motor start DODGE NEON 2000 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1000 of 1285

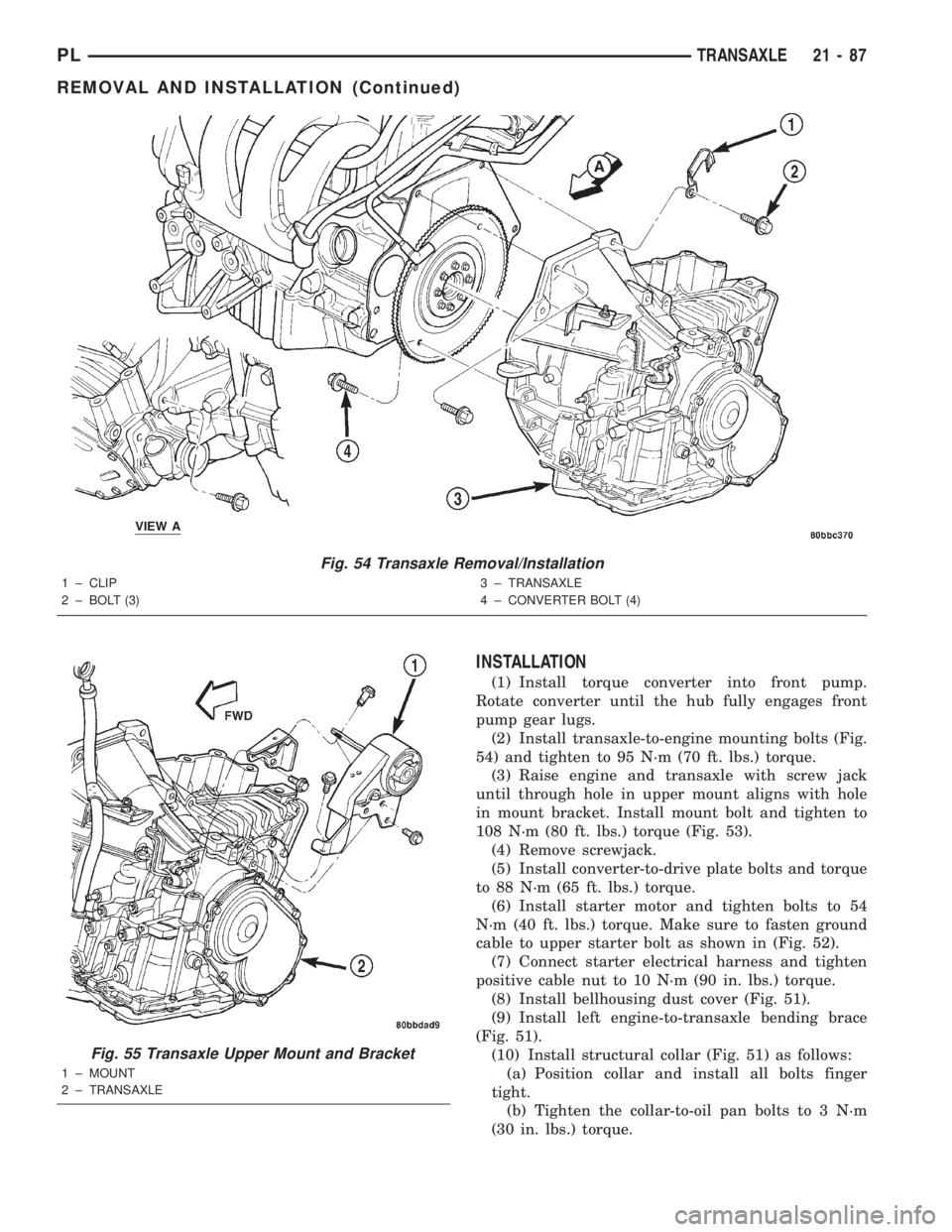

INSTALLATION

(1) Install torque converter into front pump.

Rotate converter until the hub fully engages front

pump gear lugs.

(2) Install transaxle-to-engine mounting bolts (Fig.

54) and tighten to 95 N´m (70 ft. lbs.) torque.

(3) Raise engine and transaxle with screw jack

until through hole in upper mount aligns with hole

in mount bracket. Install mount bolt and tighten to

108 N´m (80 ft. lbs.) torque (Fig. 53).

(4) Remove screwjack.

(5) Install converter-to-drive plate bolts and torque

to 88 N´m (65 ft. lbs.) torque.

(6) Install starter motor and tighten bolts to 54

N´m (40 ft. lbs.) torque. Make sure to fasten ground

cable to upper starter bolt as shown in (Fig. 52).

(7) Connect starter electrical harness and tighten

positive cable nut to 10 N´m (90 in. lbs.) torque.

(8) Install bellhousing dust cover (Fig. 51).

(9) Install left engine-to-transaxle bending brace

(Fig. 51).

(10) Install structural collar (Fig. 51) as follows:

(a) Position collar and install all bolts finger

tight.

(b) Tighten the collar-to-oil pan bolts to 3 N´m

(30 in. lbs.) torque.

Fig. 54 Transaxle Removal/Installation

1 ± CLIP

2 ± BOLT (3)3 ± TRANSAXLE

4 ± CONVERTER BOLT (4)

Fig. 55 Transaxle Upper Mount and Bracket

1 ± MOUNT

2 ± TRANSAXLE

PLTRANSAXLE 21 - 87

REMOVAL AND INSTALLATION (Continued)

