clock DODGE NEON 2000 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 532 of 1285

8W-43 AIRBAG SYSTEM

Component Page

Airbag Control Module..............8W-43-2, 3

Clockspring.........................8W-43-3

Data Link Connector.................8W-43-2

Driver Airbag.......................8W-43-3

Fuse 5 (FB).........................8W-43-2

Fuse 8 (FB).........................8W-43-2

Fuse 9 (FB).........................8W-43-2

Fuse 10 (FB)........................8W-43-2Component Page

Fuse 11 (FB)........................8W-43-2

Fuse 12 (FB)........................8W-43-2

Fuse Block.........................8W-43-2

G202..............................8W-43-2

Instrument Cluster...................8W-43-2

Passenger Airbag....................8W-43-3

Powertrain Control Module............8W-43-2

PL8W - 43 AIRBAG SYSTEM 8W - 43 - 1

Page 534 of 1285

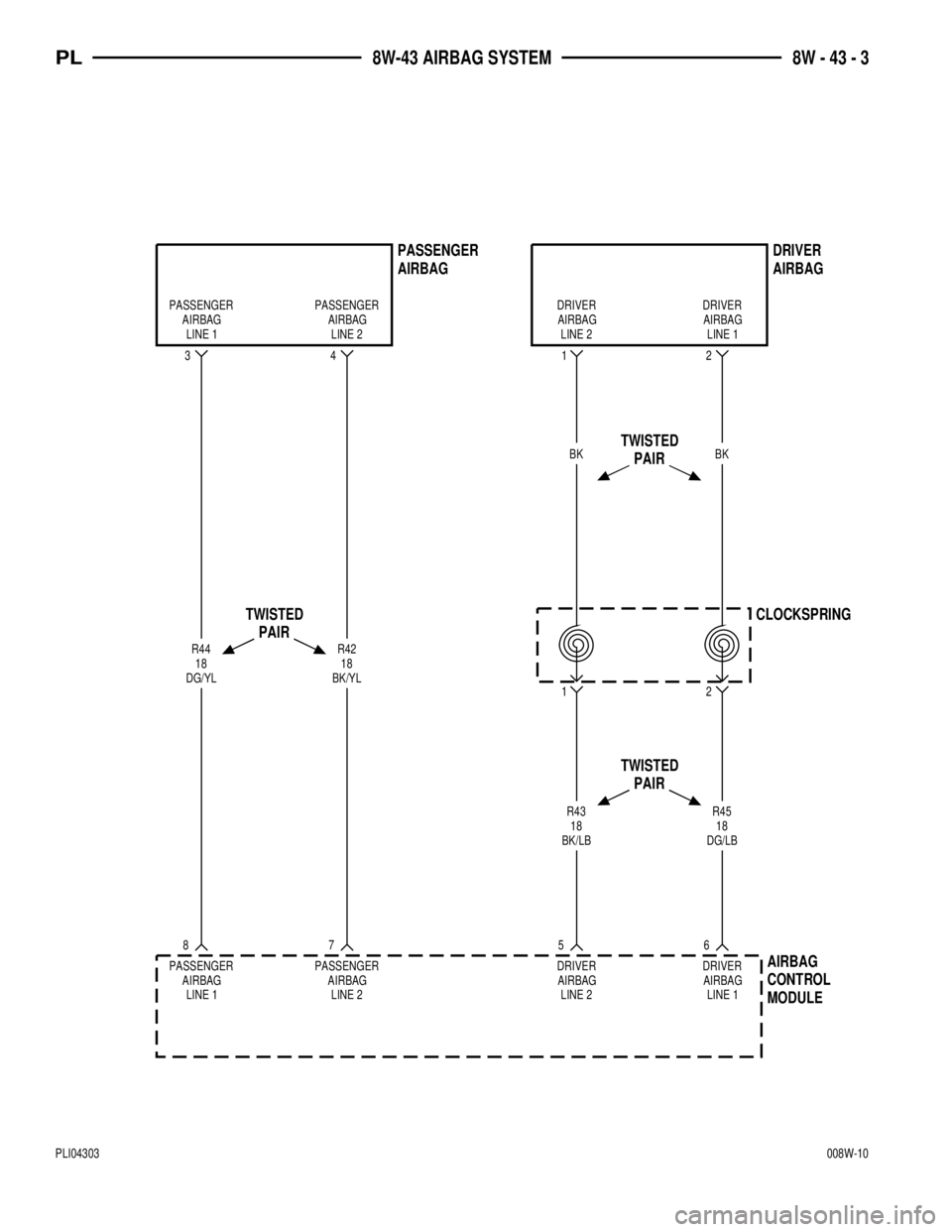

12

43

AIRBAG PASSENGER

AIRBAG DRIVER

CLOCKSPRING

8756

MODULE CONTROL

AIRBAG

PASSENGER

AIRBAG

LINE 1 LINE 2AIRBAG PASSENGER DRIVER

AIRBAG

LINE 1 LINE 2 AIRBAG DRIVER

PAIR TWISTED

PAIR TWISTED

PAIR TWISTED

PASSENGER

AIRBAG

LINE 2 LINE 1 AIRBAG PASSENGER DRIVER

AIRBAG

LINE 2 LINE 1AIRBAG DRIVER BK

R43

18

BK/LBR45

18

DG/LB

BK

R42

18

BK/YLR44

18

DG/YL

12

PL8W-43 AIRBAG SYSTEM 8W - 43 - 3

PLI04303008W-10

Page 610 of 1285

8W-80 CONNECTOR PIN-OUTS

Component Page

A/C Compressor Clutch................8W-80-4

A/C Cycling Switch...................8W-80-4

A/C Heater Blower Motor..............8W-80-4

A/C Heater Control...................8W-80-4

A/C High Pressure Switch.............8W-80-4

A/C Low Pressure Switch..............8W-80-5

Airbag Control Module................8W-80-5

Back-Up Lamp Switch................8W-80-5

Blower Motor Resistor Block...........8W-80-6

