lock DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1004 of 1285

ASSEMBLY

When rebuilding, reverse the above procedure.

VALVE BODY

NOTE: Tighten all valve body screws to 5 N´m (40

in. lbs.)CAUTION: Do not clamp any portion of valve body

or transfer plate in a vise. Any slight distortion of

the aluminum body or transfer plate will result in

sticking valves, excessive leakage, or both. When

removing or installing valves or plugs, slide them in

or out carefully. Do not use force.

NOTE: TAG ALL SPRINGS AS THEY ARE

REMOVED FOR REASSEMBLY IDENTIFICATION.

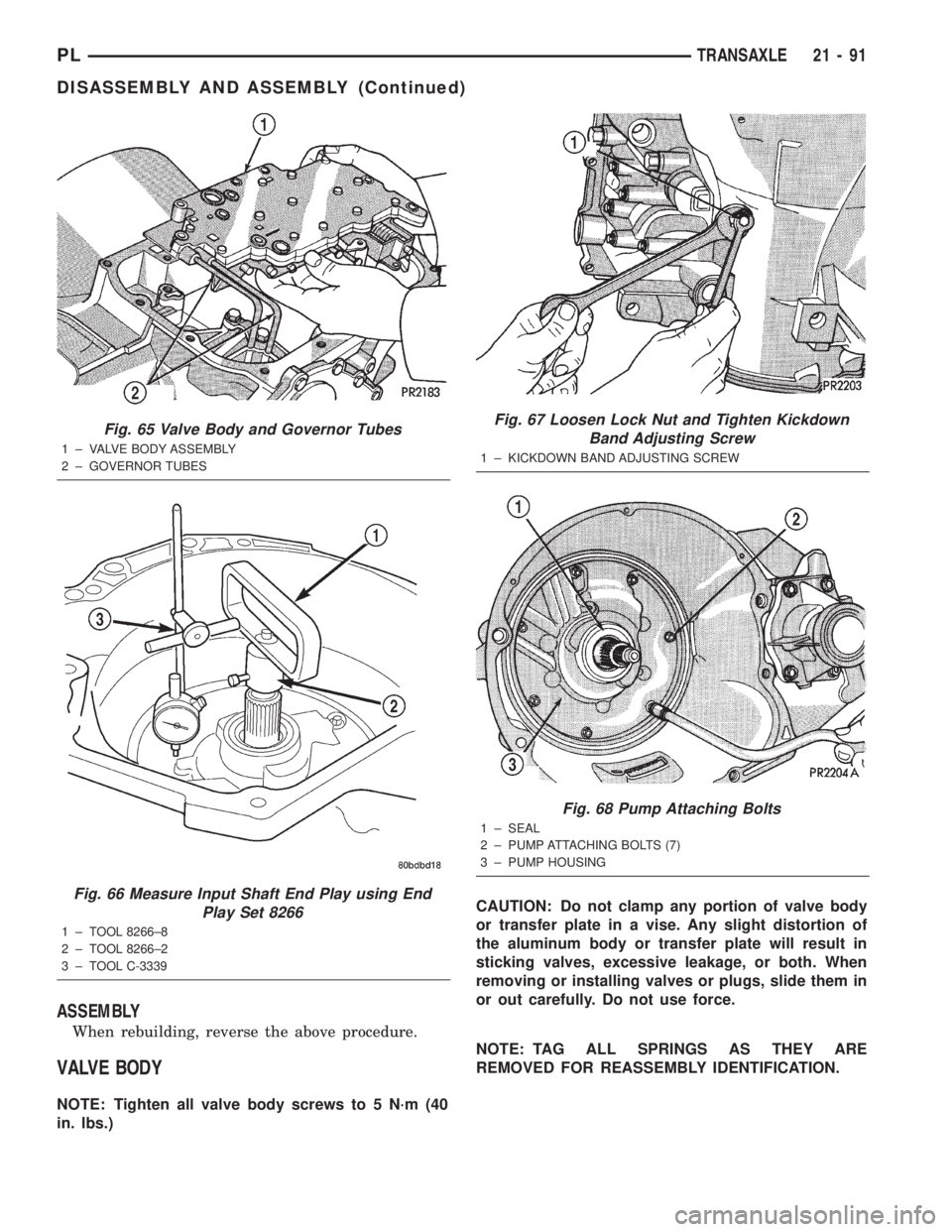

Fig. 65 Valve Body and Governor Tubes

1 ± VALVE BODY ASSEMBLY

2 ± GOVERNOR TUBES

Fig. 66 Measure Input Shaft End Play using End

Play Set 8266

1 ± TOOL 8266±8

2 ± TOOL 8266±2

3 ± TOOL C-3339

Fig. 67 Loosen Lock Nut and Tighten Kickdown

Band Adjusting Screw

1 ± KICKDOWN BAND ADJUSTING SCREW

Fig. 68 Pump Attaching Bolts

1 ± SEAL

2 ± PUMP ATTACHING BOLTS (7)

