clutch DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1249 of 1285

CAUTION: Do not overcharge refrigerant system,

as excessive compressor head pressure can cause

noise and system failure.

After the system has been tested for leaks and

evacuated, a refrigerant (R-134a) charge can be

injected into the system.

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) If using a separate vacuum pump close all

valves before disconnecting pump. Connect manifold

gauge set to the A/C service ports (Fig. 16).

NOTE: The air conditioning system in this vehicle

holds (27 oz. or 1.69 lbs.) of R-134a refrigerant.

(2) Measure refrigerant (refer to capacities). Refer

to the instructions provided with the equipment

being used.

(3) Verify engine is shut off. Open the suction and

discharge valves. Open the charge valve to allow the

refrigerant to flow into the system. When the trans-

fer of refrigerant has stopped, close the suction and

discharge valve.

(4) If all of the charge did not transfer from the

dispensing device, put vehicle controls into the fol-

lowing mode:

²Automatic transaxle in park or manual tran-

saxle in neutral

²Engine idling at 700 rpm

²A/C control set in 100 percent outside air

²Panel mode

²Blower motor ON high speed

²Vehicle windows closed

If the A/C compressor does not engage, test the

compressor clutch control circuit and correct any fail-

ure. Refer to Group 8W, Wiring Diagrams.

(5) Open the suction valve to allow the remaining

refrigerant to transfer to the system.

WARNING: TAKE CARE NOT TO OPEN THE DIS-

CHARGE (HIGH-PRESSURE) VALVE AT THIS TIME.

(6) Close all valves and test the A/C system perfor-

mance.

(7) Disconnect the charging station or manifold

gauge set. Install the service port caps.

EVACUATING REFRIGERANT SYSTEM

NOTE: Special effort must be used to prevent mois-

ture from entering the A/C system oil. Moisture in

the oil is very difficult to remove and will cause a

reliability problem with the compressor.If a compressor designed to use R-134a refrigerant

is left open to the atmosphere for an extended period

of time. It is recommended that the refrigerant oil be

drained and replaced with new oil or a new compres-

sor be used. This will eliminate the possibility of con-

taminating the refrigerant system.

If the refrigerant system has been open to the

atmosphere, it must be evacuated before the system

can be filled. Moisture and air mixed with the refrig-

erant will raise the compressor head pressure above

acceptable operating levels. This will reduce the per-

formance of the air conditioner and damage the com-

pressor. Moisture will boil at near room temperature

when exposed to vacuum. To evacuate the refrigerant

system:

