steering DODGE NEON 2000 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 159 of 1285

(7) Disconnect the primary and secondary brake

tubes from the master cylinder (Fig. 15). Install

plugs in the master cylinder outlet ports.

(8) Disconnect the 25-way connector from the con-

troller antilock brake (CAB) mounted on the inte-

grated control unit (ICU) and move it out of the way.

The connector is disconnected by pulling outward on

the connector lock (Fig. 16). This will unlock and

raise the 25-way connector out of the socket on the

CAB.(9) Tag the brake tubes coming from the master

cylinder as primary and secondary (Fig. 15). This is

done to avoid mix-up once the tubes are removed

from the vehicle.

(10) Disconnect and remove the primary and sec-

ondary brake tubes coming from the master cylinder

at the ICU hydraulic control unit (HCU) (Fig. 15).

(11) Disconnect the brake tubes going to each indi-

vidual brake at the HCU (Fig. 15).

(12) Remove the 3 bolts attaching the ICU to its

mounting bracket (Fig. 17).

(13) Remove the ICU from the vehicle.

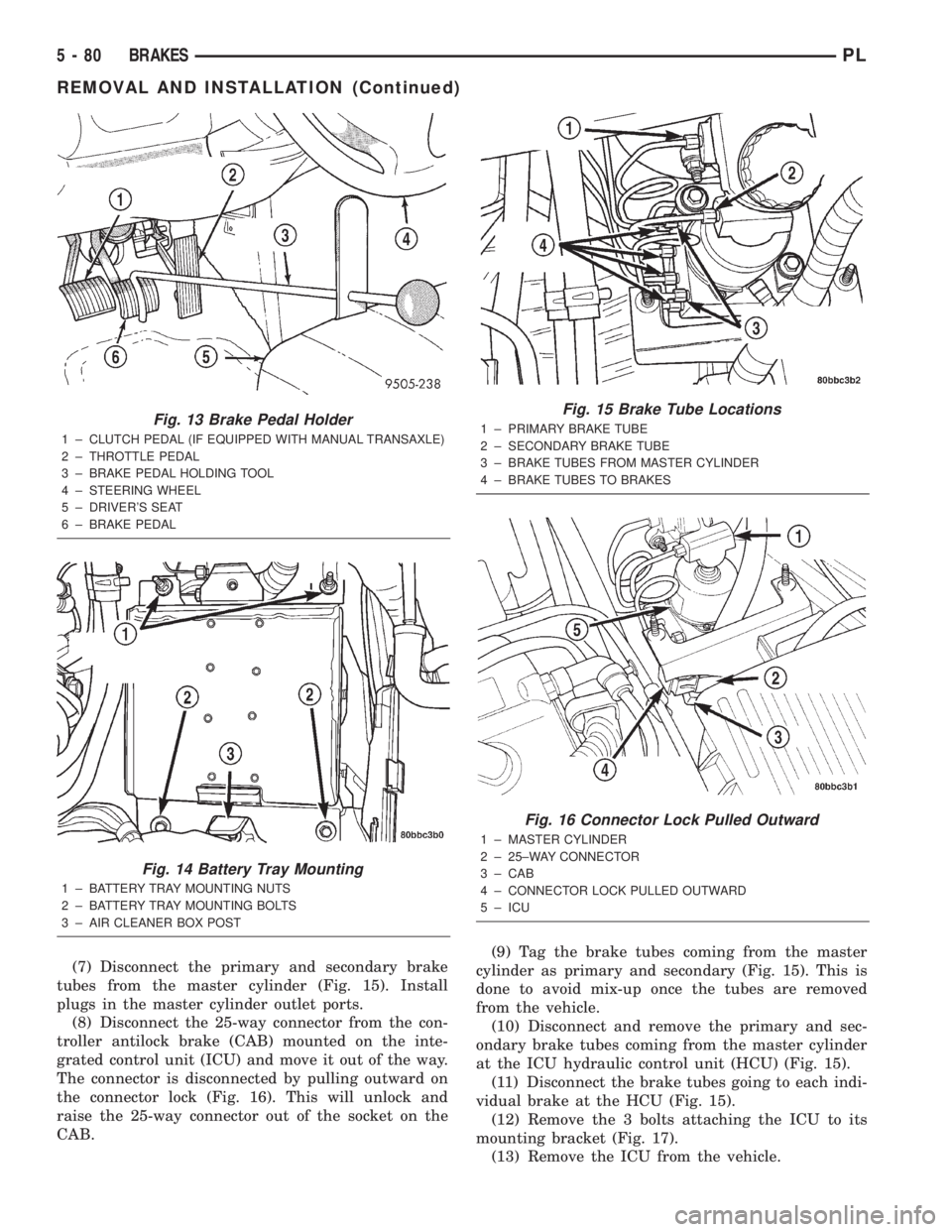

Fig. 13 Brake Pedal Holder

1 ± CLUTCH PEDAL (IF EQUIPPED WITH MANUAL TRANSAXLE)

