lock DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1117 of 1285

INSTALLATION

(1) Install EVAP canister to Bracket (Fig. 8).

(2) Install 2 nuts to EVAP canister and bracket

and tighten nuts to 6.7 N´m (60 in. lbs.).

(3) Connect hoses.

(4) Install EVAP canister and bracket to vehicle

and tighten nut 22.4 N´m (250 in. lbs.).

(5) Lower vehicle.

(6) Connect negative battery cable.

LEAK DETECTION PUMP

REMOVAL

(1) Raise and support vehicle on a hoist.

(2) Push locking tab on electrical connector to

unlock and remove connector.

(3) loosen the sway bar bracket to remove the

pump bracket.

(4) Remove pump and bracket as an assembly.

(5) Disconnect lines from LDP.

(6) Remove filter.

(7) Remove pump from bracket.

INSTALLATION

(1) Install pump to bracket and tighten bolts to 1.2

N´m (10.6 in. lbs.).

(2) Install filter and tighten to 2.8 N´m (25 in.

lbs.).

(3)Before installing hoses to LDP, make sure

they are not cracked or split. If a hose leaks, it

will cause the Check Engine Lamp to illumi-

nate.Connect lines to the LDP.

NOTE: The LDP bracket must be between the rail

and sway bar bracket.

(4) Install pump and bracket assembly to body and

tighten bolts to 5.0 N´m (45 in. lbs.).

(5) Install sway bar bracket bolt and tighten bolts

to 33.8 N´m (25 ft. lbs.).

(6) Install electrical connector to pump and push

locking tab to lock.

(7) Lower vehicle(8) Use the DRB scan tool, verify proper operation

of LDP.

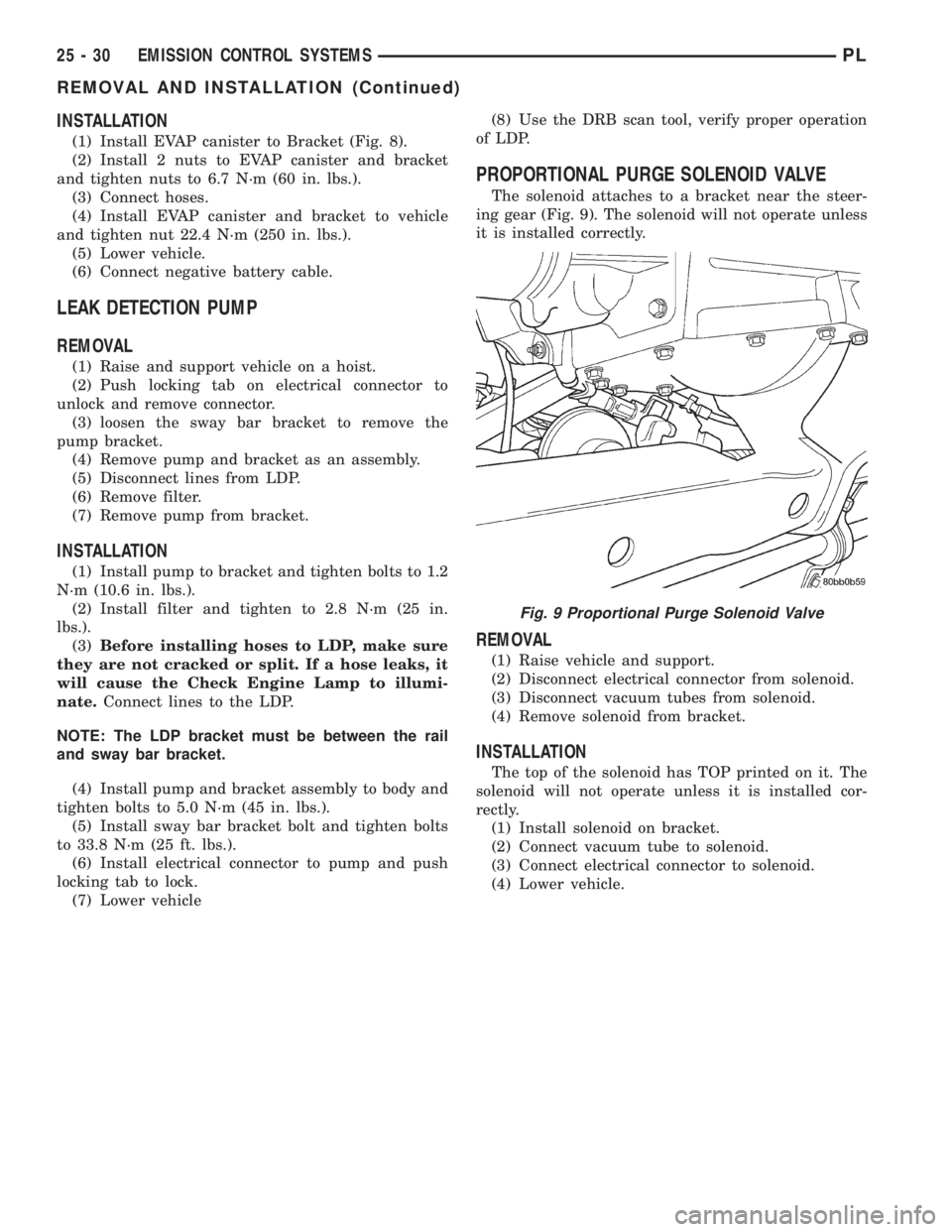

PROPORTIONAL PURGE SOLENOID VALVE

The solenoid attaches to a bracket near the steer-

ing gear (Fig. 9). The solenoid will not operate unless

it is installed correctly.

REMOVAL

(1) Raise vehicle and support.

(2) Disconnect electrical connector from solenoid.

(3) Disconnect vacuum tubes from solenoid.

(4) Remove solenoid from bracket.

INSTALLATION

The top of the solenoid has TOP printed on it. The

solenoid will not operate unless it is installed cor-

rectly.

(1) Install solenoid on bracket.

(2) Connect vacuum tube to solenoid.

(3) Connect electrical connector to solenoid.

(4) Lower vehicle.

Fig. 9 Proportional Purge Solenoid Valve

25 - 30 EMISSION CONTROL SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 1122 of 1285

(4) Place protective covers over instrument panel

and hood.