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

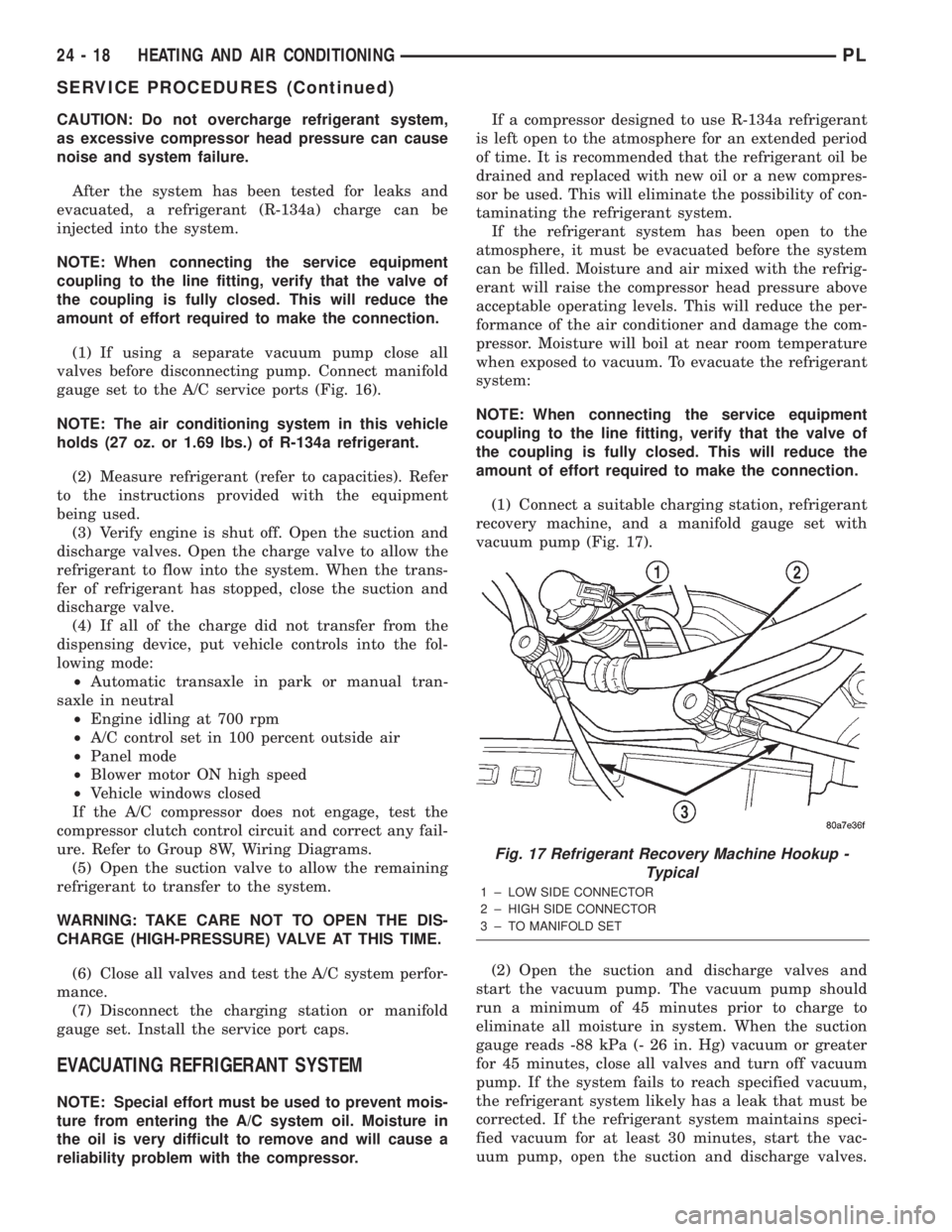

(1) Connect a suitable charging station, refrigerant

recovery machine, and a manifold gauge set with

vacuum pump (Fig. 17).

(2) Open the suction and discharge valves and

start the vacuum pump. The vacuum pump should

run a minimum of 45 minutes prior to charge to

eliminate all moisture in system. When the suction

gauge reads -88 kPa (- 26 in. Hg) vacuum or greater

for 45 minutes, close all valves and turn off vacuum

pump. If the system fails to reach specified vacuum,

the refrigerant system likely has a leak that must be

corrected. If the refrigerant system maintains speci-

fied vacuum for at least 30 minutes, start the vac-

uum pump, open the suction and discharge valves.

Fig. 17 Refrigerant Recovery Machine Hookup -

Typical

1 ± LOW SIDE CONNECTOR

2 ± HIGH SIDE CONNECTOR

3 ± TO MANIFOLD SET

24 - 18 HEATING AND AIR CONDITIONINGPL

SERVICE PROCEDURES (Continued)

Page 1253 of 1285

BLOWER MOTOR RESISTOR

CAUTION: Stay clear of the blower motor and resis-

tor block (Hot). Do not operate the blower motor

with the resistor block removed.

