lock DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 928 of 1285

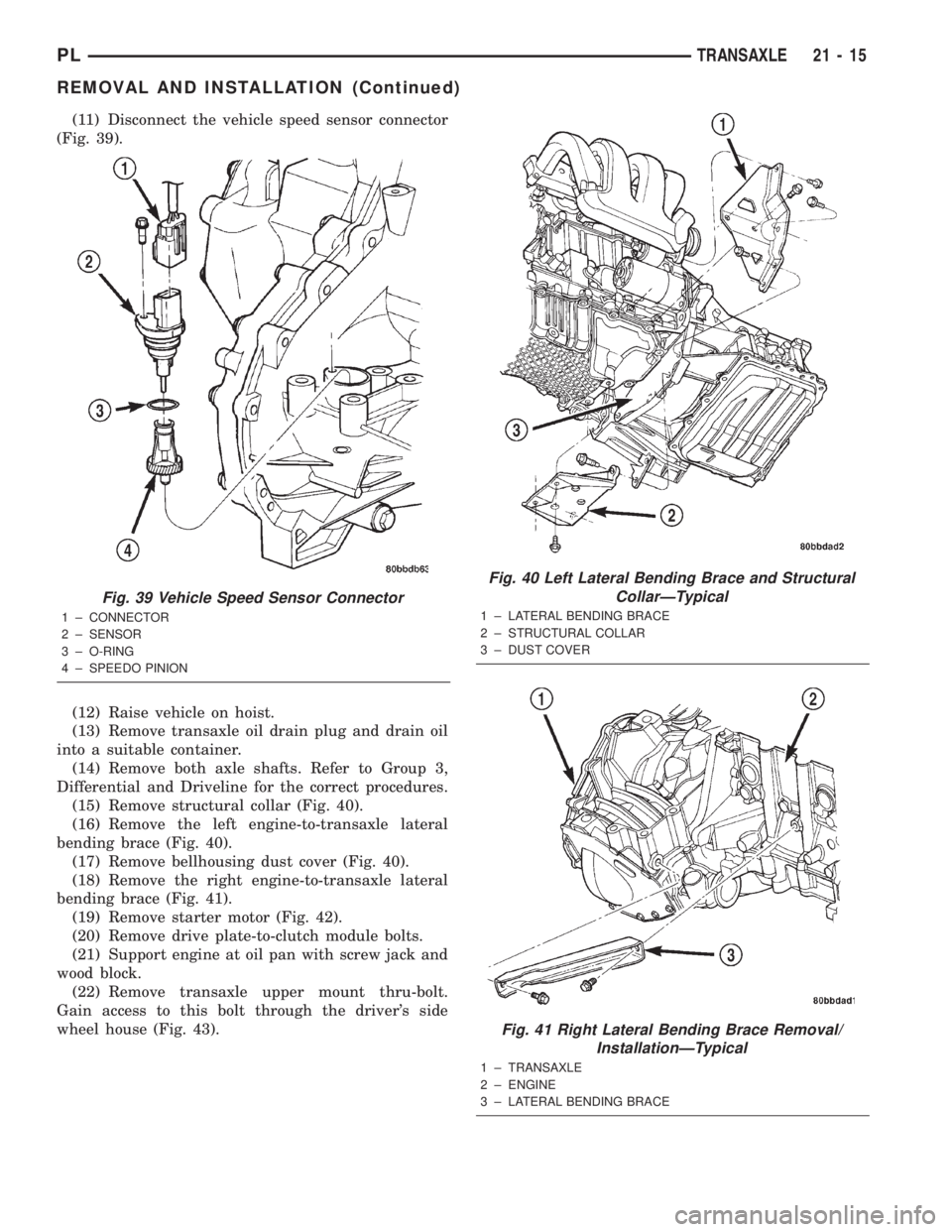

(11) Disconnect the vehicle speed sensor connector

(Fig. 39).

(12) Raise vehicle on hoist.

(13) Remove transaxle oil drain plug and drain oil

into a suitable container.

