differential DODGE NEON 2000 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 943 of 1285

DIFFERENTIAL BEARING PRELOAD ADJUSTMENT

NOTE: True bearing turning±torque readings can

be obtained only with the geartrain removed from

the case.

(1) Remove bearing cup and existing shim from

clutch bellhousing case.

(2) Press in new bearing cup into bellhousing case

(or use a cup that has been ground down on the

outer edge for ease of measurement).

(3) Press in new bearing cup into gear case side.

(4) Oil differential bearings with Moparttype M.

S. 9417 Manual Transaxle Fluid. Install differential

assembly in transaxle gear case. Install clutch bell-

housing over gear case. Install and torque case bolts

to 29 N´m (21 ft. lbs.).

(5) Position transaxle with bellhousing facing

down on workbench with C-clamps. Position dial

indicator.

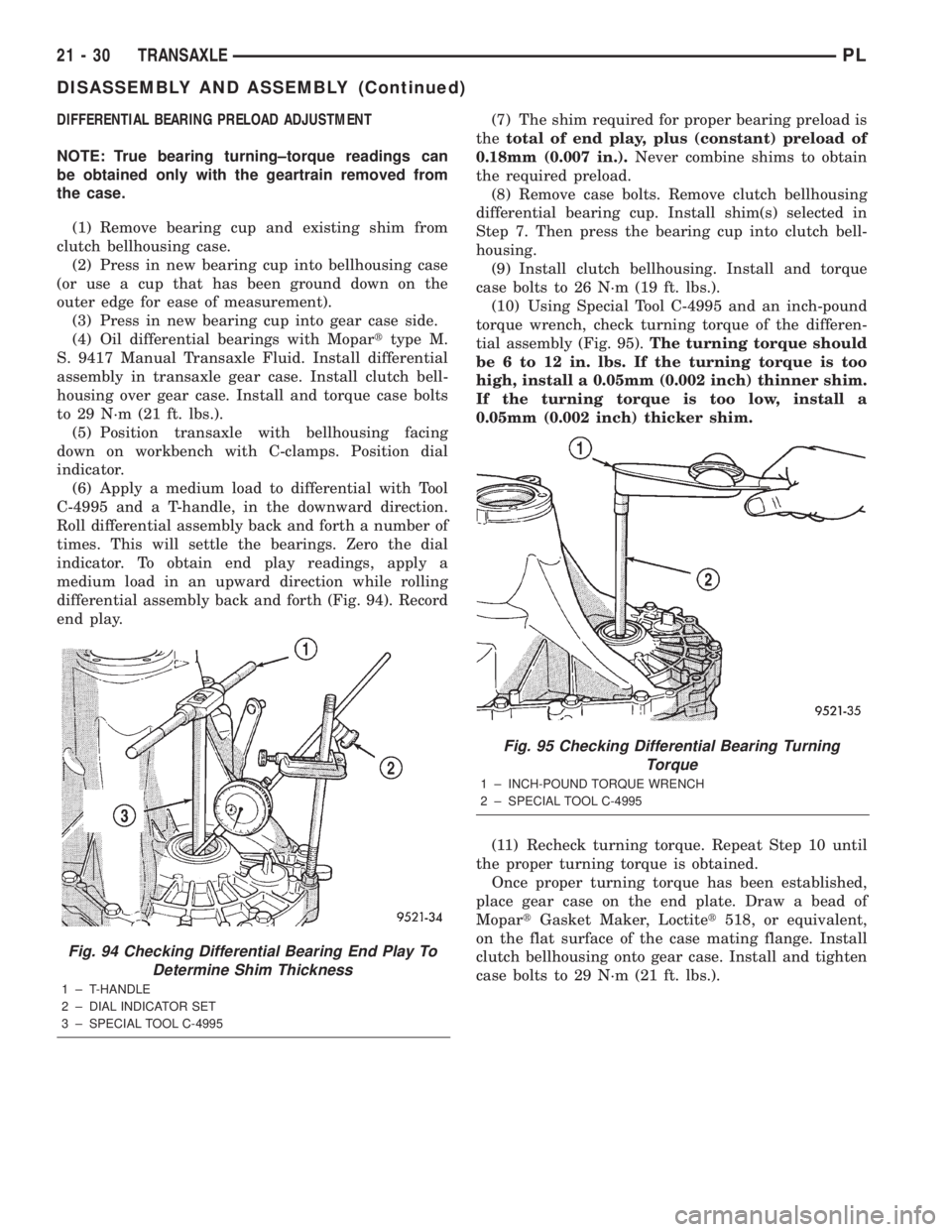

(6) Apply a medium load to differential with Tool

C-4995 and a T-handle, in the downward direction.

Roll differential assembly back and forth a number of

times. This will settle the bearings. Zero the dial

indicator. To obtain end play readings, apply a

medium load in an upward direction while rolling

differential assembly back and forth (Fig. 94). Record

end play.(7) The shim required for proper bearing preload is

thetotal of end play, plus (constant) preload of

0.18mm (0.007 in.).Never combine shims to obtain

the required preload.

(8) Remove case bolts. Remove clutch bellhousing

differential bearing cup. Install shim(s) selected in

Step 7. Then press the bearing cup into clutch bell-

housing.

(9) Install clutch bellhousing. Install and torque

case bolts to 26 N´m (19 ft. lbs.).

