lock DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 908 of 1285

bolt nut to a torque of 28 N´m (250 in. lbs.). Install

the pinch bolt retainer pin.

(11) Install the upper and lower steering column

shrouds onto the steering column (Fig. 9). Snap the

two shrouds together and then install and tighten

the two screws securing the shrouds to the column.

(12) Install the steering column cover that mounts

below the steering column on the instrument panel

by first aligning the retainer clips and snapping the

cover into place. Install the two screws along the bot-

tom of the steering column cover.

(13) Align the clips along the outer edge of the

instrument cluster bezel with the mounting holes in

the instrument panel and install the bezel.

(14) Align the clips on the bottom of the instru-

ment panel top cover with the mounting holes in the

instrument panel and install the top cover by push-

ing it down into place.

(15) Install the screw securing the left end of the

top cover to the instrument panel.

CAUTION: If there is any question as to whether

the clockspring is in the centered position, the

clock spring needs to be recentered before install-

ing the steering wheel. If the clockspring is not cen-

tered, it may be overextended, causing the

clockspring to become inoperative.

(16) Center the clockspring using the following

procedure:

²Using your fingers, rotate the clockspring rotor

in the CLOCKWISE DIRECTION to the end of the

travel. Do not apply excessive torque.

²From the end of travel, rotate the rotor two full

turns and an additional half turn in the counter-

clockwise direction. (The wires should end up at the

bottom of the clockspring).

CAUTION: Do not install the steering wheel onto

the shaft of the steering column by driving it onto

the shaft.

(17) Feed the clockspring wiring leads through the

hole in the steering wheel (Fig. 6). Align the steering

wheel's wide mounting spline with the steering col-

umn shaft missing spline area and push the wheel

onto the shaft. Make sure the clockspring squares up

with the back of the wheel and does not bind.

(18) Install the steering wheel retaining nut and

tighten it until the steering wheel is fully installed

on shaft. Tighten the steering wheel retaining nut to

a torque of 61 N´m (45 ft. lbs.).

(19) Connect the clockspring electrical leads to the

speed control switches and reinstall the switches on

the steering wheel (Fig. 6).

(20) Install the airbag electrical lead from the

clockspring into the connector on the back of the air-bag module (Fig. 6). Be sure electrical connector from

clockspring is securely latched into airbag module

connector.

(21) Connect the horn switch electrical lead to the

connector on the back of the airbag module (Fig. 6).

CAUTION: The fasteners originally used for the air-

bag components are specifically designed for the

airbag system. They must never be replaced with

any substitutes. Anytime a new fastener is needed,

replace it with only the correct fastener listed in the

parts book.

(22) Install the airbag module into the center of

the steering wheel. Align the airbag module mount-

ing holes with the bolt holes in steering wheel (Fig.

6). Install only the two original or identical replace-

ment airbag module mounting screws. Tighten the

two air bag module attaching bolts to a torque of 10

N´m (90 in. lbs.).

(23) Install the airbag mounting screw trim caps

on the steering wheel rear cover (Fig. 7). One belongs

on each side of the steering wheel.

NOTE: When reconnecting the battery on a vehicle

that has had the airbag module removed, the fol-

lowing procedure should be used.

(24) Reconnect the ground cable to the negative

post of the battery in the following manor:

²Connect a scan tool (DRBIIIt) to the data link

diagnostic connector located below the steering col-

umn.

²Turn the ignition key to the ON position. Exit

the vehicle with the scan tool leaving the scan tool

harness plugged in.

²Ensuring that there are no occupants in the

vehicle, connect the ground (-) cable to the negative

post of the battery.

²Using the scan tool, read and record any fault

codes. Refer to the DRIVER AND PASSENGER AIR-

BAG SYSTEM diagnostic manual if any faults are

found.

²Erase any stored faults if there are no active

fault codes. If a problem exists, the fault code will

not erase.

²Reach around the back of the steering wheel (in

front of the instrument cluster) and turn the ignition

key to OFF, then back ON while observing the

instrument cluster airbag lamp. It should go on for

six to eight seconds, then go out. This will indicate

that the airbag system is functioning normally. If air-

bag warning lamp fails to light, blinks on and off, or

goes on and stays on, there is an airbag system mal-

function. Refer to the BODY DIAGNOSTIC PROCE-

DURES manual to diagnose the system malfunction.

PLSTEERING 19 - 37

REMOVAL AND INSTALLATION (Continued)

Page 909 of 1285

(25) Turn the key to OFF and remove the scan tool

from the vehicle.

(26) Test the operation of the horn, wipers and any

other functions that are steering column operated. If

applicable, reset the radio and the clock.

(27) If the steering column is a tilt column, verify

the tilt mechanism operates properly.

(28) Road test the vehicle to ensure proper opera-

tion of the steering system and the speed control sys-

tem.

STEERING COLUMN LOWER COUPLING

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section and in STEERING

GEAR.