Page 1097 of 1285

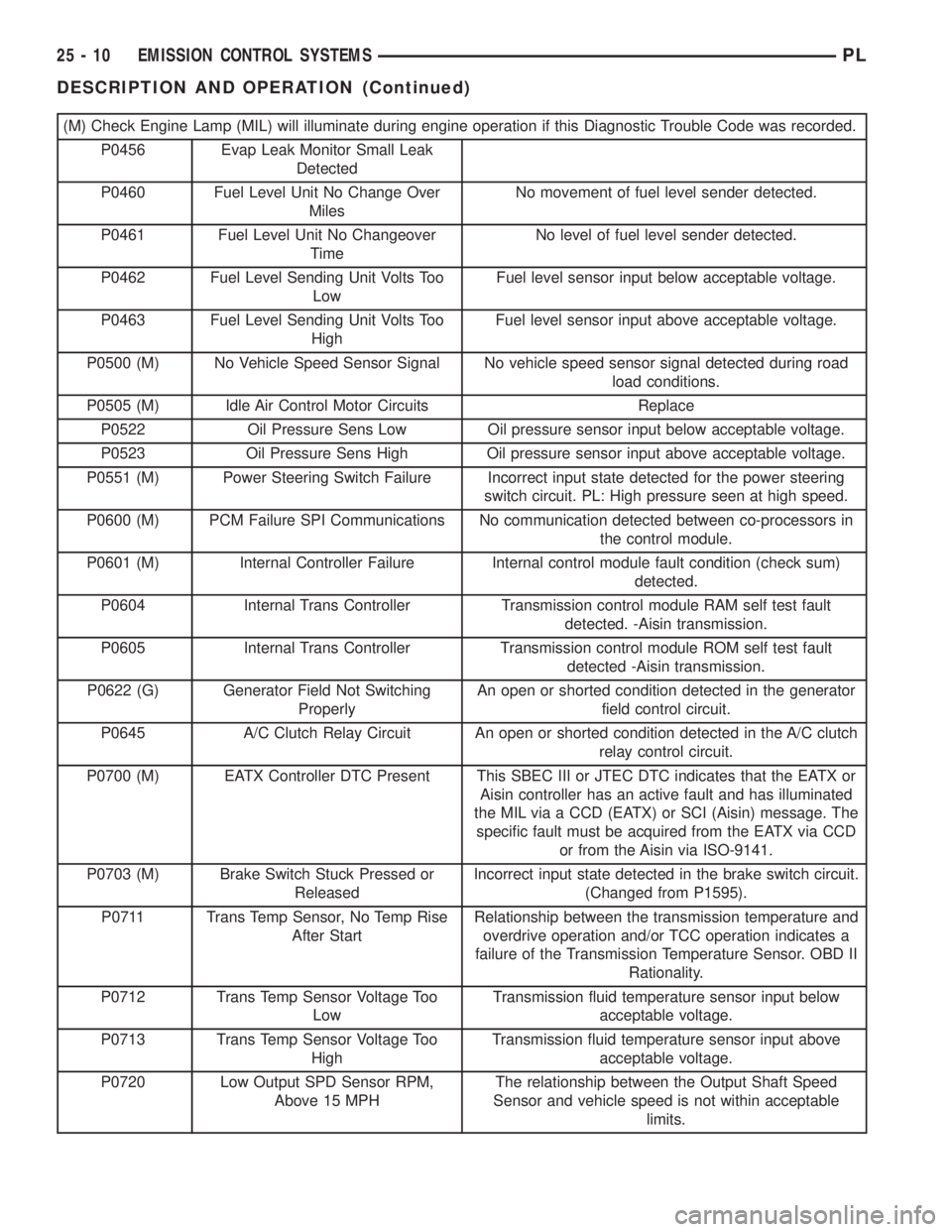

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

P0456 Evap Leak Monitor Small Leak

Detected

P0460 Fuel Level Unit No Change Over

MilesNo movement of fuel level sender detected.

P0461 Fuel Level Unit No Changeover

TimeNo level of fuel level sender detected.

P0462 Fuel Level Sending Unit Volts Too

LowFuel level sensor input below acceptable voltage.

P0463 Fuel Level Sending Unit Volts Too

HighFuel level sensor input above acceptable voltage.

P0500 (M) No Vehicle Speed Sensor Signal No vehicle speed sensor signal detected during road

load conditions.

P0505 (M) Idle Air Control Motor Circuits Replace

P0522 Oil Pressure Sens Low Oil pressure sensor input below acceptable voltage.

P0523 Oil Pressure Sens High Oil pressure sensor input above acceptable voltage.

P0551 (M) Power Steering Switch Failure Incorrect input state detected for the power steering

switch circuit. PL: High pressure seen at high speed.

P0600 (M) PCM Failure SPI Communications No communication detected between co-processors in

the control module.

P0601 (M) Internal Controller Failure Internal control module fault condition (check sum)

detected.

P0604 Internal Trans Controller Transmission control module RAM self test fault

detected. -Aisin transmission.

P0605 Internal Trans Controller Transmission control module ROM self test fault

detected -Aisin transmission.

P0622 (G) Generator Field Not Switching

ProperlyAn open or shorted condition detected in the generator

field control circuit.

P0645 A/C Clutch Relay Circuit An open or shorted condition detected in the A/C clutch

relay control circuit.

P0700 (M) EATX Controller DTC Present This SBEC III or JTEC DTC indicates that the EATX or

Aisin controller has an active fault and has illuminated

the MIL via a CCD (EATX) or SCI (Aisin) message. The

specific fault must be acquired from the EATX via CCD

or from the Aisin via ISO-9141.

P0703 (M) Brake Switch Stuck Pressed or

ReleasedIncorrect input state detected in the brake switch circuit.

(Changed from P1595).

P0711 Trans Temp Sensor, No Temp Rise

After StartRelationship between the transmission temperature and

overdrive operation and/or TCC operation indicates a

failure of the Transmission Temperature Sensor. OBD II

Rationality.

P0712 Trans Temp Sensor Voltage Too

LowTransmission fluid temperature sensor input below

acceptable voltage.

P0713 Trans Temp Sensor Voltage Too

HighTransmission fluid temperature sensor input above

acceptable voltage.

P0720 Low Output SPD Sensor RPM,

Above 15 MPHThe relationship between the Output Shaft Speed

Sensor and vehicle speed is not within acceptable

limits.

25 - 10 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1108 of 1285

from memory after 40 consecutive warm-up cycles

without test failure.

