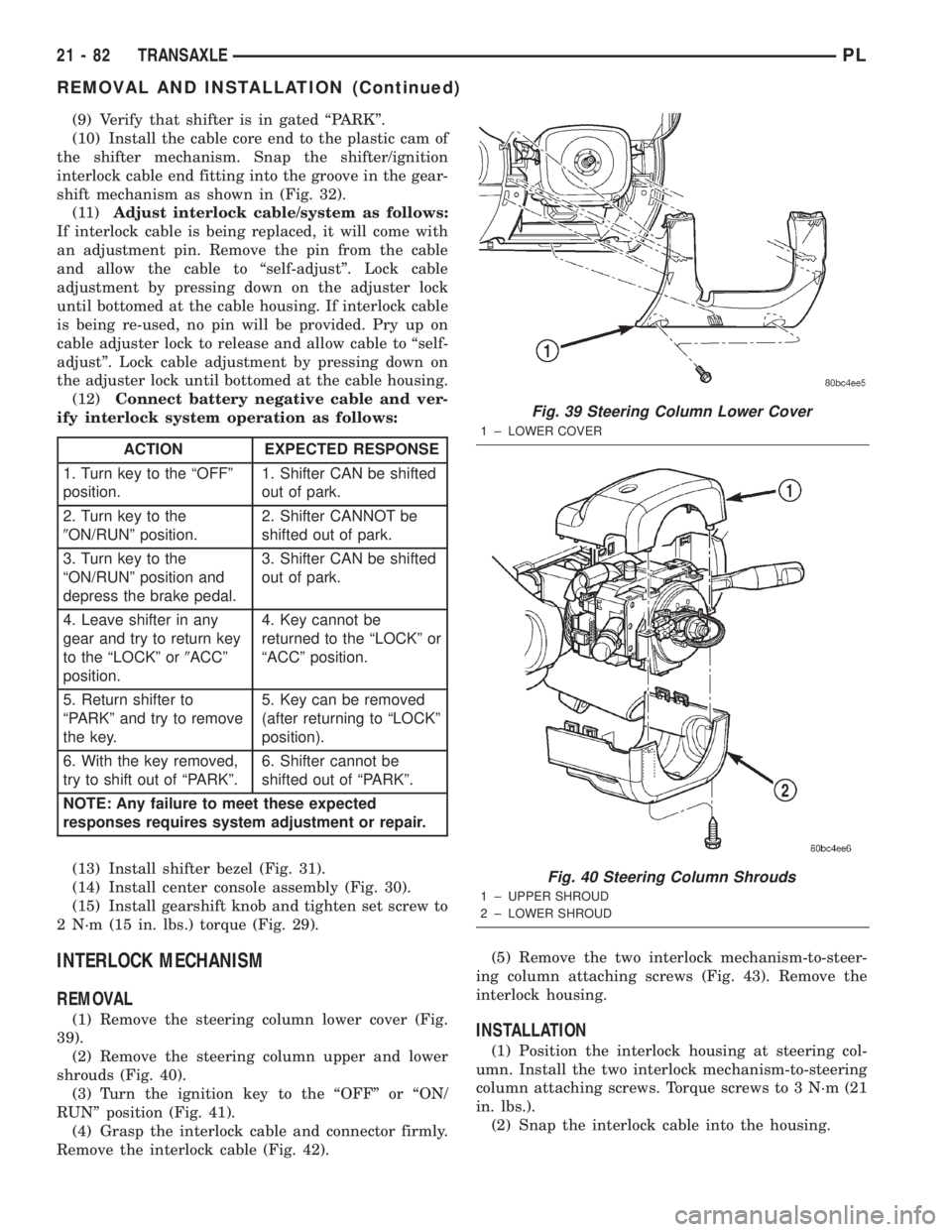

(1) Disconnect the battery negative cable.

(2) Loosen set screw and remove knob from shifter

handle (Fig. 29).

(3) Remove the center console assembly as shown

in (Fig. 30).