2 ± THROTTLE PEDAL

3 ± BRAKE PEDAL HOLDING TOOL

4 ± STEERING WHEEL

5 ± DRIVER'S SEAT

6 ± BRAKE PEDAL

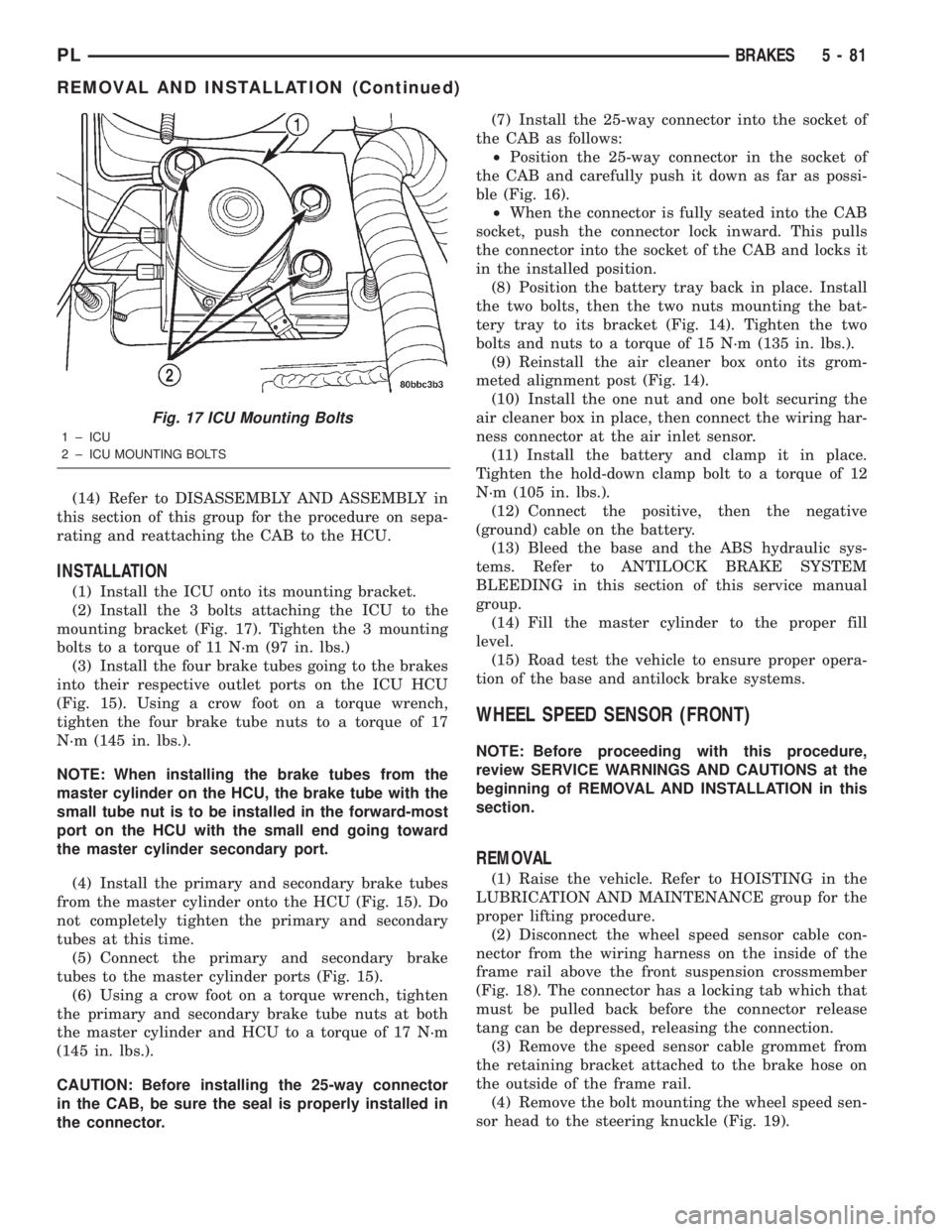

Fig. 14 Battery Tray Mounting

1 ± BATTERY TRAY MOUNTING NUTS

2 ± BATTERY TRAY MOUNTING BOLTS

3 ± AIR CLEANER BOX POST

Fig. 15 Brake Tube Locations

1 ± PRIMARY BRAKE TUBE

2 ± SECONDARY BRAKE TUBE

3 ± BRAKE TUBES FROM MASTER CYLINDER

4 ± BRAKE TUBES TO BRAKES

Fig. 16 Connector Lock Pulled Outward

1 ± MASTER CYLINDER

2 ± 25±WAY CONNECTOR

3 ± CAB

4 ± CONNECTOR LOCK PULLED OUTWARD

5 ± ICU

5 - 80 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 160 of 1285

(14) Refer to DISASSEMBLY AND ASSEMBLY in

this section of this group for the procedure on sepa-

rating and reattaching the CAB to the HCU.

INSTALLATION

(1) Install the ICU onto its mounting bracket.

(2) Install the 3 bolts attaching the ICU to the

mounting bracket (Fig. 17). Tighten the 3 mounting

bolts to a torque of 11 N´m (97 in. lbs.)

(3) Install the four brake tubes going to the brakes

into their respective outlet ports on the ICU HCU

(Fig. 15). Using a crow foot on a torque wrench,

tighten the four brake tube nuts to a torque of 17

N´m (145 in. lbs.).

NOTE: When installing the brake tubes from the

master cylinder on the HCU, the brake tube with the

small tube nut is to be installed in the forward-most

port on the HCU with the small end going toward

the master cylinder secondary port.

(4) Install the primary and secondary brake tubes

from the master cylinder onto the HCU (Fig. 15). Do

not completely tighten the primary and secondary

tubes at this time.

(5) Connect the primary and secondary brake

tubes to the master cylinder ports (Fig. 15).

(6) Using a crow foot on a torque wrench, tighten

the primary and secondary brake tube nuts at both

the master cylinder and HCU to a torque of 17 N´m

(145 in. lbs.).

CAUTION: Before installing the 25-way connector

in the CAB, be sure the seal is properly installed in

the connector.(7) Install the 25-way connector into the socket of

the CAB as follows:

²Position the 25-way connector in the socket of

the CAB and carefully push it down as far as possi-

ble (Fig. 16).

²When the connector is fully seated into the CAB

socket, push the connector lock inward. This pulls

the connector into the socket of the CAB and locks it

in the installed position.

(8) Position the battery tray back in place. Install

the two bolts, then the two nuts mounting the bat-

tery tray to its bracket (Fig. 14). Tighten the two

bolts and nuts to a torque of 15 N´m (135 in. lbs.).

(9) Reinstall the air cleaner box onto its grom-

meted alignment post (Fig. 14).

(10) Install the one nut and one bolt securing the

air cleaner box in place, then connect the wiring har-

ness connector at the air inlet sensor.

(11) Install the battery and clamp it in place.

Tighten the hold-down clamp bolt to a torque of 12

N´m (105 in. lbs.).

(12) Connect the positive, then the negative

(ground) cable on the battery.

(13) Bleed the base and the ABS hydraulic sys-

tems. Refer to ANTILOCK BRAKE SYSTEM

BLEEDING in this section of this service manual

group.

(14) Fill the master cylinder to the proper fill

level.

(15) Road test the vehicle to ensure proper opera-

tion of the base and antilock brake systems.

WHEEL SPEED SENSOR (FRONT)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Disconnect the wheel speed sensor cable con-

nector from the wiring harness on the inside of the

frame rail above the front suspension crossmember

(Fig. 18). The connector has a locking tab which that

must be pulled back before the connector release

tang can be depressed, releasing the connection.

(3) Remove the speed sensor cable grommet from

the retaining bracket attached to the brake hose on

the outside of the frame rail.

(4) Remove the bolt mounting the wheel speed sen-

sor head to the steering knuckle (Fig. 19).

Fig. 17 ICU Mounting Bolts

1 ± ICU

2 ± ICU MOUNTING BOLTS

PLBRAKES 5 - 81

REMOVAL AND INSTALLATION (Continued)

Page 161 of 1285

CAUTION: When removing a wheel speed sensor

from the knuckle, do not use pliers on the sensor

head. This may damage the sensor head. If the sen-

sor has seized, use a hammer and a punch to tap

the edge of the sensor head ear, rocking the sensor

side-to-side until free.

(5) Carefully, remove the sensor head from the

steering knuckle.(6) Remove the screw securing the wheel speed

sensor to the rear of the strut (Fig. 20). Remove the

wheel speed sensor.

INSTALLATION

CAUTION: Failure to install speed sensor cables

properly may result in contact with moving parts or

an over extension of cables causing an open cir-

cuit. Be sure that cables are installed, routed, and

clipped properly.

(1) Attach the wheel speed sensor to the strut

using the its mounting screw (Fig. 20).

(2) Install the wheel speed sensor head in the

steering knuckle (Fig. 19). Install the mounting bolt.

Tighten the mounting bolt to a torque of 12 N´m (105

in. lbs.).

(3) From the sensor bracket on the strut, loop the

sensor cable upward, then downward at the outside

of the frame rail. Install the speed sensor cable grom-

met onto the retaining bracket attached to the brake

hose on the outside of the frame rail.