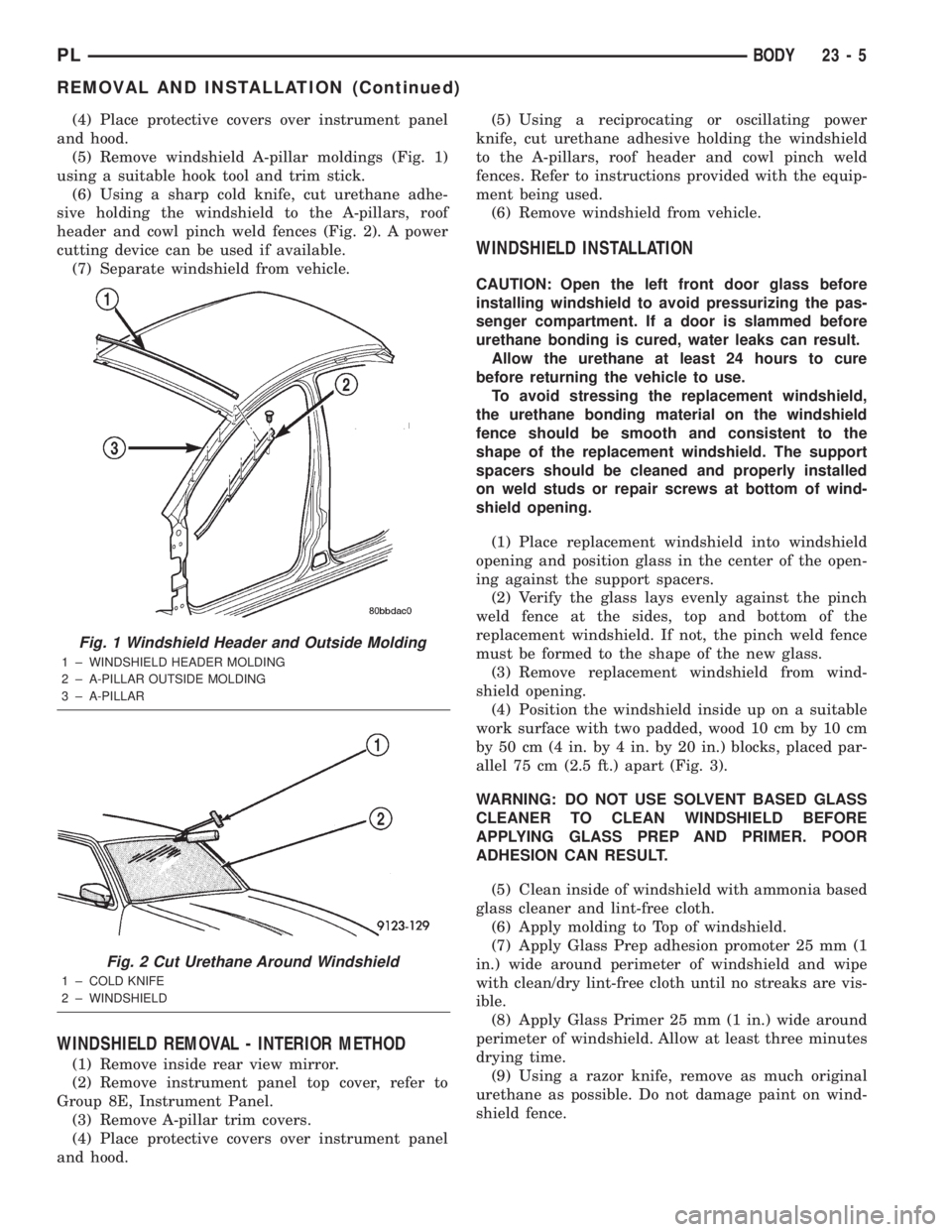

(5) Remove windshield A-pillar moldings (Fig. 1)

using a suitable hook tool and trim stick.

(6) Using a sharp cold knife, cut urethane adhe-

sive holding the windshield to the A-pillars, roof

header and cowl pinch weld fences (Fig. 2). A power

cutting device can be used if available.

(7) Separate windshield from vehicle.

WINDSHIELD REMOVAL - INTERIOR METHOD

(1) Remove inside rear view mirror.

(2) Remove instrument panel top cover, refer to

Group 8E, Instrument Panel.

(3) Remove A-pillar trim covers.

(4) Place protective covers over instrument panel

and hood.(5) Using a reciprocating or oscillating power

knife, cut urethane adhesive holding the windshield

to the A-pillars, roof header and cowl pinch weld

fences. Refer to instructions provided with the equip-

ment being used.

(6) Remove windshield from vehicle.

WINDSHIELD INSTALLATION

CAUTION: Open the left front door glass before

installing windshield to avoid pressurizing the pas-

senger compartment. If a door is slammed before

urethane bonding is cured, water leaks can result.

Allow the urethane at least 24 hours to cure

before returning the vehicle to use.

To avoid stressing the replacement windshield,

the urethane bonding material on the windshield

fence should be smooth and consistent to the

shape of the replacement windshield. The support

spacers should be cleaned and properly installed

on weld studs or repair screws at bottom of wind-

shield opening.

(1) Place replacement windshield into windshield

opening and position glass in the center of the open-

ing against the support spacers.

(2) Verify the glass lays evenly against the pinch

weld fence at the sides, top and bottom of the

replacement windshield. If not, the pinch weld fence

must be formed to the shape of the new glass.

(3) Remove replacement windshield from wind-

shield opening.