Brake Lamp Switch..................8W-80-6

Brake Shift Interlock Solenoid..........8W-80-6

Brake Warning Indicator Switch........8W-80-6

C101..............................8W-80-7

C102..............................8W-80-7

C103..............................8W-80-8

C104..............................8W-80-9

C105.............................8W-80-10

C106.............................8W-80-10

C107.............................8W-80-10

C108.............................8W-80-10

C109.............................8W-80-11

C110 .............................8W-80-11

C111 .............................8W-80-11

C201.............................8W-80-12

C202.............................8W-80-13

C203.............................8W-80-13

C204.............................8W-80-13

C205.............................8W-80-14

C301.............................8W-80-15

C302.............................8W-80-15Component Page

C303.............................8W-80-15

C304.............................8W-80-15

C305..........................8W-80-16, 17

C306.............................8W-80-17

Camshaft Position Sensor.............8W-80-18

Cargo Lamp.......................8W-80-18

Center High Mounted Stop Lamp.......8W-80-18

Center Stack Lamp..................8W-80-18

Cigar Lighter/Power Outlet............8W-80-18

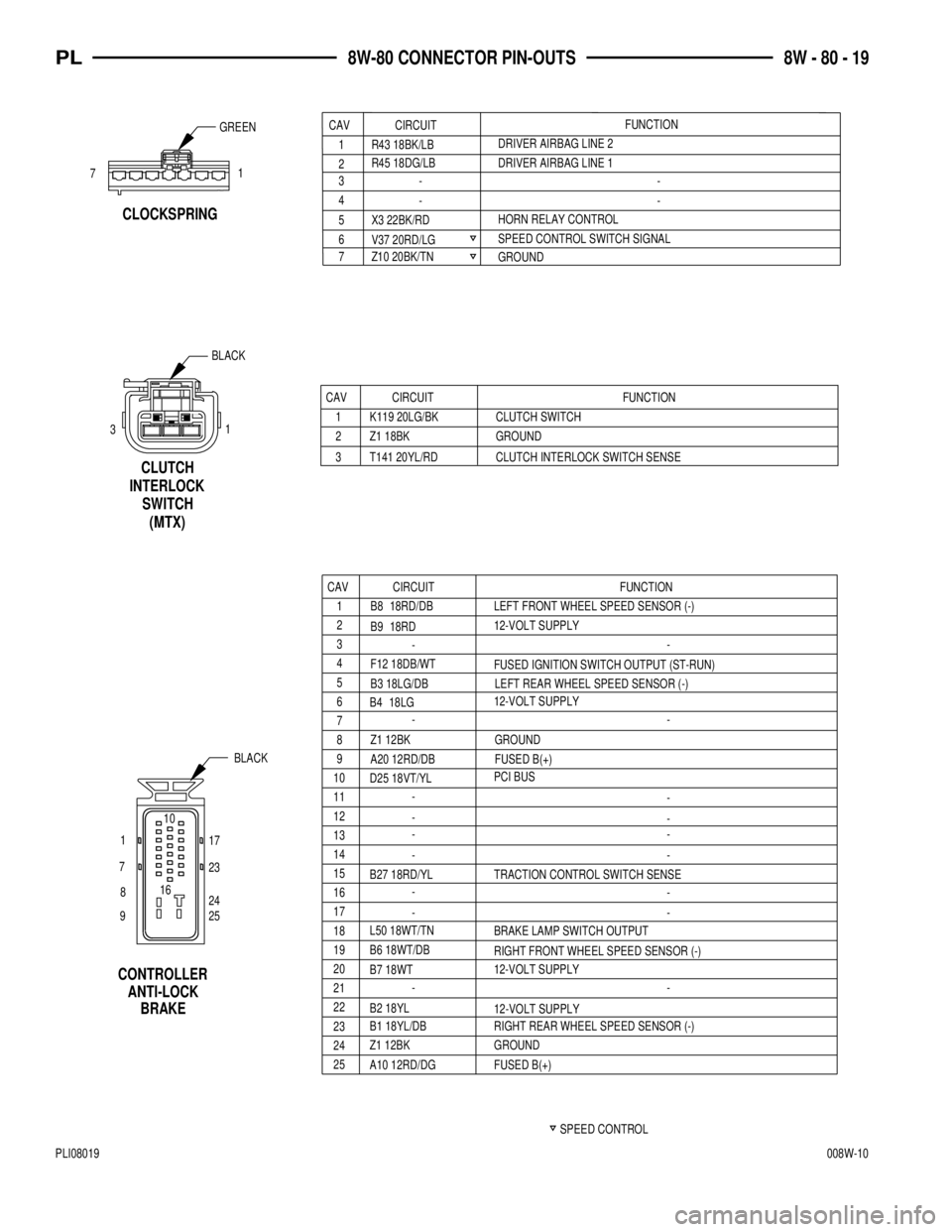

Clockspring........................8W-80-19

Clutch Interlock Switch..............8W-80-19

Controller Anti-Lock Brake............8W-80-19

Crankshaft Position Sensor............8W-80-20

Data Link Connector.................8W-80-20

Decklid Solenoid....................8W-80-20

Dome Lamp.......................8W-80-20

Dome Lamp/Intrusion Sensor..........8W-80-21

Driver Airbag......................8W-80-21

Driver Cylinder Lock Switch...........8W-80-21