REMOVAL

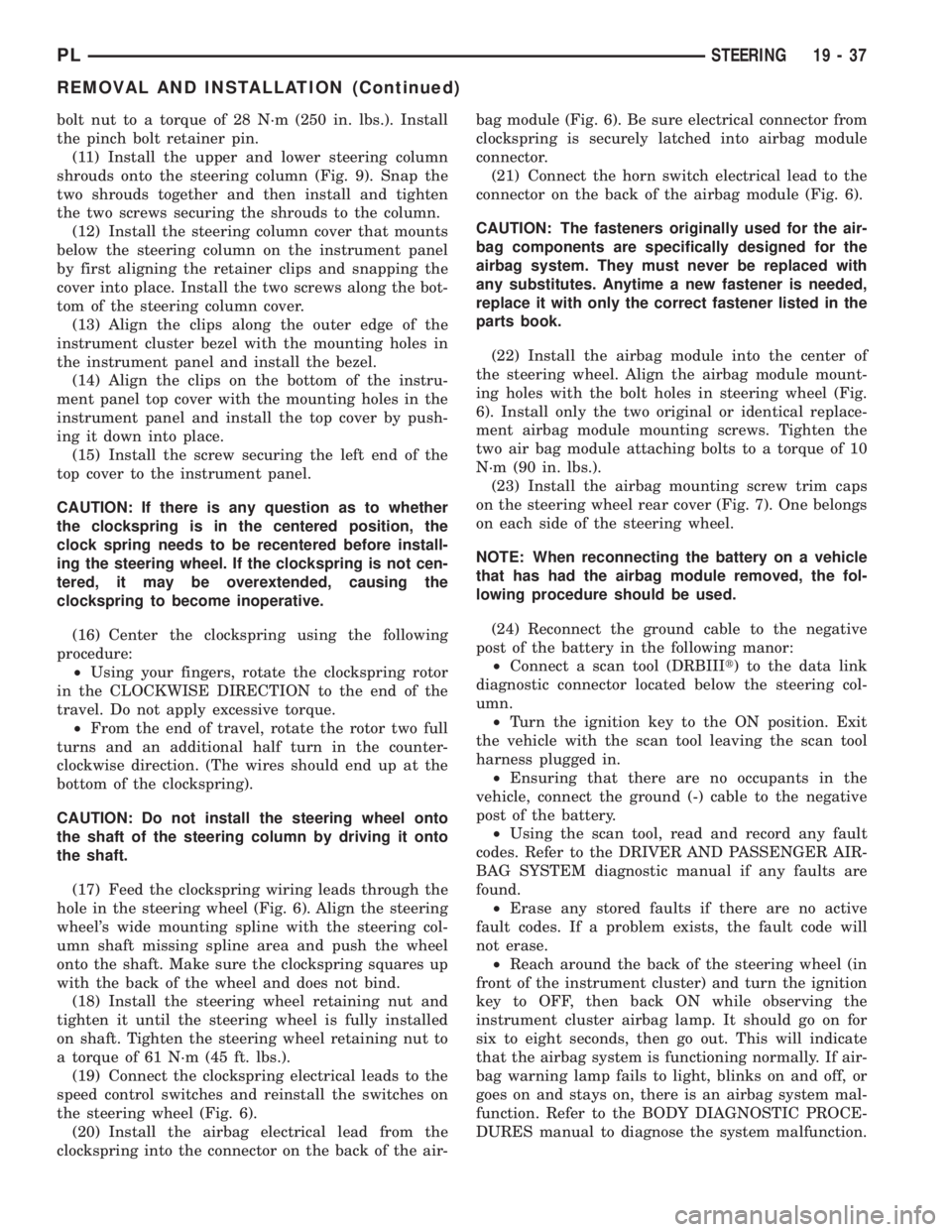

(1) Place the steering wheel in the STRAIGHT-

AHEAD position. Using a steering wheel holder, lock

the steering wheel in place to keep it from rotating

(Fig. 21). This keeps the clockspring in the proper

orientation.

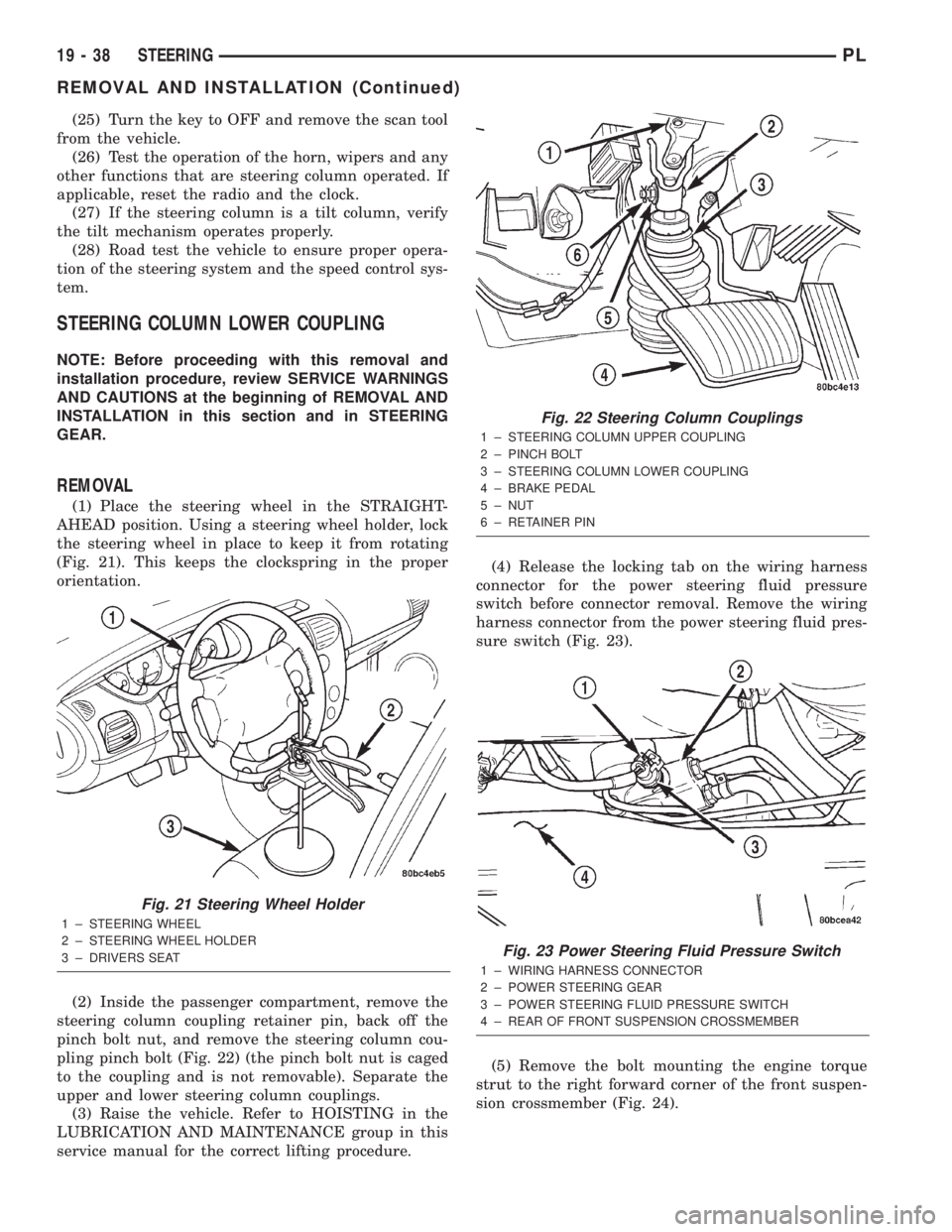

(2) Inside the passenger compartment, remove the

steering column coupling retainer pin, back off the

pinch bolt nut, and remove the steering column cou-

pling pinch bolt (Fig. 22) (the pinch bolt nut is caged

to the coupling and is not removable). Separate the

upper and lower steering column couplings.

