differential DODGE NEON 2000 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 174 of 1285

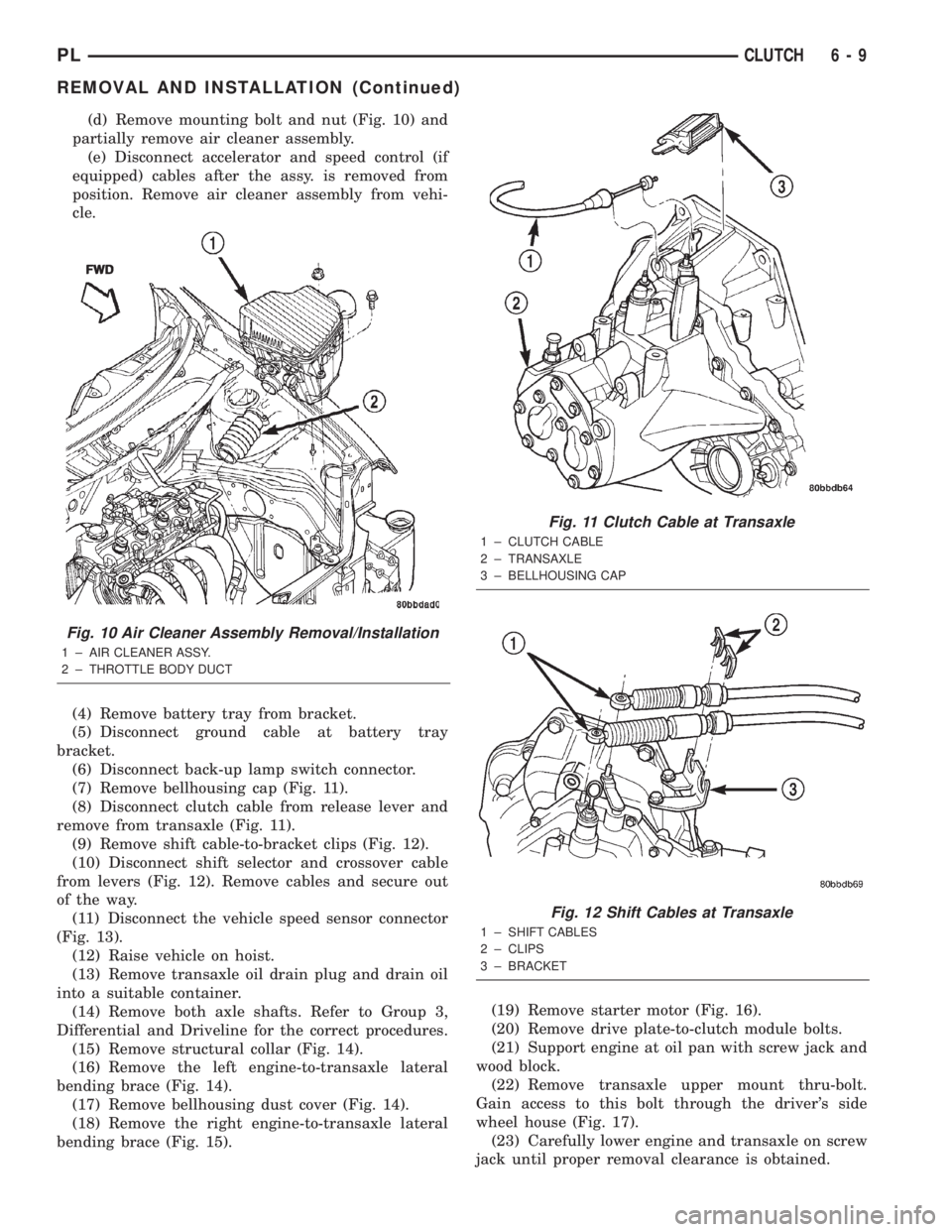

(d) Remove mounting bolt and nut (Fig. 10) and

partially remove air cleaner assembly.

(e) Disconnect accelerator and speed control (if

equipped) cables after the assy. is removed from

position. Remove air cleaner assembly from vehi-

cle.

(4) Remove battery tray from bracket.

(5) Disconnect ground cable at battery tray

bracket.

(6) Disconnect back-up lamp switch connector.

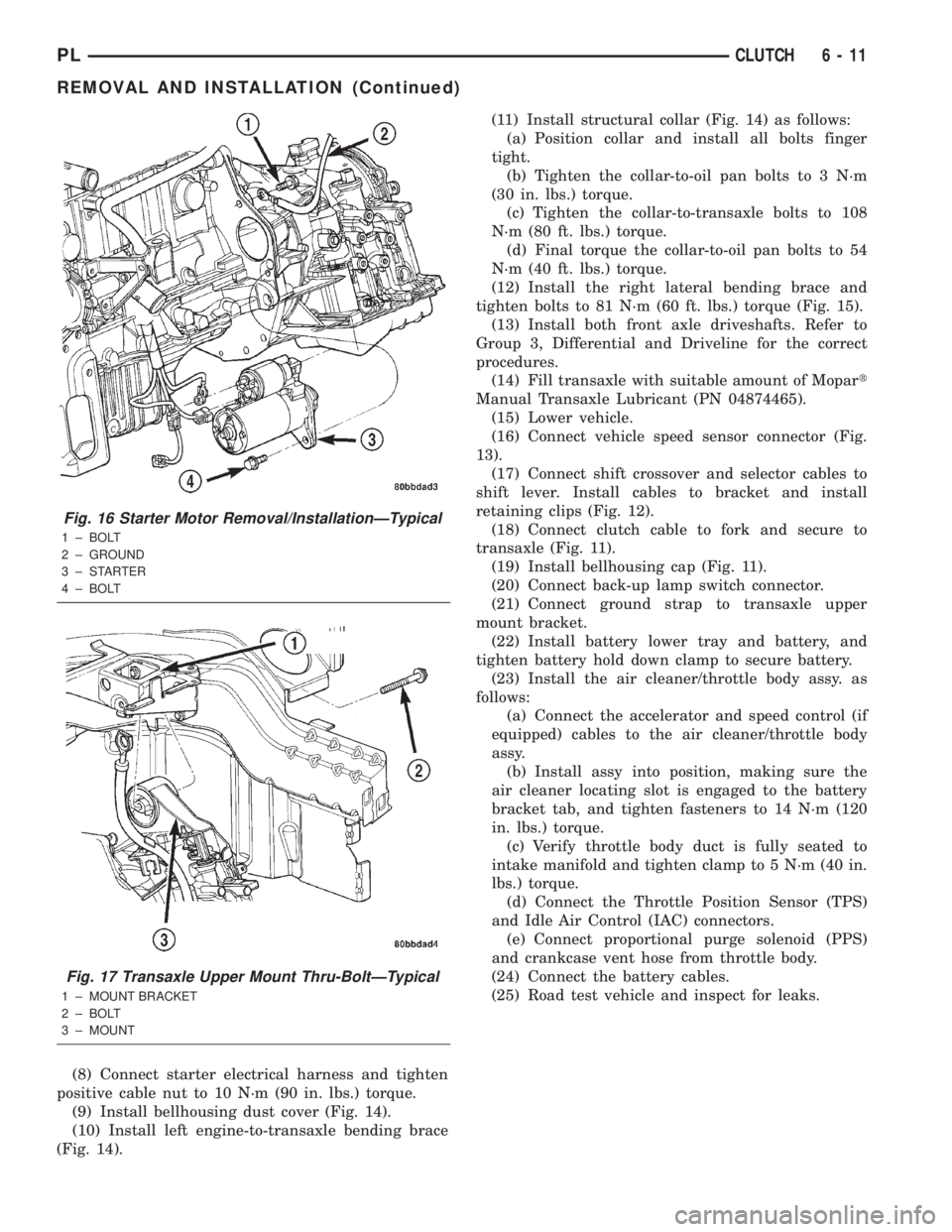

(7) Remove bellhousing cap (Fig. 11).

