steering DODGE NEON 2000 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 92 of 1285

Some discoloration or wear of the rotor surface is

normal and does not require resurfacing when lin-

ings are replaced. If cracks or burned spots are evi-

dent, the rotor must be replaced.

ROTOR MINIMUM THICKNESS

Measure rotor thickness at the center of the brake

shoe contact surface. Replace the rotor if it is worn

below minimum thickness or if machining the rotor

will cause its thickness to fall below specifications.

CAUTION: Do not machine the rotor if it will cause

the rotor to fall below minimum thickness.

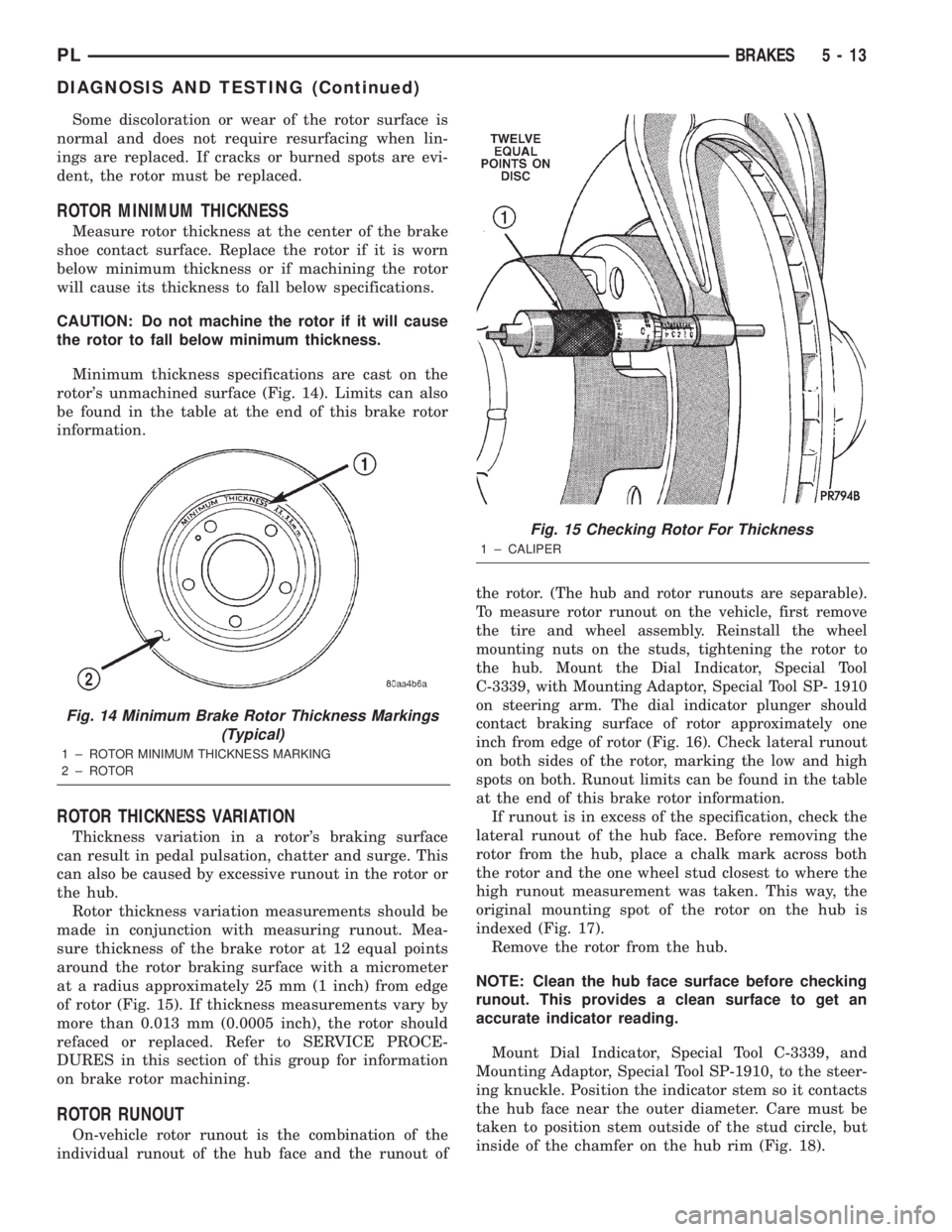

Minimum thickness specifications are cast on the

rotor's unmachined surface (Fig. 14). Limits can also

be found in the table at the end of this brake rotor

information.

ROTOR THICKNESS VARIATION

Thickness variation in a rotor's braking surface

can result in pedal pulsation, chatter and surge. This

can also be caused by excessive runout in the rotor or

the hub.

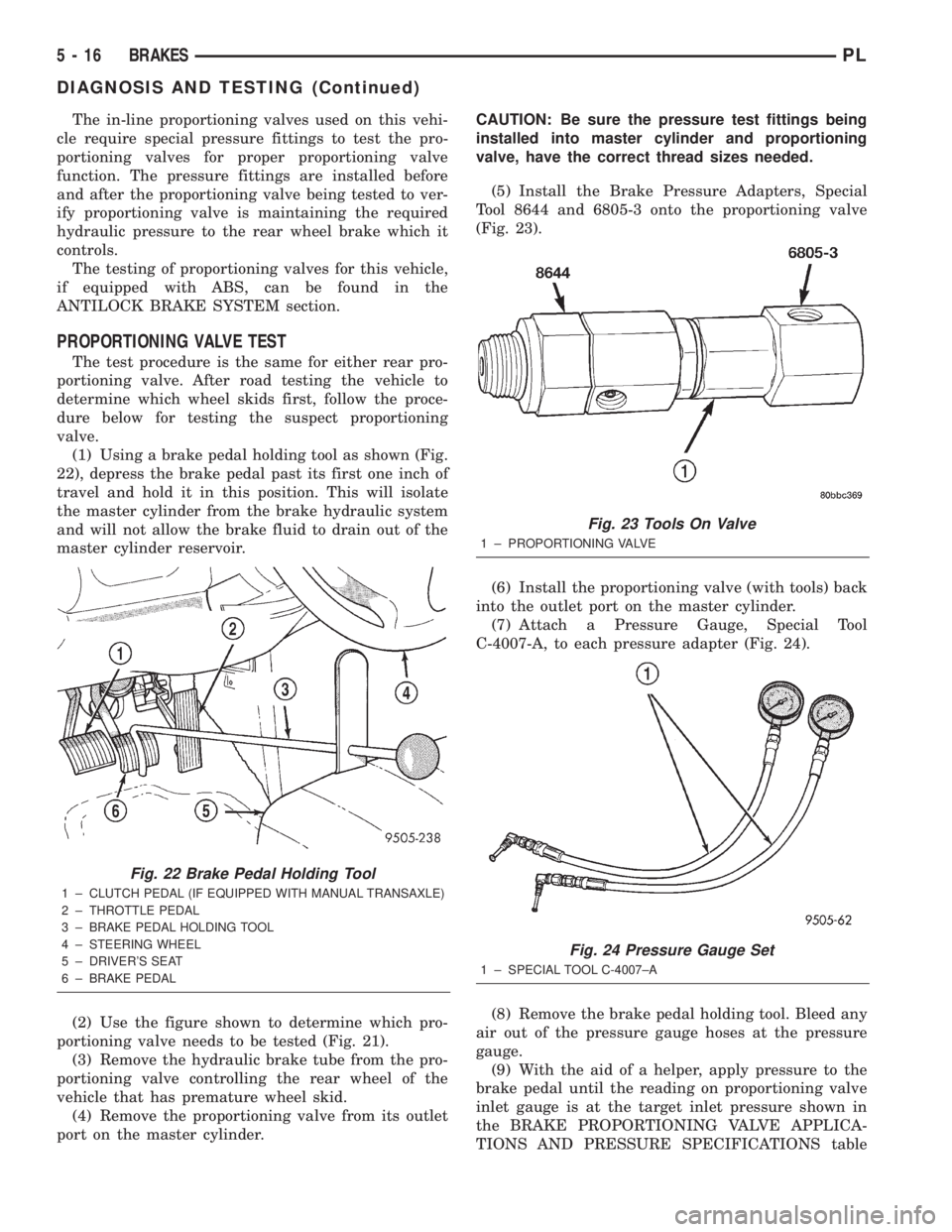

Rotor thickness variation measurements should be

made in conjunction with measuring runout. Mea-

sure thickness of the brake rotor at 12 equal points

around the rotor braking surface with a micrometer

at a radius approximately 25 mm (1 inch) from edge

of rotor (Fig. 15). If thickness measurements vary by

more than 0.013 mm (0.0005 inch), the rotor should

refaced or replaced. Refer to SERVICE PROCE-

DURES in this section of this group for information

on brake rotor machining.

