fuse box DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 214 of 1285

be checked. To determine if a high current draw con-

dition exists first check the vehicle with a test lamp.

(1) Verify that all electrical accessories are OFF.

²Remove key from ignition switch

²Turn off all lights

²Trunk lid is closed

²Engine compartment hood lamp is disconnected

or lamp removed

²Map lamp on rear view mirror

²Glove box door is closed

²Sun visor vanity lights are OFF

²All doors are closed

²Allow the ignition key lamp system to time out

in approximately 30 seconds, if equipped.

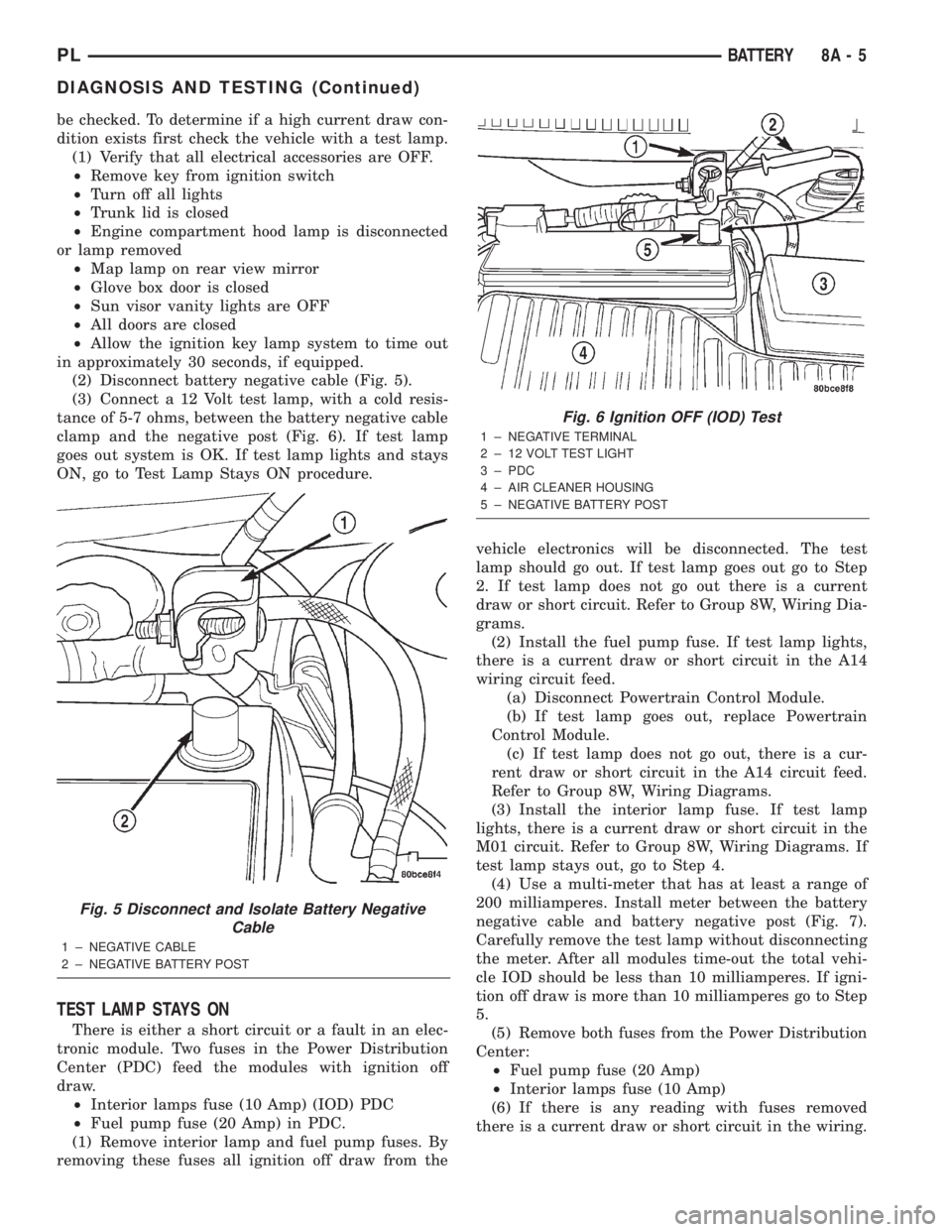

(2) Disconnect battery negative cable (Fig. 5).