(3) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

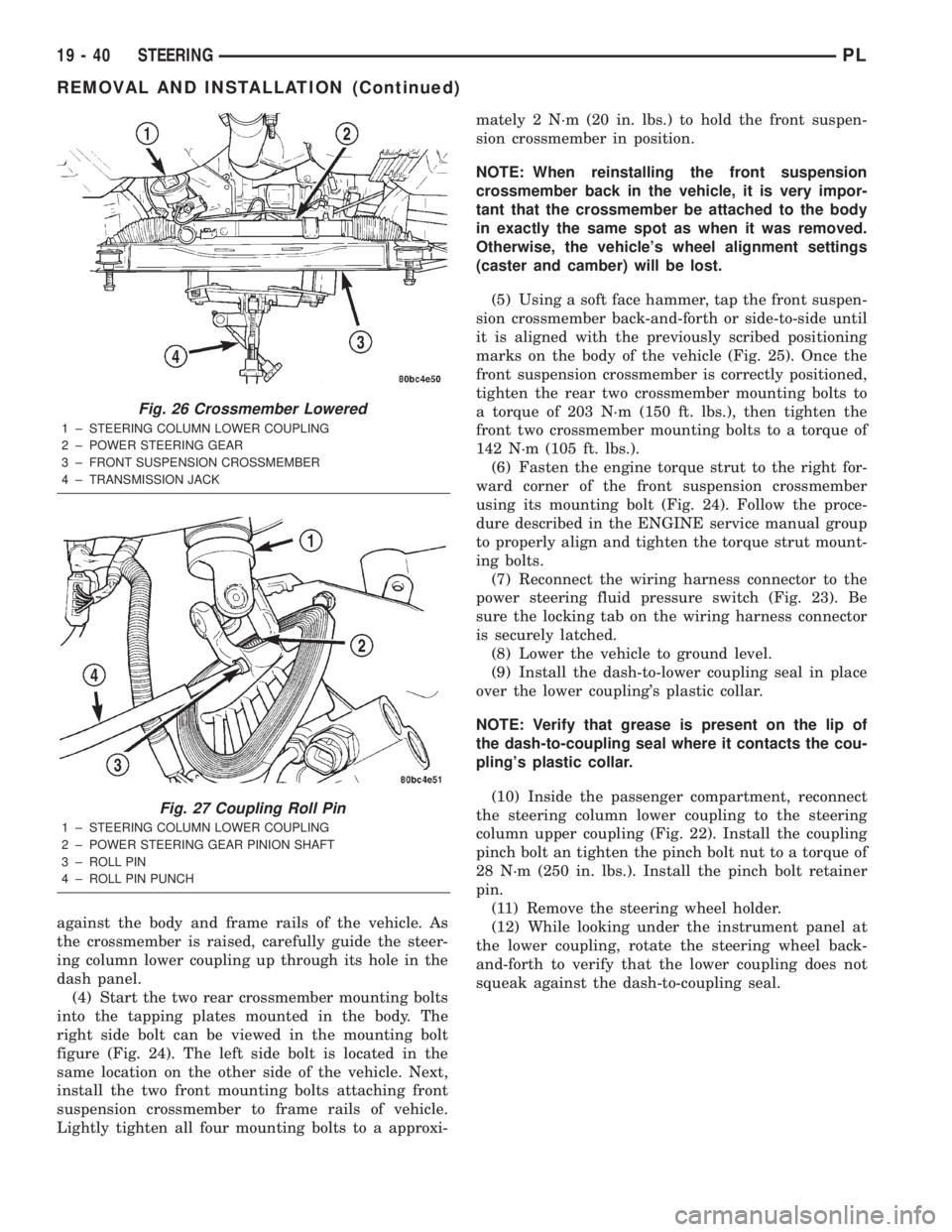

service manual for the correct lifting procedure.(4) Release the locking tab on the wiring harness

connector for the power steering fluid pressure

switch before connector removal. Remove the wiring

harness connector from the power steering fluid pres-

sure switch (Fig. 23).

(5) Remove the bolt mounting the engine torque

strut to the right forward corner of the front suspen-

sion crossmember (Fig. 24).

Fig. 21 Steering Wheel Holder

1 ± STEERING WHEEL

2 ± STEERING WHEEL HOLDER

3 ± DRIVERS SEAT

Fig. 22 Steering Column Couplings

1 ± STEERING COLUMN UPPER COUPLING

2 ± PINCH BOLT

3 ± STEERING COLUMN LOWER COUPLING

4 ± BRAKE PEDAL

5 ± NUT

6 ± RETAINER PIN

Fig. 23 Power Steering Fluid Pressure Switch

1 ± WIRING HARNESS CONNECTOR

2 ± POWER STEERING GEAR

3 ± POWER STEERING FLUID PRESSURE SWITCH

4 ± REAR OF FRONT SUSPENSION CROSSMEMBER

19 - 38 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 911 of 1285

against the body and frame rails of the vehicle. As

the crossmember is raised, carefully guide the steer-

ing column lower coupling up through its hole in the

dash panel.

(4) Start the two rear crossmember mounting bolts

into the tapping plates mounted in the body. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 24). The left side bolt is located in the

same location on the other side of the vehicle. Next,

install the two front mounting bolts attaching front

suspension crossmember to frame rails of vehicle.

Lightly tighten all four mounting bolts to a approxi-mately 2 N´m (20 in. lbs.) to hold the front suspen-

sion crossmember in position.

NOTE: When reinstalling the front suspension

crossmember back in the vehicle, it is very impor-

tant that the crossmember be attached to the body

in exactly the same spot as when it was removed.

Otherwise, the vehicle's wheel alignment settings

(caster and camber) will be lost.

(5) Using a soft face hammer, tap the front suspen-

sion crossmember back-and-forth or side-to-side until

it is aligned with the previously scribed positioning

marks on the body of the vehicle (Fig. 25). Once the

front suspension crossmember is correctly positioned,

tighten the rear two crossmember mounting bolts to

a torque of 203 N´m (150 ft. lbs.), then tighten the

front two crossmember mounting bolts to a torque of

142 N´m (105 ft. lbs.).

(6) Fasten the engine torque strut to the right for-

ward corner of the front suspension crossmember

using its mounting bolt (Fig. 24). Follow the proce-

dure described in the ENGINE service manual group

to properly align and tighten the torque strut mount-

ing bolts.

(7) Reconnect the wiring harness connector to the

power steering fluid pressure switch (Fig. 23). Be

sure the locking tab on the wiring harness connector

is securely latched.

(8) Lower the vehicle to ground level.

(9) Install the dash-to-lower coupling seal in place

over the lower coupling's plastic collar.

NOTE: Verify that grease is present on the lip of

the dash-to-coupling seal where it contacts the cou-

pling's plastic collar.

(10) Inside the passenger compartment, reconnect

the steering column lower coupling to the steering

column upper coupling (Fig. 22). Install the coupling

pinch bolt an tighten the pinch bolt nut to a torque of

28 N´m (250 in. lbs.). Install the pinch bolt retainer

pin.

(11) Remove the steering wheel holder.

(12) While looking under the instrument panel at

the lower coupling, rotate the steering wheel back-

and-forth to verify that the lower coupling does not

squeak against the dash-to-coupling seal.