(4) Loop the wheel speed sensor cable around the

bottom of the frame rail and connect it to the wiring

harness connector on the inside of the frame rail

(Fig. 18). Remember to push in the locking tab on the

connector.

(5) Install the tire and wheel assembly.

(6) Lower the vehicle.

(7) Road test vehicle to ensure proper operation of

the base brakes and ABS.

Fig. 18 Wiring Harness Connector

1 ± RIGHT FRONT WHEEL SPEED SENSOR CONNECTOR

2 ± RIGHT FRONT DRIVESHAFT

3 ± ENGINE OIL FILTER

Fig. 19 Wheel Speed Sensor

1 ± RIGHT FRONT WHEEL SPEED SENSOR

2 ± TONE WHEEL

Fig. 20 Wheel Speed Sensor At Strut

1 ± ABS WHEEL SPEED SENSOR ROUTING BRACKET (IF

EQUIPPED)

2 ± GROUND STRAP

3 ± GROUND STRAP SCREW

4 ± ABS SENSOR BRACKET SCREW (IF EQUIPPED)

5 - 82 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 185 of 1285

AUTOMATIC TRANSMISSION OIL COOLER

Oil coolers are internal oil to coolant type, mounted

in the radiator lower tank (Fig. 9). Rubber oil lines

feed the oil cooler and the automatic transmission.

Use only approved transmission oil cooler hose. Since

these are molded to fit space available, molded hoses

are recommended. Tighten Oil Cooler Hose Clamps

to 2 N´m (18 in. lbs.).

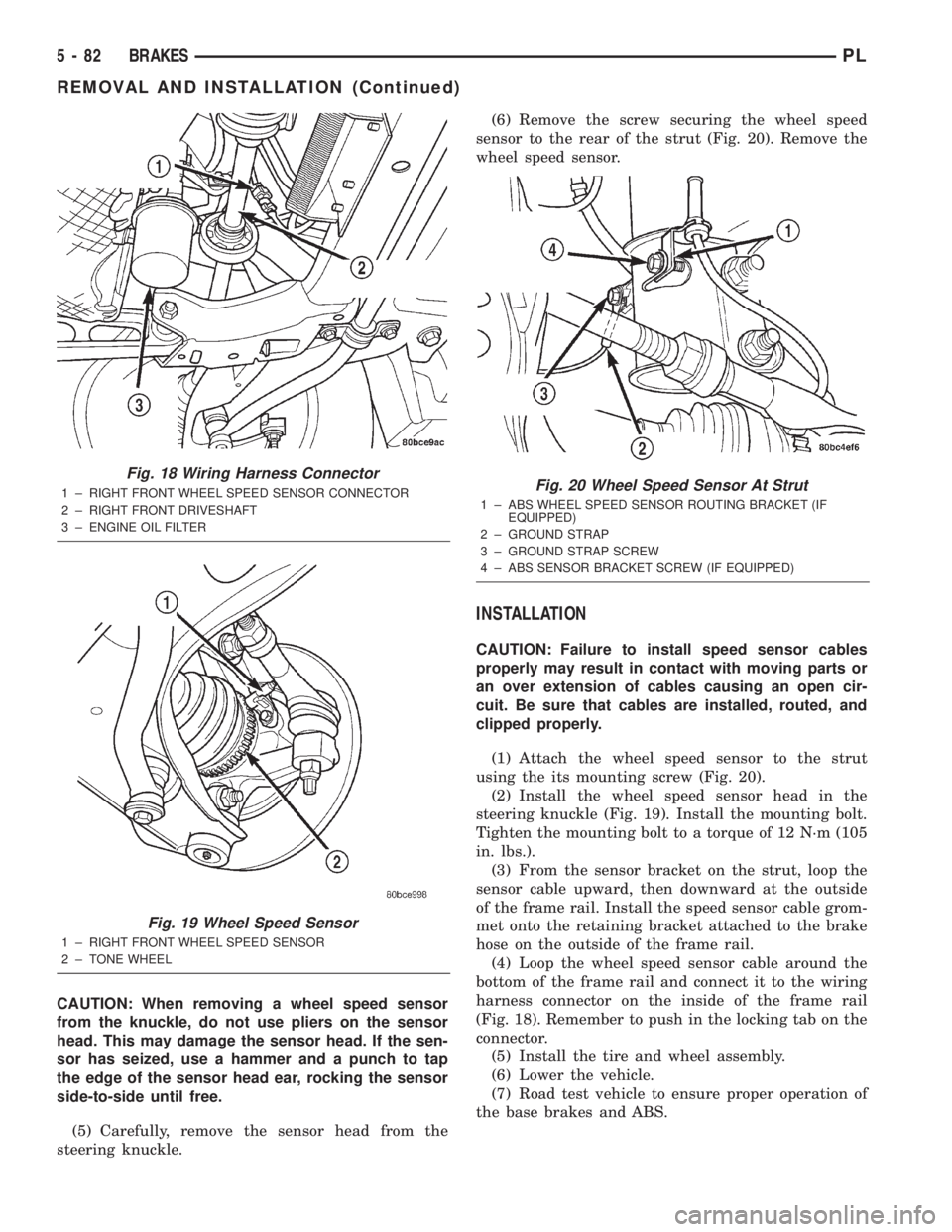

ACCESSORY DRIVE BELTS

The accessory drive consist of two Poly-V type

drive belts (Fig. 10). One belt drives the generator,

the other drives the power steering pump and air

conditioning compressor (if equipped). The power

steering/air conditioning belt is tensioned by an auto-

matically controlled belt tensioner. The generator

belt is manually tensioned using an adjusting bolt

and a locking nut.