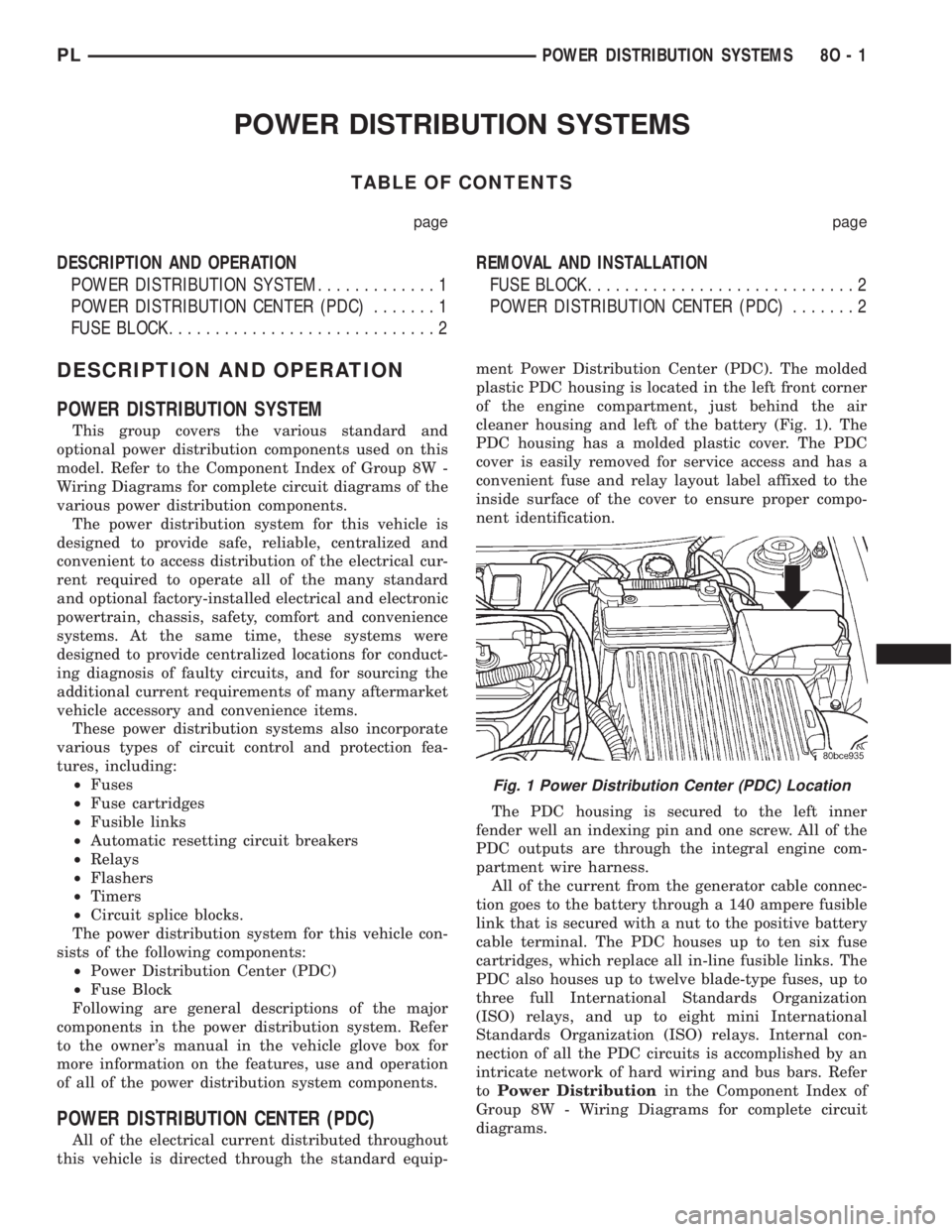

(3) Connect a 12 Volt test lamp, with a cold resis-

tance of 5-7 ohms, between the battery negative cable

clamp and the negative post (Fig. 6). If test lamp

goes out system is OK. If test lamp lights and stays

ON, go to Test Lamp Stays ON procedure.

TEST LAMP STAYS ON

There is either a short circuit or a fault in an elec-

tronic module. Two fuses in the Power Distribution

Center (PDC) feed the modules with ignition off

draw.

²Interior lamps fuse (10 Amp) (IOD) PDC

²Fuel pump fuse (20 Amp) in PDC.

(1) Remove interior lamp and fuel pump fuses. By

removing these fuses all ignition off draw from thevehicle electronics will be disconnected. The test

lamp should go out. If test lamp goes out go to Step

2. If test lamp does not go out there is a current

draw or short circuit. Refer to Group 8W, Wiring Dia-

grams.

(2) Install the fuel pump fuse. If test lamp lights,

there is a current draw or short circuit in the A14

wiring circuit feed.

(a) Disconnect Powertrain Control Module.

(b) If test lamp goes out, replace Powertrain

Control Module.

(c) If test lamp does not go out, there is a cur-

rent draw or short circuit in the A14 circuit feed.

Refer to Group 8W, Wiring Diagrams.

(3) Install the interior lamp fuse. If test lamp

lights, there is a current draw or short circuit in the

M01 circuit. Refer to Group 8W, Wiring Diagrams. If

test lamp stays out, go to Step 4.

(4) Use a multi-meter that has at least a range of

200 milliamperes. Install meter between the battery

negative cable and battery negative post (Fig. 7).

Carefully remove the test lamp without disconnecting

the meter. After all modules time-out the total vehi-

cle IOD should be less than 10 milliamperes. If igni-

tion off draw is more than 10 milliamperes go to Step

5.

(5) Remove both fuses from the Power Distribution

Center:

²Fuel pump fuse (20 Amp)

²Interior lamps fuse (10 Amp)

(6) If there is any reading with fuses removed

there is a current draw or short circuit in the wiring.

Fig. 5 Disconnect and Isolate Battery Negative

Cable

1 ± NEGATIVE CABLE

2 ± NEGATIVE BATTERY POST

Fig. 6 Ignition OFF (IOD) Test

1 ± NEGATIVE TERMINAL

2 ± 12 VOLT TEST LIGHT

3 ± PDC

4 ± AIR CLEANER HOUSING

5 ± NEGATIVE BATTERY POST

PLBATTERY 8A - 5

DIAGNOSIS AND TESTING (Continued)

Page 360 of 1285

POWER DISTRIBUTION SYSTEMS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

POWER DISTRIBUTION SYSTEM.............1

POWER DISTRIBUTION CENTER (PDC).......1

FUSE BLOCK.............................2REMOVAL AND INSTALLATION

FUSE BLOCK.............................2

POWER DISTRIBUTION CENTER (PDC).......2

DESCRIPTION AND OPERATION

POWER DISTRIBUTION SYSTEM

This group covers the various standard and

optional power distribution components used on this

model. Refer to the Component Index of Group 8W -

Wiring Diagrams for complete circuit diagrams of the

various power distribution components.

The power distribution system for this vehicle is

designed to provide safe, reliable, centralized and

convenient to access distribution of the electrical cur-

rent required to operate all of the many standard

and optional factory-installed electrical and electronic

powertrain, chassis, safety, comfort and convenience

systems. At the same time, these systems were

designed to provide centralized locations for conduct-

ing diagnosis of faulty circuits, and for sourcing the

additional current requirements of many aftermarket

vehicle accessory and convenience items.

These power distribution systems also incorporate

various types of circuit control and protection fea-

tures, including:

²Fuses

²Fuse cartridges

²Fusible links

²Automatic resetting circuit breakers

²Relays

²Flashers

²Timers

²Circuit splice blocks.

The power distribution system for this vehicle con-

sists of the following components:

²Power Distribution Center (PDC)

²Fuse Block

Following are general descriptions of the major

components in the power distribution system. Refer

to the owner's manual in the vehicle glove box for

more information on the features, use and operation

of all of the power distribution system components.

