tra DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 906 of 1285

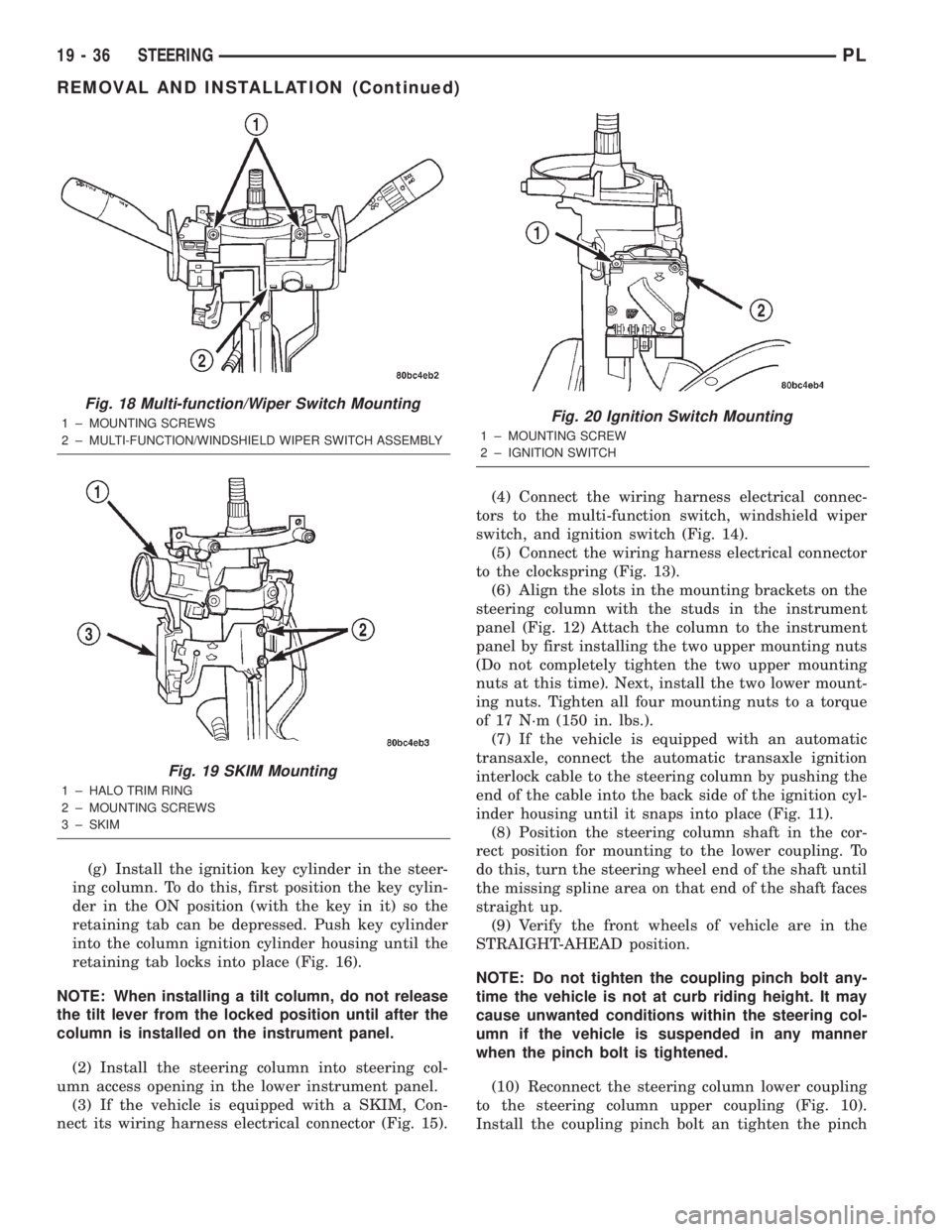

(b) Disengage the latch hooks on the back of the

clockspring by lifting the clockspring slightly to

clear the column housing with the top latch hook.

Next, lower the clockspring slightly to do the same

for the lower latch hook (Fig. 17). Remove the

clockspring from the column.

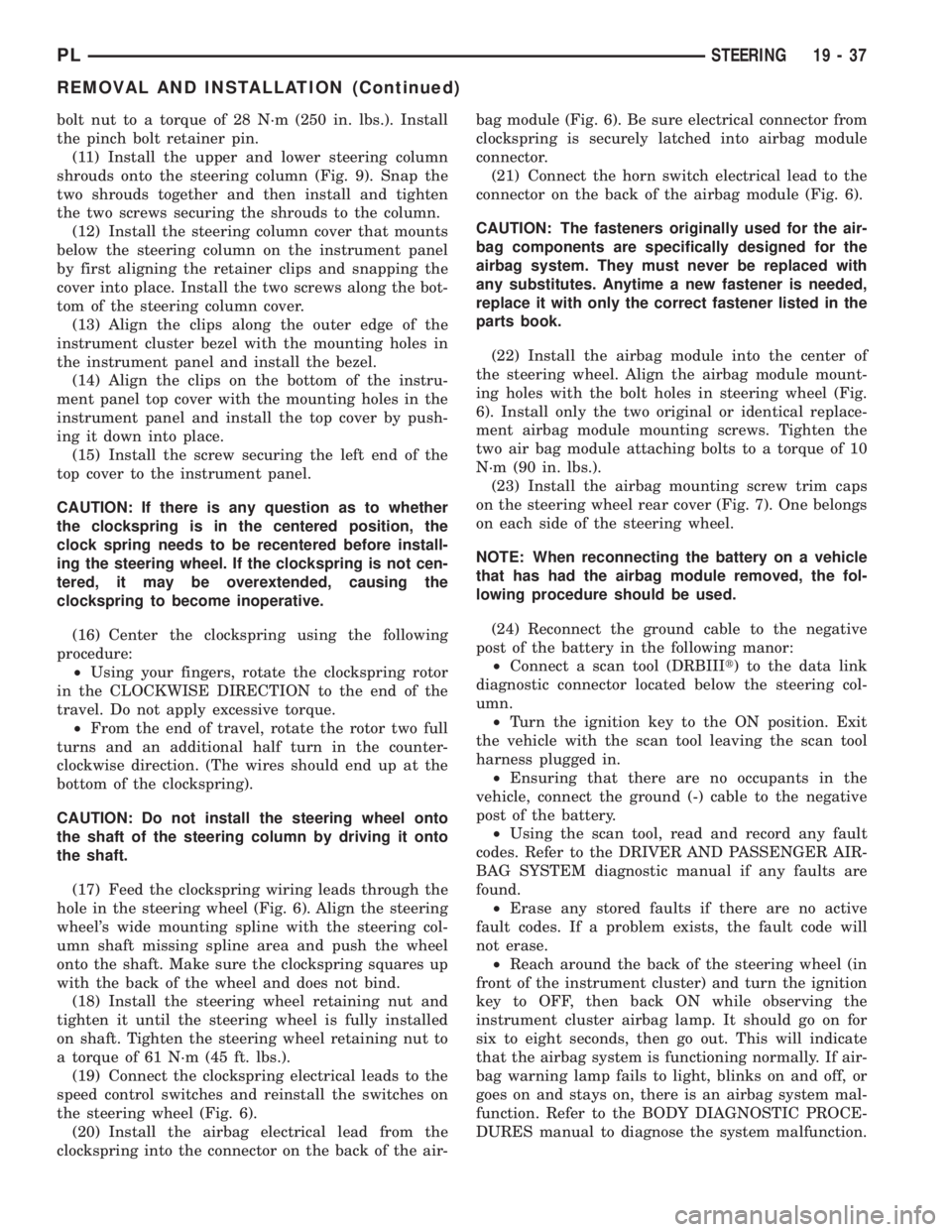

(c) Remove the two screws securing the multi-

function/windshield wiper switch to the steering

column (Fig. 18). Pull the switch straight away

from the column to remove it.

(d) If the column is equipped with a SKIM,

remove the module from the column by removing

the two mounting screws and sliding the SKIM off

the non-halo trim ring (Fig. 19).

(e) Remove the non-halo trim ring from the col-

umn by unclipping it from the ignition cylinder

housing (Fig. 19).

(f) Remove the ignition switch from the steering

column by first removing the mounting screw (Fig.