Driver Door Lock Motor..............8W-80-21

Driver Door Lock Switch..............8W-80-21

Driver Power Mirror.................8W-80-22

Driver Power Window Motor...........8W-80-22

Driver Power Window Switch..........8W-80-23

Engine Coolant Temperature Sensor.....8W-80-23

Engine Oil Pressure Switch...........8W-80-24

Fuel Injector No. 1..................8W-80-24

Fuel Injector No. 2..................8W-80-24

Fuel Injector No. 3..................8W-80-24

Fuel Injector No. 4..................8W-80-24

PL8W - 80 CONNECTOR PIN-OUTS 8W - 80 - 1

Page 628 of 1285

CAV CIRCUIT FUNCTION

1 B8 18RD/DB LEFT FRONT WHEEL SPEED SENSOR (-)

2

3B9 18RD

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

CONTROLLER

ANTI-LOCK

BRAKE

BLACK

23 17 1

7

8

924

25 1610

D25 18VT/YLF12 18DB/WT

Z1 12BK GROUND

FUSED B(+) A20 12RD/DB12-VOLT SUPPLY

FUSED IGNITION SWITCH OUTPUT (ST-RUN)

PCI BUS

L50 18WT/TN

B6 18WT/DB

B7 18WT

B1 18YL/DB RIGHT REAR WHEEL SPEED SENSOR (-)

Z1 12BK GROUNDBRAKE LAMP SWITCH OUTPUT

FUSED B(+) A10 12RD/DG--

--

--

---

B3 18LG/DB

18LG B4 LEFT REAR WHEEL SPEED SENSOR (-)

12-VOLT SUPPLY

- -

B27 18RD/YL TRACTION CONTROL SWITCH SENSE

-

B2 18YL

12-VOLT SUPPLY 12-VOLT SUPPLY RIGHT FRONT WHEEL SPEED SENSOR (-)-

(MTX) SWITCH

CLUTCH INTERLOCK SWITCH SENSE T141 20YL/RD 3

1

3

INTERLOCKCLUTCH

GROUND Z1 18BK 2CLUTCH SWITCH K119 20LG/BK 1

FUNCTION CIRCUIT CAV

BLACK

-

- -

-

-

SPEED CONTROL

CLOCKSPRING5

6

7 3

4 2 1CIRCUIT CAV

1

7

X3 22BK/RD-

-

FUNCTION

DRIVER AIRBAG LINE 2

DRIVER AIRBAG LINE 1 R43 18BK/LB

R45 18DG/LB

V37 20RD/LG

Z10 20BK/TNSPEED CONTROL SWITCH SIGNAL HORN RELAY CONTROL

GROUND-

- GREEN

PL8W-80 CONNECTOR PIN-OUTS 8W - 80 - 19

PLI08019008W-10

Page 659 of 1285

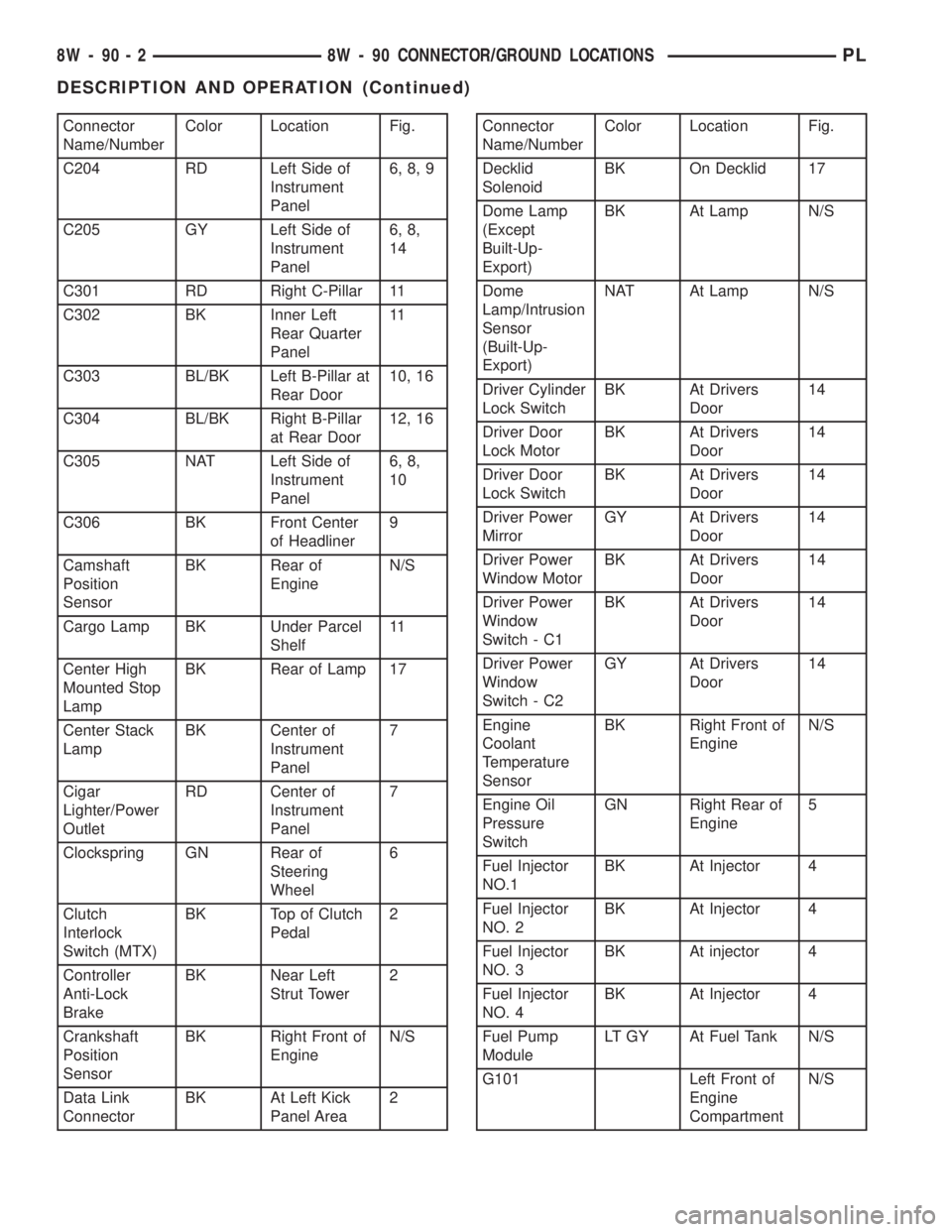

Connector

Name/NumberColor Location Fig.

