exhaust DODGE NEON 2000 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 854 of 1285

grammed (fixed) values and inputs from other sen-

sors.

DOWNSTREAM OXYGEN SENSOR 1/2

The Downstream O2 Sensor has two functions.

One function is measuring catalyst efficiency. This is

an OBD II requirement. The oxygen content of theexhaust gasses has significantly less fluctuation than

at the inlet if the converter is working properly. The

PCM compares upstream and Downstream O2 Sen-

sor switch rates under specific operating conditions

to determine if the catalyst is functioning properly.

The other function is a downstream fuel control

which was introduced in 1996. The upstream O2 goal

varies within the window of operation of the O2 Sen-

sor. In the past the goal was a preprogrammed fixed

value based upon where it believed the catalyst oper-

ated most efficiently.

While the Upstream O2 Sensor input is used to

maintain the 14.7:1 air/fuel ratio, variations in

engines, exhaust systems and catalytic converters

may cause this ratio to not be the most ideal for a

particular catalyst and engine. To help maintain the

catalyst operating at maximum efficiency, the PCM

will fine tune the air/fuel ratio entering the catalyst

based upon the oxygen content leaving the catalyst.

This is accomplished by modifying the Upstream O2

Sensor voltage goal.

If the exhaust leaving the catalyst has too much

oxygen (lean ) the PCM increases the upstream O2

goal which increases fuel in the mixture causing less

oxygen to be left over. Conversely, if the oxygen con-

tent leaving the catalyst has is too little oxygen (rich)

the PCM decreases the upstream O2 goal down

which removes fuel from the mixture causing more

oxygen to be left over. This function only occurs dur-

ing downstream closed loop mode operation.

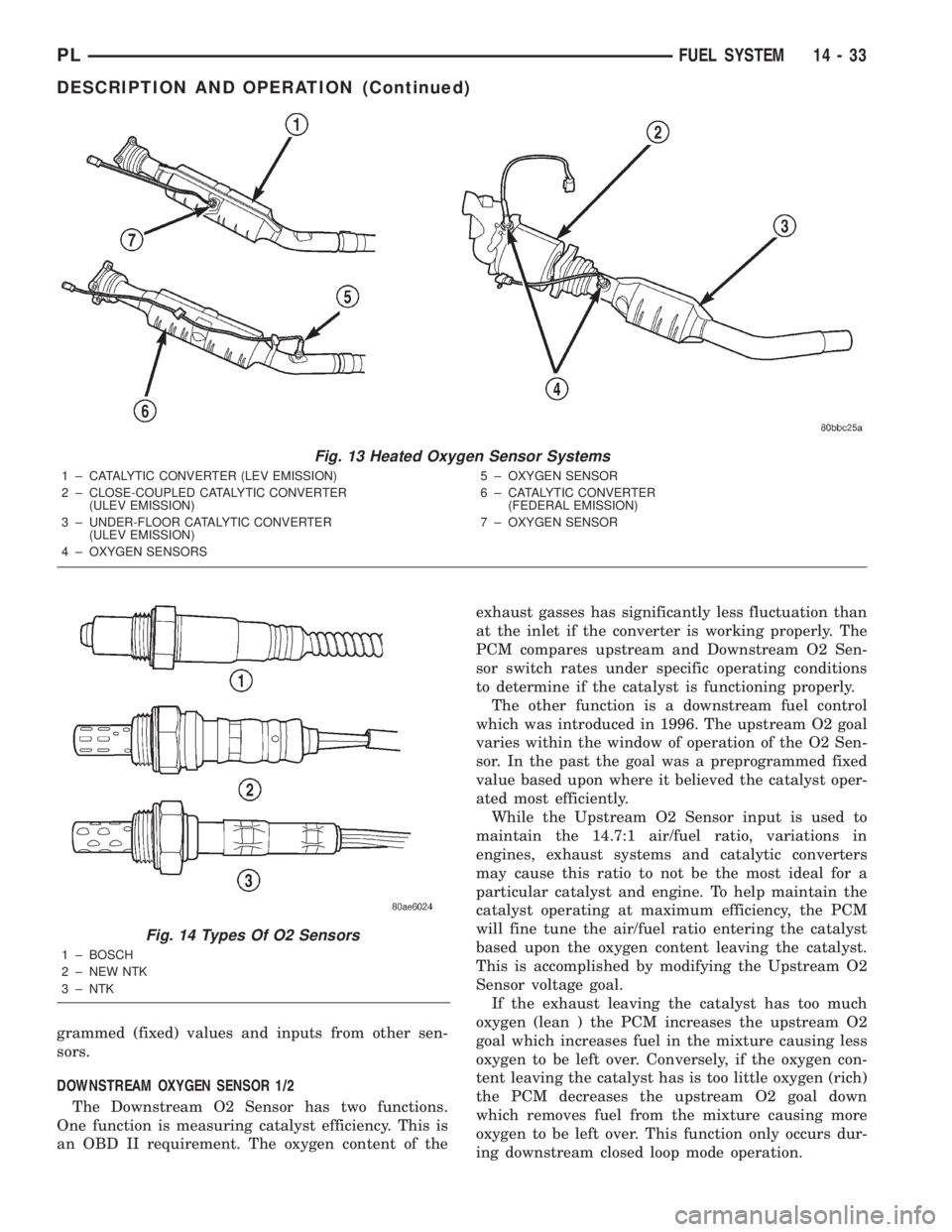

Fig. 13 Heated Oxygen Sensor Systems

1 ± CATALYTIC CONVERTER (LEV EMISSION)

2 ± CLOSE-COUPLED CATALYTIC CONVERTER

(ULEV EMISSION)

3 ± UNDER-FLOOR CATALYTIC CONVERTER

(ULEV EMISSION)

4 ± OXYGEN SENSORS5 ± OXYGEN SENSOR

6 ± CATALYTIC CONVERTER

(FEDERAL EMISSION)