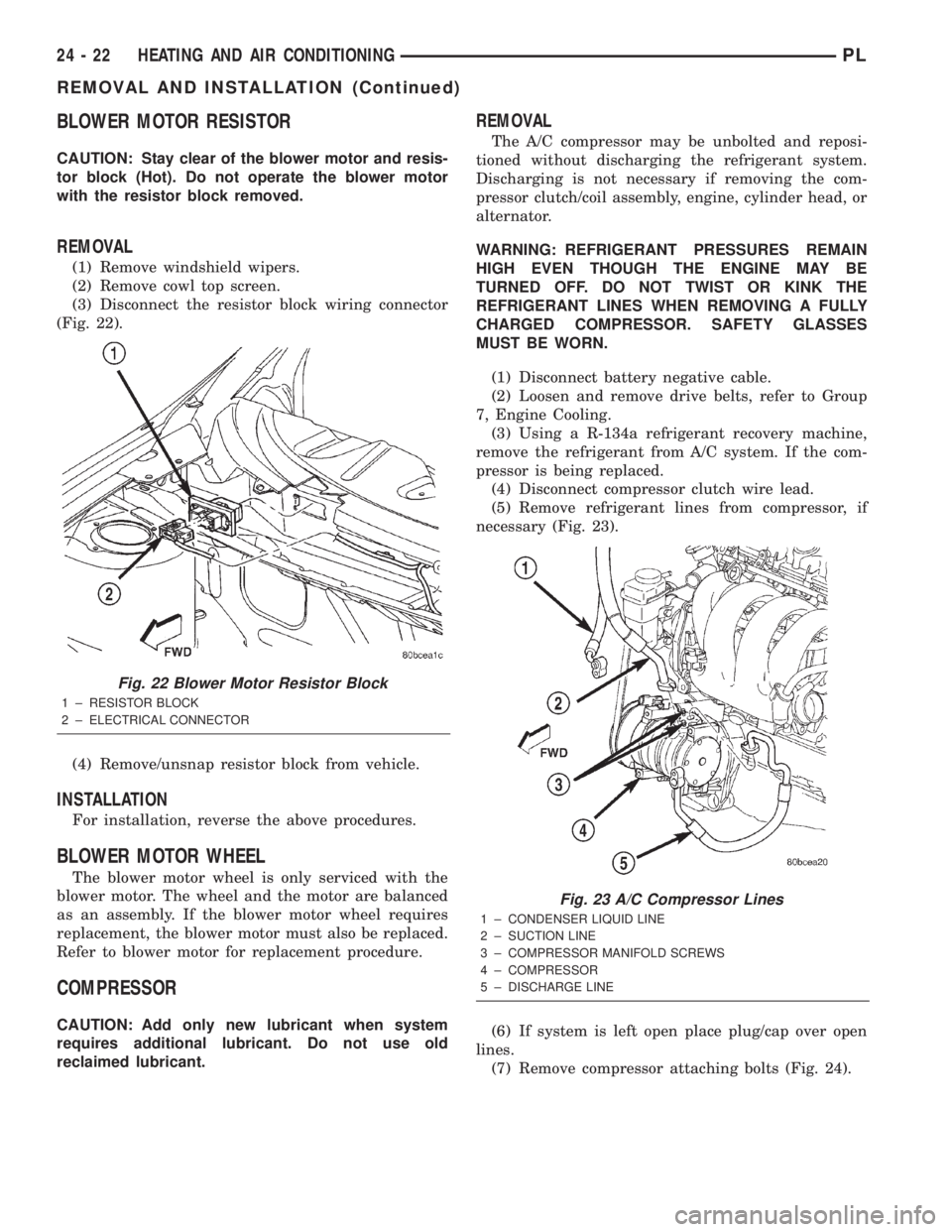

REMOVAL

(1) Remove windshield wipers.

(2) Remove cowl top screen.

(3) Disconnect the resistor block wiring connector

(Fig. 22).

(4) Remove/unsnap resistor block from vehicle.

INSTALLATION

For installation, reverse the above procedures.

BLOWER MOTOR WHEEL

The blower motor wheel is only serviced with the

blower motor. The wheel and the motor are balanced

as an assembly. If the blower motor wheel requires

replacement, the blower motor must also be replaced.

Refer to blower motor for replacement procedure.