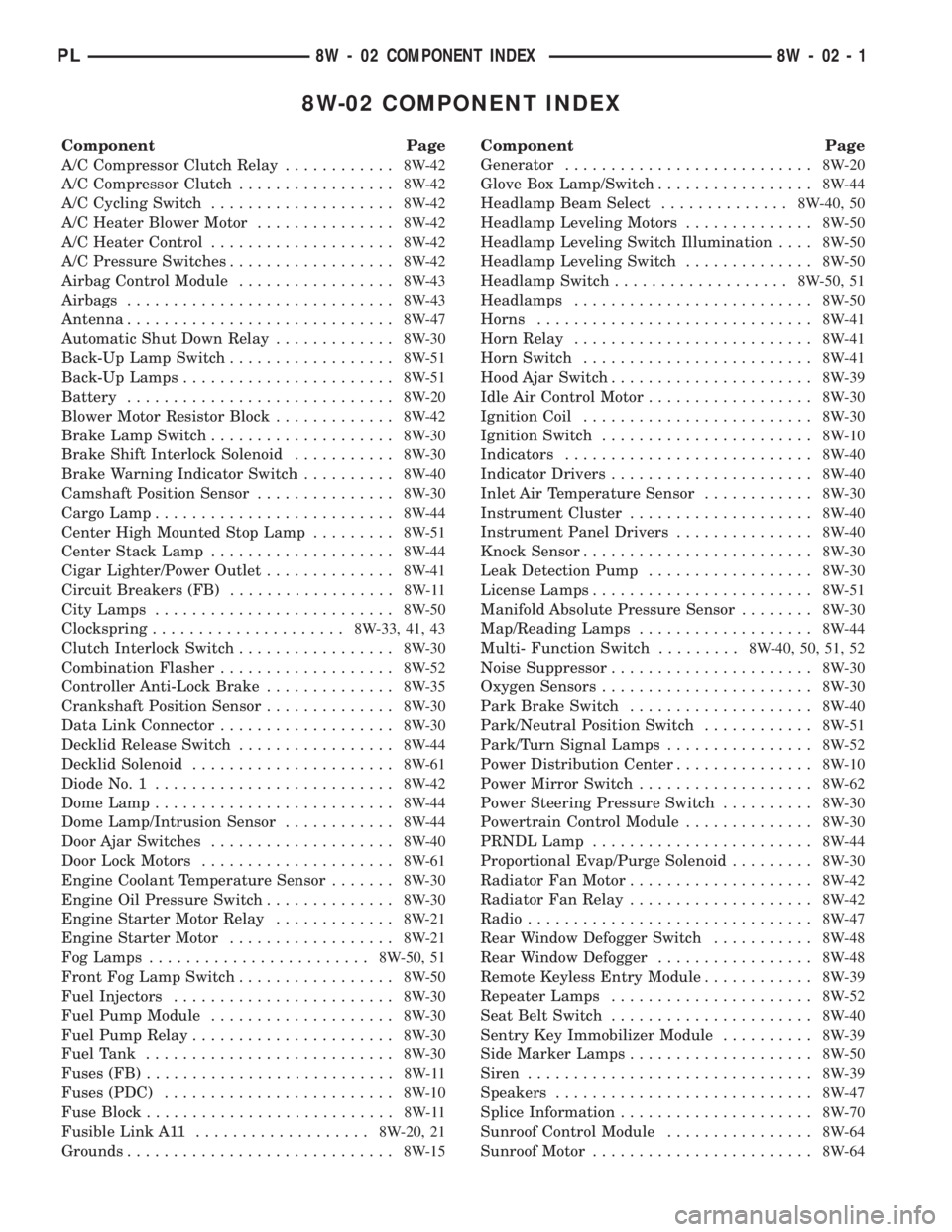

POWER DISTRIBUTION CENTER (PDC)

All of the electrical current distributed throughout

this vehicle is directed through the standard equip-ment Power Distribution Center (PDC). The molded

plastic PDC housing is located in the left front corner

of the engine compartment, just behind the air

cleaner housing and left of the battery (Fig. 1). The

PDC housing has a molded plastic cover. The PDC

cover is easily removed for service access and has a

convenient fuse and relay layout label affixed to the

inside surface of the cover to ensure proper compo-

nent identification.

The PDC housing is secured to the left inner

fender well an indexing pin and one screw. All of the

PDC outputs are through the integral engine com-

partment wire harness.

All of the current from the generator cable connec-

tion goes to the battery through a 140 ampere fusible

link that is secured with a nut to the positive battery

cable terminal. The PDC houses up to ten six fuse

cartridges, which replace all in-line fusible links. The

PDC also houses up to twelve blade-type fuses, up to

three full International Standards Organization

(ISO) relays, and up to eight mini International

Standards Organization (ISO) relays. Internal con-

nection of all the PDC circuits is accomplished by an

intricate network of hard wiring and bus bars. Refer

toPower Distributionin the Component Index of

Group 8W - Wiring Diagrams for complete circuit

diagrams.