20). Once the screw is removed, pull the switch

straight out away from the column ignition cylin-

der housing.

INSTALLATION

(1) If the steering column is being replaced, per-

form the following on the column before installing it

on the vehicle:

(a) Ensure the ignition switch is positioned in

the ON position.

(b) Install the ignition switch on the steering

column by pushing the tapered end onto the shaft

and steering column ignition cylinder housing.

Install the screw securing the switch to the column

(Fig. 20).(c) Install the non-halo trim ring on the column

until its tabs snap into place on the ignition cylin-

der housing (Fig. 19).

(d) If the column is equipped with a Sentry Key

Immobilizer Module (SKIM), install the module on

the column by sliding the module onto the non halo

trim ring and installing the two mounting screws

(Fig. 19). Tighten the mounting screws to a torque

of 3 N´m (25 in. lbs.).

(e) Position the multi-function/windshield wiper

switch in onto the top of the column and install the

two screws securing the switch in place (Fig. 18).

(f) Place the clockspring onto the end of the col-

umn engaging the clockspring latch hooks into the

column (Fig. 17).

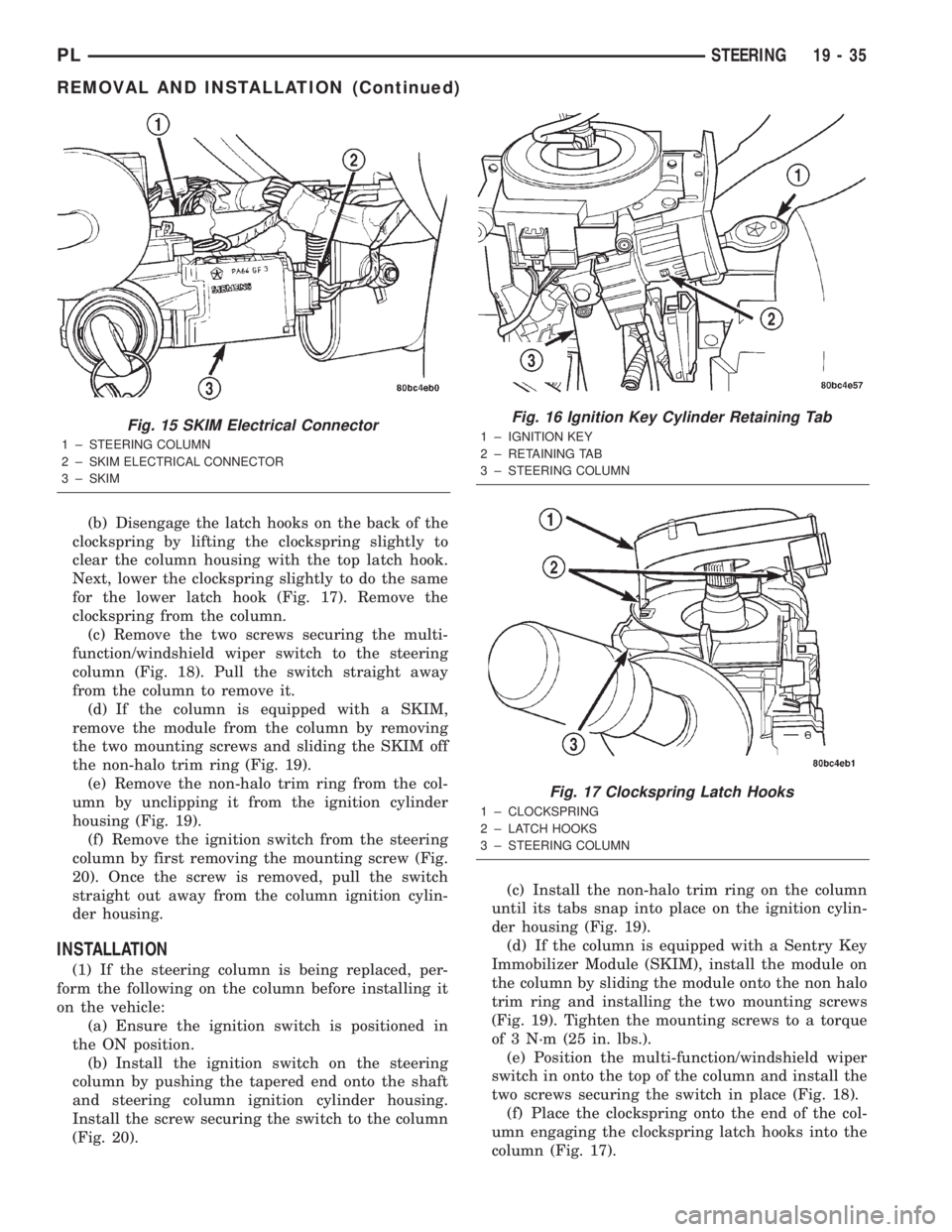

Fig. 15 SKIM Electrical Connector

1 ± STEERING COLUMN

2 ± SKIM ELECTRICAL CONNECTOR

3 ± SKIM

Fig. 16 Ignition Key Cylinder Retaining Tab

1 ± IGNITION KEY

2 ± RETAINING TAB

3 ± STEERING COLUMN

Fig. 17 Clockspring Latch Hooks

1 ± CLOCKSPRING

2 ± LATCH HOOKS

3 ± STEERING COLUMN

PLSTEERING 19 - 35

REMOVAL AND INSTALLATION (Continued)

Page 907 of 1285

(g) Install the ignition key cylinder in the steer-

ing column. To do this, first position the key cylin-

der in the ON position (with the key in it) so the

retaining tab can be depressed. Push key cylinder

into the column ignition cylinder housing until the

retaining tab locks into place (Fig. 16).

NOTE: When installing a tilt column, do not release

the tilt lever from the locked position until after the

column is installed on the instrument panel.

(2) Install the steering column into steering col-

umn access opening in the lower instrument panel.

(3) If the vehicle is equipped with a SKIM, Con-

nect its wiring harness electrical connector (Fig. 15).(4) Connect the wiring harness electrical connec-

tors to the multi-function switch, windshield wiper

switch, and ignition switch (Fig. 14).

(5) Connect the wiring harness electrical connector

to the clockspring (Fig. 13).

(6) Align the slots in the mounting brackets on the

steering column with the studs in the instrument

panel (Fig. 12) Attach the column to the instrument

panel by first installing the two upper mounting nuts

(Do not completely tighten the two upper mounting

nuts at this time). Next, install the two lower mount-

ing nuts. Tighten all four mounting nuts to a torque

of 17 N´m (150 in. lbs.).

(7) If the vehicle is equipped with an automatic

transaxle, connect the automatic transaxle ignition

interlock cable to the steering column by pushing the

end of the cable into the back side of the ignition cyl-

inder housing until it snaps into place (Fig. 11).

(8) Position the steering column shaft in the cor-

rect position for mounting to the lower coupling. To

do this, turn the steering wheel end of the shaft until

the missing spline area on that end of the shaft faces

straight up.

(9) Verify the front wheels of vehicle are in the

STRAIGHT-AHEAD position.

NOTE: Do not tighten the coupling pinch bolt any-

time the vehicle is not at curb riding height. It may

cause unwanted conditions within the steering col-

umn if the vehicle is suspended in any manner

when the pinch bolt is tightened.

(10) Reconnect the steering column lower coupling

to the steering column upper coupling (Fig. 10).

Install the coupling pinch bolt an tighten the pinch

Fig. 18 Multi-function/Wiper Switch Mounting

1 ± MOUNTING SCREWS

2 ± MULTI-FUNCTION/WINDSHIELD WIPER SWITCH ASSEMBLY

Fig. 19 SKIM Mounting

1 ± HALO TRIM RING

2 ± MOUNTING SCREWS

3 ± SKIM

Fig. 20 Ignition Switch Mounting

1 ± MOUNTING SCREW

2 ± IGNITION SWITCH

19 - 36 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 908 of 1285

bolt nut to a torque of 28 N´m (250 in. lbs.). Install

the pinch bolt retainer pin.

(11) Install the upper and lower steering column

shrouds onto the steering column (Fig. 9). Snap the

two shrouds together and then install and tighten

the two screws securing the shrouds to the column.

