exhaust DODGE NEON 2000 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 801 of 1285

DIAGNOSIS AND TESTING

EXHAUST SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE

EXHAUST NOISE

(UNDER HOOD)1. Exhaust manifold cracked or broken. 1. Replace manifold.

2. Manifold to cylinder head leak. 2. Tighten manifold and/or replace gasket.

3. Exhaust Flex joint to manifold leak. 3. Tighten fasteners or replace gasket.

4. Exhaust flex joint. 4. Replace catalytic converter assembly.

5. Pipe and shell noise from front exhaust

pipe.5. Characteristic of single wall pipes.

EXCESSIVE

EXHAUST NOISE1. Leaks at pipe joints. 1. Tighten or replace clamps at leaking

joints.

2. Burned, blown, or rusted out exhaust

pipe or muffler.2. Replace muffler or exhaust pipes.

3. Restriction in muffler or tailpipe. 3. Remove restriction, if possible or replace

as necessary.

4. Catalytic converter material in muffler. 4. Replace muffler and converter assembly.

Check fuel injection and ignition systems for

proper operation.

REMOVAL AND INSTALLATION

EXHAUST PIPE AND MUFFLER

REMOVAL

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-

VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATING TIME.

(1) Raise vehicle on hoist and apply penetrating oil

to band clamp fastener of component being removed.

NOTE: Do not use petroleum-based lubricants

when removing/installing muffler or exhaust pipe

isolators as it may compromise the life of the part.

A suitable substitute is a mixture of liquid dish

soap and water.

(2) Remove exhaust system ground strap.

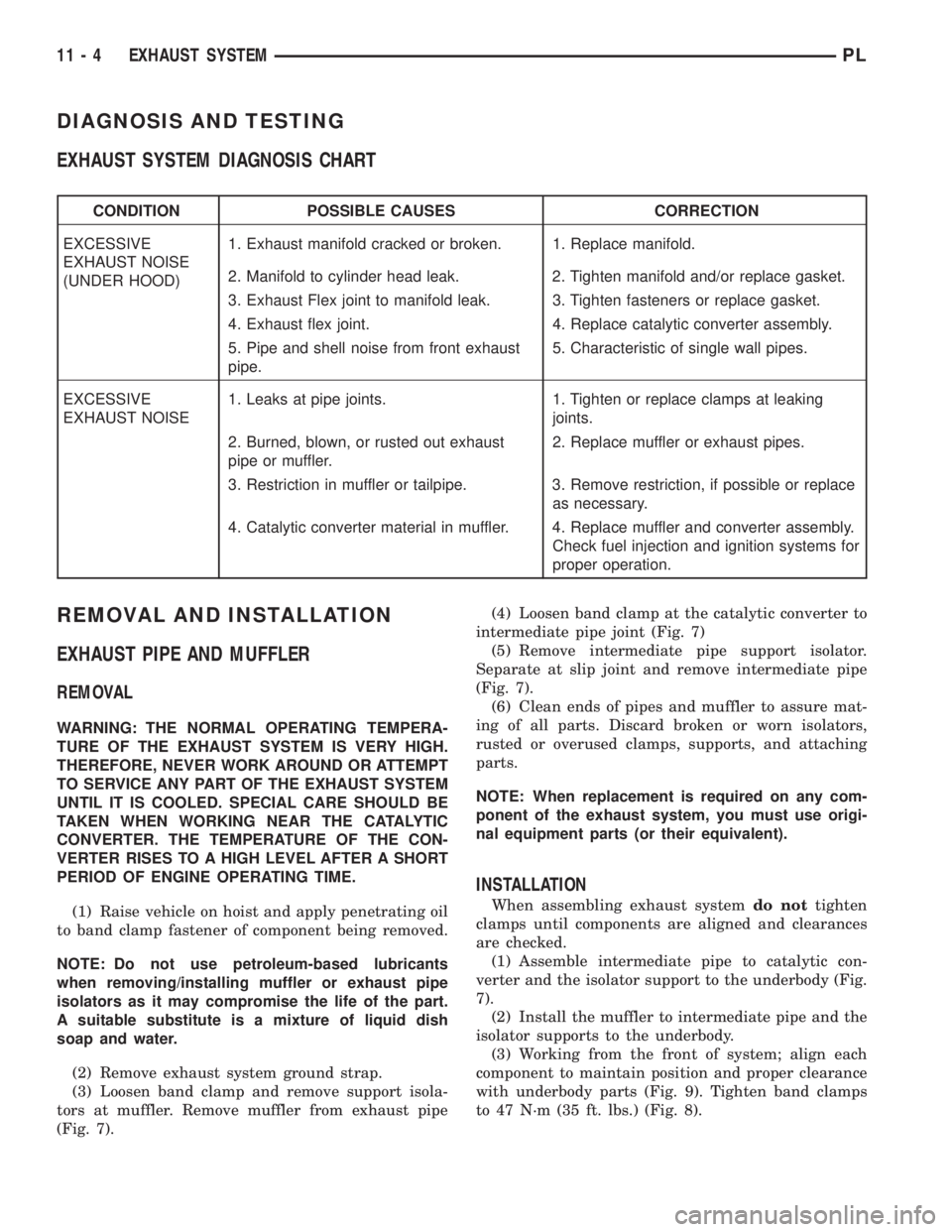

(3) Loosen band clamp and remove support isola-

tors at muffler. Remove muffler from exhaust pipe

(Fig. 7).(4) Loosen band clamp at the catalytic converter to

intermediate pipe joint (Fig. 7)

(5) Remove intermediate pipe support isolator.

Separate at slip joint and remove intermediate pipe

(Fig. 7).

(6) Clean ends of pipes and muffler to assure mat-

ing of all parts. Discard broken or worn isolators,

rusted or overused clamps, supports, and attaching

parts.

NOTE: When replacement is required on any com-

ponent of the exhaust system, you must use origi-

nal equipment parts (or their equivalent).

INSTALLATION

When assembling exhaust systemdo nottighten

clamps until components are aligned and clearances

are checked.

(1) Assemble intermediate pipe to catalytic con-

verter and the isolator support to the underbody (Fig.

7).

(2) Install the muffler to intermediate pipe and the

isolator supports to the underbody.