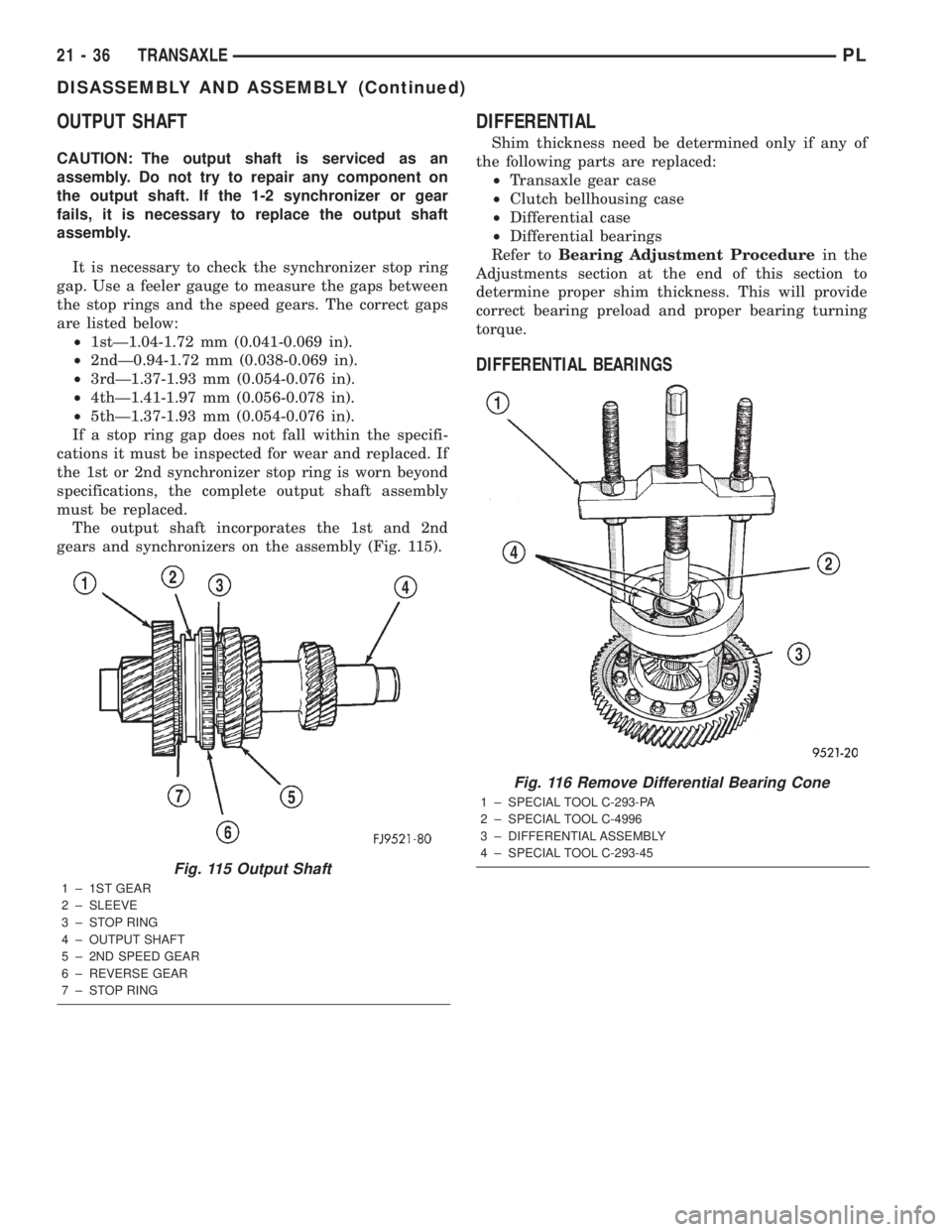

(10) Using Special Tool C-4995 and an inch-pound

torque wrench, check turning torque of the differen-

tial assembly (Fig. 95).The turning torque should

be 6 to 12 in. lbs. If the turning torque is too

high, install a 0.05mm (0.002 inch) thinner shim.

If the turning torque is too low, install a

0.05mm (0.002 inch) thicker shim.

(11) Recheck turning torque. Repeat Step 10 until

the proper turning torque is obtained.

Once proper turning torque has been established,

place gear case on the end plate. Draw a bead of

MopartGasket Maker, Loctitet518, or equivalent,

on the flat surface of the case mating flange. Install

clutch bellhousing onto gear case. Install and tighten

case bolts to 29 N´m (21 ft. lbs.).

Fig. 94 Checking Differential Bearing End Play To

Determine Shim Thickness

1 ± T-HANDLE

2 ± DIAL INDICATOR SET

3 ± SPECIAL TOOL C-4995

Fig. 95 Checking Differential Bearing Turning

Torque

1 ± INCH-POUND TORQUE WRENCH

2 ± SPECIAL TOOL C-4995

21 - 30 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 949 of 1285

OUTPUT SHAFT

CAUTION: The output shaft is serviced as an

assembly. Do not try to repair any component on

the output shaft. If the 1-2 synchronizer or gear

fails, it is necessary to replace the output shaft

assembly.

It is necessary to check the synchronizer stop ring

gap. Use a feeler gauge to measure the gaps between

the stop rings and the speed gears. The correct gaps

are listed below:

²1stÐ1.04-1.72 mm (0.041-0.069 in).

²2ndÐ0.94-1.72 mm (0.038-0.069 in).

²3rdÐ1.37-1.93 mm (0.054-0.076 in).

²4thÐ1.41-1.97 mm (0.056-0.078 in).

²5thÐ1.37-1.93 mm (0.054-0.076 in).

If a stop ring gap does not fall within the specifi-

cations it must be inspected for wear and replaced. If

the 1st or 2nd synchronizer stop ring is worn beyond

specifications, the complete output shaft assembly

must be replaced.