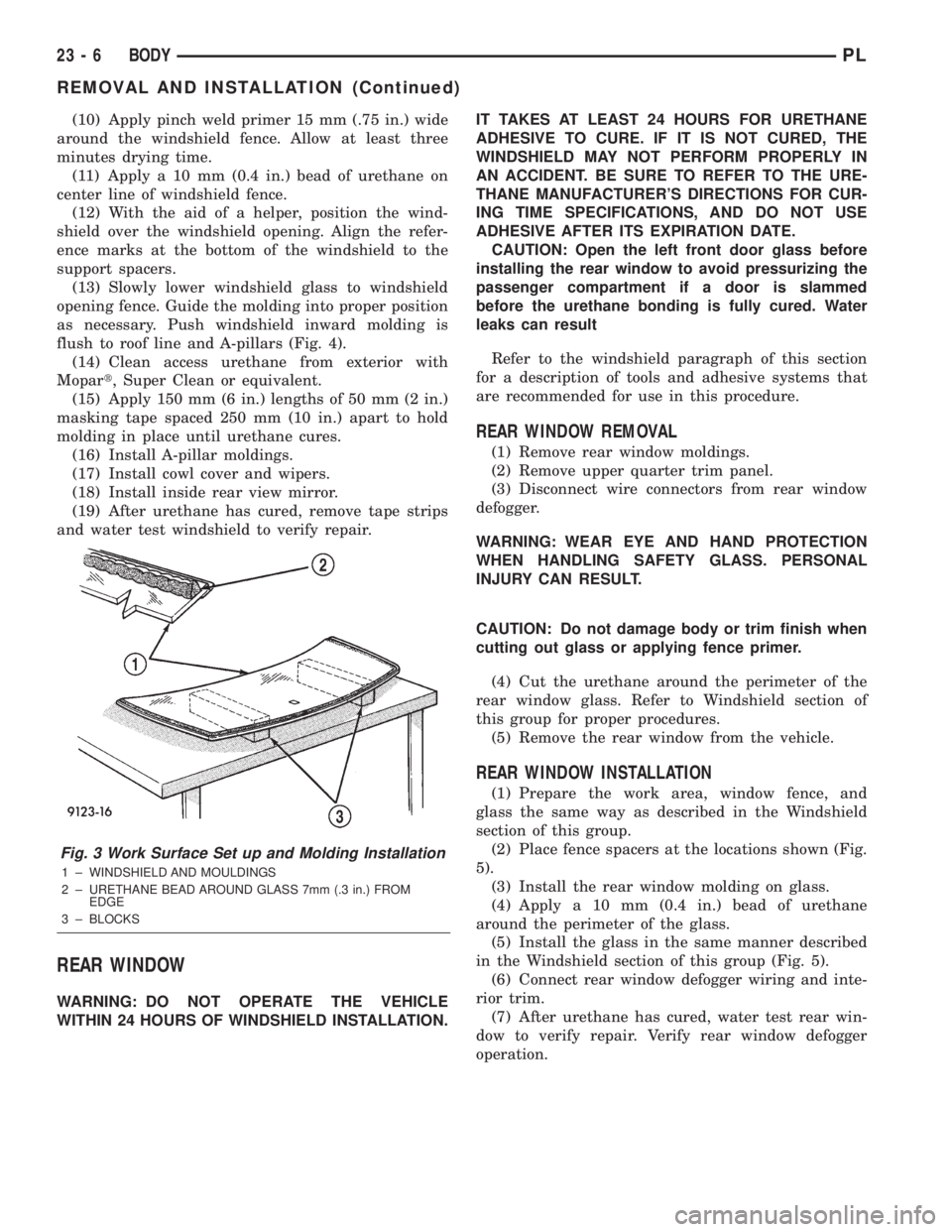

(4) Position the windshield inside up on a suitable

work surface with two padded, wood 10 cm by 10 cm

by 50 cm (4 in. by 4 in. by 20 in.) blocks, placed par-

allel 75 cm (2.5 ft.) apart (Fig. 3).

WARNING: DO NOT USE SOLVENT BASED GLASS

CLEANER TO CLEAN WINDSHIELD BEFORE

APPLYING GLASS PREP AND PRIMER. POOR

ADHESION CAN RESULT.

(5) Clean inside of windshield with ammonia based

glass cleaner and lint-free cloth.

(6) Apply molding to Top of windshield.

(7) Apply Glass Prep adhesion promoter 25 mm (1

in.) wide around perimeter of windshield and wipe

with clean/dry lint-free cloth until no streaks are vis-

ible.

(8) Apply Glass Primer 25 mm (1 in.) wide around

perimeter of windshield. Allow at least three minutes

drying time.

(9) Using a razor knife, remove as much original

urethane as possible. Do not damage paint on wind-

shield fence.

Fig. 1 Windshield Header and Outside Molding

1 ± WINDSHIELD HEADER MOLDING

2 ± A-PILLAR OUTSIDE MOLDING

3 ± A-PILLAR

Fig. 2 Cut Urethane Around Windshield

1 ± COLD KNIFE

2 ± WINDSHIELD

PLBODY 23 - 5

REMOVAL AND INSTALLATION (Continued)

Page 1123 of 1285

(10) Apply pinch weld primer 15 mm (.75 in.) wide

around the windshield fence. Allow at least three

minutes drying time.

(11) Apply a 10 mm (0.4 in.) bead of urethane on

center line of windshield fence.

(12) With the aid of a helper, position the wind-

shield over the windshield opening. Align the refer-

ence marks at the bottom of the windshield to the

support spacers.

(13) Slowly lower windshield glass to windshield

opening fence. Guide the molding into proper position

as necessary. Push windshield inward molding is

flush to roof line and A-pillars (Fig. 4).

(14) Clean access urethane from exterior with

Mopart, Super Clean or equivalent.

(15) Apply 150 mm (6 in.) lengths of 50 mm (2 in.)

masking tape spaced 250 mm (10 in.) apart to hold

molding in place until urethane cures.

(16) Install A-pillar moldings.

(17) Install cowl cover and wipers.

(18) Install inside rear view mirror.

(19) After urethane has cured, remove tape strips

and water test windshield to verify repair.

REAR WINDOW

WARNING: DO NOT OPERATE THE VEHICLE

WITHIN 24 HOURS OF WINDSHIELD INSTALLATION.IT TAKES AT LEAST 24 HOURS FOR URETHANE

ADHESIVE TO CURE. IF IT IS NOT CURED, THE

WINDSHIELD MAY NOT PERFORM PROPERLY IN

AN ACCIDENT. BE SURE TO REFER TO THE URE-

THANE MANUFACTURER'S DIRECTIONS FOR CUR-

ING TIME SPECIFICATIONS, AND DO NOT USE

ADHESIVE AFTER ITS EXPIRATION DATE.

CAUTION: Open the left front door glass before

installing the rear window to avoid pressurizing the

passenger compartment if a door is slammed

before the urethane bonding is fully cured. Water

leaks can result

Refer to the windshield paragraph of this section

for a description of tools and adhesive systems that

are recommended for use in this procedure.

REAR WINDOW REMOVAL

(1) Remove rear window moldings.

(2) Remove upper quarter trim panel.

(3) Disconnect wire connectors from rear window

defogger.

WARNING: WEAR EYE AND HAND PROTECTION

WHEN HANDLING SAFETY GLASS. PERSONAL

INJURY CAN RESULT.

CAUTION: Do not damage body or trim finish when

cutting out glass or applying fence primer.

(4) Cut the urethane around the perimeter of the

rear window glass. Refer to Windshield section of

this group for proper procedures.

(5) Remove the rear window from the vehicle.

REAR WINDOW INSTALLATION

(1) Prepare the work area, window fence, and

glass the same way as described in the Windshield

section of this group.

(2) Place fence spacers at the locations shown (Fig.

5).

(3) Install the rear window molding on glass.

(4) Apply a 10 mm (0.4 in.) bead of urethane

around the perimeter of the glass.

(5) Install the glass in the same manner described

in the Windshield section of this group (Fig. 5).

(6) Connect rear window defogger wiring and inte-

rior trim.

(7) After urethane has cured, water test rear win-

dow to verify repair. Verify rear window defogger

operation.