(14) Remove both axle shafts. Refer to Group 3,

Differential and Driveline for the correct procedures.

(15) Remove structural collar (Fig. 40).

(16) Remove the left engine-to-transaxle lateral

bending brace (Fig. 40).

(17) Remove bellhousing dust cover (Fig. 40).

(18) Remove the right engine-to-transaxle lateral

bending brace (Fig. 41).

(19) Remove starter motor (Fig. 42).

(20) Remove drive plate-to-clutch module bolts.

(21) Support engine at oil pan with screw jack and

wood block.

(22) Remove transaxle upper mount thru-bolt.

Gain access to this bolt through the driver's side

wheel house (Fig. 43).

Fig. 39 Vehicle Speed Sensor Connector

1 ± CONNECTOR

2 ± SENSOR

3 ± O-RING

4 ± SPEEDO PINION

Fig. 40 Left Lateral Bending Brace and Structural

CollarÐTypical

1 ± LATERAL BENDING BRACE

2 ± STRUCTURAL COLLAR

3 ± DUST COVER

Fig. 41 Right Lateral Bending Brace Removal/

InstallationÐTypical

1 ± TRANSAXLE

2 ± ENGINE

3 ± LATERAL BENDING BRACE

PLTRANSAXLE 21 - 15

REMOVAL AND INSTALLATION (Continued)

Page 933 of 1285

(11) Remove reverse idler gear and spacer (Fig.

53).

(12) Remove two screws retaining reverse fork

bracket (Fig. 54). Remove reverse fork bracket and

reverse cam blockout assembly (Fig. 55).(13) Using snap±ring pliers, remove selector shaft

spacer (Fig. 56).

(14) Pull the selector shaft shift pin out of the slot

in the blocker assembly. Turn selector shaft up and

out of the way (Fig. 57).

Fig. 53 Reverse Idler Gear and Spacer Removal

1 ± SPACER

2 ± REVERSE IDLER GEAR

Fig. 54 Screws Retaining Reverse Fork Bracket

1 ± SCREWS (2)

2 ± REVERSE FORK BRACKET

Fig. 55 Remove Reverse Fork Bracket

1 ± REVERSE FORK BRACKET

2 ± REVERSE CAM BLOCKOUT

3 ± SHIFT BLOCKER ASSEMBLY

Fig. 56 Remove Selector Shaft Spacer

1 ± SHIFT BLOCKER ASSEMBLY

2 ± SELECTOR SHAFT SPACER (PLASTIC)

3 ± SNAP RING PLIERS

21 - 20 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 936 of 1285

(22)TRANSAXLE W/REVERSE BRAKE:

Remove the reverse brake blocking ring, shim,

reverse brake friction cone, bearing and race from

the input shaft assembly (Fig. 66) (Fig. 67) (Fig. 68)

(Fig. 69) (Fig. 70).TRANSAXLE W/O REVERSE

BRAKE:Remove plastic spacer from the input shaft

assembly.

Fig. 65 Oil Feed Trough

1 ± OIL FEED TROUGH

Fig. 66 Reverse Brake Shim

1 ± REVERSE BRAKE SHIM

2 ± REVERSE BRAKE FRICTION CONE

Fig. 67 Reverse Brake Friction Cone

1 ± REVERSE BRAKE FRICTION CONE

Fig. 68 Reverse Brake Blocking Ring

1 ± REVERSE BRAKE BLOCKING RING

Fig. 69 Reverse Brake Needle Bearing

1 ± REVERSE BRAKE NEEDLE BEARING

PLTRANSAXLE 21 - 23

DISASSEMBLY AND ASSEMBLY (Continued)