(8) Disconnect clutch cable from release lever and

remove from transaxle (Fig. 11).

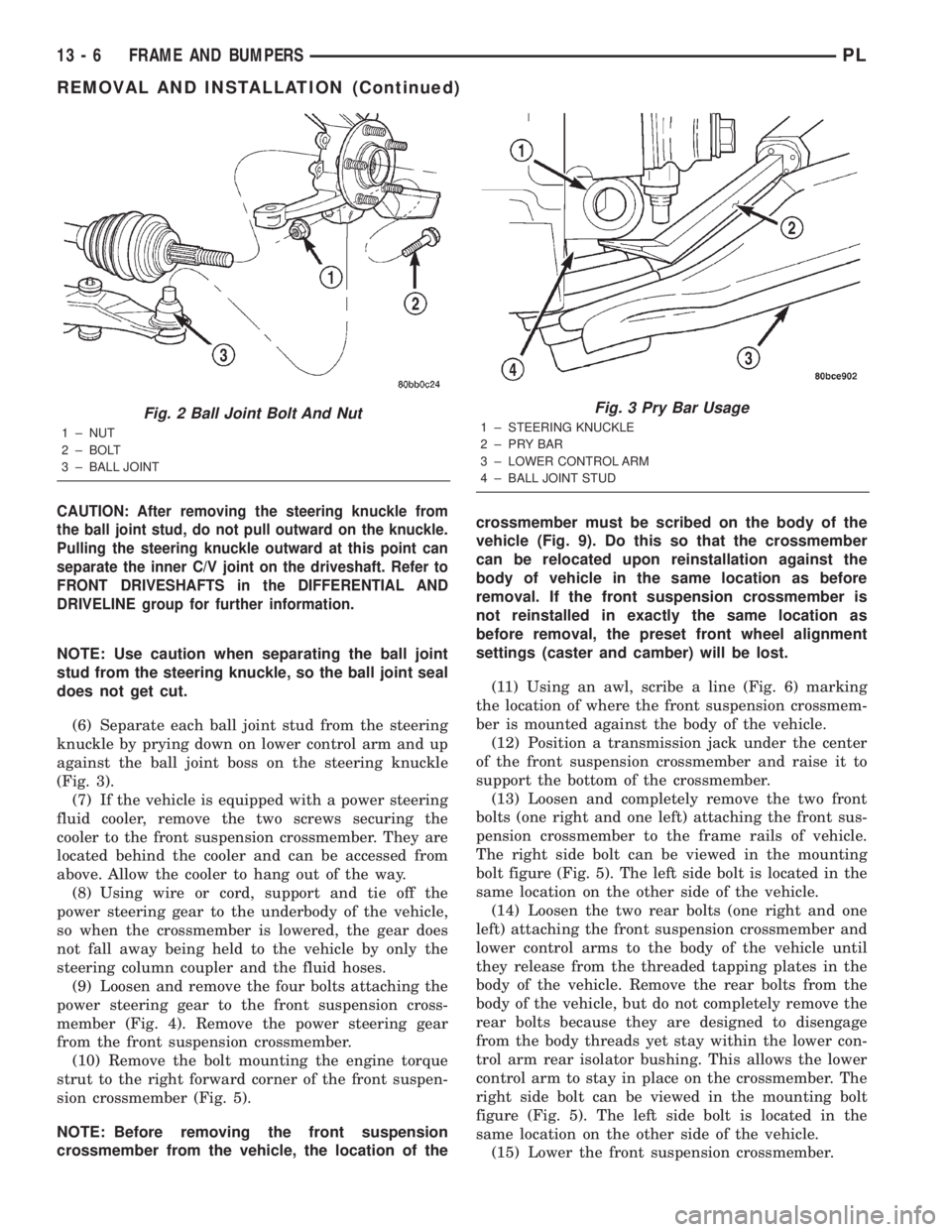

(9) Remove shift cable-to-bracket clips (Fig. 12).

(10) Disconnect shift selector and crossover cable

from levers (Fig. 12). Remove cables and secure out

of the way.

(11) Disconnect the vehicle speed sensor connector

(Fig. 13).

(12) Raise vehicle on hoist.

(13) Remove transaxle oil drain plug and drain oil

into a suitable container.

(14) Remove both axle shafts. Refer to Group 3,

Differential and Driveline for the correct procedures.

(15) Remove structural collar (Fig. 14).

(16) Remove the left engine-to-transaxle lateral

bending brace (Fig. 14).

(17) Remove bellhousing dust cover (Fig. 14).

(18) Remove the right engine-to-transaxle lateral

bending brace (Fig. 15).(19) Remove starter motor (Fig. 16).

(20) Remove drive plate-to-clutch module bolts.

(21) Support engine at oil pan with screw jack and

wood block.

(22) Remove transaxle upper mount thru-bolt.

Gain access to this bolt through the driver's side

wheel house (Fig. 17).

(23) Carefully lower engine and transaxle on screw

jack until proper removal clearance is obtained.

Fig. 10 Air Cleaner Assembly Removal/Installation

1 ± AIR CLEANER ASSY.

2 ± THROTTLE BODY DUCTFWD

Fig. 11 Clutch Cable at Transaxle

1 ± CLUTCH CABLE

2 ± TRANSAXLE

3 ± BELLHOUSING CAP

Fig. 12 Shift Cables at Transaxle

1 ± SHIFT CABLES

2 ± CLIPS

3 ± BRACKET

PLCLUTCH 6 - 9

REMOVAL AND INSTALLATION (Continued)

Page 176 of 1285

(8) Connect starter electrical harness and tighten

positive cable nut to 10 N´m (90 in. lbs.) torque.

(9) Install bellhousing dust cover (Fig. 14).

(10) Install left engine-to-transaxle bending brace

(Fig. 14).(11) Install structural collar (Fig. 14) as follows:

(a) Position collar and install all bolts finger

tight.

(b) Tighten the collar-to-oil pan bolts to 3 N´m

(30 in. lbs.) torque.

(c) Tighten the collar-to-transaxle bolts to 108

N´m (80 ft. lbs.) torque.

(d) Final torque the collar-to-oil pan bolts to 54

N´m (40 ft. lbs.) torque.

(12) Install the right lateral bending brace and

tighten bolts to 81 N´m (60 ft. lbs.) torque (Fig. 15).

(13) Install both front axle driveshafts. Refer to

Group 3, Differential and Driveline for the correct

procedures.

(14) Fill transaxle with suitable amount of Mopart

Manual Transaxle Lubricant (PN 04874465).

(15) Lower vehicle.

(16) Connect vehicle speed sensor connector (Fig.

13).

(17) Connect shift crossover and selector cables to

shift lever. Install cables to bracket and install

retaining clips (Fig. 12).

(18) Connect clutch cable to fork and secure to

transaxle (Fig. 11).

(19) Install bellhousing cap (Fig. 11).

(20) Connect back-up lamp switch connector.

(21) Connect ground strap to transaxle upper

mount bracket.

(22) Install battery lower tray and battery, and

tighten battery hold down clamp to secure battery.

(23) Install the air cleaner/throttle body assy. as

follows:

(a) Connect the accelerator and speed control (if

equipped) cables to the air cleaner/throttle body

assy.

(b) Install assy into position, making sure the

air cleaner locating slot is engaged to the battery

bracket tab, and tighten fasteners to 14 N´m (120

in. lbs.) torque.