7 ± OXYGEN SENSOR

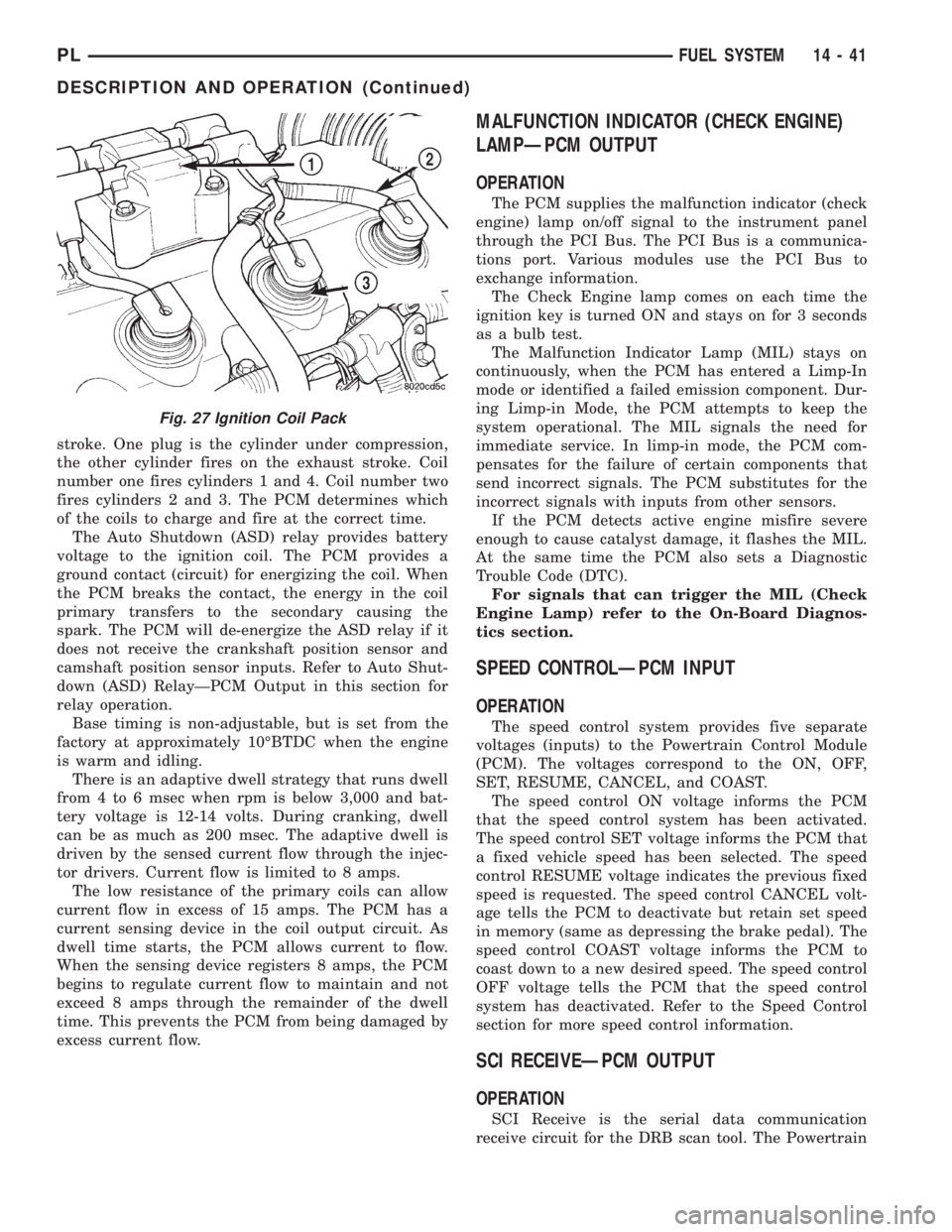

Fig. 14 Types Of O2 Sensors

1 ± BOSCH

2 ± NEW NTK

3 ± NTK

PLFUEL SYSTEM 14 - 33

DESCRIPTION AND OPERATION (Continued)

Page 862 of 1285

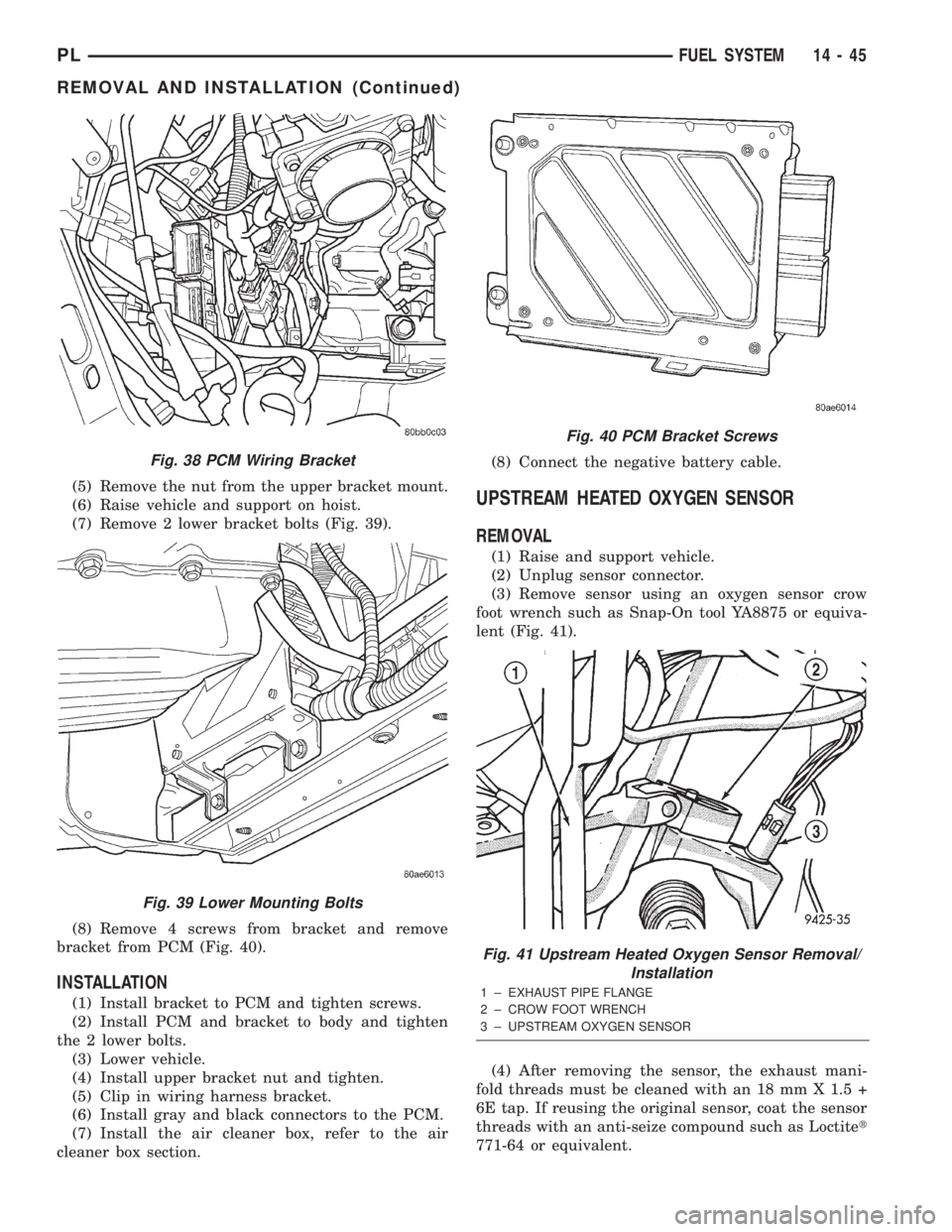

stroke. One plug is the cylinder under compression,

the other cylinder fires on the exhaust stroke. Coil

number one fires cylinders 1 and 4. Coil number two

fires cylinders 2 and 3. The PCM determines which

of the coils to charge and fire at the correct time.

The Auto Shutdown (ASD) relay provides battery

voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil. When

the PCM breaks the contact, the energy in the coil

primary transfers to the secondary causing the

spark. The PCM will de-energize the ASD relay if it

does not receive the crankshaft position sensor and

camshaft position sensor inputs. Refer to Auto Shut-

down (ASD) RelayÐPCM Output in this section for

relay operation.

Base timing is non-adjustable, but is set from the

factory at approximately 10ÉBTDC when the engine

is warm and idling.

There is an adaptive dwell strategy that runs dwell

from 4 to 6 msec when rpm is below 3,000 and bat-

tery voltage is 12-14 volts. During cranking, dwell

can be as much as 200 msec. The adaptive dwell is

driven by the sensed current flow through the injec-

tor drivers. Current flow is limited to 8 amps.

The low resistance of the primary coils can allow

current flow in excess of 15 amps. The PCM has a

current sensing device in the coil output circuit. As

dwell time starts, the PCM allows current to flow.

When the sensing device registers 8 amps, the PCM

begins to regulate current flow to maintain and not

exceed 8 amps through the remainder of the dwell

time. This prevents the PCM from being damaged by

excess current flow.

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUT

OPERATION

The PCM supplies the malfunction indicator (check

engine) lamp on/off signal to the instrument panel

through the PCI Bus. The PCI Bus is a communica-

tions port. Various modules use the PCI Bus to

exchange information.

The Check Engine lamp comes on each time the

ignition key is turned ON and stays on for 3 seconds

as a bulb test.

The Malfunction Indicator Lamp (MIL) stays on

continuously, when the PCM has entered a Limp-In

mode or identified a failed emission component. Dur-

ing Limp-in Mode, the PCM attempts to keep the

system operational. The MIL signals the need for

immediate service. In limp-in mode, the PCM com-

pensates for the failure of certain components that

send incorrect signals. The PCM substitutes for the

incorrect signals with inputs from other sensors.

