clutch DODGE NEON 2000 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 175 of 1285

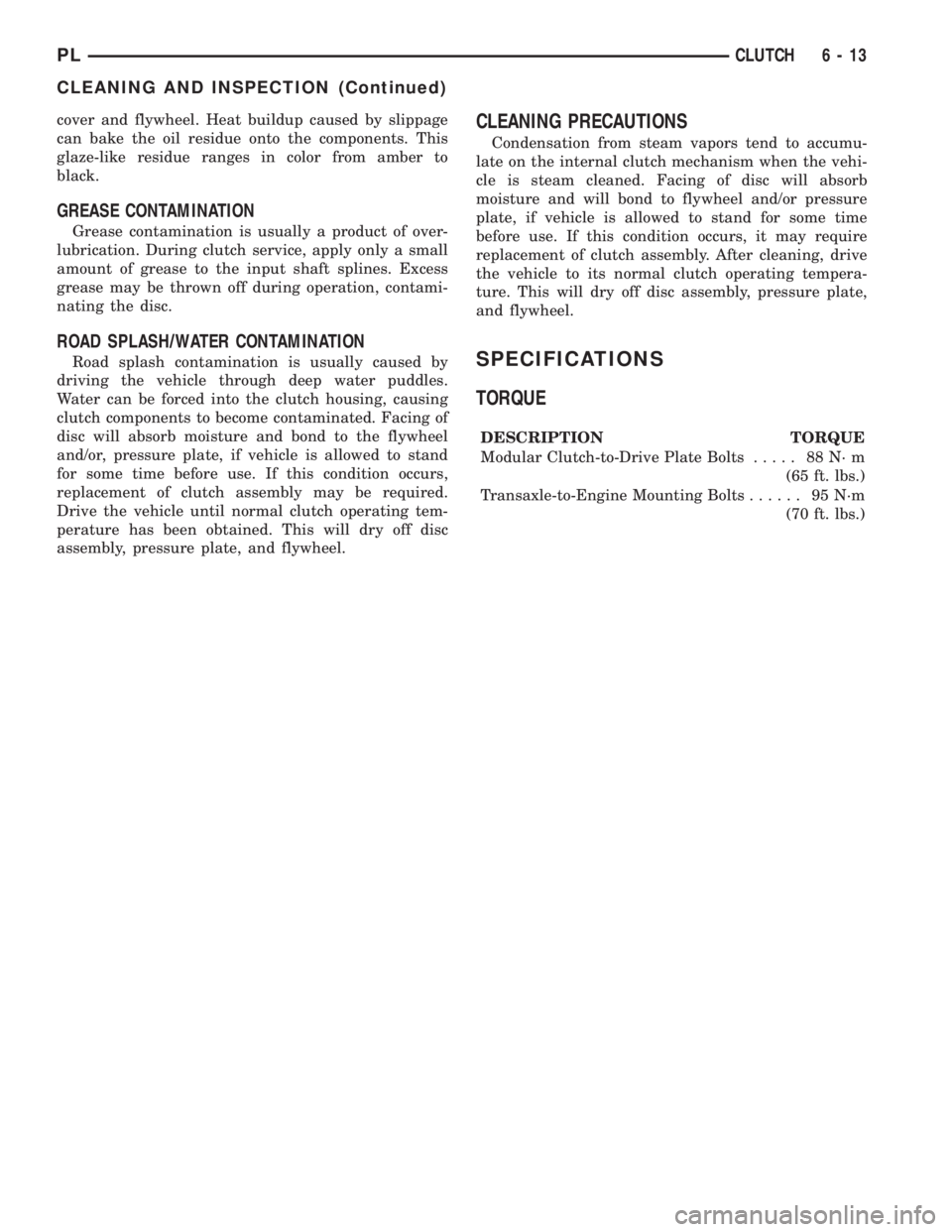

(24) Obtain a helper to assist in holding transaxle

while removing transaxle-to-engine mounting bolts

(Fig. 18).

(25) Remove transaxle from vehicle (Fig. 18).

(26) Remove modular clutch assembly from tran-

saxle input shaft.

INSTALLATION

(1) Inspect clutch release bearing and lever for

excessive wear and replace as necessary.

(2) Install clutch module onto input shaft. Install

transaxle into position.

(3) Install transaxle-to-engine mounting bolts (Fig.

18) and tighten to 95 N´m (70 ft. lbs.) torque.

(4) Raise engine and transaxle with screw jack

until through hole in upper mount aligns with hole

in mount bracket. Install mount bolt and tighten to

108 N´m (70 ft. lbs.) torque (Fig. 17).

(5) Remove screwjack.

(6) Install NEW drive plate-to-clutch module bolts

and progressively tighten all bolts in a criss-cross

pattern until the modular clutch assembly seats

against the drive plate. Final torque the bolts to 88

N´m (65 ft. lbs.) torque.