C204 RD Left Side of

Instrument

Panel6, 8, 9

C205 GY Left Side of

Instrument

Panel6, 8,

14

C301 RD Right C-Pillar 11

C302 BK Inner Left

Rear Quarter

Panel11

C303 BL/BK Left B-Pillar at

Rear Door10, 16

C304 BL/BK Right B-Pillar

at Rear Door12, 16

C305 NAT Left Side of

Instrument

Panel6, 8,

10

C306 BK Front Center

of Headliner9

Camshaft

Position

SensorBK Rear of

EngineN/S

Cargo Lamp BK Under Parcel

Shelf11

Center High

Mounted Stop

LampBK Rear of Lamp 17

Center Stack

LampBK Center of

Instrument

Panel7

Cigar

Lighter/Power

OutletRD Center of

Instrument

Panel7

Clockspring GN Rear of

Steering

Wheel6

Clutch

Interlock

Switch (MTX)BK Top of Clutch

Pedal2

Controller

Anti-Lock

BrakeBK Near Left

Strut Tower2

Crankshaft

Position

SensorBK Right Front of

EngineN/S

Data Link

ConnectorBK At Left Kick

Panel Area2Connector

Name/NumberColor Location Fig.

Decklid

SolenoidBK On Decklid 17

Dome Lamp

(Except

Built-Up-

Export)BK At Lamp N/S

Dome

Lamp/Intrusion

Sensor

(Built-Up-

Export)NAT At Lamp N/S

Driver Cylinder

Lock SwitchBK At Drivers

Door14

Driver Door

Lock MotorBK At Drivers

Door14

Driver Door

Lock SwitchBK At Drivers

Door14

Driver Power

MirrorGY At Drivers

Door14

Driver Power

Window MotorBK At Drivers

Door14

Driver Power

Window

Switch - C1BK At Drivers

Door14

Driver Power

Window

Switch - C2GY At Drivers

Door14

Engine

Coolant

Temperature

SensorBK Right Front of

EngineN/S

Engine Oil

Pressure

SwitchGN Right Rear of

Engine5

Fuel Injector

NO.1BK At Injector 4

Fuel Injector

NO. 2BK At Injector 4

Fuel Injector

NO. 3BK At injector 4

Fuel Injector

NO. 4BK At Injector 4

Fuel Pump

ModuleLT GY At Fuel Tank N/S

G101 Left Front of

Engine

CompartmentN/S

8W - 90 - 2 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

Page 679 of 1285

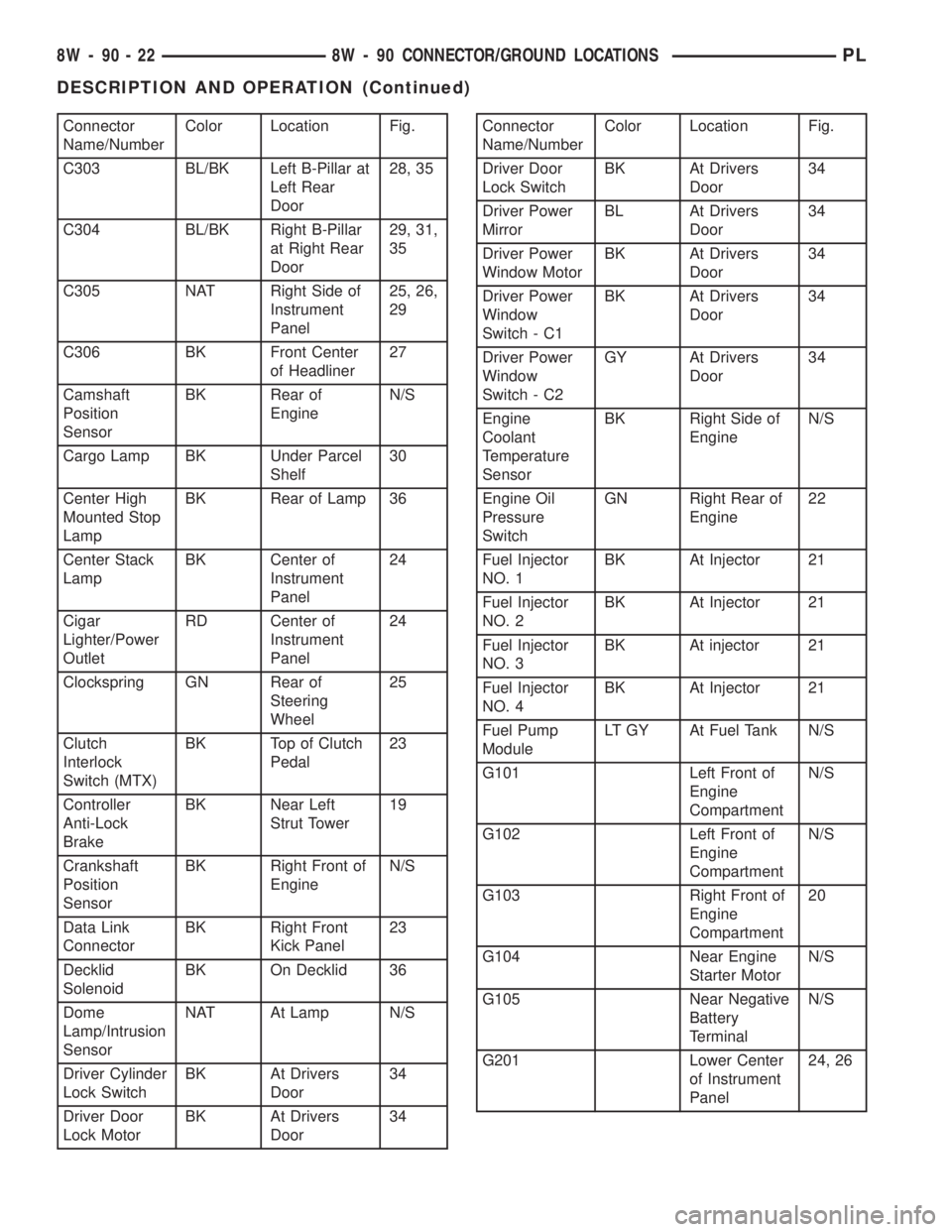

Connector

Name/NumberColor Location Fig.

C303 BL/BK Left B-Pillar at

Left Rear

Door28, 35

C304 BL/BK Right B-Pillar

at Right Rear

Door29, 31,

35

C305 NAT Right Side of

Instrument

Panel25, 26,

29

C306 BK Front Center

of Headliner27

Camshaft

Position

SensorBK Rear of

EngineN/S

Cargo Lamp BK Under Parcel

Shelf30

Center High

Mounted Stop

LampBK Rear of Lamp 36

Center Stack

LampBK Center of

Instrument

Panel24

Cigar

Lighter/Power

OutletRD Center of

Instrument

Panel24

Clockspring GN Rear of

Steering

Wheel25

Clutch

Interlock

Switch (MTX)BK Top of Clutch

Pedal23

Controller

Anti-Lock

BrakeBK Near Left

Strut Tower19

Crankshaft

Position

SensorBK Right Front of

EngineN/S

Data Link

ConnectorBK Right Front

Kick Panel23

Decklid

SolenoidBK On Decklid 36

Dome

Lamp/Intrusion

SensorNAT At Lamp N/S

Driver Cylinder

Lock SwitchBK At Drivers

Door34

Driver Door

Lock MotorBK At Drivers

Door34Connector

Name/NumberColor Location Fig.