(12) Install the steering column cover that mounts

below the steering column on the instrument panel

by first aligning the retainer clips and snapping the

cover into place. Install the two screws along the bot-

tom of the steering column cover.

(13) Align the clips along the outer edge of the

instrument cluster bezel with the mounting holes in

the instrument panel and install the bezel.

(14) Align the clips on the bottom of the instru-

ment panel top cover with the mounting holes in the

instrument panel and install the top cover by push-

ing it down into place.

(15) Install the screw securing the left end of the

top cover to the instrument panel.

CAUTION: If there is any question as to whether

the clockspring is in the centered position, the

clock spring needs to be recentered before install-

ing the steering wheel. If the clockspring is not cen-

tered, it may be overextended, causing the

clockspring to become inoperative.

(16) Center the clockspring using the following

procedure:

²Using your fingers, rotate the clockspring rotor

in the CLOCKWISE DIRECTION to the end of the

travel. Do not apply excessive torque.

²From the end of travel, rotate the rotor two full

turns and an additional half turn in the counter-

clockwise direction. (The wires should end up at the

bottom of the clockspring).

CAUTION: Do not install the steering wheel onto

the shaft of the steering column by driving it onto

the shaft.

(17) Feed the clockspring wiring leads through the

hole in the steering wheel (Fig. 6). Align the steering

wheel's wide mounting spline with the steering col-

umn shaft missing spline area and push the wheel

onto the shaft. Make sure the clockspring squares up

with the back of the wheel and does not bind.

(18) Install the steering wheel retaining nut and

tighten it until the steering wheel is fully installed

on shaft. Tighten the steering wheel retaining nut to

a torque of 61 N´m (45 ft. lbs.).

(19) Connect the clockspring electrical leads to the

speed control switches and reinstall the switches on

the steering wheel (Fig. 6).

(20) Install the airbag electrical lead from the

clockspring into the connector on the back of the air-bag module (Fig. 6). Be sure electrical connector from

clockspring is securely latched into airbag module

connector.

(21) Connect the horn switch electrical lead to the

connector on the back of the airbag module (Fig. 6).

CAUTION: The fasteners originally used for the air-

bag components are specifically designed for the

airbag system. They must never be replaced with

any substitutes. Anytime a new fastener is needed,

replace it with only the correct fastener listed in the

parts book.

(22) Install the airbag module into the center of

the steering wheel. Align the airbag module mount-

ing holes with the bolt holes in steering wheel (Fig.

6). Install only the two original or identical replace-

ment airbag module mounting screws. Tighten the

two air bag module attaching bolts to a torque of 10

N´m (90 in. lbs.).

(23) Install the airbag mounting screw trim caps

on the steering wheel rear cover (Fig. 7). One belongs

on each side of the steering wheel.

NOTE: When reconnecting the battery on a vehicle

that has had the airbag module removed, the fol-

lowing procedure should be used.

(24) Reconnect the ground cable to the negative

post of the battery in the following manor:

²Connect a scan tool (DRBIIIt) to the data link

diagnostic connector located below the steering col-

umn.

²Turn the ignition key to the ON position. Exit

the vehicle with the scan tool leaving the scan tool

harness plugged in.

²Ensuring that there are no occupants in the

vehicle, connect the ground (-) cable to the negative

post of the battery.

²Using the scan tool, read and record any fault

codes. Refer to the DRIVER AND PASSENGER AIR-

BAG SYSTEM diagnostic manual if any faults are

found.

²Erase any stored faults if there are no active

fault codes. If a problem exists, the fault code will

not erase.

²Reach around the back of the steering wheel (in

front of the instrument cluster) and turn the ignition

key to OFF, then back ON while observing the

instrument cluster airbag lamp. It should go on for

six to eight seconds, then go out. This will indicate

that the airbag system is functioning normally. If air-

bag warning lamp fails to light, blinks on and off, or

goes on and stays on, there is an airbag system mal-

function. Refer to the BODY DIAGNOSTIC PROCE-

DURES manual to diagnose the system malfunction.

PLSTEERING 19 - 37

REMOVAL AND INSTALLATION (Continued)

Page 909 of 1285

(25) Turn the key to OFF and remove the scan tool

from the vehicle.

(26) Test the operation of the horn, wipers and any

other functions that are steering column operated. If

applicable, reset the radio and the clock.

(27) If the steering column is a tilt column, verify

the tilt mechanism operates properly.

(28) Road test the vehicle to ensure proper opera-

tion of the steering system and the speed control sys-

tem.

STEERING COLUMN LOWER COUPLING

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section and in STEERING

GEAR.

REMOVAL

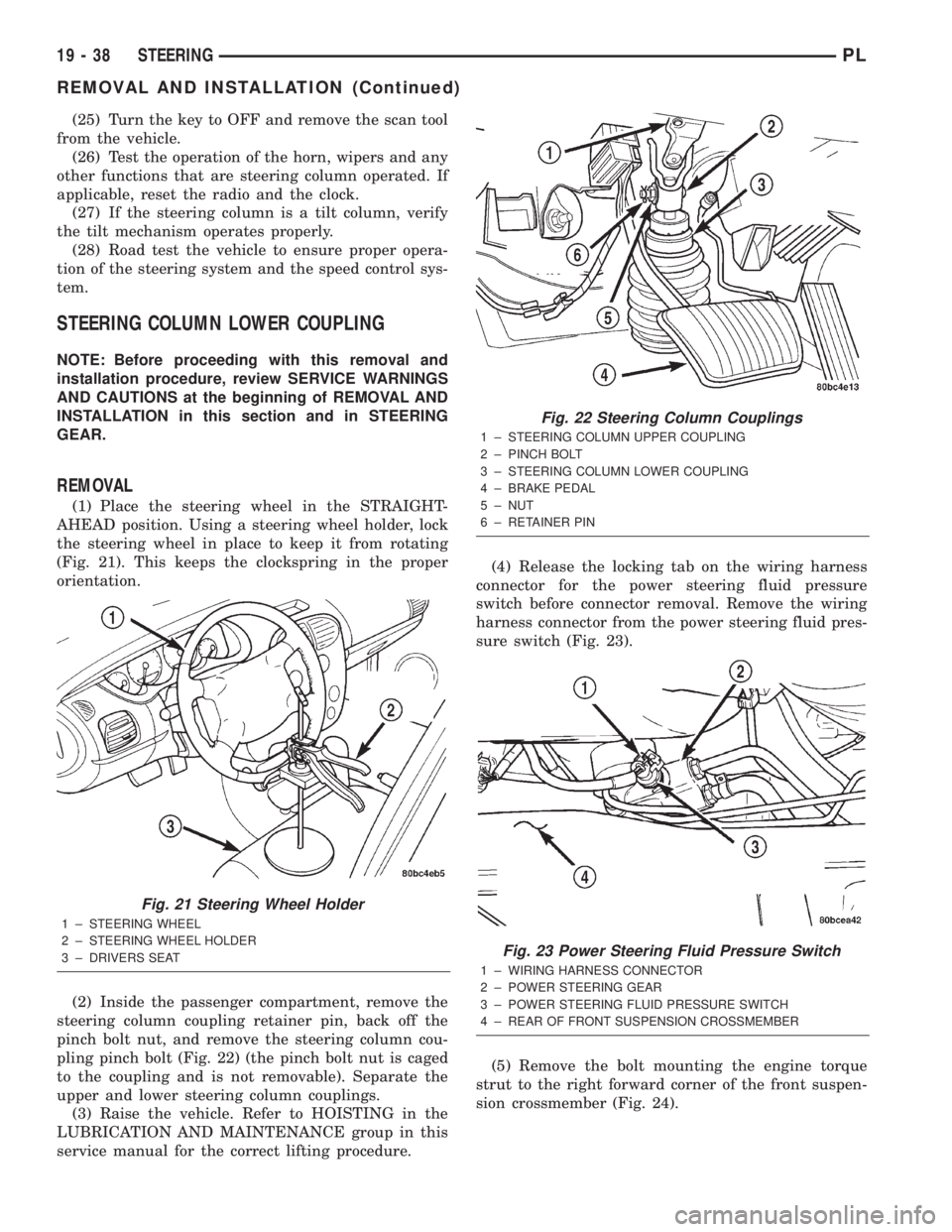

(1) Place the steering wheel in the STRAIGHT-

AHEAD position. Using a steering wheel holder, lock

the steering wheel in place to keep it from rotating

(Fig. 21). This keeps the clockspring in the proper

orientation.