COMPRESSOR

CAUTION: Add only new lubricant when system

requires additional lubricant. Do not use old

reclaimed lubricant.

REMOVAL

The A/C compressor may be unbolted and reposi-

tioned without discharging the refrigerant system.

Discharging is not necessary if removing the com-

pressor clutch/coil assembly, engine, cylinder head, or

alternator.

WARNING: REFRIGERANT PRESSURES REMAIN

HIGH EVEN THOUGH THE ENGINE MAY BE

TURNED OFF. DO NOT TWIST OR KINK THE

REFRIGERANT LINES WHEN REMOVING A FULLY

CHARGED COMPRESSOR. SAFETY GLASSES

MUST BE WORN.

(1) Disconnect battery negative cable.

(2) Loosen and remove drive belts, refer to Group

7, Engine Cooling.

(3) Using a R-134a refrigerant recovery machine,

remove the refrigerant from A/C system. If the com-

pressor is being replaced.

(4) Disconnect compressor clutch wire lead.

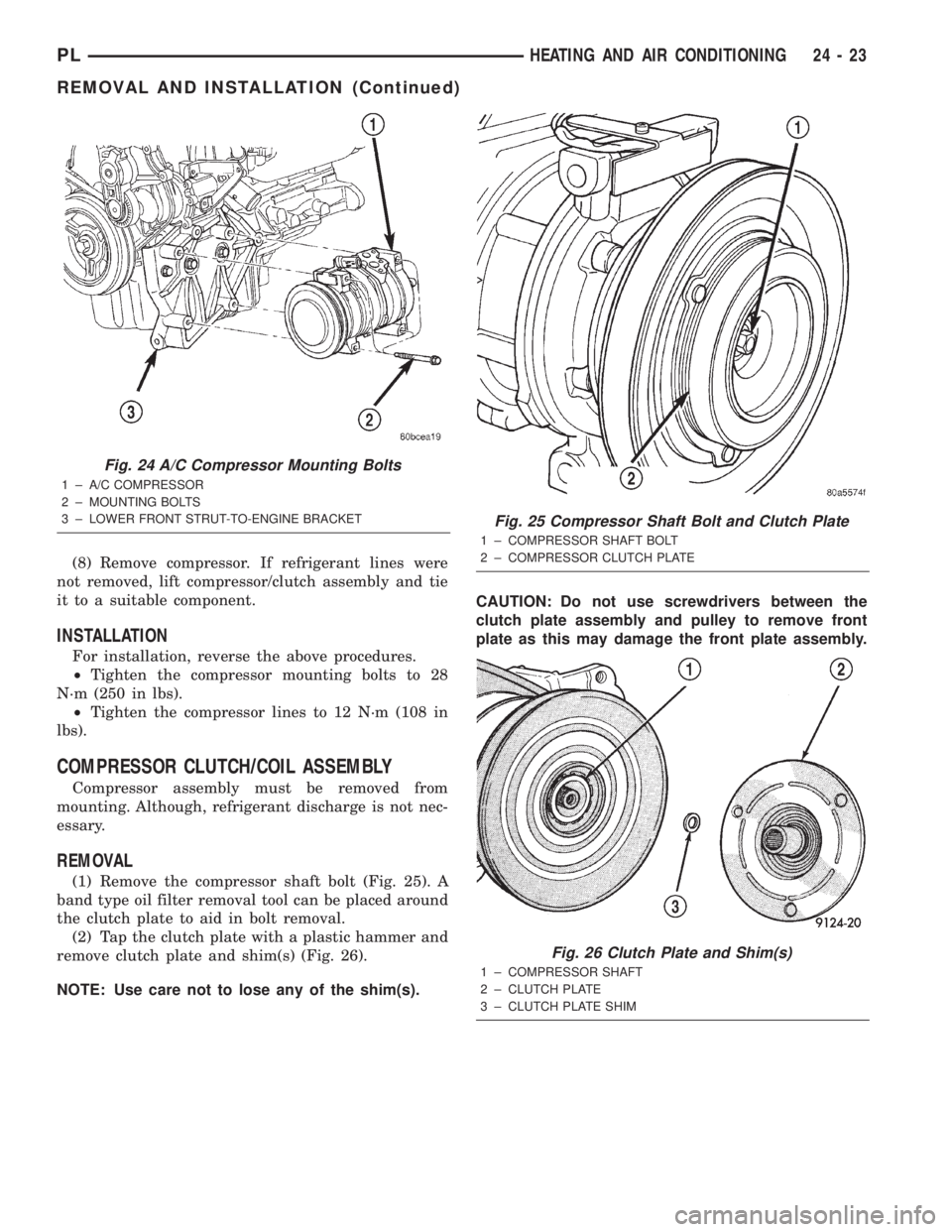

(5) Remove refrigerant lines from compressor, if

necessary (Fig. 23).

(6) If system is left open place plug/cap over open

lines.

(7) Remove compressor attaching bolts (Fig. 24).

Fig. 22 Blower Motor Resistor Block

1 ± RESISTOR BLOCK

2 ± ELECTRICAL CONNECTOR

Fig. 23 A/C Compressor Lines

1 ± CONDENSER LIQUID LINE

2 ± SUCTION LINE

3 ± COMPRESSOR MANIFOLD SCREWS

4 ± COMPRESSOR

5 ± DISCHARGE LINE

24 - 22 HEATING AND AIR CONDITIONINGPL

REMOVAL AND INSTALLATION (Continued)

Page 1254 of 1285

(8) Remove compressor. If refrigerant lines were

not removed, lift compressor/clutch assembly and tie

it to a suitable component.

INSTALLATION

For installation, reverse the above procedures.

²Tighten the compressor mounting bolts to 28

N´m (250 in lbs).

²Tighten the compressor lines to 12 N´m (108 in

lbs).

COMPRESSOR CLUTCH/COIL ASSEMBLY

Compressor assembly must be removed from

mounting. Although, refrigerant discharge is not nec-

essary.