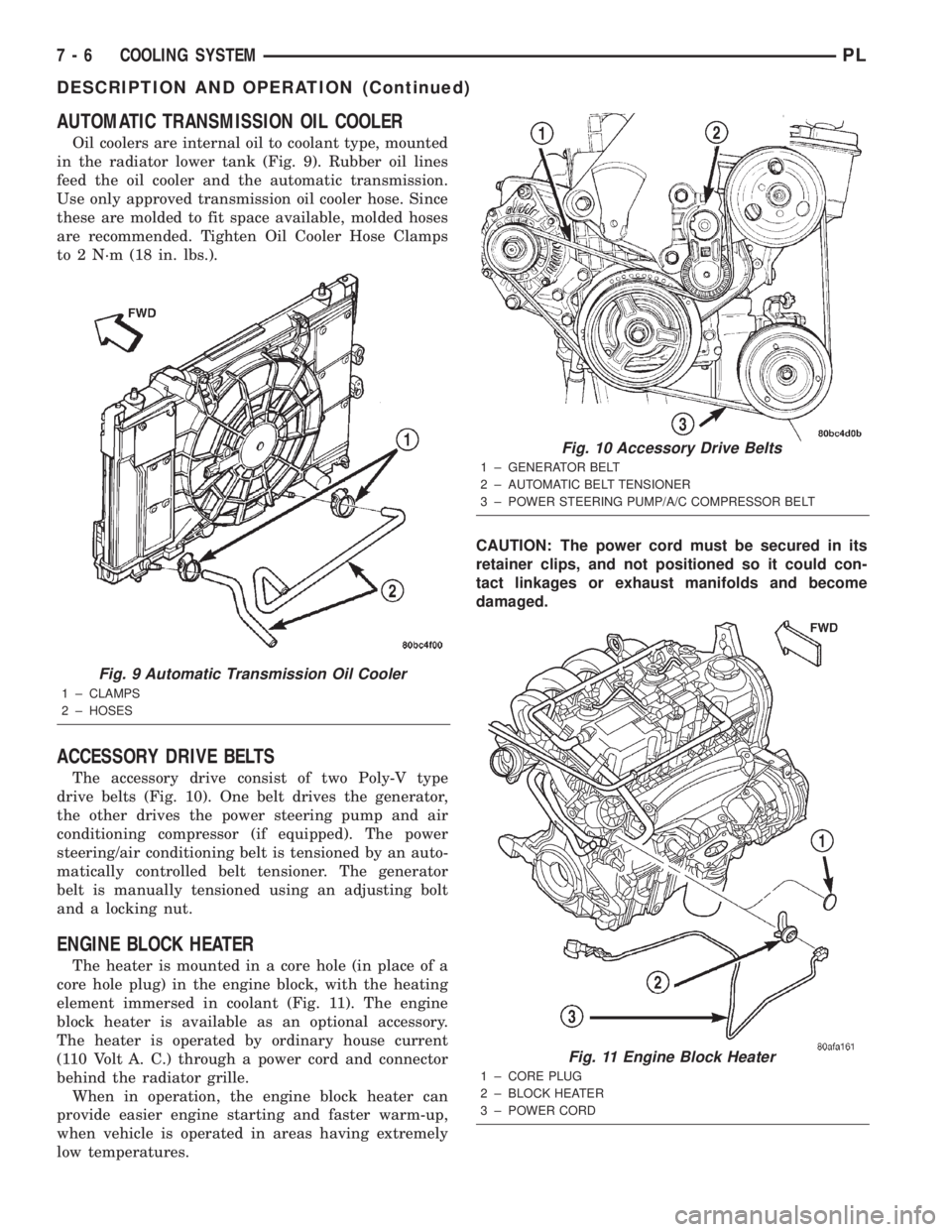

ENGINE BLOCK HEATER

The heater is mounted in a core hole (in place of a

core hole plug) in the engine block, with the heating

element immersed in coolant (Fig. 11). The engine

block heater is available as an optional accessory.

The heater is operated by ordinary house current

(110 Volt A. C.) through a power cord and connector

behind the radiator grille.

When in operation, the engine block heater can

provide easier engine starting and faster warm-up,

when vehicle is operated in areas having extremely

low temperatures.CAUTION: The power cord must be secured in its

retainer clips, and not positioned so it could con-

tact linkages or exhaust manifolds and become

damaged.

Fig. 9 Automatic Transmission Oil Cooler

1 ± CLAMPS

2 ± HOSES

Fig. 10 Accessory Drive Belts

1 ± GENERATOR BELT

2 ± AUTOMATIC BELT TENSIONER

3 ± POWER STEERING PUMP/A/C COMPRESSOR BELT

Fig. 11 Engine Block Heater

1 ± CORE PLUG

2 ± BLOCK HEATER

3 ± POWER CORD

7 - 6 COOLING SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 193 of 1285

ENGINE THERMOSTAT TESTING

The thermostat is operated by a wax filled con-

tainer (pellet) which is sealed. When heated coolant

reaches a predetermined temperature the wax pellet

expands enough to overcome the closing spring and

water pump pressure, which forces the valve to open.

Coolant leakage into the pellet will cause a thermo-

stat to fail open. Do not attempt to free up a thermo-

stat with a screwdriver.

The thermostat that opens too soon type failure

mode is included in the on-board diagnosis. Thecheck engine light will not be lit by an open too soon

condition. If it has failed open, a diagnostic trouble

code (DTC) will be set. Do not change a thermostat

for lack of heater performance or temperature gauge

position, unless a DTC is present. See Diagnosis for

other probable causes. Thermostat failing shut is the

normal long term mode of failure, and normally, only

on high mileage vehicles. The temperature gauge will

indicate this. Refer to Diagnosis in this section.

ACCESSORY DRIVE BELT DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

BELT SLIPPAGE 1. Belt slipping because of

insufficient tension.1. Retension generator belt.

Replace the power steering belt's

automatic belt tensioner.

2. Belt excessively glazed or

hardened from heat and excessive

slippage.2. Replace belt.

3. Incorrect belt. 3. Replace belt.

4. Driven component bearing

failure.4. Replace faulty component.

5. Belt or pulley subjected to

substance (belt dressing, oil,

ethylene glycol) that has reduced

friction.5. Replace belt and clean pulleys.

BELT NOISE (OBJECTIONABLE

SQUEAL, SQUEAK, OR RUMBLE)1. Belt slippage. 1. Retension generator belt, replace

belt, or automatic belt tensioner.

2. Foreign material imbedded in

belt.2. Replace belt.

3. Non-uniform belt. 3. Replace belt.

4. Misaligned pulley(s). 4. Align accessories.

5. Non-uniform groove or eccentric

pulley.5. Replace pulley(s).

6. Bearing noise. 6. Locate and repair.

BELT ROLLED OVER IN GROOVE

OR BELT JUMPS OFF1. Broken cord in belt. 1. Replace belt.

2. Belt tension too loose, or too

tight.2. Retension generator belt.

Replace the power steering belt's

automatic belt tensioner.

3. Misaligned pulleys. 3. Align accessories.

4. Non-uniform grooves or eccentric

pulley.4. Replace pulley(s).

5. Foreign object(s) in grooves. 5. Remove foreign objects in

groove.

7 - 14 COOLING SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 198 of 1285