Enabling ConditionsÐThe following conditions

must typically be met for the PCM to run the oxygen

sensor monitor:

²Battery voltage

²Engine temperature

²Engine run time

²Engine run time at a predetermined speed

²Engine run time at a predetermined speed and

throttle opening

²Transmission in gear (automatic only)

²Fuel system in Closed Loop

²Long Term Adaptive (within parameters)

²Power Steering Switch in low PSI (no load)

²Engine at idle

²Fuel level above 15%

²Ambient air temperature

²Barometric pressure

²Engine RPM within acceptable range of desired

idle

²Closed throttle speed

Pending ConditionsÐThe Task Manager typi-

cally does not run the Oxygen Sensor Monitor if over-

lapping monitors are running or the MIL is

illuminated for any of the following:

²Misfire Monitor

²Front Oxygen Sensor and Heater Monitor

²MAP Sensor

²Vehicle Speed Sensor

²Engine Coolant Temperature Sensor

²Throttle Position Sensor

²Engine Controller Self Test Faults

²Cam or Crank Sensor

²Injector and Coil

²Idle Air Control Motor

²EVAP Electrical

²EGR Solenoid Electrical

²Intake Air Temperature

²5 Volt Feed

ConflictÐThe Task Manager does not run the

Oxygen Sensor Monitor if any of the following condi-

tions are present:

²A/C ON (A/C clutch cycling temporarily sus-

pends monitor)

²Purge flow in progress

SuspendÐThe Task Manager suspends maturing

a fault for the Oxygen Sensor Monitor if an of the fol-

lowing are present:

²Oxygen Sensor Heater Monitor, Priority 1

²Misfire Monitor, Priority 2

OXYGEN SENSOR HEATER MONITOR

DESCRIPTIONÐIf there is an oxygen sensor

(O2S) DTC as well as a O2S heater DTC, the O2S

fault MUST be repaired first. After the O2S fault isrepaired, verify that the heater circuit is operating

correctly.

The voltage readings taken from the O2S are very

temperature sensitive. The readings are not accurate

below 300ÉC. Heating of the O2S is done to allow the

engine controller to shift to closed loop control as

soon as possible. The heating element used to heat

the O2S must be tested to ensure that it is heating

the sensor properly.

The heater element itself is not tested. The sensor

output is used to test the heater by isolating the

effect of the heater element on the O2S output volt-

age from the other effects. The resistance is normally

between 100 ohms and 4.5 megaohms. When oxygen

sensor temperature increases, the resistance in the

internal circuit decreases. The PCM sends a 5 volts

biased signal through the oxygen sensors to ground

this monitoring circuit. As the temperature increases,

resistance decreases and the PCM detects a lower

voltage at the reference signal. Inversely, as the tem-

perature decreases, the resistance increases and the

PCM detects a higher voltage at the reference signal.

an The O2S circuit is monitored for a drop in voltage.

OPERATIONÐThe Oxygen Sensor Heater Moni-

tor begins after the ignition has been turned OFF

and the O2 sensors have cooled. The PCM sends a 5

volt bias to the oxygen sensor every 1.6 seconds. The

PCM keeps it biased for 35 ms each time. As the sen-

sor cools down, the resistance increases and the PCM

reads the increase in voltage. Once voltage has

increased to a predetermined amount, higher than

when the test started, the oxygen sensor is cool

enough to test heater operation.

When the oxygen sensor is cool enough, the PCM

energizes the ASD relay. Voltage to the O2 sensor

begins to increase the temperature. As the sensor

temperature increases, the internal resistance

decreases. The PCM continues biasing the 5 volt sig-

nal to the sensor. Each time the signal is biased, the

PCM reads a voltage decrease. When the PCM

detects a voltage decrease of a predetermined value

for several biased pulses, the test passes.

The heater elements are tested each time the

engine is turned OFF if all the enabling conditions

are met. If the monitor fails, the PCM stores a

maturing fault and a Freeze Frame is entered. If two

consecutive tests fail, a DTC is stored. Because the

ignition is OFF, the MIL is illuminated at the begin-

ning of the next key cycle.

Enabling ConditionsÐThe following conditions

must be met for the PCM to run the oxygen sensor

heater test:

²Engine run time of at least 5.1 minutes

²Key OFF power down

²Battery voltage of at least 10 volts

²Sufficient Oxygen Sensor cool down

PLEMISSION CONTROL SYSTEMS 25 - 21

DESCRIPTION AND OPERATION (Continued)

Page 1110 of 1285

Pending ConditionsÐ

²Misfire DTC

²Front Oxygen Sensor Response

²Front Oxygen Sensor Heater Monitor

²Front Oxygen Sensor Electrical

²Rear Oxygen Sensor Rationality (middle check)

²Rear Oxygen Sensor Heater Monitor

²Rear Oxygen Sensor Electrical

²Fuel System Monitor

²All TPS faults

²All MAP faults

²All ECT sensor faults

²Purge flow solenoid functionality

²Purge flow solenoid electrical

²All PCM self test faults

²All CMP and CKP sensor faults

²All injector and ignition electrical faults

²Idle Air Control (IAC) motor functionality

²Vehicle Speed Sensor

²Brake switch

²Intake air temperature

ConflictÐThe catalyst monitor does not run if

any of the following are conditions are present:

²EGR Monitor in progress

²Fuel system rich intrusive test in progress

²EVAP Monitor in progress

²Time since start is less than 60 seconds

²Low fuel level

²Low ambient air temperature

SuspendÐThe Task Manager does not mature a

catalyst fault if any of the following are present:

²Oxygen Sensor Monitor, Priority 1

²Upstream Oxygen Sensor Heater, Priority 1

²EGR Monitor, Priority 1

²EVAP Monitor, Priority 1

²Fuel System Monitor, Priority 2

²Misfire Monitor, Priority 2

NON-MONITORED CIRCUITS

OPERATION

The PCM does not monitor all circuits, systems

and conditions that could have malfunctions causing

driveability problems. However, problems with these

systems may cause the PCM to store diagnostic trou-

ble codes for other systems or components. For exam-

ple, a fuel pressure problem will not register a fault

directly, but could cause a rich/lean condition or mis-

fire. This could cause the PCM to store an oxygen

sensor or misfire diagnostic trouble code.

The major non-monitored circuits are listed below

along with examples of failures modes that do not

directly cause the PCM to set a DTC, but for a sys-

tem that is monitored.FUEL PRESSURE

The fuel pressure regulator controls fuel system

pressure. The PCM cannot detect a clogged fuel

pump inlet filter, clogged in-line fuel filter, or a

pinched fuel supply or return line. However, these

could result in a rich or lean condition causing the

PCM to store an oxygen sensor or fuel system diag-

nostic trouble code.

SECONDARY IGNITION CIRCUIT

The PCM cannot detect an inoperative ignition coil,

fouled or worn spark plugs, ignition cross firing, or

open spark plug cables.

CYLINDER COMPRESSION

The PCM cannot detect uneven, low, or high engine

cylinder compression.

EXHAUST SYSTEM

The PCM cannot detect a plugged, restricted or

leaking exhaust system. It may set a EGR or Fuel

system fault or O2S.