(2) Inside the passenger compartment, remove the

steering column coupling retainer pin, back off the

pinch bolt nut, and remove the steering column cou-

pling pinch bolt (Fig. 22) (the pinch bolt nut is caged

to the coupling and is not removable). Separate the

upper and lower steering column couplings.

(3) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.(4) Release the locking tab on the wiring harness

connector for the power steering fluid pressure

switch before connector removal. Remove the wiring

harness connector from the power steering fluid pres-

sure switch (Fig. 23).

(5) Remove the bolt mounting the engine torque

strut to the right forward corner of the front suspen-

sion crossmember (Fig. 24).

Fig. 21 Steering Wheel Holder

1 ± STEERING WHEEL

2 ± STEERING WHEEL HOLDER

3 ± DRIVERS SEAT

Fig. 22 Steering Column Couplings

1 ± STEERING COLUMN UPPER COUPLING

2 ± PINCH BOLT

3 ± STEERING COLUMN LOWER COUPLING

4 ± BRAKE PEDAL

5 ± NUT

6 ± RETAINER PIN

Fig. 23 Power Steering Fluid Pressure Switch

1 ± WIRING HARNESS CONNECTOR

2 ± POWER STEERING GEAR

3 ± POWER STEERING FLUID PRESSURE SWITCH

4 ± REAR OF FRONT SUSPENSION CROSSMEMBER

19 - 38 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 910 of 1285

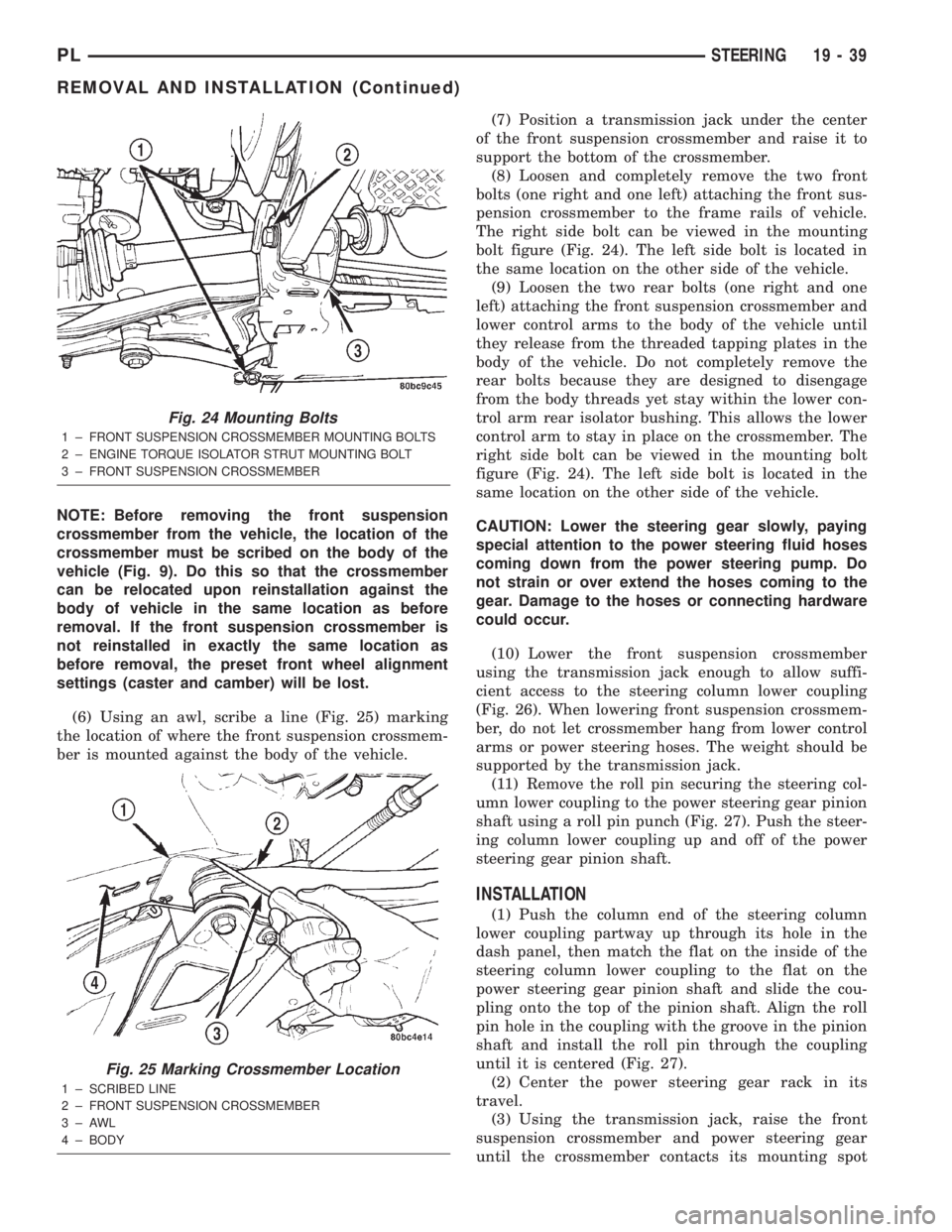

NOTE: Before removing the front suspension

crossmember from the vehicle, the location of the

crossmember must be scribed on the body of the

vehicle (Fig. 9). Do this so that the crossmember

can be relocated upon reinstallation against the

body of vehicle in the same location as before

removal. If the front suspension crossmember is

not reinstalled in exactly the same location as

before removal, the preset front wheel alignment

settings (caster and camber) will be lost.