Page 937 of 1285

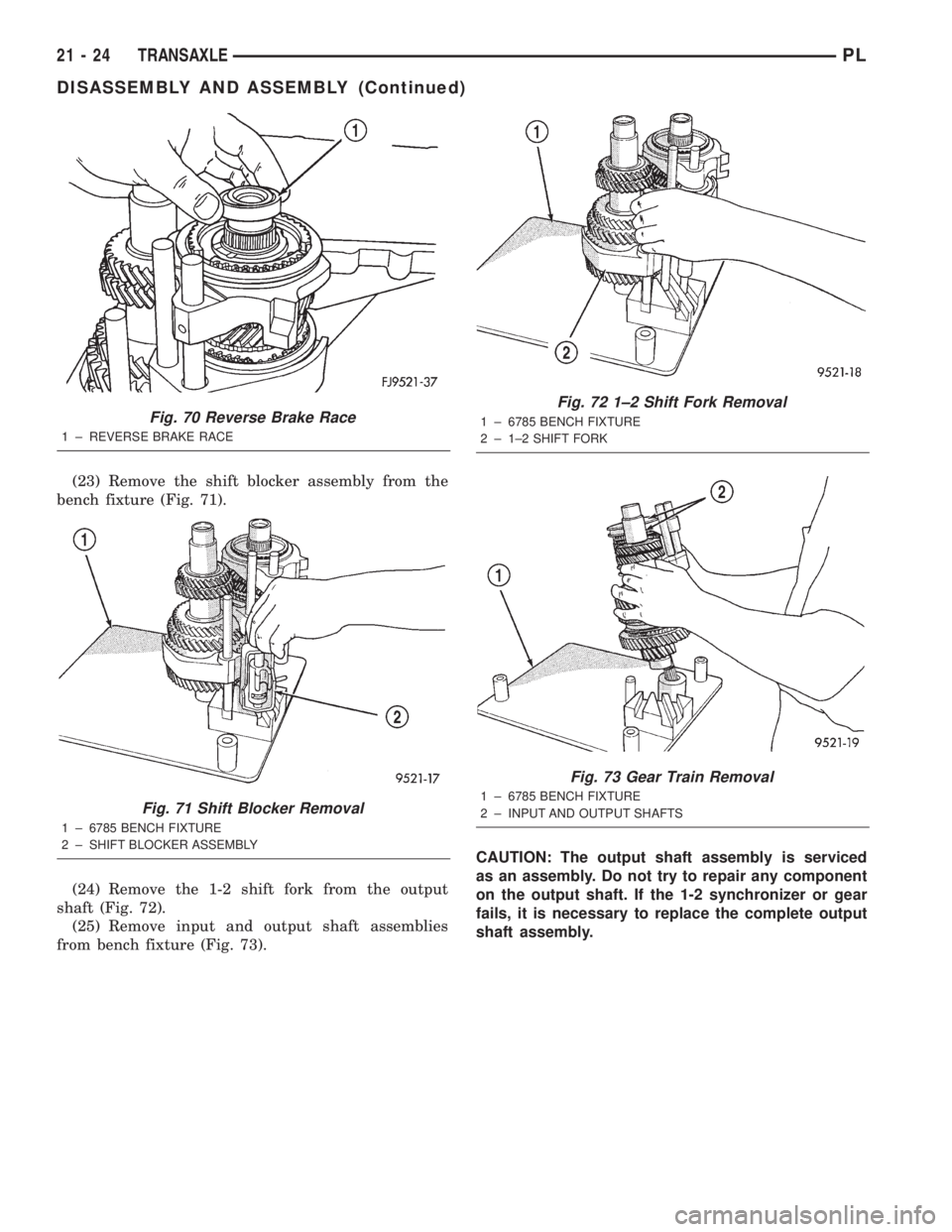

(23) Remove the shift blocker assembly from the

bench fixture (Fig. 71).

(24) Remove the 1-2 shift fork from the output

shaft (Fig. 72).

(25) Remove input and output shaft assemblies

from bench fixture (Fig. 73).CAUTION: The output shaft assembly is serviced

as an assembly. Do not try to repair any component

on the output shaft. If the 1-2 synchronizer or gear

fails, it is necessary to replace the complete output

shaft assembly.

