differential DODGE NEON 2000 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1006 of 1285

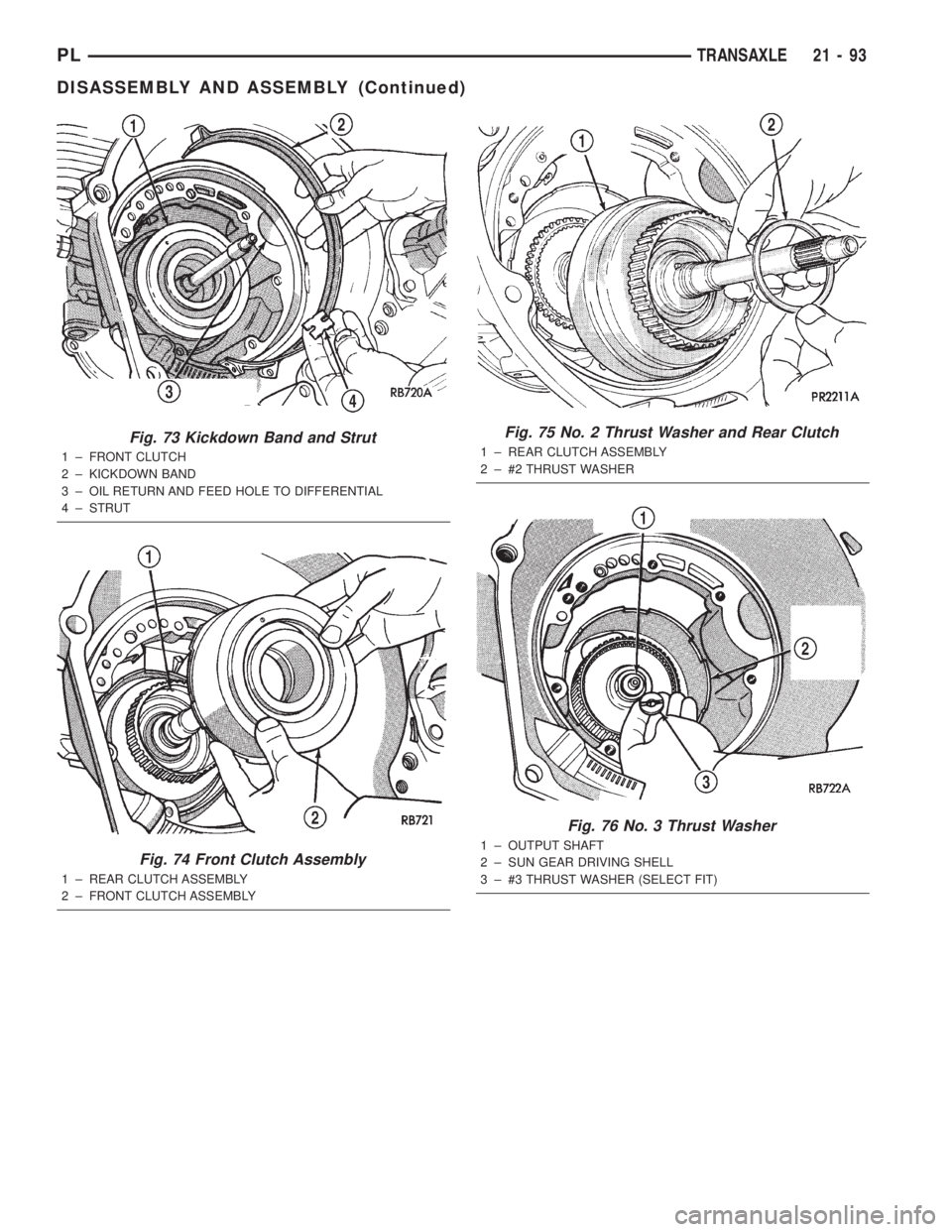

Fig. 73 Kickdown Band and Strut

1 ± FRONT CLUTCH

2 ± KICKDOWN BAND

3 ± OIL RETURN AND FEED HOLE TO DIFFERENTIAL

4 ± STRUT

Fig. 74 Front Clutch Assembly

1 ± REAR CLUTCH ASSEMBLY

2 ± FRONT CLUTCH ASSEMBLY

Fig. 75 No. 2 Thrust Washer and Rear Clutch

1 ± REAR CLUTCH ASSEMBLY

2 ± #2 THRUST WASHER

Fig. 76 No. 3 Thrust Washer

1 ± OUTPUT SHAFT

2 ± SUN GEAR DRIVING SHELL

3 ± #3 THRUST WASHER (SELECT FIT)