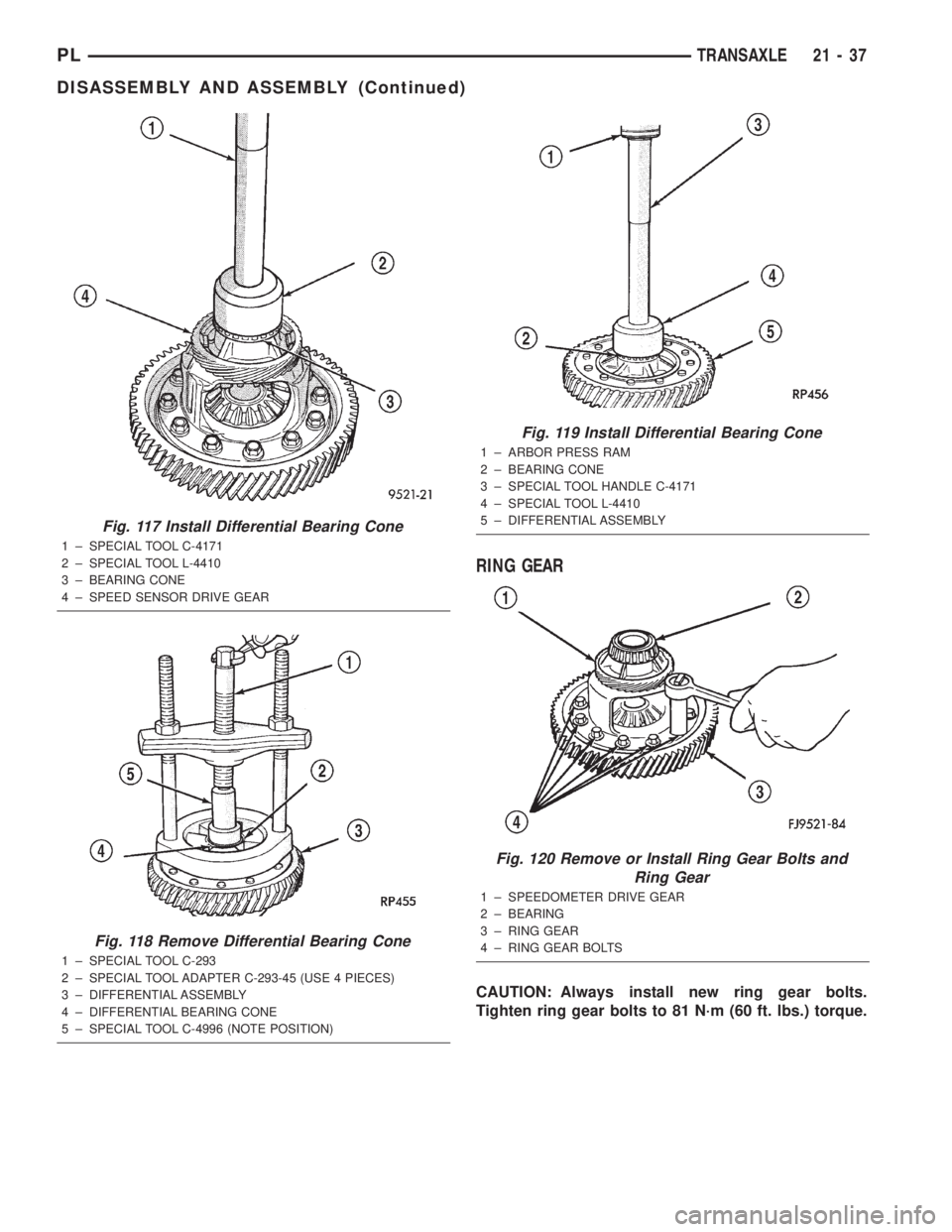

The output shaft incorporates the 1st and 2nd

gears and synchronizers on the assembly (Fig. 115).

DIFFERENTIAL

Shim thickness need be determined only if any of

the following parts are replaced:

²Transaxle gear case

²Clutch bellhousing case

²Differential case

²Differential bearings

Refer toBearing Adjustment Procedurein the

Adjustments section at the end of this section to

determine proper shim thickness. This will provide

correct bearing preload and proper bearing turning

torque.

DIFFERENTIAL BEARINGS

Fig. 115 Output Shaft

1 ± 1ST GEAR

2 ± SLEEVE

3 ± STOP RING

4 ± OUTPUT SHAFT

5 ± 2ND SPEED GEAR

6 ± REVERSE GEAR

7 ± STOP RING

Fig. 116 Remove Differential Bearing Cone

1 ± SPECIAL TOOL C-293-PA

2 ± SPECIAL TOOL C-4996

3 ± DIFFERENTIAL ASSEMBLY

4 ± SPECIAL TOOL C-293-45

21 - 36 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 950 of 1285

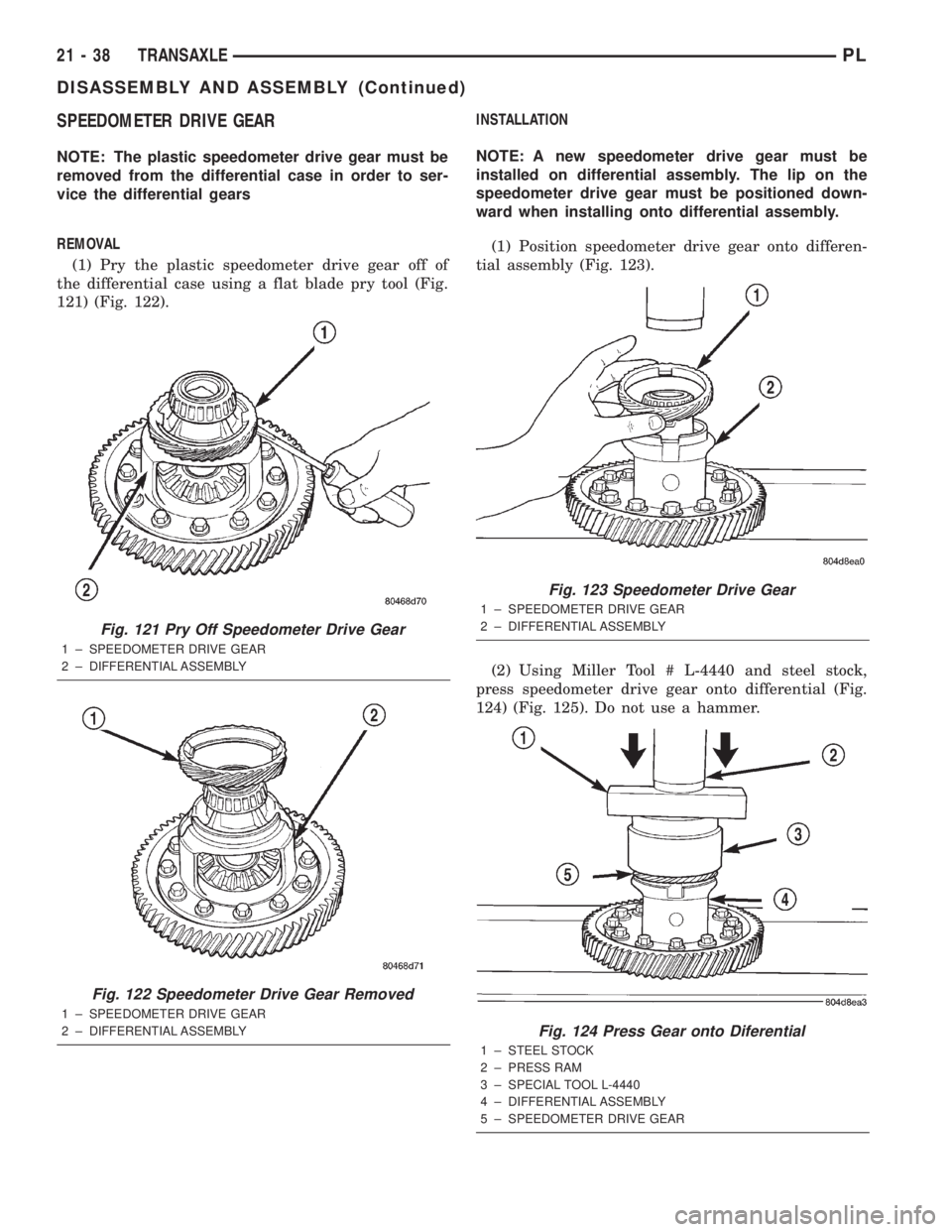

RING GEAR

CAUTION: Always install new ring gear bolts.

Tighten ring gear bolts to 81 N´m (60 ft. lbs.) torque.

Fig. 117 Install Differential Bearing Cone

1 ± SPECIAL TOOL C-4171

2 ± SPECIAL TOOL L-4410

3 ± BEARING CONE

4 ± SPEED SENSOR DRIVE GEAR

Fig. 118 Remove Differential Bearing Cone

1 ± SPECIAL TOOL C-293

2 ± SPECIAL TOOL ADAPTER C-293-45 (USE 4 PIECES)

3 ± DIFFERENTIAL ASSEMBLY

4 ± DIFFERENTIAL BEARING CONE

5 ± SPECIAL TOOL C-4996 (NOTE POSITION)

Fig. 119 Install Differential Bearing Cone

1 ± ARBOR PRESS RAM

2 ± BEARING CONE

3 ± SPECIAL TOOL HANDLE C-4171

4 ± SPECIAL TOOL L-4410

5 ± DIFFERENTIAL ASSEMBLY

Fig. 120 Remove or Install Ring Gear Bolts and

Ring Gear

1 ± SPEEDOMETER DRIVE GEAR

2 ± BEARING

3 ± RING GEAR

4 ± RING GEAR BOLTS

PLTRANSAXLE 21 - 37

DISASSEMBLY AND ASSEMBLY (Continued)

Page 951 of 1285

SPEEDOMETER DRIVE GEAR

NOTE: The plastic speedometer drive gear must be

removed from the differential case in order to ser-

vice the differential gears

REMOVAL

(1) Pry the plastic speedometer drive gear off of

the differential case using a flat blade pry tool (Fig.