ROTOR RUNOUT

On-vehicle rotor runout is the combination of the

individual runout of the hub face and the runout ofthe rotor. (The hub and rotor runouts are separable).

To measure rotor runout on the vehicle, first remove

the tire and wheel assembly. Reinstall the wheel

mounting nuts on the studs, tightening the rotor to

the hub. Mount the Dial Indicator, Special Tool

C-3339, with Mounting Adaptor, Special Tool SP- 1910

on steering arm. The dial indicator plunger should

contact braking surface of rotor approximately one

inch from edge of rotor (Fig. 16). Check lateral runout

on both sides of the rotor, marking the low and high

spots on both. Runout limits can be found in the table

at the end of this brake rotor information.

If runout is in excess of the specification, check the

lateral runout of the hub face. Before removing the

rotor from the hub, place a chalk mark across both

the rotor and the one wheel stud closest to where the

high runout measurement was taken. This way, the

original mounting spot of the rotor on the hub is

indexed (Fig. 17).

Remove the rotor from the hub.

NOTE: Clean the hub face surface before checking

runout. This provides a clean surface to get an

accurate indicator reading.

Mount Dial Indicator, Special Tool C-3339, and

Mounting Adaptor, Special Tool SP-1910, to the steer-

ing knuckle. Position the indicator stem so it contacts

the hub face near the outer diameter. Care must be

taken to position stem outside of the stud circle, but

inside of the chamfer on the hub rim (Fig. 18).

Fig. 14 Minimum Brake Rotor Thickness Markings

(Typical)

1 ± ROTOR MINIMUM THICKNESS MARKING

2 ± ROTOR

Fig. 15 Checking Rotor For Thickness

1 ± CALIPER

PLBRAKES 5 - 13

DIAGNOSIS AND TESTING (Continued)

Page 95 of 1285

The in-line proportioning valves used on this vehi-

cle require special pressure fittings to test the pro-

portioning valves for proper proportioning valve

function. The pressure fittings are installed before

and after the proportioning valve being tested to ver-

ify proportioning valve is maintaining the required

hydraulic pressure to the rear wheel brake which it

controls.

The testing of proportioning valves for this vehicle,

if equipped with ABS, can be found in the

ANTILOCK BRAKE SYSTEM section.

PROPORTIONING VALVE TEST

The test procedure is the same for either rear pro-

portioning valve. After road testing the vehicle to

determine which wheel skids first, follow the proce-

dure below for testing the suspect proportioning

valve.

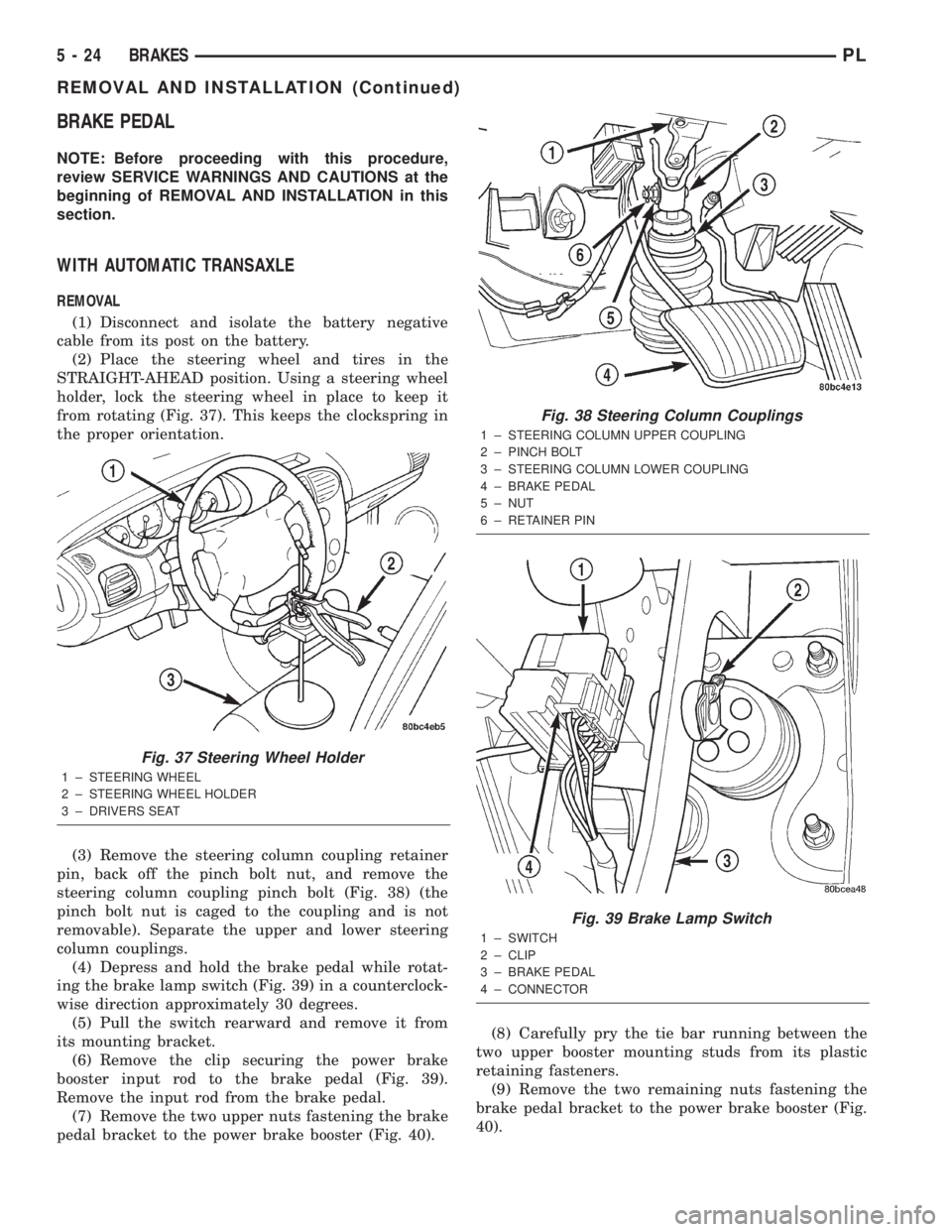

(1) Using a brake pedal holding tool as shown (Fig.

22), depress the brake pedal past its first one inch of

travel and hold it in this position. This will isolate

the master cylinder from the brake hydraulic system

and will not allow the brake fluid to drain out of the

master cylinder reservoir.

(2) Use the figure shown to determine which pro-

portioning valve needs to be tested (Fig. 21).

(3) Remove the hydraulic brake tube from the pro-

portioning valve controlling the rear wheel of the

vehicle that has premature wheel skid.

(4) Remove the proportioning valve from its outlet

port on the master cylinder.CAUTION: Be sure the pressure test fittings being

installed into master cylinder and proportioning

valve, have the correct thread sizes needed.

(5) Install the Brake Pressure Adapters, Special

Tool 8644 and 6805-3 onto the proportioning valve

(Fig. 23).

(6) Install the proportioning valve (with tools) back

into the outlet port on the master cylinder.

(7) Attach a Pressure Gauge, Special Tool

C-4007-A, to each pressure adapter (Fig. 24).