PLTRANSAXLE 21 - 93

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1042 of 1285

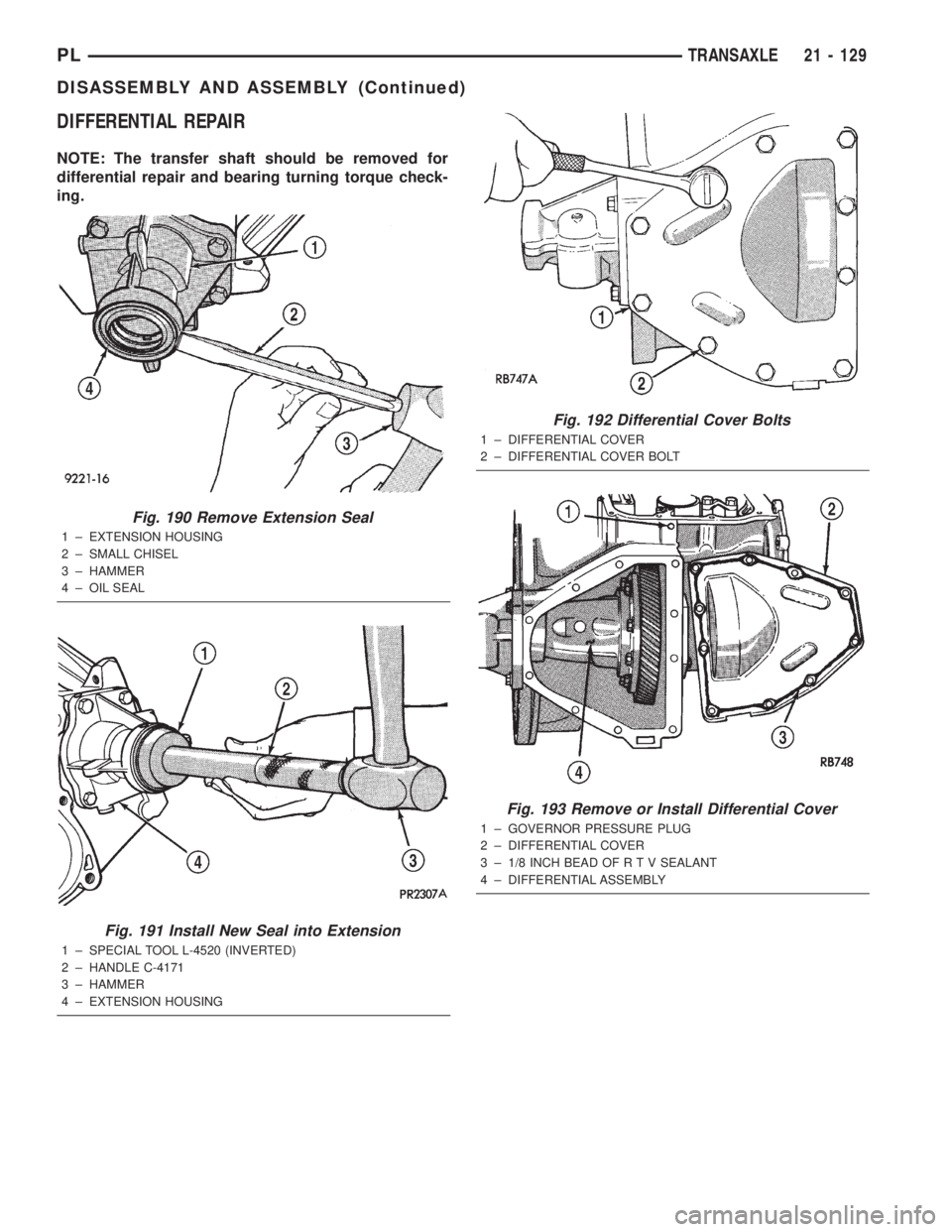

DIFFERENTIAL REPAIR

NOTE: The transfer shaft should be removed for

differential repair and bearing turning torque check-

ing.

Fig. 190 Remove Extension Seal

1 ± EXTENSION HOUSING

2 ± SMALL CHISEL

3 ± HAMMER

4 ± OIL SEAL

Fig. 191 Install New Seal into Extension

1 ± SPECIAL TOOL L-4520 (INVERTED)

2 ± HANDLE C-4171

3 ± HAMMER

4 ± EXTENSION HOUSING

Fig. 192 Differential Cover Bolts

1 ± DIFFERENTIAL COVER

2 ± DIFFERENTIAL COVER BOLT

Fig. 193 Remove or Install Differential Cover

1 ± GOVERNOR PRESSURE PLUG

2 ± DIFFERENTIAL COVER

3 ± 1/8 INCH BEAD OF R T V SEALANT

4 ± DIFFERENTIAL ASSEMBLY

PLTRANSAXLE 21 - 129

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1043 of 1285

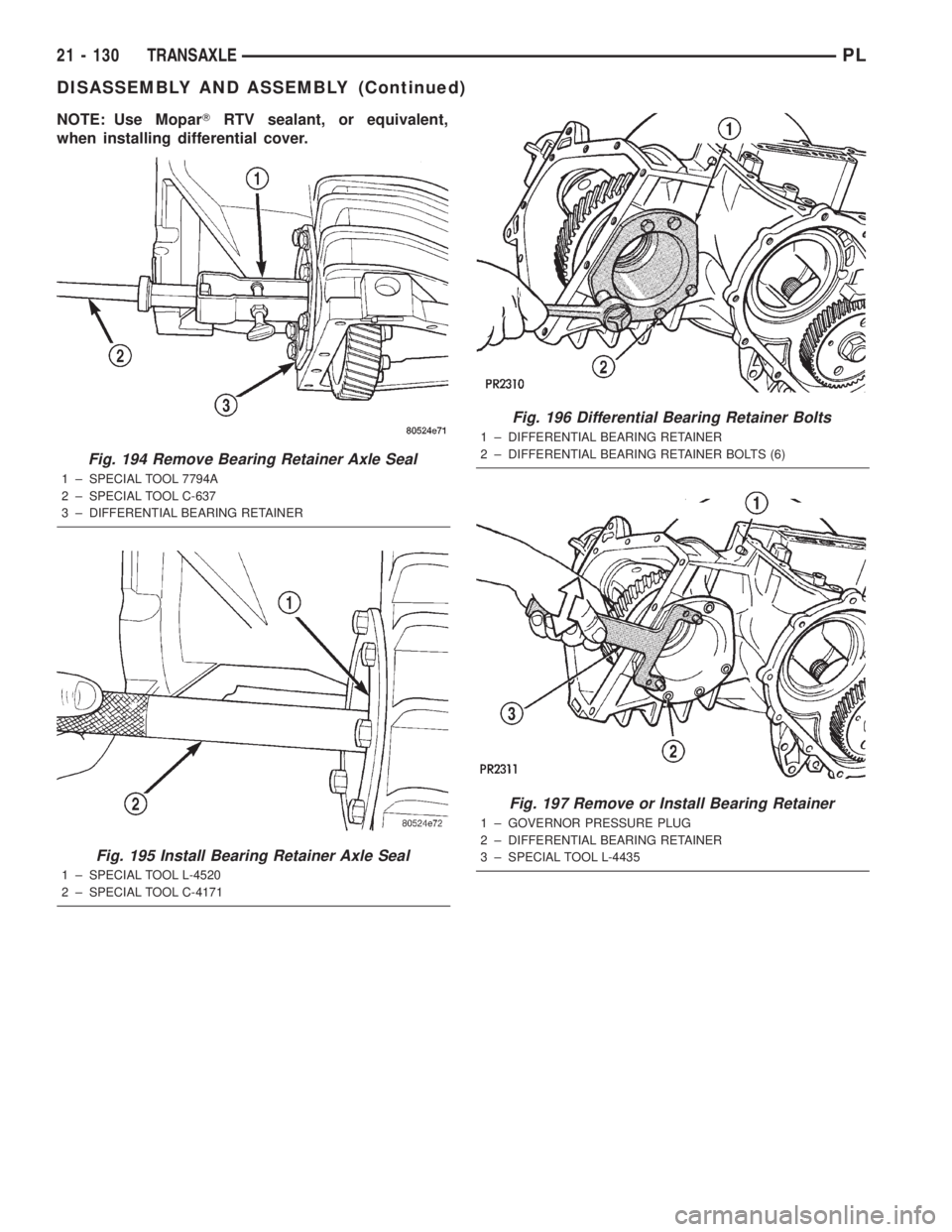

NOTE: Use MoparTRTV sealant, or equivalent,

when installing differential cover.