(c) Verify throttle body duct is fully seated to

intake manifold and tighten clamp to 5 N´m (40 in.

lbs.) torque.

(d) Connect the Throttle Position Sensor (TPS)

and Idle Air Control (IAC) connectors.

(e) Connect proportional purge solenoid (PPS)

and crankcase vent hose from throttle body.

(24) Connect the battery cables.

(25) Road test vehicle and inspect for leaks.

Fig. 16 Starter Motor Removal/InstallationÐTypical

1 ± BOLT

2 ± GROUND

3±STARTER

4 ± BOLT

Fig. 17 Transaxle Upper Mount Thru-BoltÐTypical

1 ± MOUNT BRACKET

2 ± BOLT

3 ± MOUNT

PLCLUTCH 6 - 11

REMOVAL AND INSTALLATION (Continued)

Page 811 of 1285

CAUTION: After removing the steering knuckle from

the ball joint stud, do not pull outward on the knuckle.

Pulling the steering knuckle outward at this point can

separate the inner C/V joint on the driveshaft. Refer to

FRONT DRIVESHAFTS in the DIFFERENTIAL AND

DRIVELINE group for further information.

NOTE: Use caution when separating the ball joint

stud from the steering knuckle, so the ball joint seal

does not get cut.

(6) Separate each ball joint stud from the steering

knuckle by prying down on lower control arm and up

against the ball joint boss on the steering knuckle

(Fig. 3).

(7) If the vehicle is equipped with a power steering

fluid cooler, remove the two screws securing the

cooler to the front suspension crossmember. They are

located behind the cooler and can be accessed from

above. Allow the cooler to hang out of the way.

(8) Using wire or cord, support and tie off the

power steering gear to the underbody of the vehicle,

so when the crossmember is lowered, the gear does

not fall away being held to the vehicle by only the

steering column coupler and the fluid hoses.

(9) Loosen and remove the four bolts attaching the

power steering gear to the front suspension cross-

member (Fig. 4). Remove the power steering gear

from the front suspension crossmember.

(10) Remove the bolt mounting the engine torque

strut to the right forward corner of the front suspen-

sion crossmember (Fig. 5).

NOTE: Before removing the front suspension

crossmember from the vehicle, the location of thecrossmember must be scribed on the body of the

vehicle (Fig. 9). Do this so that the crossmember

can be relocated upon reinstallation against the

body of vehicle in the same location as before

removal. If the front suspension crossmember is

not reinstalled in exactly the same location as

before removal, the preset front wheel alignment

settings (caster and camber) will be lost.

(11) Using an awl, scribe a line (Fig. 6) marking

the location of where the front suspension crossmem-

ber is mounted against the body of the vehicle.

(12) Position a transmission jack under the center

of the front suspension crossmember and raise it to

support the bottom of the crossmember.

(13) Loosen and completely remove the two front

bolts (one right and one left) attaching the front sus-

pension crossmember to the frame rails of vehicle.

The right side bolt can be viewed in the mounting

bolt figure (Fig. 5). The left side bolt is located in the

same location on the other side of the vehicle.

(14) Loosen the two rear bolts (one right and one

left) attaching the front suspension crossmember and

lower control arms to the body of the vehicle until

they release from the threaded tapping plates in the

body of the vehicle. Remove the rear bolts from the

body of the vehicle, but do not completely remove the

rear bolts because they are designed to disengage

from the body threads yet stay within the lower con-

trol arm rear isolator bushing. This allows the lower

control arm to stay in place on the crossmember. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 5). The left side bolt is located in the

same location on the other side of the vehicle.

(15) Lower the front suspension crossmember.

Fig. 2 Ball Joint Bolt And Nut

1 ± NUT

2 ± BOLT

3 ± BALL JOINT

Fig. 3 Pry Bar Usage

1 ± STEERING KNUCKLE

2±PRYBAR

3 ± LOWER CONTROL ARM

4 ± BALL JOINT STUD

13 - 6 FRAME AND BUMPERSPL

REMOVAL AND INSTALLATION (Continued)