(8) Remove the brake pedal holding tool. Bleed any

air out of the pressure gauge hoses at the pressure

gauge.

(9) With the aid of a helper, apply pressure to the

brake pedal until the reading on proportioning valve

inlet gauge is at the target inlet pressure shown in

the BRAKE PROPORTIONING VALVE APPLICA-

TIONS AND PRESSURE SPECIFICATIONS table

Fig. 22 Brake Pedal Holding Tool

1 ± CLUTCH PEDAL (IF EQUIPPED WITH MANUAL TRANSAXLE)

2 ± THROTTLE PEDAL

3 ± BRAKE PEDAL HOLDING TOOL

4 ± STEERING WHEEL

5 ± DRIVER'S SEAT

6 ± BRAKE PEDAL

Fig. 23 Tools On Valve

1 ± PROPORTIONING VALVE

Fig. 24 Pressure Gauge Set

1 ± SPECIAL TOOL C-4007±A

5 - 16 BRAKESPL

DIAGNOSIS AND TESTING (Continued)

Page 103 of 1285

BRAKE PEDAL

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

WITH AUTOMATIC TRANSAXLE

REMOVAL

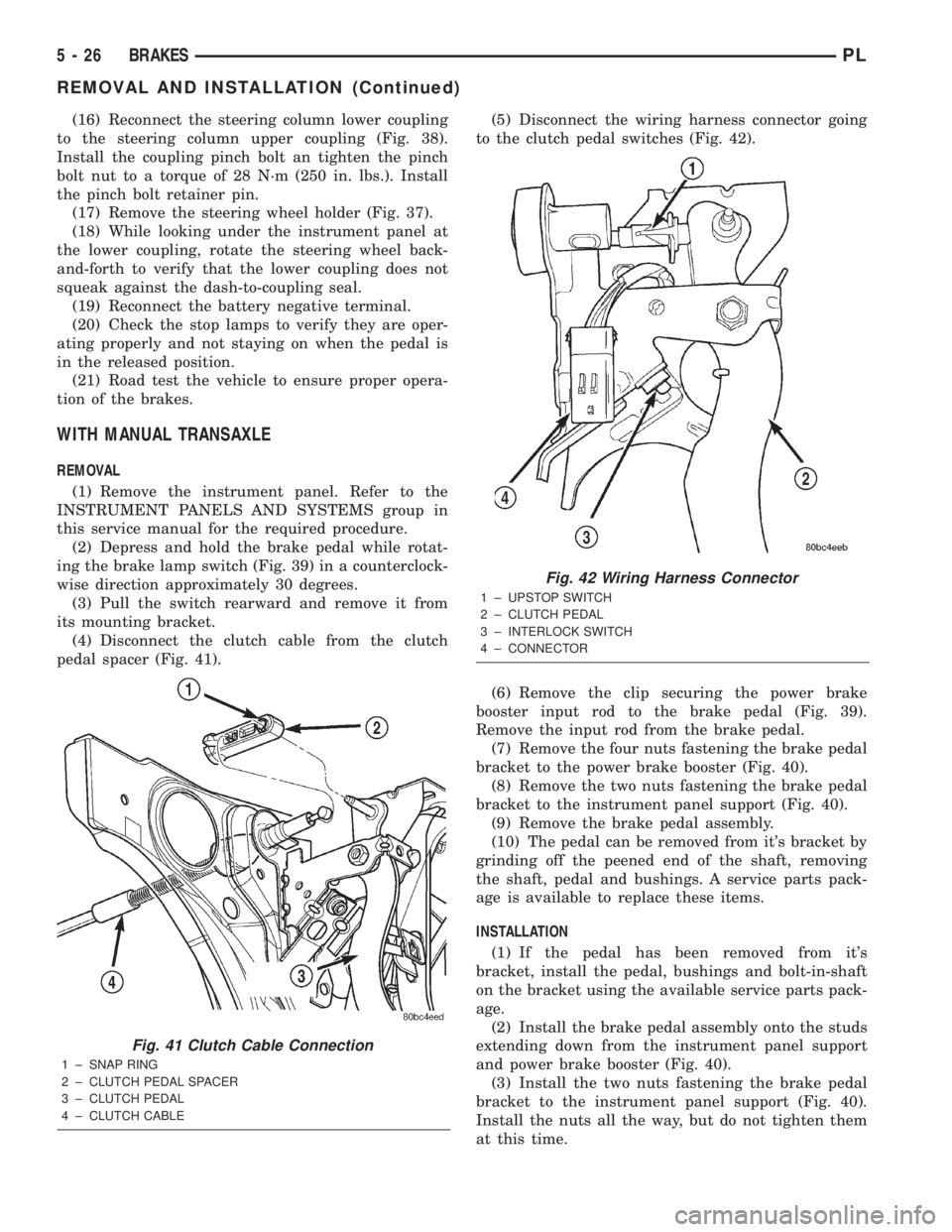

(1) Disconnect and isolate the battery negative

cable from its post on the battery.

(2) Place the steering wheel and tires in the

STRAIGHT-AHEAD position. Using a steering wheel

holder, lock the steering wheel in place to keep it

from rotating (Fig. 37). This keeps the clockspring in

the proper orientation.

(3) Remove the steering column coupling retainer

pin, back off the pinch bolt nut, and remove the

steering column coupling pinch bolt (Fig. 38) (the

pinch bolt nut is caged to the coupling and is not

removable). Separate the upper and lower steering

column couplings.

(4) Depress and hold the brake pedal while rotat-

ing the brake lamp switch (Fig. 39) in a counterclock-

wise direction approximately 30 degrees.

(5) Pull the switch rearward and remove it from

its mounting bracket.

(6) Remove the clip securing the power brake

booster input rod to the brake pedal (Fig. 39).

Remove the input rod from the brake pedal.

(7) Remove the two upper nuts fastening the brake

pedal bracket to the power brake booster (Fig. 40).(8) Carefully pry the tie bar running between the

two upper booster mounting studs from its plastic

retaining fasteners.

(9) Remove the two remaining nuts fastening the

brake pedal bracket to the power brake booster (Fig.

40).

Fig. 37 Steering Wheel Holder

1 ± STEERING WHEEL

2 ± STEERING WHEEL HOLDER

3 ± DRIVERS SEAT

Fig. 38 Steering Column Couplings

1 ± STEERING COLUMN UPPER COUPLING

2 ± PINCH BOLT

3 ± STEERING COLUMN LOWER COUPLING

4 ± BRAKE PEDAL

5 ± NUT

6 ± RETAINER PIN

Fig. 39 Brake Lamp Switch

1 ± SWITCH

2 ± CLIP

3 ± BRAKE PEDAL

4 ± CONNECTOR

5 - 24 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 105 of 1285

(16) Reconnect the steering column lower coupling

to the steering column upper coupling (Fig. 38).

Install the coupling pinch bolt an tighten the pinch

bolt nut to a torque of 28 N´m (250 in. lbs.). Install

the pinch bolt retainer pin.

(17) Remove the steering wheel holder (Fig. 37).

(18) While looking under the instrument panel at

the lower coupling, rotate the steering wheel back-

and-forth to verify that the lower coupling does not

squeak against the dash-to-coupling seal.

(19) Reconnect the battery negative terminal.

(20) Check the stop lamps to verify they are oper-

ating properly and not staying on when the pedal is

in the released position.

(21) Road test the vehicle to ensure proper opera-

tion of the brakes.

WITH MANUAL TRANSAXLE

REMOVAL

(1) Remove the instrument panel. Refer to the

INSTRUMENT PANELS AND SYSTEMS group in

this service manual for the required procedure.

(2) Depress and hold the brake pedal while rotat-

ing the brake lamp switch (Fig. 39) in a counterclock-

wise direction approximately 30 degrees.

(3) Pull the switch rearward and remove it from

its mounting bracket.

(4) Disconnect the clutch cable from the clutch

pedal spacer (Fig. 41).(5) Disconnect the wiring harness connector going

to the clutch pedal switches (Fig. 42).