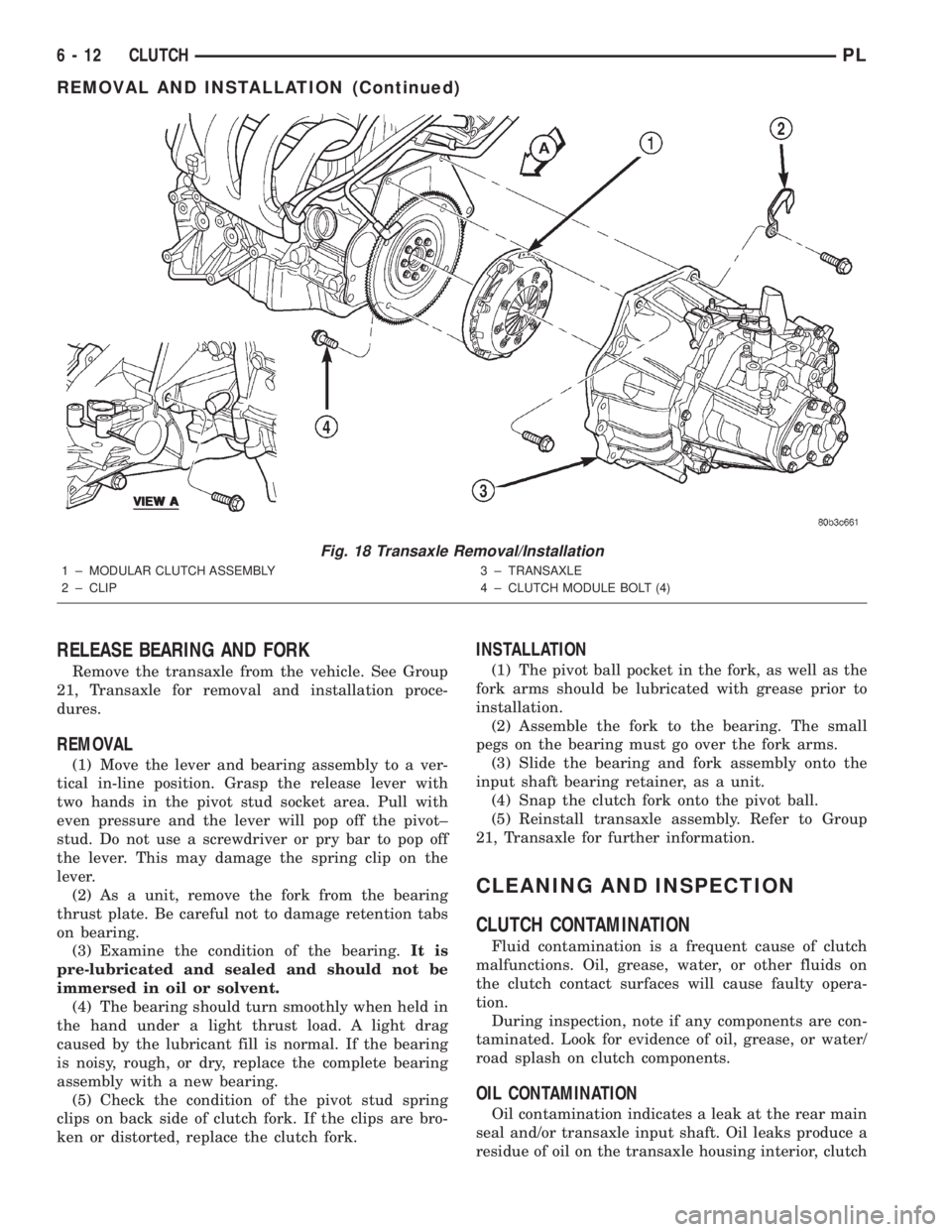

(7) Install starter motor and tighten bolts to 54

N´m (40 ft. lbs.) torque. Make sure to fasten ground

cable to upper starter bolt as shown in (Fig. 16).