Fig. 27 Throttle Valve Cable Adjustment

1 ± TAB UNLOCKED

Fig. 28 Cable Locking Clip

1 ± TAB LOCKED

2 ± THROTTLE VALVE CABLE

Fig. 29 Gearshift Knob Removal/Installation

1 ± SHIFTER KNOB

2 ± SET SCREW

Fig. 30 Center Console Removal/Installation

1 ± CONSOLE

2 ± SCREW (4)

3 ± SCREW (2)

PLTRANSAXLE 21 - 79

REMOVAL AND INSTALLATION (Continued)

Page 995 of 1285

(9) Verify that shifter is in gated ªPARKº.

(10) Install the cable core end to the plastic cam of

the shifter mechanism. Snap the shifter/ignition

interlock cable end fitting into the groove in the gear-

shift mechanism as shown in (Fig. 32).

(11)Adjust interlock cable/system as follows:

If interlock cable is being replaced, it will come with

an adjustment pin. Remove the pin from the cable

and allow the cable to ªself-adjustº. Lock cable

adjustment by pressing down on the adjuster lock

until bottomed at the cable housing. If interlock cable

is being re-used, no pin will be provided. Pry up on

cable adjuster lock to release and allow cable to ªself-

adjustº. Lock cable adjustment by pressing down on

the adjuster lock until bottomed at the cable housing.

(12)Connect battery negative cable and ver-

ify interlock system operation as follows:

(13) Install shifter bezel (Fig. 31).

(14) Install center console assembly (Fig. 30).

(15) Install gearshift knob and tighten set screw to

2 N´m (15 in. lbs.) torque (Fig. 29).

INTERLOCK MECHANISM

REMOVAL

(1) Remove the steering column lower cover (Fig.

39).

(2) Remove the steering column upper and lower

shrouds (Fig. 40).

(3) Turn the ignition key to the ªOFFº or ªON/

RUNº position (Fig. 41).

(4) Grasp the interlock cable and connector firmly.

Remove the interlock cable (Fig. 42).(5) Remove the two interlock mechanism-to-steer-

ing column attaching screws (Fig. 43). Remove the

interlock housing.INSTALLATION

(1) Position the interlock housing at steering col-

umn. Install the two interlock mechanism-to-steering

column attaching screws. Torque screws to 3 N´m (21

in. lbs.).

(2) Snap the interlock cable into the housing.

ACTION EXPECTED RESPONSE

1. Turn key to the ªOFFº

position.1. Shifter CAN be shifted

out of park.

2. Turn key to the

9ON/RUNº position.2. Shifter CANNOT be

shifted out of park.

3. Turn key to the

ªON/RUNº position and

depress the brake pedal.3. Shifter CAN be shifted

out of park.

4. Leave shifter in any

gear and try to return key

to the ªLOCKº or9ACCº

position.4. Key cannot be

returned to the ªLOCKº or

ªACCº position.

5. Return shifter to

ªPARKº and try to remove

the key.5. Key can be removed

(after returning to ªLOCKº

position).

6. With the key removed,

try to shift out of ªPARKº.6. Shifter cannot be

shifted out of ªPARKº.

NOTE: Any failure to meet these expected

responses requires system adjustment or repair.

Fig. 39 Steering Column Lower Cover

1 ± LOWER COVER

Fig. 40 Steering Column Shrouds

1 ± UPPER SHROUD

2 ± LOWER SHROUD

21 - 82 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 997 of 1285

PARK/NEUTRAL STARTING AND BACK-UP

LAMP SWITCH

TEST

The park/neutral starting switch is the center ter-

minal of the three terminal switch. It provides

ground for the starter solenoid circuit through the

selector lever in PARK and NEUTRAL positions only.

(1) To test switch, remove wiring connector from

switch and test for continuity between center pin of

switch and transaxle case. Continuity should exist

only when transaxle is in PARK or NEUTRAL.

(2) Check gearshift cable adjustment before replac-

ing a switch that tests bad.

REMOVAL

(1) Unscrew switch from transaxle case allowing

fluid to drain into a container. Move selector lever to

PARK, then to NEUTRAL position, and inspect to see

the switch operating lever fingers are centered in

switch opening.