(6) Remove the clip securing the power brake

booster input rod to the brake pedal (Fig. 39).

Remove the input rod from the brake pedal.

(7) Remove the four nuts fastening the brake pedal

bracket to the power brake booster (Fig. 40).

(8) Remove the two nuts fastening the brake pedal

bracket to the instrument panel support (Fig. 40).

(9) Remove the brake pedal assembly.

(10) The pedal can be removed from it's bracket by

grinding off the peened end of the shaft, removing

the shaft, pedal and bushings. A service parts pack-

age is available to replace these items.

INSTALLATION

(1) If the pedal has been removed from it's

bracket, install the pedal, bushings and bolt-in-shaft

on the bracket using the available service parts pack-

age.

(2) Install the brake pedal assembly onto the studs

extending down from the instrument panel support

and power brake booster (Fig. 40).

(3) Install the two nuts fastening the brake pedal

bracket to the instrument panel support (Fig. 40).

Install the nuts all the way, but do not tighten them

at this time.

Fig. 41 Clutch Cable Connection

1 ± SNAP RING

2 ± CLUTCH PEDAL SPACER

3 ± CLUTCH PEDAL

4 ± CLUTCH CABLE

Fig. 42 Wiring Harness Connector

1 ± UPSTOP SWITCH

2 ± CLUTCH PEDAL

3 ± INTERLOCK SWITCH

4 ± CONNECTOR

5 - 26 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 111 of 1285

CAUTION: Use only a new brake booster input rod-

to-brake pedal retaining clip to ensure proper

retainment.

(4) Connect the power brake booster input rod-to-

brake pedal pin. Install a new retaining clip. Do not

use the old clip.

(5) Connect all previously removed vacuum hoses

to the vacuum check valve (Fig. 49).

(6) If the vehicle is equipped with ABS, install the

ICU mounting bracket on the frame rail using its

three bolts. Tighten the nuts to a torque of 23 N´m

(200 in. lbs.).

(7) If the vehicle is equipped with ABS, reinstall

the ICU. Refer to INTEGRATED CONTROL UNIT in

REMOVAL AND INSTALLATION within the

ANTILOCK BRAKE SYSTEM section of this service

manual group for the procedure.

(8) Install the master cylinder. For the master cyl-

inder without ABS removal and installation proce-

dure, refer to MASTER CYLINDER in this section of

this service manual group. For the master cylinder

with ABS removal and installation procedure, refer

to MASTER CYLINDER in the ANTILOCK BRAKE

SYSTEM section of this service manual group.

(9) Position the battery tray back in place. Install

the two bolts, then the two nuts mounting the bat-

tery tray to its bracket (Fig. 48). Tighten the two

bolts and nuts to a torque of 34 N´m (25 ft. lbs.).

(10) Reinstall the air cleaner box onto its grom-

meted alignment post (Fig. 48).

(11) Install the one nut and one bolt securing the

air cleaner box in place, then connect the wiring har-

ness connector at the air inlet sensor.

(12) Install the battery and clamp it in place.

(13) Connect the positive, then the negative

(ground) cable on the battery.

(14) Adjust the stop lamp switch as necessary.

Refer to STOP LAMP SWITCH in the ADJUST-

MENTS section of this group.

(15) Bleed the base brake system.

(16) Road test the vehicle to ensure proper opera-

tion of the brakes.

PROPORTIONING VALVE

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

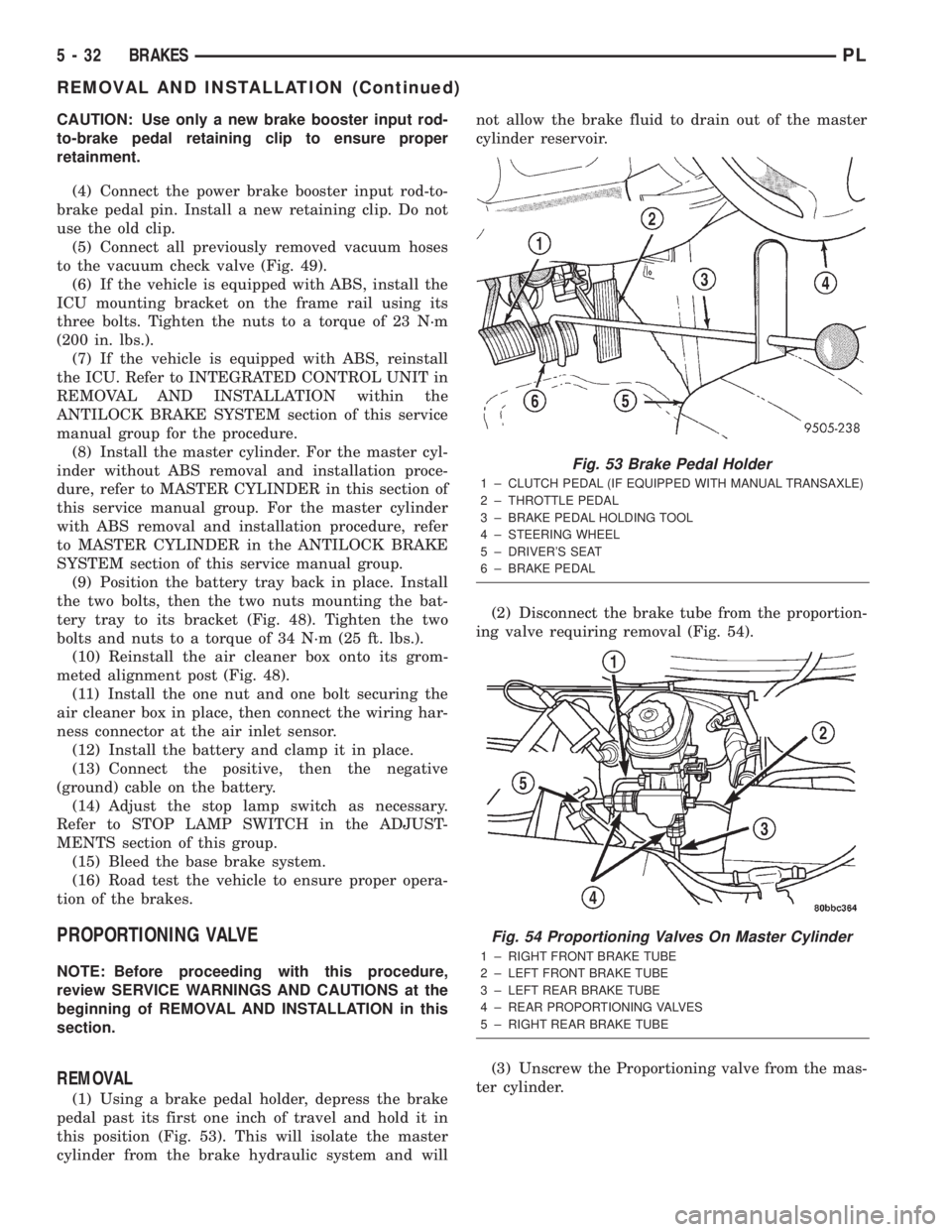

(1) Using a brake pedal holder, depress the brake

pedal past its first one inch of travel and hold it in

this position (Fig. 53). This will isolate the master

cylinder from the brake hydraulic system and willnot allow the brake fluid to drain out of the master

cylinder reservoir.