Fig. 1 Power Distribution Center (PDC) Location

PLPOWER DISTRIBUTION SYSTEMS 8O - 1

Page 410 of 1285

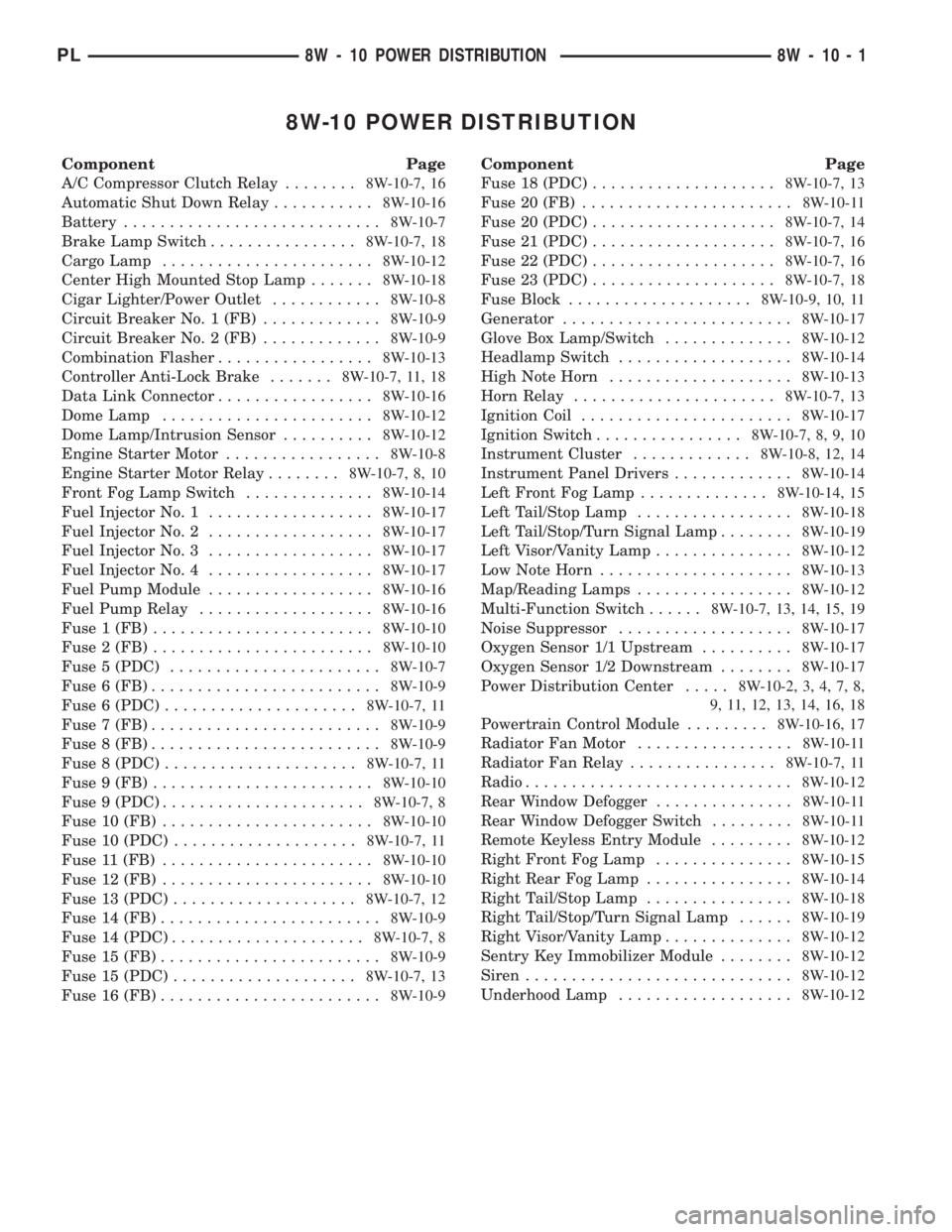

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch Relay............8W-42

A/C Compressor Clutch.................8W-42

A/C Cycling Switch....................8W-42

A/C Heater Blower Motor...............8W-42

A/C Heater Control....................8W-42

A/C Pressure Switches..................8W-42

Airbag Control Module.................8W-43

Airbags.............................8W-43

Antenna.............................8W-47

Automatic Shut Down Relay.............8W-30

Back-Up Lamp Switch..................8W-51

Back-Up Lamps.......................8W-51

Battery.............................8W-20

Blower Motor Resistor Block.............8W-42

Brake Lamp Switch....................8W-30

Brake Shift Interlock Solenoid...........8W-30

Brake Warning Indicator Switch..........8W-40

Camshaft Position Sensor...............8W-30

Cargo Lamp..........................8W-44

Center High Mounted Stop Lamp.........8W-51

Center Stack Lamp....................8W-44

Cigar Lighter/Power Outlet..............8W-41

Circuit Breakers (FB)..................8W-11

City Lamps..........................8W-50

Clockspring.....................8W-33, 41, 43

Clutch Interlock Switch.................8W-30

Combination Flasher...................8W-52

Controller Anti-Lock Brake..............8W-35

Crankshaft Position Sensor..............8W-30

Data Link Connector...................8W-30

Decklid Release Switch.................8W-44

Decklid Solenoid......................8W-61

Diode No. 1..........................8W-42

Dome Lamp..........................8W-44

Dome Lamp/Intrusion Sensor............8W-44

Door Ajar Switches....................8W-40

Door Lock Motors.....................8W-61

Engine Coolant Temperature Sensor.......8W-30

Engine Oil Pressure Switch..............8W-30

Engine Starter Motor Relay.............8W-21

Engine Starter Motor..................8W-21

Fog Lamps........................8W-50, 51

Front Fog Lamp Switch.................8W-50

Fuel Injectors........................8W-30

Fuel Pump Module....................8W-30

Fuel Pump Relay......................8W-30

Fuel Tank...........................8W-30

Fuses (FB)...........................8W-11

Fuses (PDC).........................8W-10

Fuse Block...........................8W-11

Fusible Link A11...................8W-20, 21

Grounds.............................8W-15Component Page

Generator...........................8W-20

Glove Box Lamp/Switch.................8W-44

Headlamp Beam Select..............8W-40, 50

Headlamp Leveling Motors..............8W-50

Headlamp Leveling Switch Illumination....8W-50

Headlamp Leveling Switch..............8W-50

Headlamp Switch...................8W-50, 51

Headlamps..........................8W-50

Horns..............................8W-41

Horn Relay..........................8W-41

Horn Switch.........................8W-41

Hood Ajar Switch......................8W-39

Idle Air Control Motor..................8W-30

Ignition Coil.........................8W-30

Ignition Switch.......................8W-10

Indicators...........................8W-40

Indicator Drivers......................8W-40

Inlet Air Temperature Sensor............8W-30

Instrument Cluster....................8W-40

Instrument Panel Drivers...............8W-40

Knock Sensor.........................8W-30

Leak Detection Pump..................8W-30

License Lamps........................8W-51

Manifold Absolute Pressure Sensor........8W-30

Map/Reading Lamps...................8W-44

Multi- Function Switch.........8W-40, 50, 51, 52

Noise Suppressor......................8W-30

Oxygen Sensors.......................8W-30

Park Brake Switch....................8W-40

Park/Neutral Position Switch............8W-51

Park/Turn Signal Lamps................8W-52

Power Distribution Center...............8W-10

Power Mirror Switch...................8W-62

Power Steering Pressure Switch..........8W-30

Powertrain Control Module..............8W-30

PRNDL Lamp........................8W-44

Proportional Evap/Purge Solenoid.........8W-30

Radiator Fan Motor....................8W-42

Radiator Fan Relay....................8W-42

Radio...............................8W-47

Rear Window Defogger Switch...........8W-48

Rear Window Defogger.................8W-48

Remote Keyless Entry Module............8W-39

Repeater Lamps......................8W-52

Seat Belt Switch......................8W-40

Sentry Key Immobilizer Module..........8W-39

Side Marker Lamps....................8W-50

Siren...............................8W-39

Speakers............................8W-47

Splice Information.....................8W-70

Sunroof Control Module................8W-64