Driver Door

Lock SwitchBK At Drivers

Door34

Driver Power

MirrorBL At Drivers

Door34

Driver Power

Window MotorBK At Drivers

Door34

Driver Power

Window

Switch - C1BK At Drivers

Door34

Driver Power

Window

Switch - C2GY At Drivers

Door34

Engine

Coolant

Temperature

SensorBK Right Side of

EngineN/S

Engine Oil

Pressure

SwitchGN Right Rear of

Engine22

Fuel Injector

NO. 1BK At Injector 21

Fuel Injector

NO. 2BK At Injector 21

Fuel Injector

NO. 3BK At injector 21

Fuel Injector

NO. 4BK At Injector 21

Fuel Pump

ModuleLT GY At Fuel Tank N/S

G101 Left Front of

Engine

CompartmentN/S

G102 Left Front of

Engine

CompartmentN/S

G103 Right Front of

Engine

Compartment20

G104 Near Engine

Starter MotorN/S

G105 Near Negative

Battery

TerminalN/S

G201 Lower Center

of Instrument

Panel24, 26

8W - 90 - 22 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

Page 767 of 1285

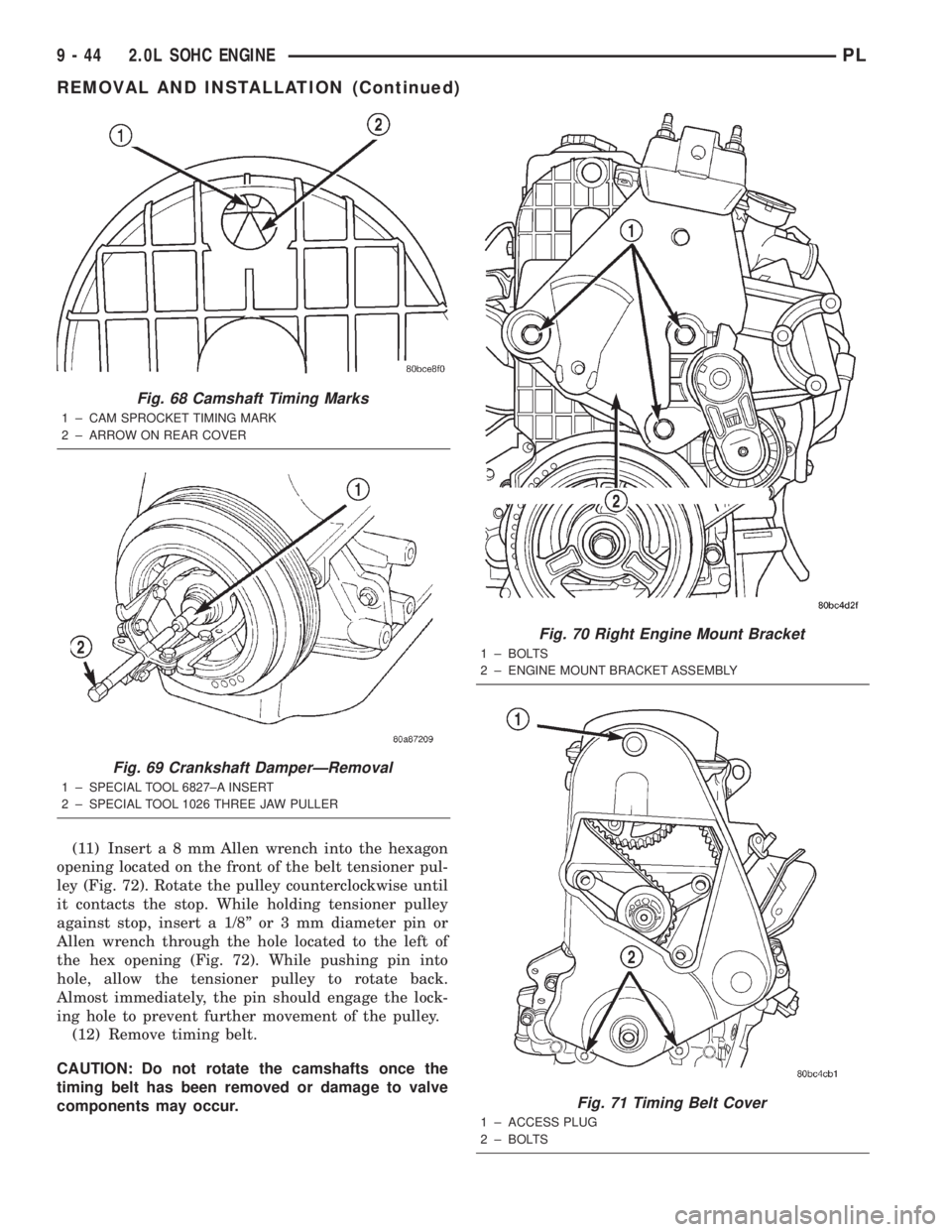

(11) Inserta8mmAllen wrench into the hexagon

opening located on the front of the belt tensioner pul-

ley (Fig. 72). Rotate the pulley counterclockwise until

it contacts the stop. While holding tensioner pulley

against stop, insert a 1/8º or 3 mm diameter pin or

Allen wrench through the hole located to the left of

the hex opening (Fig. 72). While pushing pin into

hole, allow the tensioner pulley to rotate back.

Almost immediately, the pin should engage the lock-

ing hole to prevent further movement of the pulley.

(12) Remove timing belt.

CAUTION: Do not rotate the camshafts once the

timing belt has been removed or damage to valve

components may occur.

Fig. 68 Camshaft Timing Marks

1 ± CAM SPROCKET TIMING MARK

2 ± ARROW ON REAR COVER

Fig. 69 Crankshaft DamperÐRemoval

1 ± SPECIAL TOOL 6827±A INSERT

2 ± SPECIAL TOOL 1026 THREE JAW PULLER

Fig. 70 Right Engine Mount Bracket

1 ± BOLTS

2 ± ENGINE MOUNT BRACKET ASSEMBLY

Fig. 71 Timing Belt Cover

1 ± ACCESS PLUG

2 ± BOLTS

9 - 44 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 778 of 1285

(17) Install rear timing belt cover and camshaft

sprocket.

(18) Install crankshaft sprocket, timing belt ten-

sioner, timing belt, and cover.

(19) Install front engine mount bracket.

(20) Remove engine from repair stand and position

on Special Tools 6135 and 6710 Engine Dolly and

Cradle. Install safety straps around the engine to

cradle and tighten and lock them into position.

(21) Install crankshaft rear oil seal. Refer to proce-

dure in this section.

(22) Install drive plate/flywheel. Apply Mopart

Lock & Seal Adhesive to bolt threads and tighten to

95 N´m (70 ft. lbs.).

(23) Install transaxle to engine.

(24) Install structural collar. Refer to procedure in

this section.

(25) Install engine assembly. Refer to procedure in

this section.