FUEL INJECTOR MECHANICAL MALFUNCTIONS

The PCM cannot determine if a fuel injector is

clogged, the needle is sticking or if the wrong injector

is installed. However, these could result in a rich or

lean condition causing the PCM to store a diagnostic

trouble code for either misfire, an oxygen sensor, or

the fuel system.

EXCESSIVE OIL CONSUMPTION

Although the PCM monitors engine exhaust oxygen

content when the system is in closed loop, it cannot

determine excessive oil consumption.

THROTTLE BODY AIR FLOW

The PCM cannot detect a clogged or restricted air

cleaner inlet or filter element.

VACUUM ASSIST

The PCM cannot detect leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices. However, these could cause the PCM

to store a MAP sensor diagnostic trouble code and

cause a high idle condition.

PCM SYSTEM GROUND

The PCM cannot determine a poor system ground.

However, one or more diagnostic trouble codes may

be generated as a result of this condition. The mod-

ule should be mounted to the body at all times, also

during diagnostic.

PLEMISSION CONTROL SYSTEMS 25 - 23

DESCRIPTION AND OPERATION (Continued)

Page 1240 of 1285

Normally, vacuum is supplied to the actuator by

placing the Circulation control knob in the Recircula-

tion position. The Mode and the circulation control

are mechanically interlocked so the circulation con-

trol cannot be placed in the RECIRC position if the

mode control is at or between the mix and defrost

positions. Vacuum is supplied to the actuator only

when circulation control is at the RECIRC position.

If the circulation control is between the outside air

position and RECIRC position the system will be in

outside air. If the circulation control is in the

RECIRC position and the mode control is moved from

the floor to the defrost positions, the circulation con-

trol will move from the RECIRC position, to the out-

side air position beginning at the mix position. This

is to prevent window fogging.

DIAGNOSIS AND TESTING

A/C PERFORMANCE TEST

The air conditioning system is designed to remove

heat and humidity from the air entering the passen-

ger compartment. The evaporator, located in the

heater A/C unit, is cooled to temperatures near the

freezing point. As warm damp air passes over the

fins in the evaporator, moisture in the air condenses

to water, dehumidifying the air. Condensation on the

evaporator fins reduces the evaporators ability to

absorb heat. During periods of high heat and humid-

ity, an air conditioning system will be less effective.

With the instrument control set to RECIRC, only air

from the passenger compartment passes through theevaporator. As the passenger compartment air dehu-

midifies, A/C performance levels rise.

PERFORMANCE TEST PROCEDURE

Review Safety Precautions and Warnings in this

group before proceeding with this procedure. Air tem-

perature in test room and on vehicle must be 21É C

(70ÉF) minimum for this test.

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) Connect a tachometer and manifold gauge set.

(2) Set control to A/C, RECIRC, and PANEL, tem-

perature lever on full cool and blower on high.

(3) Start engine and hold at 1000 rpm with A/C

clutch engaged.

(4) Engine should be warmed up with doors and

windows closed.

(5) Insert a thermometer in the left center A/C

outlet and operate the engine for five minutes. The

A/C clutch may cycle depending on ambient condi-

tions.

(6) With the A/C clutch engaged, compare the dis-

charge air temperature to the A/C Performance Tem-

peratures chart.

(7) If the discharge air temperature fails to meet

the specifications in the performance temperature

chart. Refer to the Refrigerant Service Procedures for

further diagnosis.

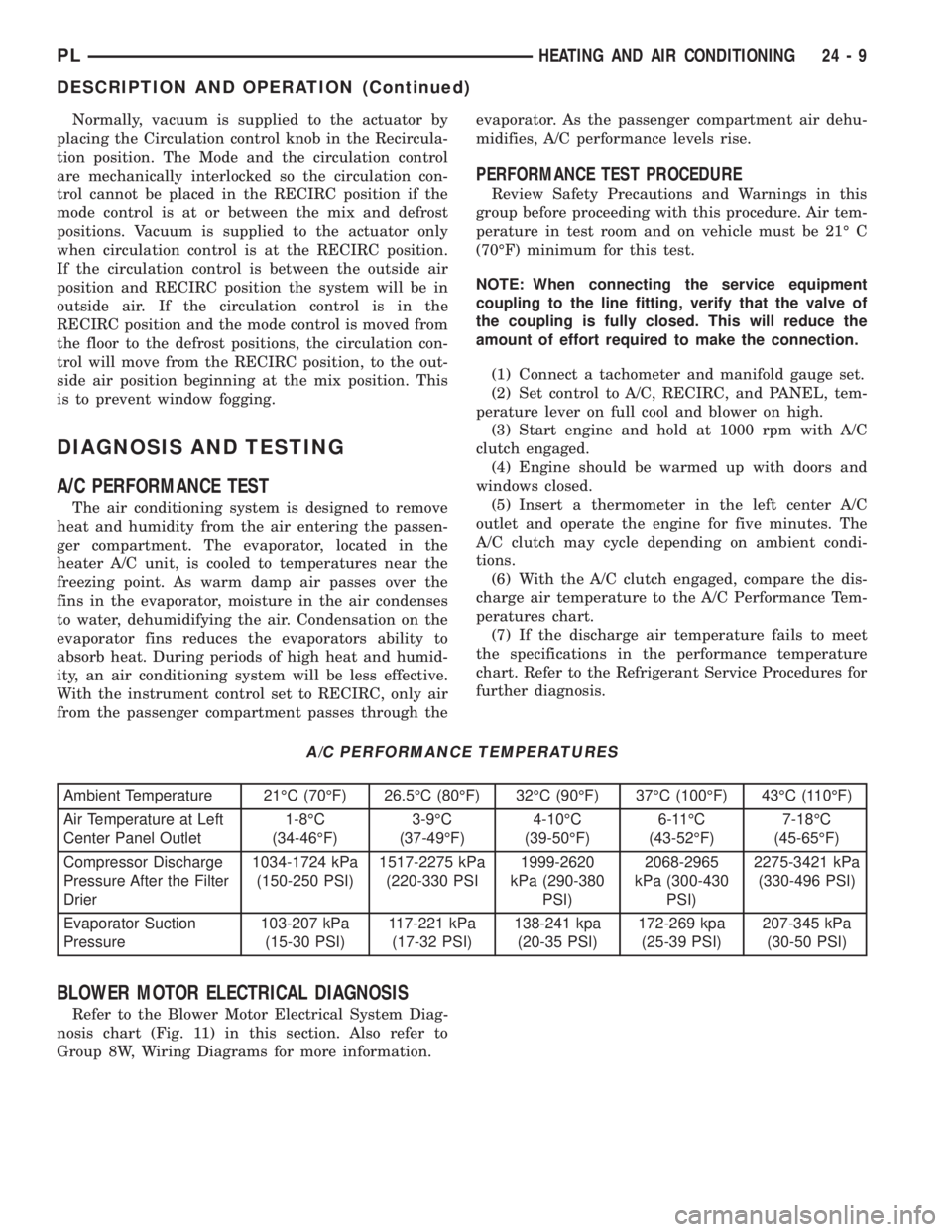

A/C PERFORMANCE TEMPERATURES

Ambient Temperature 21ÉC (70ÉF) 26.5ÉC (80ÉF) 32ÉC (90ÉF) 37ÉC (100ÉF) 43ÉC (110ÉF)