Fig. 3 Work Surface Set up and Molding Installation

1 ± WINDSHIELD AND MOULDINGS

2 ± URETHANE BEAD AROUND GLASS 7mm (.3 in.) FROM

EDGE

3 ± BLOCKS

23 - 6 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1125 of 1285

SEATS

TABLE OF CONTENTS

page page

REMOVAL AND INSTALLATION

FRONT SEAT.............................8

FRONT SEAT BACK........................8

FRONT SEAT BACK COVER.................9FRONT SEAT CUSHION COVER..............9

FRONT SEAT CUSHION....................9

REAR SEAT BACK........................10

REAR SEAT CUSHION.....................11

REMOVAL AND INSTALLATION

FRONT SEAT

REMOVAL

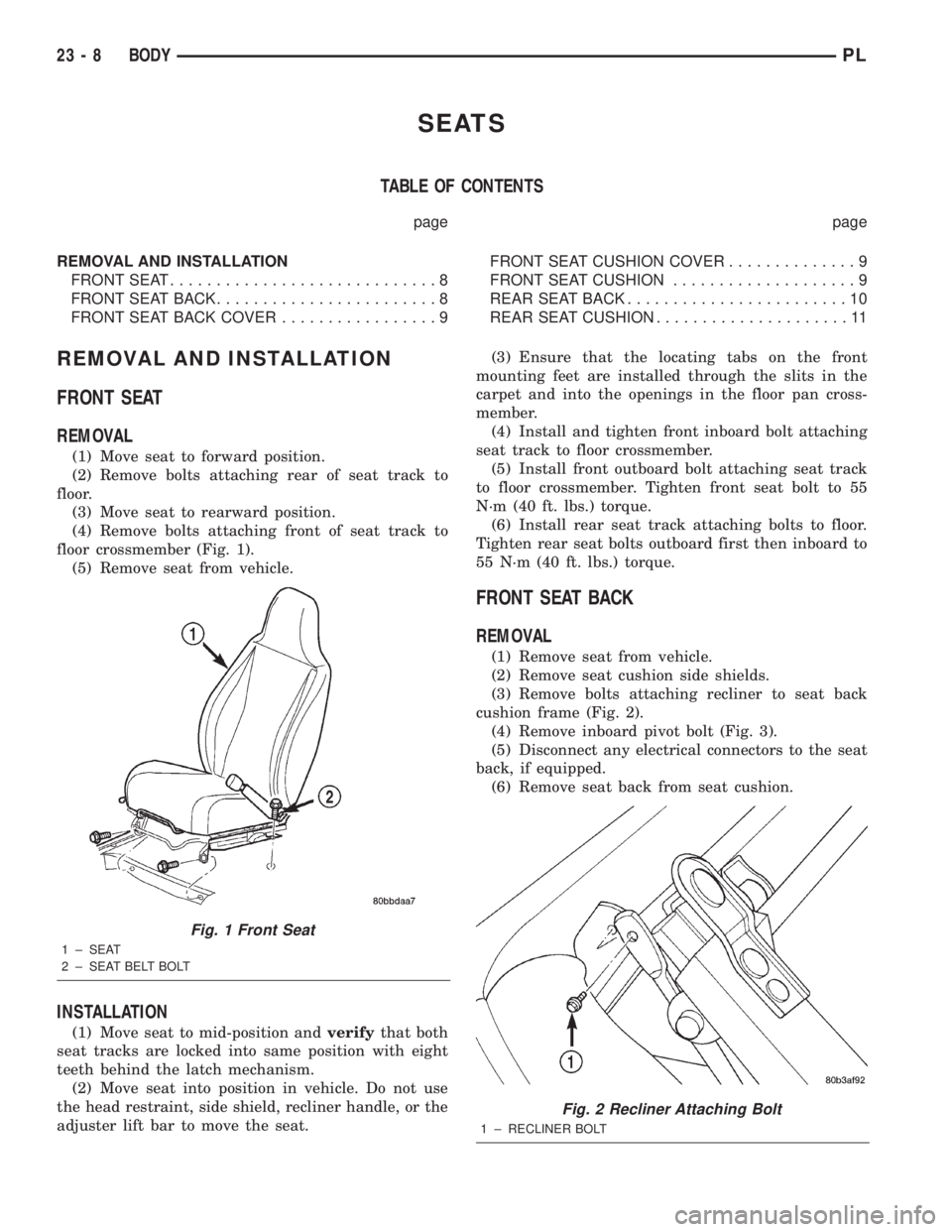

(1) Move seat to forward position.

(2) Remove bolts attaching rear of seat track to

floor.

(3) Move seat to rearward position.

(4) Remove bolts attaching front of seat track to

floor crossmember (Fig. 1).

(5) Remove seat from vehicle.

INSTALLATION

(1) Move seat to mid-position andverifythat both

seat tracks are locked into same position with eight

teeth behind the latch mechanism.

(2) Move seat into position in vehicle. Do not use

the head restraint, side shield, recliner handle, or the

adjuster lift bar to move the seat.(3) Ensure that the locating tabs on the front

mounting feet are installed through the slits in the

carpet and into the openings in the floor pan cross-

member.

(4) Install and tighten front inboard bolt attaching

seat track to floor crossmember.

(5) Install front outboard bolt attaching seat track

to floor crossmember. Tighten front seat bolt to 55

N´m (40 ft. lbs.) torque.

(6) Install rear seat track attaching bolts to floor.

Tighten rear seat bolts outboard first then inboard to

55 N´m (40 ft. lbs.) torque.

FRONT SEAT BACK

REMOVAL

(1) Remove seat from vehicle.

(2) Remove seat cushion side shields.

(3) Remove bolts attaching recliner to seat back

cushion frame (Fig. 2).

(4) Remove inboard pivot bolt (Fig. 3).

(5) Disconnect any electrical connectors to the seat

back, if equipped.

(6) Remove seat back from seat cushion.