Fig. 70 Reverse Brake Race

1 ± REVERSE BRAKE RACE

Fig. 71 Shift Blocker Removal

1 ± 6785 BENCH FIXTURE

2 ± SHIFT BLOCKER ASSEMBLY

Fig. 72 1±2 Shift Fork Removal

1 ± 6785 BENCH FIXTURE

2 ± 1±2 SHIFT FORK

Fig. 73 Gear Train Removal

1 ± 6785 BENCH FIXTURE

2 ± INPUT AND OUTPUT SHAFTS

21 - 24 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 938 of 1285

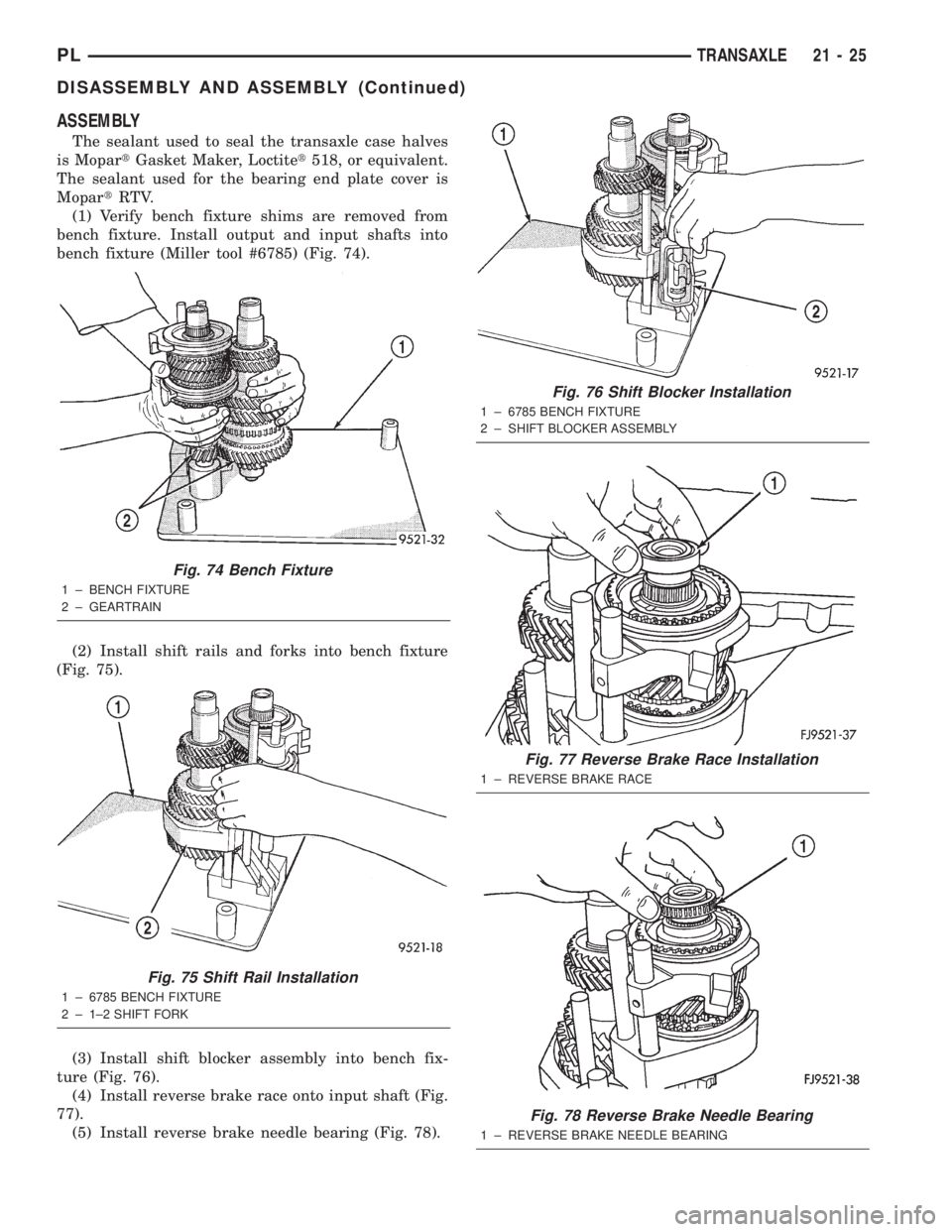

ASSEMBLY

The sealant used to seal the transaxle case halves

is MopartGasket Maker, Loctitet518, or equivalent.