Fig. 194 Remove Bearing Retainer Axle Seal

1 ± SPECIAL TOOL 7794A

2 ± SPECIAL TOOL C-637

3 ± DIFFERENTIAL BEARING RETAINER

Fig. 195 Install Bearing Retainer Axle Seal

1 ± SPECIAL TOOL L-4520

2 ± SPECIAL TOOL C-4171

Fig. 196 Differential Bearing Retainer Bolts

1 ± DIFFERENTIAL BEARING RETAINER

2 ± DIFFERENTIAL BEARING RETAINER BOLTS (6)

Fig. 197 Remove or Install Bearing Retainer

1 ± GOVERNOR PRESSURE PLUG

2 ± DIFFERENTIAL BEARING RETAINER

3 ± SPECIAL TOOL L-4435

21 - 130 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1044 of 1285

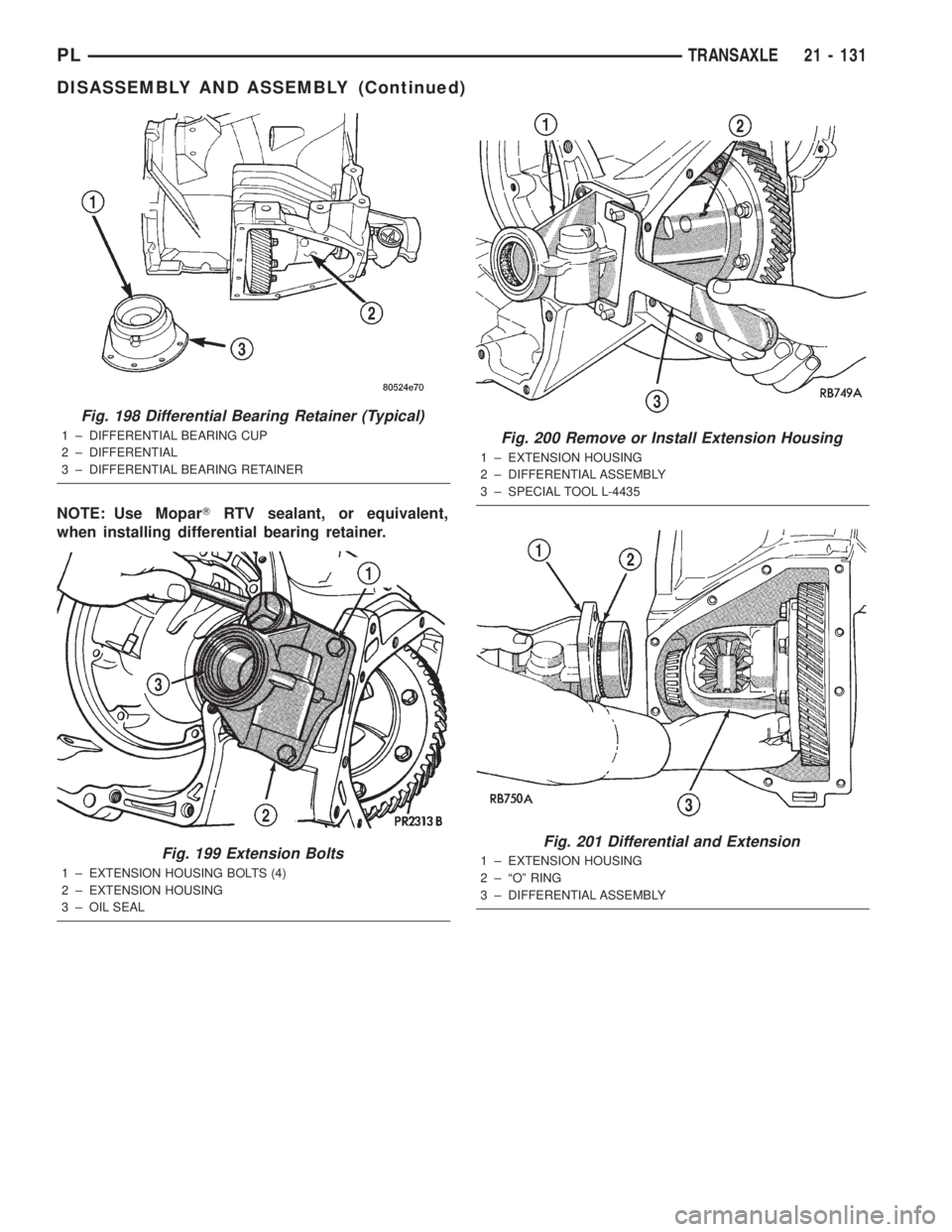

NOTE: Use MoparTRTV sealant, or equivalent,

when installing differential bearing retainer.

Fig. 198 Differential Bearing Retainer (Typical)

1 ± DIFFERENTIAL BEARING CUP

2 ± DIFFERENTIAL

3 ± DIFFERENTIAL BEARING RETAINER

Fig. 199 Extension Bolts

1 ± EXTENSION HOUSING BOLTS (4)