3 ± PUMP HOUSING

PLTRANSAXLE 21 - 91

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1009 of 1285

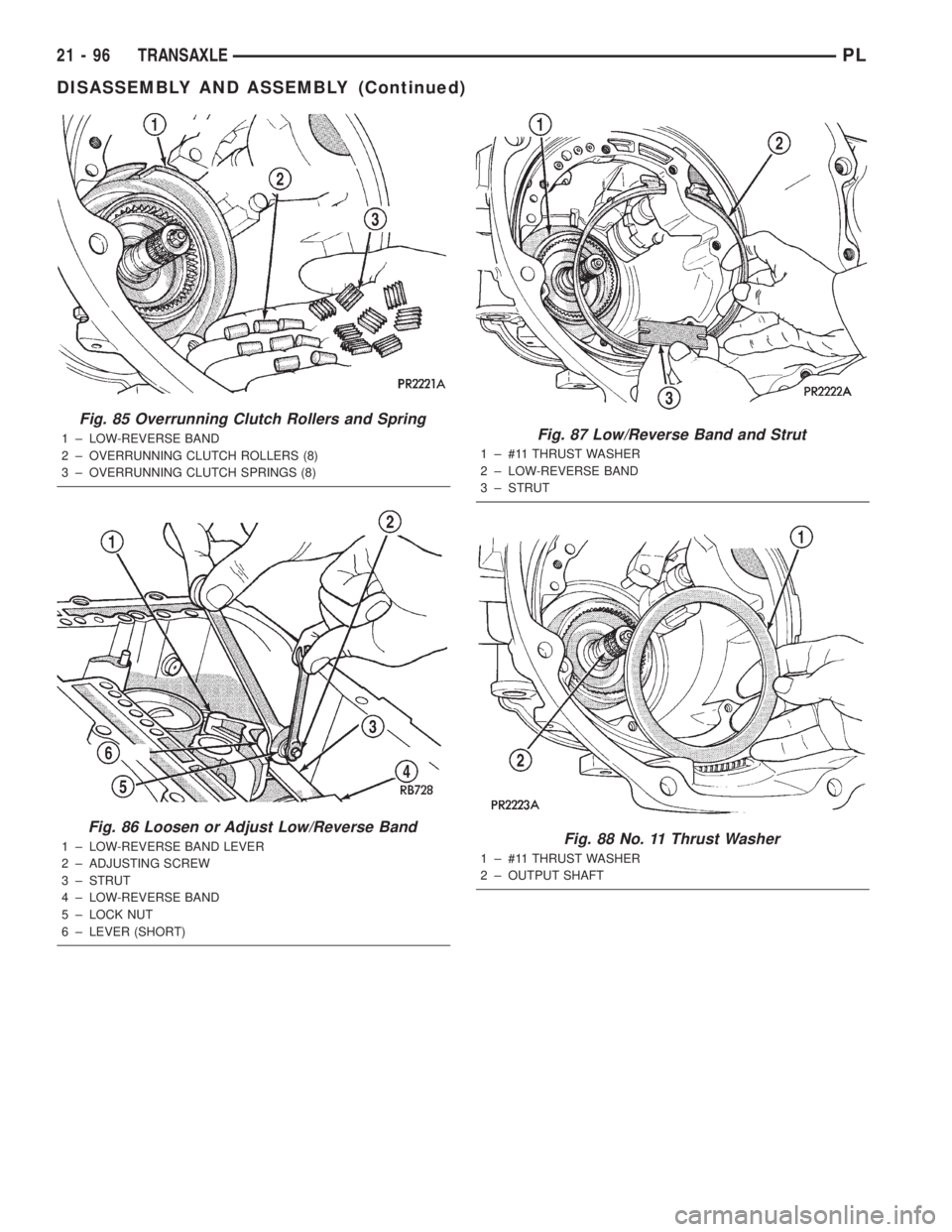

Fig. 85 Overrunning Clutch Rollers and Spring

1 ± LOW-REVERSE BAND

2 ± OVERRUNNING CLUTCH ROLLERS (8)

3 ± OVERRUNNING CLUTCH SPRINGS (8)

Fig. 86 Loosen or Adjust Low/Reverse Band

1 ± LOW-REVERSE BAND LEVER

2 ± ADJUSTING SCREW

3 ± STRUT

4 ± LOW-REVERSE BAND

5 ± LOCK NUT

6 ± LEVER (SHORT)

Fig. 87 Low/Reverse Band and Strut

1 ± #11 THRUST WASHER

2 ± LOW-REVERSE BAND

3 ± STRUT

Fig. 88 No. 11 Thrust Washer

1 ± #11 THRUST WASHER

2 ± OUTPUT SHAFT

21 - 96 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1033 of 1285

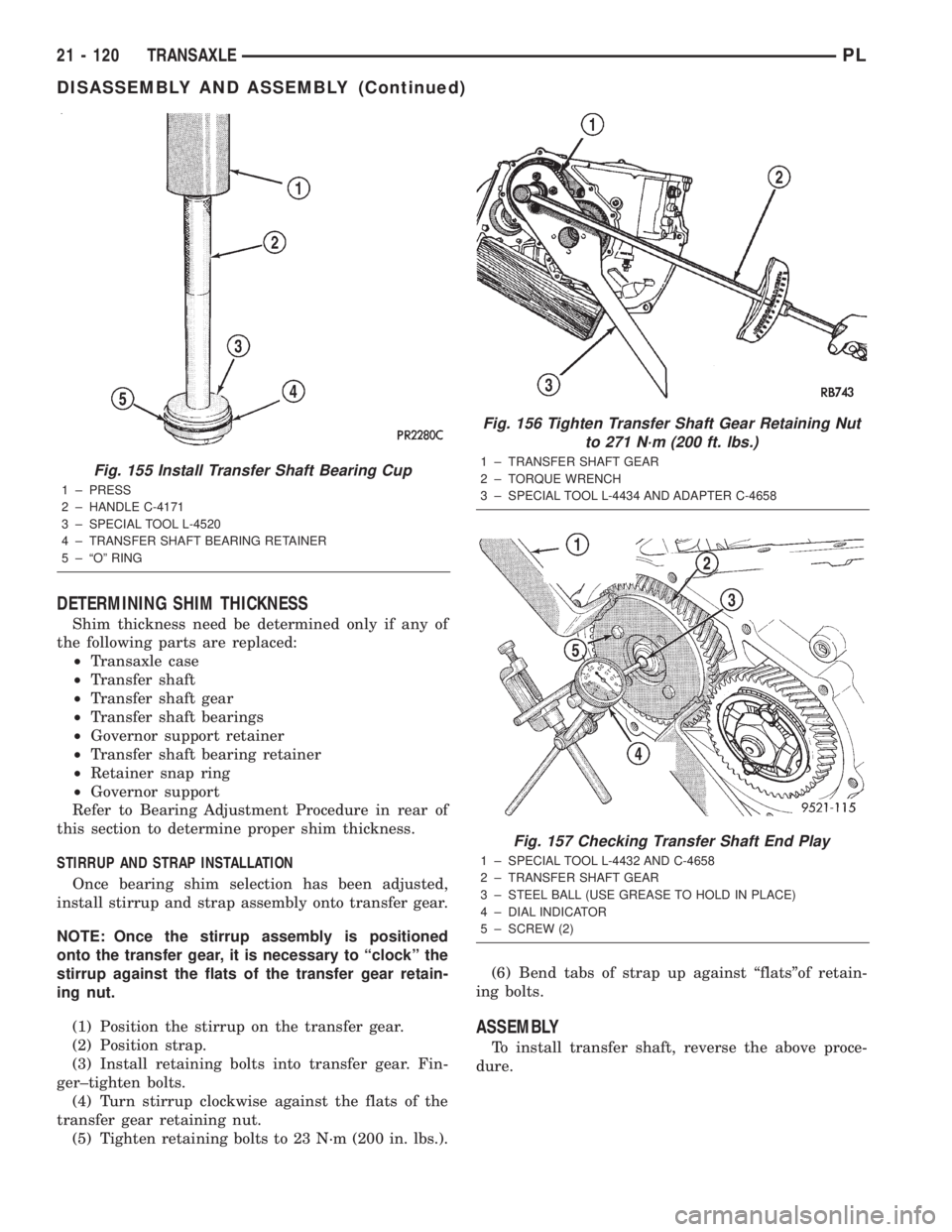

DETERMINING SHIM THICKNESS

Shim thickness need be determined only if any of

the following parts are replaced:

²Transaxle case

²Transfer shaft

²Transfer shaft gear

²Transfer shaft bearings

²Governor support retainer

²Transfer shaft bearing retainer

²Retainer snap ring

²Governor support

Refer to Bearing Adjustment Procedure in rear of

this section to determine proper shim thickness.

STIRRUP AND STRAP INSTALLATION

Once bearing shim selection has been adjusted,

install stirrup and strap assembly onto transfer gear.

NOTE: Once the stirrup assembly is positioned

onto the transfer gear, it is necessary to ªclockº the

stirrup against the flats of the transfer gear retain-

ing nut.

(1) Position the stirrup on the transfer gear.

(2) Position strap.

(3) Install retaining bolts into transfer gear. Fin-

ger±tighten bolts.

(4) Turn stirrup clockwise against the flats of the

transfer gear retaining nut.

(5) Tighten retaining bolts to 23 N´m (200 in. lbs.).(6) Bend tabs of strap up against ªflatsºof retain-

ing bolts.

ASSEMBLY

To install transfer shaft, reverse the above proce-

dure.