INSTALLATION

(1) Screw the switch with a new seal into tran-

saxle case and tighten to 33 N´m (24 ft. lbs.). Retest

switch with the test lamp.

(2) Add fluid to transaxle to bring up to proper

level.

(3) The back-up lamp switch circuit is through the

two outside terminals of the three terminal switch.

(4) To test switch, remove wiring connector from

switch and test for continuity between the two out-

side pins.

(5) Continuity should exist only with transaxle in

REVERSE position.

(6) No continuity should exist from either pin to

the case.

TRANSAXLE AND TORQUE CONVERTER

REMOVAL

(1) Raise hood.

(2) Disconnect both battery cables, remove battery

hold down clamp and bolt, and remove battery.

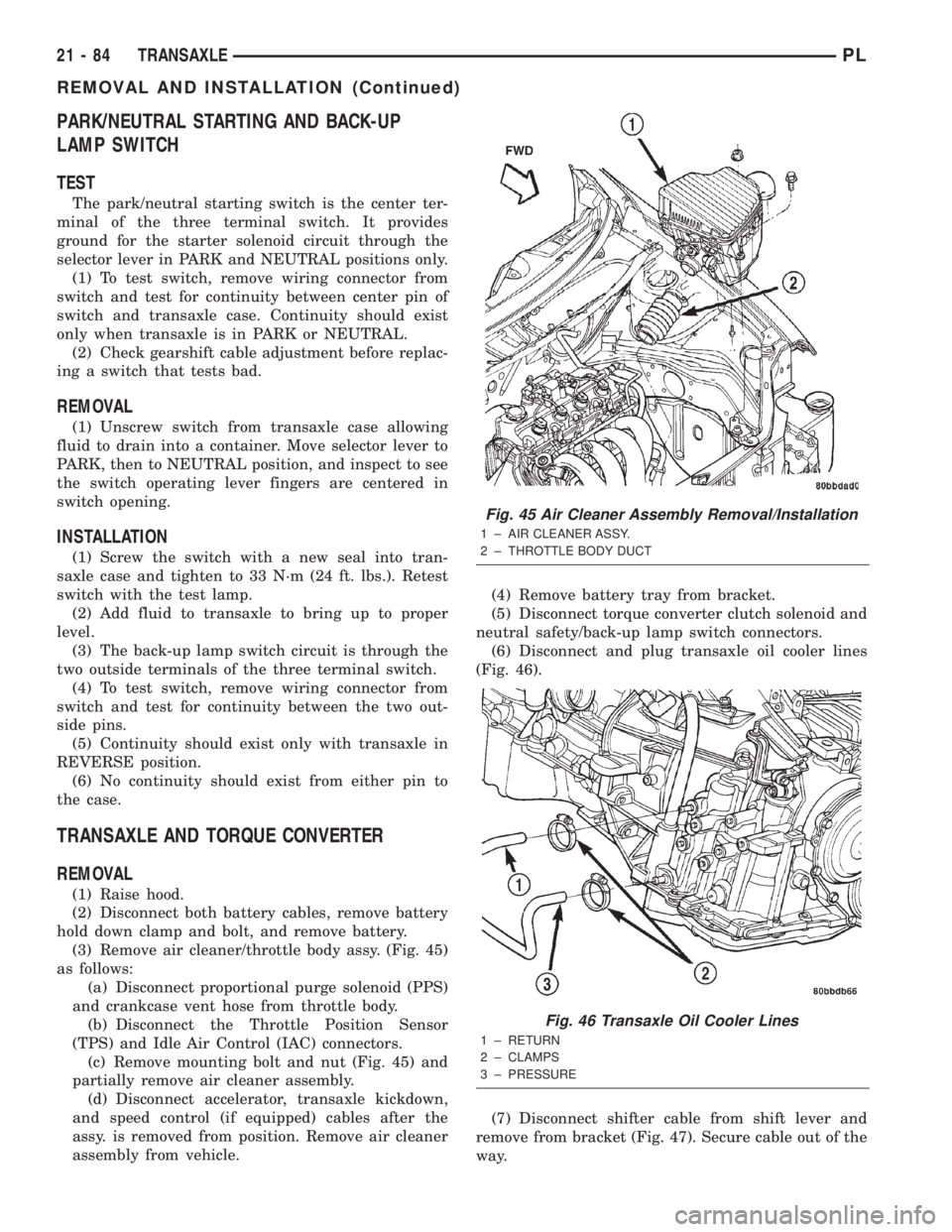

(3) Remove air cleaner/throttle body assy. (Fig. 45)

as follows:

(a) Disconnect proportional purge solenoid (PPS)

and crankcase vent hose from throttle body.

(b) Disconnect the Throttle Position Sensor

(TPS) and Idle Air Control (IAC) connectors.

(c) Remove mounting bolt and nut (Fig. 45) and

partially remove air cleaner assembly.

(d) Disconnect accelerator, transaxle kickdown,

and speed control (if equipped) cables after the

assy. is removed from position. Remove air cleaner

assembly from vehicle.(4) Remove battery tray from bracket.

(5) Disconnect torque converter clutch solenoid and

neutral safety/back-up lamp switch connectors.

(6) Disconnect and plug transaxle oil cooler lines

(Fig. 46).

(7) Disconnect shifter cable from shift lever and

remove from bracket (Fig. 47). Secure cable out of the

way.

Fig. 45 Air Cleaner Assembly Removal/Installation

1 ± AIR CLEANER ASSY.

2 ± THROTTLE BODY DUCT

Fig. 46 Transaxle Oil Cooler Lines

1 ± RETURN

2 ± CLAMPS

3 ± PRESSURE

21 - 84 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 1001 of 1285

(c) Tighten the collar-to-transaxle bolts to 108

N´m (80 ft. lbs.) torque.

(d) Final torque the collar-to-oil pan bolts to 54

N´m (40 ft. lbs.) torque.

(11) Install both front axle driveshafts. Refer to

Group 3, Differential and Driveline for the correct

procedures.

(12) Connect vehicle speed sensor connector (Fig.

50).

(13) Install right lateral bending brace and tighten

bolts to 81 N´m (60 ft. lbs.) torque.

(14) Lower vehicle.

(15) Connect transaxle cooler lines and tighten

clamps (Fig. 46).

(16) Connect torque converter clutch solenoid and

neutral safety/back-up lamp switch connectors.

(17) Install transaxle dipstick tube.

(18) Install gear shift cable to bracket and connect

to shift lever (Fig. 47).

(19) Install transaxle kickdown cable to bracket

and lever as shown in (Fig. 48).

(20) Install battery lower tray and battery, and

tighten battery hold down clamp to secure battery.

(21) Install the air cleaner/throttle body assy. as

follows:

(a) Connect the accelerator, transaxle kickdown,

and speed control (if equipped) cables to the air

cleaner/throttle body assy.

(b) Install assy into position and tighten fasten-

ers to 14 N´m (120 in. lbs.) torque.

(c) Connect the Throttle Position Sensor (TPS)

and Idle Air Control (IAC) connectors.

(d) Connect proportional purge solenoid (PPS)

and crankcase vent hose from throttle body.

(22) Fill transaxle with a suitable amount of

ATF+4.

(23) Road test vehicle.

(24) Check for leaks, inspect fluid level, and adjust

as necessary.