Page 914 of 1285

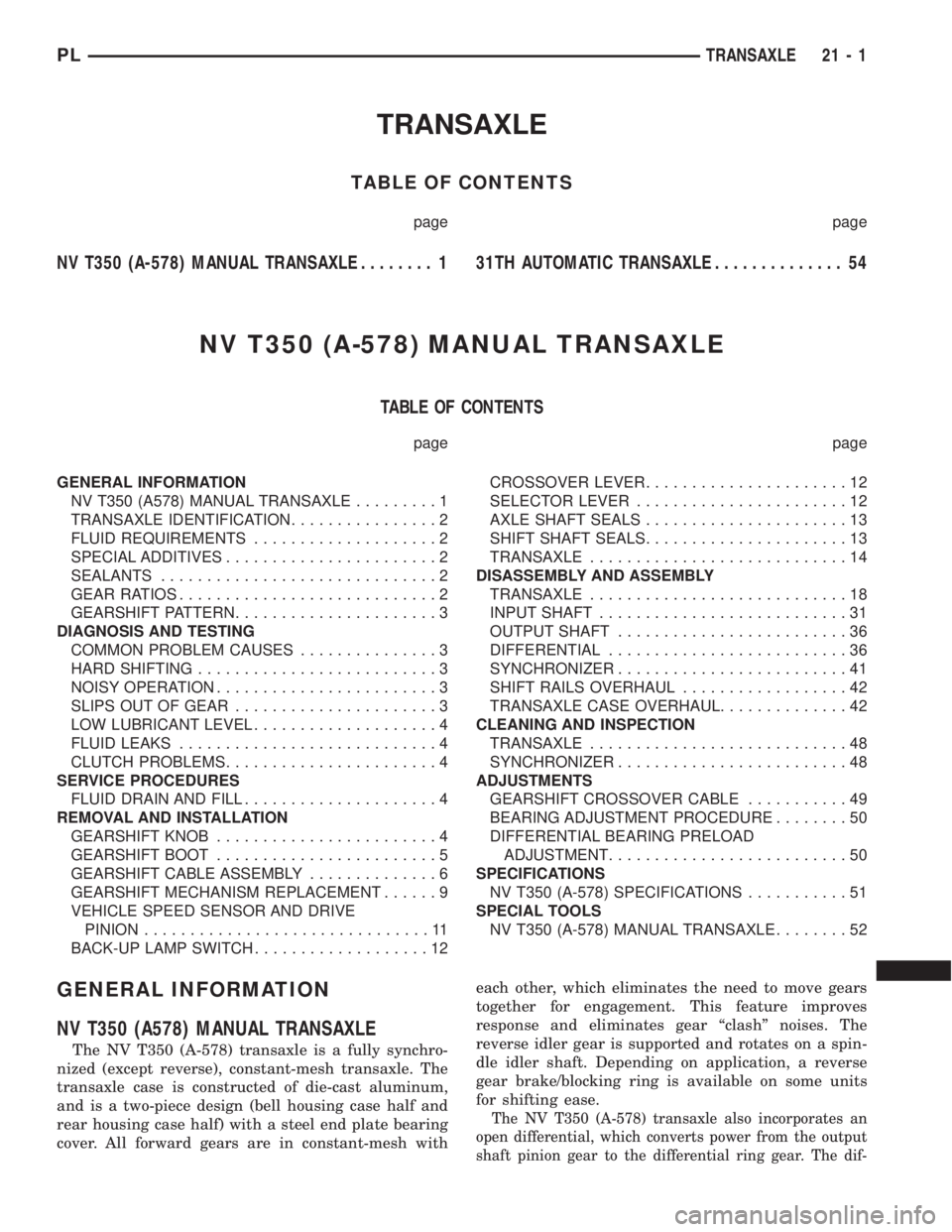

TRANSAXLE

TABLE OF CONTENTS

page page

NV T350 (A-578) MANUAL TRANSAXLE........ 131TH AUTOMATIC TRANSAXLE.............. 54

NV T350 (A-578) MANUAL TRANSAXLE

TABLE OF CONTENTS

page page

GENERAL INFORMATION

NV T350 (A578) MANUAL TRANSAXLE.........1

TRANSAXLE IDENTIFICATION................2

FLUID REQUIREMENTS....................2

SPECIAL ADDITIVES.......................2

SEALANTS..............................2

GEAR RATIOS............................2

GEARSHIFT PATTERN......................3

DIAGNOSIS AND TESTING

COMMON PROBLEM CAUSES...............3

HARD SHIFTING..........................3

NOISY OPERATION........................3

SLIPS OUT OF GEAR......................3

LOW LUBRICANT LEVEL....................4

FLUID LEAKS............................4

CLUTCH PROBLEMS.......................4

SERVICE PROCEDURES

FLUID DRAIN AND FILL.....................4

REMOVAL AND INSTALLATION

GEARSHIFT KNOB........................4

GEARSHIFT BOOT........................5

GEARSHIFT CABLE ASSEMBLY..............6

GEARSHIFT MECHANISM REPLACEMENT......9

VEHICLE SPEED SENSOR AND DRIVE

PINION...............................11

BACK-UP LAMP SWITCH...................12CROSSOVER LEVER......................12

SELECTOR LEVER.......................12

AXLE SHAFT SEALS......................13

SHIFT SHAFT SEALS......................13

TRANSAXLE............................14

DISASSEMBLY AND ASSEMBLY

TRANSAXLE............................18

INPUT SHAFT...........................31

OUTPUT SHAFT.........................36

DIFFERENTIAL..........................36

SYNCHRONIZER.........................41

SHIFT RAILS OVERHAUL..................42

TRANSAXLE CASE OVERHAUL..............42

CLEANING AND INSPECTION

TRANSAXLE............................48

SYNCHRONIZER.........................48

ADJUSTMENTS

GEARSHIFT CROSSOVER CABLE...........49

BEARING ADJUSTMENT PROCEDURE........50

DIFFERENTIAL BEARING PRELOAD

ADJUSTMENT..........................50

SPECIFICATIONS

NV T350 (A-578) SPECIFICATIONS...........51

SPECIAL TOOLS

NV T350 (A-578) MANUAL TRANSAXLE........52

GENERAL INFORMATION

NV T350 (A578) MANUAL TRANSAXLE

The NV T350 (A-578) transaxle is a fully synchro-

nized (except reverse), constant-mesh transaxle. The

transaxle case is constructed of die-cast aluminum,

and is a two-piece design (bell housing case half and

rear housing case half) with a steel end plate bearing

cover. All forward gears are in constant-mesh witheach other, which eliminates the need to move gears

together for engagement. This feature improves

response and eliminates gear ªclashº noises. The

reverse idler gear is supported and rotates on a spin-

dle idler shaft. Depending on application, a reverse

gear brake/blocking ring is available on some units

for shifting ease.

The NV T350 (A-578) transaxle also incorporates an

open differential, which converts power from the output

shaft pinion gear to the differential ring gear. The dif-

PLTRANSAXLE 21 - 1

Page 915 of 1285

ferential case transfers torque from the ring gear to the

drive axles by means of differential side gears.

The NV T350 (A-578) transaxle internal components

can only be serviced by separating the case halves.

CAUTION: The transaxle output shaft is serviced as

a unit. No disassembly and reassembly is possible.

Damage to the transaxle may result.

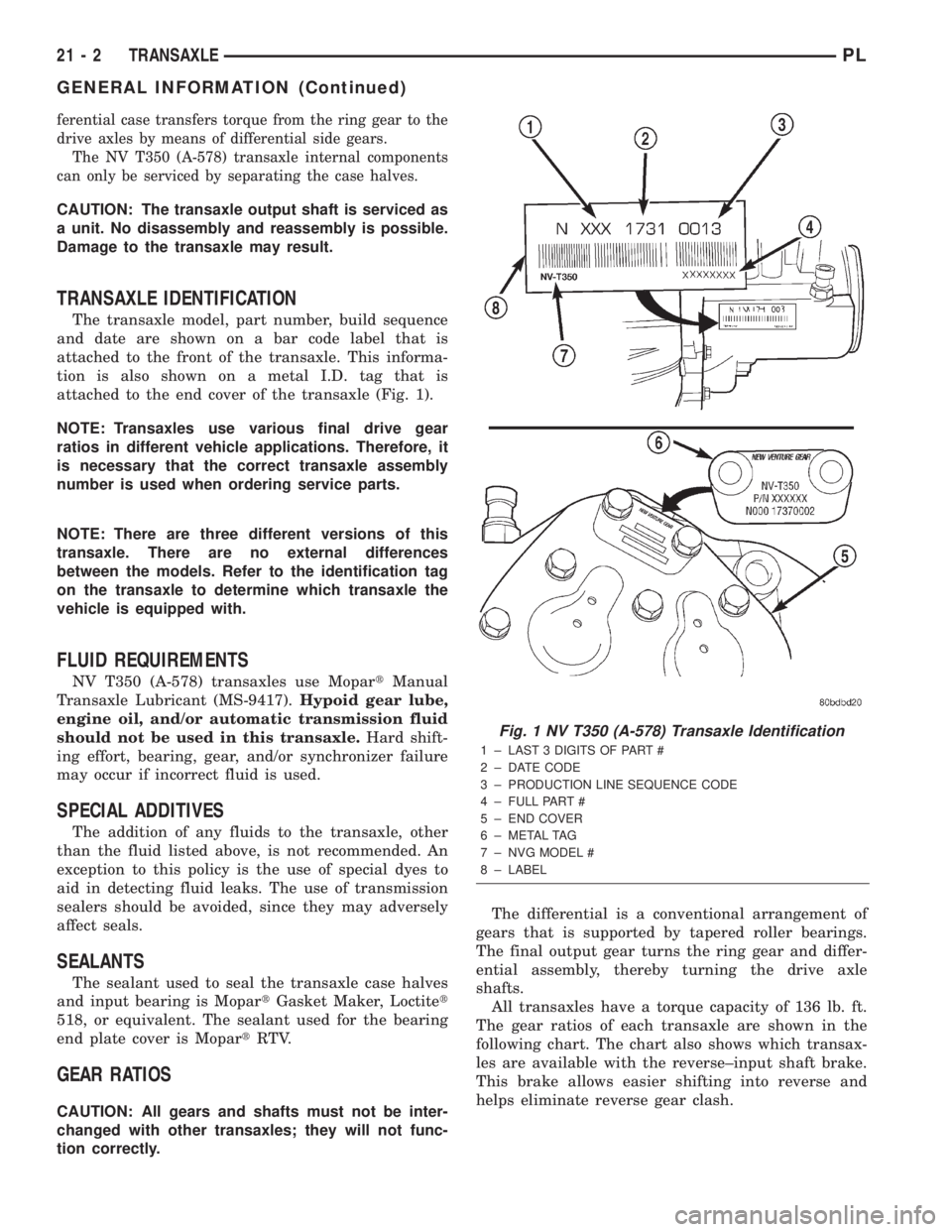

TRANSAXLE IDENTIFICATION

The transaxle model, part number, build sequence

and date are shown on a bar code label that is

attached to the front of the transaxle. This informa-

tion is also shown on a metal I.D. tag that is

attached to the end cover of the transaxle (Fig. 1).