Sunroof Motor........................8W-64

PL8W - 02 COMPONENT INDEX 8W - 02 - 1

Page 412 of 1285

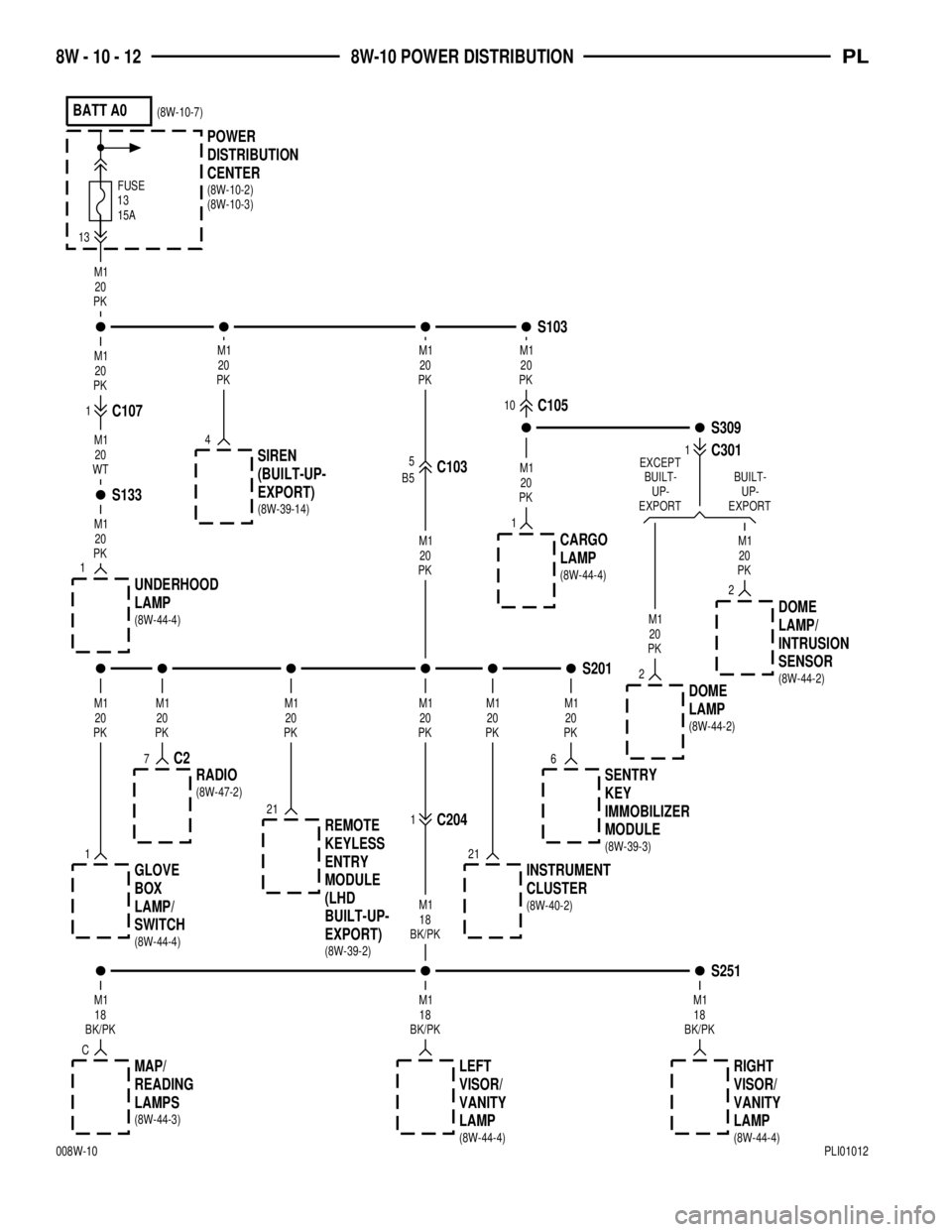

8W-10 POWER DISTRIBUTION

Component Page

A/C Compressor Clutch Relay........8W-10-7, 16

Automatic Shut Down Relay...........8W-10-16

Battery............................8W-10-7

Brake Lamp Switch................8W-10-7, 18

Cargo Lamp.......................8W-10-12

Center High Mounted Stop Lamp.......8W-10-18

Cigar Lighter/Power Outlet............8W-10-8

Circuit Breaker No. 1 (FB).............8W-10-9

Circuit Breaker No. 2 (FB).............8W-10-9

Combination Flasher.................8W-10-13

Controller Anti-Lock Brake.......8W-10-7, 11, 18

Data Link Connector.................8W-10-16

Dome Lamp.......................8W-10-12

Dome Lamp/Intrusion Sensor..........8W-10-12

Engine Starter Motor.................8W-10-8

Engine Starter Motor Relay........8W-10-7, 8, 10

Front Fog Lamp Switch..............8W-10-14

Fuel Injector No. 1..................8W-10-17

Fuel Injector No. 2..................8W-10-17

Fuel Injector No. 3..................8W-10-17

Fuel Injector No. 4..................8W-10-17

Fuel Pump Module..................8W-10-16

Fuel Pump Relay...................8W-10-16

Fuse 1 (FB)........................8W-10-10

Fuse 2 (FB)........................8W-10-10

Fuse 5 (PDC).......................8W-10-7

Fuse 6 (FB).........................8W-10-9

Fuse 6 (PDC).....................8W-10-7, 11

Fuse 7 (FB).........................8W-10-9

Fuse 8 (FB).........................8W-10-9

Fuse 8 (PDC).....................8W-10-7, 11

Fuse 9 (FB)........................8W-10-10

Fuse 9 (PDC)......................8W-10-7, 8

Fuse 10 (FB).......................8W-10-10

Fuse 10 (PDC)....................8W-10-7, 11

Fuse 11 (FB).......................8W-10-10

Fuse 12 (FB).......................8W-10-10

Fuse 13 (PDC)....................8W-10-7, 12

Fuse 14 (FB)........................8W-10-9

Fuse 14 (PDC).....................8W-10-7, 8

Fuse 15 (FB)........................8W-10-9

Fuse 15 (PDC)....................8W-10-7, 13

Fuse 16 (FB)........................8W-10-9Component Page

Fuse 18 (PDC)....................8W-10-7, 13

Fuse 20 (FB).......................8W-10-11

Fuse 20 (PDC)....................8W-10-7, 14

Fuse 21 (PDC)....................8W-10-7, 16

Fuse 22 (PDC)....................8W-10-7, 16

Fuse 23 (PDC)....................8W-10-7, 18

Fuse Block....................8W-10-9, 10, 11

Generator.........................8W-10-17

Glove Box Lamp/Switch..............8W-10-12

Headlamp Switch...................8W-10-14

High Note Horn....................8W-10-13

Horn Relay......................8W-10-7, 13

Ignition Coil.......................8W-10-17

Ignition Switch................8W-10-7, 8, 9, 10

Instrument Cluster.............8W-10-8, 12, 14

Instrument Panel Drivers.............8W-10-14

Left Front Fog Lamp..............8W-10-14, 15

Left Tail/Stop Lamp.................8W-10-18

Left Tail/Stop/Turn Signal Lamp........8W-10-19

Left Visor/Vanity Lamp...............8W-10-12

Low Note Horn.....................8W-10-13

Map/Reading Lamps.................8W-10-12

Multi-Function Switch......8W-10-7, 13, 14, 15, 19

Noise Suppressor...................8W-10-17

Oxygen Sensor 1/1 Upstream..........8W-10-17

Oxygen Sensor 1/2 Downstream........8W-10-17

Power Distribution Center.....8W-10-2, 3, 4, 7, 8,

9, 11, 12, 13, 14, 16, 18

Powertrain Control Module.........8W-10-16, 17

Radiator Fan Motor.................8W-10-11

Radiator Fan Relay................8W-10-7, 11

Radio.............................8W-10-12

Rear Window Defogger...............8W-10-11

Rear Window Defogger Switch.........8W-10-11

Remote Keyless Entry Module.........8W-10-12

Right Front Fog Lamp...............8W-10-15

Right Rear Fog Lamp................8W-10-14

Right Tail/Stop Lamp................8W-10-18

Right Tail/Stop/Turn Signal Lamp......8W-10-19

Right Visor/Vanity Lamp..............8W-10-12

Sentry Key Immobilizer Module........8W-10-12

Siren.............................8W-10-12

Underhood Lamp...................8W-10-12

PL8W - 10 POWER DISTRIBUTION 8W - 10 - 1

Page 423 of 1285

13FUSE15A

13

BATT A0

B5C103

M1

20

WT

LAMP UNDERHOOD

M1

20

PK

LAMP CARGO

LAMP

DOMEM1

20

PK

1C204

M1

18

BK/PK

M1

20

PK

1

7

RADIO

M1

20

PK

21

CLUSTER INSTRUMENT

M1

20

PK

M1

18

BK/PK

C

MAP/

READING

LAMPS

M1

18

BK/PK

LAMP VANITY

VISOR/

LEFT RIGHT

VISOR/

VANITY

LAMP

BK/PK18 M1

S251

2

CENTER DISTRIBUTION

POWER

C2

SWITCH LAMP/

BOX

GLOVE

1

6

C1071

PK20 M1

1

S103

M1

20

PK

M1

20

PK

5M1

20

PK

10C105

S309

M1

20

PK

M1

20

PK

M1

20

PK

MODULE IMMOBILIZER

KEY

SENTRY

4

M1

20

PK

(BUILT-UP- SIREN

EXPORT)