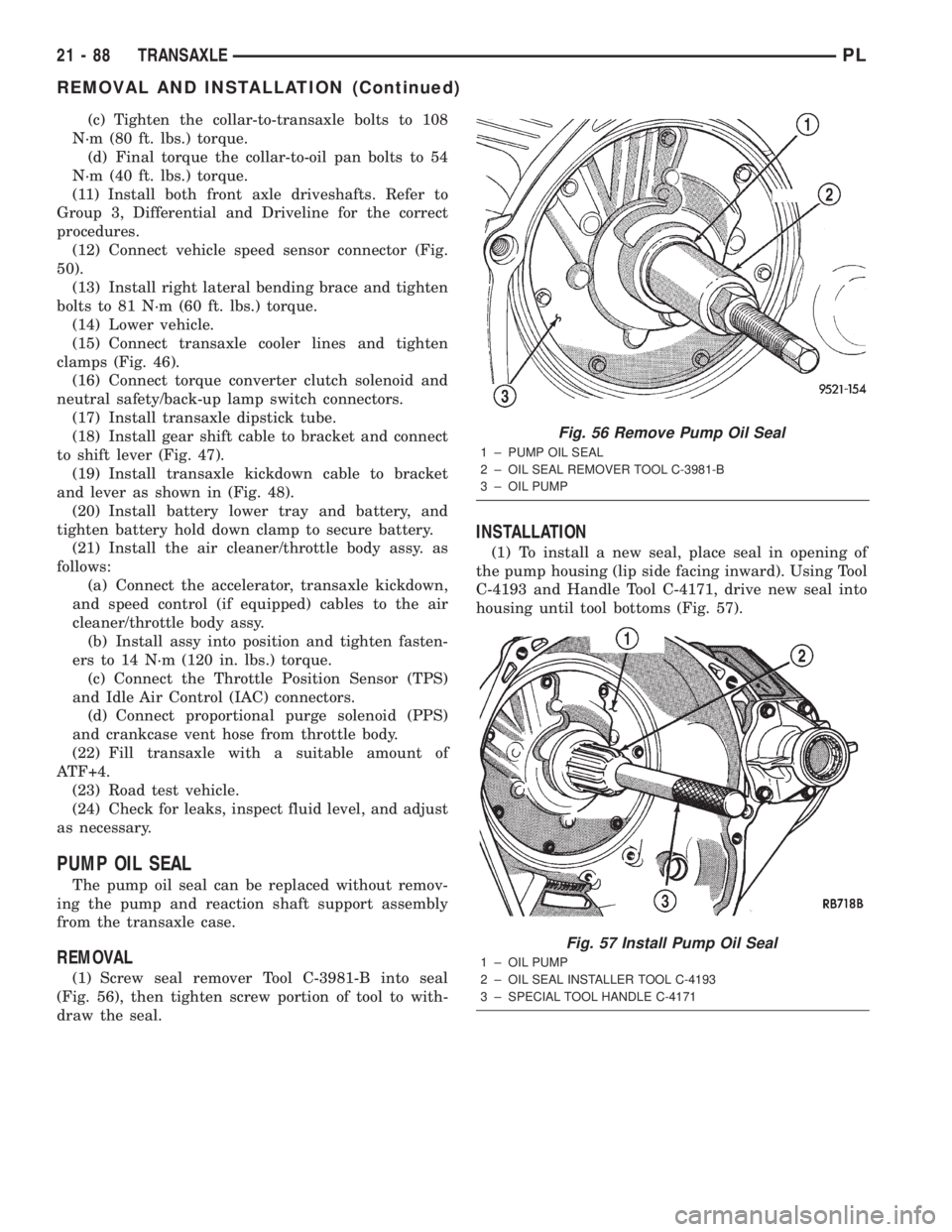

PUMP OIL SEAL

The pump oil seal can be replaced without remov-

ing the pump and reaction shaft support assembly

from the transaxle case.

REMOVAL

(1) Screw seal remover Tool C-3981-B into seal

(Fig. 56), then tighten screw portion of tool to with-

draw the seal.