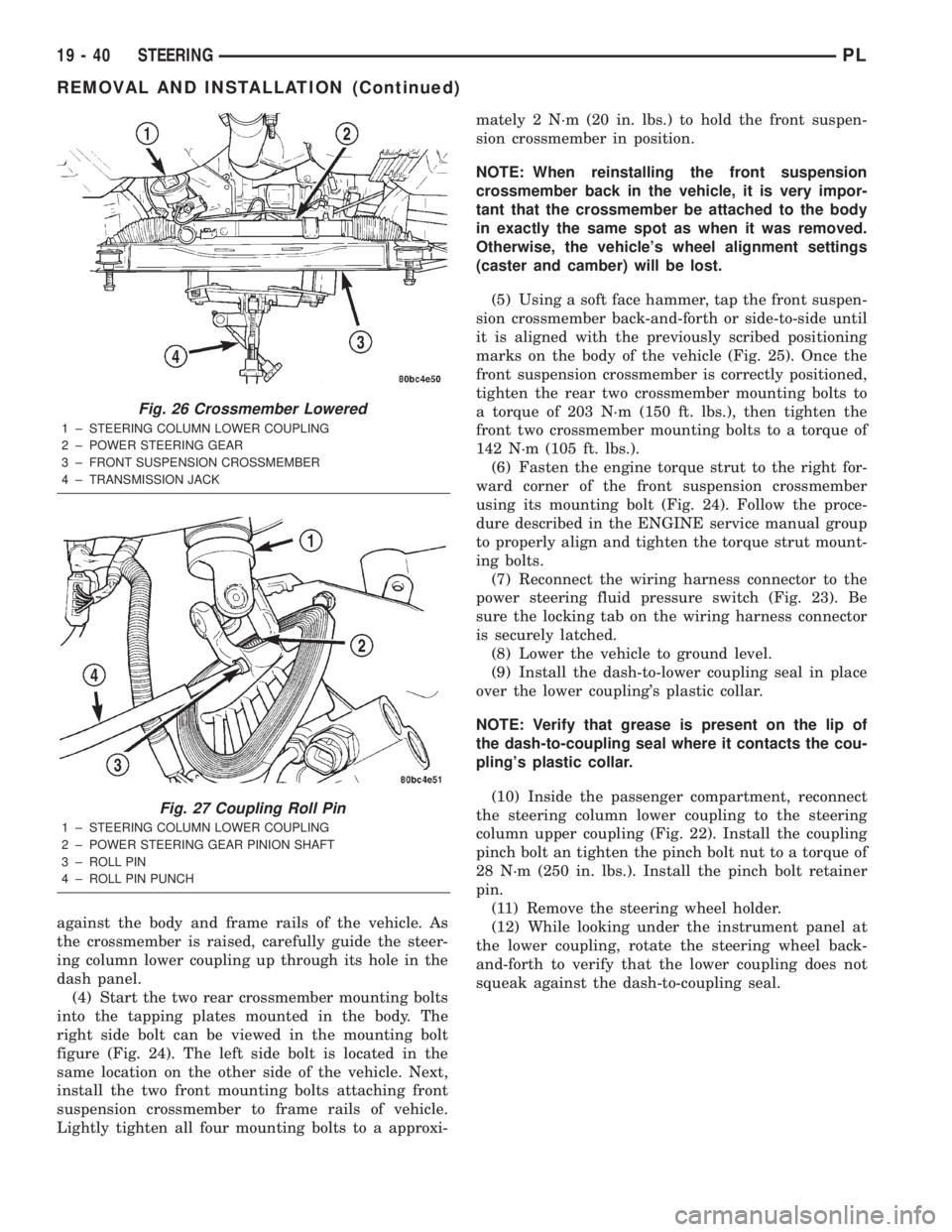

(6) Using an awl, scribe a line (Fig. 25) marking

the location of where the front suspension crossmem-

ber is mounted against the body of the vehicle.(7) Position a transmission jack under the center

of the front suspension crossmember and raise it to

support the bottom of the crossmember.

(8) Loosen and completely remove the two front

bolts (one right and one left) attaching the front sus-

pension crossmember to the frame rails of vehicle.

The right side bolt can be viewed in the mounting

bolt figure (Fig. 24). The left side bolt is located in

the same location on the other side of the vehicle.

(9) Loosen the two rear bolts (one right and one

left) attaching the front suspension crossmember and

lower control arms to the body of the vehicle until

they release from the threaded tapping plates in the

body of the vehicle. Do not completely remove the

rear bolts because they are designed to disengage

from the body threads yet stay within the lower con-

trol arm rear isolator bushing. This allows the lower

control arm to stay in place on the crossmember. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 24). The left side bolt is located in the

same location on the other side of the vehicle.

CAUTION: Lower the steering gear slowly, paying

special attention to the power steering fluid hoses

coming down from the power steering pump. Do

not strain or over extend the hoses coming to the

gear. Damage to the hoses or connecting hardware

could occur.

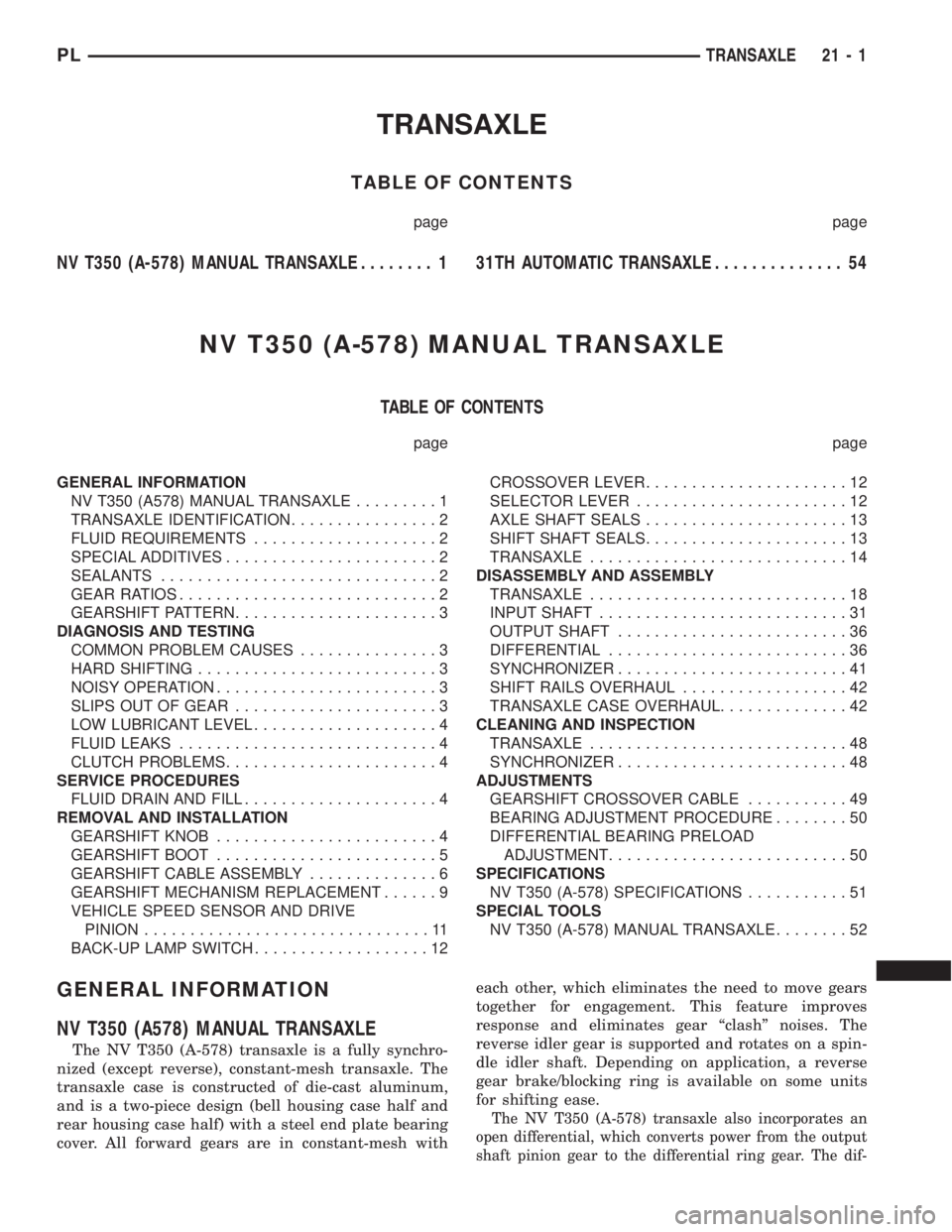

(10) Lower the front suspension crossmember

using the transmission jack enough to allow suffi-

cient access to the steering column lower coupling

(Fig. 26). When lowering front suspension crossmem-

ber, do not let crossmember hang from lower control

arms or power steering hoses. The weight should be

supported by the transmission jack.

(11) Remove the roll pin securing the steering col-

umn lower coupling to the power steering gear pinion

shaft using a roll pin punch (Fig. 27). Push the steer-

ing column lower coupling up and off of the power

steering gear pinion shaft.

INSTALLATION

(1) Push the column end of the steering column

lower coupling partway up through its hole in the

dash panel, then match the flat on the inside of the

steering column lower coupling to the flat on the

power steering gear pinion shaft and slide the cou-

pling onto the top of the pinion shaft. Align the roll

pin hole in the coupling with the groove in the pinion

shaft and install the roll pin through the coupling

until it is centered (Fig. 27).

(2) Center the power steering gear rack in its

travel.

(3) Using the transmission jack, raise the front

suspension crossmember and power steering gear

until the crossmember contacts its mounting spot

Fig. 24 Mounting Bolts

1 ± FRONT SUSPENSION CROSSMEMBER MOUNTING BOLTS

2 ± ENGINE TORQUE ISOLATOR STRUT MOUNTING BOLT

3 ± FRONT SUSPENSION CROSSMEMBER

Fig. 25 Marking Crossmember Location

1 ± SCRIBED LINE

2 ± FRONT SUSPENSION CROSSMEMBER

3±AWL

4 ± BODY

PLSTEERING 19 - 39

REMOVAL AND INSTALLATION (Continued)

Page 911 of 1285

against the body and frame rails of the vehicle. As

the crossmember is raised, carefully guide the steer-

ing column lower coupling up through its hole in the

dash panel.

(4) Start the two rear crossmember mounting bolts

into the tapping plates mounted in the body. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 24). The left side bolt is located in the

same location on the other side of the vehicle. Next,

install the two front mounting bolts attaching front

suspension crossmember to frame rails of vehicle.