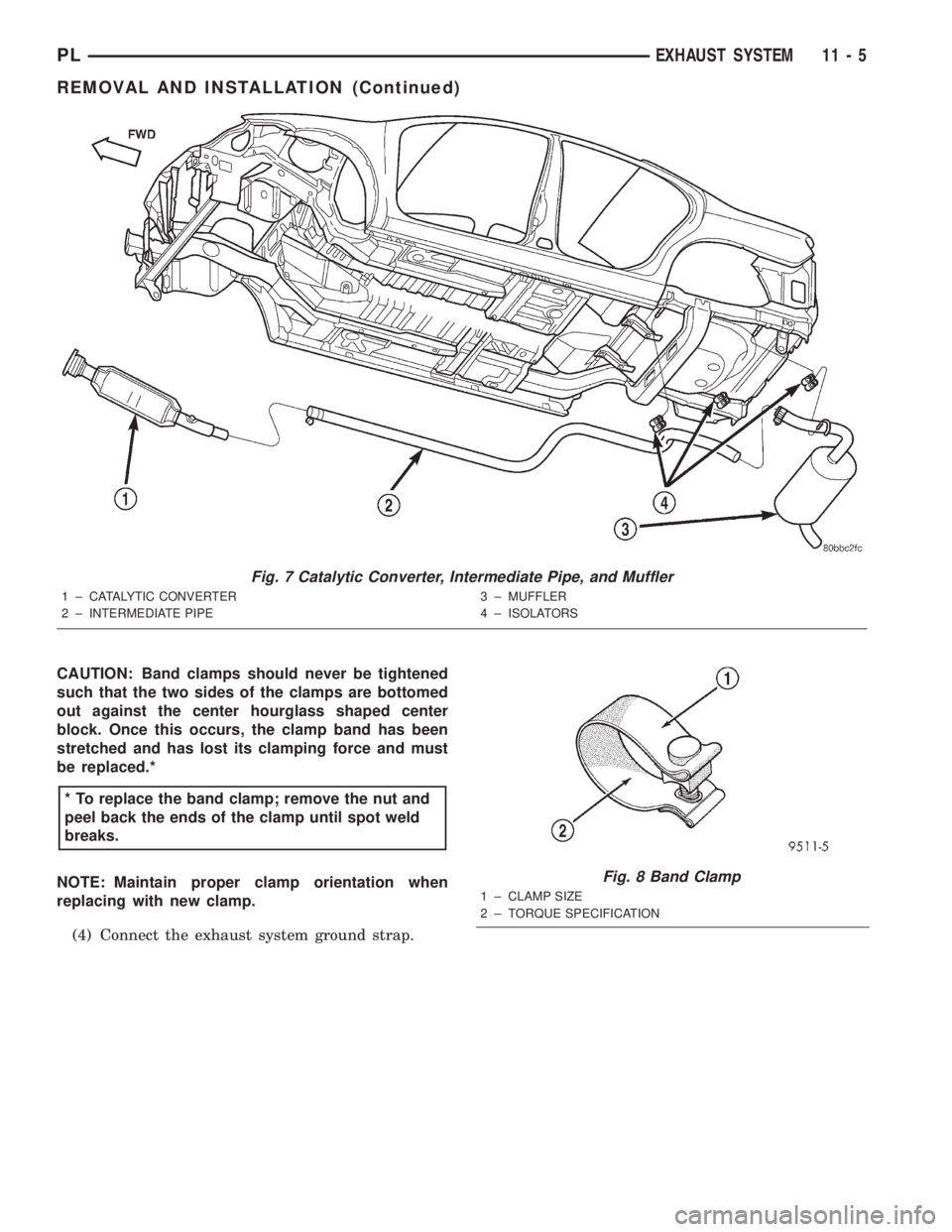

(3) Working from the front of system; align each

component to maintain position and proper clearance

with underbody parts (Fig. 9). Tighten band clamps

to 47 N´m (35 ft. lbs.) (Fig. 8).

11 - 4 EXHAUST SYSTEMPL

Page 802 of 1285

CAUTION: Band clamps should never be tightened

such that the two sides of the clamps are bottomed

out against the center hourglass shaped center

block. Once this occurs, the clamp band has been

stretched and has lost its clamping force and must

be replaced.*

NOTE: Maintain proper clamp orientation when

replacing with new clamp.

(4) Connect the exhaust system ground strap.

Fig. 7 Catalytic Converter, Intermediate Pipe, and Muffler

1 ± CATALYTIC CONVERTER

2 ± INTERMEDIATE PIPE3 ± MUFFLER

4 ± ISOLATORS

* To replace the band clamp; remove the nut and

peel back the ends of the clamp until spot weld

breaks.

Fig. 8 Band Clamp

1 ± CLAMP SIZE

2 ± TORQUE SPECIFICATION

PLEXHAUST SYSTEM 11 - 5

REMOVAL AND INSTALLATION (Continued)