Fig. 26 Crossmember Lowered

1 ± STEERING COLUMN LOWER COUPLING

2 ± POWER STEERING GEAR

3 ± FRONT SUSPENSION CROSSMEMBER

4 ± TRANSMISSION JACK

Fig. 27 Coupling Roll Pin

1 ± STEERING COLUMN LOWER COUPLING

2 ± POWER STEERING GEAR PINION SHAFT

3 ± ROLL PIN

4 ± ROLL PIN PUNCH

19 - 40 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 914 of 1285

TRANSAXLE

TABLE OF CONTENTS

page page

NV T350 (A-578) MANUAL TRANSAXLE........ 131TH AUTOMATIC TRANSAXLE.............. 54

NV T350 (A-578) MANUAL TRANSAXLE

TABLE OF CONTENTS

page page

GENERAL INFORMATION

NV T350 (A578) MANUAL TRANSAXLE.........1

TRANSAXLE IDENTIFICATION................2

FLUID REQUIREMENTS....................2

SPECIAL ADDITIVES.......................2

SEALANTS..............................2

GEAR RATIOS............................2

GEARSHIFT PATTERN......................3

DIAGNOSIS AND TESTING

COMMON PROBLEM CAUSES...............3

HARD SHIFTING..........................3

NOISY OPERATION........................3

SLIPS OUT OF GEAR......................3

LOW LUBRICANT LEVEL....................4

FLUID LEAKS............................4

CLUTCH PROBLEMS.......................4

SERVICE PROCEDURES

FLUID DRAIN AND FILL.....................4

REMOVAL AND INSTALLATION

GEARSHIFT KNOB........................4

GEARSHIFT BOOT........................5

GEARSHIFT CABLE ASSEMBLY..............6

GEARSHIFT MECHANISM REPLACEMENT......9

VEHICLE SPEED SENSOR AND DRIVE

PINION...............................11

BACK-UP LAMP SWITCH...................12CROSSOVER LEVER......................12

SELECTOR LEVER.......................12

AXLE SHAFT SEALS......................13

SHIFT SHAFT SEALS......................13

TRANSAXLE............................14

DISASSEMBLY AND ASSEMBLY

TRANSAXLE............................18

INPUT SHAFT...........................31

OUTPUT SHAFT.........................36

DIFFERENTIAL..........................36

SYNCHRONIZER.........................41

SHIFT RAILS OVERHAUL..................42

TRANSAXLE CASE OVERHAUL..............42

CLEANING AND INSPECTION

TRANSAXLE............................48

SYNCHRONIZER.........................48

ADJUSTMENTS

GEARSHIFT CROSSOVER CABLE...........49

BEARING ADJUSTMENT PROCEDURE........50

DIFFERENTIAL BEARING PRELOAD

ADJUSTMENT..........................50

SPECIFICATIONS

NV T350 (A-578) SPECIFICATIONS...........51

SPECIAL TOOLS

NV T350 (A-578) MANUAL TRANSAXLE........52

GENERAL INFORMATION

NV T350 (A578) MANUAL TRANSAXLE

The NV T350 (A-578) transaxle is a fully synchro-

nized (except reverse), constant-mesh transaxle. The

transaxle case is constructed of die-cast aluminum,

and is a two-piece design (bell housing case half and

rear housing case half) with a steel end plate bearing

cover. All forward gears are in constant-mesh witheach other, which eliminates the need to move gears

together for engagement. This feature improves

response and eliminates gear ªclashº noises. The

reverse idler gear is supported and rotates on a spin-

dle idler shaft. Depending on application, a reverse

gear brake/blocking ring is available on some units

for shifting ease.

The NV T350 (A-578) transaxle also incorporates an

open differential, which converts power from the output

shaft pinion gear to the differential ring gear. The dif-

PLTRANSAXLE 21 - 1

Page 917 of 1285

LOW LUBRICANT LEVEL

Insufficient transaxle lubricant is usually the

result of leaks, or inaccurate fluid level check or refill

method. Leakage is evident by the presence of oil

around the leak point. If leakage is not evident, the

condition is probably the result of an underfill.

If air±powered lubrication equipment is used to fill

a transaxle, be sure the equipment is properly cali-

brated. Equipment out of calibration can lead to an

underfill condition.

FLUID LEAKS

Fluid leaks can occur around the input shaft seal,

axleshaft seals, case split lines, and the end cover. Be

careful not to misdiagnose an input shaft seal leak

for an engine rear main seal leak. Also, the transaxle

case sealer (split line) will accumulate dirt and look

like an oil leak.

CLUTCH PROBLEMS

Worn, damaged, or misaligned clutch components

can cause difficult shifting, gear clash, and noise.

A worn or damaged clutch disc, pressure plate, or

release bearing can cause hard shifting and gear

clash.

SERVICE PROCEDURES

FLUID DRAIN AND FILL

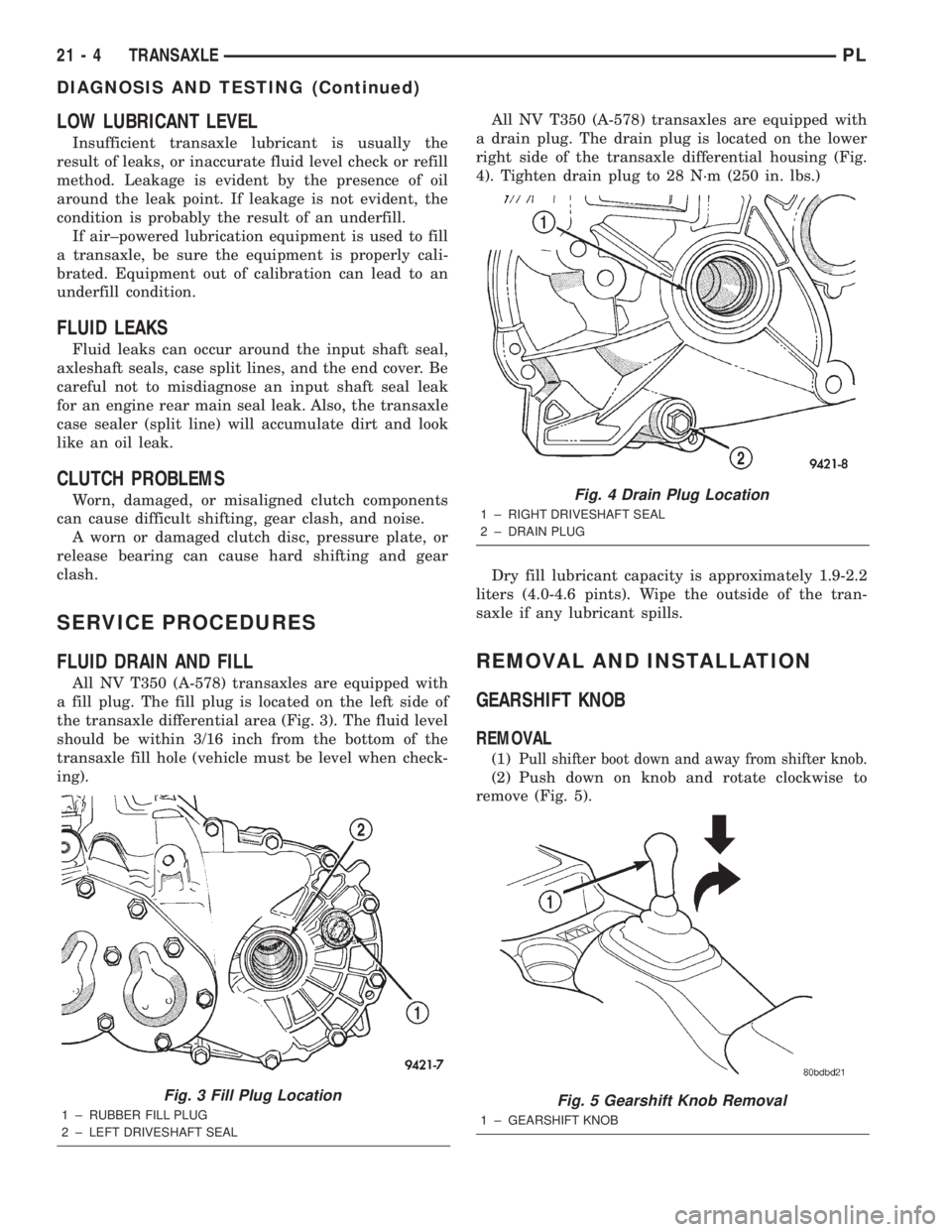

All NV T350 (A-578) transaxles are equipped with

a fill plug. The fill plug is located on the left side of

the transaxle differential area (Fig. 3). The fluid level

should be within 3/16 inch from the bottom of the

transaxle fill hole (vehicle must be level when check-

ing).All NV T350 (A-578) transaxles are equipped with

a drain plug. The drain plug is located on the lower

right side of the transaxle differential housing (Fig.