(26) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

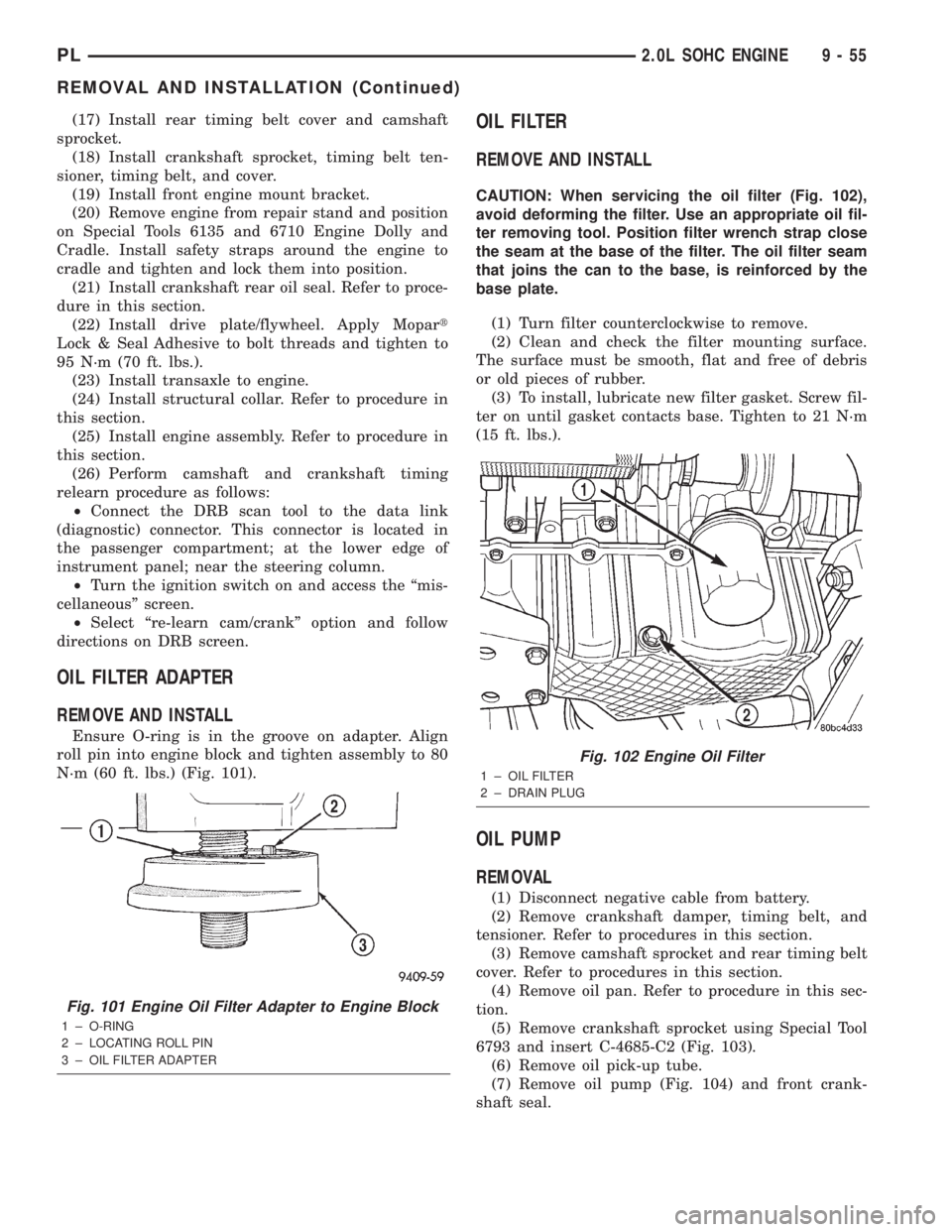

OIL FILTER ADAPTER

REMOVE AND INSTALL

Ensure O-ring is in the groove on adapter. Align

roll pin into engine block and tighten assembly to 80

N´m (60 ft. lbs.) (Fig. 101).

OIL FILTER

REMOVE AND INSTALL

CAUTION: When servicing the oil filter (Fig. 102),

avoid deforming the filter. Use an appropriate oil fil-

ter removing tool. Position filter wrench strap close

the seam at the base of the filter. The oil filter seam

that joins the can to the base, is reinforced by the

base plate.

(1) Turn filter counterclockwise to remove.

(2) Clean and check the filter mounting surface.

The surface must be smooth, flat and free of debris

or old pieces of rubber.

(3) To install, lubricate new filter gasket. Screw fil-

ter on until gasket contacts base. Tighten to 21 N´m

(15 ft. lbs.).

OIL PUMP

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove crankshaft damper, timing belt, and

tensioner. Refer to procedures in this section.

(3) Remove camshaft sprocket and rear timing belt

cover. Refer to procedures in this section.

(4) Remove oil pan. Refer to procedure in this sec-

tion.

(5) Remove crankshaft sprocket using Special Tool

6793 and insert C-4685-C2 (Fig. 103).

(6) Remove oil pick-up tube.

(7) Remove oil pump (Fig. 104) and front crank-

shaft seal.

Fig. 101 Engine Oil Filter Adapter to Engine Block

1 ± O-RING

2 ± LOCATING ROLL PIN

3 ± OIL FILTER ADAPTER

Fig. 102 Engine Oil Filter

1 ± OIL FILTER

2 ± DRAIN PLUG

PL2.0L SOHC ENGINE 9 - 55

REMOVAL AND INSTALLATION (Continued)