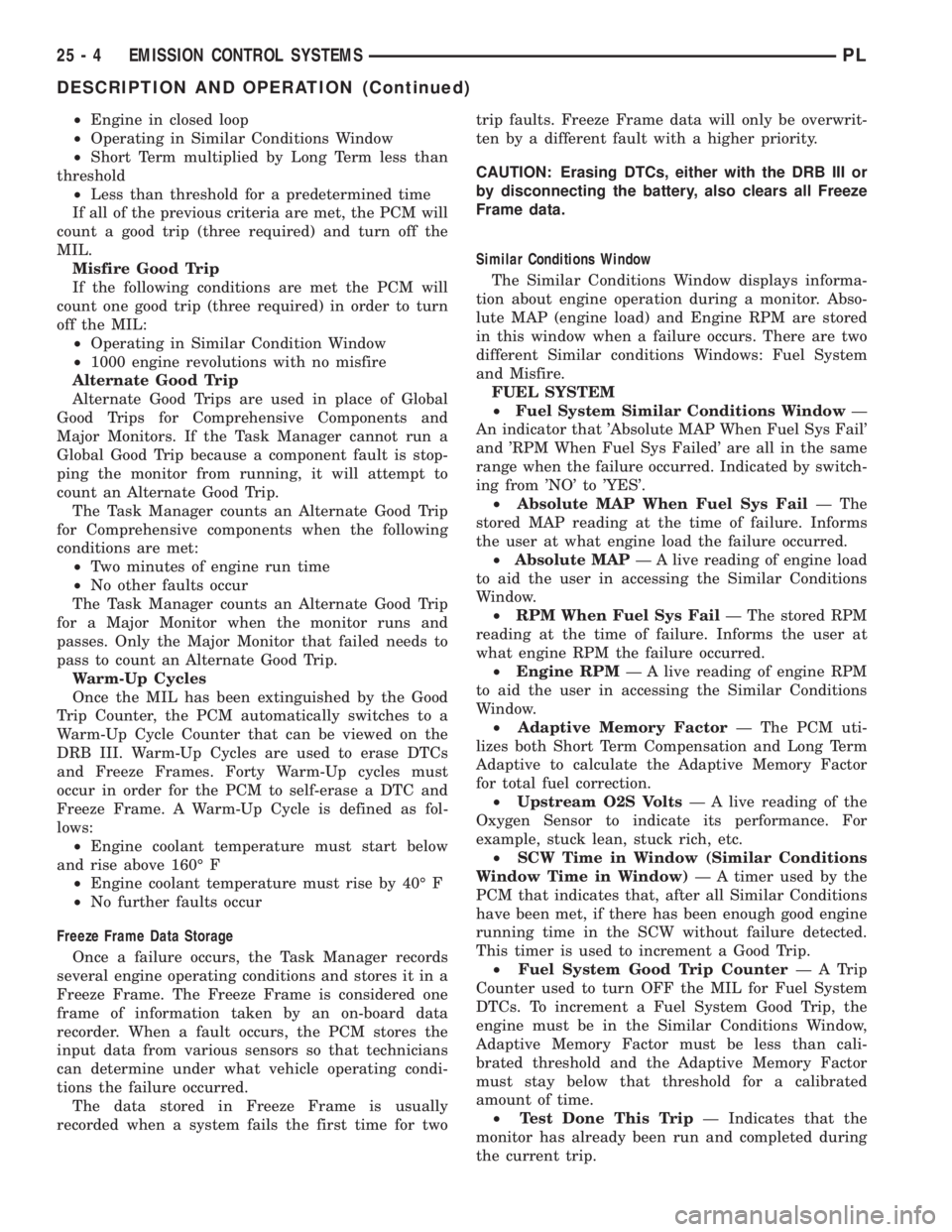

INSTALLATION

(1) To install a new seal, place seal in opening of

the pump housing (lip side facing inward). Using Tool

C-4193 and Handle Tool C-4171, drive new seal into

housing until tool bottoms (Fig. 57).

Fig. 56 Remove Pump Oil Seal

1 ± PUMP OIL SEAL

2 ± OIL SEAL REMOVER TOOL C-3981-B

3 ± OIL PUMP

Fig. 57 Install Pump Oil Seal

1 ± OIL PUMP

2 ± OIL SEAL INSTALLER TOOL C-4193

3 ± SPECIAL TOOL HANDLE C-4171

21 - 88 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 1091 of 1285

²Engine in closed loop

²Operating in Similar Conditions Window

²Short Term multiplied by Long Term less than

threshold

²Less than threshold for a predetermined time

If all of the previous criteria are met, the PCM will

count a good trip (three required) and turn off the

MIL.