Lightly tighten all four mounting bolts to a approxi-mately 2 N´m (20 in. lbs.) to hold the front suspen-

sion crossmember in position.

NOTE: When reinstalling the front suspension

crossmember back in the vehicle, it is very impor-

tant that the crossmember be attached to the body

in exactly the same spot as when it was removed.

Otherwise, the vehicle's wheel alignment settings

(caster and camber) will be lost.

(5) Using a soft face hammer, tap the front suspen-

sion crossmember back-and-forth or side-to-side until

it is aligned with the previously scribed positioning

marks on the body of the vehicle (Fig. 25). Once the

front suspension crossmember is correctly positioned,

tighten the rear two crossmember mounting bolts to

a torque of 203 N´m (150 ft. lbs.), then tighten the

front two crossmember mounting bolts to a torque of

142 N´m (105 ft. lbs.).

(6) Fasten the engine torque strut to the right for-

ward corner of the front suspension crossmember

using its mounting bolt (Fig. 24). Follow the proce-

dure described in the ENGINE service manual group

to properly align and tighten the torque strut mount-

ing bolts.

(7) Reconnect the wiring harness connector to the

power steering fluid pressure switch (Fig. 23). Be

sure the locking tab on the wiring harness connector

is securely latched.

(8) Lower the vehicle to ground level.

(9) Install the dash-to-lower coupling seal in place

over the lower coupling's plastic collar.

NOTE: Verify that grease is present on the lip of

the dash-to-coupling seal where it contacts the cou-

pling's plastic collar.

(10) Inside the passenger compartment, reconnect

the steering column lower coupling to the steering

column upper coupling (Fig. 22). Install the coupling

pinch bolt an tighten the pinch bolt nut to a torque of

28 N´m (250 in. lbs.). Install the pinch bolt retainer

pin.

(11) Remove the steering wheel holder.

(12) While looking under the instrument panel at

the lower coupling, rotate the steering wheel back-

and-forth to verify that the lower coupling does not

squeak against the dash-to-coupling seal.

Fig. 26 Crossmember Lowered

1 ± STEERING COLUMN LOWER COUPLING

2 ± POWER STEERING GEAR

3 ± FRONT SUSPENSION CROSSMEMBER

4 ± TRANSMISSION JACK

Fig. 27 Coupling Roll Pin

1 ± STEERING COLUMN LOWER COUPLING

2 ± POWER STEERING GEAR PINION SHAFT

3 ± ROLL PIN

4 ± ROLL PIN PUNCH

19 - 40 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 914 of 1285

TRANSAXLE

TABLE OF CONTENTS

page page

NV T350 (A-578) MANUAL TRANSAXLE........ 131TH AUTOMATIC TRANSAXLE.............. 54

NV T350 (A-578) MANUAL TRANSAXLE

TABLE OF CONTENTS

page page

GENERAL INFORMATION

NV T350 (A578) MANUAL TRANSAXLE.........1

TRANSAXLE IDENTIFICATION................2

FLUID REQUIREMENTS....................2

SPECIAL ADDITIVES.......................2

SEALANTS..............................2

GEAR RATIOS............................2

GEARSHIFT PATTERN......................3

DIAGNOSIS AND TESTING

COMMON PROBLEM CAUSES...............3

HARD SHIFTING..........................3

NOISY OPERATION........................3

SLIPS OUT OF GEAR......................3

LOW LUBRICANT LEVEL....................4

FLUID LEAKS............................4

CLUTCH PROBLEMS.......................4

SERVICE PROCEDURES

FLUID DRAIN AND FILL.....................4

REMOVAL AND INSTALLATION

GEARSHIFT KNOB........................4

GEARSHIFT BOOT........................5

GEARSHIFT CABLE ASSEMBLY..............6

GEARSHIFT MECHANISM REPLACEMENT......9

VEHICLE SPEED SENSOR AND DRIVE

PINION...............................11

BACK-UP LAMP SWITCH...................12CROSSOVER LEVER......................12

SELECTOR LEVER.......................12

AXLE SHAFT SEALS......................13

SHIFT SHAFT SEALS......................13

TRANSAXLE............................14

DISASSEMBLY AND ASSEMBLY

TRANSAXLE............................18

INPUT SHAFT...........................31

OUTPUT SHAFT.........................36

DIFFERENTIAL..........................36

SYNCHRONIZER.........................41

SHIFT RAILS OVERHAUL..................42

TRANSAXLE CASE OVERHAUL..............42

CLEANING AND INSPECTION

TRANSAXLE............................48

SYNCHRONIZER.........................48

ADJUSTMENTS

GEARSHIFT CROSSOVER CABLE...........49

BEARING ADJUSTMENT PROCEDURE........50

DIFFERENTIAL BEARING PRELOAD

ADJUSTMENT..........................50

SPECIFICATIONS

NV T350 (A-578) SPECIFICATIONS...........51

SPECIAL TOOLS

NV T350 (A-578) MANUAL TRANSAXLE........52

GENERAL INFORMATION

NV T350 (A578) MANUAL TRANSAXLE

The NV T350 (A-578) transaxle is a fully synchro-

nized (except reverse), constant-mesh transaxle. The

transaxle case is constructed of die-cast aluminum,

and is a two-piece design (bell housing case half and

rear housing case half) with a steel end plate bearing

cover. All forward gears are in constant-mesh witheach other, which eliminates the need to move gears

together for engagement. This feature improves

response and eliminates gear ªclashº noises. The

reverse idler gear is supported and rotates on a spin-

dle idler shaft. Depending on application, a reverse

gear brake/blocking ring is available on some units

for shifting ease.

The NV T350 (A-578) transaxle also incorporates an

open differential, which converts power from the output

shaft pinion gear to the differential ring gear. The dif-

PLTRANSAXLE 21 - 1

Page 915 of 1285

ferential case transfers torque from the ring gear to the

drive axles by means of differential side gears.

The NV T350 (A-578) transaxle internal components

can only be serviced by separating the case halves.

CAUTION: The transaxle output shaft is serviced as

a unit. No disassembly and reassembly is possible.

Damage to the transaxle may result.