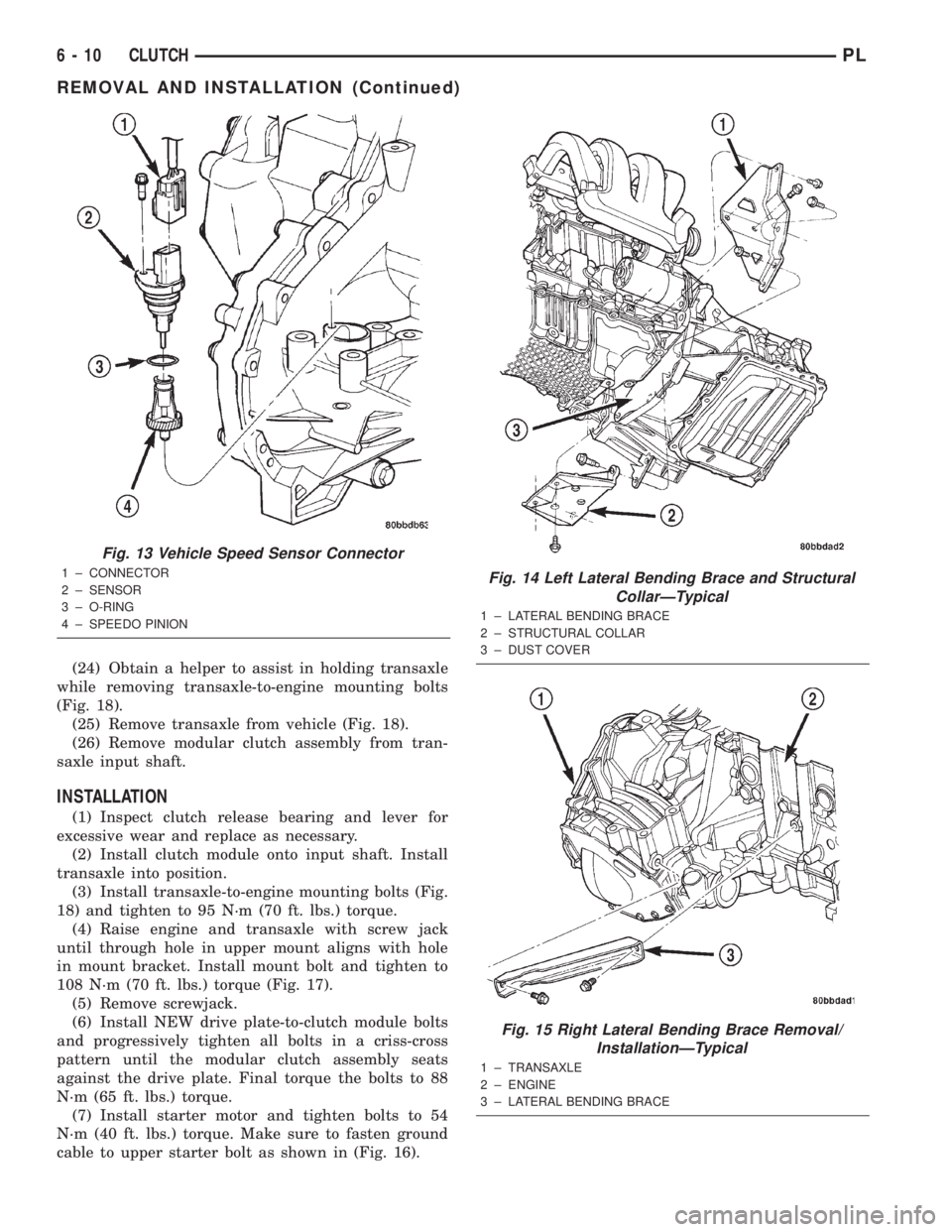

Fig. 13 Vehicle Speed Sensor Connector

1 ± CONNECTOR

2 ± SENSOR

3 ± O-RING

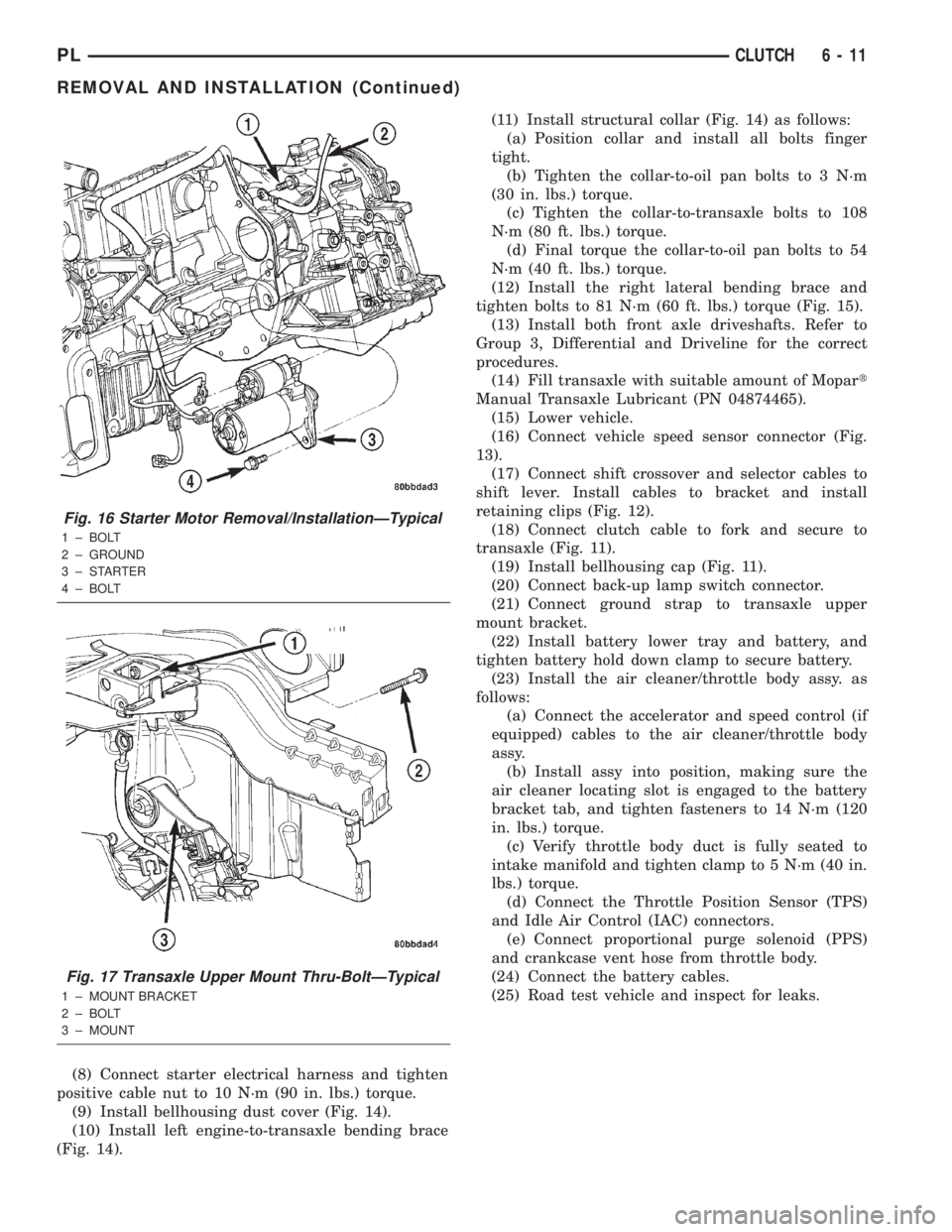

4 ± SPEEDO PINIONFig. 14 Left Lateral Bending Brace and Structural

CollarÐTypical

1 ± LATERAL BENDING BRACE

2 ± STRUCTURAL COLLAR

3 ± DUST COVER

Fig. 15 Right Lateral Bending Brace Removal/

InstallationÐTypical

1 ± TRANSAXLE

2 ± ENGINE

3 ± LATERAL BENDING BRACE

6 - 10 CLUTCHPL

REMOVAL AND INSTALLATION (Continued)

Page 176 of 1285

(8) Connect starter electrical harness and tighten

positive cable nut to 10 N´m (90 in. lbs.) torque.

(9) Install bellhousing dust cover (Fig. 14).

(10) Install left engine-to-transaxle bending brace

(Fig. 14).(11) Install structural collar (Fig. 14) as follows:

(a) Position collar and install all bolts finger

tight.

(b) Tighten the collar-to-oil pan bolts to 3 N´m

(30 in. lbs.) torque.

(c) Tighten the collar-to-transaxle bolts to 108

N´m (80 ft. lbs.) torque.

(d) Final torque the collar-to-oil pan bolts to 54

N´m (40 ft. lbs.) torque.

(12) Install the right lateral bending brace and

tighten bolts to 81 N´m (60 ft. lbs.) torque (Fig. 15).

(13) Install both front axle driveshafts. Refer to

Group 3, Differential and Driveline for the correct

procedures.

(14) Fill transaxle with suitable amount of Mopart

Manual Transaxle Lubricant (PN 04874465).

(15) Lower vehicle.

(16) Connect vehicle speed sensor connector (Fig.

13).

(17) Connect shift crossover and selector cables to

shift lever. Install cables to bracket and install

retaining clips (Fig. 12).

(18) Connect clutch cable to fork and secure to

transaxle (Fig. 11).

(19) Install bellhousing cap (Fig. 11).

(20) Connect back-up lamp switch connector.

(21) Connect ground strap to transaxle upper

mount bracket.

(22) Install battery lower tray and battery, and

tighten battery hold down clamp to secure battery.

(23) Install the air cleaner/throttle body assy. as

follows:

(a) Connect the accelerator and speed control (if

equipped) cables to the air cleaner/throttle body

assy.

(b) Install assy into position, making sure the

air cleaner locating slot is engaged to the battery

bracket tab, and tighten fasteners to 14 N´m (120

in. lbs.) torque.

(c) Verify throttle body duct is fully seated to

intake manifold and tighten clamp to 5 N´m (40 in.

lbs.) torque.

(d) Connect the Throttle Position Sensor (TPS)

and Idle Air Control (IAC) connectors.

(e) Connect proportional purge solenoid (PPS)

and crankcase vent hose from throttle body.

(24) Connect the battery cables.

(25) Road test vehicle and inspect for leaks.

Fig. 16 Starter Motor Removal/InstallationÐTypical

1 ± BOLT

2 ± GROUND

3±STARTER

4 ± BOLT

Fig. 17 Transaxle Upper Mount Thru-BoltÐTypical

1 ± MOUNT BRACKET

2 ± BOLT

3 ± MOUNT

PLCLUTCH 6 - 11

REMOVAL AND INSTALLATION (Continued)

Page 177 of 1285

RELEASE BEARING AND FORK

Remove the transaxle from the vehicle. See Group

21, Transaxle for removal and installation proce-

dures.

REMOVAL

(1) Move the lever and bearing assembly to a ver-

tical in-line position. Grasp the release lever with

two hands in the pivot stud socket area. Pull with

even pressure and the lever will pop off the pivot±

stud. Do not use a screwdriver or pry bar to pop off

the lever. This may damage the spring clip on the

lever.

(2) As a unit, remove the fork from the bearing

thrust plate. Be careful not to damage retention tabs

on bearing.

(3) Examine the condition of the bearing.It is

pre-lubricated and sealed and should not be

immersed in oil or solvent.

(4) The bearing should turn smoothly when held in

the hand under a light thrust load. A light drag

caused by the lubricant fill is normal. If the bearing

is noisy, rough, or dry, replace the complete bearing

assembly with a new bearing.

(5) Check the condition of the pivot stud spring

clips on back side of clutch fork. If the clips are bro-

ken or distorted, replace the clutch fork.

INSTALLATION

(1) The pivot ball pocket in the fork, as well as the

fork arms should be lubricated with grease prior to

installation.

(2) Assemble the fork to the bearing. The small

pegs on the bearing must go over the fork arms.

(3) Slide the bearing and fork assembly onto the

input shaft bearing retainer, as a unit.

(4) Snap the clutch fork onto the pivot ball.

(5) Reinstall transaxle assembly. Refer to Group

21, Transaxle for further information.

CLEANING AND INSPECTION

CLUTCH CONTAMINATION

Fluid contamination is a frequent cause of clutch

malfunctions. Oil, grease, water, or other fluids on

the clutch contact surfaces will cause faulty opera-

tion.

During inspection, note if any components are con-

taminated. Look for evidence of oil, grease, or water/

road splash on clutch components.

OIL CONTAMINATION

Oil contamination indicates a leak at the rear main

seal and/or transaxle input shaft. Oil leaks produce a

residue of oil on the transaxle housing interior, clutch

Fig. 18 Transaxle Removal/Installation

1 ± MODULAR CLUTCH ASSEMBLY

2 ± CLIP3 ± TRANSAXLE

4 ± CLUTCH MODULE BOLT (4)

VIEW A

6 - 12 CLUTCHPL

REMOVAL AND INSTALLATION (Continued)

Page 178 of 1285

cover and flywheel. Heat buildup caused by slippage

can bake the oil residue onto the components. This

glaze-like residue ranges in color from amber to

black.

GREASE CONTAMINATION

Grease contamination is usually a product of over-

lubrication. During clutch service, apply only a small

amount of grease to the input shaft splines. Excess

grease may be thrown off during operation, contami-

nating the disc.

ROAD SPLASH/WATER CONTAMINATION

Road splash contamination is usually caused by

driving the vehicle through deep water puddles.