4). Tighten drain plug to 28 N´m (250 in. lbs.)

Dry fill lubricant capacity is approximately 1.9-2.2

liters (4.0-4.6 pints). Wipe the outside of the tran-

saxle if any lubricant spills.

REMOVAL AND INSTALLATION

GEARSHIFT KNOB

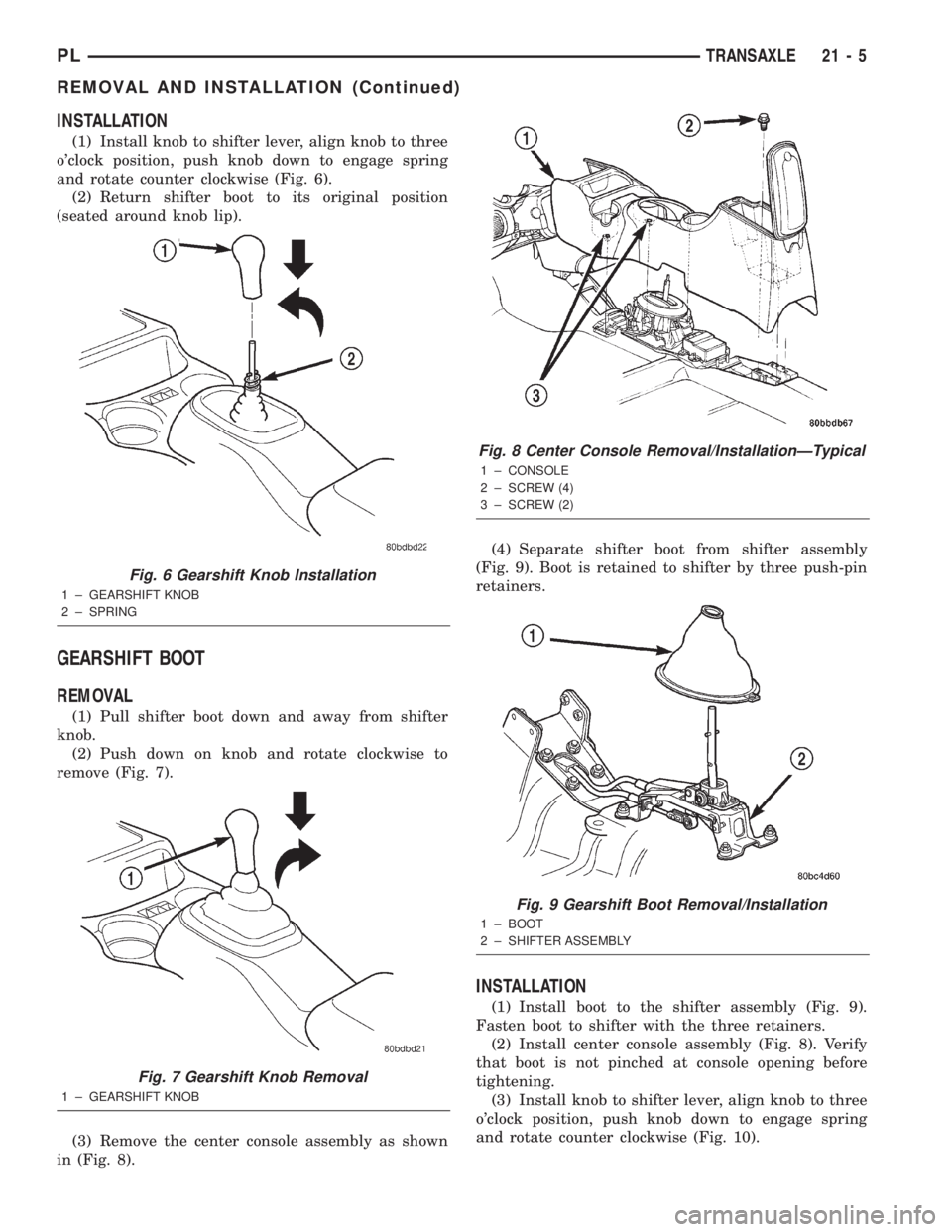

REMOVAL

(1)Pull shifter boot down and away from shifter knob.

(2) Push down on knob and rotate clockwise to

remove (Fig. 5).

Fig. 3 Fill Plug Location

1 ± RUBBER FILL PLUG

2 ± LEFT DRIVESHAFT SEAL

Fig. 4 Drain Plug Location

1 ± RIGHT DRIVESHAFT SEAL

2 ± DRAIN PLUG

Fig. 5 Gearshift Knob Removal

1 ± GEARSHIFT KNOB

21 - 4 TRANSAXLEPL

DIAGNOSIS AND TESTING (Continued)

Page 918 of 1285

INSTALLATION

(1) Install knob to shifter lever, align knob to three

o'clock position, push knob down to engage spring

and rotate counter clockwise (Fig. 6).

(2) Return shifter boot to its original position

(seated around knob lip).