If the PCM detects active engine misfire severe

enough to cause catalyst damage, it flashes the MIL.

At the same time the PCM also sets a Diagnostic

Trouble Code (DTC).

For signals that can trigger the MIL (Check

Engine Lamp) refer to the On-Board Diagnos-

tics section.

SPEED CONTROLÐPCM INPUT

OPERATION

The speed control system provides five separate

voltages (inputs) to the Powertrain Control Module

(PCM). The voltages correspond to the ON, OFF,

SET, RESUME, CANCEL, and COAST.

The speed control ON voltage informs the PCM

that the speed control system has been activated.

The speed control SET voltage informs the PCM that

a fixed vehicle speed has been selected. The speed

control RESUME voltage indicates the previous fixed

speed is requested. The speed control CANCEL volt-

age tells the PCM to deactivate but retain set speed

in memory (same as depressing the brake pedal). The

speed control COAST voltage informs the PCM to

coast down to a new desired speed. The speed control

OFF voltage tells the PCM that the speed control

system has deactivated. Refer to the Speed Control

section for more speed control information.

SCI RECEIVEÐPCM OUTPUT

OPERATION

SCI Receive is the serial data communication

receive circuit for the DRB scan tool. The Powertrain

Fig. 27 Ignition Coil Pack

PLFUEL SYSTEM 14 - 41

DESCRIPTION AND OPERATION (Continued)

Page 866 of 1285

(5) Remove the nut from the upper bracket mount.

(6) Raise vehicle and support on hoist.

(7) Remove 2 lower bracket bolts (Fig. 39).

(8) Remove 4 screws from bracket and remove

bracket from PCM (Fig. 40).

INSTALLATION

(1) Install bracket to PCM and tighten screws.

(2) Install PCM and bracket to body and tighten

the 2 lower bolts.

(3) Lower vehicle.

(4) Install upper bracket nut and tighten.

(5) Clip in wiring harness bracket.

(6) Install gray and black connectors to the PCM.

(7) Install the air cleaner box, refer to the air

cleaner box section.(8) Connect the negative battery cable.

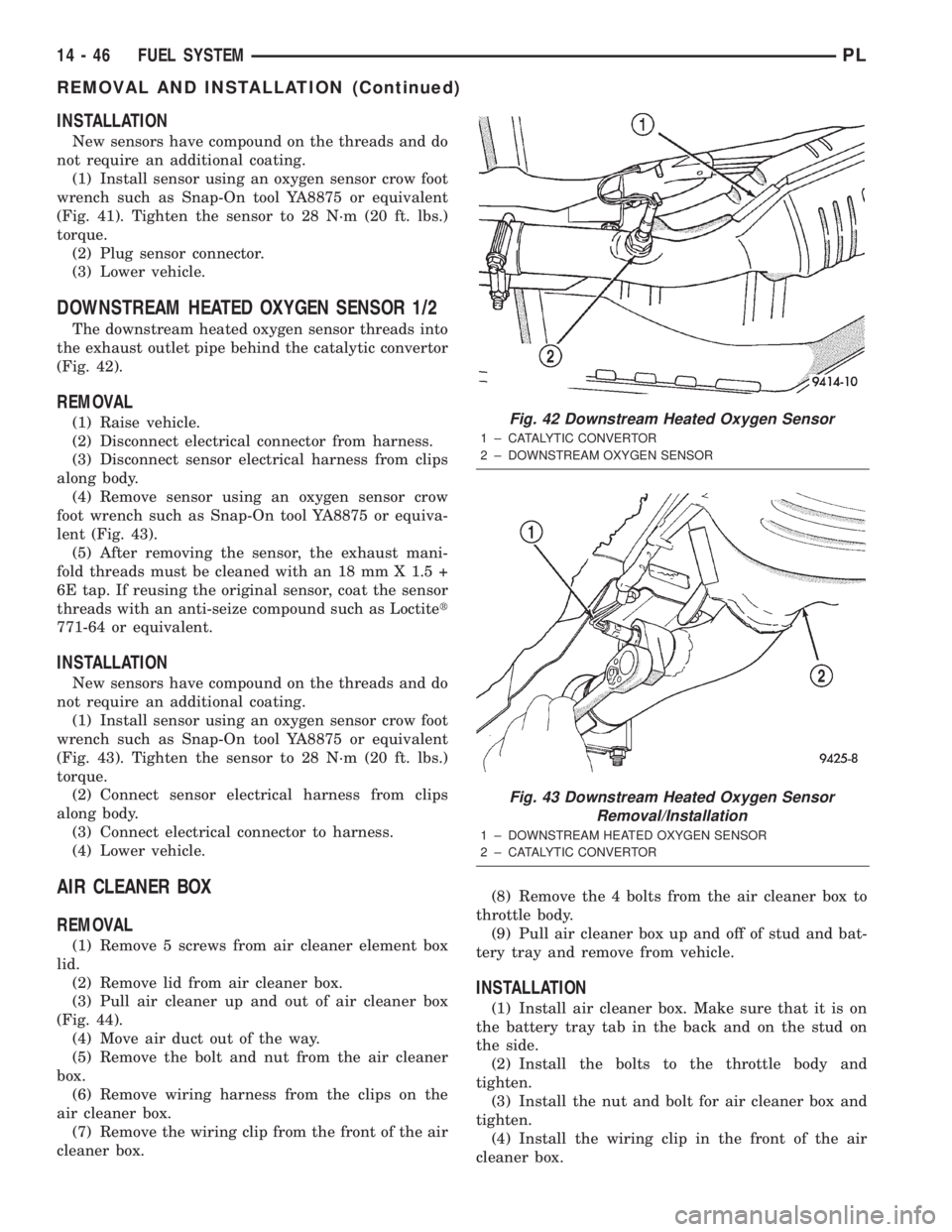

UPSTREAM HEATED OXYGEN SENSOR

REMOVAL

(1) Raise and support vehicle.

(2) Unplug sensor connector.

(3) Remove sensor using an oxygen sensor crow

foot wrench such as Snap-On tool YA8875 or equiva-

lent (Fig. 41).

(4) After removing the sensor, the exhaust mani-

fold threads must be cleaned with an 18 mm X 1.5 +

6E tap. If reusing the original sensor, coat the sensor

threads with an anti-seize compound such as Loctitet

771-64 or equivalent.

Fig. 38 PCM Wiring Bracket

Fig. 39 Lower Mounting Bolts

Fig. 40 PCM Bracket Screws

Fig. 41 Upstream Heated Oxygen Sensor Removal/

Installation

1 ± EXHAUST PIPE FLANGE

2 ± CROW FOOT WRENCH

3 ± UPSTREAM OXYGEN SENSOR

PLFUEL SYSTEM 14 - 45

REMOVAL AND INSTALLATION (Continued)

Page 867 of 1285

INSTALLATION

New sensors have compound on the threads and do

not require an additional coating.

(1) Install sensor using an oxygen sensor crow foot

wrench such as Snap-On tool YA8875 or equivalent

(Fig. 41). Tighten the sensor to 28 N´m (20 ft. lbs.)

torque.

(2) Plug sensor connector.

(3) Lower vehicle.

DOWNSTREAM HEATED OXYGEN SENSOR 1/2

The downstream heated oxygen sensor threads into

the exhaust outlet pipe behind the catalytic convertor

(Fig. 42).

REMOVAL

(1) Raise vehicle.

(2) Disconnect electrical connector from harness.

(3) Disconnect sensor electrical harness from clips

along body.

(4) Remove sensor using an oxygen sensor crow

foot wrench such as Snap-On tool YA8875 or equiva-

lent (Fig. 43).

(5) After removing the sensor, the exhaust mani-

fold threads must be cleaned with an 18 mm X 1.5 +

6E tap. If reusing the original sensor, coat the sensor

threads with an anti-seize compound such as Loctitet

771-64 or equivalent.

INSTALLATION

New sensors have compound on the threads and do

not require an additional coating.