121) (Fig. 122).INSTALLATION

NOTE: A new speedometer drive gear must be

installed on differential assembly. The lip on the

speedometer drive gear must be positioned down-

ward when installing onto differential assembly.

(1) Position speedometer drive gear onto differen-

tial assembly (Fig. 123).

(2) Using Miller Tool # L-4440 and steel stock,

press speedometer drive gear onto differential (Fig.

124) (Fig. 125). Do not use a hammer.

Fig. 121 Pry Off Speedometer Drive Gear

1 ± SPEEDOMETER DRIVE GEAR

2 ± DIFFERENTIAL ASSEMBLY

Fig. 122 Speedometer Drive Gear Removed

1 ± SPEEDOMETER DRIVE GEAR

2 ± DIFFERENTIAL ASSEMBLY

Fig. 123 Speedometer Drive Gear

1 ± SPEEDOMETER DRIVE GEAR

2 ± DIFFERENTIAL ASSEMBLY

Fig. 124 Press Gear onto Diferential

1 ± STEEL STOCK

2 ± PRESS RAM

3 ± SPECIAL TOOL L-4440

4 ± DIFFERENTIAL ASSEMBLY

5 ± SPEEDOMETER DRIVE GEAR

21 - 38 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 952 of 1285

DIFFERENTIAL GEARS

NOTE: The plastic speedometer drive gear must be

removed from the differential case in order to ser-

vice the differential gears. Refer to Speedometer

Drive Gear for service information.

REMOVAL

(1) Remove pinion shaft retaining pin (Fig. 126)

(Fig. 127).(2) Remove pinion shaft (Fig. 128).

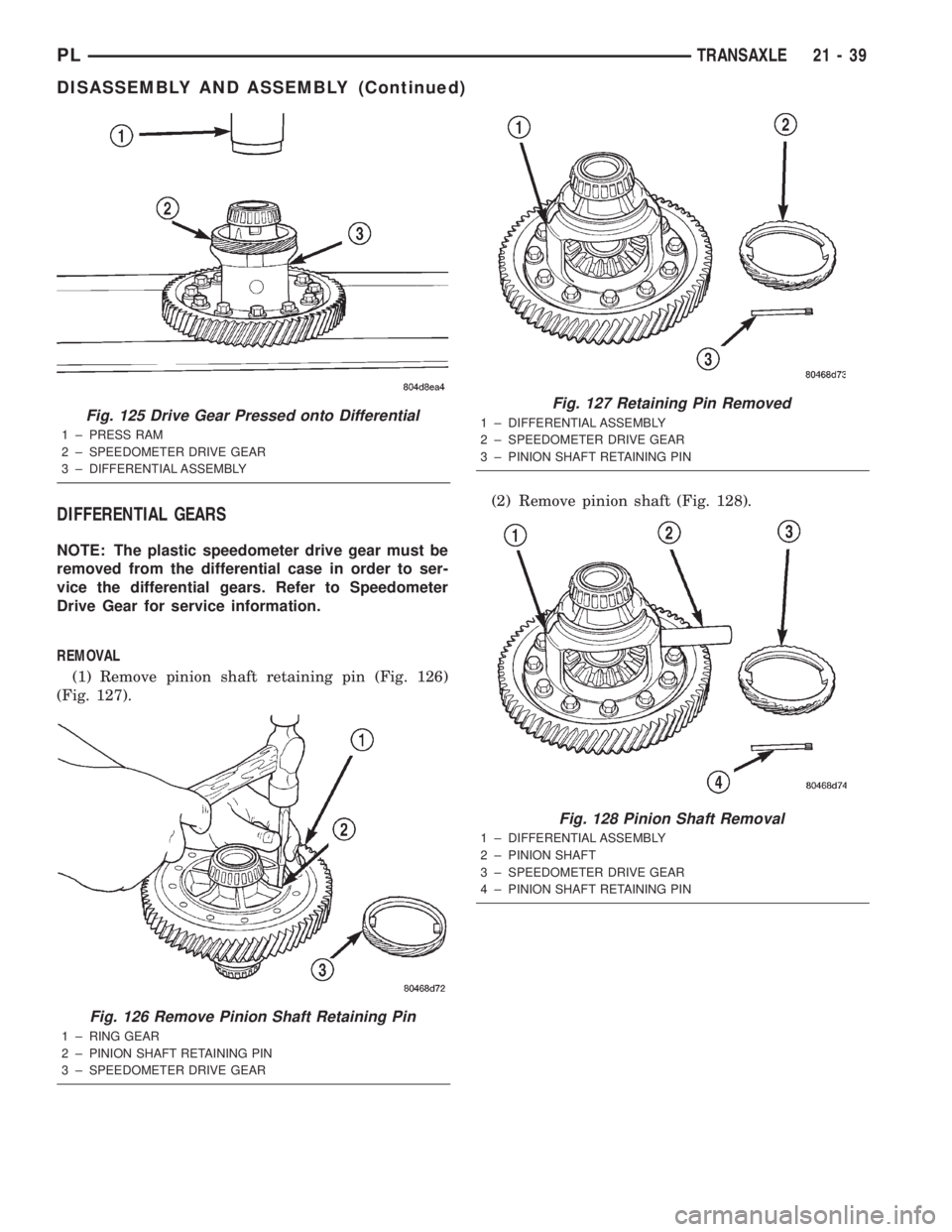

Fig. 125 Drive Gear Pressed onto Differential

1 ± PRESS RAM

2 ± SPEEDOMETER DRIVE GEAR

3 ± DIFFERENTIAL ASSEMBLY

Fig. 126 Remove Pinion Shaft Retaining Pin

1 ± RING GEAR

2 ± PINION SHAFT RETAINING PIN

3 ± SPEEDOMETER DRIVE GEAR

Fig. 127 Retaining Pin Removed

1 ± DIFFERENTIAL ASSEMBLY

2 ± SPEEDOMETER DRIVE GEAR

3 ± PINION SHAFT RETAINING PIN

Fig. 128 Pinion Shaft Removal

1 ± DIFFERENTIAL ASSEMBLY

2 ± PINION SHAFT

3 ± SPEEDOMETER DRIVE GEAR

4 ± PINION SHAFT RETAINING PIN

PLTRANSAXLE 21 - 39

DISASSEMBLY AND ASSEMBLY (Continued)