C3011

21

M1

20

PK

BUILT-UP- (LHD

MODULE

ENTRY

KEYLESS

REMOTE

EXPORT)S201

EXCEPT

EXPORTUP- BUILT-

EXPORTUP- BUILT-

PK20 M1

2

DOME

LAMP/

INTRUSION

SENSOR

S133

M1

20

PK

(8W-44-4)(8W-44-4)

(8W-44-2)

(8W-47-2)

(8W-40-2)

(8W-44-3)

(8W-44-4) (8W-44-4) (8W-10-7)

(8W-44-4)(8W-10-2)

(8W-10-3)

(8W-39-3) (8W-39-14)

(8W-39-2)(8W-44-2)

8W - 10 - 12 8W-10 POWER DISTRIBUTIONPL

008W-10PLI01012

Page 536 of 1285

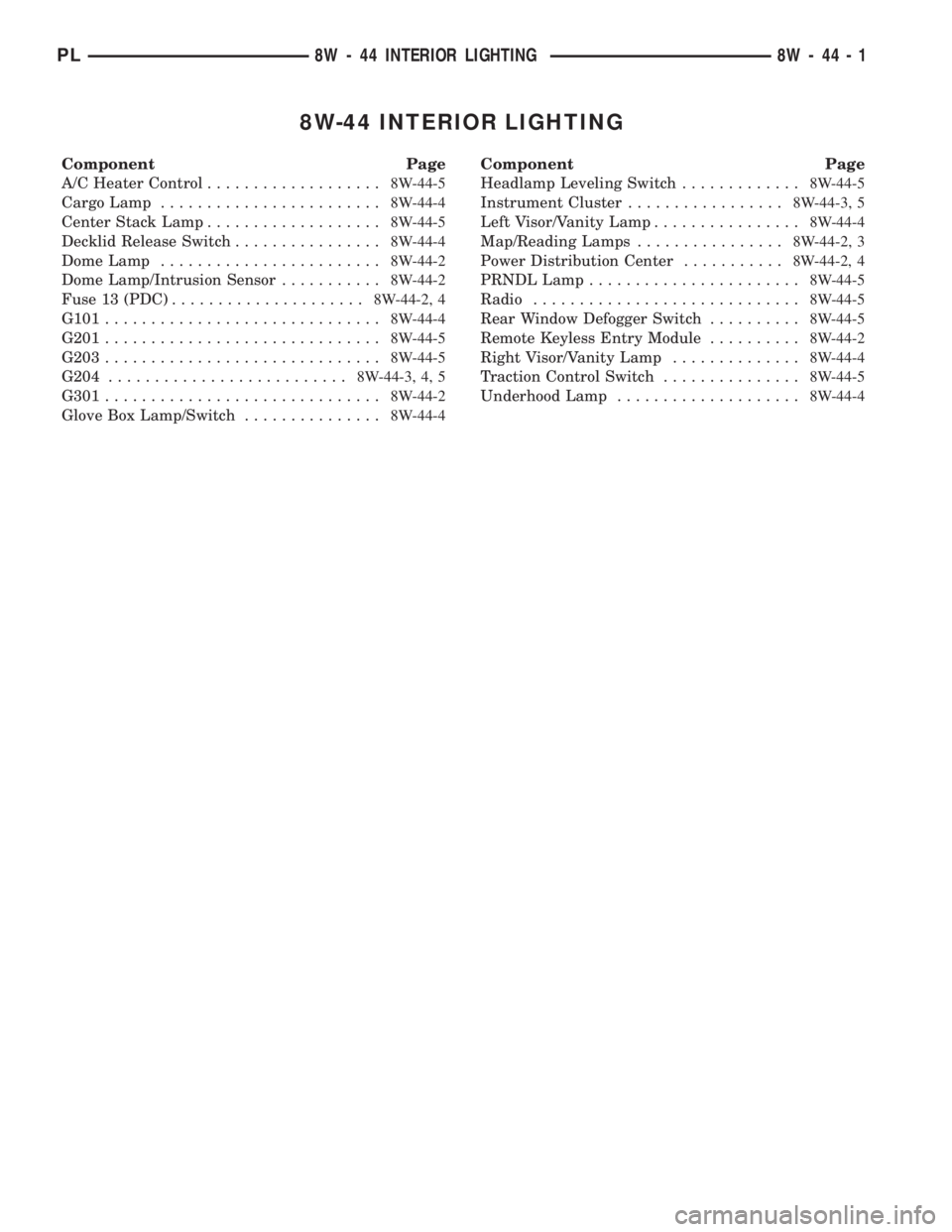

8W-44 INTERIOR LIGHTING

Component Page

A/C Heater Control...................8W-44-5

Cargo Lamp........................8W-44-4

Center Stack Lamp...................8W-44-5

Decklid Release Switch................8W-44-4

Dome Lamp........................8W-44-2

Dome Lamp/Intrusion Sensor...........8W-44-2

Fuse 13 (PDC).....................8W-44-2, 4

G101..............................8W-44-4

G201..............................8W-44-5

G203..............................8W-44-5

G204..........................8W-44-3, 4, 5

G301..............................8W-44-2

Glove Box Lamp/Switch...............8W-44-4Component Page

Headlamp Leveling Switch.............8W-44-5

Instrument Cluster.................8W-44-3, 5

Left Visor/Vanity Lamp................8W-44-4