NOTE: Transaxles use various final drive gear

ratios in different vehicle applications. Therefore, it

is necessary that the correct transaxle assembly

number is used when ordering service parts.

NOTE: There are three different versions of this

transaxle. There are no external differences

between the models. Refer to the identification tag

on the transaxle to determine which transaxle the

vehicle is equipped with.

FLUID REQUIREMENTS

NV T350 (A-578) transaxles use MopartManual

Transaxle Lubricant (MS-9417).Hypoid gear lube,

engine oil, and/or automatic transmission fluid

should not be used in this transaxle.Hard shift-

ing effort, bearing, gear, and/or synchronizer failure

may occur if incorrect fluid is used.

SPECIAL ADDITIVES

The addition of any fluids to the transaxle, other

than the fluid listed above, is not recommended. An

exception to this policy is the use of special dyes to

aid in detecting fluid leaks. The use of transmission

sealers should be avoided, since they may adversely

affect seals.

SEALANTS

The sealant used to seal the transaxle case halves

and input bearing is MopartGasket Maker, Loctitet

518, or equivalent. The sealant used for the bearing

end plate cover is MopartRTV.

GEAR RATIOS

CAUTION: All gears and shafts must not be inter-

changed with other transaxles; they will not func-

tion correctly.The differential is a conventional arrangement of

gears that is supported by tapered roller bearings.

The final output gear turns the ring gear and differ-

ential assembly, thereby turning the drive axle

shafts.

All transaxles have a torque capacity of 136 lb. ft.

The gear ratios of each transaxle are shown in the

following chart. The chart also shows which transax-

les are available with the reverse±input shaft brake.

This brake allows easier shifting into reverse and

helps eliminate reverse gear clash.

Fig. 1 NV T350 (A-578) Transaxle Identification

1 ± LAST 3 DIGITS OF PART #

2 ± DATE CODE

3 ± PRODUCTION LINE SEQUENCE CODE

4 ± FULL PART #

5 ± END COVER

6 ± METAL TAG

7 ± NVG MODEL #

8 ± LABEL

21 - 2 TRANSAXLEPL

GENERAL INFORMATION (Continued)

Page 917 of 1285

LOW LUBRICANT LEVEL

Insufficient transaxle lubricant is usually the

result of leaks, or inaccurate fluid level check or refill

method. Leakage is evident by the presence of oil

around the leak point. If leakage is not evident, the

condition is probably the result of an underfill.

If air±powered lubrication equipment is used to fill

a transaxle, be sure the equipment is properly cali-

brated. Equipment out of calibration can lead to an

underfill condition.

FLUID LEAKS

Fluid leaks can occur around the input shaft seal,

axleshaft seals, case split lines, and the end cover. Be

careful not to misdiagnose an input shaft seal leak

for an engine rear main seal leak. Also, the transaxle

case sealer (split line) will accumulate dirt and look

like an oil leak.

CLUTCH PROBLEMS

Worn, damaged, or misaligned clutch components

can cause difficult shifting, gear clash, and noise.

A worn or damaged clutch disc, pressure plate, or

release bearing can cause hard shifting and gear

clash.

SERVICE PROCEDURES

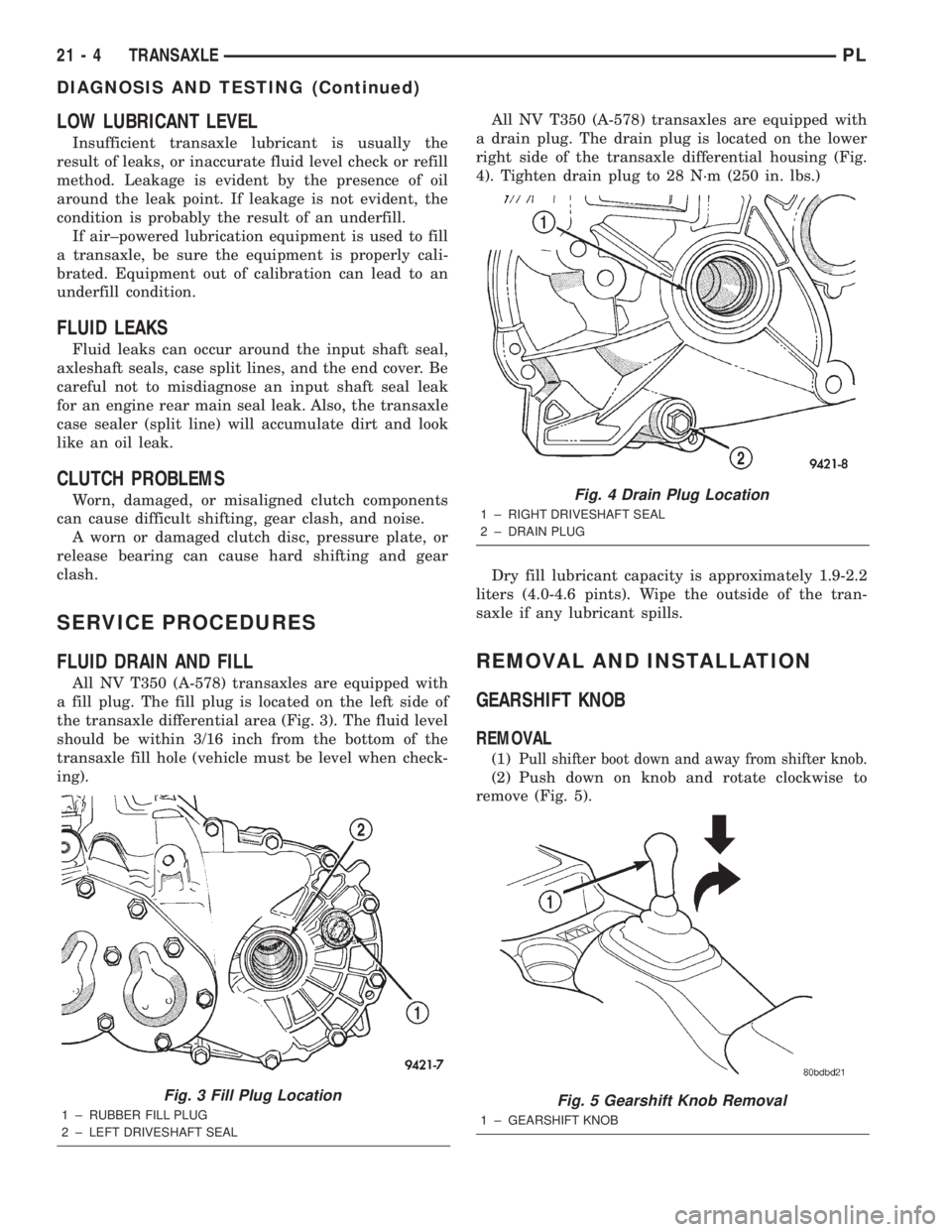

FLUID DRAIN AND FILL

All NV T350 (A-578) transaxles are equipped with

a fill plug. The fill plug is located on the left side of

the transaxle differential area (Fig. 3). The fluid level

should be within 3/16 inch from the bottom of the

transaxle fill hole (vehicle must be level when check-

ing).All NV T350 (A-578) transaxles are equipped with

a drain plug. The drain plug is located on the lower

right side of the transaxle differential housing (Fig.

4). Tighten drain plug to 28 N´m (250 in. lbs.)

Dry fill lubricant capacity is approximately 1.9-2.2

liters (4.0-4.6 pints). Wipe the outside of the tran-

saxle if any lubricant spills.

REMOVAL AND INSTALLATION

GEARSHIFT KNOB

REMOVAL

(1)Pull shifter boot down and away from shifter knob.