Air Temperature at Left

Center Panel Outlet1-8ÉC

(34-46ÉF)3-9ÉC

(37-49ÉF)4-10ÉC

(39-50ÉF)6-11ÉC

(43-52ÉF)7-18ÉC

(45-65ÉF)

Compressor Discharge

Pressure After the Filter

Drier1034-1724 kPa

(150-250 PSI)1517-2275 kPa

(220-330 PSI1999-2620

kPa (290-380

PSI)2068-2965

kPa (300-430

PSI)2275-3421 kPa

(330-496 PSI)

Evaporator Suction

Pressure103-207 kPa

(15-30 PSI)117-221 kPa

(17-32 PSI)138-241 kpa

(20-35 PSI)172-269 kpa

(25-39 PSI)207-345 kPa

(30-50 PSI)

BLOWER MOTOR ELECTRICAL DIAGNOSIS

Refer to the Blower Motor Electrical System Diag-

nosis chart (Fig. 11) in this section. Also refer to

Group 8W, Wiring Diagrams for more information.

PLHEATING AND AIR CONDITIONING 24 - 9

DESCRIPTION AND OPERATION (Continued)

Page 1242 of 1285

BLOWER MOTOR VIBRATION AND/OR NOISE

DIAGNOSIS

The resistor block supplies the blower motor with

varied voltage (low and middle speeds) or battery

voltage (high speed).

CAUTION: Stay clear of the blower motor and resis-

tor block (Hot). Do not operate the blower motor

with the resistor block removed from the heater-A/C

housing.

Refer to the Blower Motor Vibration/Noise chart

for diagnosis.

COMPRESSOR NOISE DIAGNOSIS

Excessive noise while the A/C is being used, can be

caused by loose mounts, loose clutch, or high operat-

ing pressure. Verify compressor drive belt condition,

proper refrigerant charge and head pressure before

compressor repair is performed.

If the A/C drive belt slips at initial start-up, it does

not necessarily mean the compressor has failed.

With the close tolerances of a compressor it is pos-

sible to experience a temporary lockup. The longer

the A/C system is inactive, the more likely the condi-

tion to occur.

This condition is the result of normal refrigerant

movement within the A/C system caused by temper-

ature changes. The refrigerant movement may wash

the oil out of the compressor.

EVAPORATOR PROBE TEST

The work area and vehicle must be between 16É C

(60É F) and 32É C (90É F) when testing the switch.

(1) Disconnect the three wire connector from the

evaporator probe lead located behind the glove box

(Fig. 12).

(2) Start engine and set A/C to low blower motor

speed, panel, full cool, and RECIRC.

(3) Using a voltmeter, check for battery voltage

between Pin 1 and 2. If no voltage is detected, there

is no power to the switch. Check wiring and fuses.

Refer to Group 8W, Wiring Diagrams for circuit diag-

nosis.

(4) Using a voltmeter, check for battery voltage

between Pin 1 and Pin 3. If no voltage is detected,

there is no voltage from the Powertrain Control Mod-

ule. Refer to Group 8W, Wiring Diagrams. If voltage

is OK, connect a jumper wire between Pin 1 and Pin

3. The compressor clutch should engage. If the clutch

engages, remove the jumper wire immediately and go

to Step 5. If the compressor clutch does not engage,

check the operation of the clutch and repair as nec-

essary.(5) If compressor clutch engages, connect the evap-

orator probe 3-way connector. The compressor clutch

should engage or cycle depending on evaporator tem-

perature. If OK, go to Step 6. If not OK, replace the

clutch cycling switch.

(6) The engine running and the A/C set to:

²Blower motor on low speed

²Panel position

²Full cool

²RECIRC.

Close all doors and windows. Place a thermometer in

the center discharge vent.

(7) If the clutch does not begin to cycle off between

2É C to 7É C (35É F to 45É F), verify that the evapo-

rator probe is fully installed and not loose in evapo-

rator. If it is not properly installed, install probe and

retest outlet temperature. If the evaporator probe is

properly installed, replace the clutch cycling switch.

EXPANSION VALVE

NOTE: Expansion valve tests should be performed

after compressor tests.

Liquid CO2 is required to test the expansion

valve. It is available from most welding supply facil-

ities. CO2 is also available from companies which

service and sell fire extinguishers.

Review Safety Precautions and Warnings in the

General Information section of this Group. The work

area and vehicle must be 21É to 27ÉC (70É to 85ÉF)

when testing expansion valve. To test the expansion

valve:

(1) Connect a charging station or manifold gauge

set to the refrigerant system service ports.

(2) Disconnect wire connector at low pressure cut-

off switch (Fig. 13). Using a jumper wire, jump ter-

minals inside wire connector boot.

(3) Close all doors, windows and vents to the pas-

senger compartment.

(4) Set Heater-A/C control to A/C, full heat, floor,

RECIRC. and high blower.

(5) Start the engine and hold the idle speed (1000

rpm). After the engine has reached running temper-

ature, allow the passenger compartment to heat up.

This will create the need for maximum refrigerant

flow into the evaporator.

(6) If the refrigerant charge is sufficient, discharge

(high pressure) gauge should read 965 to 2620 kPa

(140 to 380 psi). Suction (low pressure) gauge should

read 103 to 2417 kPa (15 to 35 psi). If system cannot

achieve proper pressure readings, replace the expan-

sion valve. If pressure is correct, proceed with test.

PLHEATING AND AIR CONDITIONING 24 - 11

DIAGNOSIS AND TESTING (Continued)

Page 1245 of 1285

POSSIBLE LOCATIONS OR CAUSE OF

OBSTRUCTED COOLANT FLOW

(1) Pinched or kinked heater hoses.