Water can be forced into the clutch housing, causing

clutch components to become contaminated. Facing of

disc will absorb moisture and bond to the flywheel

and/or, pressure plate, if vehicle is allowed to stand

for some time before use. If this condition occurs,

replacement of clutch assembly may be required.

Drive the vehicle until normal clutch operating tem-

perature has been obtained. This will dry off disc

assembly, pressure plate, and flywheel.

CLEANING PRECAUTIONS

Condensation from steam vapors tend to accumu-

late on the internal clutch mechanism when the vehi-

cle is steam cleaned. Facing of disc will absorb

moisture and will bond to flywheel and/or pressure

plate, if vehicle is allowed to stand for some time

before use. If this condition occurs, it may require

replacement of clutch assembly. After cleaning, drive

the vehicle to its normal clutch operating tempera-

ture. This will dry off disc assembly, pressure plate,

and flywheel.

SPECIFICATIONS

TORQUE

DESCRIPTION TORQUE

Modular Clutch-to-Drive Plate Bolts..... 88N´m

(65 ft. lbs.)

Transaxle-to-Engine Mounting Bolts...... 95N´m

(70 ft. lbs.)

PLCLUTCH 6 - 13

CLEANING AND INSPECTION (Continued)

Page 183 of 1285

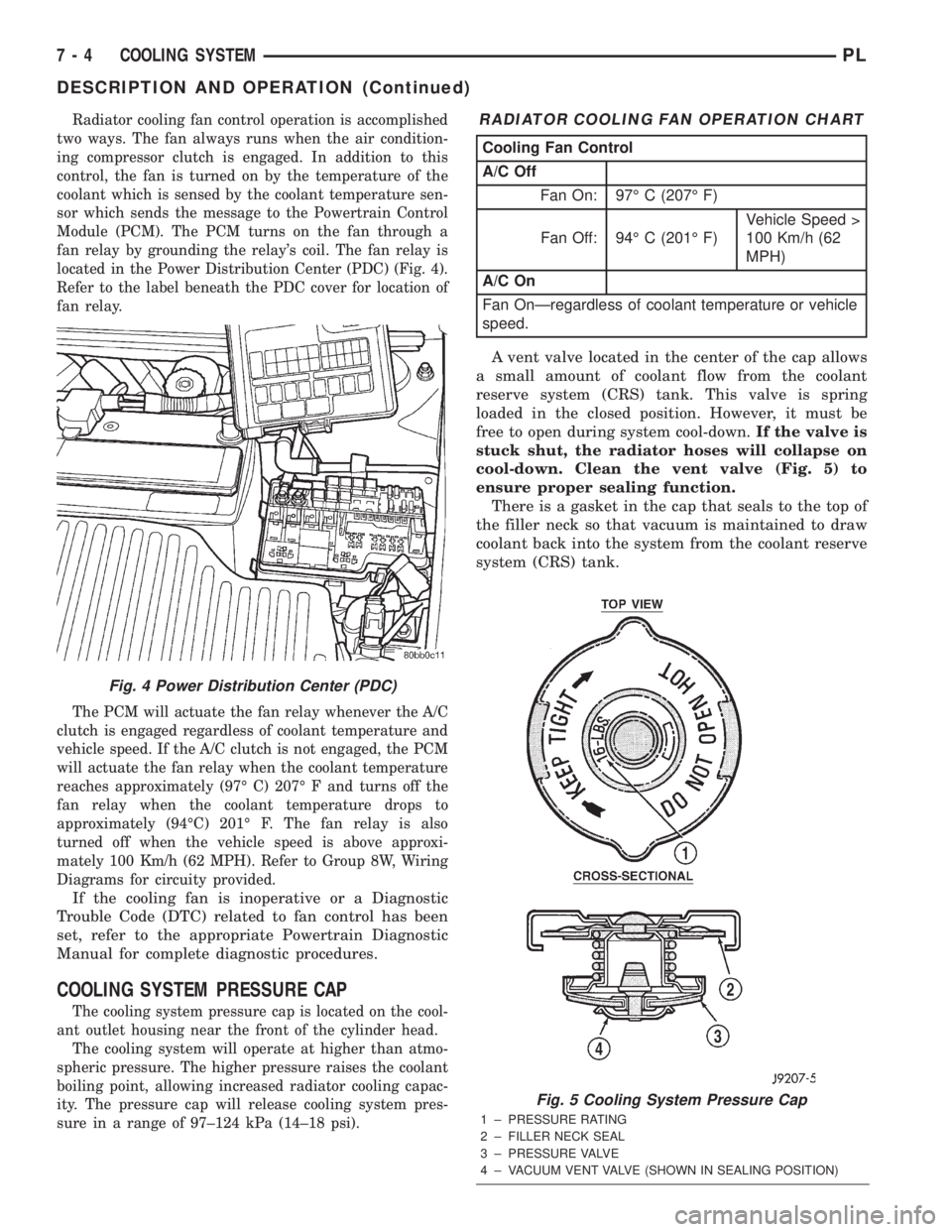

Radiator cooling fan control operation is accomplished

two ways. The fan always runs when the air condition-

ing compressor clutch is engaged. In addition to this

control, the fan is turned on by the temperature of the

coolant which is sensed by the coolant temperature sen-

sor which sends the message to the Powertrain Control

Module (PCM). The PCM turns on the fan through a

fan relay by grounding the relay's coil. The fan relay is

located in the Power Distribution Center (PDC) (Fig. 4).

Refer to the label beneath the PDC cover for location of

fan relay.

The PCM will actuate the fan relay whenever the A/C

clutch is engaged regardless of coolant temperature and

vehicle speed. If the A/C clutch is not engaged, the PCM

will actuate the fan relay when the coolant temperature

reaches approximately (97É C) 207É F and turns off the

fan relay when the coolant temperature drops to

approximately (94ÉC) 201É F. The fan relay is also

turned off when the vehicle speed is above approxi-

mately 100 Km/h (62 MPH). Refer to Group 8W, Wiring

Diagrams for circuity provided.

If the cooling fan is inoperative or a Diagnostic

Trouble Code (DTC) related to fan control has been

set, refer to the appropriate Powertrain Diagnostic

Manual for complete diagnostic procedures.