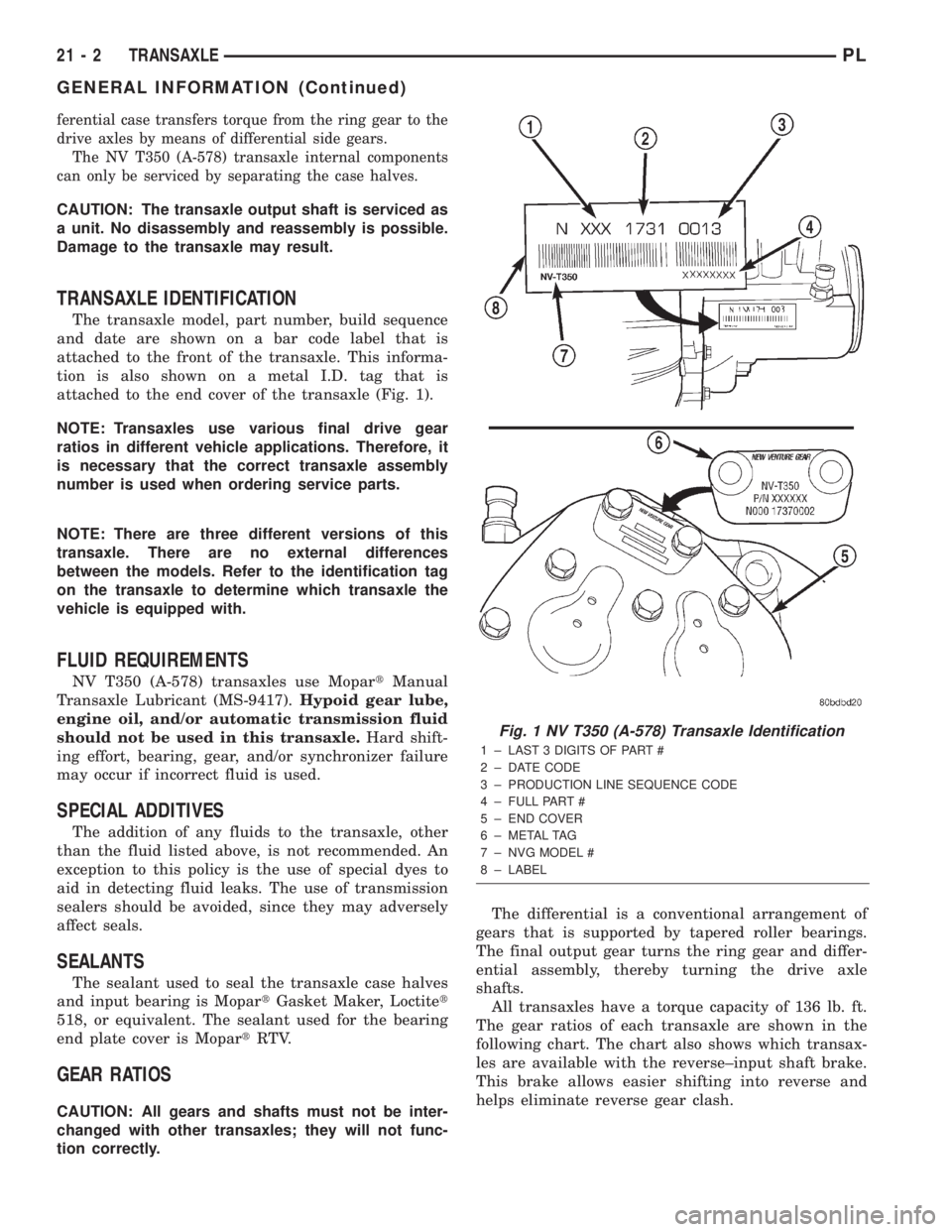

TRANSAXLE IDENTIFICATION

The transaxle model, part number, build sequence

and date are shown on a bar code label that is

attached to the front of the transaxle. This informa-

tion is also shown on a metal I.D. tag that is

attached to the end cover of the transaxle (Fig. 1).

NOTE: Transaxles use various final drive gear

ratios in different vehicle applications. Therefore, it

is necessary that the correct transaxle assembly

number is used when ordering service parts.

NOTE: There are three different versions of this

transaxle. There are no external differences

between the models. Refer to the identification tag

on the transaxle to determine which transaxle the

vehicle is equipped with.

FLUID REQUIREMENTS

NV T350 (A-578) transaxles use MopartManual

Transaxle Lubricant (MS-9417).Hypoid gear lube,

engine oil, and/or automatic transmission fluid

should not be used in this transaxle.Hard shift-

ing effort, bearing, gear, and/or synchronizer failure

may occur if incorrect fluid is used.

SPECIAL ADDITIVES

The addition of any fluids to the transaxle, other

than the fluid listed above, is not recommended. An

exception to this policy is the use of special dyes to

aid in detecting fluid leaks. The use of transmission

sealers should be avoided, since they may adversely

affect seals.

SEALANTS

The sealant used to seal the transaxle case halves

and input bearing is MopartGasket Maker, Loctitet

518, or equivalent. The sealant used for the bearing

end plate cover is MopartRTV.

GEAR RATIOS

CAUTION: All gears and shafts must not be inter-

changed with other transaxles; they will not func-

tion correctly.The differential is a conventional arrangement of

gears that is supported by tapered roller bearings.

The final output gear turns the ring gear and differ-

ential assembly, thereby turning the drive axle

shafts.

All transaxles have a torque capacity of 136 lb. ft.

The gear ratios of each transaxle are shown in the

following chart. The chart also shows which transax-

les are available with the reverse±input shaft brake.

This brake allows easier shifting into reverse and

helps eliminate reverse gear clash.

Fig. 1 NV T350 (A-578) Transaxle Identification

1 ± LAST 3 DIGITS OF PART #

2 ± DATE CODE

3 ± PRODUCTION LINE SEQUENCE CODE

4 ± FULL PART #

5 ± END COVER

6 ± METAL TAG

7 ± NVG MODEL #

8 ± LABEL

21 - 2 TRANSAXLEPL

GENERAL INFORMATION (Continued)

Page 916 of 1285

ENGINE 2.0 SOHC EUROPE AND

U. S.1.8 BUX or 2.0L SALES

CODE ACR1.8 RIGHT HAND DRIVE

ONLY

GEAR

1st 3.54 3.54 3.54

2nd 2.13 2.13 2.13

3rd 1.36 1.36 1.36

4th 1.03 1.03 1.03

5th 0.72 0.81 0.81

FINAL DRIVE 3.55 3.94 3.94

REVERSE BRAKE NO YES YES

CLUTCH RELEASE

SYSTEMCABLE CABLE HYDRAULIC

GEARSHIFT PATTERN

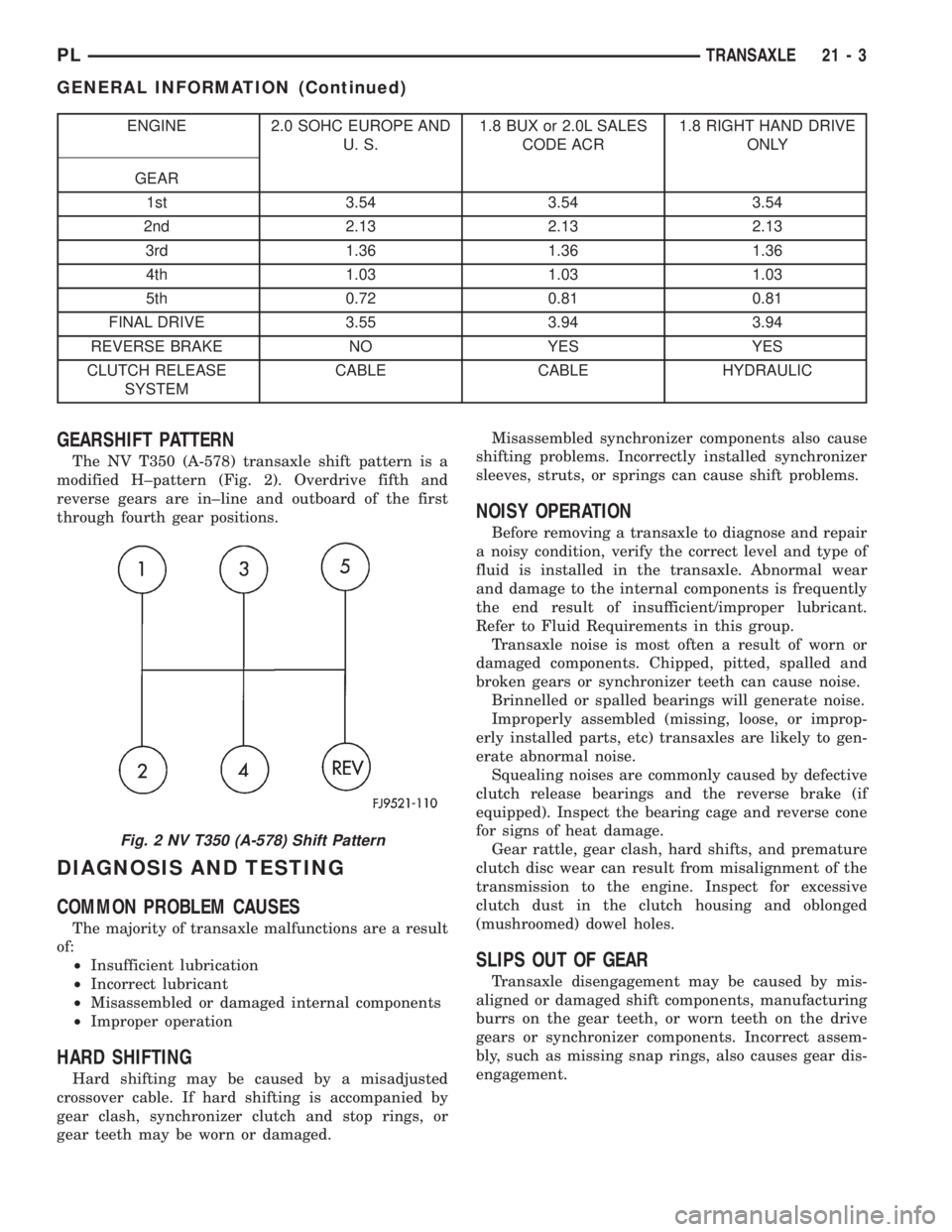

The NV T350 (A-578) transaxle shift pattern is a

modified H±pattern (Fig. 2). Overdrive fifth and

reverse gears are in±line and outboard of the first

through fourth gear positions.