Page 834 of 1285

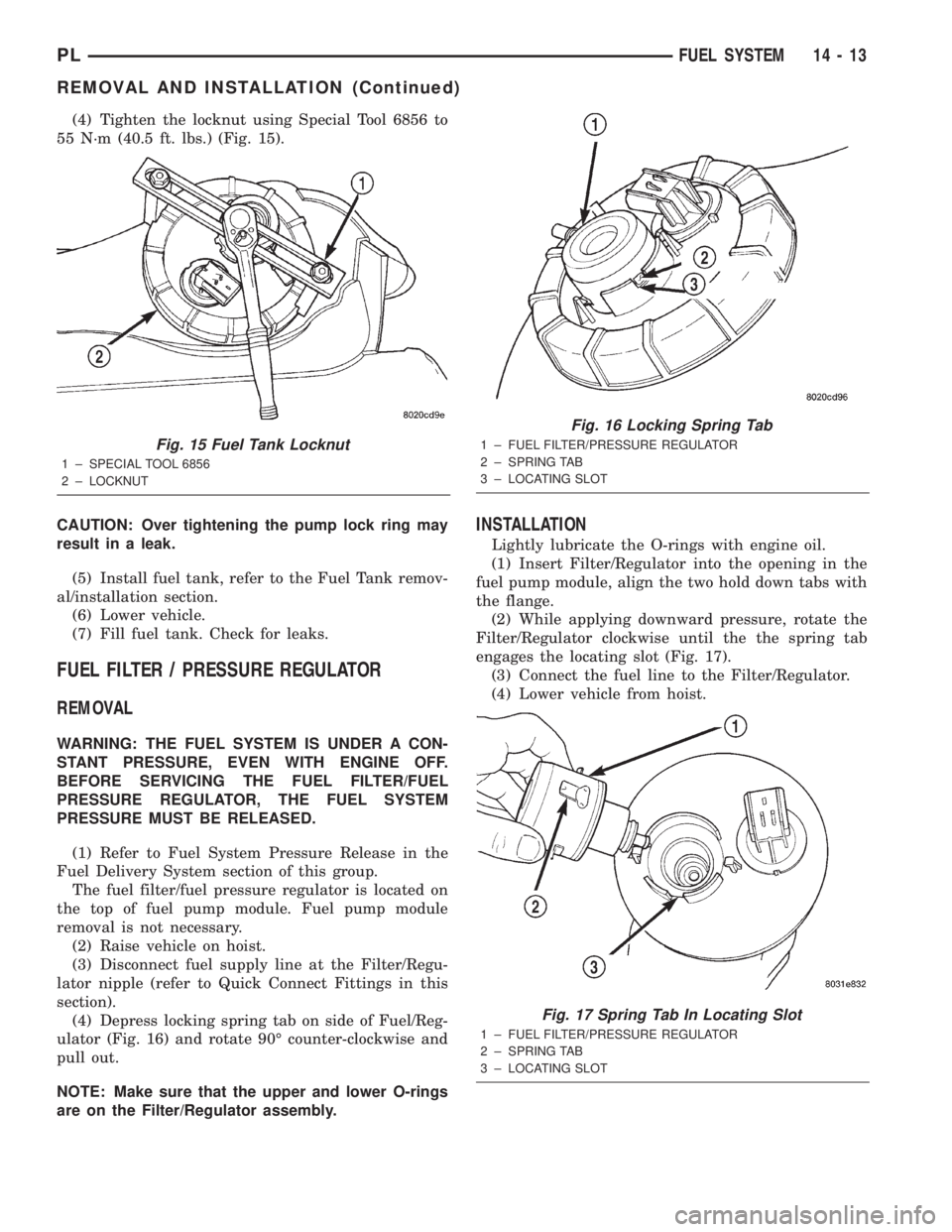

(4) Tighten the locknut using Special Tool 6856 to

55 N´m (40.5 ft. lbs.) (Fig. 15).

CAUTION: Over tightening the pump lock ring may

result in a leak.

(5) Install fuel tank, refer to the Fuel Tank remov-

al/installation section.

(6) Lower vehicle.

(7) Fill fuel tank. Check for leaks.

FUEL FILTER / PRESSURE REGULATOR

REMOVAL

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE, EVEN WITH ENGINE OFF.

BEFORE SERVICING THE FUEL FILTER/FUEL

PRESSURE REGULATOR, THE FUEL SYSTEM

PRESSURE MUST BE RELEASED.

(1) Refer to Fuel System Pressure Release in the

Fuel Delivery System section of this group.

The fuel filter/fuel pressure regulator is located on

the top of fuel pump module. Fuel pump module

removal is not necessary.

(2) Raise vehicle on hoist.

(3) Disconnect fuel supply line at the Filter/Regu-

lator nipple (refer to Quick Connect Fittings in this

section).

(4) Depress locking spring tab on side of Fuel/Reg-

ulator (Fig. 16) and rotate 90É counter-clockwise and

pull out.

NOTE: Make sure that the upper and lower O-rings

are on the Filter/Regulator assembly.

INSTALLATION

Lightly lubricate the O-rings with engine oil.

(1) Insert Filter/Regulator into the opening in the

fuel pump module, align the two hold down tabs with

the flange.

(2) While applying downward pressure, rotate the

Filter/Regulator clockwise until the the spring tab

engages the locating slot (Fig. 17).

(3) Connect the fuel line to the Filter/Regulator.

(4) Lower vehicle from hoist.

Fig. 15 Fuel Tank Locknut

1 ± SPECIAL TOOL 6856

2 ± LOCKNUT

Fig. 16 Locking Spring Tab

1 ± FUEL FILTER/PRESSURE REGULATOR

2 ± SPRING TAB

3 ± LOCATING SLOT

Fig. 17 Spring Tab In Locating Slot

1 ± FUEL FILTER/PRESSURE REGULATOR

2 ± SPRING TAB

3 ± LOCATING SLOT

PLFUEL SYSTEM 14 - 13

REMOVAL AND INSTALLATION (Continued)

Page 879 of 1285

CONDITION POSSIBLE CAUSES CORRECTION

6. Damaged, mis-positioned or

un-lubricated steering column

coupler to dash seal.**6. Replace, reposition, or lubricate dash

seal.

7. Binding upper strut bearing. 7. Disassemble strut assembly. Correct

binding condition in strut bearing or replace

bearing.

8. Tight shaft bearing in steering

column.8. Replace the steering column.