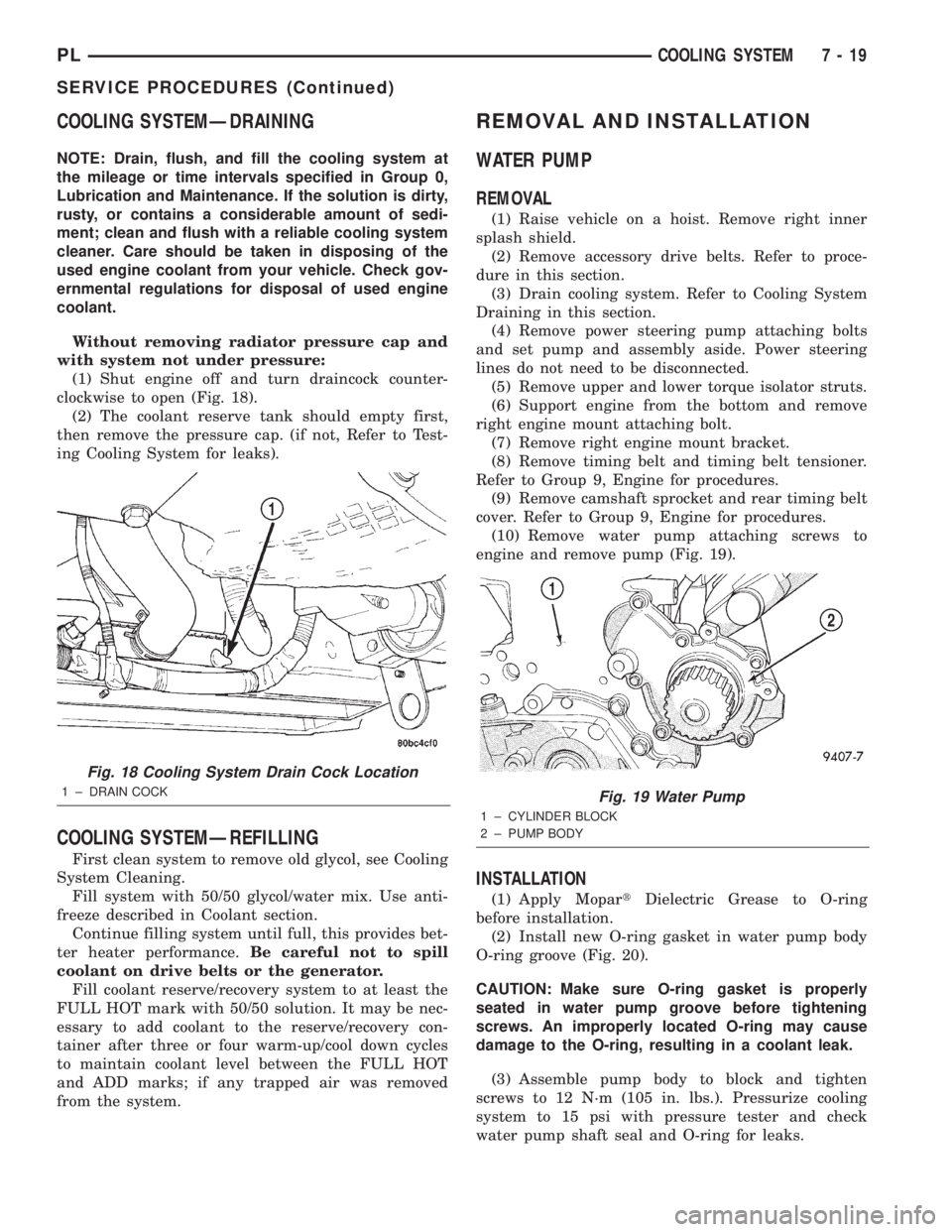

COOLING SYSTEMÐDRAINING

NOTE: Drain, flush, and fill the cooling system at

the mileage or time intervals specified in Group 0,

Lubrication and Maintenance. If the solution is dirty,

rusty, or contains a considerable amount of sedi-

ment; clean and flush with a reliable cooling system

cleaner. Care should be taken in disposing of the

used engine coolant from your vehicle. Check gov-

ernmental regulations for disposal of used engine

coolant.

Without removing radiator pressure cap and

with system not under pressure:

(1) Shut engine off and turn draincock counter-

clockwise to open (Fig. 18).

(2) The coolant reserve tank should empty first,

then remove the pressure cap. (if not, Refer to Test-

ing Cooling System for leaks).

COOLING SYSTEMÐREFILLING

First clean system to remove old glycol, see Cooling

System Cleaning.

Fill system with 50/50 glycol/water mix. Use anti-

freeze described in Coolant section.

Continue filling system until full, this provides bet-

ter heater performance.Be careful not to spill

coolant on drive belts or the generator.

Fill coolant reserve/recovery system to at least the

FULL HOT mark with 50/50 solution. It may be nec-

essary to add coolant to the reserve/recovery con-

tainer after three or four warm-up/cool down cycles

to maintain coolant level between the FULL HOT

and ADD marks; if any trapped air was removed

from the system.

REMOVAL AND INSTALLATION

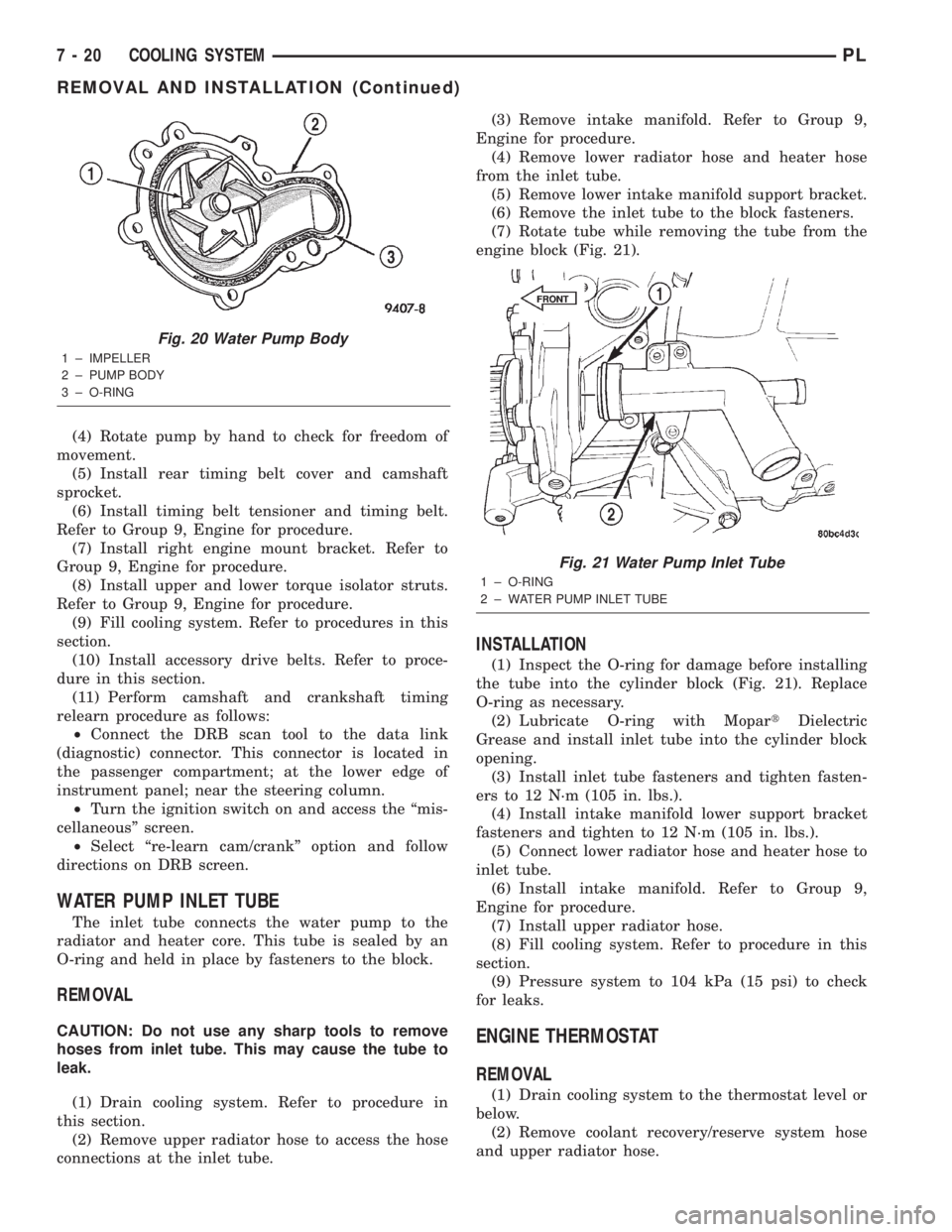

WATER PUMP

REMOVAL

(1) Raise vehicle on a hoist. Remove right inner

splash shield.