Page 803 of 1285

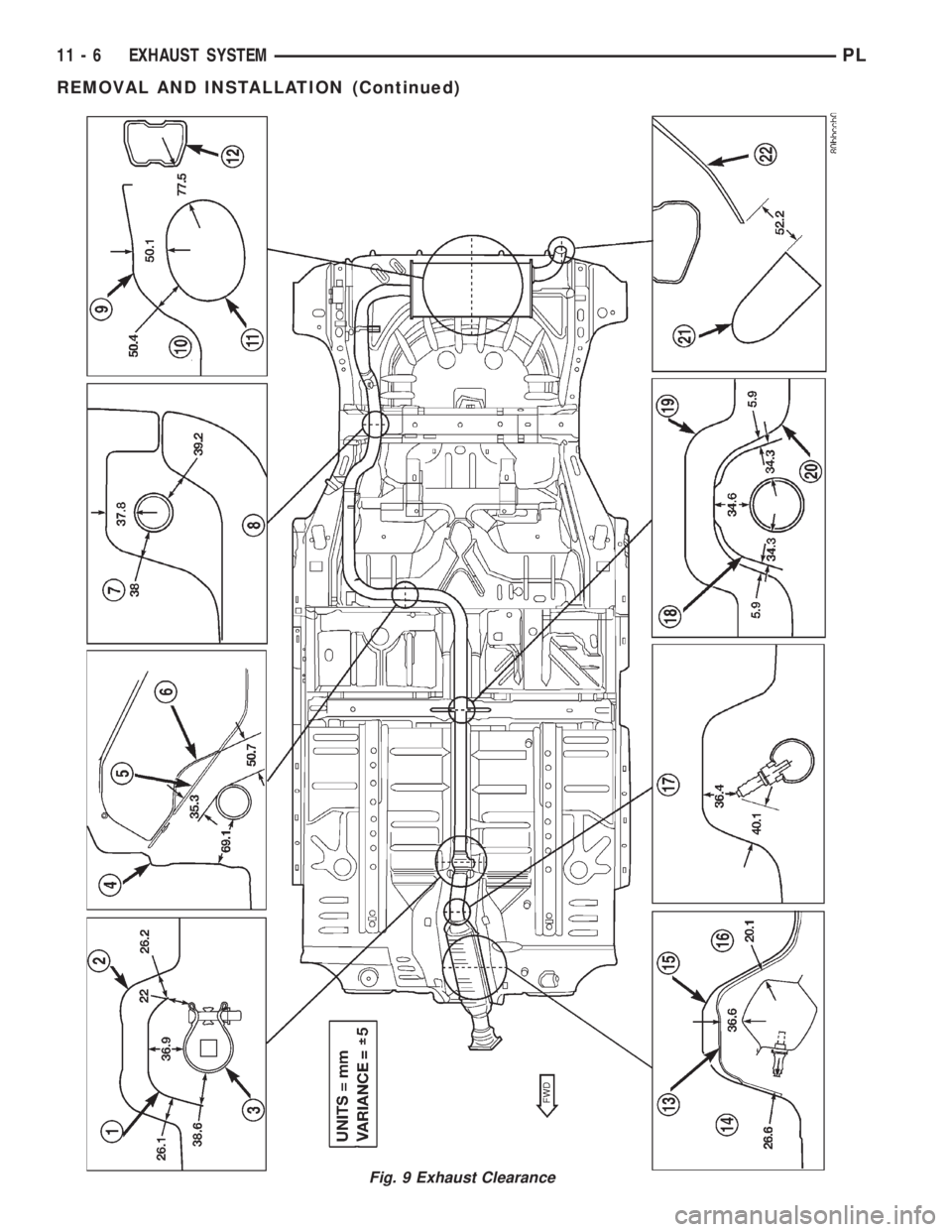

Fig. 9 Exhaust Clearance

11 - 6 EXHAUST SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 804 of 1285

CATALYTIC CONVERTER

REMOVAL

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER ATTEMPT TO SERVICE ANY

PART OF THE EXHAUST SYSTEM UNTIL IT IS

COOLED. SPECIAL CARE SHOULD BE TAKEN

WHEN WORKING NEAR THE CATALYTIC CON-

VERTER. THE TEMPERATURE OF THE CONVERTER

RISES TO A HIGH LEVEL AFTER A SHORT PERIOD

OF ENGINE OPERATION TIME.

NOTE: Vehicles equipped with the ULEV emission

package are equipped with an additional catalytic

converter that is integral to the exhaust manifold.

Refer to Exhaust Manifold in Group 9, Engine for

procedure.

(1) Remove muffler and exhaust pipe. Refer to pro-

cedure in this section.

(2) Disconnect downstream oxygen sensor electri-

cal connector.

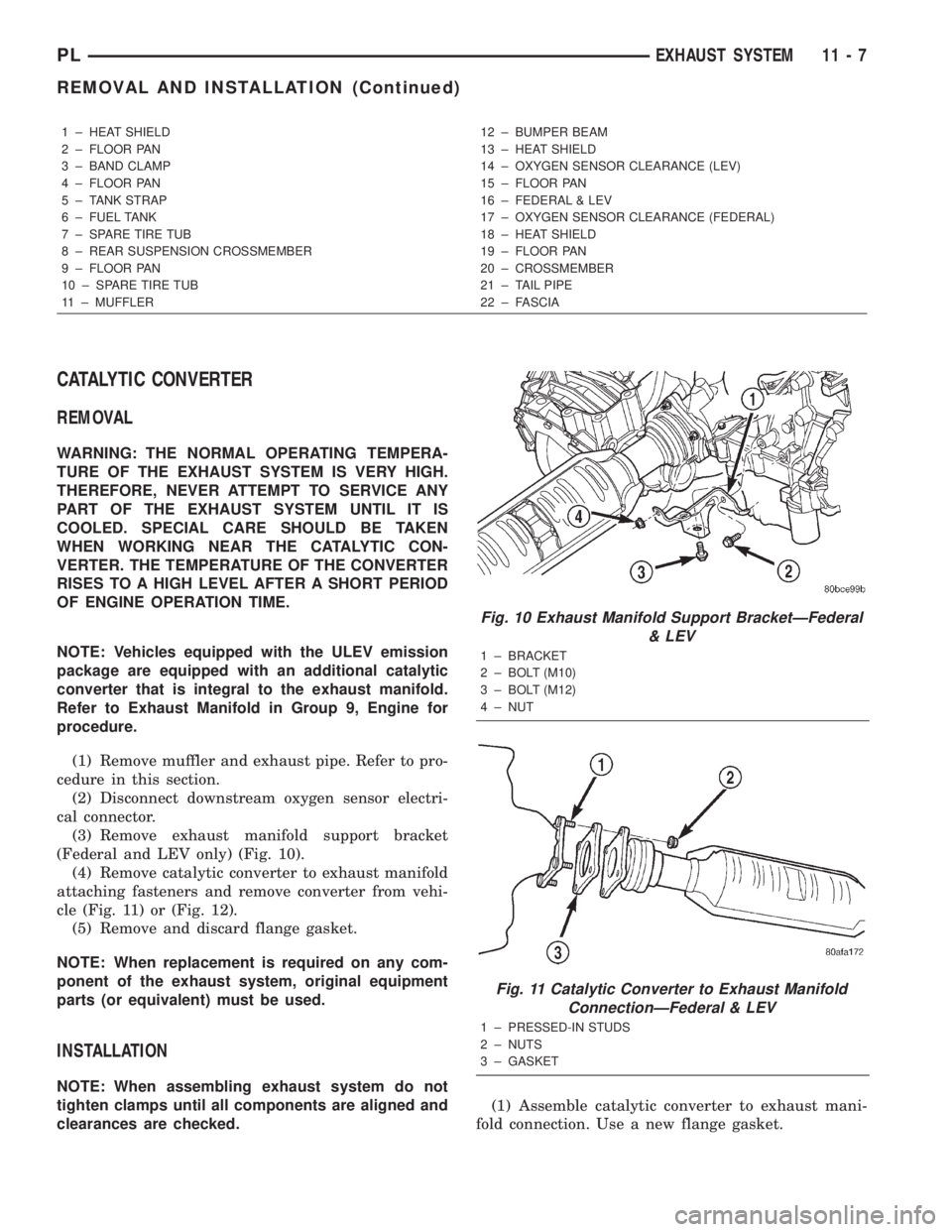

(3) Remove exhaust manifold support bracket

(Federal and LEV only) (Fig. 10).

(4) Remove catalytic converter to exhaust manifold

attaching fasteners and remove converter from vehi-

cle (Fig. 11) or (Fig. 12).

(5) Remove and discard flange gasket.