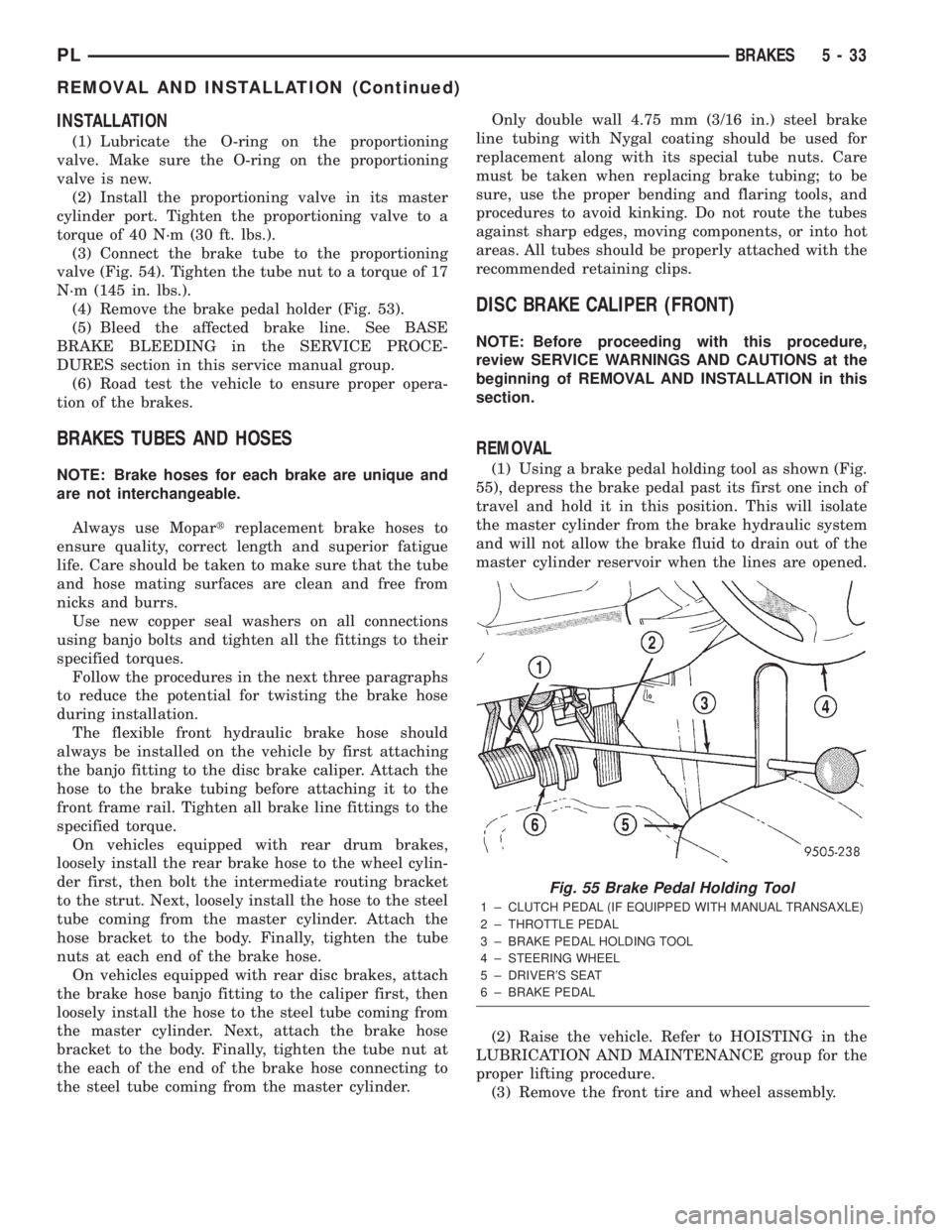

(2) Disconnect the brake tube from the proportion-

ing valve requiring removal (Fig. 54).

(3) Unscrew the Proportioning valve from the mas-

ter cylinder.

Fig. 53 Brake Pedal Holder

1 ± CLUTCH PEDAL (IF EQUIPPED WITH MANUAL TRANSAXLE)

2 ± THROTTLE PEDAL

3 ± BRAKE PEDAL HOLDING TOOL

4 ± STEERING WHEEL

5 ± DRIVER'S SEAT

6 ± BRAKE PEDAL

Fig. 54 Proportioning Valves On Master Cylinder

1 ± RIGHT FRONT BRAKE TUBE

2 ± LEFT FRONT BRAKE TUBE

3 ± LEFT REAR BRAKE TUBE

4 ± REAR PROPORTIONING VALVES

5 ± RIGHT REAR BRAKE TUBE

5 - 32 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 112 of 1285

INSTALLATION

(1) Lubricate the O-ring on the proportioning

valve. Make sure the O-ring on the proportioning

valve is new.

(2) Install the proportioning valve in its master

cylinder port. Tighten the proportioning valve to a

torque of 40 N´m (30 ft. lbs.).

(3) Connect the brake tube to the proportioning

valve (Fig. 54). Tighten the tube nut to a torque of 17

N´m (145 in. lbs.).

(4) Remove the brake pedal holder (Fig. 53).

(5) Bleed the affected brake line. See BASE

BRAKE BLEEDING in the SERVICE PROCE-

DURES section in this service manual group.

(6) Road test the vehicle to ensure proper opera-

tion of the brakes.

BRAKES TUBES AND HOSES

NOTE: Brake hoses for each brake are unique and

are not interchangeable.

Always use Mopartreplacement brake hoses to

ensure quality, correct length and superior fatigue

life. Care should be taken to make sure that the tube

and hose mating surfaces are clean and free from

nicks and burrs.

Use new copper seal washers on all connections

using banjo bolts and tighten all the fittings to their

specified torques.

Follow the procedures in the next three paragraphs

to reduce the potential for twisting the brake hose

during installation.

The flexible front hydraulic brake hose should

always be installed on the vehicle by first attaching

the banjo fitting to the disc brake caliper. Attach the

hose to the brake tubing before attaching it to the

front frame rail. Tighten all brake line fittings to the

specified torque.

On vehicles equipped with rear drum brakes,

loosely install the rear brake hose to the wheel cylin-

der first, then bolt the intermediate routing bracket

to the strut. Next, loosely install the hose to the steel

tube coming from the master cylinder. Attach the

hose bracket to the body. Finally, tighten the tube

nuts at each end of the brake hose.

On vehicles equipped with rear disc brakes, attach

the brake hose banjo fitting to the caliper first, then

loosely install the hose to the steel tube coming from

the master cylinder. Next, attach the brake hose

bracket to the body. Finally, tighten the tube nut at

the each of the end of the brake hose connecting to

the steel tube coming from the master cylinder.Only double wall 4.75 mm (3/16 in.) steel brake

line tubing with Nygal coating should be used for

replacement along with its special tube nuts. Care

must be taken when replacing brake tubing; to be

sure, use the proper bending and flaring tools, and

procedures to avoid kinking. Do not route the tubes

against sharp edges, moving components, or into hot

areas. All tubes should be properly attached with the

recommended retaining clips.

DISC BRAKE CALIPER (FRONT)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Using a brake pedal holding tool as shown (Fig.

55), depress the brake pedal past its first one inch of

travel and hold it in this position. This will isolate

the master cylinder from the brake hydraulic system

and will not allow the brake fluid to drain out of the

master cylinder reservoir when the lines are opened.

(2) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(3) Remove the front tire and wheel assembly.