Map/Reading Lamps................8W-44-2, 3

Power Distribution Center...........8W-44-2, 4

PRNDL Lamp.......................8W-44-5

Radio.............................8W-44-5

Rear Window Defogger Switch..........8W-44-5

Remote Keyless Entry Module..........8W-44-2

Right Visor/Vanity Lamp..............8W-44-4

Traction Control Switch...............8W-44-5

Underhood Lamp....................8W-44-4

PL8W - 44 INTERIOR LIGHTING 8W - 44 - 1

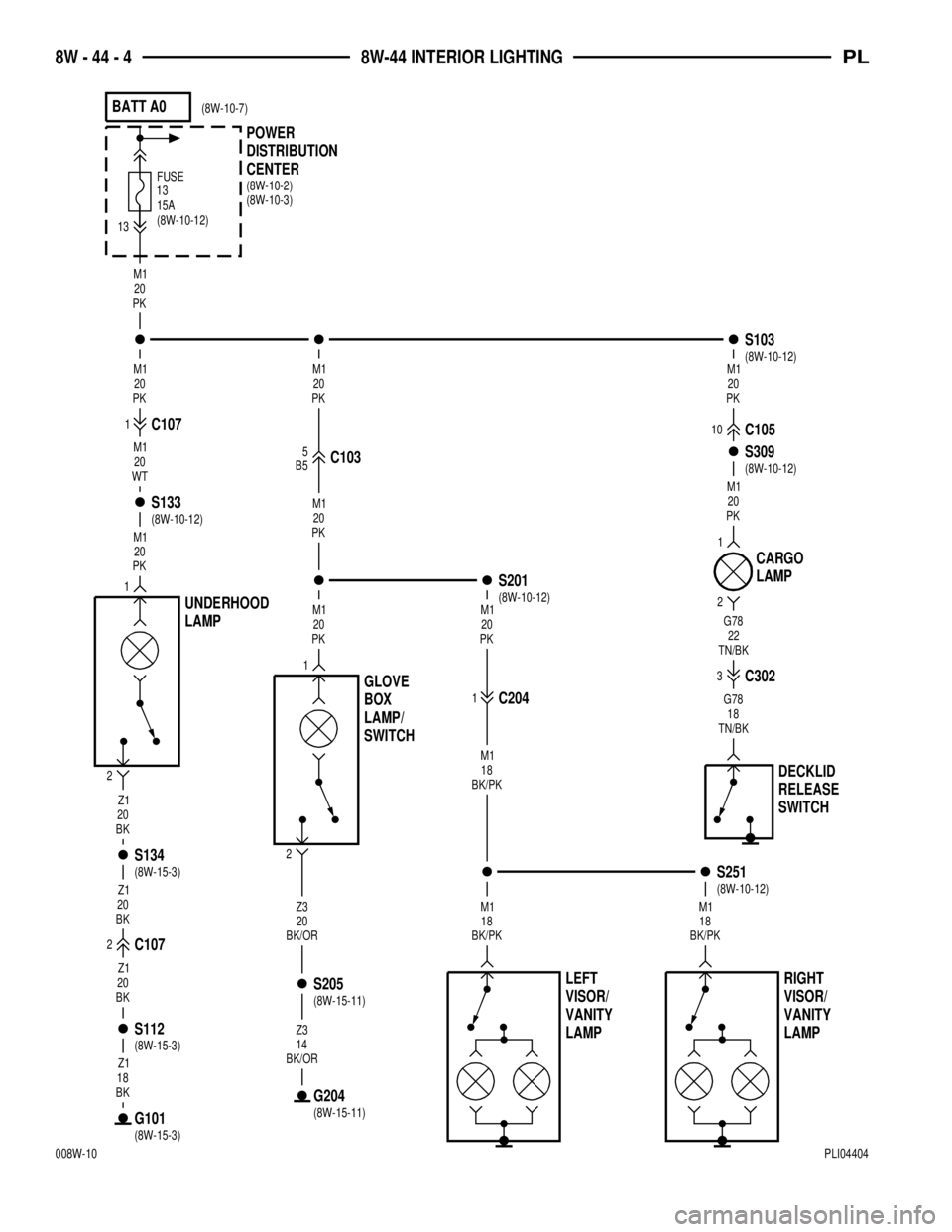

Page 539 of 1285

13

15A

FUSE

13

BATT A0

POWER

DISTRIBUTION

CENTER

1

2

G101

S112

C1071

UNDERHOOD

LAMP

21

SWITCH LAMP/

BOX

GLOVE

G204

S205

LAMP

VANITY

VISOR/

LEFT RIGHT

VISOR/

VANITY

LAMP

C204121

DECKLID

RELEASE CARGO

LAMP

C3023

S309

10C105

B5C1035

S201

M1

20

PK

M1

20

PK

M1

20

WT

M1

18

BK/PK

M1

18

BK/PKM1

18

BK/PK

M1

20

PKM1

20

PK

M1

20

PK

M1

20

PKM1

20

PK

M1

20

PK

Z1

20

BK

Z1

18

BK

Z3

20

BK/OR

Z3

14

BK/OR

S103

S251

G78

22

TN/BK

G78

18

TN/BK

SWITCH

2C107

BK20Z1

S133

S134

Z1

20

BK

M1

20

PK

(8W-10-12)(8W-10-7)

(8W-10-2)

(8W-10-3)

(8W-15-3) (8W-15-3)

(8W-15-11) (8W-15-11)(8W-10-12)

(8W-10-12)(8W-10-12)

(8W-10-12) (8W-10-12)

(8W-15-3)