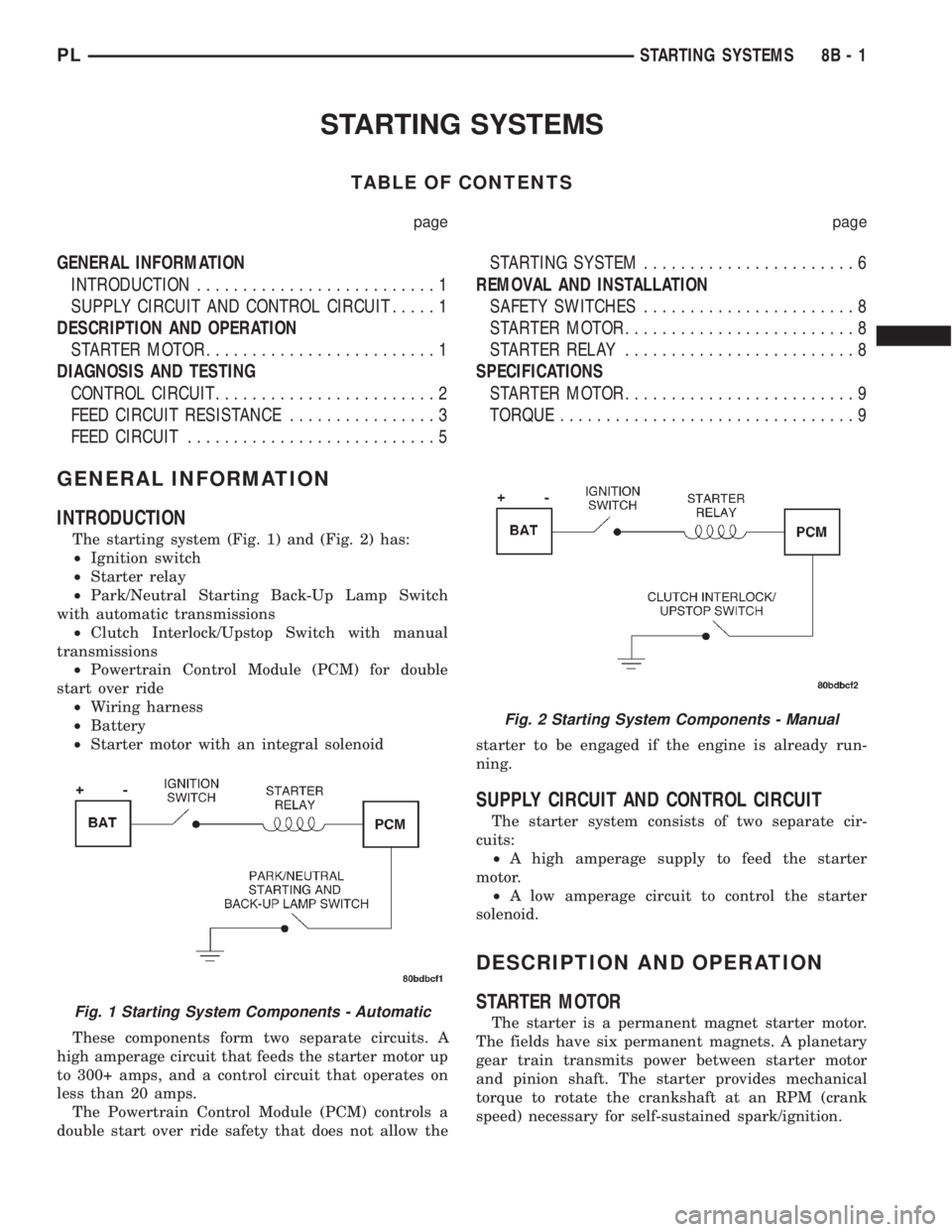

COOLING SYSTEM PRESSURE CAP

The cooling system pressure cap is located on the cool-

ant outlet housing near the front of the cylinder head.

The cooling system will operate at higher than atmo-

spheric pressure. The higher pressure raises the coolant

boiling point, allowing increased radiator cooling capac-

ity. The pressure cap will release cooling system pres-

sure in a range of 97±124 kPa (14±18 psi).

A vent valve located in the center of the cap allows

a small amount of coolant flow from the coolant

reserve system (CRS) tank. This valve is spring

loaded in the closed position. However, it must be

free to open during system cool-down.If the valve is

stuck shut, the radiator hoses will collapse on

cool-down. Clean the vent valve (Fig. 5) to

ensure proper sealing function.

There is a gasket in the cap that seals to the top of

the filler neck so that vacuum is maintained to draw

coolant back into the system from the coolant reserve

system (CRS) tank.

Fig. 4 Power Distribution Center (PDC)

RADIATOR COOLING FAN OPERATION CHART

Cooling Fan Control

A/C Off

Fan On: 97É C (207É F)

Fan Off: 94É C (201É F)Vehicle Speed >

100 Km/h (62

MPH)

A/C On

Fan OnÐregardless of coolant temperature or vehicle

speed.

Fig. 5 Cooling System Pressure Cap

1 ± PRESSURE RATING

2 ± FILLER NECK SEAL

3 ± PRESSURE VALVE

4 ± VACUUM VENT VALVE (SHOWN IN SEALING POSITION)

7 - 4 COOLING SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 222 of 1285

STARTING SYSTEMS

TABLE OF CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION..........................1

SUPPLY CIRCUIT AND CONTROL CIRCUIT.....1

DESCRIPTION AND OPERATION

STARTER MOTOR.........................1

DIAGNOSIS AND TESTING

CONTROL CIRCUIT........................2

FEED CIRCUIT RESISTANCE................3

FEED CIRCUIT...........................5STARTING SYSTEM.......................6

REMOVAL AND INSTALLATION

SAFETY SWITCHES.......................8

STARTER MOTOR.........................8

STARTER RELAY.........................8

SPECIFICATIONS

STARTER MOTOR.........................9

TORQUE................................9

GENERAL INFORMATION

INTRODUCTION

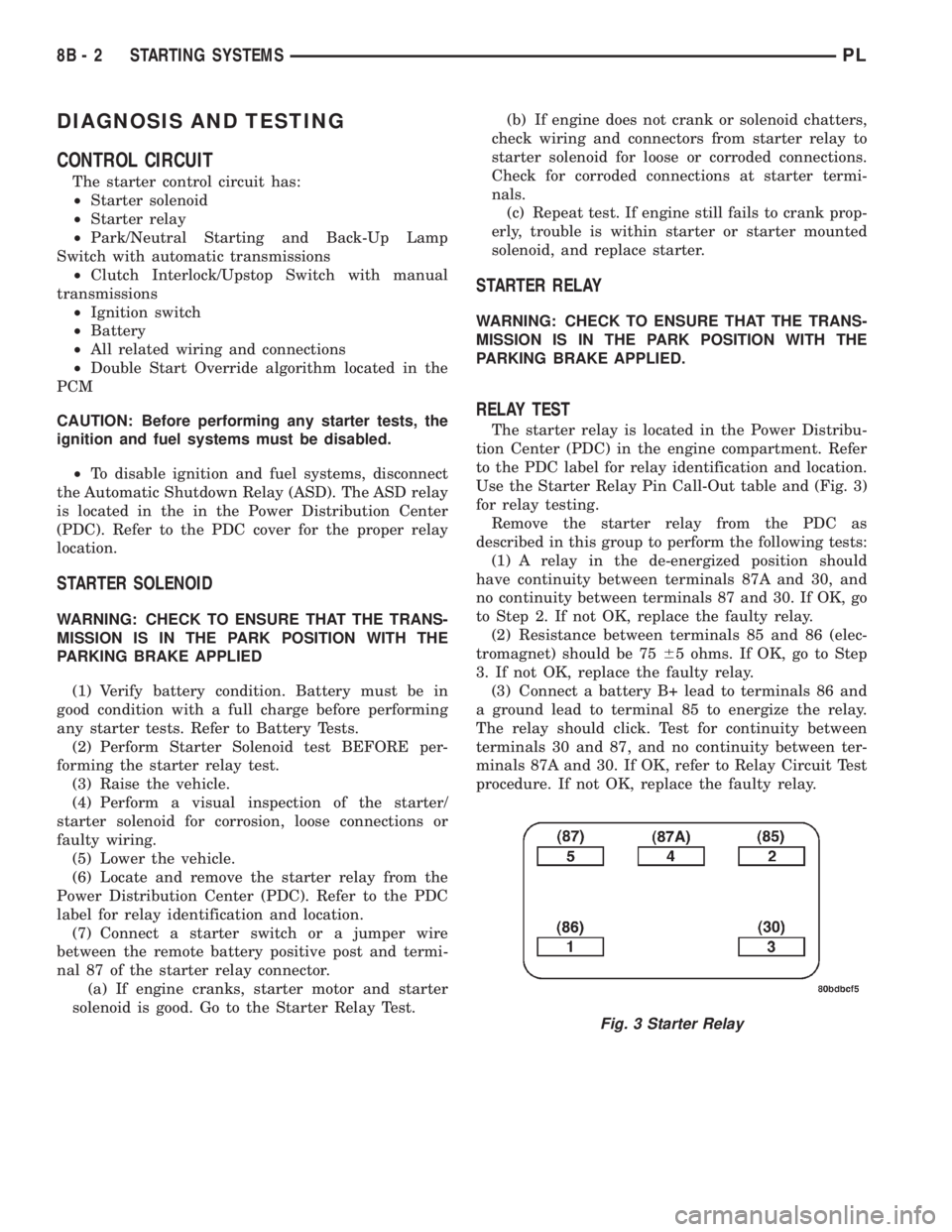

The starting system (Fig. 1) and (Fig. 2) has:

²Ignition switch

²Starter relay

²Park/Neutral Starting Back-Up Lamp Switch

with automatic transmissions

²Clutch Interlock/Upstop Switch with manual

transmissions

²Powertrain Control Module (PCM) for double

start over ride

²Wiring harness

²Battery

²Starter motor with an integral solenoid

These components form two separate circuits. A

high amperage circuit that feeds the starter motor up

to 300+ amps, and a control circuit that operates on

less than 20 amps.

The Powertrain Control Module (PCM) controls a

double start over ride safety that does not allow thestarter to be engaged if the engine is already run-

ning.

SUPPLY CIRCUIT AND CONTROL CIRCUIT

The starter system consists of two separate cir-

cuits:

²A high amperage supply to feed the starter

motor.

²A low amperage circuit to control the starter

solenoid.

DESCRIPTION AND OPERATION

STARTER MOTOR

The starter is a permanent magnet starter motor.

The fields have six permanent magnets. A planetary

gear train transmits power between starter motor

and pinion shaft. The starter provides mechanical

torque to rotate the crankshaft at an RPM (crank

speed) necessary for self-sustained spark/ignition.Fig. 1 Starting System Components - Automatic

Fig. 2 Starting System Components - Manual

PLSTARTING SYSTEMS 8B - 1

Page 223 of 1285

DIAGNOSIS AND TESTING

CONTROL CIRCUIT

The starter control circuit has:

²Starter solenoid

²Starter relay

²Park/Neutral Starting and Back-Up Lamp

Switch with automatic transmissions

²Clutch Interlock/Upstop Switch with manual

transmissions

²Ignition switch

²Battery

²All related wiring and connections

²Double Start Override algorithm located in the

PCM

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.

²To disable ignition and fuel systems, disconnect

the Automatic Shutdown Relay (ASD). The ASD relay

is located in the in the Power Distribution Center

(PDC). Refer to the PDC cover for the proper relay

location.

STARTER SOLENOID

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN THE PARK POSITION WITH THE

PARKING BRAKE APPLIED

(1) Verify battery condition. Battery must be in

good condition with a full charge before performing

any starter tests. Refer to Battery Tests.

(2) Perform Starter Solenoid test BEFORE per-

forming the starter relay test.

(3) Raise the vehicle.

(4) Perform a visual inspection of the starter/

starter solenoid for corrosion, loose connections or

faulty wiring.

(5) Lower the vehicle.

(6) Locate and remove the starter relay from the

Power Distribution Center (PDC). Refer to the PDC

label for relay identification and location.

(7) Connect a starter switch or a jumper wire

between the remote battery positive post and termi-

nal 87 of the starter relay connector.

(a) If engine cranks, starter motor and starter

solenoid is good. Go to the Starter Relay Test.(b) If engine does not crank or solenoid chatters,

check wiring and connectors from starter relay to

starter solenoid for loose or corroded connections.

Check for corroded connections at starter termi-

nals.

(c) Repeat test. If engine still fails to crank prop-

erly, trouble is within starter or starter mounted

solenoid, and replace starter.

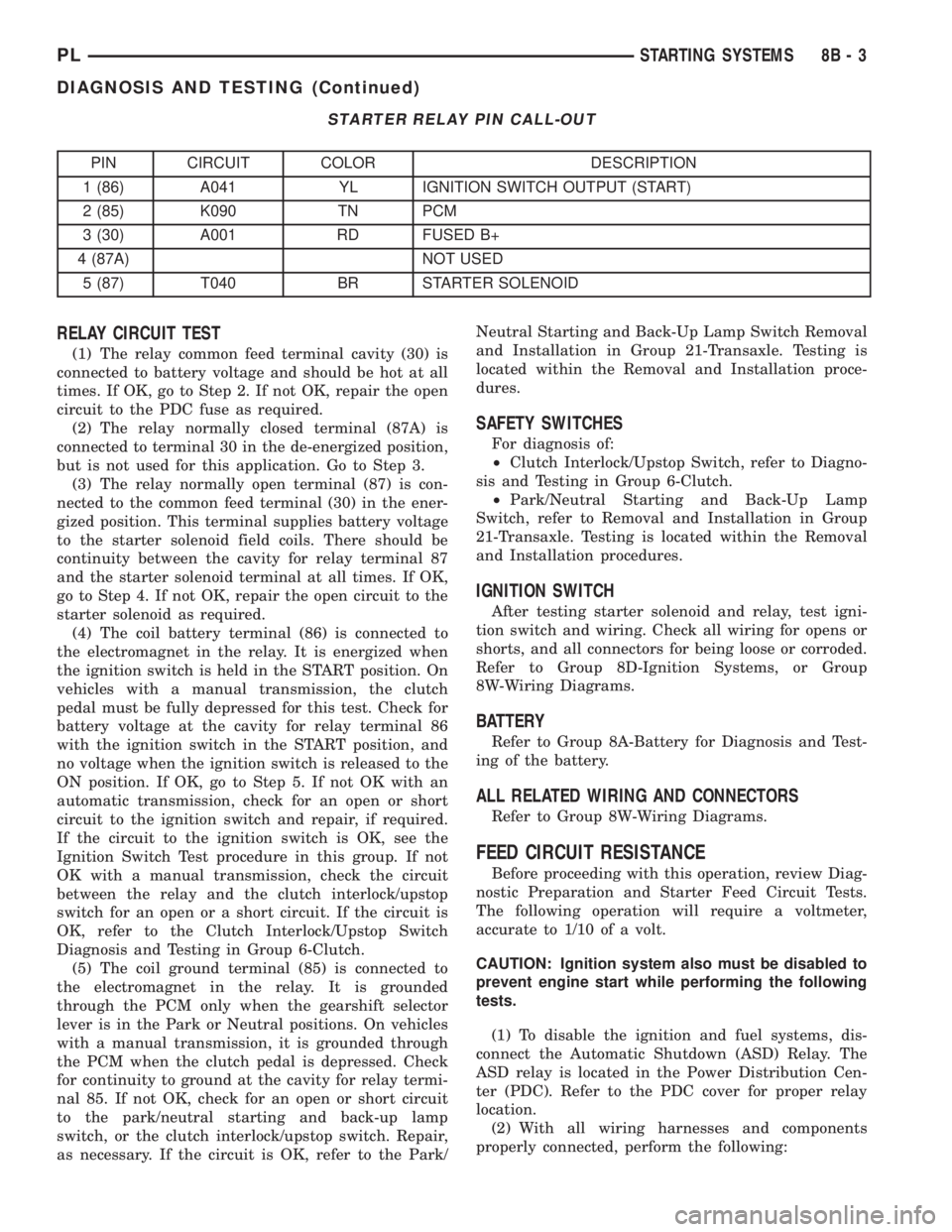

STARTER RELAY

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN THE PARK POSITION WITH THE

PARKING BRAKE APPLIED.