NOTE: When replacement is required on any com-

ponent of the exhaust system, original equipment

parts (or equivalent) must be used.

INSTALLATION

NOTE: When assembling exhaust system do not

tighten clamps until all components are aligned and

clearances are checked.(1) Assemble catalytic converter to exhaust mani-

fold connection. Use a new flange gasket.

1 ± HEAT SHIELD

2 ± FLOOR PAN

3 ± BAND CLAMP

4 ± FLOOR PAN

5 ± TANK STRAP

6 ± FUEL TANK

7 ± SPARE TIRE TUB

8 ± REAR SUSPENSION CROSSMEMBER

9 ± FLOOR PAN

10 ± SPARE TIRE TUB

11 ± MUFFLER12 ± BUMPER BEAM

13 ± HEAT SHIELD

14 ± OXYGEN SENSOR CLEARANCE (LEV)

15 ± FLOOR PAN

16 ± FEDERAL & LEV

17 ± OXYGEN SENSOR CLEARANCE (FEDERAL)

18 ± HEAT SHIELD

19 ± FLOOR PAN

20 ± CROSSMEMBER

21 ± TAIL PIPE

22 ± FASCIA

Fig. 10 Exhaust Manifold Support BracketÐFederal

& LEV

1 ± BRACKET

2 ± BOLT (M10)

3 ± BOLT (M12)

4 ± NUT

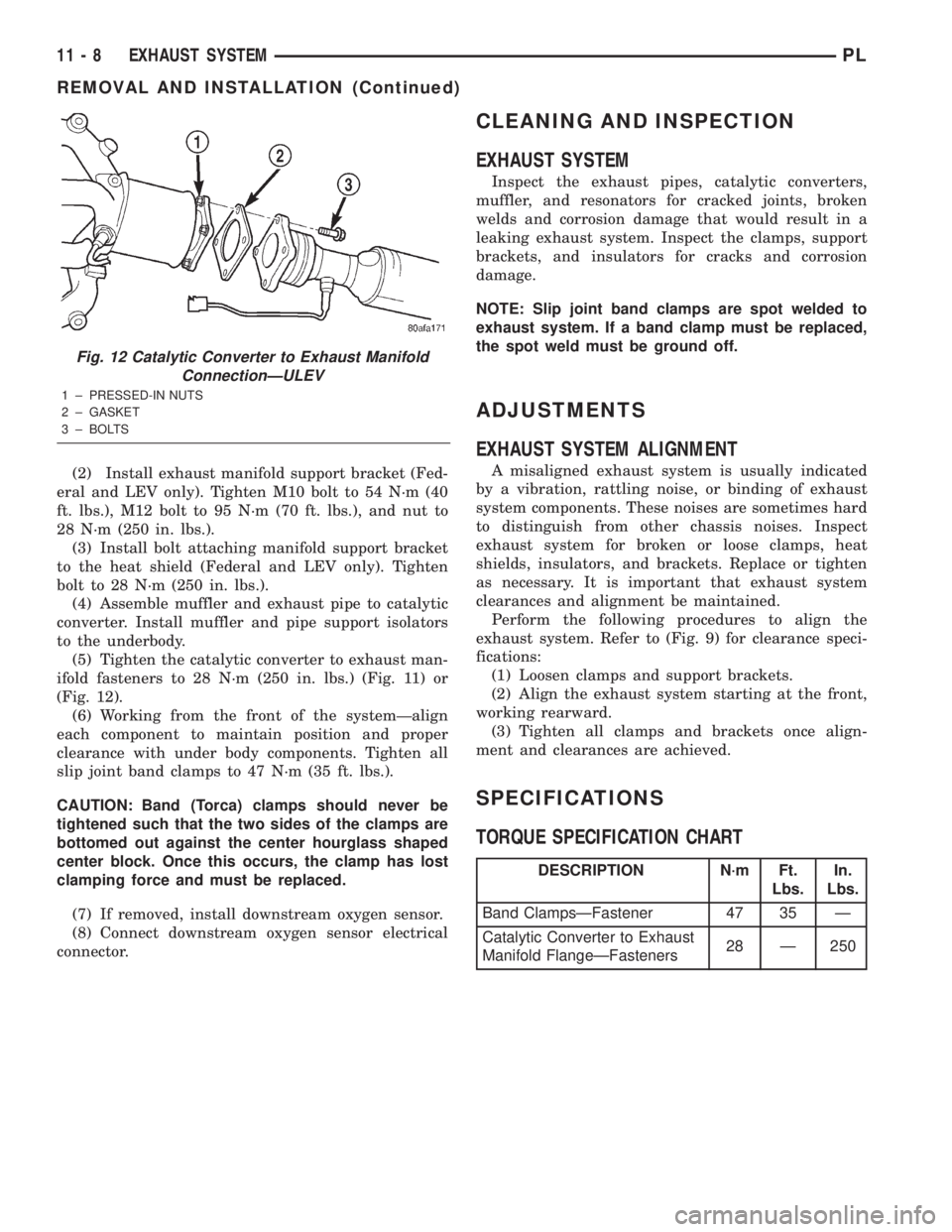

Fig. 11 Catalytic Converter to Exhaust Manifold

ConnectionÐFederal & LEV

1 ± PRESSED-IN STUDS

2 ± NUTS

3 ± GASKET

PLEXHAUST SYSTEM 11 - 7

REMOVAL AND INSTALLATION (Continued)

Page 805 of 1285

(2) Install exhaust manifold support bracket (Fed-

eral and LEV only). Tighten M10 bolt to 54 N´m (40

ft. lbs.), M12 bolt to 95 N´m (70 ft. lbs.), and nut to

28 N´m (250 in. lbs.).

(3) Install bolt attaching manifold support bracket

to the heat shield (Federal and LEV only). Tighten

bolt to 28 N´m (250 in. lbs.).

(4) Assemble muffler and exhaust pipe to catalytic

converter. Install muffler and pipe support isolators

to the underbody.

(5) Tighten the catalytic converter to exhaust man-

ifold fasteners to 28 N´m (250 in. lbs.) (Fig. 11) or

(Fig. 12).

(6) Working from the front of the systemÐalign

each component to maintain position and proper

clearance with under body components. Tighten all

slip joint band clamps to 47 N´m (35 ft. lbs.).

CAUTION: Band (Torca) clamps should never be

tightened such that the two sides of the clamps are

bottomed out against the center hourglass shaped

center block. Once this occurs, the clamp has lost

clamping force and must be replaced.

(7) If removed, install downstream oxygen sensor.

(8) Connect downstream oxygen sensor electrical

connector.