Fig. 155 Install Transfer Shaft Bearing Cup

1 ± PRESS

2 ± HANDLE C-4171

3 ± SPECIAL TOOL L-4520

4 ± TRANSFER SHAFT BEARING RETAINER

5 ± ªOº RING

Fig. 156 Tighten Transfer Shaft Gear Retaining Nut

to 271 N´m (200 ft. lbs.)

1 ± TRANSFER SHAFT GEAR

2 ± TORQUE WRENCH

3 ± SPECIAL TOOL L-4434 AND ADAPTER C-4658

Fig. 157 Checking Transfer Shaft End Play

1 ± SPECIAL TOOL L-4432 AND C-4658

2 ± TRANSFER SHAFT GEAR

3 ± STEEL BALL (USE GREASE TO HOLD IN PLACE)

4 ± DIAL INDICATOR

5 ± SCREW (2)

21 - 120 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1041 of 1285

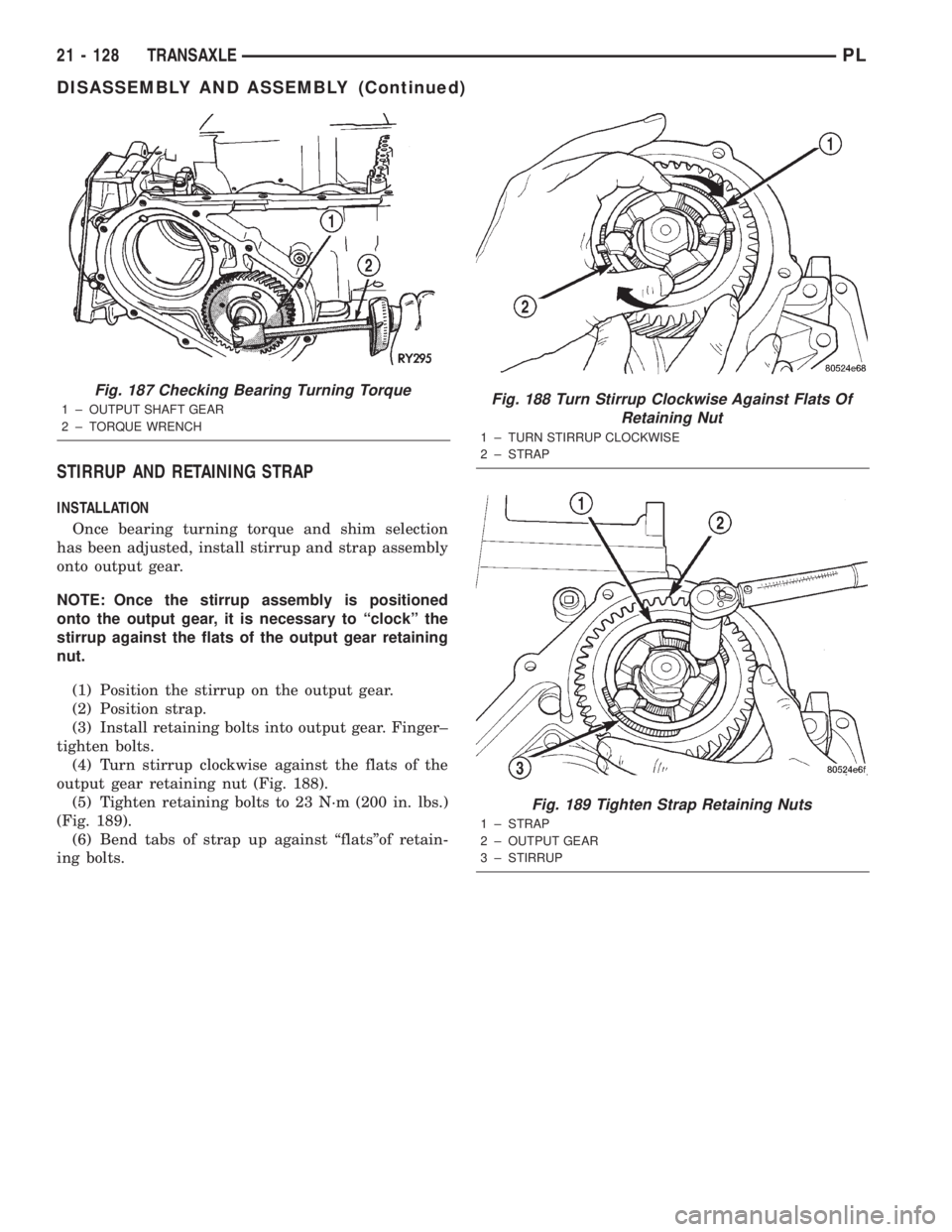

STIRRUP AND RETAINING STRAP

INSTALLATION

Once bearing turning torque and shim selection

has been adjusted, install stirrup and strap assembly

onto output gear.

NOTE: Once the stirrup assembly is positioned

onto the output gear, it is necessary to ªclockº the

stirrup against the flats of the output gear retaining

nut.

(1) Position the stirrup on the output gear.

(2) Position strap.

(3) Install retaining bolts into output gear. Finger±

tighten bolts.

(4) Turn stirrup clockwise against the flats of the

output gear retaining nut (Fig. 188).

(5) Tighten retaining bolts to 23 N´m (200 in. lbs.)

(Fig. 189).

(6) Bend tabs of strap up against ªflatsºof retain-

ing bolts.