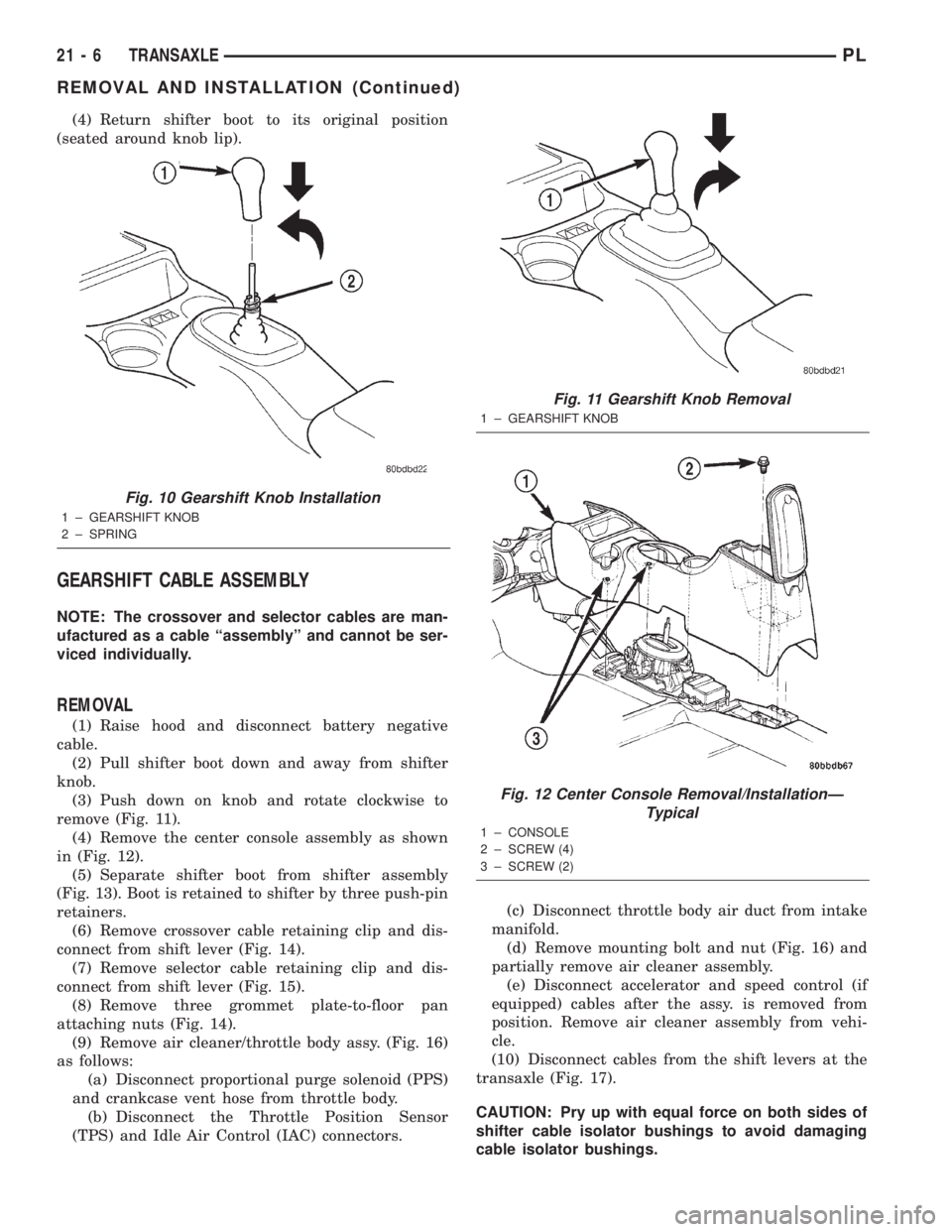

GEARSHIFT BOOT

REMOVAL

(1) Pull shifter boot down and away from shifter

knob.

(2) Push down on knob and rotate clockwise to

remove (Fig. 7).

(3) Remove the center console assembly as shown

in (Fig. 8).(4) Separate shifter boot from shifter assembly

(Fig. 9). Boot is retained to shifter by three push-pin

retainers.

INSTALLATION

(1) Install boot to the shifter assembly (Fig. 9).

Fasten boot to shifter with the three retainers.

(2) Install center console assembly (Fig. 8). Verify

that boot is not pinched at console opening before

tightening.

(3) Install knob to shifter lever, align knob to three

o'clock position, push knob down to engage spring

and rotate counter clockwise (Fig. 10).

Fig. 6 Gearshift Knob Installation

1 ± GEARSHIFT KNOB

2 ± SPRING

Fig. 7 Gearshift Knob Removal

1 ± GEARSHIFT KNOB

Fig. 8 Center Console Removal/InstallationÐTypical

1 ± CONSOLE

2 ± SCREW (4)

3 ± SCREW (2)

Fig. 9 Gearshift Boot Removal/Installation

1 ± BOOT

2 ± SHIFTER ASSEMBLY

PLTRANSAXLE 21 - 5

REMOVAL AND INSTALLATION (Continued)

Page 919 of 1285

(4) Return shifter boot to its original position

(seated around knob lip).

GEARSHIFT CABLE ASSEMBLY

NOTE: The crossover and selector cables are man-

ufactured as a cable ªassemblyº and cannot be ser-

viced individually.

REMOVAL

(1) Raise hood and disconnect battery negative

cable.

(2) Pull shifter boot down and away from shifter

knob.

(3) Push down on knob and rotate clockwise to

remove (Fig. 11).

(4) Remove the center console assembly as shown

in (Fig. 12).

(5) Separate shifter boot from shifter assembly

(Fig. 13). Boot is retained to shifter by three push-pin

retainers.

(6) Remove crossover cable retaining clip and dis-

connect from shift lever (Fig. 14).

(7) Remove selector cable retaining clip and dis-

connect from shift lever (Fig. 15).

(8) Remove three grommet plate-to-floor pan

attaching nuts (Fig. 14).

(9) Remove air cleaner/throttle body assy. (Fig. 16)

as follows:

(a) Disconnect proportional purge solenoid (PPS)

and crankcase vent hose from throttle body.

(b) Disconnect the Throttle Position Sensor

(TPS) and Idle Air Control (IAC) connectors.(c) Disconnect throttle body air duct from intake

manifold.

(d) Remove mounting bolt and nut (Fig. 16) and

partially remove air cleaner assembly.

(e) Disconnect accelerator and speed control (if

equipped) cables after the assy. is removed from

position. Remove air cleaner assembly from vehi-

cle.

(10) Disconnect cables from the shift levers at the

transaxle (Fig. 17).

CAUTION: Pry up with equal force on both sides of

shifter cable isolator bushings to avoid damaging

cable isolator bushings.

Fig. 10 Gearshift Knob Installation

1 ± GEARSHIFT KNOB

2 ± SPRING

Fig. 11 Gearshift Knob Removal

1 ± GEARSHIFT KNOB

Fig. 12 Center Console Removal/InstallationÐ

Typical

1 ± CONSOLE

2 ± SCREW (4)

3 ± SCREW (2)