CLEANING AND INSPECTION

EXHAUST SYSTEM

Inspect the exhaust pipes, catalytic converters,

muffler, and resonators for cracked joints, broken

welds and corrosion damage that would result in a

leaking exhaust system. Inspect the clamps, support

brackets, and insulators for cracks and corrosion

damage.

NOTE: Slip joint band clamps are spot welded to

exhaust system. If a band clamp must be replaced,

the spot weld must be ground off.

ADJUSTMENTS

EXHAUST SYSTEM ALIGNMENT

A misaligned exhaust system is usually indicated

by a vibration, rattling noise, or binding of exhaust

system components. These noises are sometimes hard

to distinguish from other chassis noises. Inspect

exhaust system for broken or loose clamps, heat

shields, insulators, and brackets. Replace or tighten

as necessary. It is important that exhaust system

clearances and alignment be maintained.

Perform the following procedures to align the

exhaust system. Refer to (Fig. 9) for clearance speci-

fications:

(1) Loosen clamps and support brackets.

(2) Align the exhaust system starting at the front,

working rearward.

(3) Tighten all clamps and brackets once align-

ment and clearances are achieved.

SPECIFICATIONS

TORQUE SPECIFICATION CHART

Fig. 12 Catalytic Converter to Exhaust Manifold

ConnectionÐULEV

1 ± PRESSED-IN NUTS

2 ± GASKET

3 ± BOLTS

DESCRIPTION N´m Ft.

Lbs.In.

Lbs.

Band ClampsÐFastener 47 35 Ð

Catalytic Converter to Exhaust

Manifold FlangeÐFasteners28 Ð 250

11 - 8 EXHAUST SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 843 of 1285

DESCRIPTION AND OPERATION

INJECTION SYSTEM

All engines used in this section have a sequential

Multi-Port Electronic Fuel Injection system. The MPI

system is computer regulated and provides precise

air/fuel ratios for all driving conditions. The Power-

train Control Module (PCM) operates the fuel injec-

tion system.

The PCM regulates:

²Ignition timing

²Air/fuel ratio

²Emission control devices

²Cooling fan

²Charging system

²Idle speed

²Vehicle speed control

Various sensors provide the inputs necessary for

the PCM to correctly operate these systems. In addi-

tion to the sensors, various switches also provide

inputs to the PCM.

All inputs to the PCM are converted into signals.

The PCM can adapt its programming to meet chang-

ing operating conditions.

Fuel is injected into the intake port above the

intake valve in precise metered amounts through

electrically operated injectors. The PCM fires the

injectors in a specific sequence. Under most operat-

ing conditions, the PCM maintains an air fuel ratio

of 14.7 parts air to 1 part fuel by constantly adjust-

ing injector pulse width. Injector pulse width is the

length of time the injector is open.

The PCM adjusts injector pulse width by opening

and closing the ground path to the injector. Engine

RPM (speed) and manifold absolute pressure (air

density) are the primary inputs that determine injec-

tor pulse width.

MODES OF OPERATION

OPERATION

As input signals to the PCM change, the PCM

adjusts its response to output devices. For example,

the PCM must calculate a different injector pulse

width and ignition timing for idle than it does for

Wide Open Throttle (WOT). There are several differ-

ent modes of operation that determine how the PCM

responds to the various input signals.

There are two different areas of operation, OPEN

LOOP and CLOSED LOOP.

During OPEN LOOP modes the PCM receives

input signals and responds according to preset PCM

programming. Inputs from the upstream and down-

stream heated oxygen sensors are not monitored dur-

ing OPEN LOOP modes, except for heated oxygensensor diagnostics (they are checked for shorted con-

ditions at all times).

During CLOSED LOOP modes the PCM monitors

the inputs from the upstream and downstream

heated oxygen sensors. The upstream heated oxygen

sensor input tells the PCM if the calculated injector

pulse width resulted in the ideal air-fuel ratio of 14.7

to one. By monitoring the exhaust oxygen content

through the upstream heated oxygen sensor, the

PCM can fine tune injector pulse width. Fine tuning

injector pulse width allows the PCM to achieve opti-

mum fuel economy combined with low emissions.

For the PCM to enter CLOSED LOOP operation,

the following must occur:

(1) Engine coolant temperature must be over 35ÉF.

²If the coolant is over 35É the PCM will wait 44

seconds.

²If the coolant is over 50ÉF the PCM will wait 38

seconds.

²If the coolant is over 167ÉF the PCM will wait

11 seconds.

(2) For other temperatures the PCM will interpo-

late the correct waiting time.

(3) O2 sensor must read either greater than 0.745

volts or less than 0.1 volt.

(4) The multi-port fuel injection systems has the

following modes of operation:

²Ignition switch ON (Zero RPM)

²Engine start-up

²Engine warm-up

²Cruise

²Idle

²Acceleration

²Deceleration

²Wide Open Throttle

²Ignition switch OFF

(5) The engine start-up (crank), engine warm-up,

deceleration with fuel shutoff and wide open throttle

modes are OPEN LOOP modes. Under most operat-

ing conditions, the acceleration, deceleration (with

A/C on), idle and cruise modes,with the engine at

operating temperatureare CLOSED LOOP modes.

IGNITION SWITCH ON (ZERO RPM) MODE

When the ignition switch activates the fuel injec-

tion system, the following actions occur:

²The PCM monitors the engine coolant tempera-

ture sensor and throttle position sensor input. The

PCM determines basic fuel injector pulse width from

this input.

²The PCM determines atmospheric air pressure

from the MAP sensor input to modify injector pulse

width.

When the key is in the ON position and the engine

is not running (zero rpm), the Auto Shutdown (ASD)

and fuel pump relays de-energize after approximately

14 - 22 FUEL SYSTEMPL

Page 844 of 1285

1 second. Therefore, battery voltage is not supplied to

the fuel pump, ignition coil, fuel injectors and heated

oxygen sensors.

ENGINE START-UP MODE

This is an OPEN LOOP mode. If the vehicle is in

park or neutral (automatic transaxles) or the clutch

pedal is depressed (manual transaxles) the ignition

switch energizes the starter relay. The following

actions occur when the starter motor is engaged.

²If the PCM receives the camshaft position sensor

and crankshaft position sensor signals, it energizes

the Auto Shutdown (ASD) relay and fuel pump relay.

If the PCM does not receive both signals within

approximately one second, it will not energize the

ASD relay and fuel pump relay. The ASD and fuel

pump relays supply battery voltage to the fuel pump,

fuel injectors, ignition coil and heated oxygen sen-

sors.