2 ± EXTENSION HOUSING

3 ± OIL SEAL

Fig. 200 Remove or Install Extension Housing

1 ± EXTENSION HOUSING

2 ± DIFFERENTIAL ASSEMBLY

3 ± SPECIAL TOOL L-4435

Fig. 201 Differential and Extension

1 ± EXTENSION HOUSING

2 ± ªOº RING

3 ± DIFFERENTIAL ASSEMBLY

PLTRANSAXLE 21 - 131

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1045 of 1285

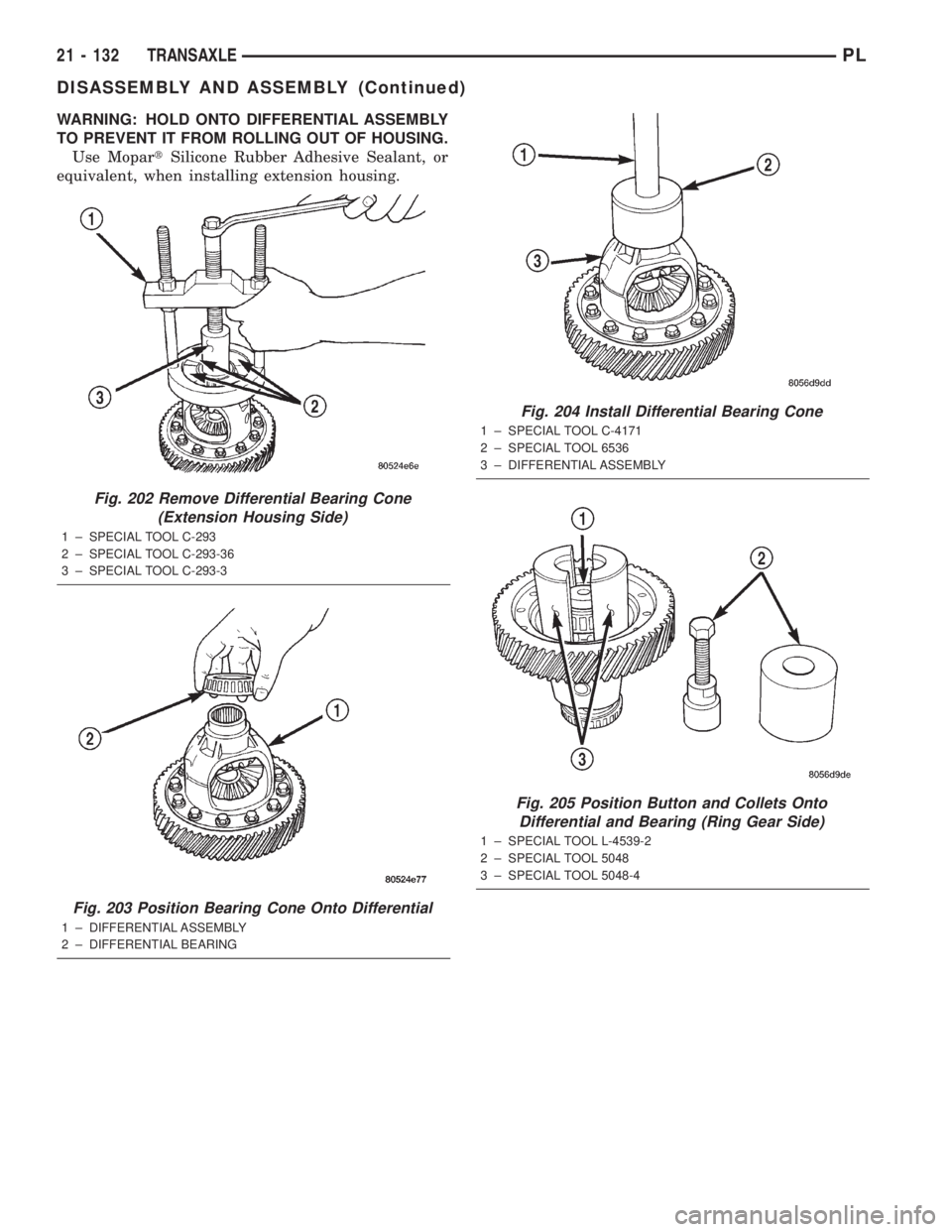

WARNING: HOLD ONTO DIFFERENTIAL ASSEMBLY

TO PREVENT IT FROM ROLLING OUT OF HOUSING.

Use MopartSilicone Rubber Adhesive Sealant, or

equivalent, when installing extension housing.

Fig. 202 Remove Differential Bearing Cone

(Extension Housing Side)

1 ± SPECIAL TOOL C-293

2 ± SPECIAL TOOL C-293-36

3 ± SPECIAL TOOL C-293-3

Fig. 203 Position Bearing Cone Onto Differential

1 ± DIFFERENTIAL ASSEMBLY

2 ± DIFFERENTIAL BEARING

Fig. 204 Install Differential Bearing Cone

1 ± SPECIAL TOOL C-4171

2 ± SPECIAL TOOL 6536

3 ± DIFFERENTIAL ASSEMBLY

Fig. 205 Position Button and Collets Onto

Differential and Bearing (Ring Gear Side)