Fig. 1 Front Seat

1 ± SEAT

2 ± SEAT BELT BOLT

Fig. 2 Recliner Attaching Bolt

1 ± RECLINER BOLT

23 - 8 BODYPL

Page 1129 of 1285

BODY COMPONENTS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

GRILLE................................13

HOOD.................................13

FRONT DOOR...........................14

SPLASH SHIELD.........................16

DIAGNOSIS AND TESTING

WATER LEAKS..........................18

WIND NOISE............................19

SERVICE PROCEDURES

HEAT STAKING..........................19

PLASTIC BODY PANEL REPAIR..............19

REMOVAL AND INSTALLATION

GRILLE................................23

HOOD LATCH...........................24

HOOD LATCH STRIKER....................24

HOOD RELEASE CABLE...................25

HOOD.................................26

HOOD SILENCER........................26

HOOD HINGE...........................26

COWL COVER...........................27

FRONT WHEELHOUSE SPLASH SHIELD......28

FENDER...............................28

EXTERIOR BADGEING ATTACHED WITH

DOUBLE SIDED FOAM TAPE..............28

EXTERIOR BADGEING/TAPE STRIPES

ATTACHED WITH ADHESIVES.............28

FRONT/REAR DOOR WINDOW CRANK........29

FRONT DOOR TRIM......................30

FRONT DOOR WATER DAM................30

DOOR OUTER BELT WEATHERSTRIP.........30

FRONT/REAR DOOR INNER BELT

WEATHERSTRIP........................32

FRONT DOOR GLASS RUN WEATHERSTRIP . . . 32

FRONT DOOR OUTSIDE HANDLE............33

DOOR LOCK CYLINDER...................33

FRONT DOOR LATCH.....................33

FRONT DOOR LATCH STRIKER.............34

FRONT VERTICAL GUIDE BAR..............34

FRONT DOOR GLASS.....................36

FRONT DOOR CHECK STRAP..............36

FRONT DOOR...........................36

FRONT DOOR HINGE.....................38

FRONT/REAR DOOR APPLIQUE.............38

SIDE VIEW MIRROR......................39

SIDE VIEW MIRROR TRIM BEZEL............39

DOOR UPPER SECONDARY WEATHERSTRIP . . 39

SILL SECONDARY WEATHERSTRIP..........40

REAR DOOR TRIM.......................40REAR DOOR WATER DAM.................40

REAR DOOR OUTSIDE HANDLE.............40

REAR DOOR LATCH......................41

REAR DOOR LATCH STRIKER..............43

REAR DOOR GLASS......................43

REAR DOOR WINDOW REGULATOR.........43

REAR DOOR GLASS RUN WEATHERSTRIP....43

REAR DOOR CHECK STRAP................45

REAR DOOR............................45

REAR DOOR HINGE......................45

FUEL FILL DOOR.........................46

DECKLID LATCH.........................47

DECKLID...............................47