(2) Remove accessory drive belts. Refer to proce-

dure in this section.

(3) Drain cooling system. Refer to Cooling System

Draining in this section.

(4) Remove power steering pump attaching bolts

and set pump and assembly aside. Power steering

lines do not need to be disconnected.

(5) Remove upper and lower torque isolator struts.

(6) Support engine from the bottom and remove

right engine mount attaching bolt.

(7) Remove right engine mount bracket.

(8) Remove timing belt and timing belt tensioner.

Refer to Group 9, Engine for procedures.

(9) Remove camshaft sprocket and rear timing belt

cover. Refer to Group 9, Engine for procedures.

(10) Remove water pump attaching screws to

engine and remove pump (Fig. 19).

INSTALLATION

(1) Apply MopartDielectric Grease to O-ring

before installation.

(2) Install new O-ring gasket in water pump body

O-ring groove (Fig. 20).

CAUTION: Make sure O-ring gasket is properly

seated in water pump groove before tightening

screws. An improperly located O-ring may cause

damage to the O-ring, resulting in a coolant leak.

(3) Assemble pump body to block and tighten

screws to 12 N´m (105 in. lbs.). Pressurize cooling

system to 15 psi with pressure tester and check

water pump shaft seal and O-ring for leaks.

Fig. 18 Cooling System Drain Cock Location

1 ± DRAIN COCKFig. 19 Water Pump

1 ± CYLINDER BLOCK

2 ± PUMP BODY

PLCOOLING SYSTEM 7 - 19

SERVICE PROCEDURES (Continued)

Page 199 of 1285

(4) Rotate pump by hand to check for freedom of

movement.

(5) Install rear timing belt cover and camshaft

sprocket.

(6) Install timing belt tensioner and timing belt.

Refer to Group 9, Engine for procedure.

(7) Install right engine mount bracket. Refer to

Group 9, Engine for procedure.

(8) Install upper and lower torque isolator struts.

Refer to Group 9, Engine for procedure.

(9) Fill cooling system. Refer to procedures in this

section.

(10) Install accessory drive belts. Refer to proce-

dure in this section.

(11) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

WATER PUMP INLET TUBE

The inlet tube connects the water pump to the

radiator and heater core. This tube is sealed by an

O-ring and held in place by fasteners to the block.

REMOVAL

CAUTION: Do not use any sharp tools to remove

hoses from inlet tube. This may cause the tube to

leak.

(1) Drain cooling system. Refer to procedure in

this section.

(2) Remove upper radiator hose to access the hose

connections at the inlet tube.(3) Remove intake manifold. Refer to Group 9,

Engine for procedure.

(4) Remove lower radiator hose and heater hose

from the inlet tube.

(5) Remove lower intake manifold support bracket.

(6) Remove the inlet tube to the block fasteners.

(7) Rotate tube while removing the tube from the

engine block (Fig. 21).

INSTALLATION

(1) Inspect the O-ring for damage before installing

the tube into the cylinder block (Fig. 21). Replace

O-ring as necessary.

(2) Lubricate O-ring with MopartDielectric

Grease and install inlet tube into the cylinder block

opening.

(3) Install inlet tube fasteners and tighten fasten-

ers to 12 N´m (105 in. lbs.).

(4) Install intake manifold lower support bracket

fasteners and tighten to 12 N´m (105 in. lbs.).

(5) Connect lower radiator hose and heater hose to

inlet tube.

(6) Install intake manifold. Refer to Group 9,

Engine for procedure.

(7) Install upper radiator hose.

(8) Fill cooling system. Refer to procedure in this

section.

(9) Pressure system to 104 kPa (15 psi) to check

for leaks.

ENGINE THERMOSTAT

REMOVAL

(1) Drain cooling system to the thermostat level or

below.

(2) Remove coolant recovery/reserve system hose

and upper radiator hose.

Fig. 20 Water Pump Body

1 ± IMPELLER

2 ± PUMP BODY

3 ± O-RING

Fig. 21 Water Pump Inlet Tube

1 ± O-RING

2 ± WATER PUMP INLET TUBE

FRONT

7 - 20 COOLING SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 203 of 1285

(2) Connect recovery hose to water outlet connec-

tor/thermostat housing (Fig. 29).

(3) Fill container to proper level. Refer to Cooling

System Refilling in this section.