1 ± SPECIAL TOOL L-4539-2

2 ± SPECIAL TOOL 5048

3 ± SPECIAL TOOL 5048-4

21 - 132 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1046 of 1285

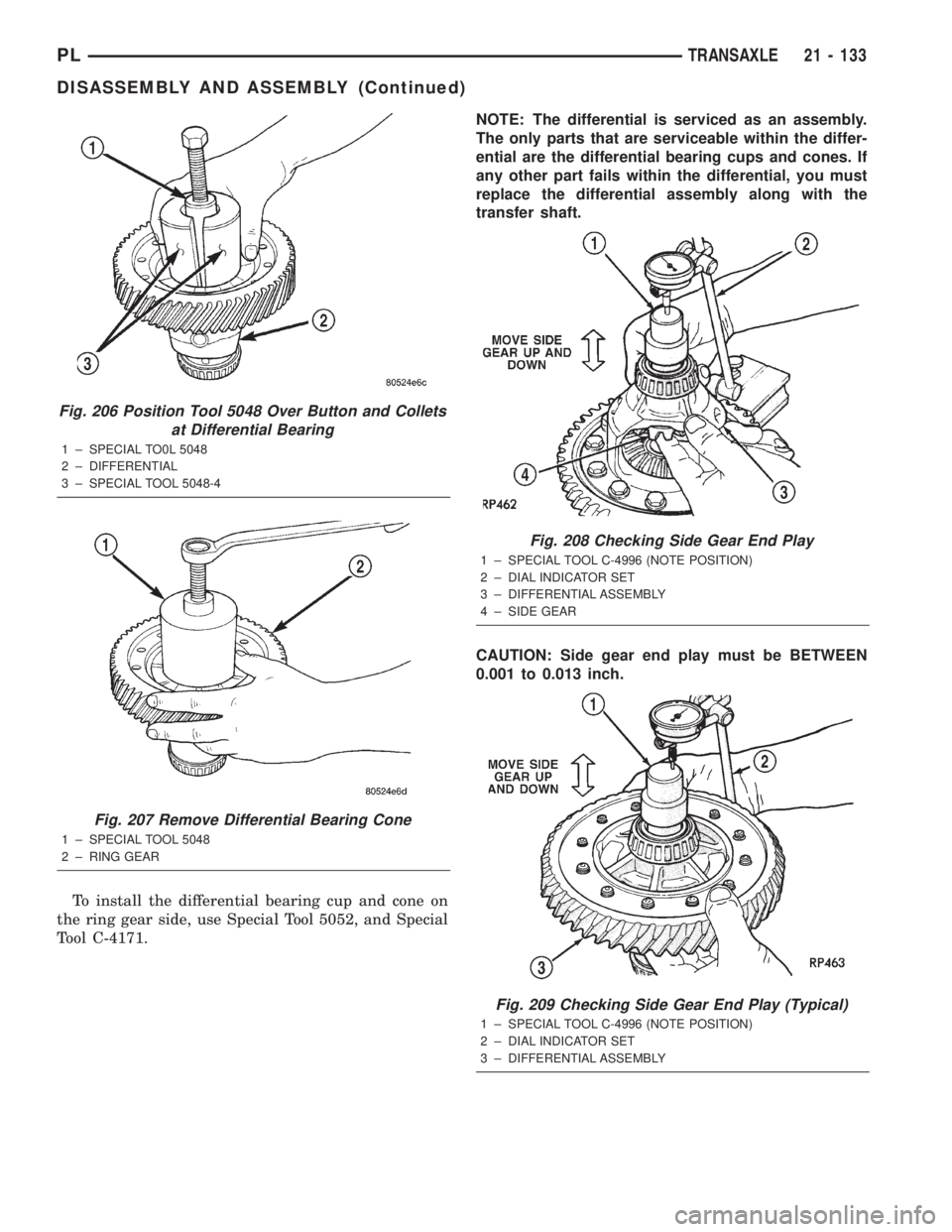

To install the differential bearing cup and cone on

the ring gear side, use Special Tool 5052, and Special

Tool C-4171.NOTE: The differential is serviced as an assembly.

The only parts that are serviceable within the differ-

ential are the differential bearing cups and cones. If

any other part fails within the differential, you must

replace the differential assembly along with the

transfer shaft.

CAUTION: Side gear end play must be BETWEEN

0.001 to 0.013 inch.

Fig. 206 Position Tool 5048 Over Button and Collets

at Differential Bearing

1 ± SPECIAL TO0L 5048

2 ± DIFFERENTIAL

3 ± SPECIAL TOOL 5048-4

Fig. 207 Remove Differential Bearing Cone

1 ± SPECIAL TOOL 5048

2 ± RING GEAR

Fig. 208 Checking Side Gear End Play

1 ± SPECIAL TOOL C-4996 (NOTE POSITION)

2 ± DIAL INDICATOR SET

3 ± DIFFERENTIAL ASSEMBLY

4 ± SIDE GEAR

Fig. 209 Checking Side Gear End Play (Typical)

1 ± SPECIAL TOOL C-4996 (NOTE POSITION)

2 ± DIAL INDICATOR SET

3 ± DIFFERENTIAL ASSEMBLY

PLTRANSAXLE 21 - 133

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1047 of 1285

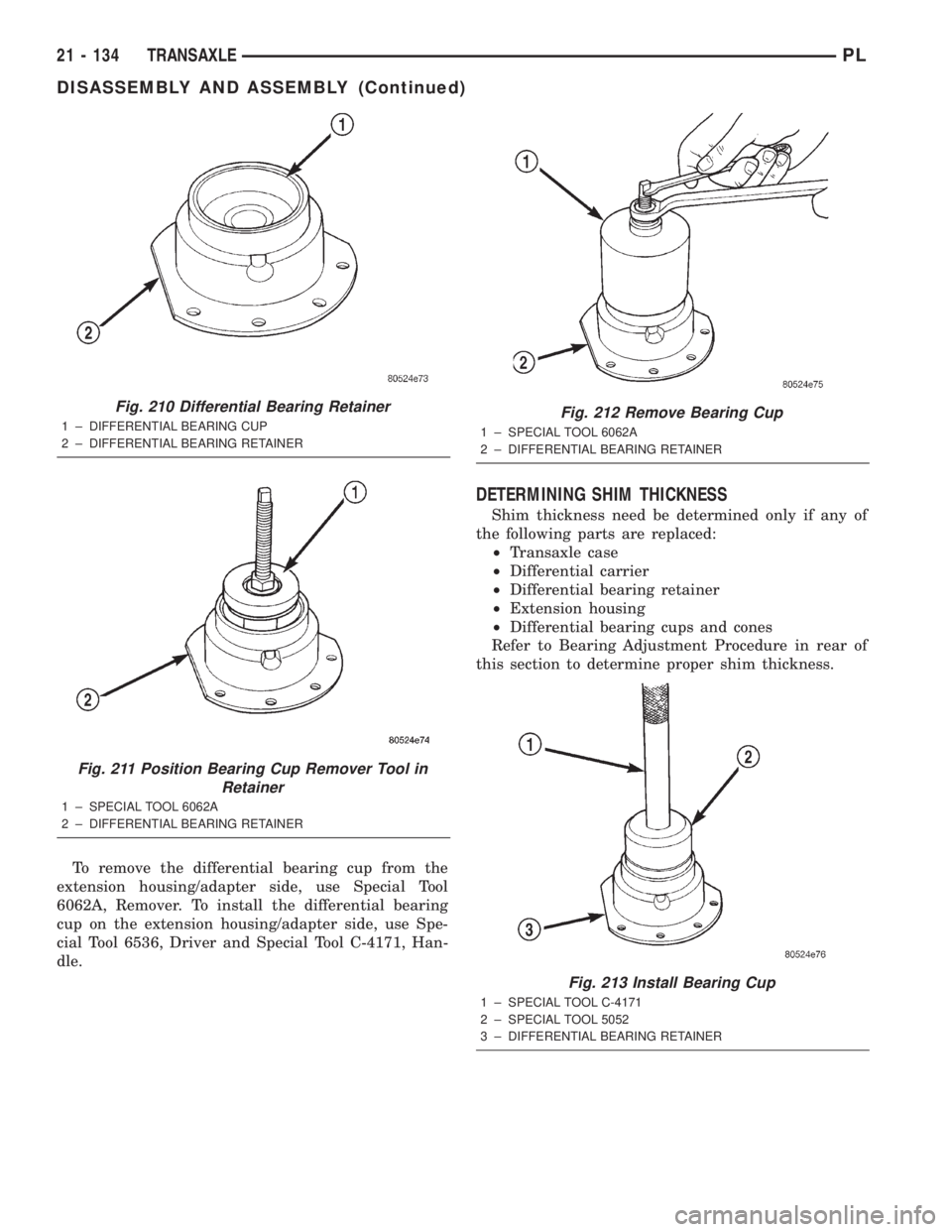

To remove the differential bearing cup from the

extension housing/adapter side, use Special Tool

6062A, Remover. To install the differential bearing

cup on the extension housing/adapter side, use Spe-

cial Tool 6536, Driver and Special Tool C-4171, Han-

dle.