Fig. 187 Checking Bearing Turning Torque

1 ± OUTPUT SHAFT GEAR

2 ± TORQUE WRENCHFig. 188 Turn Stirrup Clockwise Against Flats Of

Retaining Nut

1 ± TURN STIRRUP CLOCKWISE

2 ± STRAP

Fig. 189 Tighten Strap Retaining Nuts

1 ± STRAP

2 ± OUTPUT GEAR

3 ± STIRRUP

21 - 128 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1049 of 1285

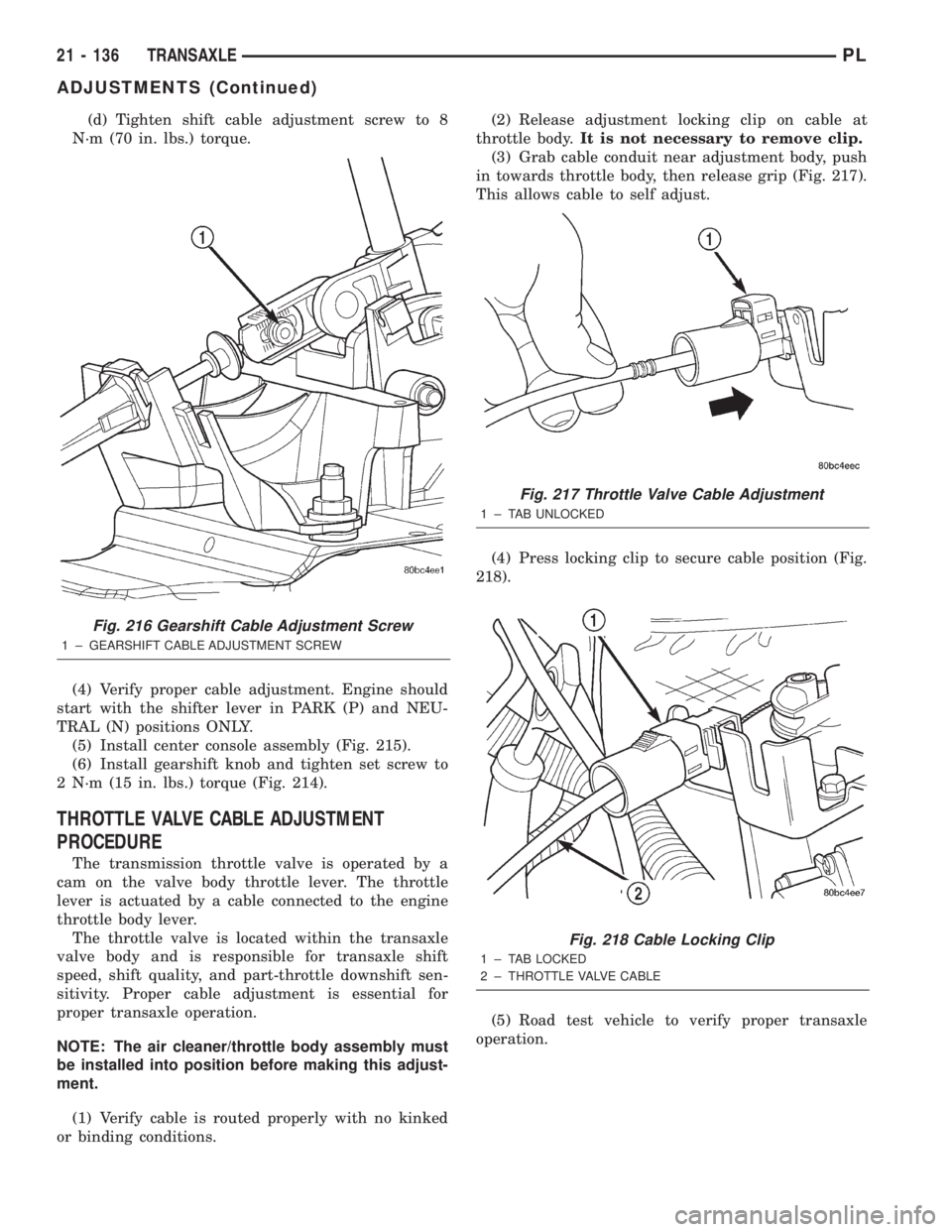

(d) Tighten shift cable adjustment screw to 8

N´m (70 in. lbs.) torque.

(4) Verify proper cable adjustment. Engine should

start with the shifter lever in PARK (P) and NEU-

TRAL (N) positions ONLY.

(5) Install center console assembly (Fig. 215).

(6) Install gearshift knob and tighten set screw to

2 N´m (15 in. lbs.) torque (Fig. 214).

THROTTLE VALVE CABLE ADJUSTMENT

PROCEDURE

The transmission throttle valve is operated by a

cam on the valve body throttle lever. The throttle

lever is actuated by a cable connected to the engine

throttle body lever.

The throttle valve is located within the transaxle

valve body and is responsible for transaxle shift

speed, shift quality, and part-throttle downshift sen-

sitivity. Proper cable adjustment is essential for

proper transaxle operation.

NOTE: The air cleaner/throttle body assembly must

be installed into position before making this adjust-

ment.

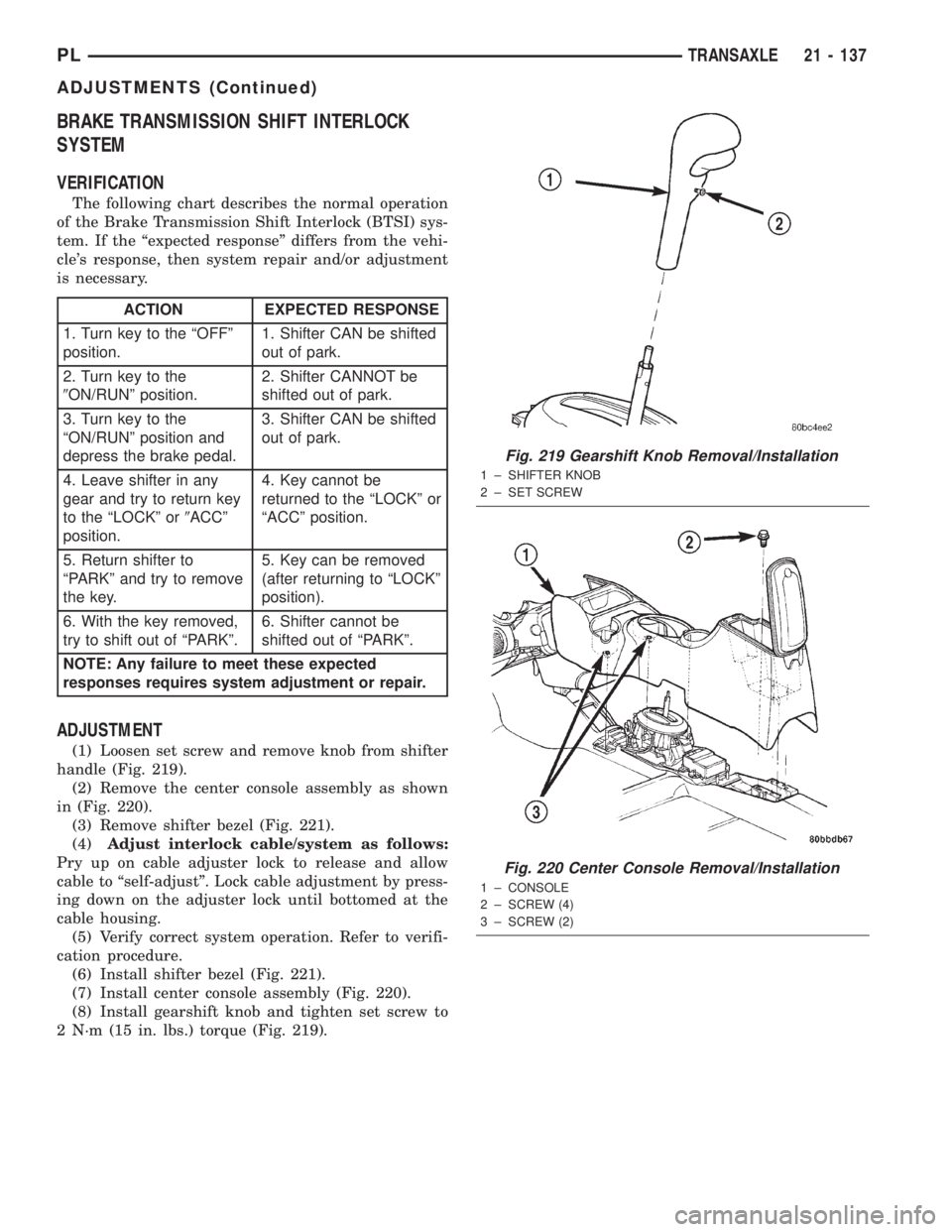

(1) Verify cable is routed properly with no kinked

or binding conditions.(2) Release adjustment locking clip on cable at

throttle body.It is not necessary to remove clip.

(3) Grab cable conduit near adjustment body, push

in towards throttle body, then release grip (Fig. 217).

This allows cable to self adjust.

(4) Press locking clip to secure cable position (Fig.

218).

(5) Road test vehicle to verify proper transaxle

operation.