Page 953 of 1285

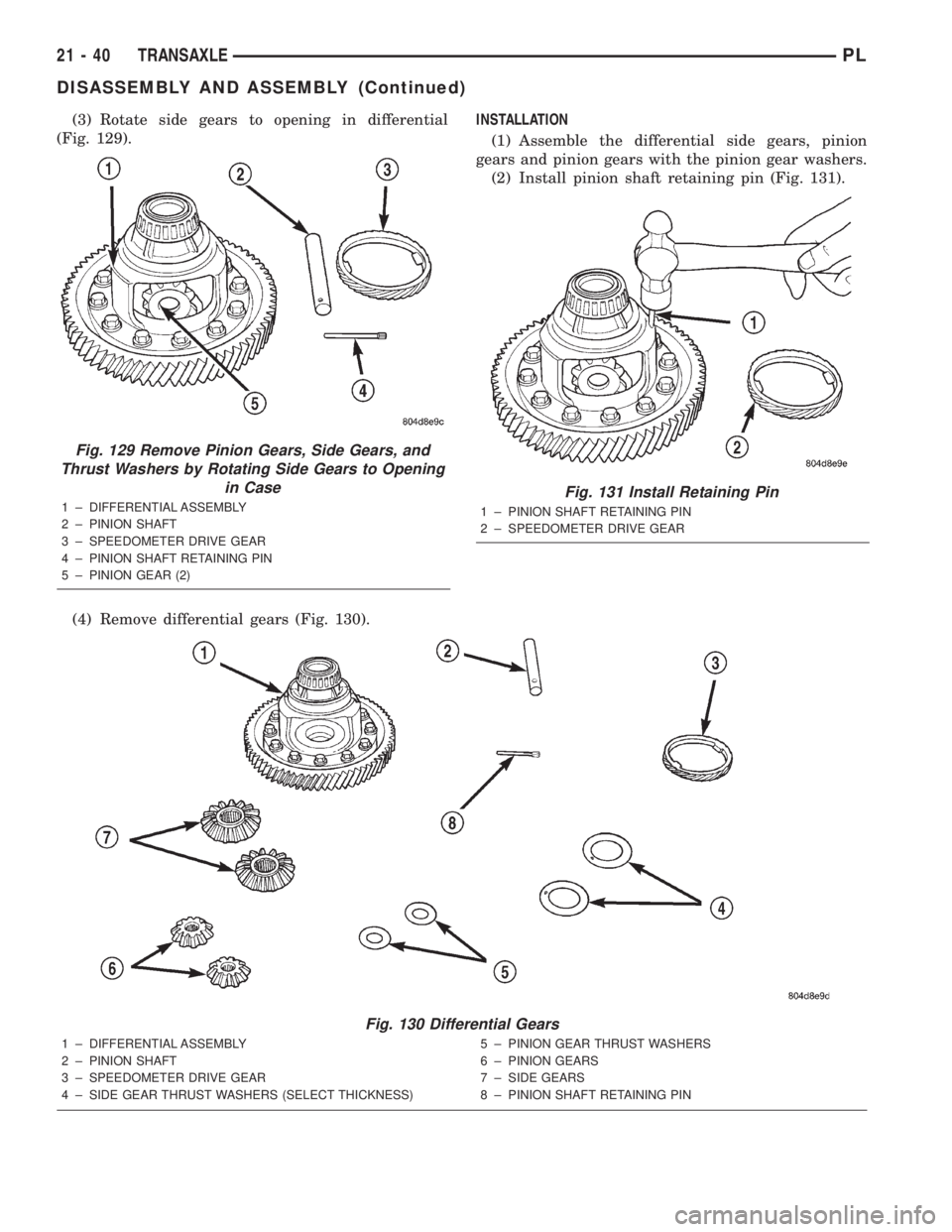

(3) Rotate side gears to opening in differential

(Fig. 129).

(4) Remove differential gears (Fig. 130).INSTALLATION

(1) Assemble the differential side gears, pinion

gears and pinion gears with the pinion gear washers.

(2) Install pinion shaft retaining pin (Fig. 131).

Fig. 129 Remove Pinion Gears, Side Gears, and

Thrust Washers by Rotating Side Gears to Opening

in Case

1 ± DIFFERENTIAL ASSEMBLY

2 ± PINION SHAFT

3 ± SPEEDOMETER DRIVE GEAR

4 ± PINION SHAFT RETAINING PIN

5 ± PINION GEAR (2)