21 - 6 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 921 of 1285

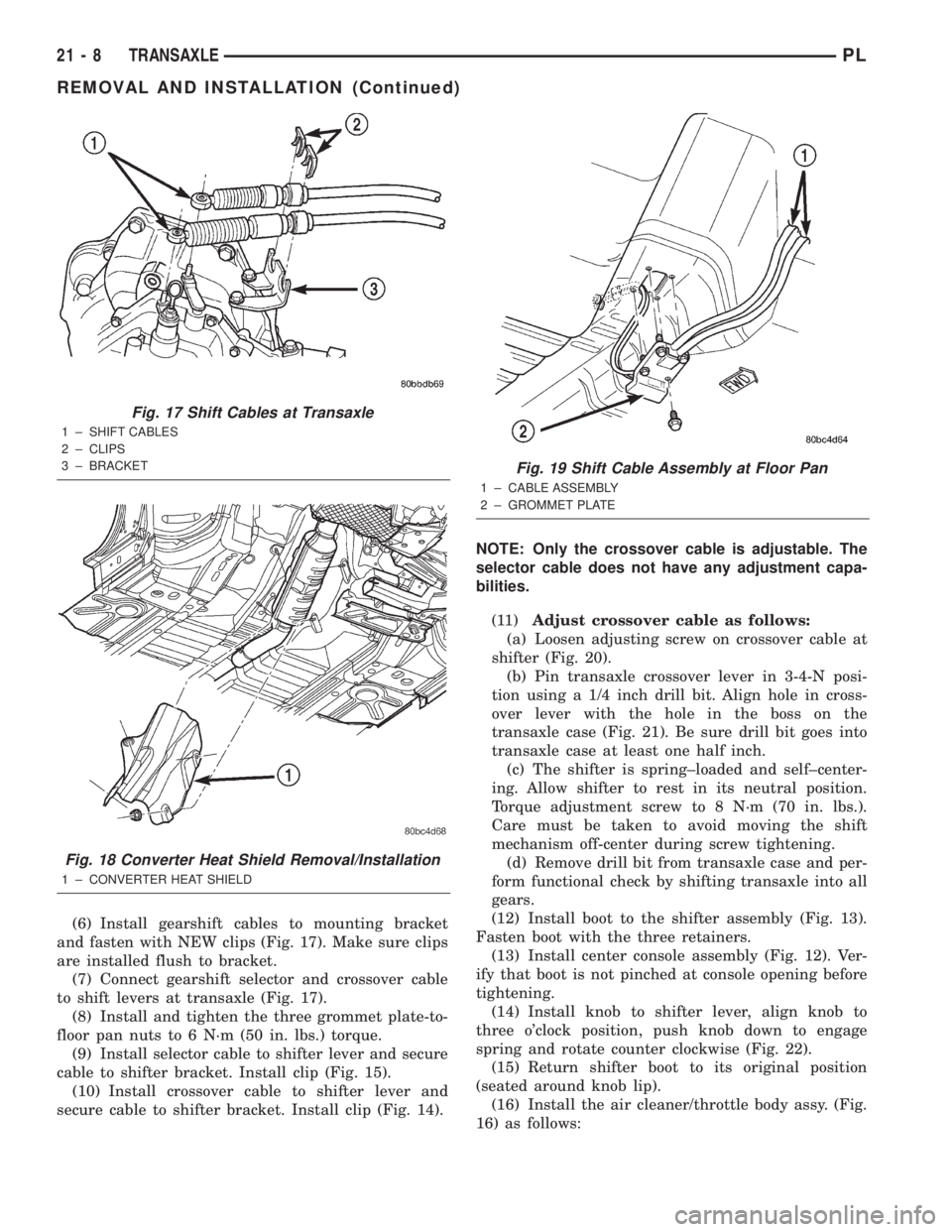

(6) Install gearshift cables to mounting bracket

and fasten with NEW clips (Fig. 17). Make sure clips

are installed flush to bracket.

(7) Connect gearshift selector and crossover cable

to shift levers at transaxle (Fig. 17).

(8) Install and tighten the three grommet plate-to-

floor pan nuts to 6 N´m (50 in. lbs.) torque.

(9) Install selector cable to shifter lever and secure

cable to shifter bracket. Install clip (Fig. 15).

(10) Install crossover cable to shifter lever and

secure cable to shifter bracket. Install clip (Fig. 14).NOTE: Only the crossover cable is adjustable. The

selector cable does not have any adjustment capa-

bilities.

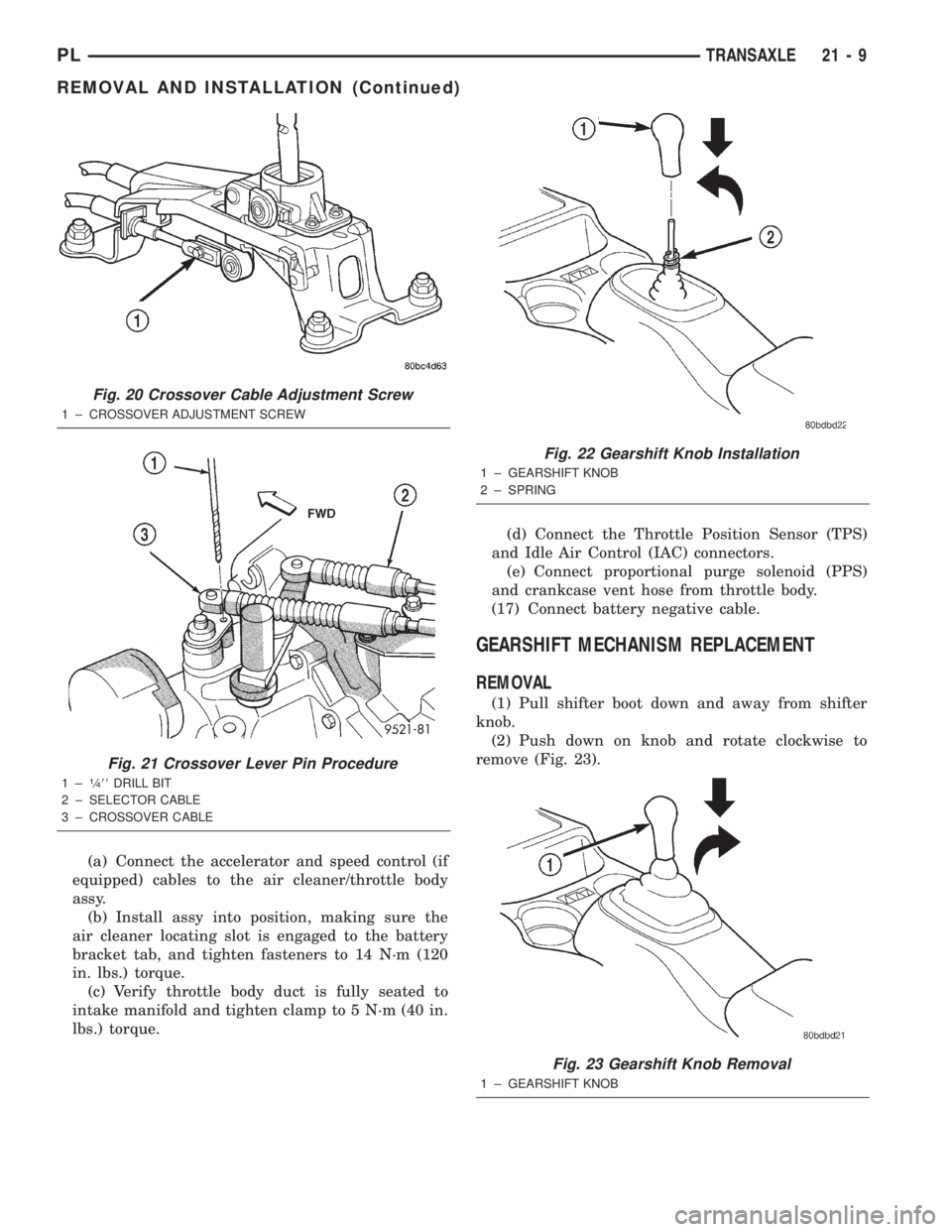

(11)Adjust crossover cable as follows:

(a) Loosen adjusting screw on crossover cable at

shifter (Fig. 20).

(b) Pin transaxle crossover lever in 3-4-N posi-

tion using a 1/4 inch drill bit. Align hole in cross-

over lever with the hole in the boss on the

transaxle case (Fig. 21). Be sure drill bit goes into

transaxle case at least one half inch.

(c) The shifter is spring±loaded and self±center-

ing. Allow shifter to rest in its neutral position.

Torque adjustment screw to 8 N´m (70 in. lbs.).

Care must be taken to avoid moving the shift

mechanism off-center during screw tightening.

(d) Remove drill bit from transaxle case and per-

form functional check by shifting transaxle into all

gears.

(12) Install boot to the shifter assembly (Fig. 13).

Fasten boot with the three retainers.

(13) Install center console assembly (Fig. 12). Ver-

ify that boot is not pinched at console opening before

tightening.

(14) Install knob to shifter lever, align knob to

three o'clock position, push knob down to engage

spring and rotate counter clockwise (Fig. 22).

(15) Return shifter boot to its original position

(seated around knob lip).