The sealant used for the bearing end plate cover is

MopartRTV.

(1) Verify bench fixture shims are removed from

bench fixture. Install output and input shafts into

bench fixture (Miller tool #6785) (Fig. 74).

(2) Install shift rails and forks into bench fixture

(Fig. 75).

(3) Install shift blocker assembly into bench fix-

ture (Fig. 76).

(4) Install reverse brake race onto input shaft (Fig.

77).

(5) Install reverse brake needle bearing (Fig. 78).

Fig. 74 Bench Fixture

1 ± BENCH FIXTURE

2 ± GEARTRAIN

Fig. 75 Shift Rail Installation

1 ± 6785 BENCH FIXTURE

2 ± 1±2 SHIFT FORK

Fig. 76 Shift Blocker Installation

1 ± 6785 BENCH FIXTURE

2 ± SHIFT BLOCKER ASSEMBLY

Fig. 77 Reverse Brake Race Installation

1 ± REVERSE BRAKE RACE

Fig. 78 Reverse Brake Needle Bearing

1 ± REVERSE BRAKE NEEDLE BEARING

PLTRANSAXLE 21 - 25

DISASSEMBLY AND ASSEMBLY (Continued)

Page 939 of 1285

(6) Install reverse brake blocking ring (Fig. 79).

(7) Install reverse brake friction cone (Fig. 80).(8) Install reverse brake shim (Fig. 81). Apply

petroleum jelly to shim to hold in place.

(9) Install gear±case half over bench fixture (Fig.

82). Line up shift finger over 3-4 lug.