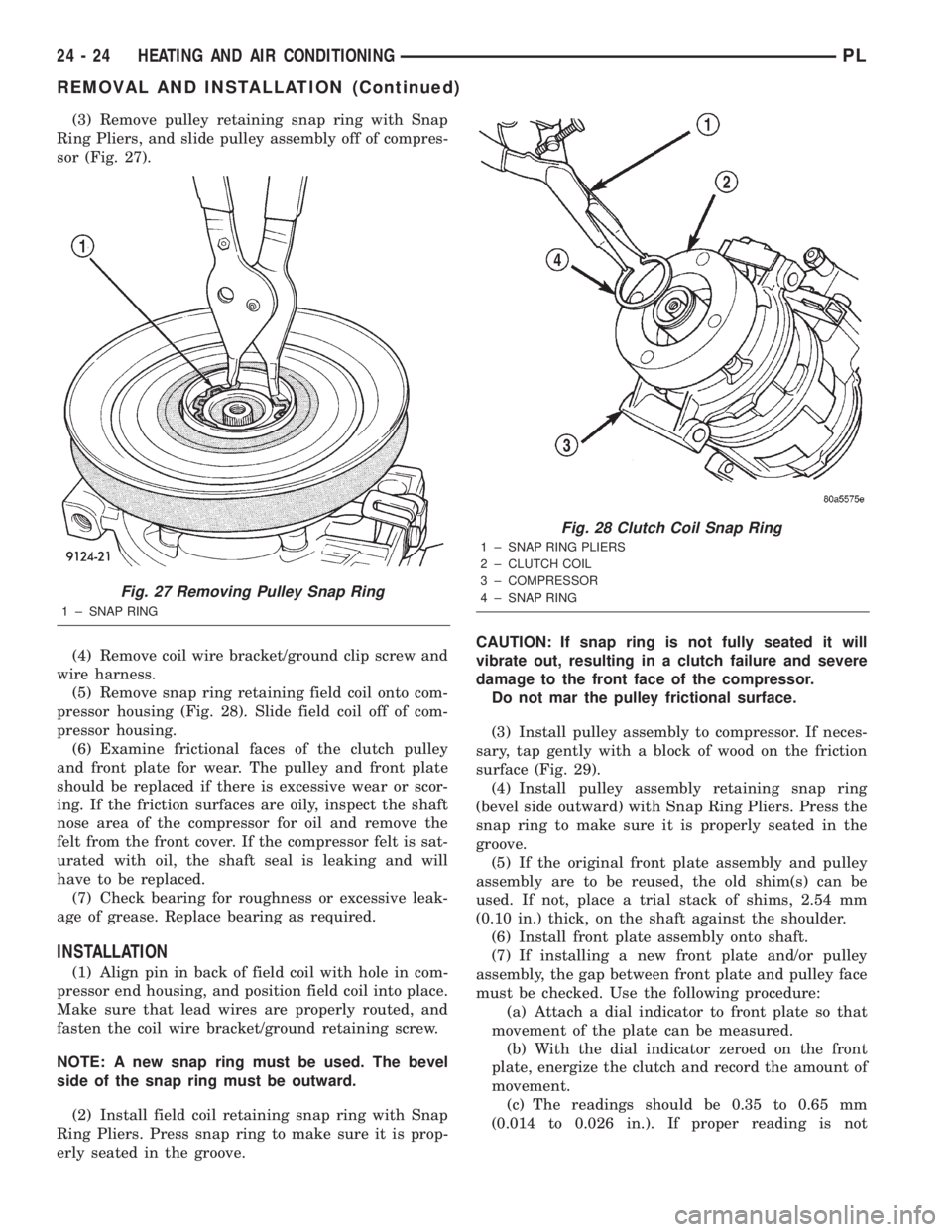

REMOVAL

(1) Remove the compressor shaft bolt (Fig. 25). A

band type oil filter removal tool can be placed around

the clutch plate to aid in bolt removal.

(2) Tap the clutch plate with a plastic hammer and

remove clutch plate and shim(s) (Fig. 26).

NOTE: Use care not to lose any of the shim(s).CAUTION: Do not use screwdrivers between the

clutch plate assembly and pulley to remove front

plate as this may damage the front plate assembly.

Fig. 24 A/C Compressor Mounting Bolts

1 ± A/C COMPRESSOR

2 ± MOUNTING BOLTS

3 ± LOWER FRONT STRUT-TO-ENGINE BRACKET

Fig. 25 Compressor Shaft Bolt and Clutch Plate

1 ± COMPRESSOR SHAFT BOLT

2 ± COMPRESSOR CLUTCH PLATE

Fig. 26 Clutch Plate and Shim(s)

1 ± COMPRESSOR SHAFT

2 ± CLUTCH PLATE

3 ± CLUTCH PLATE SHIM

PLHEATING AND AIR CONDITIONING 24 - 23

REMOVAL AND INSTALLATION (Continued)

Page 1255 of 1285

(3) Remove pulley retaining snap ring with Snap

Ring Pliers, and slide pulley assembly off of compres-

sor (Fig. 27).

(4) Remove coil wire bracket/ground clip screw and

wire harness.

(5) Remove snap ring retaining field coil onto com-

pressor housing (Fig. 28). Slide field coil off of com-

pressor housing.

(6) Examine frictional faces of the clutch pulley

and front plate for wear. The pulley and front plate

should be replaced if there is excessive wear or scor-

ing. If the friction surfaces are oily, inspect the shaft

nose area of the compressor for oil and remove the

felt from the front cover. If the compressor felt is sat-

urated with oil, the shaft seal is leaking and will

have to be replaced.

(7) Check bearing for roughness or excessive leak-

age of grease. Replace bearing as required.

INSTALLATION

(1) Align pin in back of field coil with hole in com-

pressor end housing, and position field coil into place.