9. Excessive friction in steering

column coupling.9. Replace steering column coupling.

10. Excessive friction in power

steering gear.10. Replace power steering gear.

EXCESSIVE STEERING

WHEEL KICKBACK OR

TOO MUCH STEERING

WHEEL FREE PLAY.1. Air in the fluid of the power

steering system.1. Bleed air from system following the the

power steering pump initial operation

service procedure.*

2. Power steering gear loose on front

suspension crossmember.2. Inspect power steering gear mounting

bolts. Replace as necessary. Tighten to the

specified torque.

3. Steering column coupling worn,

broken or loose.3. Replace steering column coupling.

4. Free play in steering column. 4. Check all components of the steering

system and repair or replace as required.

5. Worn control arm ball joints. 5. Replace ball joint or control arm as

required.

6. Loose steering knuckle to ball joint

stud pinch bolt.6. Inspect pinch bolts, replace as

necessary, and tighten to specified torque.

7. Front wheel bearings loose or

worn.7. Replace wheel bearing or knuckle as

necessary.

8. Loose outer tie rod ends. 8. Replace outer tie rod ends that have

excessive free play.

9. Loose inner tie rod ends. 9. Replace power steering gear.

10 Defective steering gear rotary

valve.10. Replace power steering gear.

NOTE: * Steering shudder can be expected in new

vehicles and vehicles with recent steering system

repairs. Shudder should dissipate after the vehicle

has been driven several weeks.

NOTE: ** To evaluate this condition, it may be nec-

essary to disconnect the coupling at the base of the

steering column. Turn the steering wheel and feel or

listen for internal rubbing in steering column. To

avoid damaging the column clockspring, note thefollowing. Before disconnecting coupling, place

tires in the straight-ahead position and center steer-

ing wheel. Once disconnected, DO NOT rotate

steering wheel more than one revolution in either

direction and place steering wheel in original loca-

tion before reconnecting coupling. If this position is

lost, the steering column clockspring must be

recentered following the procedure found within the

procedure for steering column installation in the

steering column section.

19 - 8 STEERINGPL

DIAGNOSIS AND TESTING (Continued)