(1) Install sensor using an oxygen sensor crow foot

wrench such as Snap-On tool YA8875 or equivalent

(Fig. 43). Tighten the sensor to 28 N´m (20 ft. lbs.)

torque.

(2) Connect sensor electrical harness from clips

along body.

(3) Connect electrical connector to harness.

(4) Lower vehicle.

AIR CLEANER BOX

REMOVAL

(1) Remove 5 screws from air cleaner element box

lid.

(2) Remove lid from air cleaner box.

(3) Pull air cleaner up and out of air cleaner box

(Fig. 44).

(4) Move air duct out of the way.

(5) Remove the bolt and nut from the air cleaner

box.

(6) Remove wiring harness from the clips on the

air cleaner box.

(7) Remove the wiring clip from the front of the air

cleaner box.(8) Remove the 4 bolts from the air cleaner box to

throttle body.

(9) Pull air cleaner box up and off of stud and bat-

tery tray and remove from vehicle.

INSTALLATION

(1) Install air cleaner box. Make sure that it is on

the battery tray tab in the back and on the stud on

the side.

(2) Install the bolts to the throttle body and

tighten.

(3) Install the nut and bolt for air cleaner box and

tighten.

(4) Install the wiring clip in the front of the air

cleaner box.

Fig. 42 Downstream Heated Oxygen Sensor

1 ± CATALYTIC CONVERTOR

2 ± DOWNSTREAM OXYGEN SENSOR

Fig. 43 Downstream Heated Oxygen Sensor

Removal/Installation

1 ± DOWNSTREAM HEATED OXYGEN SENSOR

2 ± CATALYTIC CONVERTOR

14 - 46 FUEL SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 882 of 1285

CAUTION: Do not force the pump to operate

against the stops for more than 5 seconds at a time

as pump damage may result.

(6) Completely open the valve on the Power Steer-

ing Analyzer flow meter. Turn the steering wheel to

the extreme left until the stop in the steering gear is

met, then turn the steering wheel to the right until

the right stop is met. Record the highest indicated

pressure at each position. Compare the recorded

readings to the specifications. If the highest output

pressure reading against one stop is within 50 psi of

the highest reading at the other stop, the steering

gear is leaking internally and must be replaced.

If the power steering gear requires replacement,

refer to the section POWER STEERING GEAR

within this group for the removal and installation

procedure.

SERVICE PROCEDURES

POWER STEERING SYSTEM FLUID LEVEL

CHECK

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

Before opening power steering system, wipe the

reservoir filler cap free of dirt and debris. Remove

the cap and check the fluid level on its dipstick.

When the fluid is at normal ambient temperature,

approximately 21ÉC to 27ÉC (70ÉF to 80ÉF), the dip-

stick level should indicateCOLD. Do not overfill the

power steering system. In all power steering systems,

use only Mopar Power Steering Fluid, or its equiva-

lent.

NOTE: Do not use any type of automatic transmis-

sion fluid in the power steering system.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

WARNING: POWER STEERING FLUID, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

CAUTION: When the system is open, cap all open

ends of the hoses, power steering pump fittings or

power steering gear ports to prevent entry of for-

eign material into the components.

NOTE: Do not use any type of automatic transmis-

sion fluid in the power steering system.

POWER STEERING FLUID PRESSURE HOSE

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

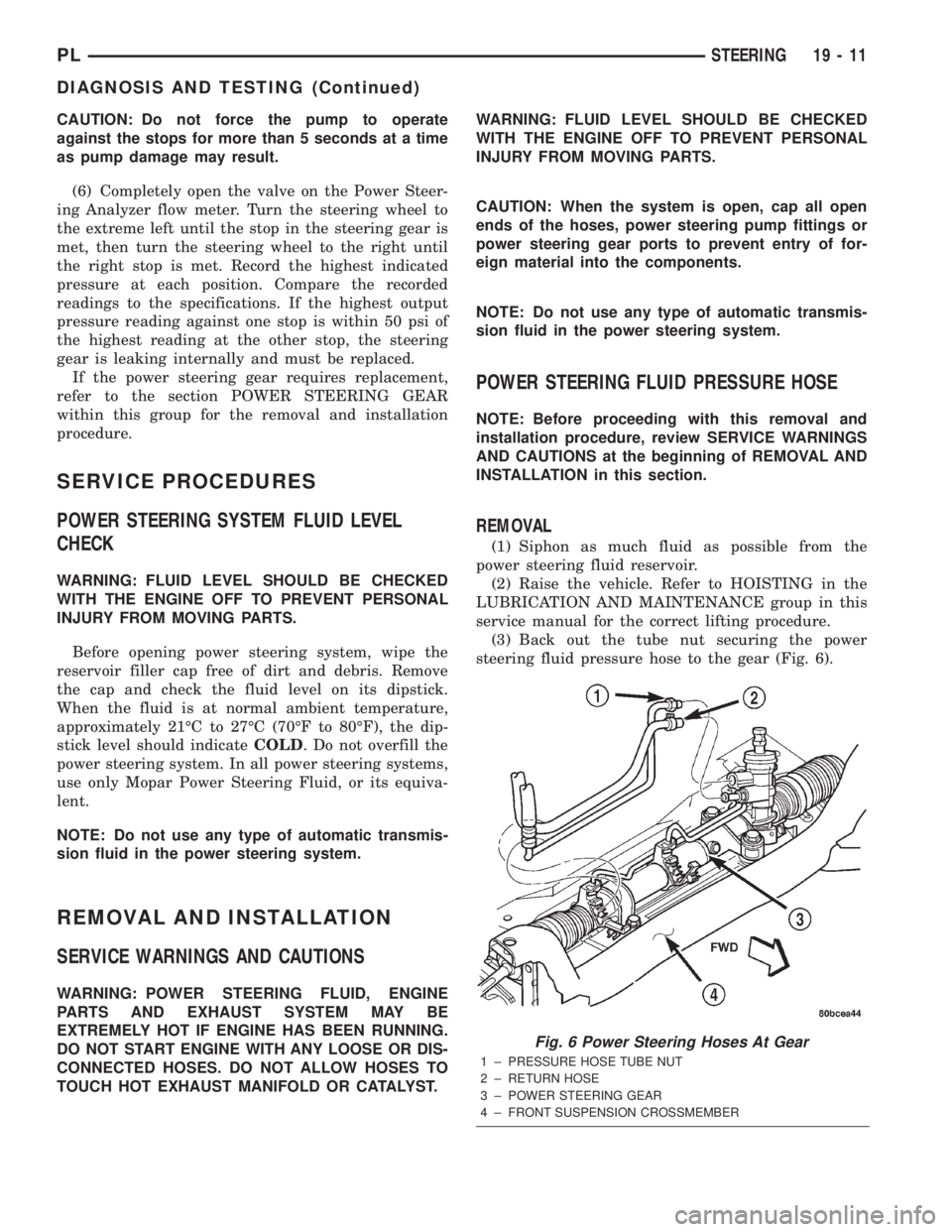

REMOVAL

(1) Siphon as much fluid as possible from the

power steering fluid reservoir.

(2) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.

(3) Back out the tube nut securing the power

steering fluid pressure hose to the gear (Fig. 6).