Fig. 55 Brake Pedal Holding Tool

1 ± CLUTCH PEDAL (IF EQUIPPED WITH MANUAL TRANSAXLE)

2 ± THROTTLE PEDAL

3 ± BRAKE PEDAL HOLDING TOOL

4 ± STEERING WHEEL

5 ± DRIVER'S SEAT

6 ± BRAKE PEDAL

PLBRAKES 5 - 33

REMOVAL AND INSTALLATION (Continued)

Page 113 of 1285

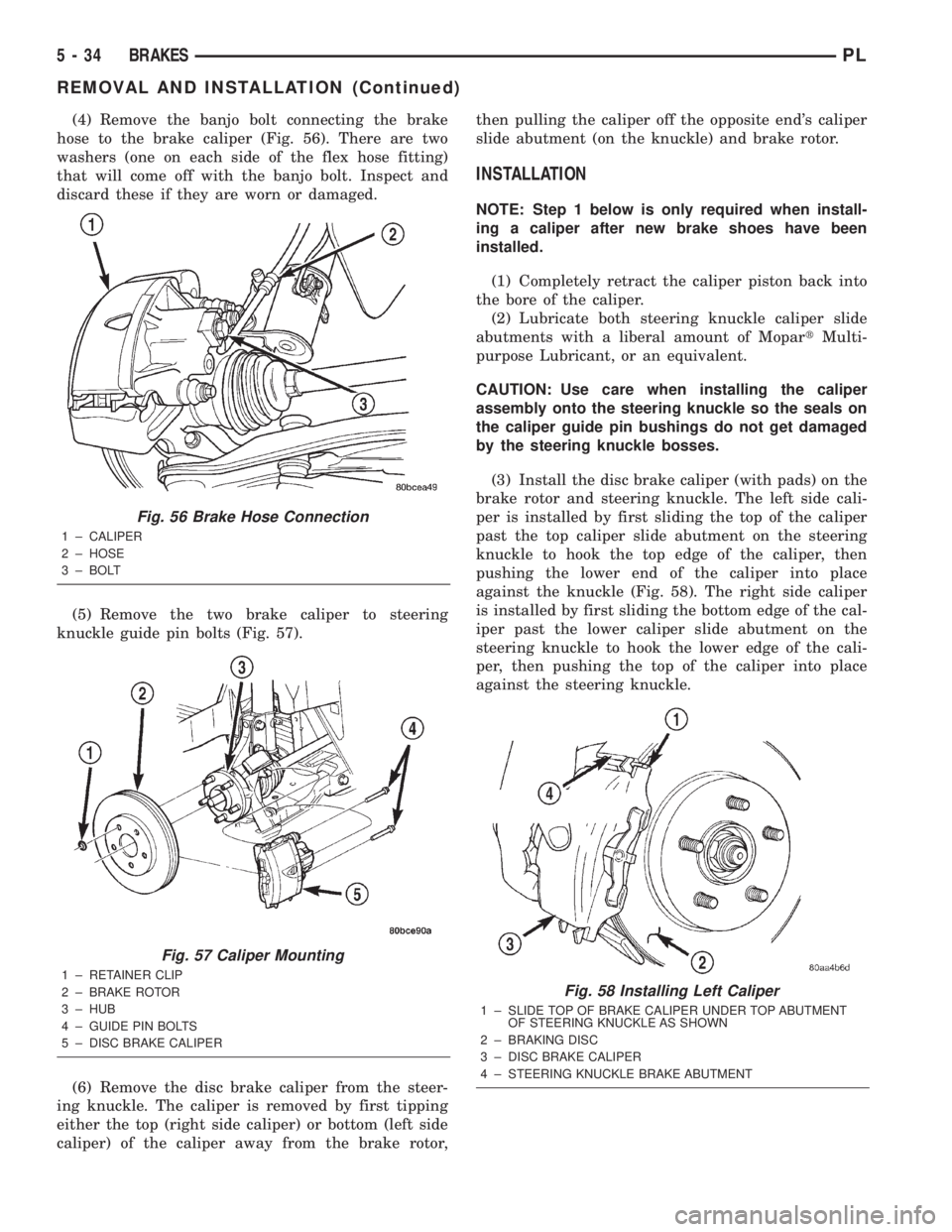

(4) Remove the banjo bolt connecting the brake

hose to the brake caliper (Fig. 56). There are two

washers (one on each side of the flex hose fitting)

that will come off with the banjo bolt. Inspect and

discard these if they are worn or damaged.

(5) Remove the two brake caliper to steering

knuckle guide pin bolts (Fig. 57).

(6) Remove the disc brake caliper from the steer-

ing knuckle. The caliper is removed by first tipping

either the top (right side caliper) or bottom (left side

caliper) of the caliper away from the brake rotor,then pulling the caliper off the opposite end's caliper

slide abutment (on the knuckle) and brake rotor.

INSTALLATION

NOTE: Step 1 below is only required when install-

ing a caliper after new brake shoes have been

installed.

(1) Completely retract the caliper piston back into

the bore of the caliper.

(2) Lubricate both steering knuckle caliper slide

abutments with a liberal amount of MopartMulti-

purpose Lubricant, or an equivalent.

CAUTION: Use care when installing the caliper

assembly onto the steering knuckle so the seals on

the caliper guide pin bushings do not get damaged

by the steering knuckle bosses.

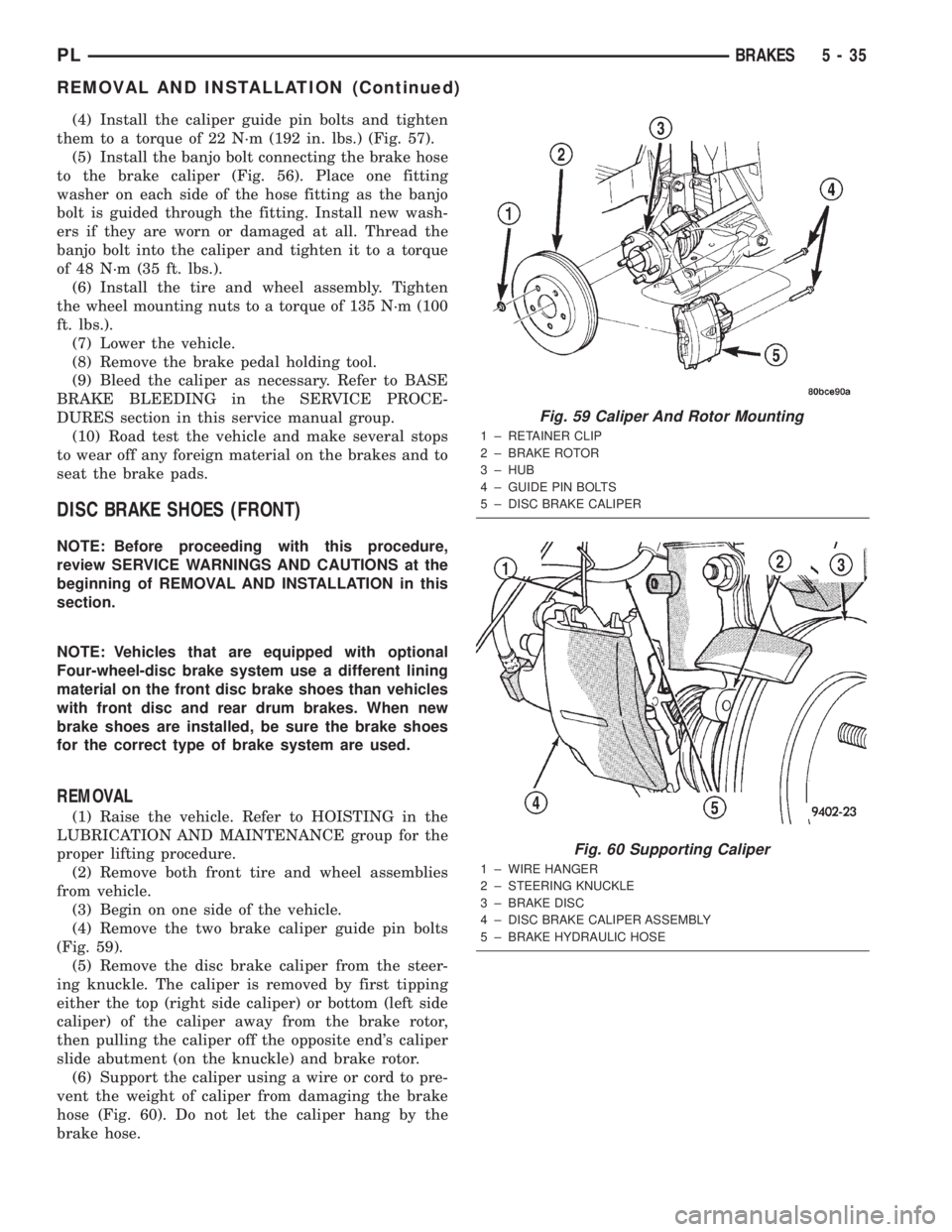

(3) Install the disc brake caliper (with pads) on the

brake rotor and steering knuckle. The left side cali-

per is installed by first sliding the top of the caliper

past the top caliper slide abutment on the steering

knuckle to hook the top edge of the caliper, then

pushing the lower end of the caliper into place

against the knuckle (Fig. 58). The right side caliper

is installed by first sliding the bottom edge of the cal-

iper past the lower caliper slide abutment on the

steering knuckle to hook the lower edge of the cali-

per, then pushing the top of the caliper into place

against the steering knuckle.