Fig. 130 Differential Gears

1 ± DIFFERENTIAL ASSEMBLY

2 ± PINION SHAFT

3 ± SPEEDOMETER DRIVE GEAR

4 ± SIDE GEAR THRUST WASHERS (SELECT THICKNESS)5 ± PINION GEAR THRUST WASHERS

6 ± PINION GEARS

7 ± SIDE GEARS

8 ± PINION SHAFT RETAINING PIN

Fig. 131 Install Retaining Pin

1 ± PINION SHAFT RETAINING PIN

2 ± SPEEDOMETER DRIVE GEAR

21 - 40 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 954 of 1285

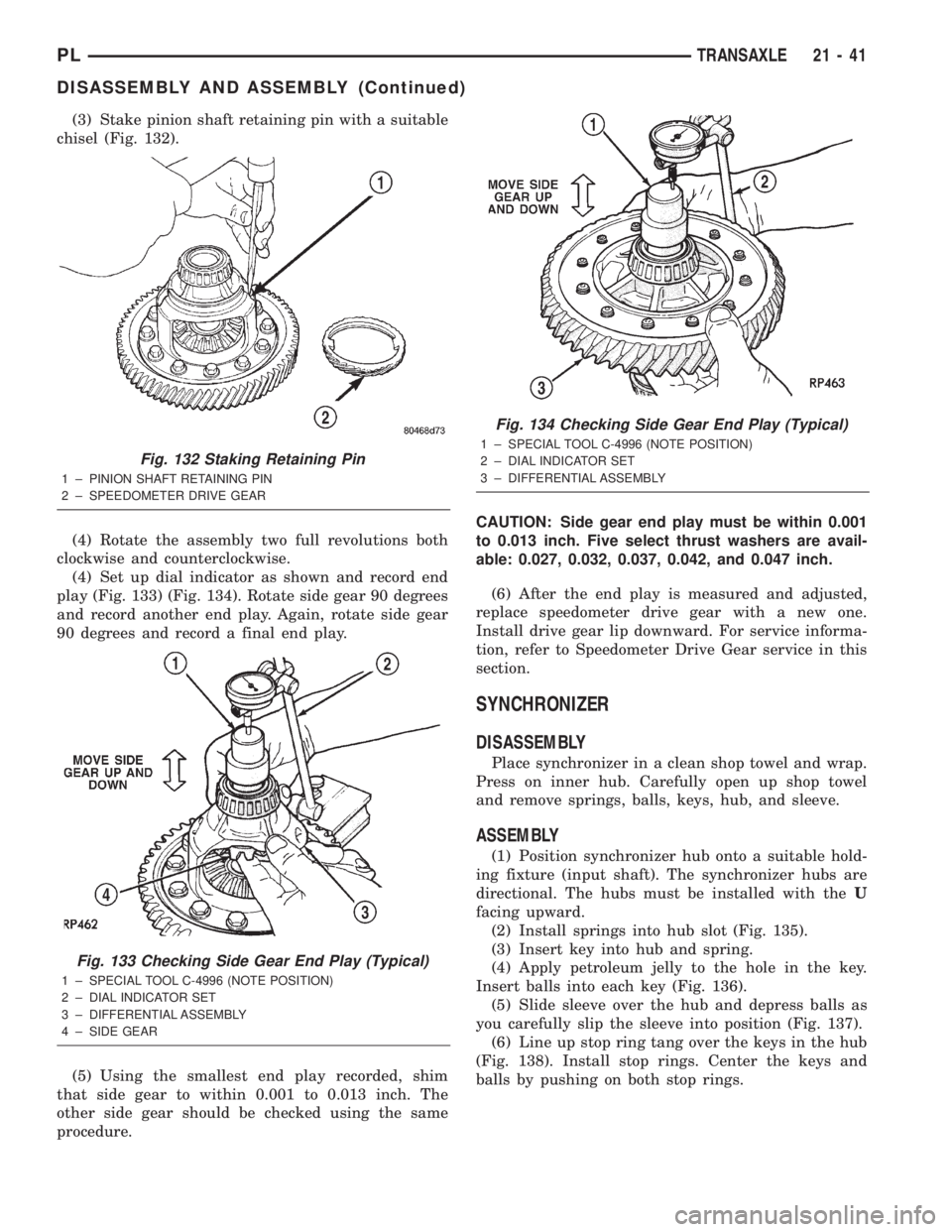

(3) Stake pinion shaft retaining pin with a suitable

chisel (Fig. 132).

(4) Rotate the assembly two full revolutions both

clockwise and counterclockwise.

(4) Set up dial indicator as shown and record end

play (Fig. 133) (Fig. 134). Rotate side gear 90 degrees

and record another end play. Again, rotate side gear

90 degrees and record a final end play.

(5) Using the smallest end play recorded, shim

that side gear to within 0.001 to 0.013 inch. The

other side gear should be checked using the same

procedure.CAUTION: Side gear end play must be within 0.001

to 0.013 inch. Five select thrust washers are avail-

able: 0.027, 0.032, 0.037, 0.042, and 0.047 inch.

(6) After the end play is measured and adjusted,

replace speedometer drive gear with a new one.

Install drive gear lip downward. For service informa-

tion, refer to Speedometer Drive Gear service in this

section.

SYNCHRONIZER

DISASSEMBLY

Place synchronizer in a clean shop towel and wrap.

Press on inner hub. Carefully open up shop towel

and remove springs, balls, keys, hub, and sleeve.

ASSEMBLY

(1) Position synchronizer hub onto a suitable hold-

ing fixture (input shaft). The synchronizer hubs are

directional. The hubs must be installed with theU

facing upward.

(2) Install springs into hub slot (Fig. 135).

(3) Insert key into hub and spring.

(4) Apply petroleum jelly to the hole in the key.

Insert balls into each key (Fig. 136).

(5) Slide sleeve over the hub and depress balls as

you carefully slip the sleeve into position (Fig. 137).

(6) Line up stop ring tang over the keys in the hub

(Fig. 138). Install stop rings. Center the keys and

balls by pushing on both stop rings.

Fig. 132 Staking Retaining Pin

1 ± PINION SHAFT RETAINING PIN

2 ± SPEEDOMETER DRIVE GEAR

Fig. 133 Checking Side Gear End Play (Typical)

1 ± SPECIAL TOOL C-4996 (NOTE POSITION)

2 ± DIAL INDICATOR SET

3 ± DIFFERENTIAL ASSEMBLY

4 ± SIDE GEAR

Fig. 134 Checking Side Gear End Play (Typical)

1 ± SPECIAL TOOL C-4996 (NOTE POSITION)

2 ± DIAL INDICATOR SET

3 ± DIFFERENTIAL ASSEMBLY

PLTRANSAXLE 21 - 41

DISASSEMBLY AND ASSEMBLY (Continued)