DETERMINING SHIM THICKNESS

Shim thickness need be determined only if any of

the following parts are replaced:

²Transaxle case

²Differential carrier

²Differential bearing retainer

²Extension housing

²Differential bearing cups and cones

Refer to Bearing Adjustment Procedure in rear of

this section to determine proper shim thickness.

Fig. 210 Differential Bearing Retainer

1 ± DIFFERENTIAL BEARING CUP

2 ± DIFFERENTIAL BEARING RETAINER

Fig. 211 Position Bearing Cup Remover Tool in

Retainer

1 ± SPECIAL TOOL 6062A

2 ± DIFFERENTIAL BEARING RETAINER

Fig. 212 Remove Bearing Cup

1 ± SPECIAL TOOL 6062A

2 ± DIFFERENTIAL BEARING RETAINER

Fig. 213 Install Bearing Cup

1 ± SPECIAL TOOL C-4171

2 ± SPECIAL TOOL 5052

3 ± DIFFERENTIAL BEARING RETAINER

21 - 134 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1052 of 1285

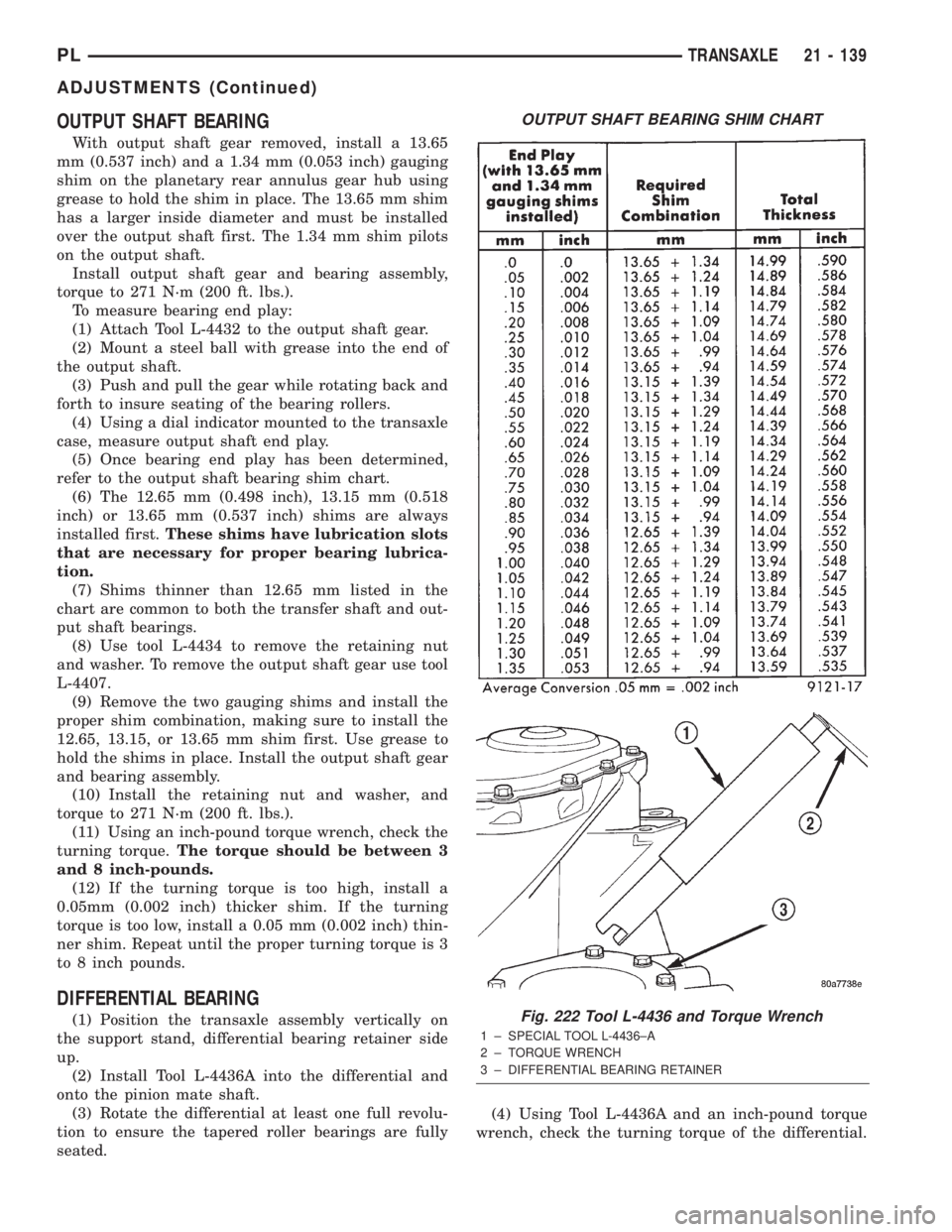

OUTPUT SHAFT BEARING

With output shaft gear removed, install a 13.65

mm (0.537 inch) and a 1.34 mm (0.053 inch) gauging

shim on the planetary rear annulus gear hub using

grease to hold the shim in place. The 13.65 mm shim

has a larger inside diameter and must be installed

over the output shaft first. The 1.34 mm shim pilots

on the output shaft.

Install output shaft gear and bearing assembly,

torque to 271 N´m (200 ft. lbs.).

To measure bearing end play:

(1) Attach Tool L-4432 to the output shaft gear.

(2) Mount a steel ball with grease into the end of

the output shaft.

(3) Push and pull the gear while rotating back and

forth to insure seating of the bearing rollers.

(4) Using a dial indicator mounted to the transaxle

case, measure output shaft end play.

(5) Once bearing end play has been determined,

refer to the output shaft bearing shim chart.

(6) The 12.65 mm (0.498 inch), 13.15 mm (0.518

inch) or 13.65 mm (0.537 inch) shims are always

installed first.These shims have lubrication slots

that are necessary for proper bearing lubrica-

tion.

(7) Shims thinner than 12.65 mm listed in the

chart are common to both the transfer shaft and out-

put shaft bearings.

(8) Use tool L-4434 to remove the retaining nut

and washer. To remove the output shaft gear use tool

L-4407.

(9) Remove the two gauging shims and install the

proper shim combination, making sure to install the

12.65, 13.15, or 13.65 mm shim first. Use grease to

hold the shims in place. Install the output shaft gear

and bearing assembly.

(10) Install the retaining nut and washer, and

torque to 271 N´m (200 ft. lbs.).

(11) Using an inch-pound torque wrench, check the

turning torque.The torque should be between 3

and 8 inch-pounds.