²The PCM energizes the injectors (on the 69É

degree falling edge) for a calculated pulse width until

it determines crankshaft position from the camshaft

position sensor and crankshaft position sensor sig-

nals. The PCM determines crankshaft position within

1 engine revolution.

²After determining crankshaft position, the PCM

begins energizing the injectors in sequence. It adjusts

injector pulse width and controls injector synchroni-

zation by turning the individual ground paths to the

injectors On and Off.

²When the engine idles within664 RPM of its

target RPM, the PCM compares current MAP sensor

value with the atmospheric pressure value received

during the Ignition Switch On (zero RPM) mode. If

the PCM does not detect a minimum difference

between the two values, it sets a MAP diagnostic

trouble code into memory.

Once the ASD and fuel pump relays have been

energized, the PCM determines injector pulse width

based on the following:

²Battery voltage

²Engine coolant temperature

²Engine RPM

²Intake air temperature (IAT)

²Throttle position

²The number of engine revolutions since cranking

was initiated.

During Start-up the PCM maintains ignition tim-

ing at 9É BTDC.

ENGINE WARM-UP MODE

This is an OPEN LOOP mode. The following inputs

are received by the PCM:

²Engine coolant temperature

²Manifold Absolute Pressure (MAP)

²Intake air temperature (IAT)²Crankshaft position (engine speed)

²Camshaft position

²Knock sensor

²Throttle position

²A/C switch

²Battery voltage

²Power steering pressure switch

²Vehicle speed

²Speed control

²O2 sensors

²All diagnostics

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off.

The PCM adjusts ignition timing and engine idle

speed. Engine idle speed is adjusted through the idle

air control motor.

CRUISE OR IDLE MODE

When the engine is at operating temperature this

is a CLOSED LOOP mode. During cruising or idle

the following inputs are received by the PCM:

²Intake air temperature

²Engine coolant temperature

²Manifold absolute pressure

²Crankshaft position (engine speed)

²Camshaft position

²Knock sensor

²Throttle position

²Exhaust gas oxygen content

²A/C control positions

²Power steering pressure switch

²Battery voltage

²Vehicle speed

The PCM adjusts injector pulse width and controls

injector synchronization by turning the individual

ground paths to the injectors On and Off.

The PCM adjusts engine idle speed and ignition

timing. The PCM adjusts the air/fuel ratio according

to the oxygen content in the exhaust gas (measured

by the upstream and downstream heated oxygen sen-

sor).

The PCM monitors for engine misfire. During

active misfire and depending on the severity, the

PCM either continuously illuminates or flashes the

malfunction indicator lamp (Check Engine light on

instrument panel). Also, the PCM stores an engine

misfire DTC in memory.

The PCM performs several diagnostic routines.

They include:

²Oxygen sensor monitor

²Downstream heated oxygen sensor diagnostics

during open loop operation (except for shorted)

²Fuel system monitor

²EGR monitor

²Purge system monitor

PLFUEL SYSTEM 14 - 23

DESCRIPTION AND OPERATION (Continued)

Page 845 of 1285

²All inputs monitored for proper voltage range.

²All monitored components (refer to the Emission

section for On-Board Diagnostics).

The PCM compares the upstream and downstream

heated oxygen sensor inputs to measure catalytic

convertor efficiency. If the catalyst efficiency drops

below the minimum acceptable percentage, the PCM

stores a diagnostic trouble code in memory.

During certain idle conditions, the PCM may enter

a variable idle speed strategy. During variable idle

speed strategy the PCM adjusts engine speed based

on the following inputs.

²A/C sense

²Battery voltage

²Battery temperature

²Engine coolant temperature

²Engine run time

²Power steering pressure switch

²Vehicle mileage

ACCELERATION MODE

This is a CLOSED LOOP mode. The PCM recog-

nizes an abrupt increase in Throttle Position sensor

output voltage or MAP sensor output voltage as a

demand for increased engine output and vehicle

acceleration. The PCM increases injector pulse width

in response to increased fuel demand.

DECELERATION MODE

This is a CLOSED LOOP mode. During decelera-

tion the following inputs are received by the PCM:

²A/C pressure transducer

²A/C sense

²Battery voltage

²Intake air temperature

²Engine coolant temperature

²Crankshaft position (engine speed)

²Exhaust gas oxygen content (upstream heated

oxygen sensor)

²Knock sensor

²Manifold absolute pressure

²Power steering pressure switch

²Throttle position

²IAC motor control changes in response to MAP

sensor feedback.

The PCM may receive a closed throttle input from

the Throttle Position Sensor (TPS) when it senses an

abrupt decrease in manifold pressure. This indicates

a hard deceleration. In response, the PCM may

momentarily turn off the injectors. This helps

improve fuel economy, emissions and engine braking.

If decel fuel shutoff is detected, downstream oxy-

gen sensor diagnostics is performed.WIDE-OPEN-THROTTLE MODE

This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are received

by the PCM:

²Intake air temperature

²Engine coolant temperature

²Engine speed

²Knock sensor

²Manifold absolute pressure

²Throttle position

When the PCM senses a wide-open-throttle condi-

tion through the Throttle Position Sensor (TPS) it de-

energizes the A/C compressor clutch relay. This

disables the air conditioning system.

The PCM does not monitor the heated oxygen sen-

sor inputs during wide-open-throttle operation except

for downstream heated oxygen sensor and both

shorted diagnostics. The PCM adjusts injector pulse

width to supply a predetermined amount of addi-

tional fuel.

IGNITION SWITCH OFF MODE

When the operator turns the ignition switch to the

OFF position, the following occurs:

²All outputs are turned off, unless 02 Heater

Monitor test is being run. Refer to the Emission sec-

tion for On-Board Diagnostics.

²No inputs are monitored except for the heated

oxygen sensors. The PCM monitors the heating ele-

ments in the oxygen sensors and then shuts down.

SYSTEM DIAGNOSIS

OPERATION

The PCM can test many of its own input and out-

put circuits. If the PCM senses a fault in a major

system, the PCM stores a Diagnostic Trouble Code

(DTC) in memory.

For DTC information see On-Board Diagnostics.