Misfire Good Trip

If the following conditions are met the PCM will

count one good trip (three required) in order to turn

off the MIL:

²Operating in Similar Condition Window

²1000 engine revolutions with no misfire

Alternate Good Trip

Alternate Good Trips are used in place of Global

Good Trips for Comprehensive Components and

Major Monitors. If the Task Manager cannot run a

Global Good Trip because a component fault is stop-

ping the monitor from running, it will attempt to

count an Alternate Good Trip.

The Task Manager counts an Alternate Good Trip

for Comprehensive components when the following

conditions are met:

²Two minutes of engine run time

²No other faults occur

The Task Manager counts an Alternate Good Trip

for a Major Monitor when the monitor runs and

passes. Only the Major Monitor that failed needs to

pass to count an Alternate Good Trip.

Warm-Up Cycles

Once the MIL has been extinguished by the Good

Trip Counter, the PCM automatically switches to a

Warm-Up Cycle Counter that can be viewed on the

DRB III. Warm-Up Cycles are used to erase DTCs

and Freeze Frames. Forty Warm-Up cycles must

occur in order for the PCM to self-erase a DTC and

Freeze Frame. A Warm-Up Cycle is defined as fol-

lows:

²Engine coolant temperature must start below

and rise above 160É F

²Engine coolant temperature must rise by 40É F

²No further faults occur

Freeze Frame Data Storage

Once a failure occurs, the Task Manager records

several engine operating conditions and stores it in a

Freeze Frame. The Freeze Frame is considered one

frame of information taken by an on-board data

recorder. When a fault occurs, the PCM stores the

input data from various sensors so that technicians

can determine under what vehicle operating condi-

tions the failure occurred.

The data stored in Freeze Frame is usually

recorded when a system fails the first time for twotrip faults. Freeze Frame data will only be overwrit-

ten by a different fault with a higher priority.

CAUTION: Erasing DTCs, either with the DRB III or

by disconnecting the battery, also clears all Freeze

Frame data.

Similar Conditions Window

The Similar Conditions Window displays informa-

tion about engine operation during a monitor. Abso-

lute MAP (engine load) and Engine RPM are stored

in this window when a failure occurs. There are two

different Similar conditions Windows: Fuel System

and Misfire.

FUEL SYSTEM

²Fuel System Similar Conditions WindowÐ

An indicator that 'Absolute MAP When Fuel Sys Fail'

and 'RPM When Fuel Sys Failed' are all in the same

range when the failure occurred. Indicated by switch-

ing from 'NO' to 'YES'.

²Absolute MAP When Fuel Sys FailÐ The

stored MAP reading at the time of failure. Informs

the user at what engine load the failure occurred.

²Absolute MAPÐ A live reading of engine load

to aid the user in accessing the Similar Conditions

Window.

²RPM When Fuel Sys FailÐ The stored RPM

reading at the time of failure. Informs the user at

what engine RPM the failure occurred.

²Engine RPMÐ A live reading of engine RPM

to aid the user in accessing the Similar Conditions

Window.

²Adaptive Memory FactorÐ The PCM uti-

lizes both Short Term Compensation and Long Term

Adaptive to calculate the Adaptive Memory Factor

for total fuel correction.

²Upstream O2S VoltsÐ A live reading of the

Oxygen Sensor to indicate its performance. For

example, stuck lean, stuck rich, etc.

²SCW Time in Window (Similar Conditions

Window Time in Window)Ð A timer used by the

PCM that indicates that, after all Similar Conditions

have been met, if there has been enough good engine

running time in the SCW without failure detected.

This timer is used to increment a Good Trip.

²Fuel System Good Trip CounterÐATrip

Counter used to turn OFF the MIL for Fuel System

DTCs. To increment a Fuel System Good Trip, the

engine must be in the Similar Conditions Window,

Adaptive Memory Factor must be less than cali-

brated threshold and the Adaptive Memory Factor

must stay below that threshold for a calibrated

amount of time.

²Test Done This TripÐ Indicates that the

monitor has already been run and completed during

the current trip.

25 - 4 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)