Fig. 79 Reverse Brake Blocking Ring Installation

1 ± REVERSE BRAKE BLOCKING RING

Fig. 80 Reverse Brake Friction Cone Installation

1 ± REVERSE BRAKE FRICTION CONE

Fig. 81 Reverse Brake Shim

1 ± REVERSE BRAKE SHIM

2 ± REVERSE BRAKE FRICTION CONE

Fig. 82 Gear Case Half

1 ± TRANSAXLE CASE

2 ± BENCH FIXTURE

3 ± GEARTRAIN

21 - 26 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 941 of 1285

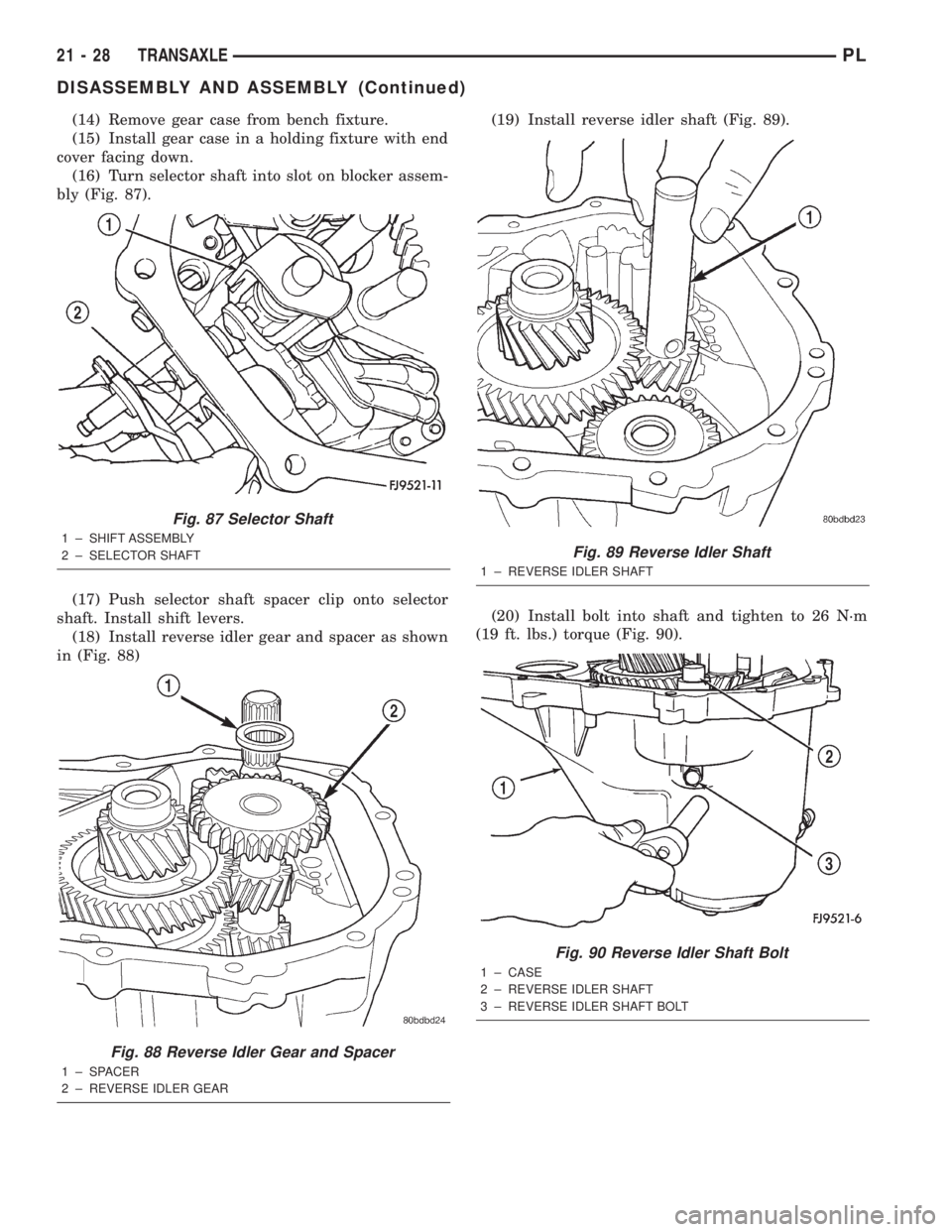

(14) Remove gear case from bench fixture.

(15) Install gear case in a holding fixture with end

cover facing down.

(16) Turn selector shaft into slot on blocker assem-

bly (Fig. 87).

(17) Push selector shaft spacer clip onto selector

shaft. Install shift levers.

(18) Install reverse idler gear and spacer as shown

in (Fig. 88)(19) Install reverse idler shaft (Fig. 89).

(20) Install bolt into shaft and tighten to 26 N´m

(19 ft. lbs.) torque (Fig. 90).