Fig. 216 Gearshift Cable Adjustment Screw

1 ± GEARSHIFT CABLE ADJUSTMENT SCREW

Fig. 217 Throttle Valve Cable Adjustment

1 ± TAB UNLOCKED

Fig. 218 Cable Locking Clip

1 ± TAB LOCKED

2 ± THROTTLE VALVE CABLE

21 - 136 TRANSAXLEPL

ADJUSTMENTS (Continued)

Page 1050 of 1285

BRAKE TRANSMISSION SHIFT INTERLOCK

SYSTEM

VERIFICATION

The following chart describes the normal operation

of the Brake Transmission Shift Interlock (BTSI) sys-

tem. If the ªexpected responseº differs from the vehi-

cle's response, then system repair and/or adjustment

is necessary.

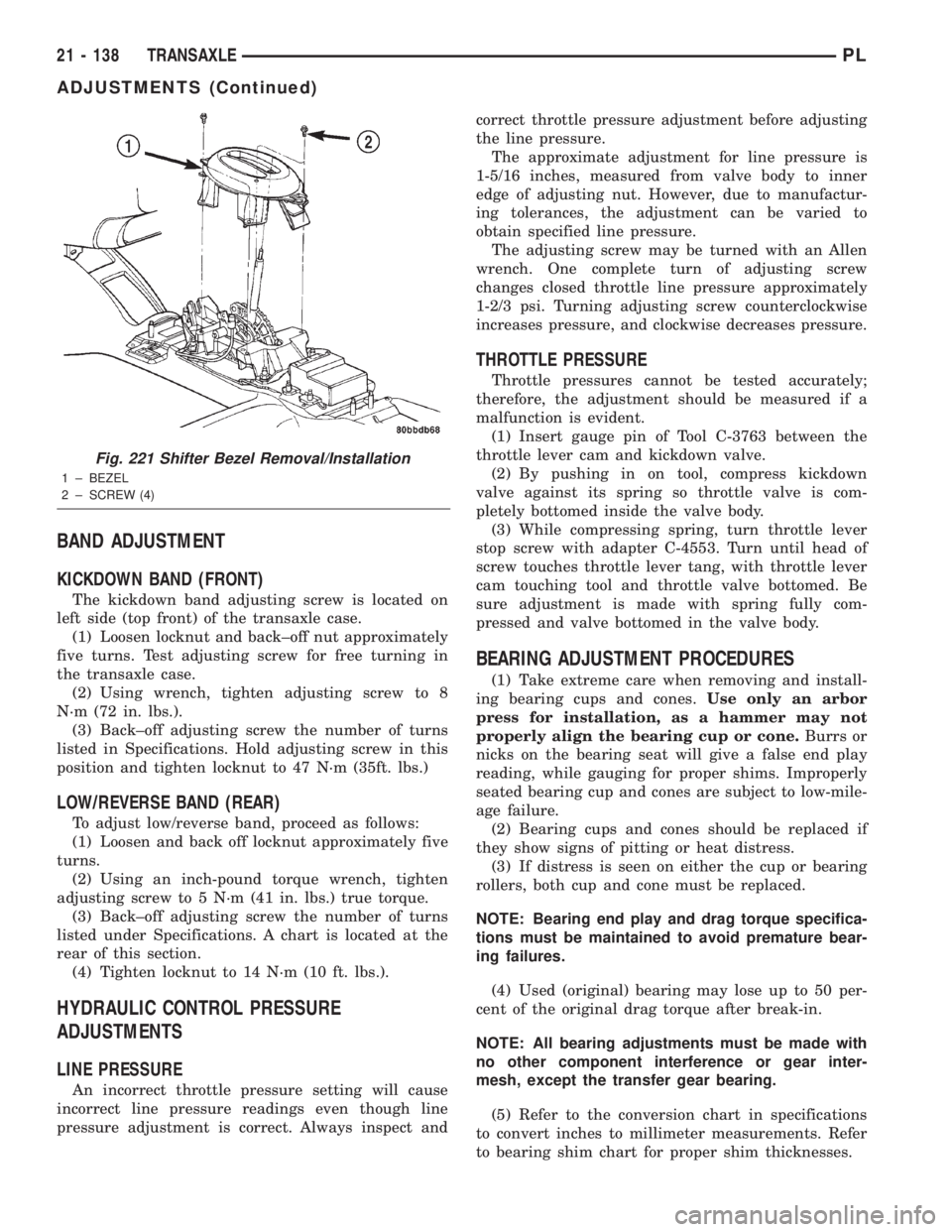

ADJUSTMENT

(1) Loosen set screw and remove knob from shifter

handle (Fig. 219).

(2) Remove the center console assembly as shown

in (Fig. 220).

(3) Remove shifter bezel (Fig. 221).

(4)Adjust interlock cable/system as follows:

Pry up on cable adjuster lock to release and allow

cable to ªself-adjustº. Lock cable adjustment by press-

ing down on the adjuster lock until bottomed at the

cable housing.

(5) Verify correct system operation. Refer to verifi-

cation procedure.

(6) Install shifter bezel (Fig. 221).

(7) Install center console assembly (Fig. 220).

(8) Install gearshift knob and tighten set screw to

2 N´m (15 in. lbs.) torque (Fig. 219).

ACTION EXPECTED RESPONSE

1. Turn key to the ªOFFº

position.1. Shifter CAN be shifted

out of park.

2. Turn key to the

9ON/RUNº position.2. Shifter CANNOT be

shifted out of park.

3. Turn key to the

ªON/RUNº position and

depress the brake pedal.3. Shifter CAN be shifted

out of park.

4. Leave shifter in any

gear and try to return key

to the ªLOCKº or9ACCº

position.4. Key cannot be

returned to the ªLOCKº or

ªACCº position.

5. Return shifter to

ªPARKº and try to remove

the key.5. Key can be removed

(after returning to ªLOCKº

position).

6. With the key removed,

try to shift out of ªPARKº.6. Shifter cannot be

shifted out of ªPARKº.

NOTE: Any failure to meet these expected

responses requires system adjustment or repair.

Fig. 219 Gearshift Knob Removal/Installation

1 ± SHIFTER KNOB

2 ± SET SCREW

Fig. 220 Center Console Removal/Installation

1 ± CONSOLE

2 ± SCREW (4)

3 ± SCREW (2)

PLTRANSAXLE 21 - 137

ADJUSTMENTS (Continued)

Page 1051 of 1285

BAND ADJUSTMENT

KICKDOWN BAND (FRONT)

The kickdown band adjusting screw is located on

left side (top front) of the transaxle case.

(1) Loosen locknut and back±off nut approximately

five turns. Test adjusting screw for free turning in

the transaxle case.

(2) Using wrench, tighten adjusting screw to 8

N´m (72 in. lbs.).

(3) Back±off adjusting screw the number of turns

listed in Specifications. Hold adjusting screw in this

position and tighten locknut to 47 N´m (35ft. lbs.)

LOW/REVERSE BAND (REAR)

To adjust low/reverse band, proceed as follows:

(1) Loosen and back off locknut approximately five

turns.

(2) Using an inch-pound torque wrench, tighten

adjusting screw to 5 N´m (41 in. lbs.) true torque.

(3) Back±off adjusting screw the number of turns

listed under Specifications. A chart is located at the

rear of this section.

(4) Tighten locknut to 14 N´m (10 ft. lbs.).

HYDRAULIC CONTROL PRESSURE

ADJUSTMENTS

LINE PRESSURE

An incorrect throttle pressure setting will cause

incorrect line pressure readings even though line

pressure adjustment is correct. Always inspect andcorrect throttle pressure adjustment before adjusting

the line pressure.