(12) If the turning torque is too high, install a

0.05mm (0.002 inch) thicker shim. If the turning

torque is too low, install a 0.05 mm (0.002 inch) thin-

ner shim. Repeat until the proper turning torque is 3

to 8 inch pounds.

DIFFERENTIAL BEARING

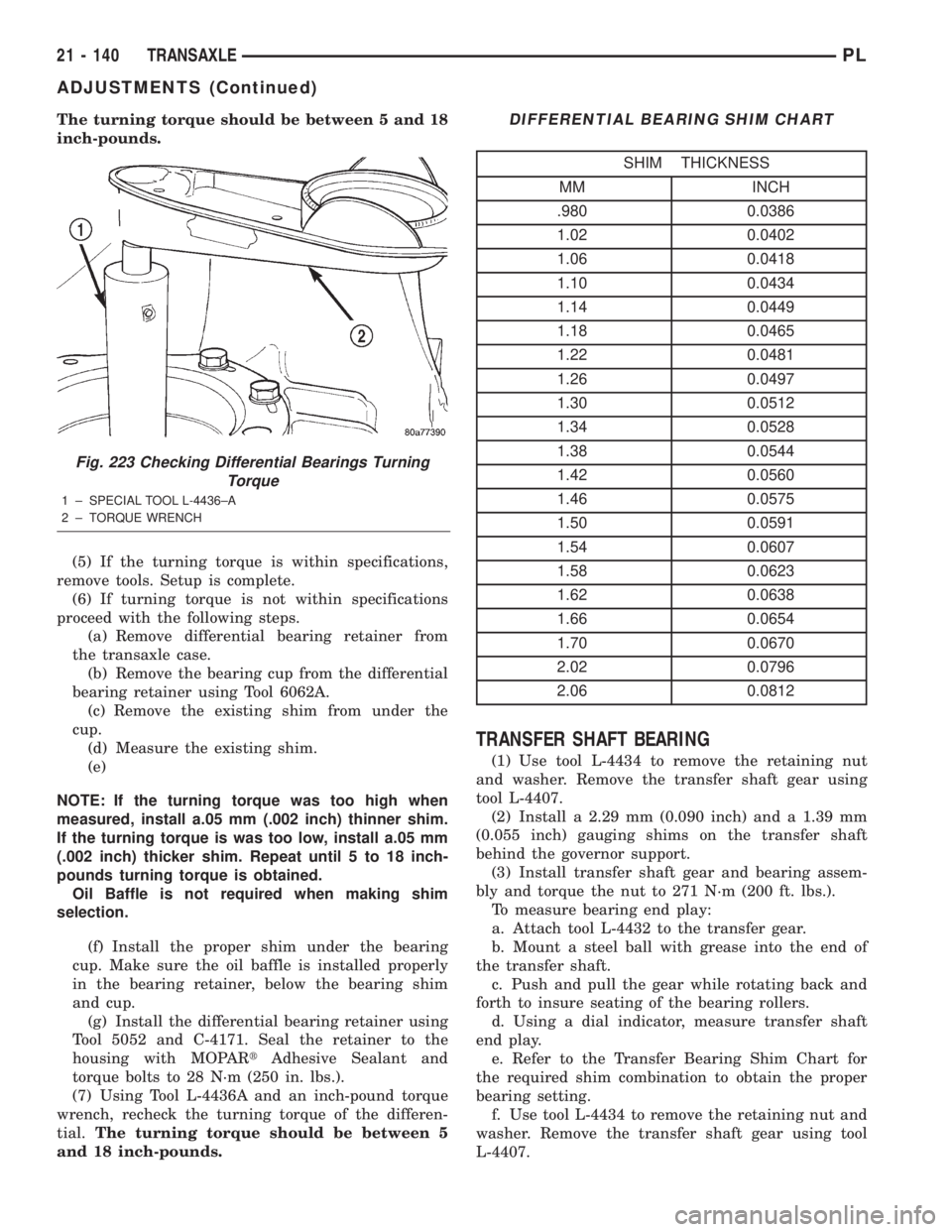

(1) Position the transaxle assembly vertically on

the support stand, differential bearing retainer side

up.

(2) Install Tool L-4436A into the differential and

onto the pinion mate shaft.

(3) Rotate the differential at least one full revolu-

tion to ensure the tapered roller bearings are fully

seated.(4) Using Tool L-4436A and an inch-pound torque

wrench, check the turning torque of the differential.

OUTPUT SHAFT BEARING SHIM CHART

Fig. 222 Tool L-4436 and Torque Wrench

1 ± SPECIAL TOOL L-4436±A

2 ± TORQUE WRENCH

3 ± DIFFERENTIAL BEARING RETAINER

PLTRANSAXLE 21 - 139

ADJUSTMENTS (Continued)

Page 1053 of 1285

The turning torque should be between 5 and 18

inch-pounds.

(5) If the turning torque is within specifications,

remove tools. Setup is complete.

(6) If turning torque is not within specifications

proceed with the following steps.

(a) Remove differential bearing retainer from

the transaxle case.

(b) Remove the bearing cup from the differential

bearing retainer using Tool 6062A.

(c) Remove the existing shim from under the

cup.

(d) Measure the existing shim.

(e)

NOTE: If the turning torque was too high when

measured, install a.05 mm (.002 inch) thinner shim.

If the turning torque is was too low, install a.05 mm

(.002 inch) thicker shim. Repeat until 5 to 18 inch-

pounds turning torque is obtained.

Oil Baffle is not required when making shim

selection.

(f) Install the proper shim under the bearing

cup. Make sure the oil baffle is installed properly

in the bearing retainer, below the bearing shim

and cup.

(g) Install the differential bearing retainer using

Tool 5052 and C-4171. Seal the retainer to the

housing with MOPARtAdhesive Sealant and

torque bolts to 28 N´m (250 in. lbs.).

(7) Using Tool L-4436A and an inch-pound torque

wrench, recheck the turning torque of the differen-

tial.The turning torque should be between 5

and 18 inch-pounds.

TRANSFER SHAFT BEARING

(1) Use tool L-4434 to remove the retaining nut

and washer. Remove the transfer shaft gear using

tool L-4407.

(2) Install a 2.29 mm (0.090 inch) and a 1.39 mm

(0.055 inch) gauging shims on the transfer shaft

behind the governor support.

(3) Install transfer shaft gear and bearing assem-

bly and torque the nut to 271 N´m (200 ft. lbs.).