Fig. 6 Power Steering Hoses At Gear

1 ± PRESSURE HOSE TUBE NUT

2 ± RETURN HOSE

3 ± POWER STEERING GEAR

4 ± FRONT SUSPENSION CROSSMEMBER

PLSTEERING 19 - 11

DIAGNOSIS AND TESTING (Continued)

Page 883 of 1285

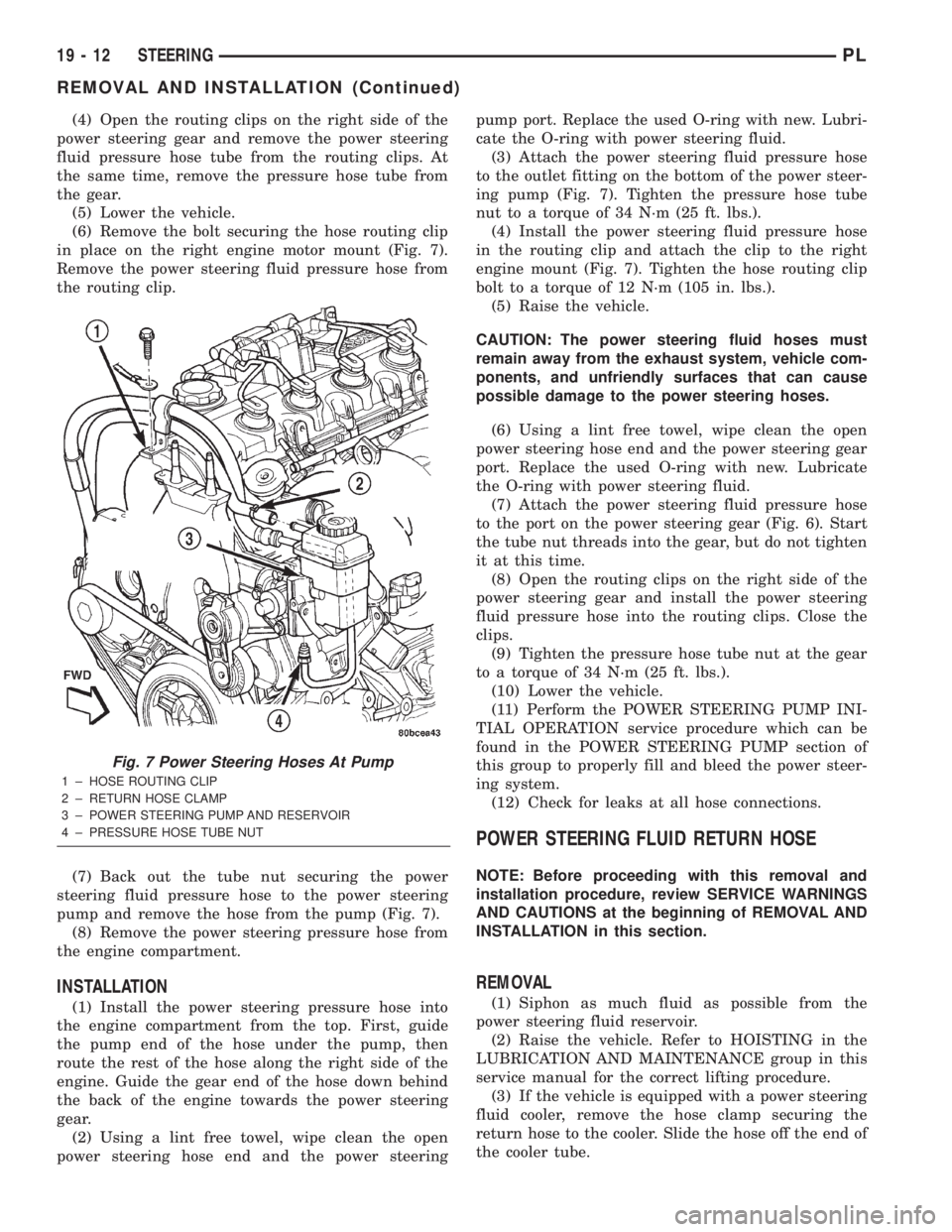

(4) Open the routing clips on the right side of the

power steering gear and remove the power steering

fluid pressure hose tube from the routing clips. At

the same time, remove the pressure hose tube from

the gear.

(5) Lower the vehicle.

(6) Remove the bolt securing the hose routing clip

in place on the right engine motor mount (Fig. 7).

Remove the power steering fluid pressure hose from

the routing clip.

(7) Back out the tube nut securing the power

steering fluid pressure hose to the power steering

pump and remove the hose from the pump (Fig. 7).

(8) Remove the power steering pressure hose from

the engine compartment.

INSTALLATION

(1) Install the power steering pressure hose into

the engine compartment from the top. First, guide

the pump end of the hose under the pump, then

route the rest of the hose along the right side of the

engine. Guide the gear end of the hose down behind

the back of the engine towards the power steering

gear.

(2) Using a lint free towel, wipe clean the open

power steering hose end and the power steeringpump port. Replace the used O-ring with new. Lubri-

cate the O-ring with power steering fluid.

(3) Attach the power steering fluid pressure hose

to the outlet fitting on the bottom of the power steer-

ing pump (Fig. 7). Tighten the pressure hose tube

nut to a torque of 34 N´m (25 ft. lbs.).

(4) Install the power steering fluid pressure hose

in the routing clip and attach the clip to the right

engine mount (Fig. 7). Tighten the hose routing clip

bolt to a torque of 12 N´m (105 in. lbs.).

(5) Raise the vehicle.

CAUTION: The power steering fluid hoses must

remain away from the exhaust system, vehicle com-

ponents, and unfriendly surfaces that can cause

possible damage to the power steering hoses.

(6) Using a lint free towel, wipe clean the open

power steering hose end and the power steering gear

port. Replace the used O-ring with new. Lubricate

the O-ring with power steering fluid.

(7) Attach the power steering fluid pressure hose

to the port on the power steering gear (Fig. 6). Start

the tube nut threads into the gear, but do not tighten

it at this time.

(8) Open the routing clips on the right side of the

power steering gear and install the power steering

fluid pressure hose into the routing clips. Close the

clips.

(9) Tighten the pressure hose tube nut at the gear

to a torque of 34 N´m (25 ft. lbs.).

(10) Lower the vehicle.

(11) Perform the POWER STEERING PUMP INI-

TIAL OPERATION service procedure which can be

found in the POWER STEERING PUMP section of

this group to properly fill and bleed the power steer-

ing system.

(12) Check for leaks at all hose connections.

POWER STEERING FLUID RETURN HOSE

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

REMOVAL

(1) Siphon as much fluid as possible from the

power steering fluid reservoir.

(2) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.

(3) If the vehicle is equipped with a power steering

fluid cooler, remove the hose clamp securing the

return hose to the cooler. Slide the hose off the end of

the cooler tube.