The approximate adjustment for line pressure is

1-5/16 inches, measured from valve body to inner

edge of adjusting nut. However, due to manufactur-

ing tolerances, the adjustment can be varied to

obtain specified line pressure.

The adjusting screw may be turned with an Allen

wrench. One complete turn of adjusting screw

changes closed throttle line pressure approximately

1-2/3 psi. Turning adjusting screw counterclockwise

increases pressure, and clockwise decreases pressure.

THROTTLE PRESSURE

Throttle pressures cannot be tested accurately;

therefore, the adjustment should be measured if a

malfunction is evident.

(1) Insert gauge pin of Tool C-3763 between the

throttle lever cam and kickdown valve.

(2) By pushing in on tool, compress kickdown

valve against its spring so throttle valve is com-

pletely bottomed inside the valve body.

(3) While compressing spring, turn throttle lever

stop screw with adapter C-4553. Turn until head of

screw touches throttle lever tang, with throttle lever

cam touching tool and throttle valve bottomed. Be

sure adjustment is made with spring fully com-

pressed and valve bottomed in the valve body.

BEARING ADJUSTMENT PROCEDURES

(1) Take extreme care when removing and install-

ing bearing cups and cones.Use only an arbor

press for installation, as a hammer may not

properly align the bearing cup or cone.Burrs or

nicks on the bearing seat will give a false end play

reading, while gauging for proper shims. Improperly

seated bearing cup and cones are subject to low-mile-

age failure.

(2) Bearing cups and cones should be replaced if

they show signs of pitting or heat distress.

(3) If distress is seen on either the cup or bearing

rollers, both cup and cone must be replaced.

NOTE: Bearing end play and drag torque specifica-

tions must be maintained to avoid premature bear-

ing failures.

(4) Used (original) bearing may lose up to 50 per-

cent of the original drag torque after break-in.

NOTE: All bearing adjustments must be made with

no other component interference or gear inter-

mesh, except the transfer gear bearing.

(5) Refer to the conversion chart in specifications

to convert inches to millimeter measurements. Refer

to bearing shim chart for proper shim thicknesses.

Fig. 221 Shifter Bezel Removal/Installation

1 ± BEZEL

2 ± SCREW (4)

21 - 138 TRANSAXLEPL

ADJUSTMENTS (Continued)

Page 1063 of 1285

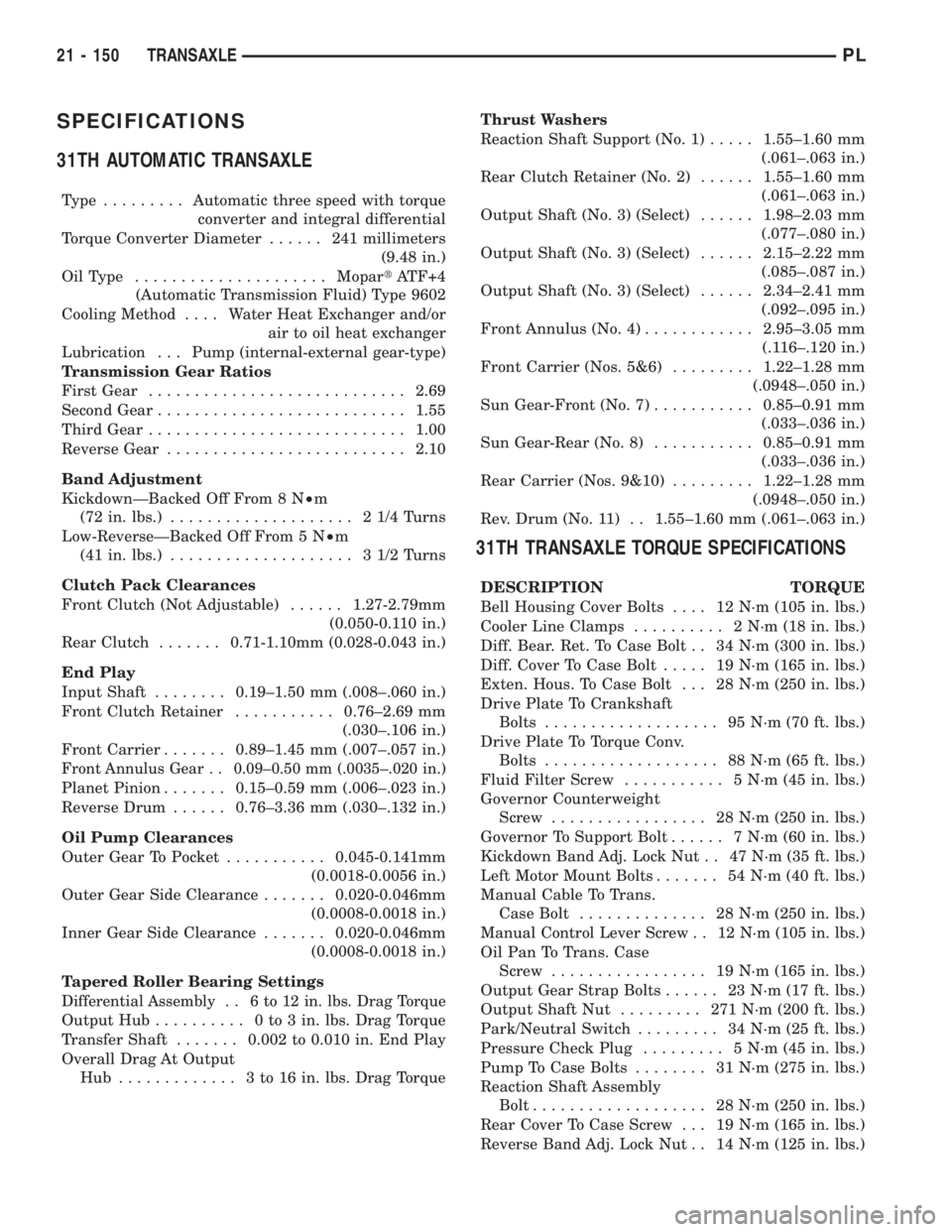

SPECIFICATIONS

31TH AUTOMATIC TRANSAXLE

Type .........Automatic three speed with torque

converter and integral differential

Torque Converter Diameter...... 241millimeters

(9.48 in.)

OilType .....................MopartATF+4

(Automatic Transmission Fluid) Type 9602

Cooling Method.... Water Heat Exchanger and/or

air to oil heat exchanger

Lubrication . . . Pump (internal-external gear-type)

Transmission Gear Ratios

First Gear............................2.69

Second Gear...........................1.55

Third Gear............................1.00

Reverse Gear..........................2.10

Band Adjustment

KickdownÐBacked Off From 8 N²m

(72 in. lbs.).................... 21/4Turns

Low-ReverseÐBacked Off From 5 N²m

(41 in. lbs.).................... 31/2Turns

Clutch Pack Clearances

Front Clutch (Not Adjustable)......1.27-2.79mm

(0.050-0.110 in.)

Rear Clutch.......0.71-1.10mm (0.028-0.043 in.)

End Play

Input Shaft........0.19±1.50 mm (.008±.060 in.)

Front Clutch Retainer...........0.76±2.69 mm

(.030±.106 in.)

Front Carrier.......0.89±1.45 mm (.007±.057 in.)