Page 956 of 1285

²Output bearing race and retainer

²Input bearing and sleeve

²Differential bearing cones

²Shift rail bushings

²Shift shafts

²Shift shaft seals

²Shift shaft bushings

²Rear bearing oil feed trough

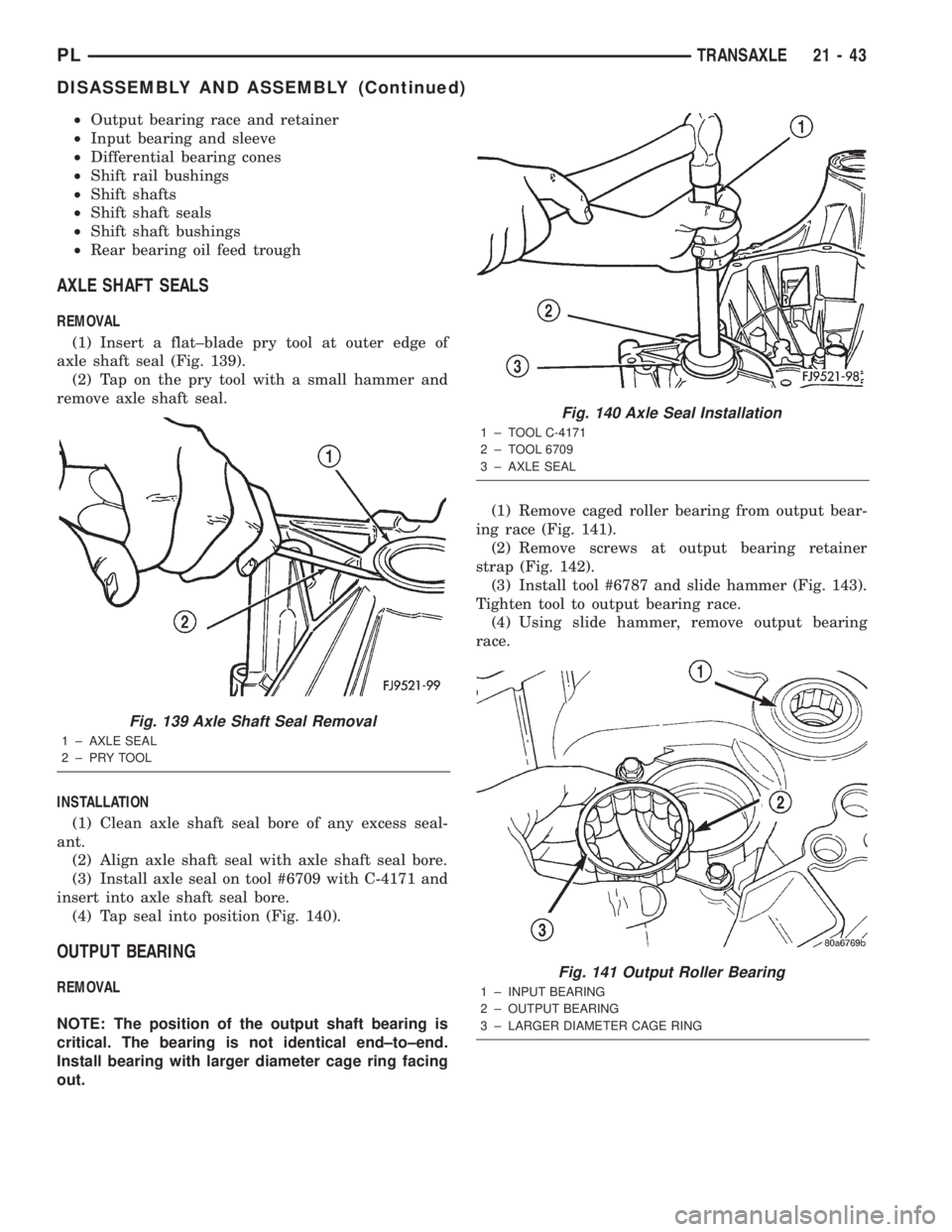

AXLE SHAFT SEALS

REMOVAL

(1) Insert a flat±blade pry tool at outer edge of

axle shaft seal (Fig. 139).

(2) Tap on the pry tool with a small hammer and

remove axle shaft seal.

INSTALLATION

(1) Clean axle shaft seal bore of any excess seal-

ant.

(2) Align axle shaft seal with axle shaft seal bore.

(3) Install axle seal on tool #6709 with C-4171 and

insert into axle shaft seal bore.

(4) Tap seal into position (Fig. 140).

OUTPUT BEARING

REMOVAL

NOTE: The position of the output shaft bearing is

critical. The bearing is not identical end±to±end.

Install bearing with larger diameter cage ring facing

out.(1) Remove caged roller bearing from output bear-

ing race (Fig. 141).

(2) Remove screws at output bearing retainer

strap (Fig. 142).

(3) Install tool #6787 and slide hammer (Fig. 143).

Tighten tool to output bearing race.

(4) Using slide hammer, remove output bearing

race.

Fig. 139 Axle Shaft Seal Removal

1 ± AXLE SEAL

2±PRYTOOL

Fig. 140 Axle Seal Installation

1 ± TOOL C-4171

2 ± TOOL 6709

3 ± AXLE SEAL

Fig. 141 Output Roller Bearing

1 ± INPUT BEARING

2 ± OUTPUT BEARING

3 ± LARGER DIAMETER CAGE RING

PLTRANSAXLE 21 - 43

DISASSEMBLY AND ASSEMBLY (Continued)

Page 958 of 1285

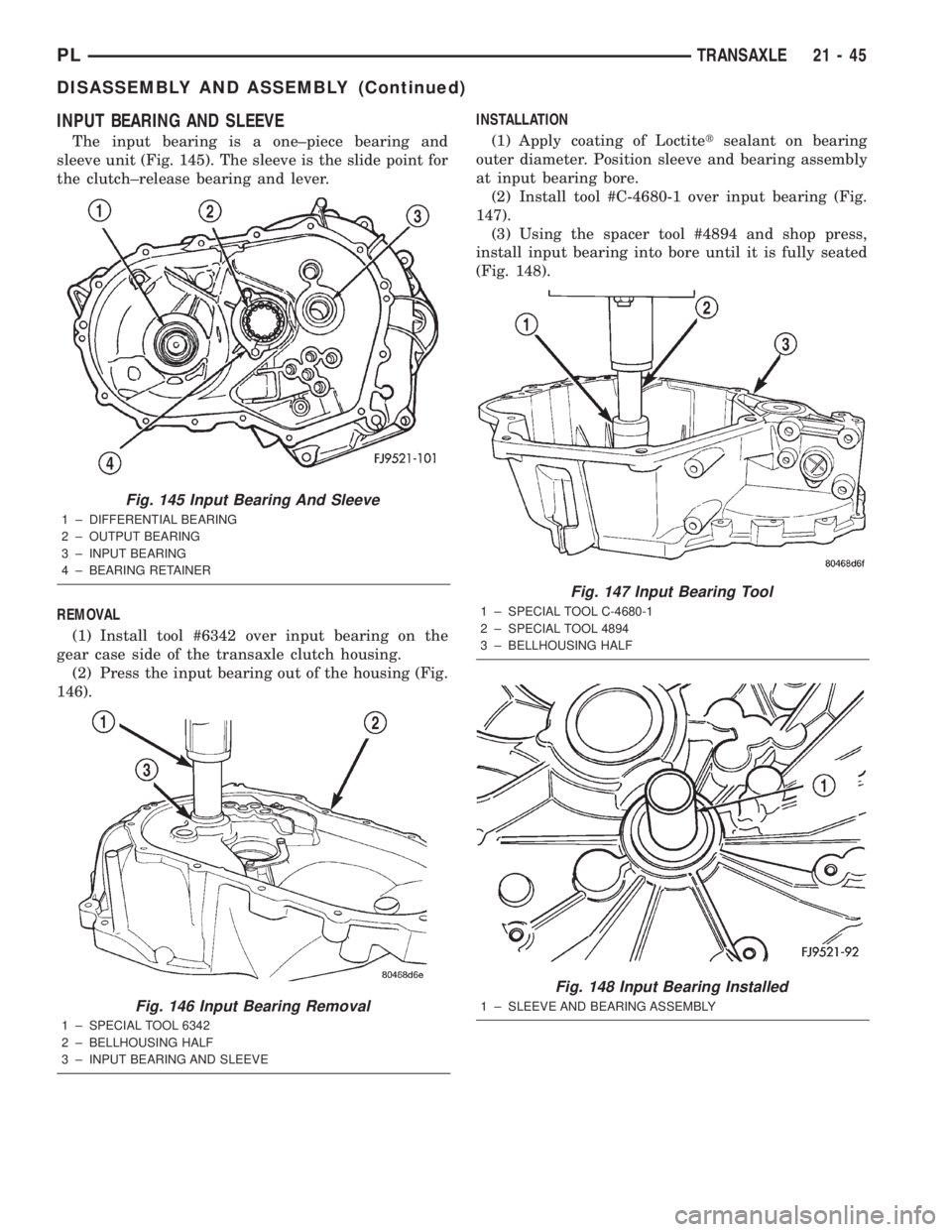

INPUT BEARING AND SLEEVE

The input bearing is a one±piece bearing and

sleeve unit (Fig. 145). The sleeve is the slide point for

the clutch±release bearing and lever.