Fig. 7 Power Steering Hoses At Pump

1 ± HOSE ROUTING CLIP

2 ± RETURN HOSE CLAMP

3 ± POWER STEERING PUMP AND RESERVOIR

4 ± PRESSURE HOSE TUBE NUT

19 - 12 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 884 of 1285

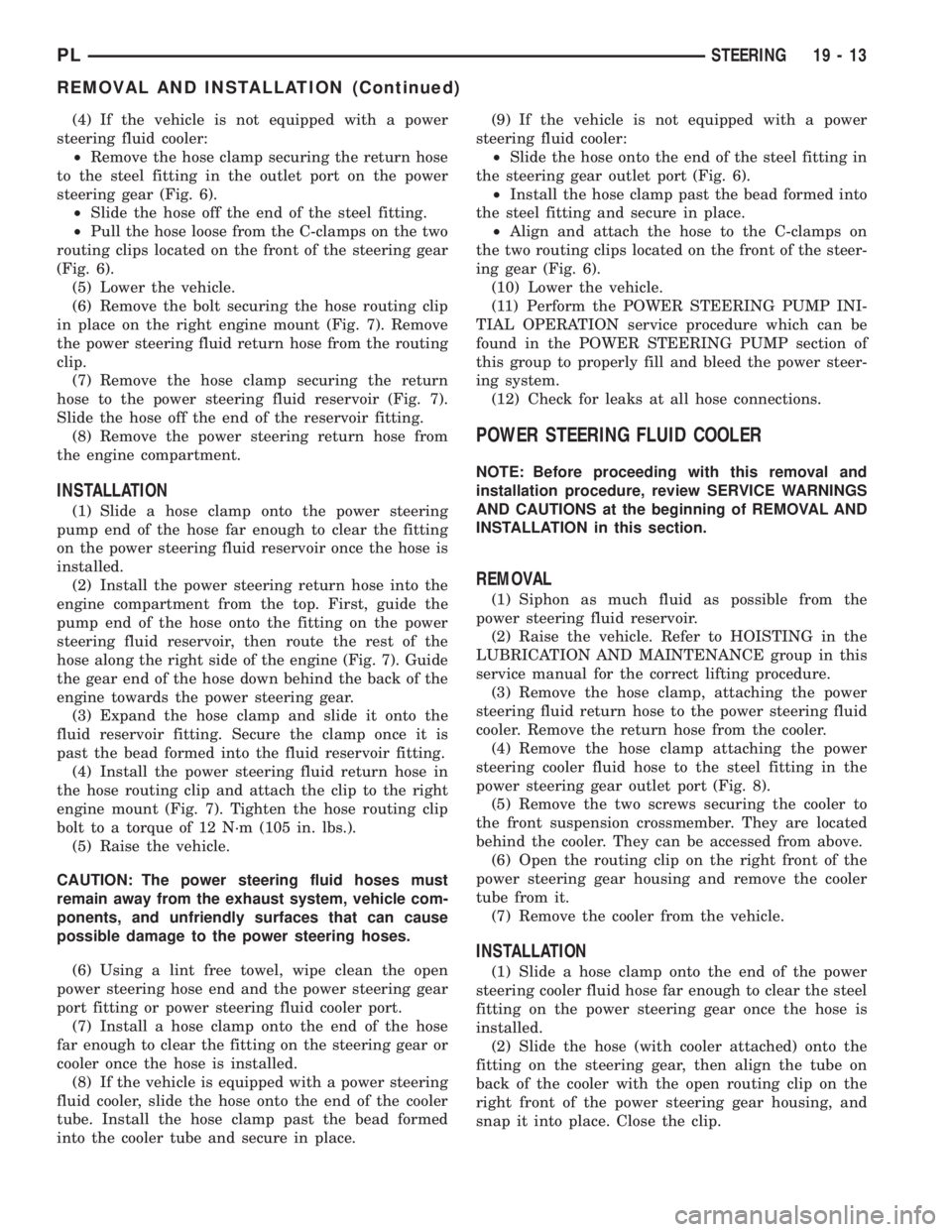

(4) If the vehicle is not equipped with a power

steering fluid cooler:

²Remove the hose clamp securing the return hose

to the steel fitting in the outlet port on the power

steering gear (Fig. 6).

²Slide the hose off the end of the steel fitting.

²Pull the hose loose from the C-clamps on the two

routing clips located on the front of the steering gear

(Fig. 6).

(5) Lower the vehicle.

(6) Remove the bolt securing the hose routing clip

in place on the right engine mount (Fig. 7). Remove

the power steering fluid return hose from the routing

clip.

(7) Remove the hose clamp securing the return

hose to the power steering fluid reservoir (Fig. 7).

Slide the hose off the end of the reservoir fitting.

(8) Remove the power steering return hose from

the engine compartment.

INSTALLATION

(1) Slide a hose clamp onto the power steering

pump end of the hose far enough to clear the fitting

on the power steering fluid reservoir once the hose is

installed.

(2) Install the power steering return hose into the

engine compartment from the top. First, guide the

pump end of the hose onto the fitting on the power

steering fluid reservoir, then route the rest of the

hose along the right side of the engine (Fig. 7). Guide

the gear end of the hose down behind the back of the

engine towards the power steering gear.

(3) Expand the hose clamp and slide it onto the

fluid reservoir fitting. Secure the clamp once it is

past the bead formed into the fluid reservoir fitting.

(4) Install the power steering fluid return hose in

the hose routing clip and attach the clip to the right

engine mount (Fig. 7). Tighten the hose routing clip

bolt to a torque of 12 N´m (105 in. lbs.).

(5) Raise the vehicle.

CAUTION: The power steering fluid hoses must

remain away from the exhaust system, vehicle com-

ponents, and unfriendly surfaces that can cause

possible damage to the power steering hoses.

(6) Using a lint free towel, wipe clean the open

power steering hose end and the power steering gear

port fitting or power steering fluid cooler port.

(7) Install a hose clamp onto the end of the hose

far enough to clear the fitting on the steering gear or

cooler once the hose is installed.

(8) If the vehicle is equipped with a power steering

fluid cooler, slide the hose onto the end of the cooler

tube. Install the hose clamp past the bead formed

into the cooler tube and secure in place.(9) If the vehicle is not equipped with a power

steering fluid cooler:

²Slide the hose onto the end of the steel fitting in

the steering gear outlet port (Fig. 6).

²Install the hose clamp past the bead formed into

the steel fitting and secure in place.

²Align and attach the hose to the C-clamps on

the two routing clips located on the front of the steer-

ing gear (Fig. 6).

(10) Lower the vehicle.

(11) Perform the POWER STEERING PUMP INI-

TIAL OPERATION service procedure which can be

found in the POWER STEERING PUMP section of

this group to properly fill and bleed the power steer-

ing system.

(12) Check for leaks at all hose connections.

POWER STEERING FLUID COOLER

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

REMOVAL

(1) Siphon as much fluid as possible from the

power steering fluid reservoir.

(2) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.

(3) Remove the hose clamp, attaching the power

steering fluid return hose to the power steering fluid

cooler. Remove the return hose from the cooler.

(4) Remove the hose clamp attaching the power

steering cooler fluid hose to the steel fitting in the

power steering gear outlet port (Fig. 8).

(5) Remove the two screws securing the cooler to

the front suspension crossmember. They are located

behind the cooler. They can be accessed from above.

(6) Open the routing clip on the right front of the

power steering gear housing and remove the cooler

tube from it.

(7) Remove the cooler from the vehicle.

INSTALLATION

(1) Slide a hose clamp onto the end of the power

steering cooler fluid hose far enough to clear the steel

fitting on the power steering gear once the hose is

installed.

(2) Slide the hose (with cooler attached) onto the

fitting on the steering gear, then align the tube on

back of the cooler with the open routing clip on the

right front of the power steering gear housing, and

snap it into place. Close the clip.

PLSTEERING 19 - 13

REMOVAL AND INSTALLATION (Continued)

Page 888 of 1285

reduces the power required to drive the pump and

holds down temperature build-up.

When steering conditions exceed maximum pres-

sure requirements, such as when the wheels are

turned against the stops, the pressure built up in the

steering gear exerts pressure on the spring end of the

flow control valve. The high pressure lifts the relief

valve ball from its seat and allows oil to flow through

a trigger orifice located in the outlet fitting. This

reduces pressure on the spring end of the flow con-

trol valve which then opens and allows the oil to

return to the intake side of the pump. This action

limits maximum pressure output of the pump to a

safe level.

Under normal power steering pump operating con-

ditions, pressure requirements of the pump are below

maximum, causing the pressure relief valve to

remain closed.

POWER STEERING FLUID RESERVOIR

The power steering fluid reservoir is mounted on

the power steering pump using 3 bolts (Fig. 1). It

stores fluid for the power steering system.

The power steering fluid reservoir is considered an

integral part of the power steering pump and is not

serviced separately.