Front Annulus Gear . . 0.09±0.50 mm (.0035±.020 in.)

Planet Pinion.......0.15±0.59 mm (.006±.023 in.)

Reverse Drum......0.76±3.36 mm (.030±.132 in.)

Oil Pump Clearances

Outer Gear To Pocket...........0.045-0.141mm

(0.0018-0.0056 in.)

Outer Gear Side Clearance.......0.020-0.046mm

(0.0008-0.0018 in.)

Inner Gear Side Clearance.......0.020-0.046mm

(0.0008-0.0018 in.)

Tapered Roller Bearing Settings

Differential Assembly . . 6 to 12 in. lbs. Drag Torque

Output Hub.......... 0to3in.lbs. Drag Torque

Transfer Shaft.......0.002 to 0.010 in. End Play

Overall Drag At Output

Hub ............. 3to16in.lbs. Drag TorqueThrust Washers

Reaction Shaft Support (No. 1).....1.55±1.60 mm

(.061±.063 in.)

Rear Clutch Retainer (No. 2)......1.55±1.60 mm

(.061±.063 in.)

Output Shaft (No. 3) (Select)......1.98±2.03 mm

(.077±.080 in.)

Output Shaft (No. 3) (Select)......2.15±2.22 mm

(.085±.087 in.)

Output Shaft (No. 3) (Select)......2.34±2.41 mm

(.092±.095 in.)

Front Annulus (No. 4)............2.95±3.05 mm

(.116±.120 in.)

Front Carrier (Nos. 5&6).........1.22±1.28 mm

(.0948±.050 in.)

Sun Gear-Front (No. 7)...........0.85±0.91 mm

(.033±.036 in.)

Sun Gear-Rear (No. 8)...........0.85±0.91 mm

(.033±.036 in.)

Rear Carrier (Nos. 9&10).........1.22±1.28 mm

(.0948±.050 in.)

Rev. Drum (No. 11) . . 1.55±1.60 mm (.061±.063 in.)

31TH TRANSAXLE TORQUE SPECIFICATIONS

DESCRIPTION TORQUE

Bell Housing Cover Bolts.... 12N´m(105 in. lbs.)

Cooler Line Clamps.......... 2N´m(18in.lbs.)

Diff. Bear. Ret. To Case Bolt . . 34 N´m (300 in. lbs.)

Diff. Cover To Case Bolt..... 19N´m(165 in. lbs.)

Exten. Hous. To Case Bolt . . . 28 N´m (250 in. lbs.)

Drive Plate To Crankshaft

Bolts................... 95N´m(70ft.lbs.)

Drive Plate To Torque Conv.

Bolts................... 88N´m(65ft.lbs.)

Fluid Filter Screw........... 5N´m(45in.lbs.)

Governor Counterweight

Screw................. 28N´m(250 in. lbs.)

Governor To Support Bolt...... 7N´m(60in.lbs.)

Kickdown Band Adj. Lock Nut . . 47 N´m (35 ft. lbs.)

Left Motor Mount Bolts....... 54N´m(40ft.lbs.)

Manual Cable To Trans.

Case Bolt.............. 28N´m(250 in. lbs.)

Manual Control Lever Screw . . 12 N´m (105 in. lbs.)

Oil Pan To Trans. Case

Screw................. 19N´m(165 in. lbs.)

Output Gear Strap Bolts...... 23N´m(17ft.lbs.)

Output Shaft Nut......... 271N´m(200 ft. lbs.)

Park/Neutral Switch......... 34N´m(25ft.lbs.)

Pressure Check Plug......... 5N´m(45in.lbs.)

Pump To Case Bolts........ 31N´m(275 in. lbs.)

Reaction Shaft Assembly

Bolt................... 28N´m(250 in. lbs.)

Rear Cover To Case Screw . . . 19 N´m (165 in. lbs.)

Reverse Band Adj. Lock Nut . . 14 N´m (125 in. lbs.)

21 - 150 TRANSAXLEPL

Page 1064 of 1285

DESCRIPTION TORQUE

Reverse Band Shaft Plug...... 7N´m(60in.lbs.)

Ring Gear Screw............ 95N´m(70ft.lbs.)

Speedo. To Ext. Hous. Screw . . . 7 N´m (60 in. lbs.)

Sprag Ret. To Transfer Case

Bolt................... 28N´m(250 in. lbs.)

Starter To Trans. Bell Bolts . . . 54 N´m (40 ft. lbs.)

Stirrup Strap Ret. Bolts..... 23N´m(200 in. lbs.)

Trans. To Cyl. Block Bolt...... 95N´m(70ft.lbs.)

Transfer Shaft Nut........ 271N´m(200 ft. lbs.)

Transfer Gear Strap Bolts..... 23N´m(17ft.lbs.)

Valve Body Assy. To Case

Bolts.................. 12N´m(105 in. lbs.)

Valve Body Screw............ 5N´m(45in.lbs.)