(2) Improper heater hose routing.

(3) Plugged heater hoses or supply and return

ports at cooling system connections, refer to Group 7,

Cooling System.

(4) Plugged heater core.

(5) Air locked heater core.

(6) If coolant flow is verified and outlet tempera-

ture is insufficient, a mechanical problem may exist.

POSSIBLE LOCATION OR CAUSE OF INSUFFICIENT

HEAT

(1) Obstructed cowl air intake.

(2) Obstructed heater system outlets.

(3) Blend-air door not functioning properly.

TEMPERATURE CONTROL

If temperature cannot be adjusted with the TEMP

lever on the control panel, the following could require

service:

(1) Blend-air door binding.

(2) Faulty blend-air door cable.

(3) Improper engine coolant temperature.

(4) Faulty Instrument Panel Control.

LOW PRESSURE CUT OFF SWITCH

The work area must not be below 21ÉC (70ÉF) to

test the compressor clutch circuit.

(1) With gear selector in park or neutral and park

brake set, start engine and allow to idle.

(2) Raise hood and disconnect low pressure cut off

switch connector boot.

(3) Using a suitable jumper wire, jump across the

terminals inside wire connector boot.

(4) If the compressor clutch does not engage, the

cycling clutch switch, wiring, relay, or fuse can be

defective. Refer to Group 8W, Wiring Diagrams.

(5) If clutch engages, connect manifold gauge set.

Read low pressure gauge. At pressure above 97 kPa

(14 psi) and above, low pressure out off switch will

complete the clutch circuit. If the low pressure gauge

reads below 140 kPa (20 psi), the system is low on

refrigerant charge or empty due to a leak. Refer to

Service Procedures, System Leak Checking in this

section.

(6) Install connector boot on switch and repeat

Step 3. If the clutch does not engage, replace the low

pressure cut off switch.

SYSTEM CHARGE LEVEL TEST

The procedure below should be used to check

and/or fill the refrigerant charge in the air condition-

ing system.

WARNING: AVOID BREATHING A/C REFRIGERANT

AND LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND THROAT. USE ONLY

APPROVED SERVICE EQUIPMENT MEETING SAE

REQUIREMENTS TO DISCHARGE R-134a SYSTEM.

IF ACCIDENTAL SYSTEM DISCHARGE OCCURS,

VENTILATE WORK AREA BEFORE RESUMING SER-

VICE.

R-134a SERVICE EQUIPMENT OR VEHICLE A/C

SYSTEM SHOULD NOT BE PRESSURE TESTED OR

LEAK TESTED WITH COMPRESSED AIR. MIXTURE

OF AIR and R-134a CAN BE COMBUSTIBLE AT ELE-

VATED PRESSURES. THESE MIXTURES ARE

POTENTIALLY DANGEROUS AND MAY RESULT IN

FIRE OR EXPLOSION CAUSING INJURY OR PROP-

ERTY DAMAGE.

NOTE: The maximum amount of R-134a refrigerant

that the air conditioning system holds is 765 grams

(27 oz. or 1.69 lbs.)

It is recommended to use the gauges or reclaim/re-

cycle equipment.

(1) Use a manifold gauge and check the liquid line

pressure.

(2) Attach a clamp-on thermocouple (P. S. E.

66-324-0014 or 80PK-1A) or equivalent to the liquid

line near the filter/drier.

(3) The vehicle must be in the following modes:

²Automatic transaxle in park or manual tran-

saxle in neutral.

²Engine at idle

²A/C controls set to outside air

²Panel mode

²A/C ON full cool

²Blower motor ON high speed

²Vehicle windows closed

(4) Operate system for a couple of minutes to allow

the system to stabilize.

(5) Observe filter/drier pressure and Liquid line

temperature. Using the Charge Determination Chart

(Fig. 14) determine where the system is currently

operating. If the system is not in the proper range,

reclaim all the refrigerant and recharge per A/C

label.

24 - 14 HEATING AND AIR CONDITIONINGPL

DIAGNOSIS AND TESTING (Continued)