To measure bearing end play:

a. Attach tool L-4432 to the transfer gear.

b. Mount a steel ball with grease into the end of

the transfer shaft.

c. Push and pull the gear while rotating back and

forth to insure seating of the bearing rollers.

d. Using a dial indicator, measure transfer shaft

end play.

e. Refer to the Transfer Bearing Shim Chart for

the required shim combination to obtain the proper

bearing setting.

f. Use tool L-4434 to remove the retaining nut and

washer. Remove the transfer shaft gear using tool

L-4407.

Fig. 223 Checking Differential Bearings Turning

Torque

1 ± SPECIAL TOOL L-4436±A

2 ± TORQUE WRENCH

DIFFERENTIAL BEARING SHIM CHART

SHIM THICKNESS

MM INCH

.980 0.0386

1.02 0.0402

1.06 0.0418

1.10 0.0434

1.14 0.0449

1.18 0.0465

1.22 0.0481

1.26 0.0497

1.30 0.0512

1.34 0.0528

1.38 0.0544

1.42 0.0560

1.46 0.0575

1.50 0.0591

1.54 0.0607

1.58 0.0623

1.62 0.0638

1.66 0.0654

1.70 0.0670

2.02 0.0796

2.06 0.0812

21 - 140 TRANSAXLEPL

ADJUSTMENTS (Continued)

Page 1063 of 1285

SPECIFICATIONS

31TH AUTOMATIC TRANSAXLE

Type .........Automatic three speed with torque

converter and integral differential

Torque Converter Diameter...... 241millimeters

(9.48 in.)

OilType .....................MopartATF+4

(Automatic Transmission Fluid) Type 9602

Cooling Method.... Water Heat Exchanger and/or

air to oil heat exchanger

Lubrication . . . Pump (internal-external gear-type)

Transmission Gear Ratios

First Gear............................2.69

Second Gear...........................1.55

Third Gear............................1.00

Reverse Gear..........................2.10

Band Adjustment

KickdownÐBacked Off From 8 N²m

(72 in. lbs.).................... 21/4Turns

Low-ReverseÐBacked Off From 5 N²m

(41 in. lbs.).................... 31/2Turns

Clutch Pack Clearances

Front Clutch (Not Adjustable)......1.27-2.79mm

(0.050-0.110 in.)

Rear Clutch.......0.71-1.10mm (0.028-0.043 in.)

End Play

Input Shaft........0.19±1.50 mm (.008±.060 in.)

Front Clutch Retainer...........0.76±2.69 mm

(.030±.106 in.)

Front Carrier.......0.89±1.45 mm (.007±.057 in.)

Front Annulus Gear . . 0.09±0.50 mm (.0035±.020 in.)

Planet Pinion.......0.15±0.59 mm (.006±.023 in.)

Reverse Drum......0.76±3.36 mm (.030±.132 in.)

Oil Pump Clearances

Outer Gear To Pocket...........0.045-0.141mm

(0.0018-0.0056 in.)

Outer Gear Side Clearance.......0.020-0.046mm

(0.0008-0.0018 in.)

Inner Gear Side Clearance.......0.020-0.046mm

(0.0008-0.0018 in.)

Tapered Roller Bearing Settings

Differential Assembly . . 6 to 12 in. lbs. Drag Torque

Output Hub.......... 0to3in.lbs. Drag Torque

Transfer Shaft.......0.002 to 0.010 in. End Play

Overall Drag At Output

Hub ............. 3to16in.lbs. Drag TorqueThrust Washers

Reaction Shaft Support (No. 1).....1.55±1.60 mm

(.061±.063 in.)

Rear Clutch Retainer (No. 2)......1.55±1.60 mm

(.061±.063 in.)

Output Shaft (No. 3) (Select)......1.98±2.03 mm

(.077±.080 in.)

Output Shaft (No. 3) (Select)......2.15±2.22 mm

(.085±.087 in.)

Output Shaft (No. 3) (Select)......2.34±2.41 mm

(.092±.095 in.)

Front Annulus (No. 4)............2.95±3.05 mm

(.116±.120 in.)

Front Carrier (Nos. 5&6).........1.22±1.28 mm

(.0948±.050 in.)

Sun Gear-Front (No. 7)...........0.85±0.91 mm

(.033±.036 in.)

Sun Gear-Rear (No. 8)...........0.85±0.91 mm

(.033±.036 in.)

Rear Carrier (Nos. 9&10).........1.22±1.28 mm

(.0948±.050 in.)

Rev. Drum (No. 11) . . 1.55±1.60 mm (.061±.063 in.)

31TH TRANSAXLE TORQUE SPECIFICATIONS

DESCRIPTION TORQUE

Bell Housing Cover Bolts.... 12N´m(105 in. lbs.)

Cooler Line Clamps.......... 2N´m(18in.lbs.)

Diff. Bear. Ret. To Case Bolt . . 34 N´m (300 in. lbs.)

Diff. Cover To Case Bolt..... 19N´m(165 in. lbs.)

Exten. Hous. To Case Bolt . . . 28 N´m (250 in. lbs.)

Drive Plate To Crankshaft

Bolts................... 95N´m(70ft.lbs.)

Drive Plate To Torque Conv.

Bolts................... 88N´m(65ft.lbs.)

Fluid Filter Screw........... 5N´m(45in.lbs.)

Governor Counterweight

Screw................. 28N´m(250 in. lbs.)

Governor To Support Bolt...... 7N´m(60in.lbs.)

Kickdown Band Adj. Lock Nut . . 47 N´m (35 ft. lbs.)

Left Motor Mount Bolts....... 54N´m(40ft.lbs.)

Manual Cable To Trans.

Case Bolt.............. 28N´m(250 in. lbs.)

Manual Control Lever Screw . . 12 N´m (105 in. lbs.)

Oil Pan To Trans. Case

Screw................. 19N´m(165 in. lbs.)

Output Gear Strap Bolts...... 23N´m(17ft.lbs.)

Output Shaft Nut......... 271N´m(200 ft. lbs.)

Park/Neutral Switch......... 34N´m(25ft.lbs.)

Pressure Check Plug......... 5N´m(45in.lbs.)

Pump To Case Bolts........ 31N´m(275 in. lbs.)

Reaction Shaft Assembly

Bolt................... 28N´m(250 in. lbs.)

Rear Cover To Case Screw . . . 19 N´m (165 in. lbs.)

Reverse Band Adj. Lock Nut . . 14 N´m (125 in. lbs.)

21 - 150 TRANSAXLEPL