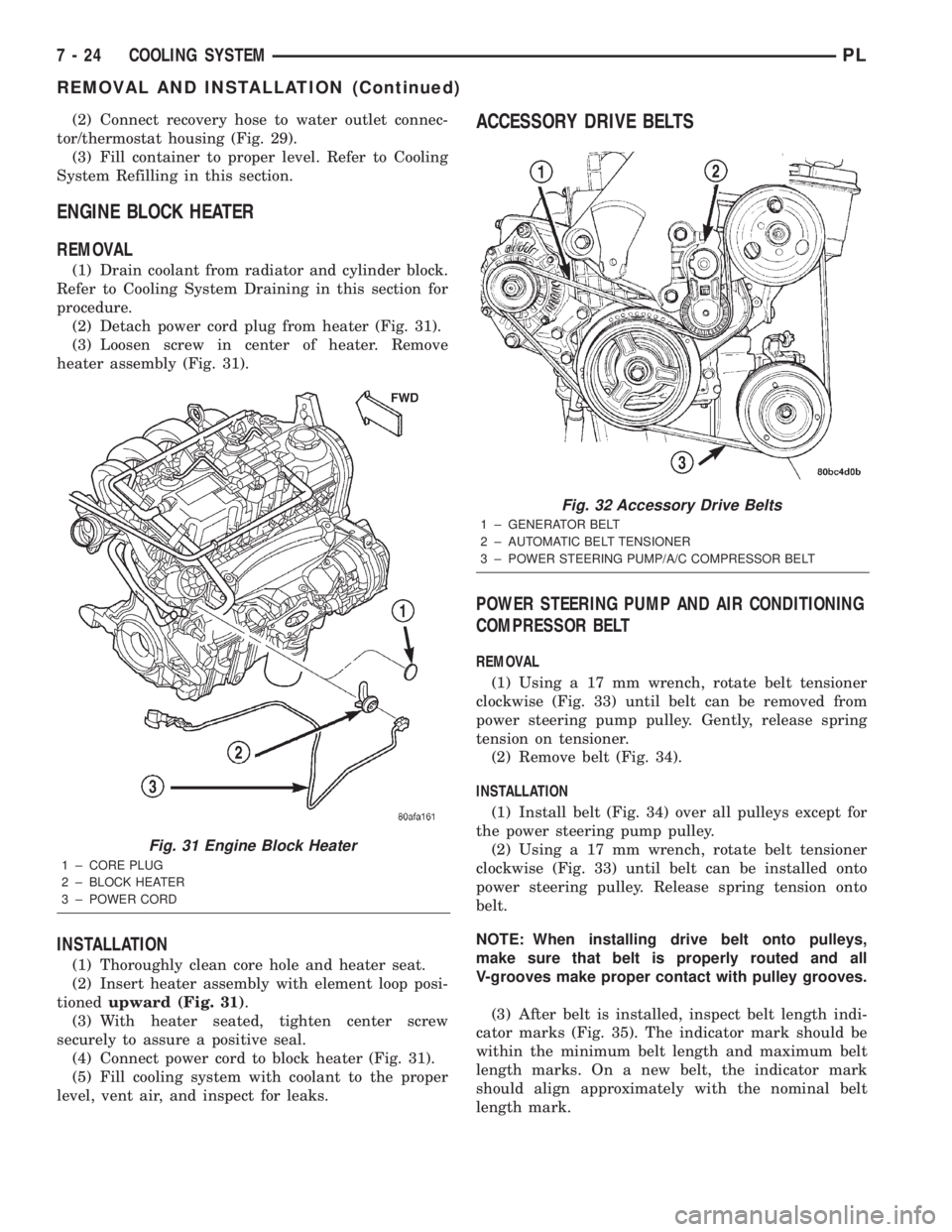

ENGINE BLOCK HEATER

REMOVAL

(1) Drain coolant from radiator and cylinder block.

Refer to Cooling System Draining in this section for

procedure.

(2) Detach power cord plug from heater (Fig. 31).

(3) Loosen screw in center of heater. Remove

heater assembly (Fig. 31).

INSTALLATION

(1) Thoroughly clean core hole and heater seat.

(2) Insert heater assembly with element loop posi-

tionedupward (Fig. 31).

(3) With heater seated, tighten center screw

securely to assure a positive seal.

(4) Connect power cord to block heater (Fig. 31).

(5) Fill cooling system with coolant to the proper

level, vent air, and inspect for leaks.

ACCESSORY DRIVE BELTS

POWER STEERING PUMP AND AIR CONDITIONING

COMPRESSOR BELT

REMOVAL

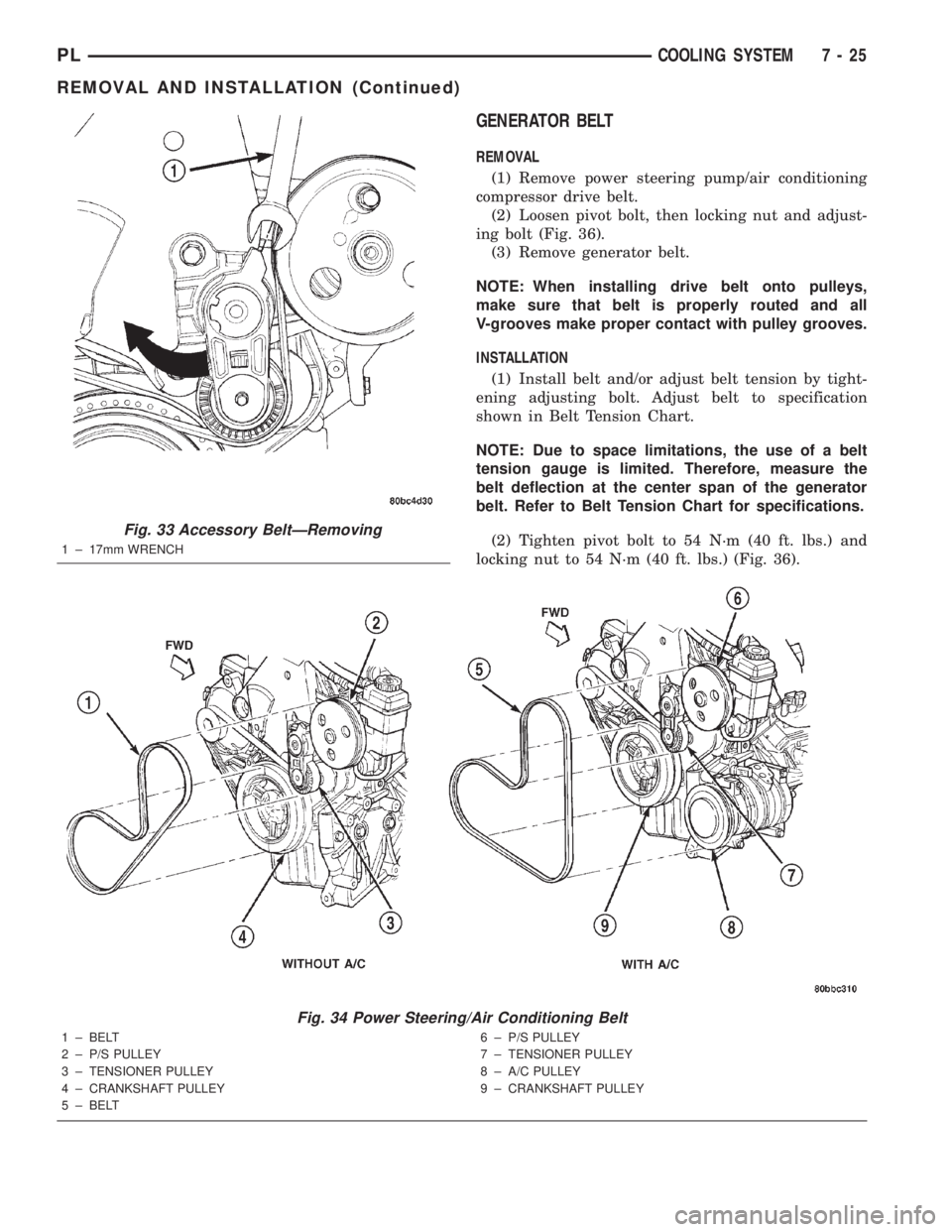

(1) Using a 17 mm wrench, rotate belt tensioner

clockwise (Fig. 33) until belt can be removed from

power steering pump pulley. Gently, release spring

tension on tensioner.

(2) Remove belt (Fig. 34).

INSTALLATION

(1) Install belt (Fig. 34) over all pulleys except for

the power steering pump pulley.

(2) Using a 17 mm wrench, rotate belt tensioner

clockwise (Fig. 33) until belt can be installed onto

power steering pulley. Release spring tension onto

belt.

NOTE: When installing drive belt onto pulleys,

make sure that belt is properly routed and all

V-grooves make proper contact with pulley grooves.

(3) After belt is installed, inspect belt length indi-

cator marks (Fig. 35). The indicator mark should be

within the minimum belt length and maximum belt

length marks. On a new belt, the indicator mark

should align approximately with the nominal belt

length mark.

Fig. 31 Engine Block Heater

1 ± CORE PLUG

2 ± BLOCK HEATER

3 ± POWER CORD

Fig. 32 Accessory Drive Belts

1 ± GENERATOR BELT

2 ± AUTOMATIC BELT TENSIONER

3 ± POWER STEERING PUMP/A/C COMPRESSOR BELT

7 - 24 COOLING SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 204 of 1285

GENERATOR BELT

REMOVAL

(1) Remove power steering pump/air conditioning

compressor drive belt.