Page 1247 of 1285

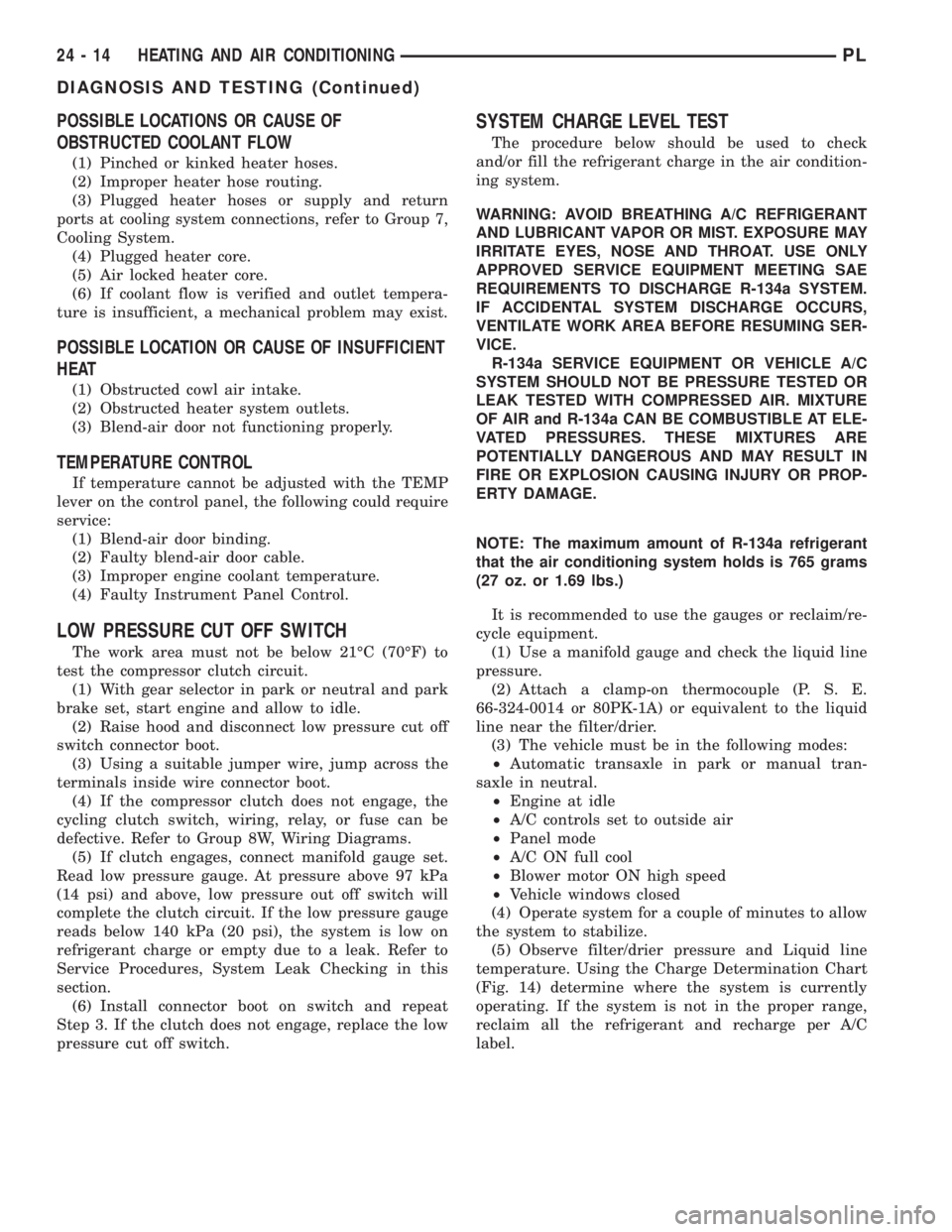

HEATER-A/C VACUUM SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO FORCED AIR IN

HEAT POSITION1. Vacuum line pinched or

leaking.

2. Faulty heat defroster or

mode door.

3. Faulty selector switch.

4. Vacuum check valve.1. Locate and repair vacuum leak or pinched line.

2. Test actuators and door operation. Repair as

necassary.

3. Test selector switch and replace if necessary.

4. Test check valve and replace if necessary.

NO FORCED AIR IN

PANEL POSITION1. Vacuum line pinched or

leaking.

2. Faulty mode door.

3. Faulty selector switch.

4. Vacuum check valve.1. Locate and repair vacuum leak or pinched line.

2. Test actuator and door operation. Repair as

necessary.

3. Test selector switch and replace if necessary.

4. Test check valve and replace if necessary.

NO FORCED AIR IN

DEFROST POSITION1. Vacuum line pinched or

leaking.

2. Faulty heat, defroster, or

mode door.

3. Faulty selector switch.

4. Vacuum check valve.1. Locate and repair vacuum leak or pinched line.

2. Test actuators and door operation. Repair as

necessary.

3. Test selector switch and replace if necessary.

4. Test check valve and replace if necessary.

ONE-WAY CHECK VALVE

(1) Disconnect the heater-A/C vacuum supply

(Black) tube in the engine compartment. This tube

passes through an opening in the dash panel.

(2) Remove the one-way vacuum check valve. The

valve is located on the (Black) vacuum supply hose at

the brake power booster.

(3) Connect the test set vacuum supply hose to the

heater side of the valve. When connected to this side

of the check valve, no vacuum should pass and the

test set gauge should return to the 27 kPa (8 in. Hg.)

setting. If OK, go to step Step 4. If not OK, replace

the faulty valve.

(4) Connect the test set vacuum supply hose to the

engine vacuum side of the valve. When connected to

this side of the check valve, vacuum should flow

through the valve without restriction. If not OK,

replace the faulty valve.

HEATER-A/C CONTROLS

The operation of the Circulation door can be

viewed by removing the blower motor and looking up

into the unit inlet. See Blower Motor Wheel and

Assembly removal and installation in this section for

service procedures.

(1) Connect the test set vacuum probe to the heat-

er-A/C vacuum supply (Black) hose in the engine

compartment. Position the test set gauge so that it

can be viewed from the passenger compartment.

(2) Start with the Mode control in the Panel posi-

tion and the Circulation control in the Outside-air

position.

(3) Move the Circulation control to the Recircula-

tion position (the Circulation door should move intothe Recirculation position). After a short pause move

the Mode control to the Defrost position (the Circula-

tion door should move to the Outside-air position).

The test gauge should return to the calibrated set-

ting of 27 kPa (8 in. Hg.) after each selection is

made. If the gauge cannot achieve the calibrated set-

ting, the vacuum circuit or a component has a leak.

(4) If the gauge achieves the calibrated setting but

the door does not move, there is either a pinched vac-

uum line or a failed actuator.

LOCATING VACUUM LEAKS

(1) Connect the test vacuum probe to the vehicles

(Black) supply hose. Position the vacuum test gauge

so it can be viewed from the passenger compartment.

(2) Place the Mode in the Panel position and the

Circulation control in the Recirculation position.

(3) Remove the center instrument panel bezel.

(4) Remove the center vent duct.

(5) Remove and block the Supply (Black) vacuum

line at the control. The test gauge should return to

the calibrated setting of 27 kPa (8 in. Hg). If not,

there is a leak in the Supply line.

(6) If there is no leak in the Supply line, reconnect

it to the Control and remove the Actuator Feed (Red)

line from the Control. Block the vacuum connection

on the Control from where the line was removed. The

test gauge should return to the calibrated setting of

27 kPa (8 in. Hg.). If not, there is a leak in the Con-

trol.

(7) If there is no leak in the Supply line or the

Control, reconnect the Actuator Feed (Red) line to the

control. Remove and block the Actuator Feed (Red)

line at the Actuator. The actuator vacuum port is

accessible behind and above the Glove Box. The test

24 - 16 HEATING AND AIR CONDITIONINGPL

DIAGNOSIS AND TESTING (Continued)

Page 1249 of 1285

CAUTION: Do not overcharge refrigerant system,

as excessive compressor head pressure can cause

noise and system failure.

After the system has been tested for leaks and

evacuated, a refrigerant (R-134a) charge can be

injected into the system.

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) If using a separate vacuum pump close all

valves before disconnecting pump. Connect manifold

gauge set to the A/C service ports (Fig. 16).

NOTE: The air conditioning system in this vehicle

holds (27 oz. or 1.69 lbs.) of R-134a refrigerant.

(2) Measure refrigerant (refer to capacities). Refer

to the instructions provided with the equipment

being used.

(3) Verify engine is shut off. Open the suction and

discharge valves. Open the charge valve to allow the

refrigerant to flow into the system. When the trans-

fer of refrigerant has stopped, close the suction and

discharge valve.