REMOVAL

(1) Install tool #6342 over input bearing on the

gear case side of the transaxle clutch housing.

(2) Press the input bearing out of the housing (Fig.

146).INSTALLATION

(1) Apply coating of Loctitetsealant on bearing

outer diameter. Position sleeve and bearing assembly

at input bearing bore.

(2) Install tool #C-4680-1 over input bearing (Fig.

147).

(3) Using the spacer tool #4894 and shop press,

install input bearing into bore until it is fully seated

(Fig. 148).

Fig. 145 Input Bearing And Sleeve

1 ± DIFFERENTIAL BEARING

2 ± OUTPUT BEARING

3 ± INPUT BEARING

4 ± BEARING RETAINER

Fig. 146 Input Bearing Removal

1 ± SPECIAL TOOL 6342

2 ± BELLHOUSING HALF

3 ± INPUT BEARING AND SLEEVE

Fig. 147 Input Bearing Tool

1 ± SPECIAL TOOL C-4680-1

2 ± SPECIAL TOOL 4894

3 ± BELLHOUSING HALF

Fig. 148 Input Bearing Installed

1 ± SLEEVE AND BEARING ASSEMBLY

PLTRANSAXLE 21 - 45

DISASSEMBLY AND ASSEMBLY (Continued)

Page 959 of 1285

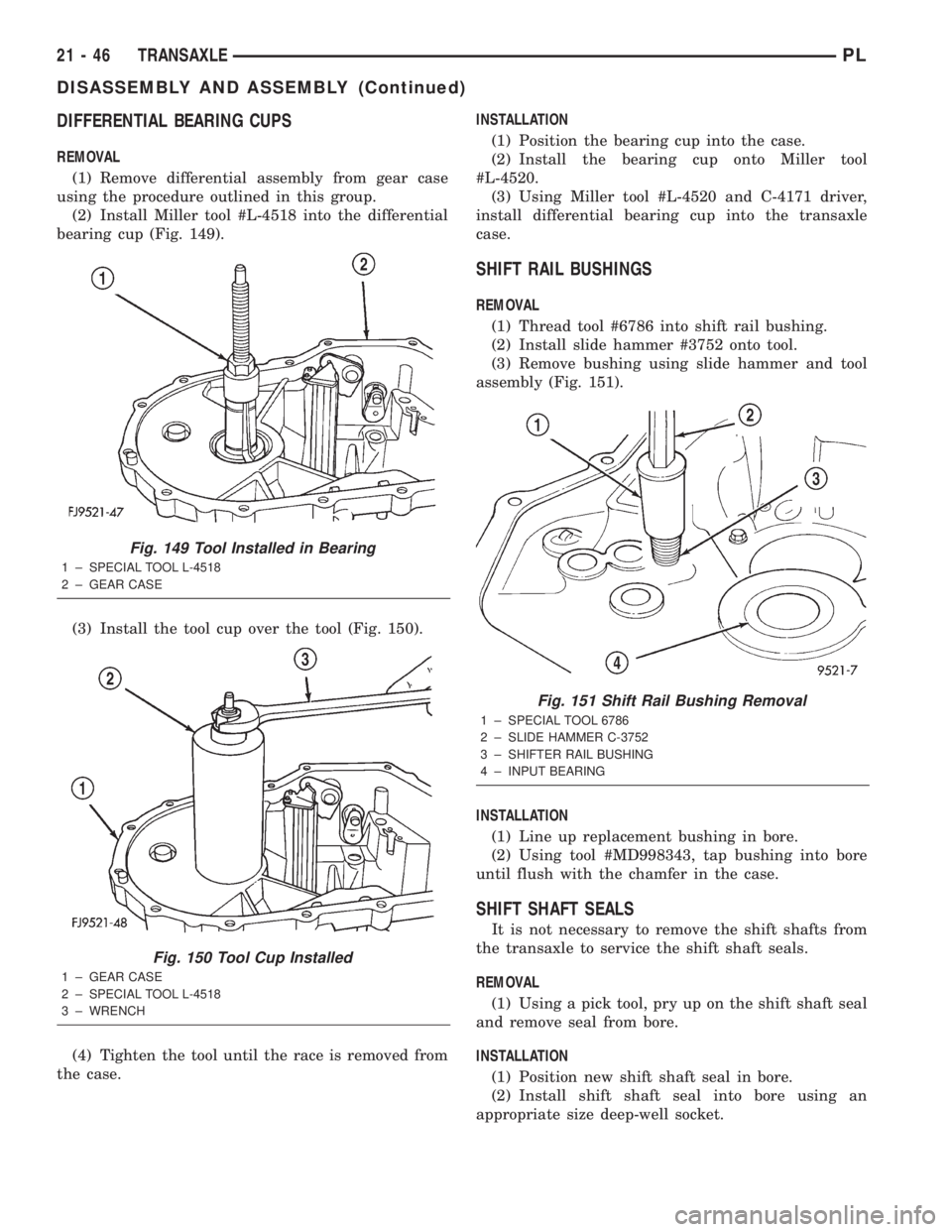

DIFFERENTIAL BEARING CUPS

REMOVAL

(1) Remove differential assembly from gear case

using the procedure outlined in this group.

(2) Install Miller tool #L-4518 into the differential

bearing cup (Fig. 149).

(3) Install the tool cup over the tool (Fig. 150).

(4) Tighten the tool until the race is removed from

the case.INSTALLATION

(1) Position the bearing cup into the case.

(2) Install the bearing cup onto Miller tool

#L-4520.

(3) Using Miller tool #L-4520 and C-4171 driver,

install differential bearing cup into the transaxle

case.

SHIFT RAIL BUSHINGS

REMOVAL

(1) Thread tool #6786 into shift rail bushing.

(2) Install slide hammer #3752 onto tool.

(3) Remove bushing using slide hammer and tool

assembly (Fig. 151).

INSTALLATION

(1) Line up replacement bushing in bore.

(2) Using tool #MD998343, tap bushing into bore

until flush with the chamfer in the case.

SHIFT SHAFT SEALS

It is not necessary to remove the shift shafts from

the transaxle to service the shift shaft seals.

REMOVAL

(1) Using a pick tool, pry up on the shift shaft seal

and remove seal from bore.

INSTALLATION

(1) Position new shift shaft seal in bore.

(2) Install shift shaft seal into bore using an

appropriate size deep-well socket.

Fig. 149 Tool Installed in Bearing

1 ± SPECIAL TOOL L-4518

2 ± GEAR CASE

Fig. 150 Tool Cup Installed

1 ± GEAR CASE

2 ± SPECIAL TOOL L-4518

3 ± WRENCH

Fig. 151 Shift Rail Bushing Removal

1 ± SPECIAL TOOL 6786

2 ± SLIDE HAMMER C-3752

3 ± SHIFTER RAIL BUSHING

4 ± INPUT BEARING

21 - 46 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)