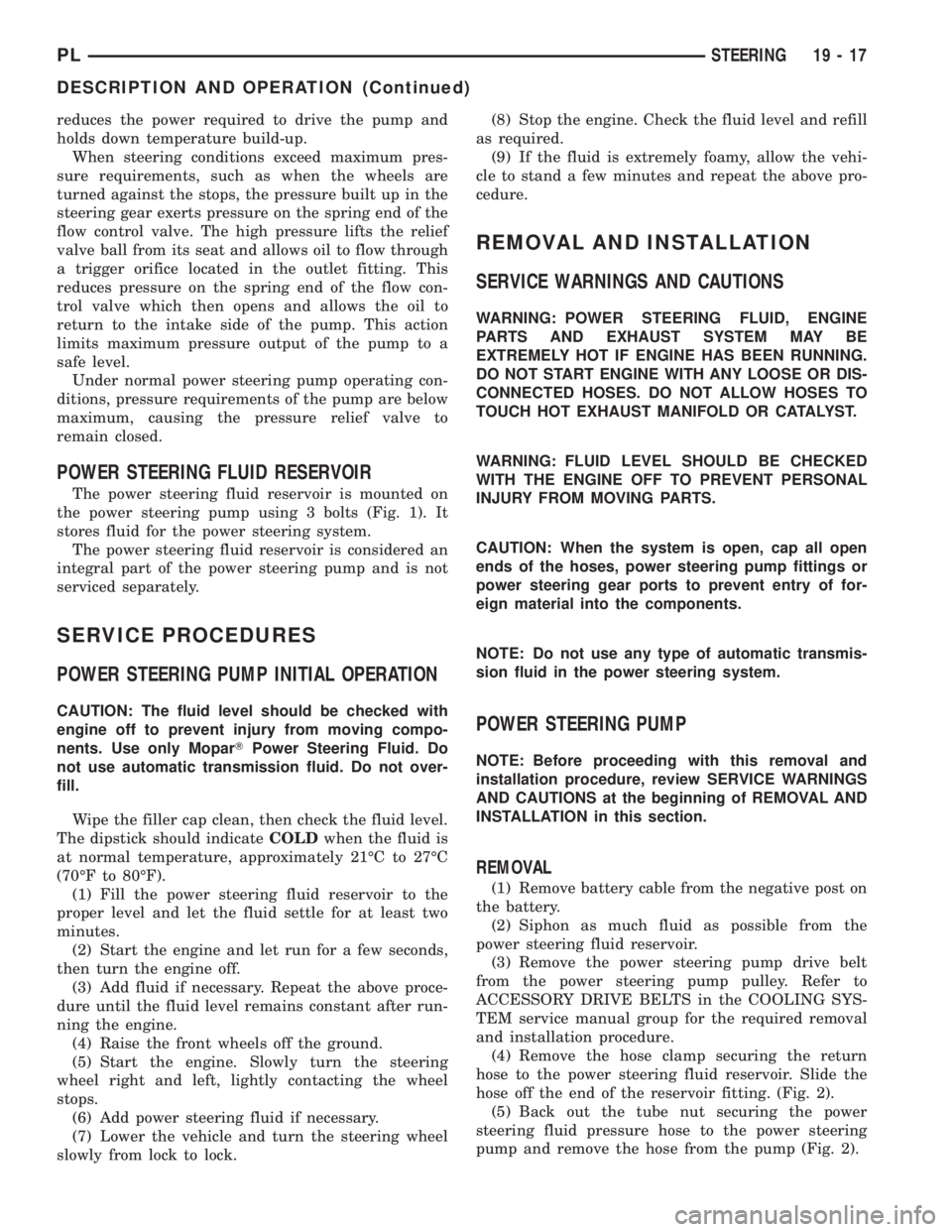

SERVICE PROCEDURES

POWER STEERING PUMP INITIAL OPERATION

CAUTION: The fluid level should be checked with

engine off to prevent injury from moving compo-

nents. Use only MoparTPower Steering Fluid. Do

not use automatic transmission fluid. Do not over-

fill.

Wipe the filler cap clean, then check the fluid level.

The dipstick should indicateCOLDwhen the fluid is

at normal temperature, approximately 21ÉC to 27ÉC

(70ÉF to 80ÉF).

(1) Fill the power steering fluid reservoir to the

proper level and let the fluid settle for at least two

minutes.

(2) Start the engine and let run for a few seconds,

then turn the engine off.

(3) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(4) Raise the front wheels off the ground.

(5) Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the wheel

stops.

(6) Add power steering fluid if necessary.

(7) Lower the vehicle and turn the steering wheel

slowly from lock to lock.(8) Stop the engine. Check the fluid level and refill

as required.

(9) If the fluid is extremely foamy, allow the vehi-

cle to stand a few minutes and repeat the above pro-

cedure.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

WARNING: POWER STEERING FLUID, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

CAUTION: When the system is open, cap all open

ends of the hoses, power steering pump fittings or

power steering gear ports to prevent entry of for-

eign material into the components.

NOTE: Do not use any type of automatic transmis-

sion fluid in the power steering system.

POWER STEERING PUMP

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

REMOVAL

(1) Remove battery cable from the negative post on

the battery.

(2) Siphon as much fluid as possible from the

power steering fluid reservoir.

(3) Remove the power steering pump drive belt

from the power steering pump pulley. Refer to

ACCESSORY DRIVE BELTS in the COOLING SYS-

TEM service manual group for the required removal

and installation procedure.

(4) Remove the hose clamp securing the return

hose to the power steering fluid reservoir. Slide the

hose off the end of the reservoir fitting. (Fig. 2).

(5) Back out the tube nut securing the power

steering fluid pressure hose to the power steering

pump and remove the hose from the pump (Fig. 2).

PLSTEERING 19 - 17

DESCRIPTION AND OPERATION (Continued)

Page 893 of 1285

NOTE: The power steering gear should not be ser-

viced or adjusted. If a malfunction or oil leak occurs

with the steering gear, the complete steering gear

needs to be replaced.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

WARNING: POWER STEERING FLUID, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

CAUTION: When the system is open, cap all open

ends of the hoses, power steering pump fittings or

power steering gear ports to prevent entry of for-

eign material into the components.

NOTE: Do not use any type of automatic transmis-

sion fluid in the power steering system.