(4) If all of the charge did not transfer from the

dispensing device, put vehicle controls into the fol-

lowing mode:

²Automatic transaxle in park or manual tran-

saxle in neutral

²Engine idling at 700 rpm

²A/C control set in 100 percent outside air

²Panel mode

²Blower motor ON high speed

²Vehicle windows closed

If the A/C compressor does not engage, test the

compressor clutch control circuit and correct any fail-

ure. Refer to Group 8W, Wiring Diagrams.

(5) Open the suction valve to allow the remaining

refrigerant to transfer to the system.

WARNING: TAKE CARE NOT TO OPEN THE DIS-

CHARGE (HIGH-PRESSURE) VALVE AT THIS TIME.

(6) Close all valves and test the A/C system perfor-

mance.

(7) Disconnect the charging station or manifold

gauge set. Install the service port caps.

EVACUATING REFRIGERANT SYSTEM

NOTE: Special effort must be used to prevent mois-

ture from entering the A/C system oil. Moisture in

the oil is very difficult to remove and will cause a

reliability problem with the compressor.If a compressor designed to use R-134a refrigerant

is left open to the atmosphere for an extended period

of time. It is recommended that the refrigerant oil be

drained and replaced with new oil or a new compres-

sor be used. This will eliminate the possibility of con-

taminating the refrigerant system.

If the refrigerant system has been open to the

atmosphere, it must be evacuated before the system

can be filled. Moisture and air mixed with the refrig-

erant will raise the compressor head pressure above

acceptable operating levels. This will reduce the per-

formance of the air conditioner and damage the com-

pressor. Moisture will boil at near room temperature

when exposed to vacuum. To evacuate the refrigerant

system:

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

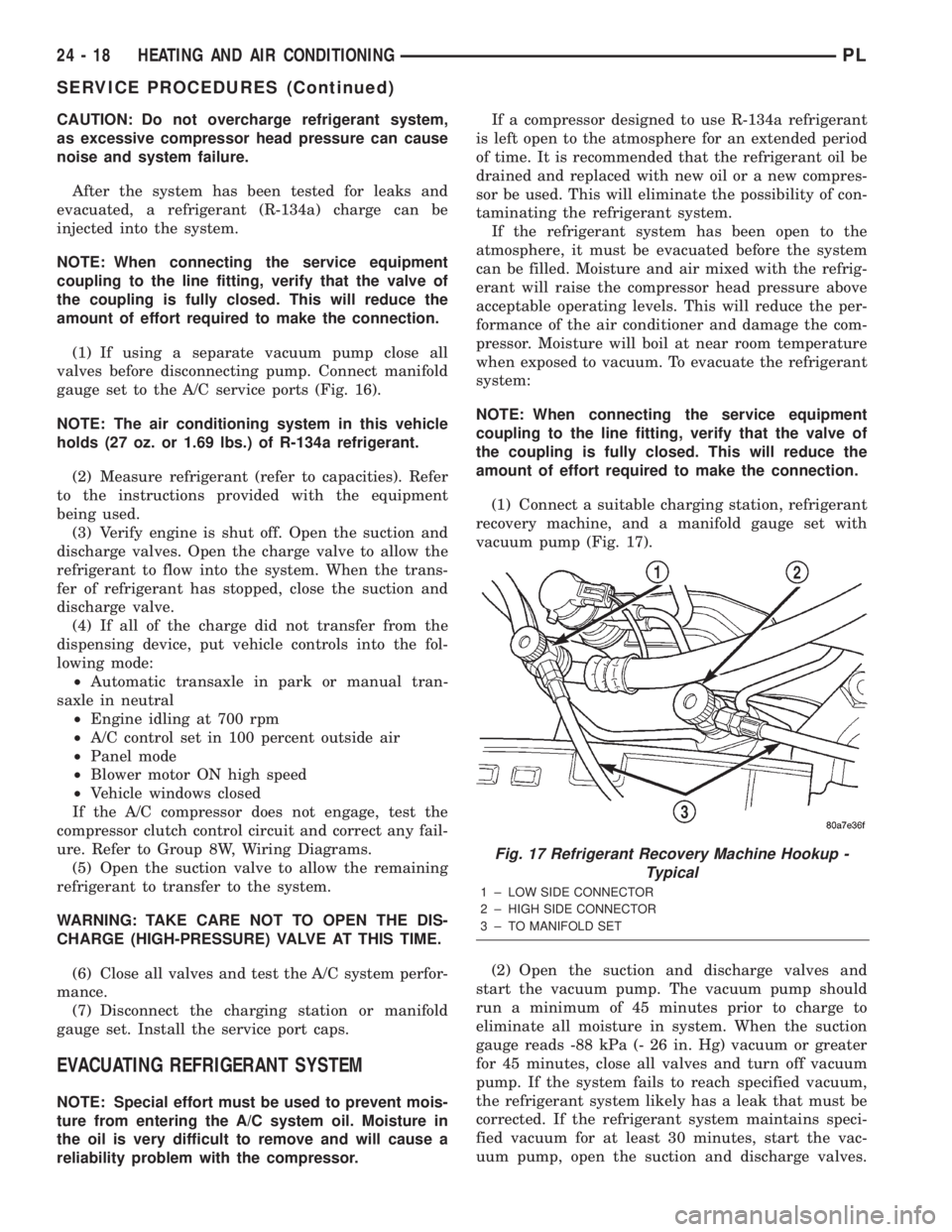

(1) Connect a suitable charging station, refrigerant

recovery machine, and a manifold gauge set with

vacuum pump (Fig. 17).

(2) Open the suction and discharge valves and

start the vacuum pump. The vacuum pump should

run a minimum of 45 minutes prior to charge to

eliminate all moisture in system. When the suction

gauge reads -88 kPa (- 26 in. Hg) vacuum or greater

for 45 minutes, close all valves and turn off vacuum

pump. If the system fails to reach specified vacuum,

the refrigerant system likely has a leak that must be

corrected. If the refrigerant system maintains speci-

fied vacuum for at least 30 minutes, start the vac-

uum pump, open the suction and discharge valves.

Fig. 17 Refrigerant Recovery Machine Hookup -

Typical

1 ± LOW SIDE CONNECTOR

2 ± HIGH SIDE CONNECTOR

3 ± TO MANIFOLD SET

24 - 18 HEATING AND AIR CONDITIONINGPL

SERVICE PROCEDURES (Continued)