DIAGNOSIS AND TESTING

COMMON PROBLEM CAUSES

The majority of transaxle malfunctions are a result

of:

²Insufficient lubrication

²Incorrect lubricant

²Misassembled or damaged internal components

²Improper operation

HARD SHIFTING

Hard shifting may be caused by a misadjusted

crossover cable. If hard shifting is accompanied by

gear clash, synchronizer clutch and stop rings, or

gear teeth may be worn or damaged.Misassembled synchronizer components also cause

shifting problems. Incorrectly installed synchronizer

sleeves, struts, or springs can cause shift problems.

NOISY OPERATION

Before removing a transaxle to diagnose and repair

a noisy condition, verify the correct level and type of

fluid is installed in the transaxle. Abnormal wear

and damage to the internal components is frequently

the end result of insufficient/improper lubricant.

Refer to Fluid Requirements in this group.

Transaxle noise is most often a result of worn or

damaged components. Chipped, pitted, spalled and

broken gears or synchronizer teeth can cause noise.

Brinnelled or spalled bearings will generate noise.

Improperly assembled (missing, loose, or improp-

erly installed parts, etc) transaxles are likely to gen-

erate abnormal noise.

Squealing noises are commonly caused by defective

clutch release bearings and the reverse brake (if

equipped). Inspect the bearing cage and reverse cone

for signs of heat damage.

Gear rattle, gear clash, hard shifts, and premature

clutch disc wear can result from misalignment of the

transmission to the engine. Inspect for excessive

clutch dust in the clutch housing and oblonged

(mushroomed) dowel holes.

SLIPS OUT OF GEAR

Transaxle disengagement may be caused by mis-

aligned or damaged shift components, manufacturing

burrs on the gear teeth, or worn teeth on the drive

gears or synchronizer components. Incorrect assem-

bly, such as missing snap rings, also causes gear dis-

engagement.

Fig. 2 NV T350 (A-578) Shift Pattern

PLTRANSAXLE 21 - 3

GENERAL INFORMATION (Continued)

Page 917 of 1285

LOW LUBRICANT LEVEL

Insufficient transaxle lubricant is usually the

result of leaks, or inaccurate fluid level check or refill

method. Leakage is evident by the presence of oil

around the leak point. If leakage is not evident, the

condition is probably the result of an underfill.

If air±powered lubrication equipment is used to fill

a transaxle, be sure the equipment is properly cali-

brated. Equipment out of calibration can lead to an

underfill condition.

FLUID LEAKS

Fluid leaks can occur around the input shaft seal,

axleshaft seals, case split lines, and the end cover. Be

careful not to misdiagnose an input shaft seal leak

for an engine rear main seal leak. Also, the transaxle

case sealer (split line) will accumulate dirt and look

like an oil leak.

CLUTCH PROBLEMS

Worn, damaged, or misaligned clutch components

can cause difficult shifting, gear clash, and noise.

A worn or damaged clutch disc, pressure plate, or

release bearing can cause hard shifting and gear

clash.

SERVICE PROCEDURES

FLUID DRAIN AND FILL

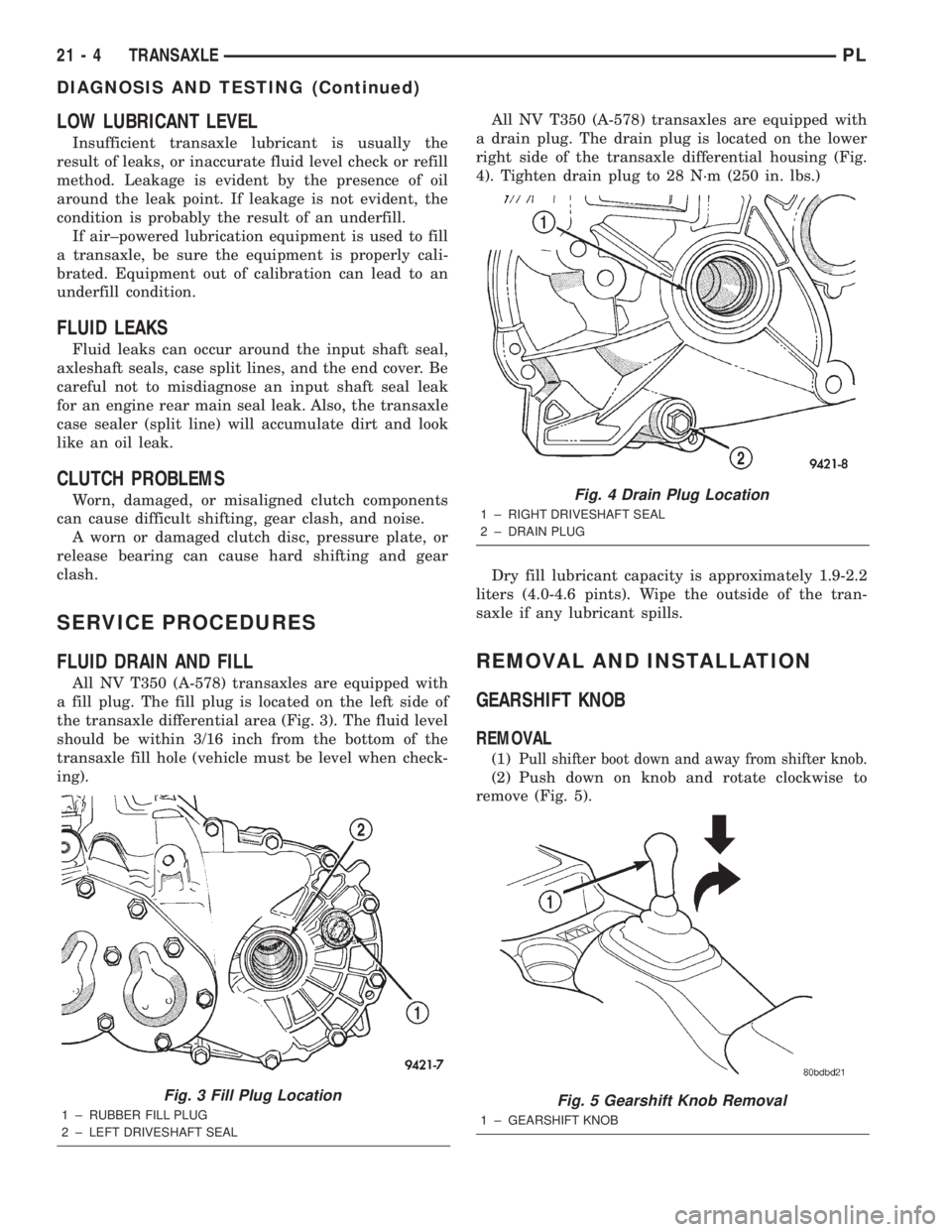

All NV T350 (A-578) transaxles are equipped with

a fill plug. The fill plug is located on the left side of

the transaxle differential area (Fig. 3). The fluid level

should be within 3/16 inch from the bottom of the

transaxle fill hole (vehicle must be level when check-

ing).All NV T350 (A-578) transaxles are equipped with

a drain plug. The drain plug is located on the lower

right side of the transaxle differential housing (Fig.

4). Tighten drain plug to 28 N´m (250 in. lbs.)

Dry fill lubricant capacity is approximately 1.9-2.2

liters (4.0-4.6 pints). Wipe the outside of the tran-

saxle if any lubricant spills.

REMOVAL AND INSTALLATION

GEARSHIFT KNOB

REMOVAL

(1)Pull shifter boot down and away from shifter knob.

(2) Push down on knob and rotate clockwise to

remove (Fig. 5).

Fig. 3 Fill Plug Location

1 ± RUBBER FILL PLUG

2 ± LEFT DRIVESHAFT SEAL

Fig. 4 Drain Plug Location

1 ± RIGHT DRIVESHAFT SEAL

2 ± DRAIN PLUG

Fig. 5 Gearshift Knob Removal

1 ± GEARSHIFT KNOB

21 - 4 TRANSAXLEPL

DIAGNOSIS AND TESTING (Continued)