Make sure that lead wires are properly routed, and

fasten the coil wire bracket/ground retaining screw.

NOTE: A new snap ring must be used. The bevel

side of the snap ring must be outward.

(2) Install field coil retaining snap ring with Snap

Ring Pliers. Press snap ring to make sure it is prop-

erly seated in the groove.CAUTION: If snap ring is not fully seated it will

vibrate out, resulting in a clutch failure and severe

damage to the front face of the compressor.

Do not mar the pulley frictional surface.

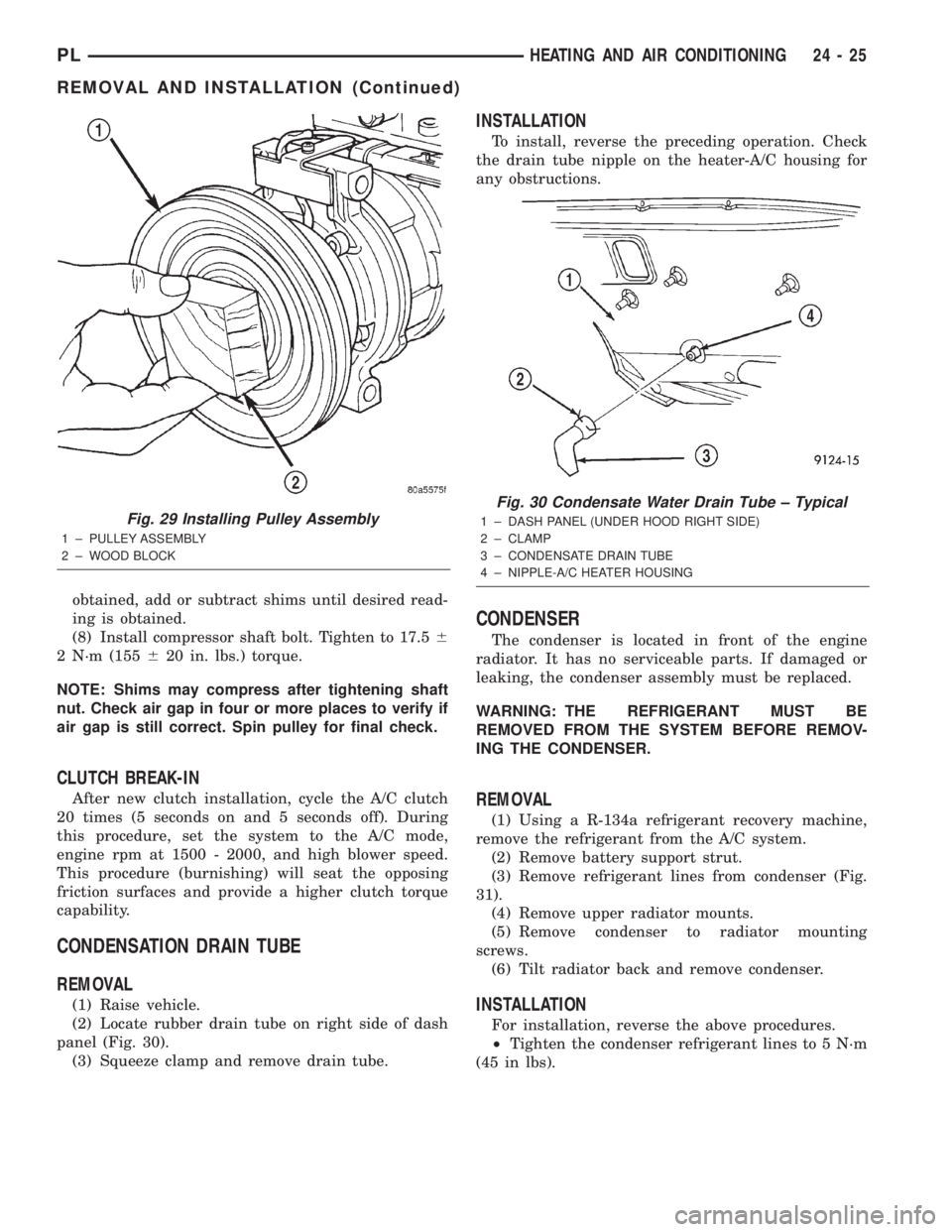

(3) Install pulley assembly to compressor. If neces-

sary, tap gently with a block of wood on the friction

surface (Fig. 29).