DECKLID LIFT SPRINGS...................47

DECKLID LOCK CYLINDER.................48

DECKLID LATCH STRIKER.................48

DECKLID OPENING WEATHERSTRIP.........49

TRUNK CARPET.........................49

DECKLID COVER.........................50

ROOF RAIL WEATHERSTRIP................50

ROOF RAIL WEATHERSTRIP RETAINER

CHANNEL.............................50

B-PILLAR WEATHERSTRIP CHANNEL.........51

A-PILLAR TRIM..........................51

DOOR SILL TRIM.........................51

SIDE COWL TRIM........................52

B-PILLAR TRIM..........................52

UPPER QUARTER TRIM...................53

LOWER QUARTER TRIM...................53

FLOOR CONSOLE........................54

FRONT SEAT BELT BUCKLE................54

FRONT SEAT BELT RETRACTOR............54

FRONT SHOULDER BELT ADJUSTER.........54

REAR SEAT BELT BUCKLE.................55

REAR SEAT BELT RETRACTOR.............55

CARPET...............................56

SUN VISOR.............................56

HEADLINER.............................57

INSIDE REAR VIEW MIRROR...............57

REAR SHELF TRIM PANEL.................57

BODY VENT.............................58

ADJUSTMENTS

FRONT DOOR LATCH ADJUSTMENT.........58

REAR DOOR LATCH ADJUSTMENT..........58

SPECIFICATIONS

BODY LUBRICATION......................59

SPECIAL TOOLS

BODY.................................59

23 - 12 BODYPL

Page 1132 of 1285

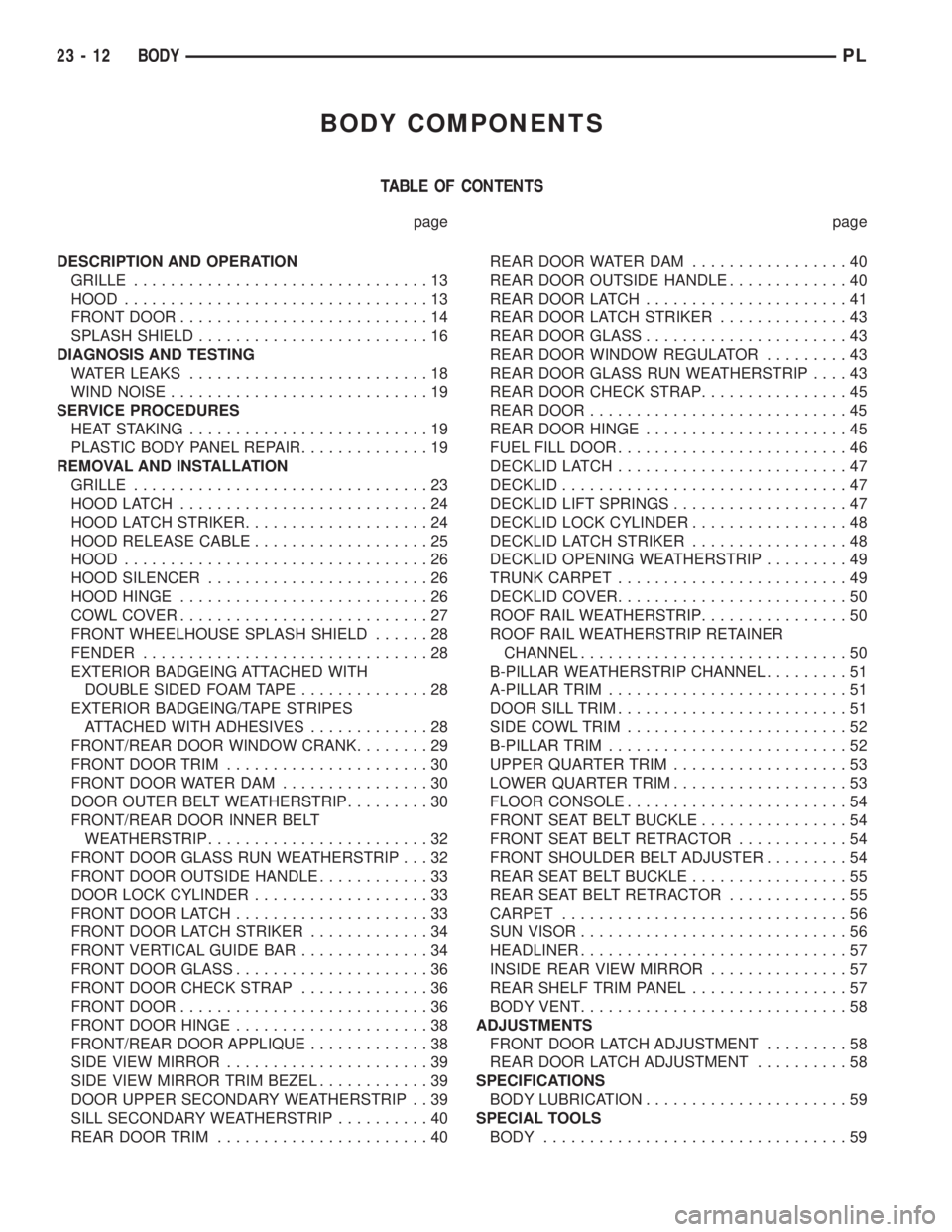

FRONT DOOR LATCH AND OUTER HANDLE

1 ± LOCK TO LATCH LINK & SLEEVE

2 ± FRONT DOOR

3 ± CENTRAL LOCKING SWITCH

4 ± OUTSIDE DOOR HANDLE5 ± LOCK CYLINDER RETAINING CLIP

6 ± LOCK CYLINDER

7 ± FRONT DOOR LATCH

8 ± INSIDE DOOR HANDLE LINK & SLEEVE

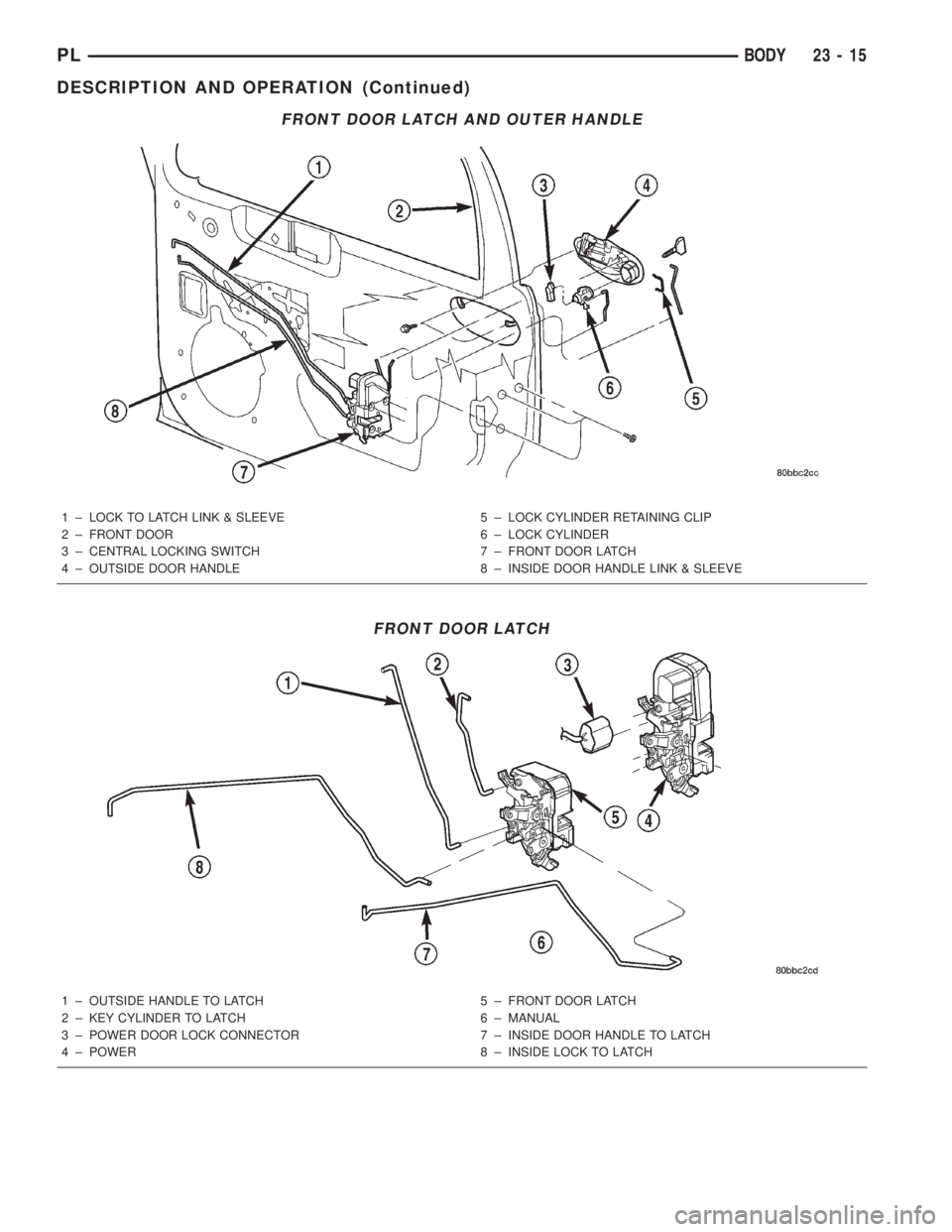

FRONT DOOR LATCH

1 ± OUTSIDE HANDLE TO LATCH

2 ± KEY CYLINDER TO LATCH

3 ± POWER DOOR LOCK CONNECTOR

4 ± POWER5 ± FRONT DOOR LATCH

6 ± MANUAL

7 ± INSIDE DOOR HANDLE TO LATCH

8 ± INSIDE LOCK TO LATCH

PLBODY 23 - 15

DESCRIPTION AND OPERATION (Continued)

Page 1135 of 1285

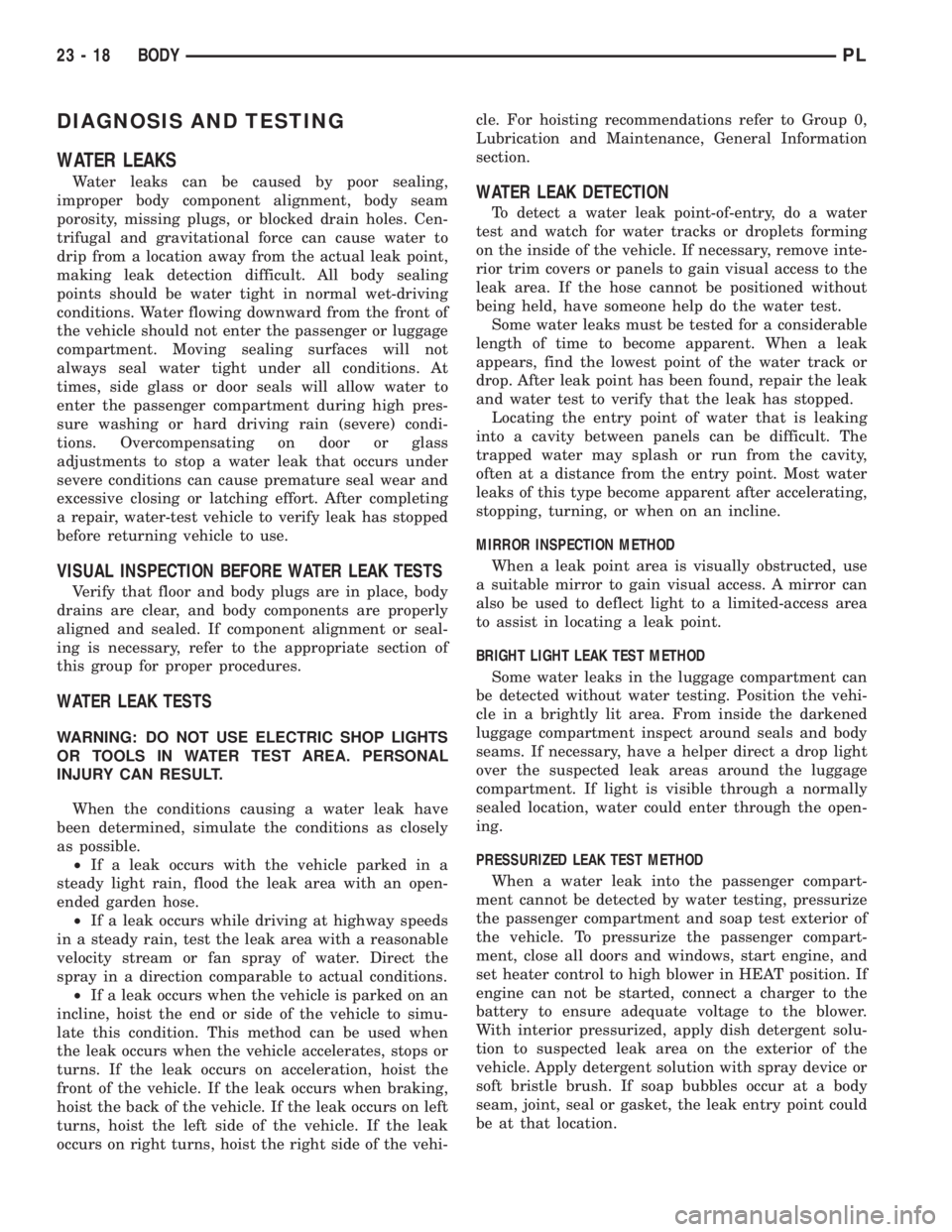

DIAGNOSIS AND TESTING

WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not

always seal water tight under all conditions. At

times, side glass or door seals will allow water to

enter the passenger compartment during high pres-

sure washing or hard driving rain (severe) condi-

tions. Overcompensating on door or glass

adjustments to stop a water leak that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After completing

a repair, water-test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.