(2) Loosen pivot bolt, then locking nut and adjust-

ing bolt (Fig. 36).

(3) Remove generator belt.

NOTE: When installing drive belt onto pulleys,

make sure that belt is properly routed and all

V-grooves make proper contact with pulley grooves.

INSTALLATION

(1) Install belt and/or adjust belt tension by tight-

ening adjusting bolt. Adjust belt to specification

shown in Belt Tension Chart.

NOTE: Due to space limitations, the use of a belt

tension gauge is limited. Therefore, measure the

belt deflection at the center span of the generator

belt. Refer to Belt Tension Chart for specifications.

(2) Tighten pivot bolt to 54 N´m (40 ft. lbs.) and

locking nut to 54 N´m (40 ft. lbs.) (Fig. 36).

Fig. 33 Accessory BeltÐRemoving

1 ± 17mm WRENCH

Fig. 34 Power Steering/Air Conditioning Belt

1 ± BELT

2 ± P/S PULLEY

3 ± TENSIONER PULLEY

4 ± CRANKSHAFT PULLEY

5 ± BELT6 ± P/S PULLEY

7 ± TENSIONER PULLEY

8 ± A/C PULLEY

9 ± CRANKSHAFT PULLEY

PLCOOLING SYSTEM 7 - 25

REMOVAL AND INSTALLATION (Continued)

Page 205 of 1285

(3) Install power steering pump and A/C compres-

sor drive belt.

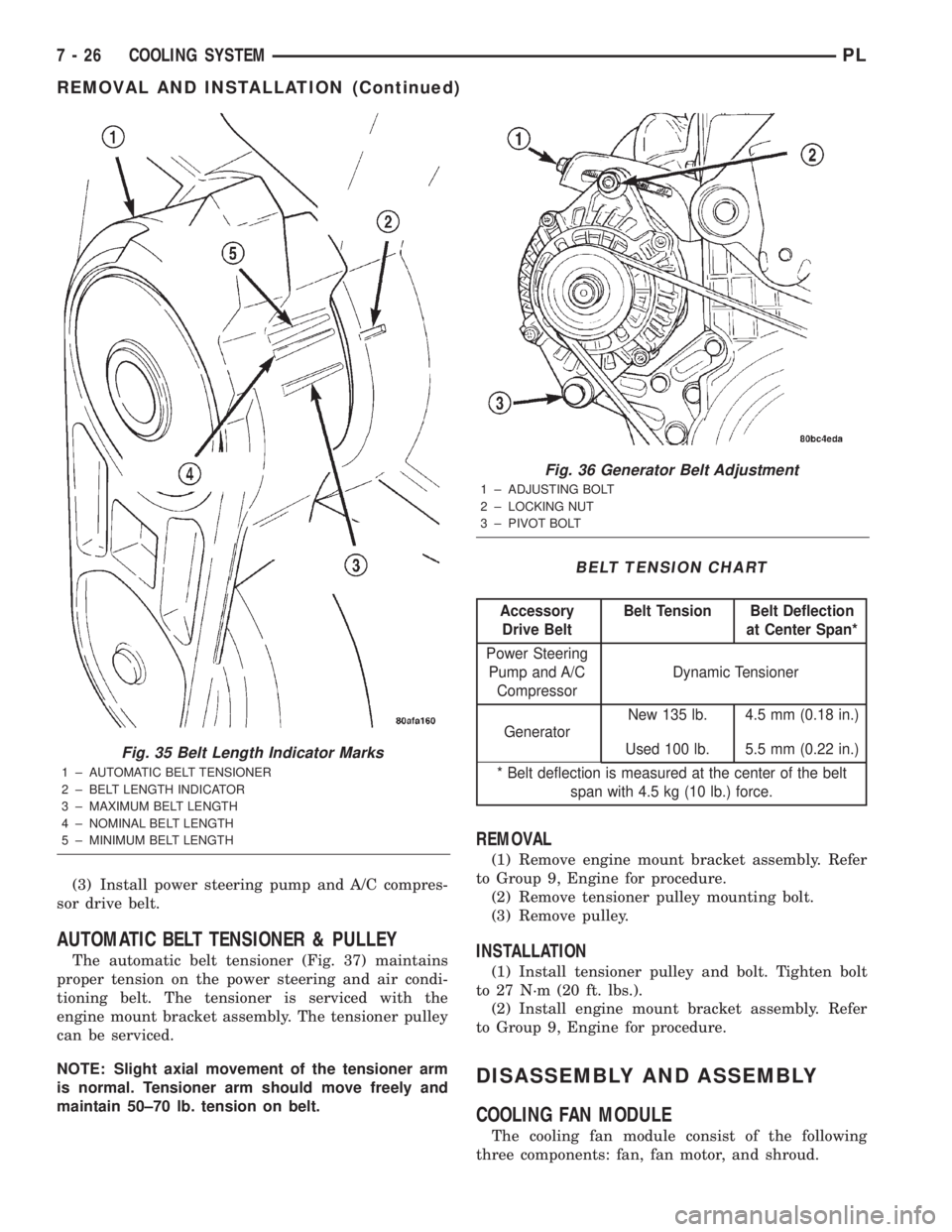

AUTOMATIC BELT TENSIONER & PULLEY

The automatic belt tensioner (Fig. 37) maintains

proper tension on the power steering and air condi-

tioning belt. The tensioner is serviced with the

engine mount bracket assembly. The tensioner pulley

can be serviced.

NOTE: Slight axial movement of the tensioner arm

is normal. Tensioner arm should move freely and

maintain 50±70 lb. tension on belt.

REMOVAL

(1) Remove engine mount bracket assembly. Refer

to Group 9, Engine for procedure.

(2) Remove tensioner pulley mounting bolt.

(3) Remove pulley.

INSTALLATION

(1) Install tensioner pulley and bolt. Tighten bolt

to 27 N´m (20 ft. lbs.).

(2) Install engine mount bracket assembly. Refer

to Group 9, Engine for procedure.

DISASSEMBLY AND ASSEMBLY

COOLING FAN MODULE

The cooling fan module consist of the following

three components: fan, fan motor, and shroud.

Fig. 35 Belt Length Indicator Marks

1 ± AUTOMATIC BELT TENSIONER

2 ± BELT LENGTH INDICATOR

3 ± MAXIMUM BELT LENGTH

4 ± NOMINAL BELT LENGTH

5 ± MINIMUM BELT LENGTH

Fig. 36 Generator Belt Adjustment

1 ± ADJUSTING BOLT

2 ± LOCKING NUT

3 ± PIVOT BOLT

BELT TENSION CHART

Accessory

Drive BeltBelt Tension Belt Deflection

at Center Span*

Power Steering

Pump and A/C

CompressorDynamic Tensioner

GeneratorNew 135 lb. 4.5 mm (0.18 in.)

Used 100 lb. 5.5 mm (0.22 in.)

* Belt deflection is measured at the center of the belt

span with 4.5 kg (10 lb.) force.

7 - 26 COOLING SYSTEMPL

REMOVAL AND INSTALLATION (Continued)