(2) Push down on knob and rotate clockwise to

remove (Fig. 5).

Fig. 3 Fill Plug Location

1 ± RUBBER FILL PLUG

2 ± LEFT DRIVESHAFT SEAL

Fig. 4 Drain Plug Location

1 ± RIGHT DRIVESHAFT SEAL

2 ± DRAIN PLUG

Fig. 5 Gearshift Knob Removal

1 ± GEARSHIFT KNOB

21 - 4 TRANSAXLEPL

DIAGNOSIS AND TESTING (Continued)

Page 928 of 1285

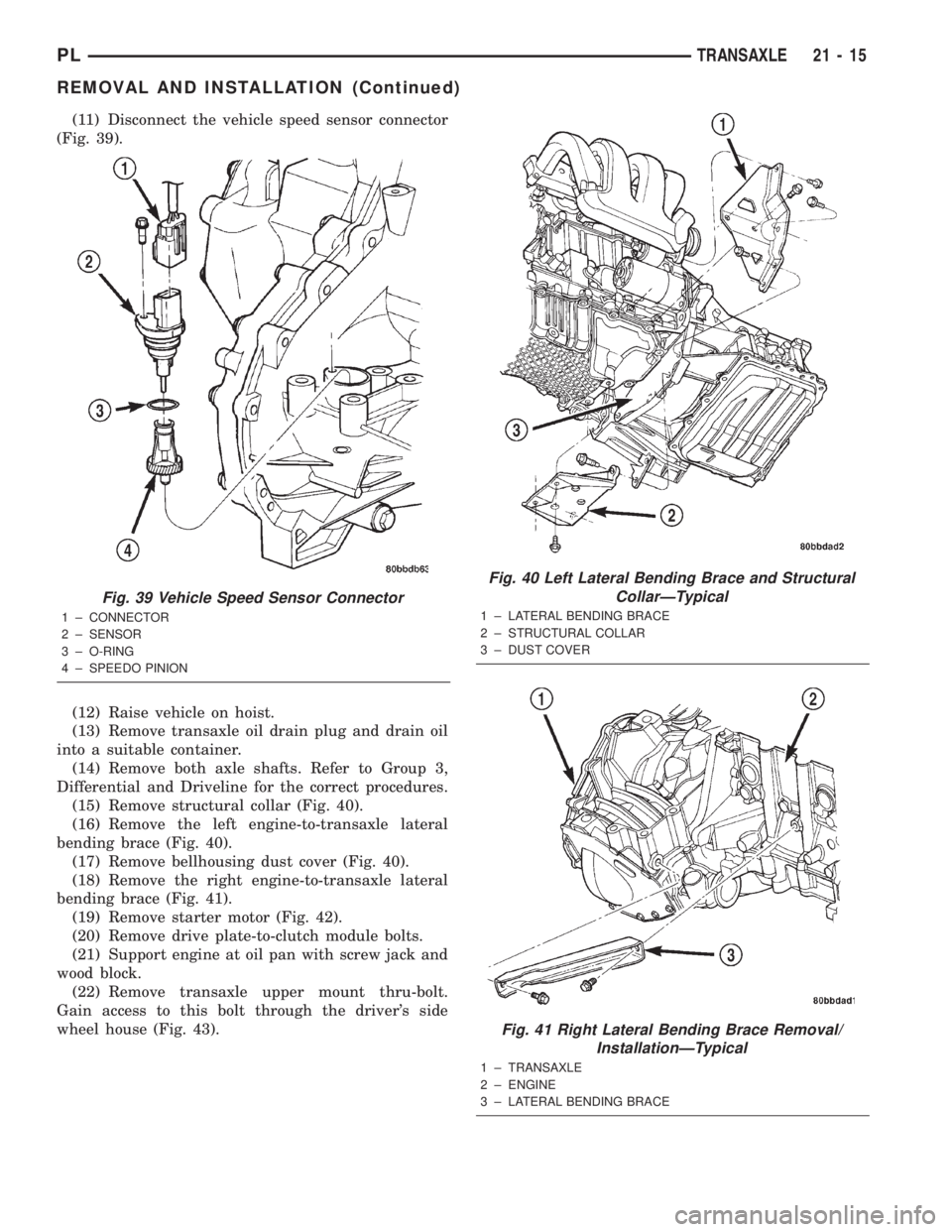

(11) Disconnect the vehicle speed sensor connector

(Fig. 39).

(12) Raise vehicle on hoist.

(13) Remove transaxle oil drain plug and drain oil

into a suitable container.

(14) Remove both axle shafts. Refer to Group 3,

Differential and Driveline for the correct procedures.

(15) Remove structural collar (Fig. 40).

(16) Remove the left engine-to-transaxle lateral

bending brace (Fig. 40).

(17) Remove bellhousing dust cover (Fig. 40).

(18) Remove the right engine-to-transaxle lateral

bending brace (Fig. 41).

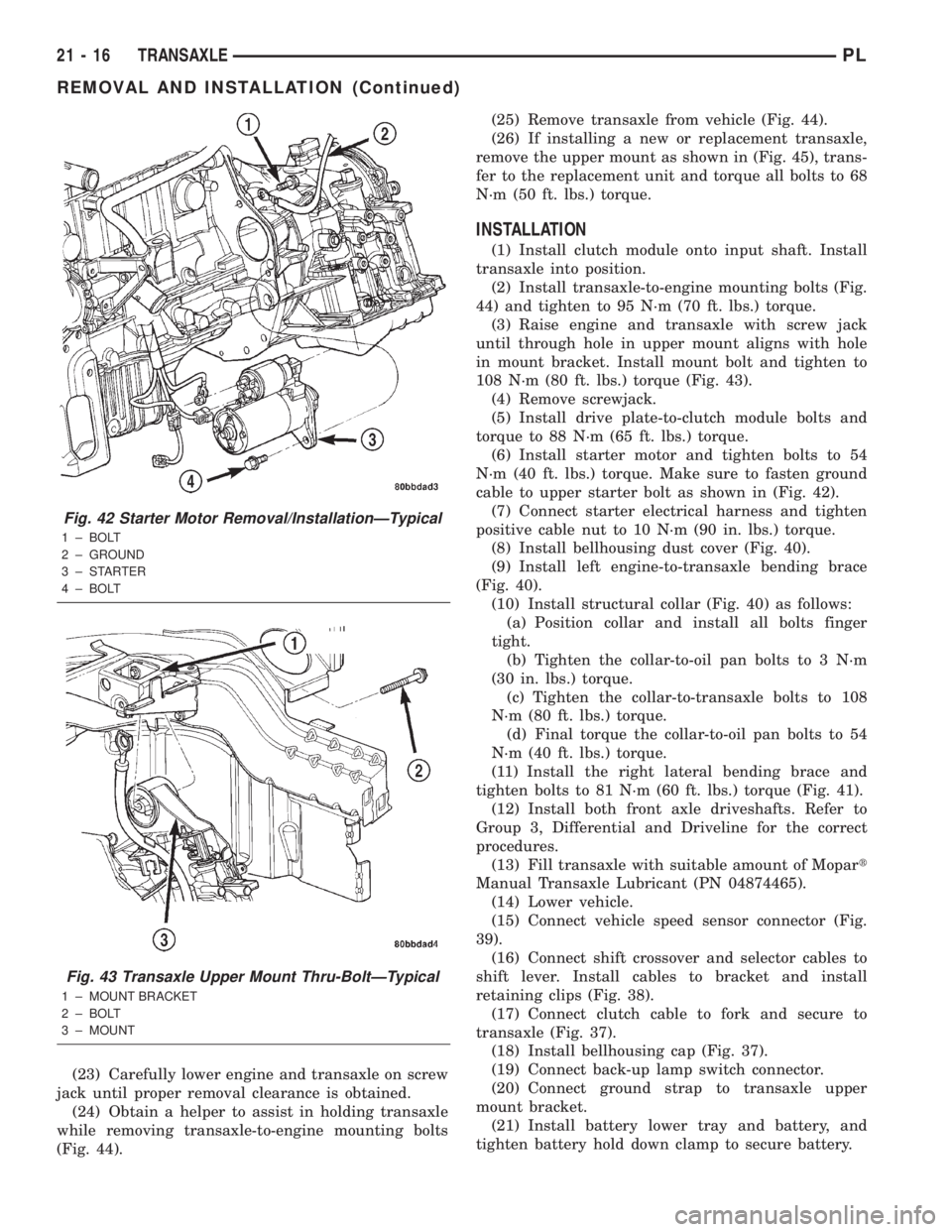

(19) Remove starter motor (Fig. 42).