When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-cle. For hoisting recommendations refer to Group 0,

Lubrication and Maintenance, General Information

section.

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the lowest point of the water track or

drop. After leak point has been found, repair the leak

and water test to verify that the leak has stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

23 - 18 BODYPL

Page 1140 of 1285

(12) Position patch in cutout against support

squares and adjust patch until the gap is equal along

all sides (Fig. 11).

(13) Drill 3 mm (0.125 in.) holes in the support

squares through the pre-drilled holes in the patch.

(14) Apply a coat of epoxy to the exposed ends of

the support squares (Fig. 12).

(15) Install screws to hold the patch to support

squares (Fig. 13). Tighten screws until patch surface

is flush with panel surface.

(16) Allow epoxy to cure, and remove all screws.

(17) Using a 125 mm (5 in.) 24 grit disc grinder,

grind a 50 mm (2 in.) to 75 mm (3 in.) wide and 2

mm (0.080 in.) deep path across the gaps around the

patch (Fig. 14). With compressed air, blow dust from

around patch.

(18) Apply adhesive backed nylon mesh (dry wall

tape) over gaps around patch (Fig. 15).

(19) Mix enough epoxy to cover the entire patch

area.

(20) Apply epoxy over the mesh around patch, and

smooth epoxy with a wide spreader to reduce finish

grinding. Use two to three layers of mesh and epoxy

to create a stronger repair (Fig. 16).

PATCHED PANEL SURFACING

After patch panel is installed, the patch area can

be finished using the same methods as finishing

other types of body panels. If mesh material is

exposed in the patched area, grind surface down, and

apply a coat of high quality rigid plastic body filler.

Prime, block sand, and paint as required.

REMOVAL AND INSTALLATION

GRILLE

REMOVAL

(1) Release hood latch, open and support hood on

prop rod.

(2) Remove screws attaching grille to parking

lamps (Fig. 17).

(3) Remove screw attaching grille to radiator clo-

sure panel.

(4) Remove grille from vehicle.

INSTALLATION

(1) Place grille into position on vehicle.

Fig. 10 Secure Support Squares To Body Panel

1 ± SUPPORT SQUARES

2 ± SCREWS

3 ± DAMAGED BODY PANEL

Fig. 11 Position Patch In Cutout And Align

1 ± CUTOUT

2 ± SUPPORT SQUARES

Fig. 12 Apply Epoxy To Support Squares

1 ± APPLICATOR

2 ± SUPPORT SQUARES

3 ± EPOXY

PLBODY 23 - 23

SERVICE PROCEDURES (Continued)

Page 1146 of 1285

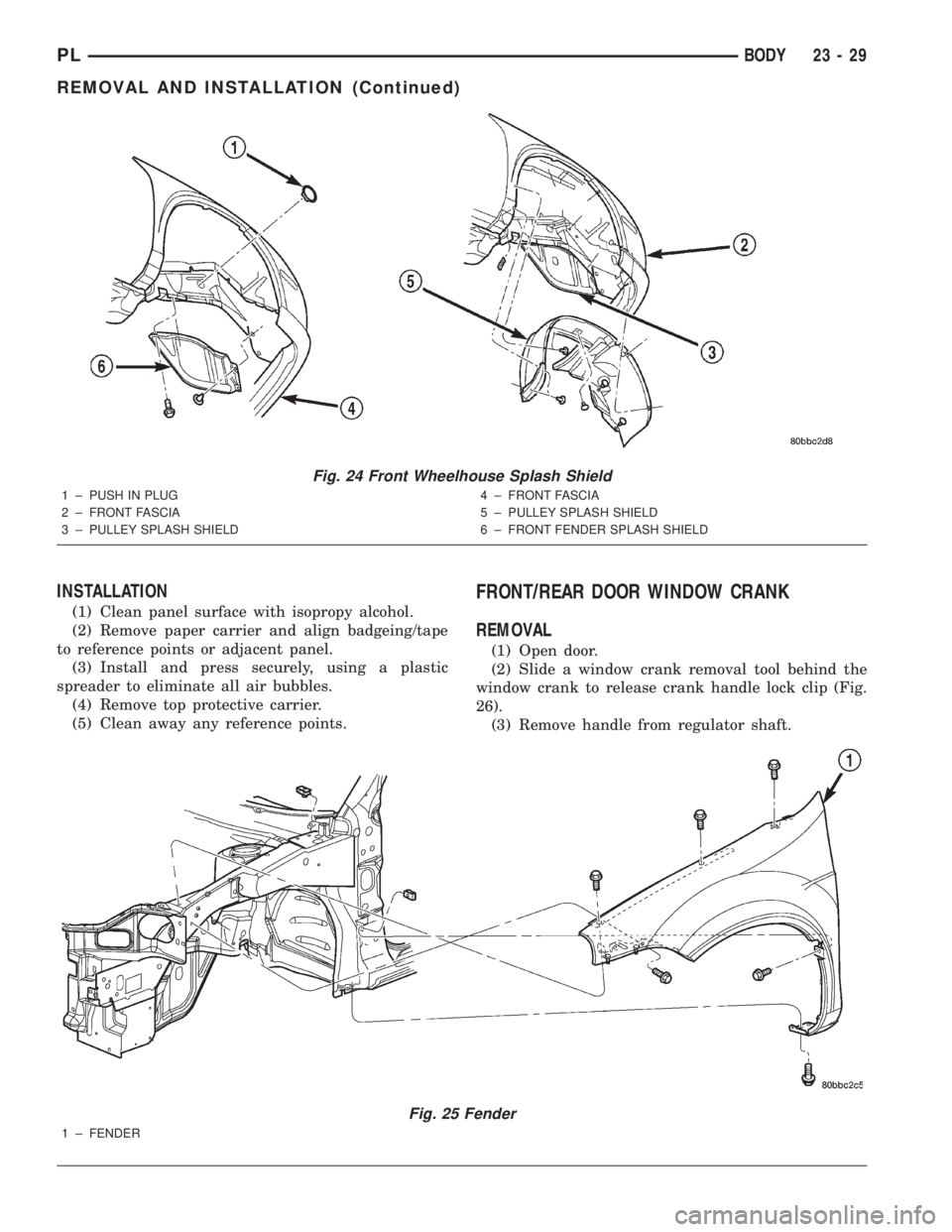

INSTALLATION

(1) Clean panel surface with isopropy alcohol.

(2) Remove paper carrier and align badgeing/tape

to reference points or adjacent panel.

(3) Install and press securely, using a plastic

spreader to eliminate all air bubbles.

(4) Remove top protective carrier.

(5) Clean away any reference points.