(4) Install pulley assembly retaining snap ring

(bevel side outward) with Snap Ring Pliers. Press the

snap ring to make sure it is properly seated in the

groove.

(5) If the original front plate assembly and pulley

assembly are to be reused, the old shim(s) can be

used. If not, place a trial stack of shims, 2.54 mm

(0.10 in.) thick, on the shaft against the shoulder.

(6) Install front plate assembly onto shaft.

(7) If installing a new front plate and/or pulley

assembly, the gap between front plate and pulley face

must be checked. Use the following procedure:

(a) Attach a dial indicator to front plate so that

movement of the plate can be measured.

(b) With the dial indicator zeroed on the front

plate, energize the clutch and record the amount of

movement.

(c) The readings should be 0.35 to 0.65 mm

(0.014 to 0.026 in.). If proper reading is not

Fig. 27 Removing Pulley Snap Ring

1 ± SNAP RING

Fig. 28 Clutch Coil Snap Ring

1 ± SNAP RING PLIERS

2 ± CLUTCH COIL

3 ± COMPRESSOR

4 ± SNAP RING

24 - 24 HEATING AND AIR CONDITIONINGPL

REMOVAL AND INSTALLATION (Continued)

Page 1256 of 1285

obtained, add or subtract shims until desired read-

ing is obtained.

(8) Install compressor shaft bolt. Tighten to 17.56

2 N´m (155620 in. lbs.) torque.

NOTE: Shims may compress after tightening shaft

nut. Check air gap in four or more places to verify if

air gap is still correct. Spin pulley for final check.

CLUTCH BREAK-IN

After new clutch installation, cycle the A/C clutch

20 times (5 seconds on and 5 seconds off). During

this procedure, set the system to the A/C mode,

engine rpm at 1500 - 2000, and high blower speed.

This procedure (burnishing) will seat the opposing

friction surfaces and provide a higher clutch torque

capability.

CONDENSATION DRAIN TUBE

REMOVAL

(1) Raise vehicle.

(2) Locate rubber drain tube on right side of dash

panel (Fig. 30).

(3) Squeeze clamp and remove drain tube.

INSTALLATION

To install, reverse the preceding operation. Check

the drain tube nipple on the heater-A/C housing for

any obstructions.

CONDENSER

The condenser is located in front of the engine

radiator. It has no serviceable parts. If damaged or

leaking, the condenser assembly must be replaced.

WARNING: THE REFRIGERANT MUST BE

REMOVED FROM THE SYSTEM BEFORE REMOV-

ING THE CONDENSER.

REMOVAL

(1) Using a R-134a refrigerant recovery machine,

remove the refrigerant from the A/C system.

(2) Remove battery support strut.

(3) Remove refrigerant lines from condenser (Fig.

31).

(4) Remove upper radiator mounts.

(5) Remove condenser to radiator mounting

screws.

(6) Tilt radiator back and remove condenser.

INSTALLATION

For installation, reverse the above procedures.

²Tighten the condenser refrigerant lines to 5 N´m

(45 in lbs).

Fig. 29 Installing Pulley Assembly

1 ± PULLEY ASSEMBLY

2 ± WOOD BLOCK

Fig. 30 Condensate Water Drain Tube ± Typical

1 ± DASH PANEL (UNDER HOOD RIGHT SIDE)

2 ± CLAMP

3 ± CONDENSATE DRAIN TUBE

4 ± NIPPLE-A/C HEATER HOUSING

PLHEATING AND AIR CONDITIONING 24 - 25

REMOVAL AND INSTALLATION (Continued)