(20) Remove drive plate-to-clutch module bolts.

(21) Support engine at oil pan with screw jack and

wood block.

(22) Remove transaxle upper mount thru-bolt.

Gain access to this bolt through the driver's side

wheel house (Fig. 43).

Fig. 39 Vehicle Speed Sensor Connector

1 ± CONNECTOR

2 ± SENSOR

3 ± O-RING

4 ± SPEEDO PINION

Fig. 40 Left Lateral Bending Brace and Structural

CollarÐTypical

1 ± LATERAL BENDING BRACE

2 ± STRUCTURAL COLLAR

3 ± DUST COVER

Fig. 41 Right Lateral Bending Brace Removal/

InstallationÐTypical

1 ± TRANSAXLE

2 ± ENGINE

3 ± LATERAL BENDING BRACE

PLTRANSAXLE 21 - 15

REMOVAL AND INSTALLATION (Continued)

Page 929 of 1285

(23) Carefully lower engine and transaxle on screw

jack until proper removal clearance is obtained.

(24) Obtain a helper to assist in holding transaxle

while removing transaxle-to-engine mounting bolts

(Fig. 44).(25) Remove transaxle from vehicle (Fig. 44).

(26) If installing a new or replacement transaxle,

remove the upper mount as shown in (Fig. 45), trans-

fer to the replacement unit and torque all bolts to 68

N´m (50 ft. lbs.) torque.

INSTALLATION

(1) Install clutch module onto input shaft. Install

transaxle into position.

(2) Install transaxle-to-engine mounting bolts (Fig.

44) and tighten to 95 N´m (70 ft. lbs.) torque.

(3) Raise engine and transaxle with screw jack

until through hole in upper mount aligns with hole

in mount bracket. Install mount bolt and tighten to

108 N´m (80 ft. lbs.) torque (Fig. 43).

(4) Remove screwjack.

(5) Install drive plate-to-clutch module bolts and

torque to 88 N´m (65 ft. lbs.) torque.

(6) Install starter motor and tighten bolts to 54

N´m (40 ft. lbs.) torque. Make sure to fasten ground

cable to upper starter bolt as shown in (Fig. 42).

(7) Connect starter electrical harness and tighten

positive cable nut to 10 N´m (90 in. lbs.) torque.

(8) Install bellhousing dust cover (Fig. 40).

(9) Install left engine-to-transaxle bending brace

(Fig. 40).

(10) Install structural collar (Fig. 40) as follows:

(a) Position collar and install all bolts finger

tight.

(b) Tighten the collar-to-oil pan bolts to 3 N´m

(30 in. lbs.) torque.

(c) Tighten the collar-to-transaxle bolts to 108

N´m (80 ft. lbs.) torque.

(d) Final torque the collar-to-oil pan bolts to 54

N´m (40 ft. lbs.) torque.

(11) Install the right lateral bending brace and

tighten bolts to 81 N´m (60 ft. lbs.) torque (Fig. 41).

(12) Install both front axle driveshafts. Refer to

Group 3, Differential and Driveline for the correct

procedures.

(13) Fill transaxle with suitable amount of Mopart

Manual Transaxle Lubricant (PN 04874465).

(14) Lower vehicle.

(15) Connect vehicle speed sensor connector (Fig.

39).

(16) Connect shift crossover and selector cables to

shift lever. Install cables to bracket and install

retaining clips (Fig. 38).

(17) Connect clutch cable to fork and secure to

transaxle (Fig. 37).

(18) Install bellhousing cap (Fig. 37).

(19) Connect back-up lamp switch connector.

(20) Connect ground strap to transaxle upper

mount bracket.

(21) Install battery lower tray and battery, and

tighten battery hold down clamp to secure battery.

Fig. 42 Starter Motor Removal/InstallationÐTypical

1 ± BOLT

2 ± GROUND

3±STARTER

4 ± BOLT

Fig. 43 Transaxle Upper Mount Thru-BoltÐTypical

1 ± MOUNT BRACKET

2 ± BOLT

3 ± MOUNT

21 - 16 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 932 of 1285

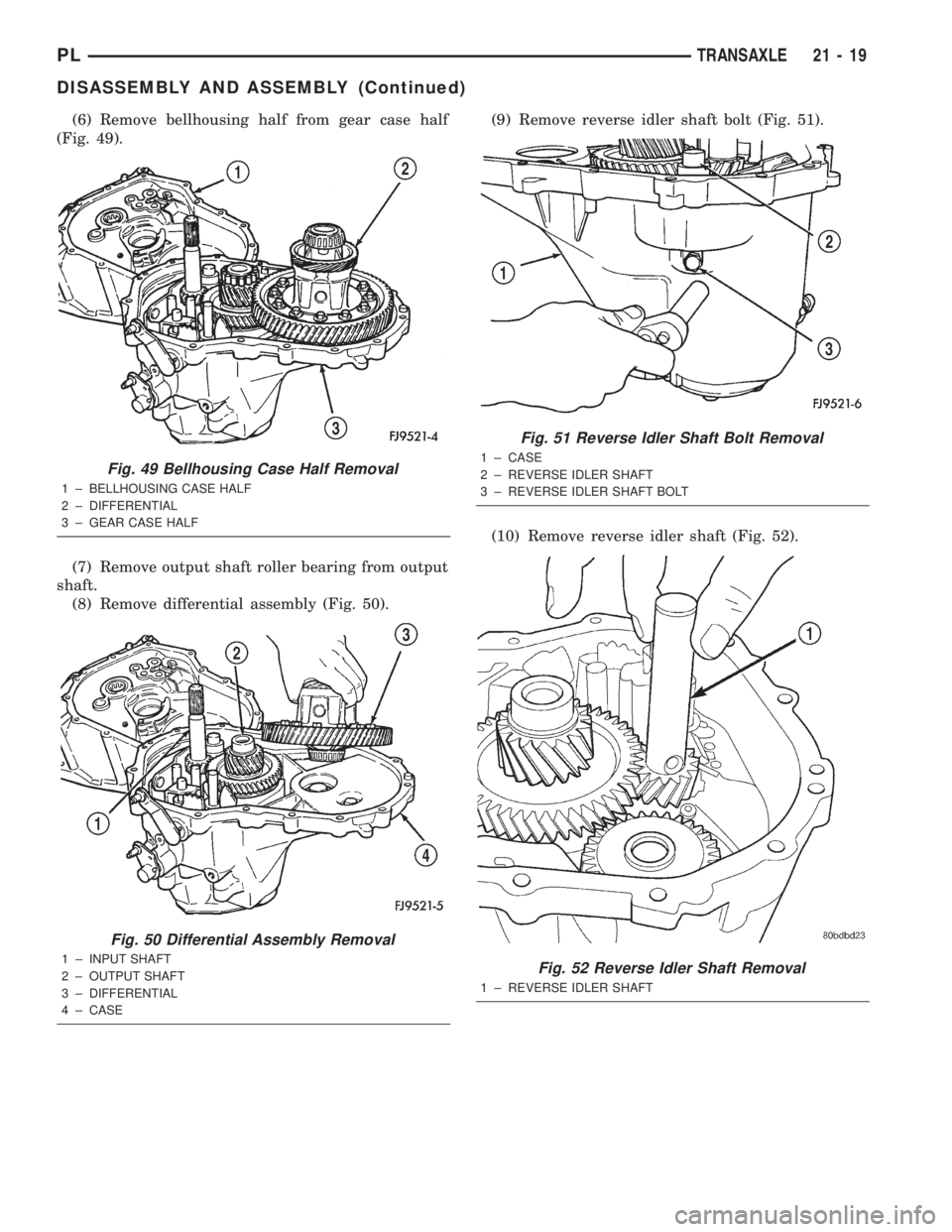

(6) Remove bellhousing half from gear case half

(Fig. 49).