FRONT/REAR DOOR WINDOW CRANK

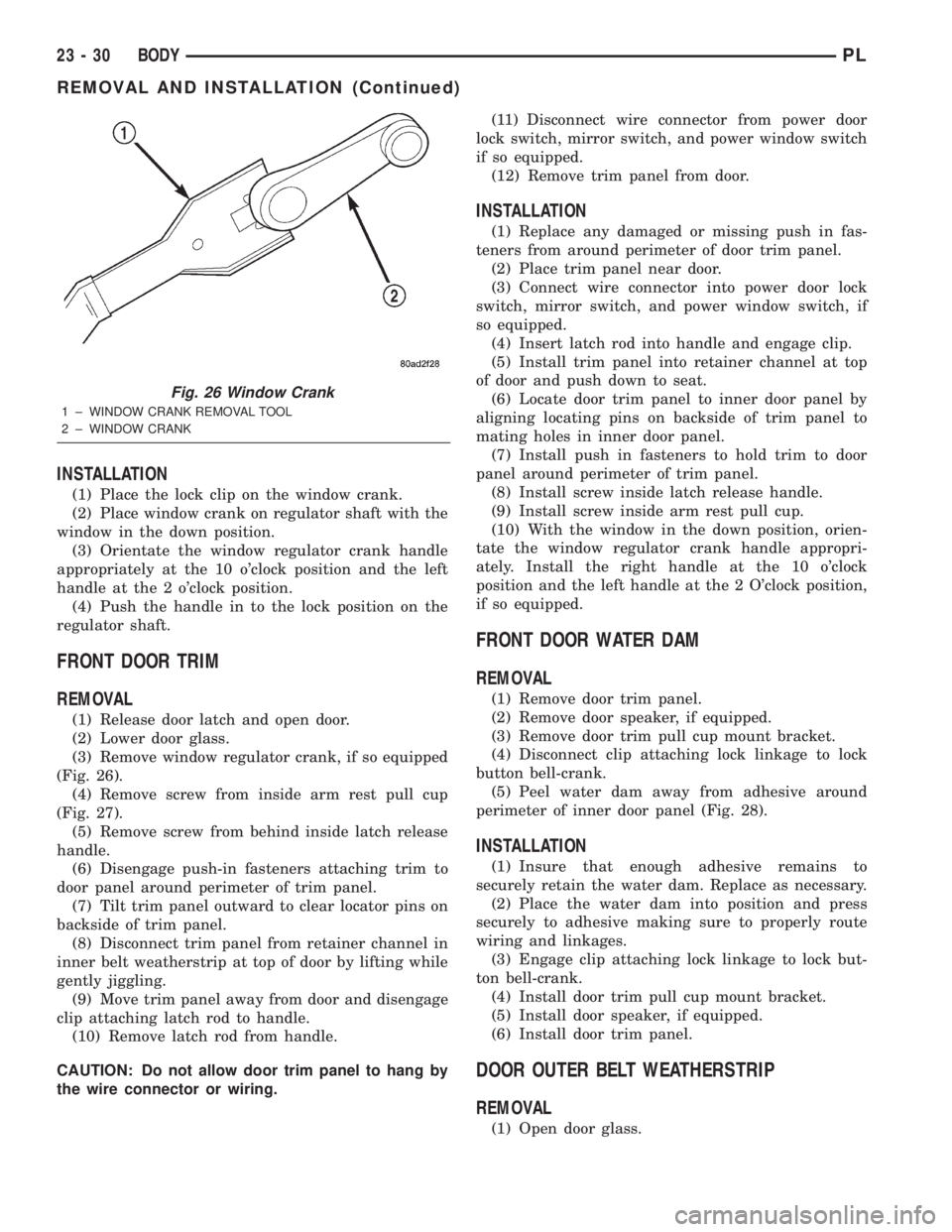

REMOVAL

(1) Open door.

(2) Slide a window crank removal tool behind the

window crank to release crank handle lock clip (Fig.

26).

(3) Remove handle from regulator shaft.

Fig. 25 Fender

1 ± FENDER

Fig. 24 Front Wheelhouse Splash Shield

1 ± PUSH IN PLUG

2 ± FRONT FASCIA

3 ± PULLEY SPLASH SHIELD4 ± FRONT FASCIA

5 ± PULLEY SPLASH SHIELD

6 ± FRONT FENDER SPLASH SHIELD

PLBODY 23 - 29

REMOVAL AND INSTALLATION (Continued)

Page 1147 of 1285

INSTALLATION

(1) Place the lock clip on the window crank.

(2) Place window crank on regulator shaft with the

window in the down position.

(3) Orientate the window regulator crank handle

appropriately at the 10 o'clock position and the left

handle at the 2 o'clock position.

(4) Push the handle in to the lock position on the

regulator shaft.

FRONT DOOR TRIM

REMOVAL

(1) Release door latch and open door.

(2) Lower door glass.

(3) Remove window regulator crank, if so equipped

(Fig. 26).

(4) Remove screw from inside arm rest pull cup

(Fig. 27).

(5) Remove screw from behind inside latch release

handle.

(6) Disengage push-in fasteners attaching trim to

door panel around perimeter of trim panel.

(7) Tilt trim panel outward to clear locator pins on

backside of trim panel.

(8) Disconnect trim panel from retainer channel in

inner belt weatherstrip at top of door by lifting while

gently jiggling.

(9) Move trim panel away from door and disengage

clip attaching latch rod to handle.

(10) Remove latch rod from handle.

CAUTION: Do not allow door trim panel to hang by

the wire connector or wiring.(11) Disconnect wire connector from power door

lock switch, mirror switch, and power window switch

if so equipped.

(12) Remove trim panel from door.

INSTALLATION

(1) Replace any damaged or missing push in fas-

teners from around perimeter of door trim panel.

(2) Place trim panel near door.

(3) Connect wire connector into power door lock

switch, mirror switch, and power window switch, if

so equipped.

(4) Insert latch rod into handle and engage clip.

(5) Install trim panel into retainer channel at top

of door and push down to seat.

(6) Locate door trim panel to inner door panel by

aligning locating pins on backside of trim panel to

mating holes in inner door panel.

(7) Install push in fasteners to hold trim to door

panel around perimeter of trim panel.

(8) Install screw inside latch release handle.

(9) Install screw inside arm rest pull cup.

(10) With the window in the down position, orien-

tate the window regulator crank handle appropri-

ately. Install the right handle at the 10 o'clock

position and the left handle at the 2 O'clock position,

if so equipped.

FRONT DOOR WATER DAM

REMOVAL

(1) Remove door trim panel.

(2) Remove door speaker, if equipped.

(3) Remove door trim pull cup mount bracket.

(4) Disconnect clip attaching lock linkage to lock

button bell-crank.

(5) Peel water dam away from adhesive around

perimeter of inner door panel (Fig. 28).

INSTALLATION

(1) Insure that enough adhesive remains to

securely retain the water dam. Replace as necessary.

(2) Place the water dam into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(3) Engage clip attaching lock linkage to lock but-

ton bell-crank.

(4) Install door trim pull cup mount bracket.

(5) Install door speaker, if equipped.

(6) Install door trim panel.

DOOR OUTER BELT WEATHERSTRIP

REMOVAL

(1) Open door glass.

Fig. 26 Window Crank

1 ± WINDOW CRANK REMOVAL TOOL

2 ± WINDOW CRANK

23 - 30 BODYPL

REMOVAL AND INSTALLATION (Continued)