Fig. 56 Brake Hose Connection

1 ± CALIPER

2 ± HOSE

3 ± BOLT

Fig. 57 Caliper Mounting

1 ± RETAINER CLIP

2 ± BRAKE ROTOR

3 ± HUB

4 ± GUIDE PIN BOLTS

5 ± DISC BRAKE CALIPER

Fig. 58 Installing Left Caliper

1 ± SLIDE TOP OF BRAKE CALIPER UNDER TOP ABUTMENT

OF STEERING KNUCKLE AS SHOWN

2 ± BRAKING DISC

3 ± DISC BRAKE CALIPER

4 ± STEERING KNUCKLE BRAKE ABUTMENT

5 - 34 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 114 of 1285

(4) Install the caliper guide pin bolts and tighten

them to a torque of 22 N´m (192 in. lbs.) (Fig. 57).

(5) Install the banjo bolt connecting the brake hose

to the brake caliper (Fig. 56). Place one fitting

washer on each side of the hose fitting as the banjo

bolt is guided through the fitting. Install new wash-

ers if they are worn or damaged at all. Thread the

banjo bolt into the caliper and tighten it to a torque

of 48 N´m (35 ft. lbs.).

(6) Install the tire and wheel assembly. Tighten

the wheel mounting nuts to a torque of 135 N´m (100

ft. lbs.).

(7) Lower the vehicle.

(8) Remove the brake pedal holding tool.

(9) Bleed the caliper as necessary. Refer to BASE

BRAKE BLEEDING in the SERVICE PROCE-

DURES section in this service manual group.

(10) Road test the vehicle and make several stops

to wear off any foreign material on the brakes and to

seat the brake pads.

DISC BRAKE SHOES (FRONT)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

NOTE: Vehicles that are equipped with optional

Four-wheel-disc brake system use a different lining

material on the front disc brake shoes than vehicles

with front disc and rear drum brakes. When new

brake shoes are installed, be sure the brake shoes

for the correct type of brake system are used.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove both front tire and wheel assemblies

from vehicle.

(3) Begin on one side of the vehicle.

(4) Remove the two brake caliper guide pin bolts

(Fig. 59).

(5) Remove the disc brake caliper from the steer-

ing knuckle. The caliper is removed by first tipping

either the top (right side caliper) or bottom (left side

caliper) of the caliper away from the brake rotor,

then pulling the caliper off the opposite end's caliper

slide abutment (on the knuckle) and brake rotor.

(6) Support the caliper using a wire or cord to pre-

vent the weight of caliper from damaging the brake

hose (Fig. 60). Do not let the caliper hang by the

brake hose.

Fig. 59 Caliper And Rotor Mounting

1 ± RETAINER CLIP

2 ± BRAKE ROTOR

3 ± HUB

4 ± GUIDE PIN BOLTS

5 ± DISC BRAKE CALIPER

Fig. 60 Supporting Caliper

1 ± WIRE HANGER

2 ± STEERING KNUCKLE

3 ± BRAKE DISC

4 ± DISC BRAKE CALIPER ASSEMBLY

5 ± BRAKE HYDRAULIC HOSE

PLBRAKES 5 - 35

REMOVAL AND INSTALLATION (Continued)

Page 115 of 1285

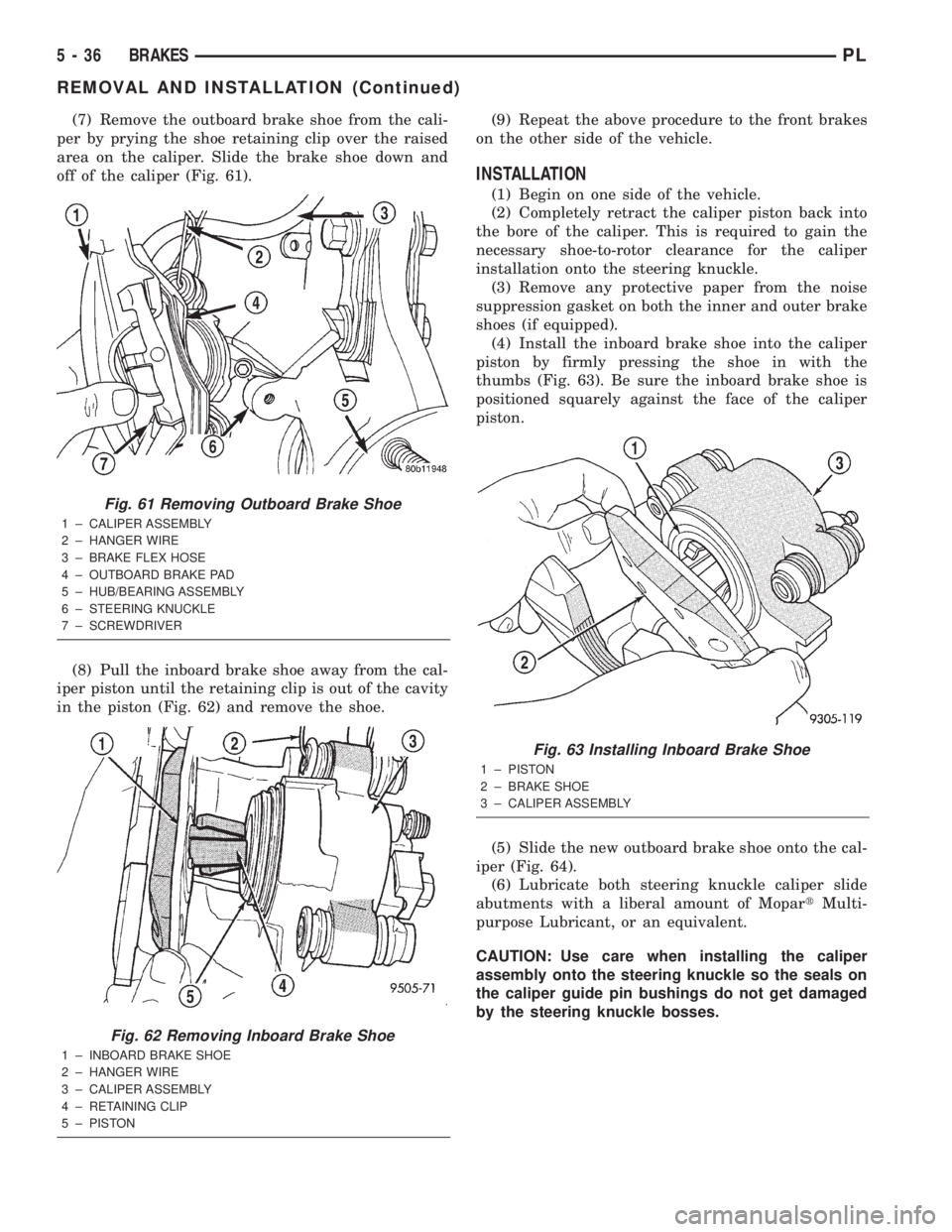

(7) Remove the outboard brake shoe from the cali-

per by prying the shoe retaining clip over the raised

area on the caliper. Slide the brake shoe down and

off of the caliper (Fig. 61).

(8) Pull the inboard brake shoe away from the cal-

iper piston until the retaining clip is out of the cavity

in the piston (Fig. 62) and remove the shoe.(9) Repeat the above procedure to the front brakes

on the other side of the vehicle.

INSTALLATION

(1) Begin on one side of the vehicle.

(2) Completely retract the caliper piston back into

the bore of the caliper. This is required to gain the

necessary shoe-to-rotor clearance for the caliper

installation onto the steering knuckle.