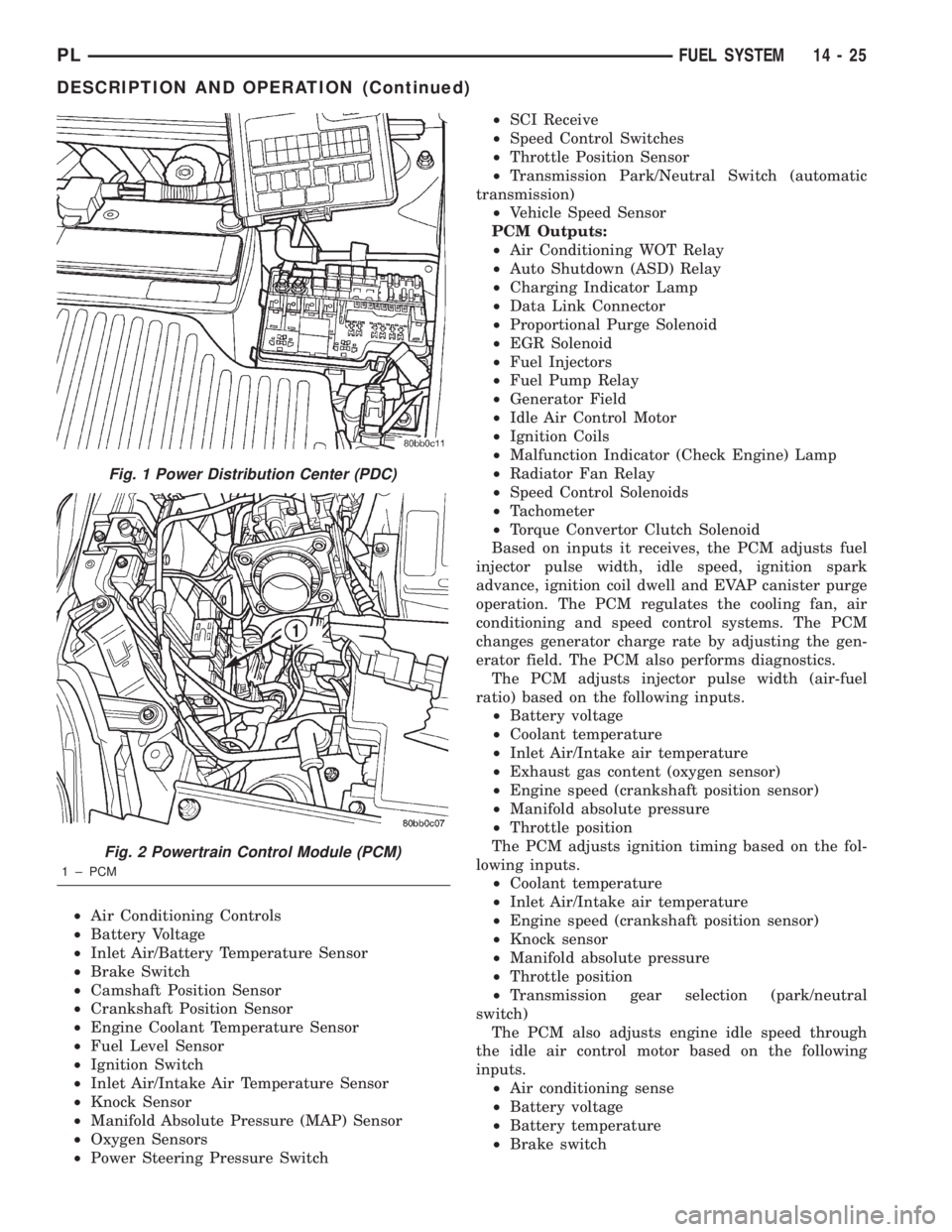

POWER DISTRIBUTION CENTER

The Power Distribution Center (PDC) is located

next to the battery (Fig. 1). The PDC contains the

starter relay, radiator fan relay, A/C compressor

clutch relay, auto shutdown relay, fuel pump relay

and several fuses.

POWERTRAIN CONTROL MODULE

The Powertrain Control Module (PCM) is a digital

computer containing a microprocessor (Fig. 2). The

PCM receives input signals from various switches

and sensors that are referred to as PCM Inputs.

Based on these inputs, the PCM adjusts various

engine and vehicle operations through devices that

are referred to as PCM Outputs.

PCM Inputs:

14 - 24 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 846 of 1285

²Air Conditioning Controls

²Battery Voltage

²Inlet Air/Battery Temperature Sensor

²Brake Switch

²Camshaft Position Sensor

²Crankshaft Position Sensor

²Engine Coolant Temperature Sensor

²Fuel Level Sensor

²Ignition Switch

²Inlet Air/Intake Air Temperature Sensor

²Knock Sensor

²Manifold Absolute Pressure (MAP) Sensor

²Oxygen Sensors

²Power Steering Pressure Switch²SCI Receive

²Speed Control Switches

²Throttle Position Sensor

²Transmission Park/Neutral Switch (automatic

transmission)

²Vehicle Speed Sensor

PCM Outputs:

²Air Conditioning WOT Relay

²Auto Shutdown (ASD) Relay

²Charging Indicator Lamp

²Data Link Connector

²Proportional Purge Solenoid

²EGR Solenoid

²Fuel Injectors

²Fuel Pump Relay

²Generator Field

²Idle Air Control Motor

²Ignition Coils

²Malfunction Indicator (Check Engine) Lamp

²Radiator Fan Relay

²Speed Control Solenoids

²Tachometer

²Torque Convertor Clutch Solenoid

Based on inputs it receives, the PCM adjusts fuel

injector pulse width, idle speed, ignition spark

advance, ignition coil dwell and EVAP canister purge

operation. The PCM regulates the cooling fan, air

conditioning and speed control systems. The PCM

changes generator charge rate by adjusting the gen-

erator field. The PCM also performs diagnostics.

The PCM adjusts injector pulse width (air-fuel

ratio) based on the following inputs.

²Battery voltage

²Coolant temperature

²Inlet Air/Intake air temperature

²Exhaust gas content (oxygen sensor)

²Engine speed (crankshaft position sensor)

²Manifold absolute pressure

²Throttle position

The PCM adjusts ignition timing based on the fol-

lowing inputs.

²Coolant temperature

²Inlet Air/Intake air temperature

²Engine speed (crankshaft position sensor)

²Knock sensor

²Manifold absolute pressure

²Throttle position

²Transmission gear selection (park/neutral

switch)

The PCM also adjusts engine idle speed through

the idle air control motor based on the following

inputs.