(16) Install the air cleaner/throttle body assy. (Fig.

16) as follows:

Fig. 17 Shift Cables at Transaxle

1 ± SHIFT CABLES

2 ± CLIPS

3 ± BRACKET

Fig. 18 Converter Heat Shield Removal/Installation

1 ± CONVERTER HEAT SHIELD

Fig. 19 Shift Cable Assembly at Floor Pan

1 ± CABLE ASSEMBLY

2 ± GROMMET PLATE

21 - 8 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 922 of 1285

(a) Connect the accelerator and speed control (if

equipped) cables to the air cleaner/throttle body

assy.

(b) Install assy into position, making sure the

air cleaner locating slot is engaged to the battery

bracket tab, and tighten fasteners to 14 N´m (120

in. lbs.) torque.

(c) Verify throttle body duct is fully seated to

intake manifold and tighten clamp to 5 N´m (40 in.

lbs.) torque.(d) Connect the Throttle Position Sensor (TPS)

and Idle Air Control (IAC) connectors.

(e) Connect proportional purge solenoid (PPS)

and crankcase vent hose from throttle body.

(17) Connect battery negative cable.

GEARSHIFT MECHANISM REPLACEMENT

REMOVAL

(1) Pull shifter boot down and away from shifter

knob.

(2) Push down on knob and rotate clockwise to

remove (Fig. 23).

Fig. 20 Crossover Cable Adjustment Screw

1 ± CROSSOVER ADJUSTMENT SCREW

Fig. 21 Crossover Lever Pin Procedure

1±1¤488DRILL BIT

2 ± SELECTOR CABLE

3 ± CROSSOVER CABLE

Fig. 22 Gearshift Knob Installation

1 ± GEARSHIFT KNOB

2 ± SPRING

Fig. 23 Gearshift Knob Removal

1 ± GEARSHIFT KNOB

PLTRANSAXLE 21 - 9

REMOVAL AND INSTALLATION (Continued)

Page 924 of 1285

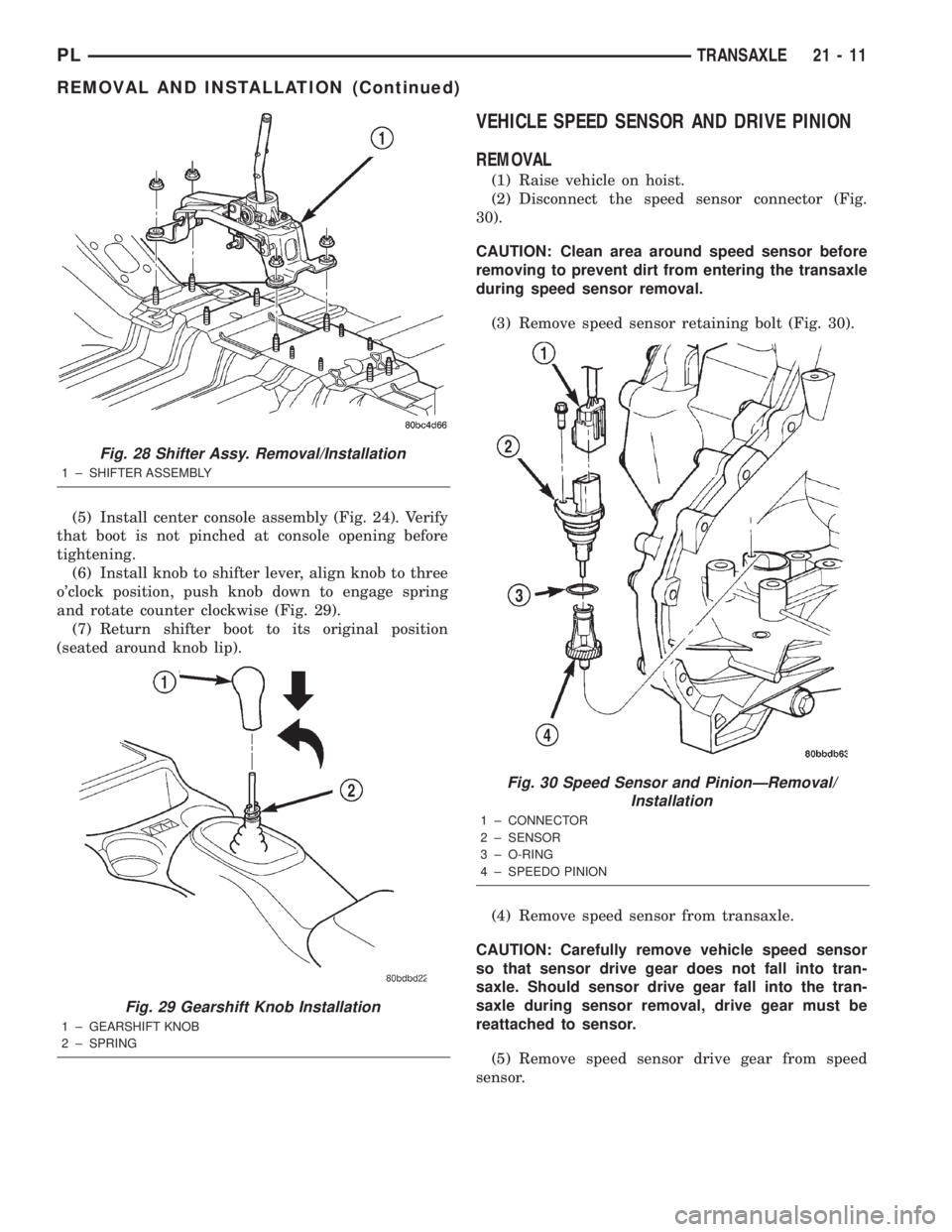

(5) Install center console assembly (Fig. 24). Verify

that boot is not pinched at console opening before

tightening.

(6) Install knob to shifter lever, align knob to three

o'clock position, push knob down to engage spring

and rotate counter clockwise (Fig. 29).

(7) Return shifter boot to its original position

(seated around knob lip).

VEHICLE SPEED SENSOR AND DRIVE PINION

REMOVAL

(1) Raise vehicle on hoist.

(2) Disconnect the speed sensor connector (Fig.

30).

CAUTION: Clean area around speed sensor before

removing to prevent dirt from entering the transaxle

during speed sensor removal.

(3) Remove speed sensor retaining bolt (Fig. 30).

(4) Remove speed sensor from transaxle.

CAUTION: Carefully remove vehicle speed sensor

so that sensor drive gear does not fall into tran-

saxle. Should sensor drive gear fall into the tran-

saxle during sensor removal, drive gear must be

reattached to sensor.

(5) Remove speed sensor drive gear from speed

sensor.

Fig. 28 Shifter Assy. Removal/Installation

1 ± SHIFTER ASSEMBLY

Fig. 29 Gearshift Knob Installation

1 ± GEARSHIFT KNOB

2 ± SPRING

Fig. 30 Speed Sensor and PinionÐRemoval/

Installation

1 ± CONNECTOR

2 ± SENSOR

3 ± O-RING

4 ± SPEEDO PINION

PLTRANSAXLE 21 - 11

REMOVAL AND INSTALLATION (Continued)