RELAY TEST

The starter relay is located in the Power Distribu-

tion Center (PDC) in the engine compartment. Refer

to the PDC label for relay identification and location.

Use the Starter Relay Pin Call-Out table and (Fig. 3)

for relay testing.

Remove the starter relay from the PDC as

described in this group to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 7565 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery B+ lead to terminals 86 and

a ground lead to terminal 85 to energize the relay.

The relay should click. Test for continuity between

terminals 30 and 87, and no continuity between ter-

minals 87A and 30. If OK, refer to Relay Circuit Test

procedure. If not OK, replace the faulty relay.

Fig. 3 Starter Relay

8B - 2 STARTING SYSTEMSPL

Page 224 of 1285

STARTER RELAY PIN CALL-OUT

PIN CIRCUIT COLOR DESCRIPTION

1 (86) A041 YL IGNITION SWITCH OUTPUT (START)

2 (85) K090 TN PCM

3 (30) A001 RD FUSED B+

4 (87A) NOT USED

5 (87) T040 BR STARTER SOLENOID

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the PDC fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the starter solenoid field coils. There should be

continuity between the cavity for relay terminal 87

and the starter solenoid terminal at all times. If OK,

go to Step 4. If not OK, repair the open circuit to the

starter solenoid as required.

(4) The coil battery terminal (86) is connected to

the electromagnet in the relay. It is energized when

the ignition switch is held in the START position. On

vehicles with a manual transmission, the clutch

pedal must be fully depressed for this test. Check for

battery voltage at the cavity for relay terminal 86

with the ignition switch in the START position, and

no voltage when the ignition switch is released to the

ON position. If OK, go to Step 5. If not OK with an

automatic transmission, check for an open or short

circuit to the ignition switch and repair, if required.

If the circuit to the ignition switch is OK, see the

Ignition Switch Test procedure in this group. If not

OK with a manual transmission, check the circuit

between the relay and the clutch interlock/upstop

switch for an open or a short circuit. If the circuit is

OK, refer to the Clutch Interlock/Upstop Switch

Diagnosis and Testing in Group 6-Clutch.

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. It is grounded

through the PCM only when the gearshift selector

lever is in the Park or Neutral positions. On vehicles

with a manual transmission, it is grounded through

the PCM when the clutch pedal is depressed. Check

for continuity to ground at the cavity for relay termi-

nal 85. If not OK, check for an open or short circuit

to the park/neutral starting and back-up lamp

switch, or the clutch interlock/upstop switch. Repair,

as necessary. If the circuit is OK, refer to the Park/Neutral Starting and Back-Up Lamp Switch Removal

and Installation in Group 21-Transaxle. Testing is

located within the Removal and Installation proce-

dures.

SAFETY SWITCHES

For diagnosis of:

²Clutch Interlock/Upstop Switch, refer to Diagno-

sis and Testing in Group 6-Clutch.

²Park/Neutral Starting and Back-Up Lamp

Switch, refer to Removal and Installation in Group

21-Transaxle. Testing is located within the Removal

and Installation procedures.

IGNITION SWITCH

After testing starter solenoid and relay, test igni-

tion switch and wiring. Check all wiring for opens or

shorts, and all connectors for being loose or corroded.

Refer to Group 8D-Ignition Systems, or Group

8W-Wiring Diagrams.

BATTERY

Refer to Group 8A-Battery for Diagnosis and Test-

ing of the battery.

ALL RELATED WIRING AND CONNECTORS

Refer to Group 8W-Wiring Diagrams.

FEED CIRCUIT RESISTANCE

Before proceeding with this operation, review Diag-

nostic Preparation and Starter Feed Circuit Tests.

The following operation will require a voltmeter,

accurate to 1/10 of a volt.

CAUTION: Ignition system also must be disabled to

prevent engine start while performing the following

tests.

(1) To disable the ignition and fuel systems, dis-

connect the Automatic Shutdown (ASD) Relay. The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(2) With all wiring harnesses and components

properly connected, perform the following:

PLSTARTING SYSTEMS 8B - 3

DIAGNOSIS AND TESTING (Continued)

Page 226 of 1285

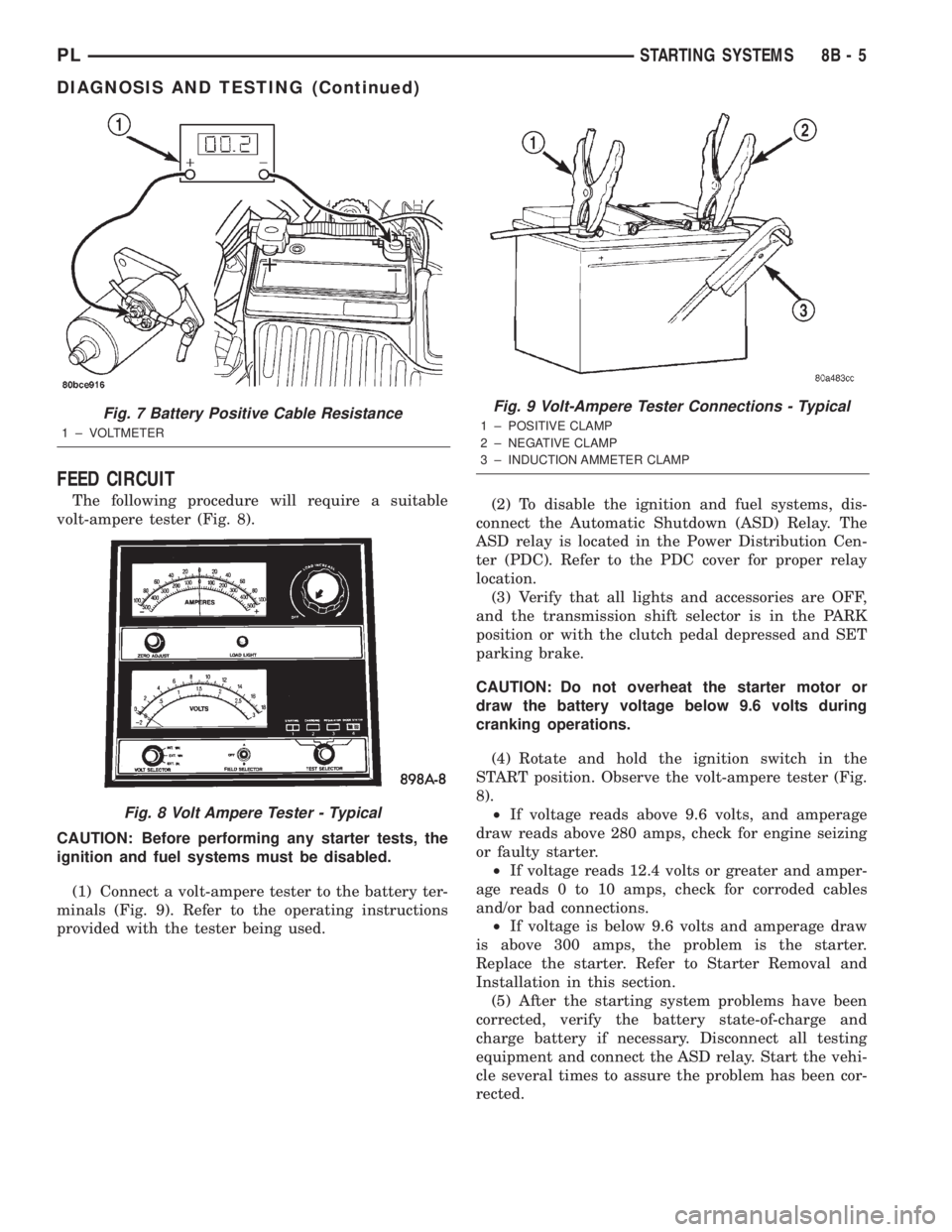

FEED CIRCUIT

The following procedure will require a suitable

volt-ampere tester (Fig. 8).