Fig. 87 Selector Shaft

1 ± SHIFT ASSEMBLY

2 ± SELECTOR SHAFT

Fig. 88 Reverse Idler Gear and Spacer

1 ± SPACER

2 ± REVERSE IDLER GEAR

Fig. 89 Reverse Idler Shaft

1 ± REVERSE IDLER SHAFT

Fig. 90 Reverse Idler Shaft Bolt

1 ± CASE

2 ± REVERSE IDLER SHAFT

3 ± REVERSE IDLER SHAFT BOLT

21 - 28 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 942 of 1285

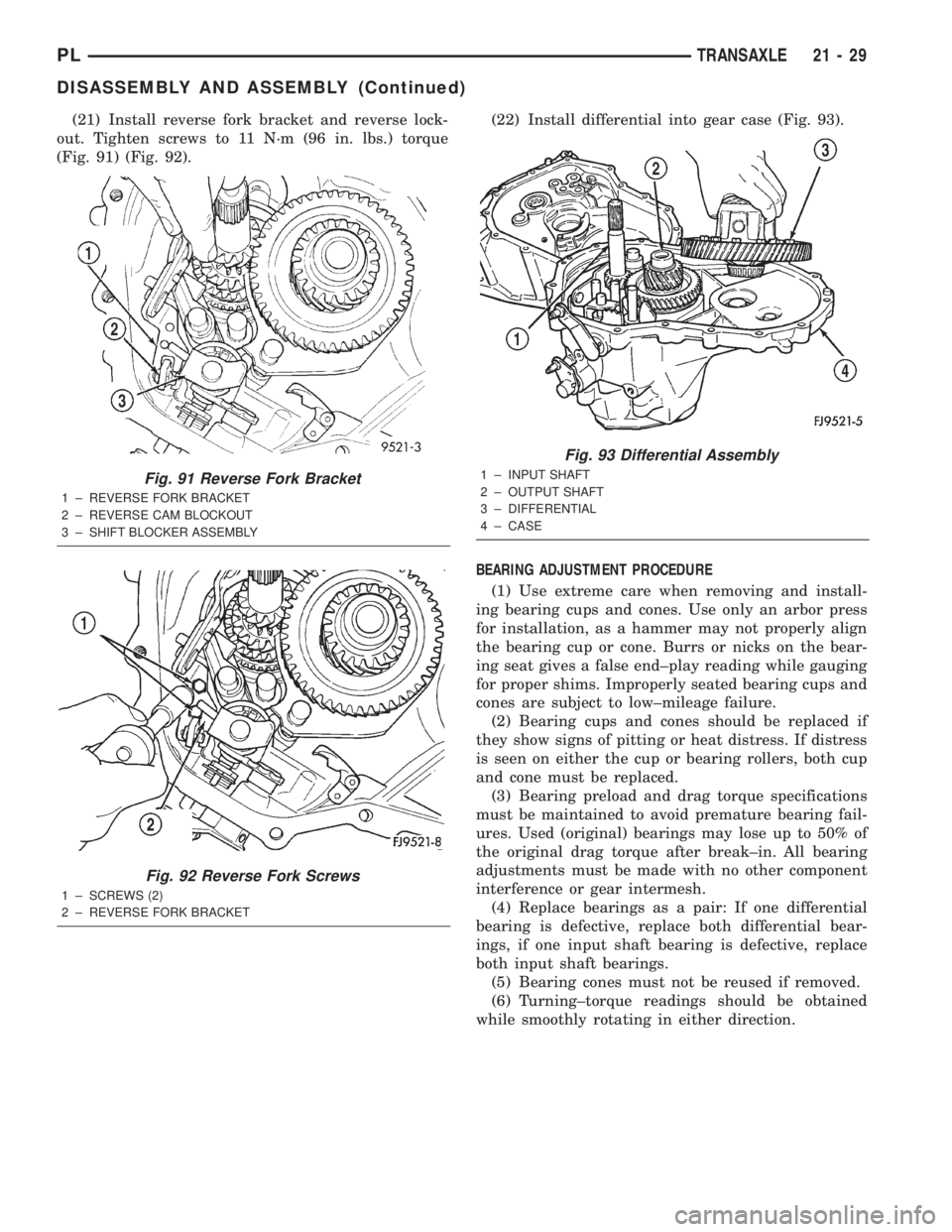

(21) Install reverse fork bracket and reverse lock-

out. Tighten screws to 11 N´m (96 in. lbs.) torque

(Fig. 91) (Fig. 92).(22) Install differential into gear case (Fig. 93).

BEARING ADJUSTMENT PROCEDURE

(1) Use extreme care when removing and install-

ing bearing cups and cones. Use only an arbor press

for installation, as a hammer may not properly align

the bearing cup or cone. Burrs or nicks on the bear-

ing seat gives a false end±play reading while gauging

for proper shims. Improperly seated bearing cups and

cones are subject to low±mileage failure.

(2) Bearing cups and cones should be replaced if

they show signs of pitting or heat distress. If distress

is seen on either the cup or bearing rollers, both cup

and cone must be replaced.

(3) Bearing preload and drag torque specifications

must be maintained to avoid premature bearing fail-

ures. Used (original) bearings may lose up to 50% of

the original drag torque after break±in. All bearing

adjustments must be made with no other component

interference or gear intermesh.