POWER STEERING GEAR

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

REMOVAL

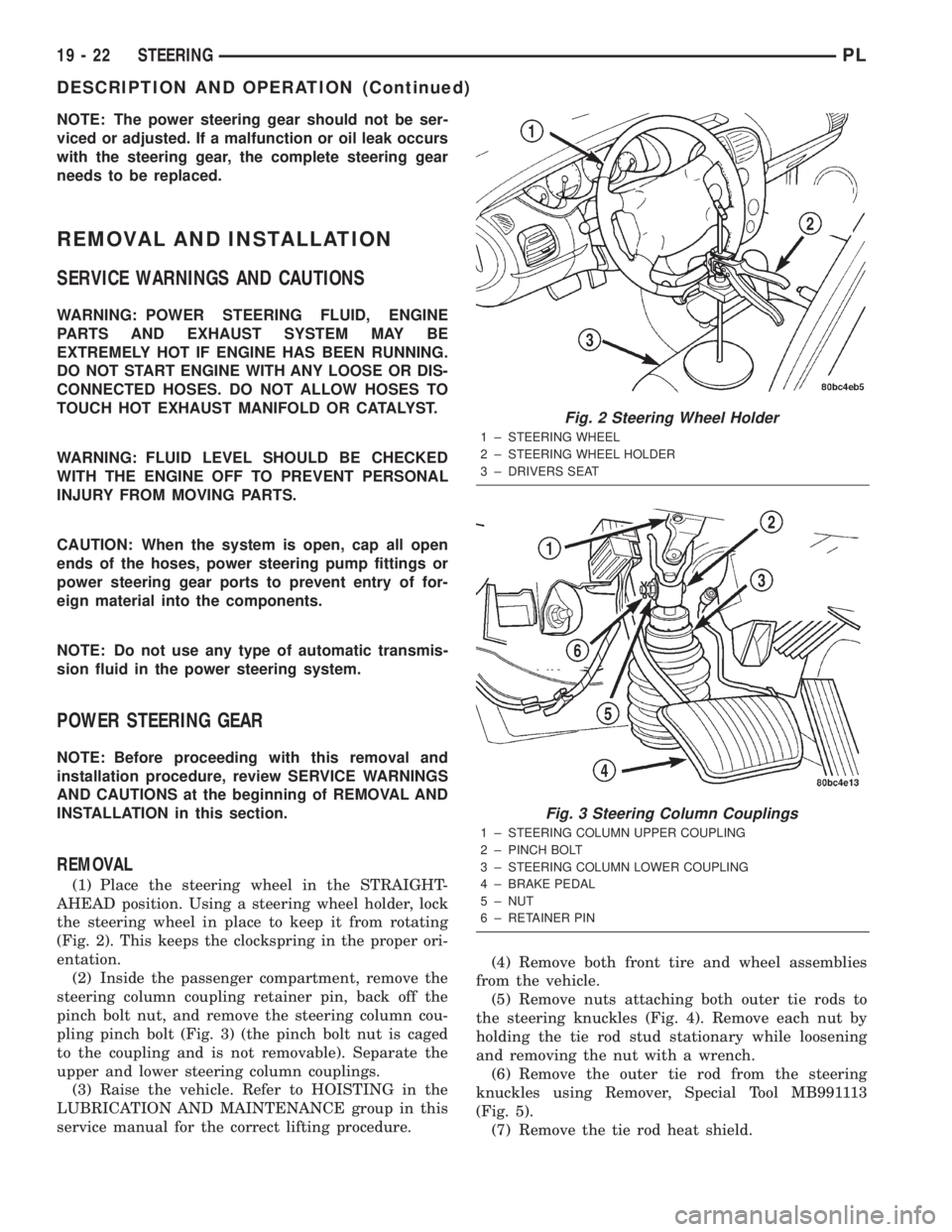

(1) Place the steering wheel in the STRAIGHT-

AHEAD position. Using a steering wheel holder, lock

the steering wheel in place to keep it from rotating

(Fig. 2). This keeps the clockspring in the proper ori-

entation.

(2) Inside the passenger compartment, remove the

steering column coupling retainer pin, back off the

pinch bolt nut, and remove the steering column cou-

pling pinch bolt (Fig. 3) (the pinch bolt nut is caged

to the coupling and is not removable). Separate the

upper and lower steering column couplings.

(3) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.(4) Remove both front tire and wheel assemblies

from the vehicle.

(5) Remove nuts attaching both outer tie rods to

the steering knuckles (Fig. 4). Remove each nut by

holding the tie rod stud stationary while loosening

and removing the nut with a wrench.

(6) Remove the outer tie rod from the steering

knuckles using Remover, Special Tool MB991113

(Fig. 5).

(7) Remove the tie rod heat shield.

Fig. 2 Steering Wheel Holder

1 ± STEERING WHEEL

2 ± STEERING WHEEL HOLDER

3 ± DRIVERS SEAT

Fig. 3 Steering Column Couplings

1 ± STEERING COLUMN UPPER COUPLING

2 ± PINCH BOLT

3 ± STEERING COLUMN LOWER COUPLING

4 ± BRAKE PEDAL

5 ± NUT

6 ± RETAINER PIN

19 - 22 STEERINGPL

DESCRIPTION AND OPERATION (Continued)

Page 1073 of 1285

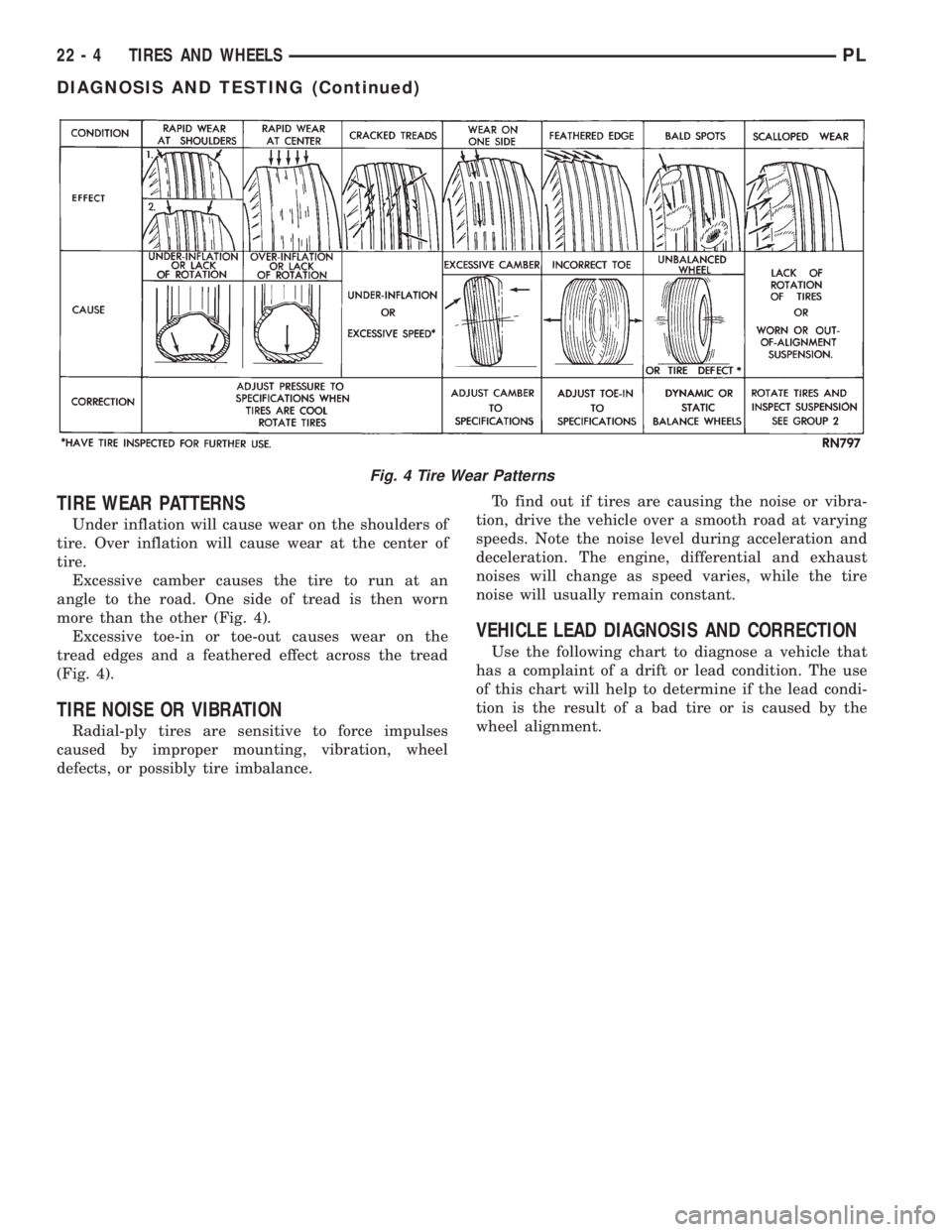

TIRE WEAR PATTERNS

Under inflation will cause wear on the shoulders of

tire. Over inflation will cause wear at the center of

tire.

Excessive camber causes the tire to run at an

angle to the road. One side of tread is then worn

more than the other (Fig. 4).

Excessive toe-in or toe-out causes wear on the

tread edges and a feathered effect across the tread

(Fig. 4).

TIRE NOISE OR VIBRATION

Radial-ply tires are sensitive to force impulses

caused by improper mounting, vibration, wheel

defects, or possibly tire imbalance.To find out if tires are causing the noise or vibra-

tion, drive the vehicle over a smooth road at varying

speeds. Note the noise level during acceleration and

deceleration. The engine, differential and exhaust

noises will change as speed varies, while the tire

noise will usually remain constant.

VEHICLE LEAD DIAGNOSIS AND CORRECTION

Use the following chart to diagnose a vehicle that

has a complaint of a drift or lead condition. The use

of this chart will help to determine if the lead condi-

tion is the result of a bad tire or is caused by the

wheel alignment.

Fig. 4 Tire Wear Patterns

22 - 4 TIRES AND WHEELSPL

DIAGNOSIS AND TESTING (Continued)