²Air conditioning sense

²Battery voltage

²Battery temperature

²Brake switch

Fig. 1 Power Distribution Center (PDC)

Fig. 2 Powertrain Control Module (PCM)

1 ± PCM

PLFUEL SYSTEM 14 - 25

DESCRIPTION AND OPERATION (Continued)

Page 853 of 1285

HEATED OXYGEN SENSOR (O2 SENSOR)Ð

PCM INPUT

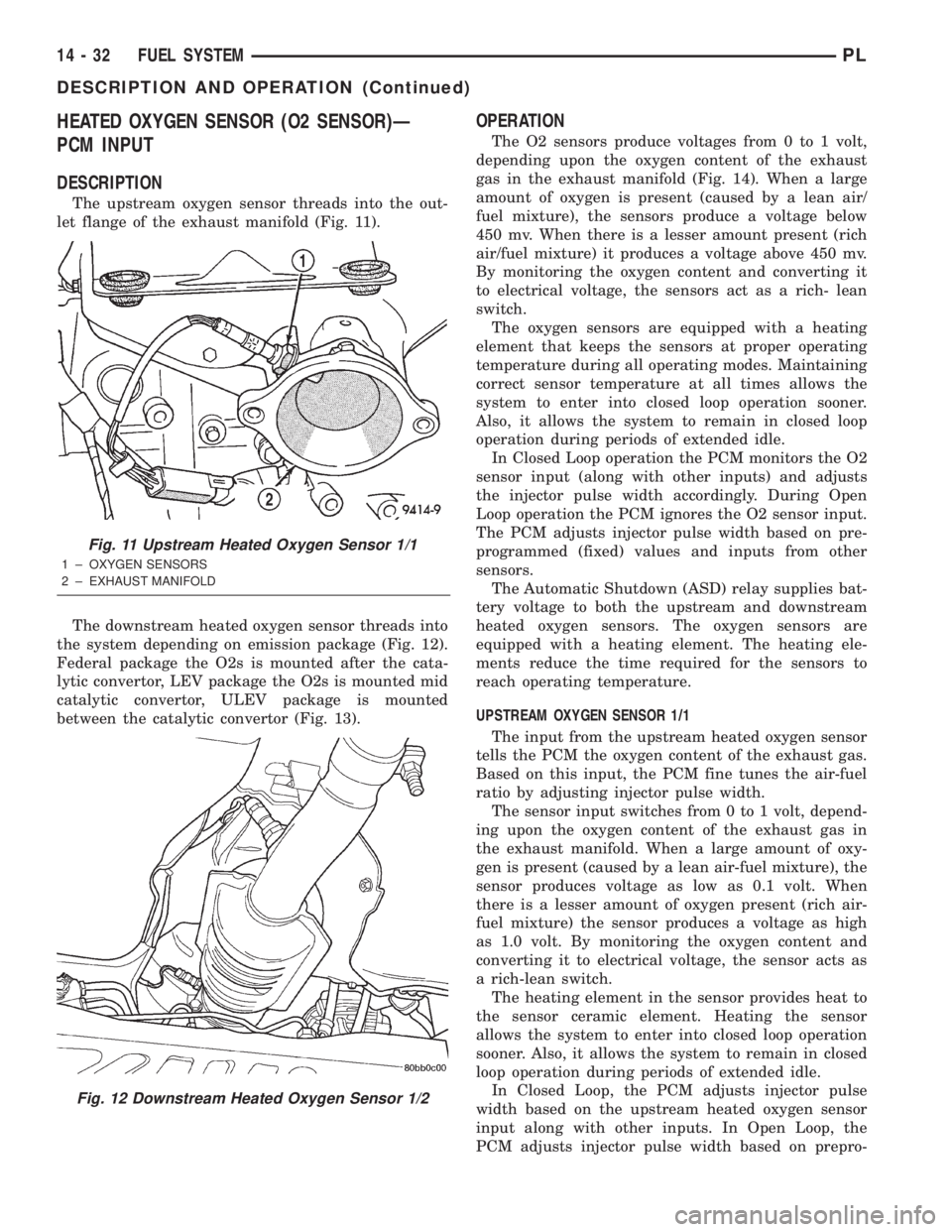

DESCRIPTION

The upstream oxygen sensor threads into the out-

let flange of the exhaust manifold (Fig. 11).

The downstream heated oxygen sensor threads into

the system depending on emission package (Fig. 12).

Federal package the O2s is mounted after the cata-

lytic convertor, LEV package the O2s is mounted mid

catalytic convertor, ULEV package is mounted

between the catalytic convertor (Fig. 13).

OPERATION

The O2 sensors produce voltages from 0 to 1 volt,

depending upon the oxygen content of the exhaust

gas in the exhaust manifold (Fig. 14). When a large

amount of oxygen is present (caused by a lean air/

fuel mixture), the sensors produce a voltage below

450 mv. When there is a lesser amount present (rich

air/fuel mixture) it produces a voltage above 450 mv.

By monitoring the oxygen content and converting it

to electrical voltage, the sensors act as a rich- lean

switch.

The oxygen sensors are equipped with a heating

element that keeps the sensors at proper operating

temperature during all operating modes. Maintaining

correct sensor temperature at all times allows the

system to enter into closed loop operation sooner.

Also, it allows the system to remain in closed loop

operation during periods of extended idle.

In Closed Loop operation the PCM monitors the O2

sensor input (along with other inputs) and adjusts

the injector pulse width accordingly. During Open

Loop operation the PCM ignores the O2 sensor input.

The PCM adjusts injector pulse width based on pre-

programmed (fixed) values and inputs from other

sensors.

The Automatic Shutdown (ASD) relay supplies bat-

tery voltage to both the upstream and downstream

heated oxygen sensors. The oxygen sensors are

equipped with a heating element. The heating ele-

ments reduce the time required for the sensors to

reach operating temperature.

UPSTREAM OXYGEN SENSOR 1/1

The input from the upstream heated oxygen sensor

tells the PCM the oxygen content of the exhaust gas.

Based on this input, the PCM fine tunes the air-fuel

ratio by adjusting injector pulse width.

The sensor input switches from 0 to 1 volt, depend-

ing upon the oxygen content of the exhaust gas in

the exhaust manifold. When a large amount of oxy-

gen is present (caused by a lean air-fuel mixture), the

sensor produces voltage as low as 0.1 volt. When

there is a lesser amount of oxygen present (rich air-

fuel mixture) the sensor produces a voltage as high

as 1.0 volt. By monitoring the oxygen content and

converting it to electrical voltage, the sensor acts as

a rich-lean switch.

The heating element in the sensor provides heat to

the sensor ceramic element. Heating the sensor

allows the system to enter into closed loop operation

sooner. Also, it allows the system to remain in closed

loop operation during periods of extended idle.

In Closed Loop, the PCM adjusts injector pulse

width based on the upstream heated oxygen sensor

input along with other inputs. In Open Loop, the

PCM adjusts injector pulse width based on prepro-

Fig. 11 Upstream Heated Oxygen Sensor 1/1

1 ± OXYGEN SENSORS

2 ± EXHAUST MANIFOLD

Fig. 12 Downstream Heated Oxygen Sensor 1/2

14 - 32 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)