(4) Replace bearings as a pair: If one differential

bearing is defective, replace both differential bear-

ings, if one input shaft bearing is defective, replace

both input shaft bearings.

(5) Bearing cones must not be reused if removed.

(6) Turning±torque readings should be obtained

while smoothly rotating in either direction.

Fig. 91 Reverse Fork Bracket

1 ± REVERSE FORK BRACKET

2 ± REVERSE CAM BLOCKOUT

3 ± SHIFT BLOCKER ASSEMBLY

Fig. 92 Reverse Fork Screws

1 ± SCREWS (2)

2 ± REVERSE FORK BRACKET

Fig. 93 Differential Assembly

1 ± INPUT SHAFT

2 ± OUTPUT SHAFT

3 ± DIFFERENTIAL

4 ± CASE

PLTRANSAXLE 21 - 29

DISASSEMBLY AND ASSEMBLY (Continued)

Page 946 of 1285

(7) Remove 4th gear (Fig. 103).

(8) Remove 4th gear caged needle bearing (Fig.

104). Check the caged needle bearing for a broken

retention spring.(9) Remove blocking ring. Remove 3-4 synchronizer

hub retaining snap ring (Fig. 105).

(10) Install input shaft in shop press. Using bear-

ing splitter, remove 3-4 synchronizer and 3rd gear

(Fig. 106).

(11) Remove 3rd gear caged needle bearing (Fig.

107). Check the caged needle bearing for a broken

retention spring.

(12) Inspect the input shaft for worn or damaged

bearing races or chipped gear teeth. Replace as nec-

essary.

Fig. 103 4th Gear Removal

1 ± INPUT SHAFT

2 ± 4TH GEAR

Fig. 104 Caged Needle Bearing Removal

1 ± INPUT SHAFT

2 ± CAGED NEEDLE BEARING

Fig. 105 3-4 Synchronizer Hub Snap Ring

1 ± SNAP RING PLIERS

2 ± SYNCHRO SNAP RING

3 ± SYNCHRONIZER ASSEMBLY

Fig. 106 3rd Gear Removal

1 ± PRESS RAM

2 ± INPUT SHAFT

3 ± 3RD GEAR

4 ± SYNCHRONIZER ASSEMBLY

PLTRANSAXLE 21 - 33

DISASSEMBLY AND ASSEMBLY (Continued)

Page 947 of 1285

ASSEMBLY

The snap rings that are used on the input shaft

are available in select fit sizes. Use the thickest snap

ring that fits in each snap ring groove.

(1) Place input shaft into shop press.

(2) Install 3rd gear caged needle bearing on input

shaft.

(3) Install 3rd gear and 3-4 synchronizer onto

input shaft. Install Tool #C-3717 over input shaft and

press on synchronizer hub and 3rd gear (Fig. 108).

The synchronizer hub has the letterUstamped on

the top face of the hub. This designates that the hub

must be installed with theUfacing upward.(4) Install 3-4 synchronizer snap ring into slot on

input shaft.

(5) Install blocking ring into 3-4 synchronizer.

Install 4th gear caged needle bearing.

(6) Install 4th gear onto input shaft.

(7) Install 4-5 split thrust washer separation pin

(Fig. 109).

(8) Install split thrust washer onto input shaft

(Fig. 110).

Fig. 107 3rd Gear Caged Needle Bearing

1 ± INPUT SHAFT

2 ± 3RD GEAR CAGED NEEDLE BEARING

Fig. 108 Press On 3rd Gear Synchronizer Hub

1 ± PRESS RAM

2 ± SPECIAL TOOL C-3717

3 ± BEARING SPLITTER

4 ± 3RD GEAR SYNCHRONIZER ASSEMBLY

Fig. 109 Split Thrust Washer Separation Pin

Installation

1 ± SEPARATION PIN

2 ± INPUT SHAFT

3 ± PLIERS

Fig. 110 Split Thrust Washer Installation

1 ± INPUT SHAFT

2 ± SPLIT THRUST WASHER

21 - 34 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)