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.

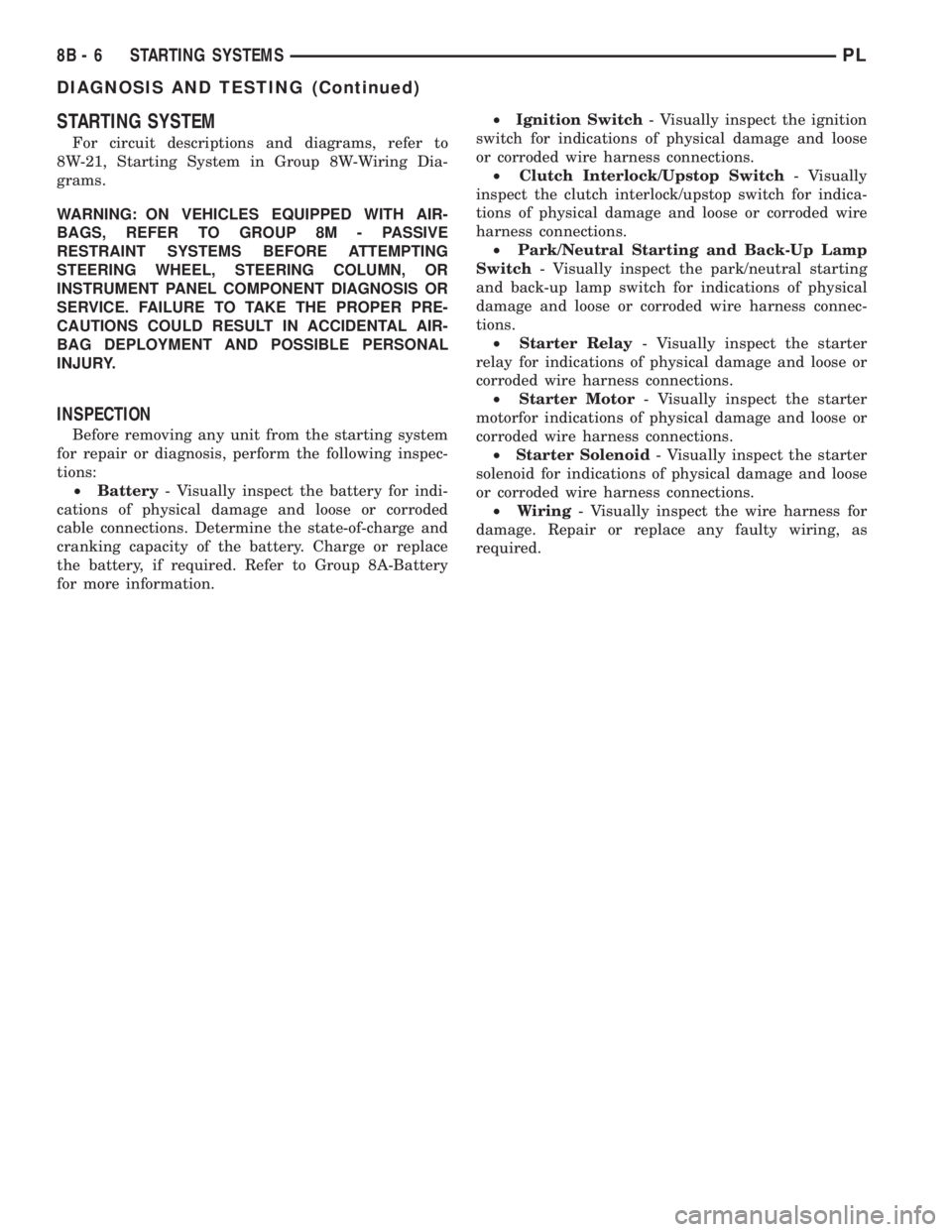

(1) Connect a volt-ampere tester to the battery ter-

minals (Fig. 9). Refer to the operating instructions

provided with the tester being used.(2) To disable the ignition and fuel systems, dis-

connect the Automatic Shutdown (ASD) Relay. The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(3) Verify that all lights and accessories are OFF,

and the transmission shift selector is in the PARK

position or with the clutch pedal depressed and SET

parking brake.

CAUTION: Do not overheat the starter motor or

draw the battery voltage below 9.6 volts during

cranking operations.

(4) Rotate and hold the ignition switch in the

START position. Observe the volt-ampere tester (Fig.

8).

²If voltage reads above 9.6 volts, and amperage

draw reads above 280 amps, check for engine seizing

or faulty starter.

²If voltage reads 12.4 volts or greater and amper-

age reads 0 to 10 amps, check for corroded cables

and/or bad connections.

²If voltage is below 9.6 volts and amperage draw

is above 300 amps, the problem is the starter.

Replace the starter. Refer to Starter Removal and

Installation in this section.

(5) After the starting system problems have been

corrected, verify the battery state-of-charge and

charge battery if necessary. Disconnect all testing

equipment and connect the ASD relay. Start the vehi-

cle several times to assure the problem has been cor-

rected.

Fig. 7 Battery Positive Cable Resistance

1 ± VOLTMETER

Fig. 8 Volt Ampere Tester - Typical

Fig. 9 Volt-Ampere Tester Connections - Typical

1 ± POSITIVE CLAMP

2 ± NEGATIVE CLAMP

3 ± INDUCTION AMMETER CLAMP

PLSTARTING SYSTEMS 8B - 5

DIAGNOSIS AND TESTING (Continued)

Page 227 of 1285

STARTING SYSTEM

For circuit descriptions and diagrams, refer to

8W-21, Starting System in Group 8W-Wiring Dia-

grams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

INSPECTION

Before removing any unit from the starting system

for repair or diagnosis, perform the following inspec-

tions:

²Battery- Visually inspect the battery for indi-

cations of physical damage and loose or corroded

cable connections. Determine the state-of-charge and

cranking capacity of the battery. Charge or replace

the battery, if required. Refer to Group 8A-Battery

for more information.²Ignition Switch- Visually inspect the ignition

switch for indications of physical damage and loose

or corroded wire harness connections.

²Clutch Interlock/Upstop Switch- Visually

inspect the clutch interlock/upstop switch for indica-

tions of physical damage and loose or corroded wire

harness connections.

²Park/Neutral Starting and Back-Up Lamp

Switch- Visually inspect the park/neutral starting

and back-up lamp switch for indications of physical

damage and loose or corroded wire harness connec-

tions.

²Starter Relay- Visually inspect the starter

relay for indications of physical damage and loose or

corroded wire harness connections.

²Starter Motor- Visually inspect the starter

motorfor indications of physical damage and loose or

corroded wire harness connections.

²Starter Solenoid- Visually inspect the starter

solenoid for indications of physical damage and loose

or corroded wire harness connections.

²Wiring- Visually inspect the wire harness for

damage. Repair or replace any faulty wiring, as

required.

8B - 6 STARTING SYSTEMSPL

DIAGNOSIS AND TESTING (Continued)