(3) Remove any protective paper from the noise

suppression gasket on both the inner and outer brake

shoes (if equipped).

(4) Install the inboard brake shoe into the caliper

piston by firmly pressing the shoe in with the

thumbs (Fig. 63). Be sure the inboard brake shoe is

positioned squarely against the face of the caliper

piston.

(5) Slide the new outboard brake shoe onto the cal-

iper (Fig. 64).

(6) Lubricate both steering knuckle caliper slide

abutments with a liberal amount of MopartMulti-

purpose Lubricant, or an equivalent.

CAUTION: Use care when installing the caliper

assembly onto the steering knuckle so the seals on

the caliper guide pin bushings do not get damaged

by the steering knuckle bosses.

Fig. 61 Removing Outboard Brake Shoe

1 ± CALIPER ASSEMBLY

2 ± HANGER WIRE

3 ± BRAKE FLEX HOSE

4 ± OUTBOARD BRAKE PAD

5 ± HUB/BEARING ASSEMBLY

6 ± STEERING KNUCKLE

7 ± SCREWDRIVER

Fig. 62 Removing Inboard Brake Shoe

1 ± INBOARD BRAKE SHOE

2 ± HANGER WIRE

3 ± CALIPER ASSEMBLY

4 ± RETAINING CLIP

5 ± PISTON

Fig. 63 Installing Inboard Brake Shoe

1 ± PISTON

2 ± BRAKE SHOE

3 ± CALIPER ASSEMBLY

5 - 36 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 116 of 1285

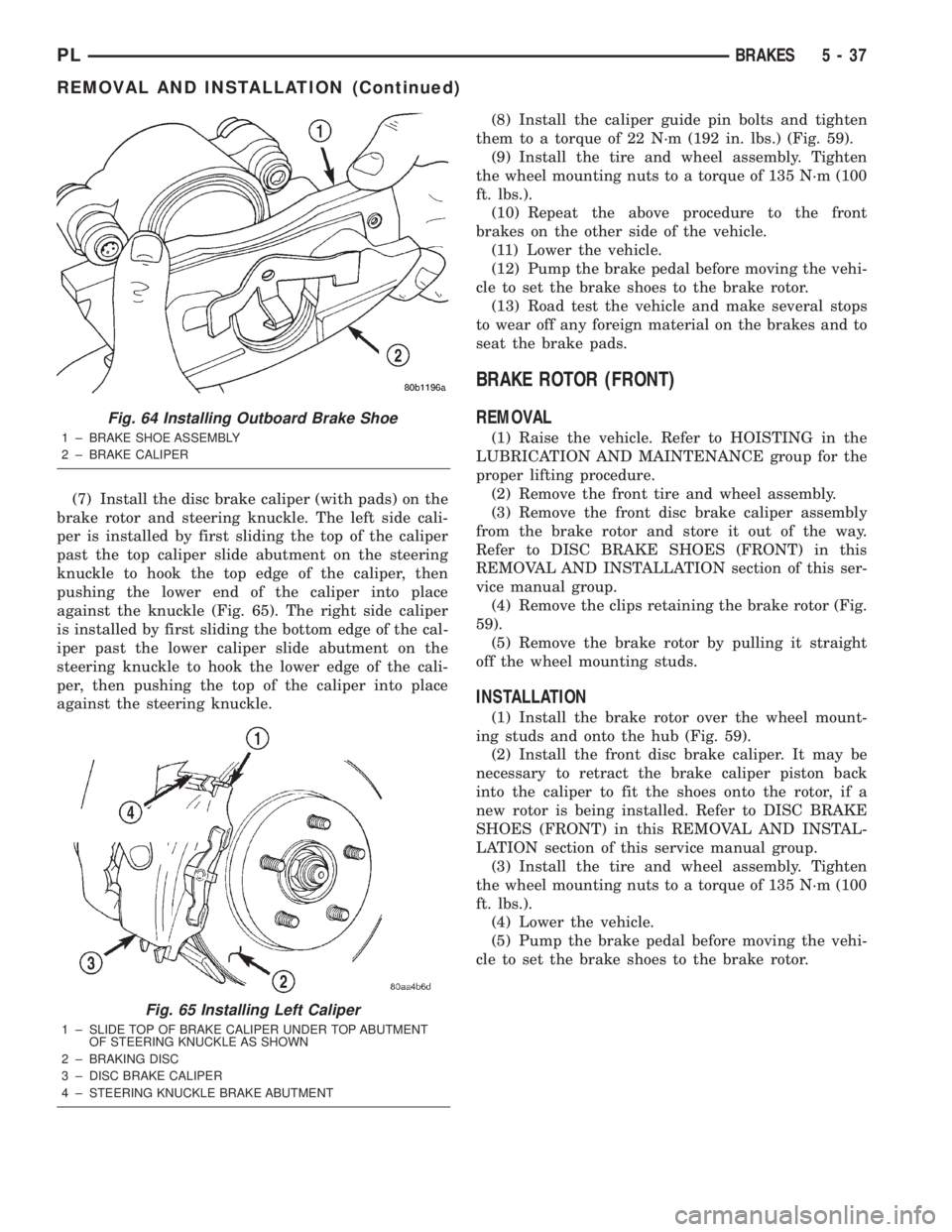

(7) Install the disc brake caliper (with pads) on the

brake rotor and steering knuckle. The left side cali-

per is installed by first sliding the top of the caliper

past the top caliper slide abutment on the steering

knuckle to hook the top edge of the caliper, then

pushing the lower end of the caliper into place

against the knuckle (Fig. 65). The right side caliper

is installed by first sliding the bottom edge of the cal-

iper past the lower caliper slide abutment on the

steering knuckle to hook the lower edge of the cali-

per, then pushing the top of the caliper into place

against the steering knuckle.(8) Install the caliper guide pin bolts and tighten

them to a torque of 22 N´m (192 in. lbs.) (Fig. 59).

(9) Install the tire and wheel assembly. Tighten

the wheel mounting nuts to a torque of 135 N´m (100

ft. lbs.).

(10) Repeat the above procedure to the front

brakes on the other side of the vehicle.

(11) Lower the vehicle.

(12) Pump the brake pedal before moving the vehi-

cle to set the brake shoes to the brake rotor.

(13) Road test the vehicle and make several stops

to wear off any foreign material on the brakes and to

seat the brake pads.

BRAKE ROTOR (FRONT)

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove the front tire and wheel assembly.

(3) Remove the front disc brake caliper assembly

from the brake rotor and store it out of the way.

Refer to DISC BRAKE SHOES (FRONT) in this

REMOVAL AND INSTALLATION section of this ser-

vice manual group.

(4) Remove the clips retaining the brake rotor (Fig.

59).

(5) Remove the brake rotor by pulling it straight

off the wheel mounting studs.

INSTALLATION

(1) Install the brake rotor over the wheel mount-

ing studs and onto the hub (Fig. 59).

(2) Install the front disc brake caliper. It may be

necessary to retract the brake caliper piston back

into the caliper to fit the shoes onto the rotor, if a

new rotor is being installed. Refer to DISC BRAKE

SHOES (FRONT) in this REMOVAL AND INSTAL-

LATION section of this service manual group.

(3) Install the tire and wheel assembly. Tighten

the wheel mounting nuts to a torque of 135 N´m (100

ft. lbs.).

(4) Lower the vehicle.

(5) Pump the brake pedal before moving the vehi-

cle to set the brake shoes to the brake rotor.

Fig. 64 Installing Outboard Brake Shoe

1 ± BRAKE SHOE ASSEMBLY

2 ± BRAKE CALIPER

Fig. 65 Installing Left Caliper

1 ± SLIDE TOP OF BRAKE CALIPER UNDER TOP ABUTMENT

OF STEERING KNUCKLE AS SHOWN

2 ± BRAKING DISC

3 ± DISC BRAKE CALIPER

4 ± STEERING KNUCKLE BRAKE ABUTMENT

PLBRAKES 5 - 37

REMOVAL AND INSTALLATION (Continued)