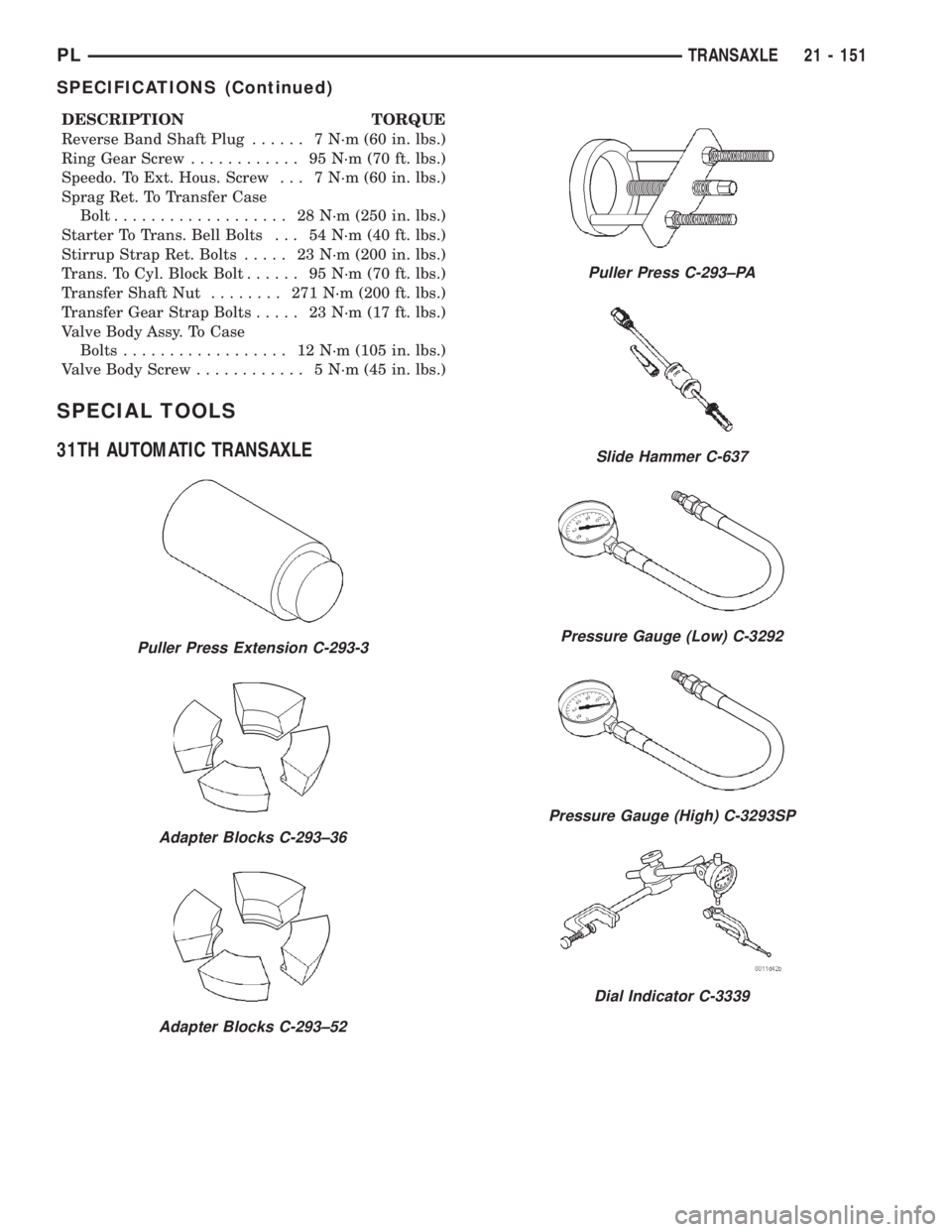

SPECIAL TOOLS

31TH AUTOMATIC TRANSAXLE

Puller Press Extension C-293-3

Adapter Blocks C-293±36

Adapter Blocks C-293±52

Puller Press C-293±PA

Slide Hammer C-637

Pressure Gauge (Low) C-3292

Pressure Gauge (High) C-3293SP

Dial Indicator C-3339

PLTRANSAXLE 21 - 151

SPECIFICATIONS (Continued)

Page 1072 of 1285

signals when the vehicle is equipped with Anti-Lock

Brakes.

The use of tires from different manufactures on the

same vehicle is NOT recommended. The proper tire

pressure should be maintained on all four tires.

SPARE TIRE±TEMPORARY

The temporary spare tire is designed for emer-

gency use only. The original tire should be repaired

or replaced at the first opportunity, then reinstalled.

Do not exceed speeds of 50 M. P. H. when using the

temporary spare tire. Refer to Owner's Manual for

complete details.

REPLACEMENT TIRES

The original equipment tires provide a proper bal-

ance of many characteristics such as:

²Ride

²Noise

²Handling

²Durability

²Tread life

²Traction

²Rolling resistance

²Speed capabilityIt is recommend that tires equivalent to the origi-

nal equipment tires be used when replacement is

needed.

Failure to use equivalent replacement tires may

adversely affect the safety and handling of the vehi-

cle.

The use of oversize tires may cause interference

with vehicle components. Under extremes of suspen-

sion and steering travel, interference with vehicle

components may cause tire damage.

WARNING: FAILURE TO EQUIP THE VEHICLE WITH

TIRES HAVING ADEQUATE SPEED CAPABILITY

CAN RESULT IN SUDDEN TIRE FAILURE.

DIAGNOSIS AND TESTING

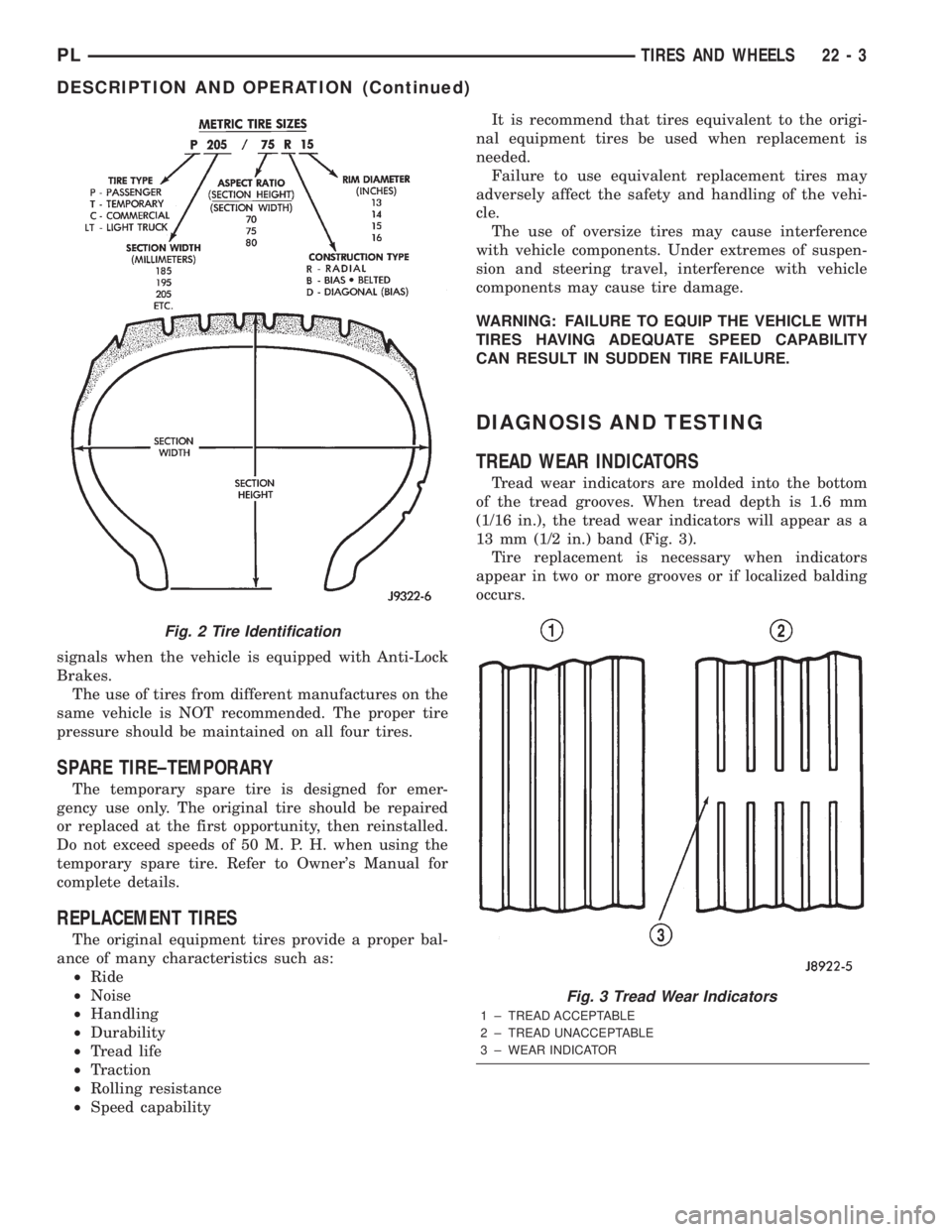

TREAD WEAR INDICATORS

Tread wear indicators are molded into the bottom

of the tread grooves. When tread depth is 1.6 mm

(1/16 in.), the tread wear indicators will appear as a

13 mm (1/2 in.) band (Fig. 3).

Tire replacement is necessary when indicators

appear in two or more grooves or if localized balding

occurs.

Fig. 2 Tire Identification

Fig. 3 Tread Wear Indicators

1 ± TREAD ACCEPTABLE

2 ± TREAD UNACCEPTABLE

3 ± WEAR INDICATOR

PLTIRES AND WHEELS 22 - 3

DESCRIPTION AND OPERATION (Continued)