(7) Remove output shaft roller bearing from output

shaft.

(8) Remove differential assembly (Fig. 50).(9) Remove reverse idler shaft bolt (Fig. 51).

(10) Remove reverse idler shaft (Fig. 52).

Fig. 49 Bellhousing Case Half Removal

1 ± BELLHOUSING CASE HALF

2 ± DIFFERENTIAL

3 ± GEAR CASE HALF

Fig. 50 Differential Assembly Removal

1 ± INPUT SHAFT

2 ± OUTPUT SHAFT

3 ± DIFFERENTIAL

4 ± CASE

Fig. 51 Reverse Idler Shaft Bolt Removal

1 ± CASE

2 ± REVERSE IDLER SHAFT

3 ± REVERSE IDLER SHAFT BOLT

Fig. 52 Reverse Idler Shaft Removal

1 ± REVERSE IDLER SHAFT

PLTRANSAXLE 21 - 19

DISASSEMBLY AND ASSEMBLY (Continued)

Page 942 of 1285

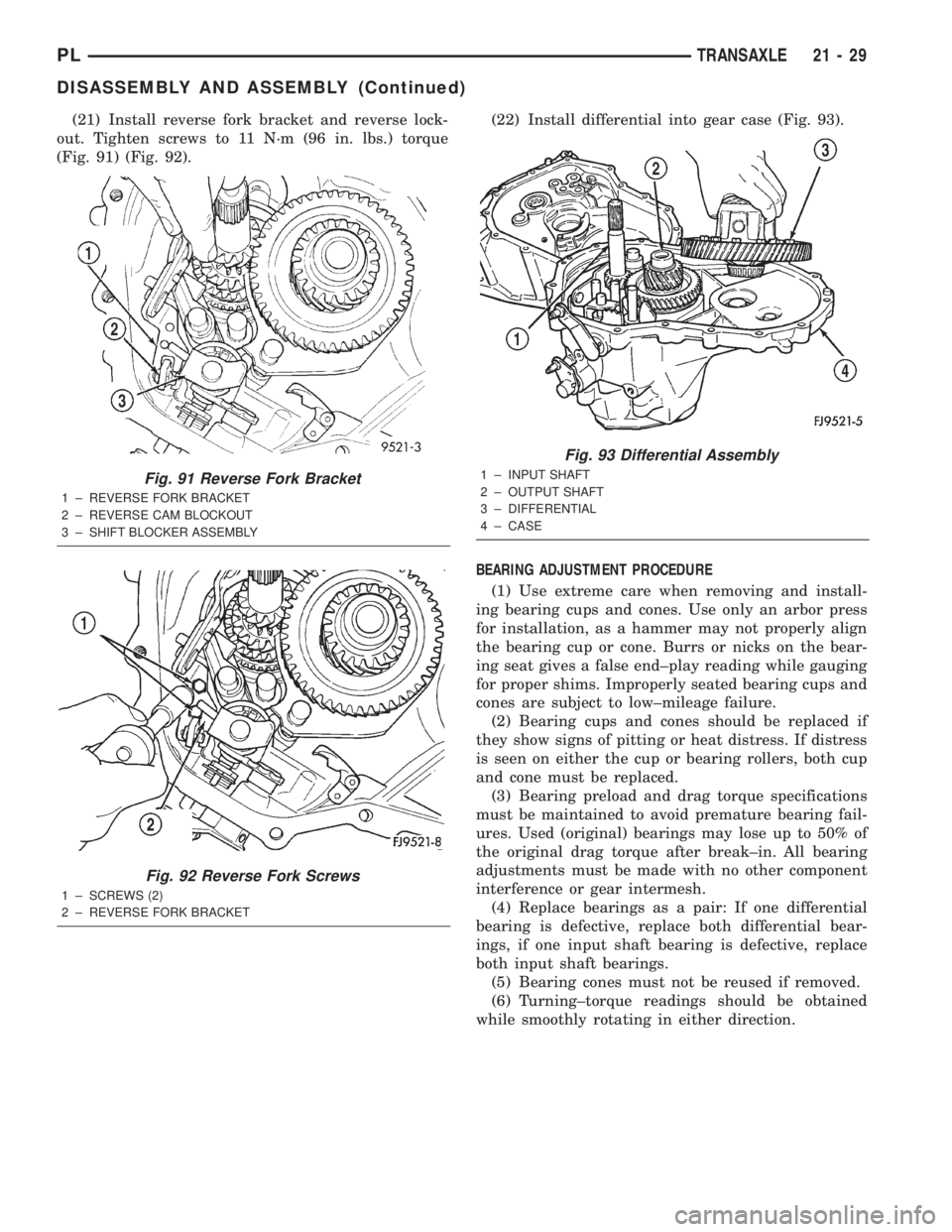

(21) Install reverse fork bracket and reverse lock-

out. Tighten screws to 11 N´m (96 in. lbs.) torque

(Fig. 91) (Fig. 92).(22) Install differential into gear case (Fig. 93).

BEARING ADJUSTMENT PROCEDURE

(1) Use extreme care when removing and install-

ing bearing cups and cones. Use only an arbor press

for installation, as a hammer may not properly align

the bearing cup or cone. Burrs or nicks on the bear-

ing seat gives a false end±play reading while gauging

for proper shims. Improperly seated bearing cups and

cones are subject to low±mileage failure.

(2) Bearing cups and cones should be replaced if

they show signs of pitting or heat distress. If distress

is seen on either the cup or bearing rollers, both cup

and cone must be replaced.

(3) Bearing preload and drag torque specifications

must be maintained to avoid premature bearing fail-

ures. Used (original) bearings may lose up to 50% of

the original drag torque after break±in. All bearing

adjustments must be made with no other component

interference or gear intermesh.

(4) Replace bearings as a pair: If one differential

bearing is defective, replace both differential bear-

ings, if one input shaft bearing is defective, replace

both input shaft bearings.

(5) Bearing cones must not be reused if removed.

(6) Turning±torque readings should be obtained

while smoothly rotating in either direction.

Fig. 91 Reverse Fork Bracket

1 ± REVERSE FORK BRACKET

2 ± REVERSE CAM BLOCKOUT

3 ± SHIFT BLOCKER ASSEMBLY

Fig. 92 Reverse Fork Screws

1 ± SCREWS (2)

2 ± REVERSE FORK BRACKET

Fig. 93 Differential Assembly

1 ± INPUT SHAFT

2 ± OUTPUT SHAFT

3 ± DIFFERENTIAL

4 ± CASE

PLTRANSAXLE 21 - 29

DISASSEMBLY AND ASSEMBLY (Continued)