8W - 44 - 4 8W-44 INTERIOR LIGHTINGPL

008W-10PLI04404

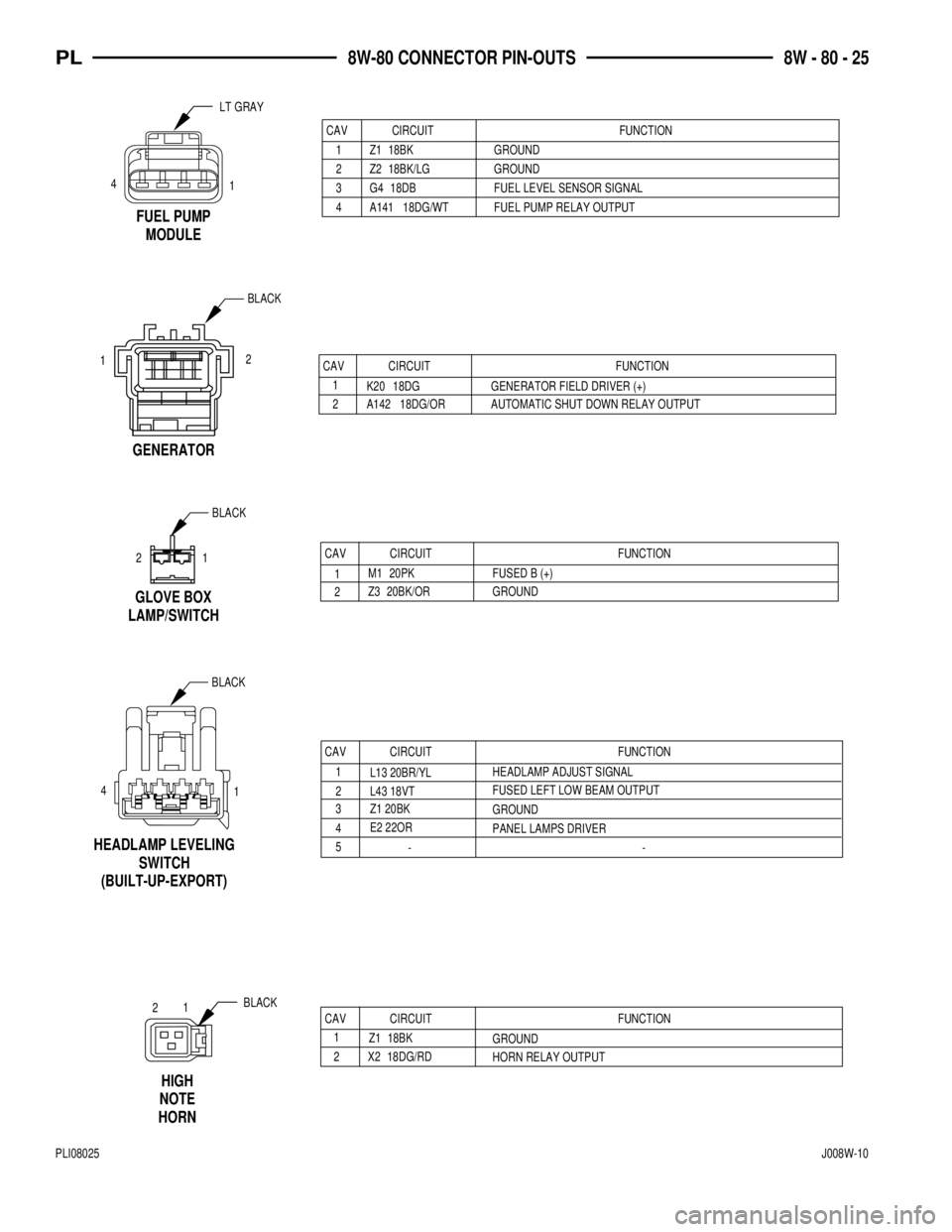

Page 634 of 1285

CAV CIRCUIT FUNCTION

1 Z1 18BK GROUND

2 Z2 18BK/LG GROUND

3 G4 18DB FUEL LEVEL SENSOR SIGNAL

4 A141 18DG/WT FUEL PUMP RELAY OUTPUT

LT GRAY

4

1

BLACK

CAV CIRCUIT FUNCTION

1

A142 18DG/OR AUTOMATIC SHUT DOWN RELAY OUTPUT 2K20 18DG GENERATOR FIELD DRIVER (+) 2

1

CAV CIRCUIT FUNCTION

1M1 20PK FUSED B (+)

2Z3 20BK/OR GROUND

1 2

FUEL PUMP

MODULE

GENERATOR

LAMP/SWITCHGLOVE BOX

HIGH

18BK Z1

2

18DG/RD X2 1

1

2BLACK

CAV CIRCUIT FUNCTION

GROUND

HORN RELAY OUTPUT

(BUILT-UP-EXPORT)SWITCH HEADLAMP LEVELING

L13 20BR/YL

E2 22OR

5 4

Z1 20BK 3

1

- - 2 L43 18VT CAV CIRCUIT FUNCTION

GROUND HEADLAMP ADJUST SIGNAL

FUSED LEFT LOW BEAM OUTPUT

PANEL LAMPS DRIVER 4

1

BLACK

BLACK

NOTE

HORN

PL8W-80 CONNECTOR PIN-OUTS 8W - 80 - 25

PLI08025J008W-10

Page 1242 of 1285

BLOWER MOTOR VIBRATION AND/OR NOISE

DIAGNOSIS

The resistor block supplies the blower motor with

varied voltage (low and middle speeds) or battery

voltage (high speed).

CAUTION: Stay clear of the blower motor and resis-

tor block (Hot). Do not operate the blower motor

with the resistor block removed from the heater-A/C

housing.

Refer to the Blower Motor Vibration/Noise chart

for diagnosis.

COMPRESSOR NOISE DIAGNOSIS

Excessive noise while the A/C is being used, can be

caused by loose mounts, loose clutch, or high operat-

ing pressure. Verify compressor drive belt condition,

proper refrigerant charge and head pressure before

compressor repair is performed.

If the A/C drive belt slips at initial start-up, it does

not necessarily mean the compressor has failed.

With the close tolerances of a compressor it is pos-

sible to experience a temporary lockup. The longer

the A/C system is inactive, the more likely the condi-

tion to occur.

This condition is the result of normal refrigerant

movement within the A/C system caused by temper-

ature changes. The refrigerant movement may wash

the oil out of the compressor.

EVAPORATOR PROBE TEST

The work area and vehicle must be between 16É C

(60É F) and 32É C (90É F) when testing the switch.

(1) Disconnect the three wire connector from the

evaporator probe lead located behind the glove box

(Fig. 12).

(2) Start engine and set A/C to low blower motor

speed, panel, full cool, and RECIRC.

(3) Using a voltmeter, check for battery voltage

between Pin 1 and 2. If no voltage is detected, there

is no power to the switch. Check wiring and fuses.

Refer to Group 8W, Wiring Diagrams for circuit diag-

nosis.

(4) Using a voltmeter, check for battery voltage

between Pin 1 and Pin 3. If no voltage is detected,

there is no voltage from the Powertrain Control Mod-

ule. Refer to Group 8W, Wiring Diagrams. If voltage

is OK, connect a jumper wire between Pin 1 and Pin

3. The compressor clutch should engage. If the clutch

engages, remove the jumper wire immediately and go

to Step 5. If the compressor clutch does not engage,

check the operation of the clutch and repair as nec-

essary.(5) If compressor clutch engages, connect the evap-

orator probe 3-way connector. The compressor clutch

should engage or cycle depending on evaporator tem-

perature. If OK, go to Step 6. If not OK, replace the

clutch cycling switch.

(6) The engine running and the A/C set to:

²Blower motor on low speed

²Panel position

²Full cool

²RECIRC.

Close all doors and windows. Place a thermometer in

the center discharge vent.

(7) If the clutch does not begin to cycle off between

2É C to 7É C (35É F to 45É F), verify that the evapo-

rator probe is fully installed and not loose in evapo-

rator. If it is not properly installed, install probe and

retest outlet temperature. If the evaporator probe is

properly installed, replace the clutch cycling switch.

EXPANSION VALVE

NOTE: Expansion valve tests should be performed

after compressor tests.

Liquid CO2 is required to test the expansion

valve. It is available from most welding supply facil-

ities. CO2 is also available from companies which

service and sell fire extinguishers.

Review Safety Precautions and Warnings in the

General Information section of this Group. The work

area and vehicle must be 21É to 27ÉC (70É to 85ÉF)

when testing expansion valve. To test the expansion

valve:

(1) Connect a charging station or manifold gauge

set to the refrigerant system service ports.

(2) Disconnect wire connector at low pressure cut-

off switch (Fig. 13). Using a jumper wire, jump ter-

minals inside wire connector boot.

(3) Close all doors, windows and vents to the pas-

senger compartment.

(4) Set Heater-A/C control to A/C, full heat, floor,

RECIRC. and high blower.

(5) Start the engine and hold the idle speed (1000

rpm). After the engine has reached running temper-

ature, allow the passenger compartment to heat up.

This will create the need for maximum refrigerant

flow into the evaporator.

(6) If the refrigerant charge is sufficient, discharge

(high pressure) gauge should read 965 to 2620 kPa

(140 to 380 psi). Suction (low pressure) gauge should

read 103 to 2417 kPa (15 to 35 psi). If system cannot

achieve proper pressure readings, replace the expan-

sion valve. If pressure is correct, proceed with test.

PLHEATING AND AIR CONDITIONING 24 - 11

DIAGNOSIS AND TESTING (Continued)