brake sensor DODGE NEON 2000 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 860 of 1285

PROPORTIONAL PURGE SOLENOIDÐPCM

OUTPUT

DESCRIPTION

OPERATION

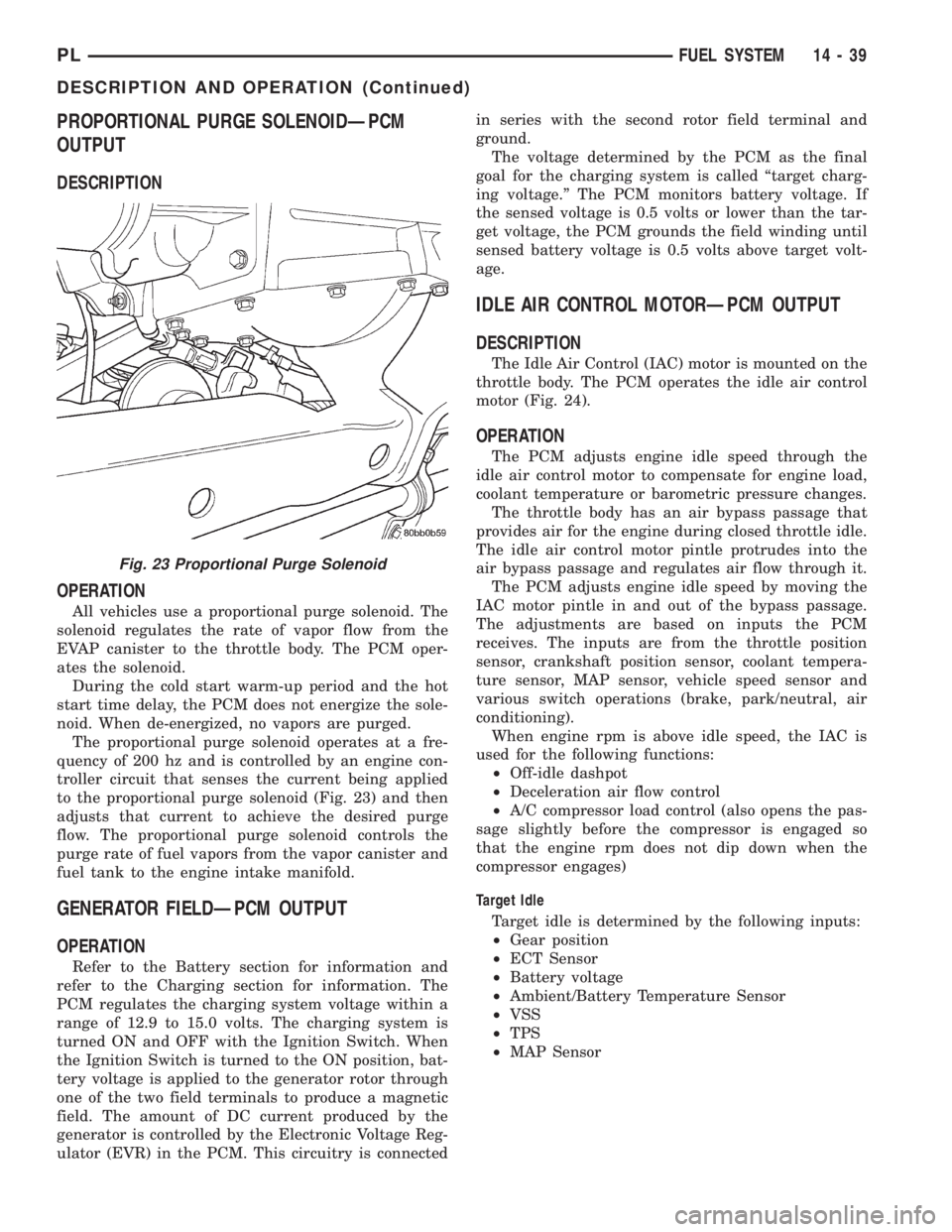

All vehicles use a proportional purge solenoid. The

solenoid regulates the rate of vapor flow from the

EVAP canister to the throttle body. The PCM oper-

ates the solenoid.

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged.

The proportional purge solenoid operates at a fre-

quency of 200 hz and is controlled by an engine con-

troller circuit that senses the current being applied

to the proportional purge solenoid (Fig. 23) and then

adjusts that current to achieve the desired purge

flow. The proportional purge solenoid controls the

purge rate of fuel vapors from the vapor canister and

fuel tank to the engine intake manifold.

GENERATOR FIELDÐPCM OUTPUT

OPERATION

Refer to the Battery section for information and

refer to the Charging section for information. The

PCM regulates the charging system voltage within a

range of 12.9 to 15.0 volts. The charging system is

turned ON and OFF with the Ignition Switch. When

the Ignition Switch is turned to the ON position, bat-

tery voltage is applied to the generator rotor through

one of the two field terminals to produce a magnetic

field. The amount of DC current produced by the

generator is controlled by the Electronic Voltage Reg-

ulator (EVR) in the PCM. This circuitry is connectedin series with the second rotor field terminal and

ground.

The voltage determined by the PCM as the final

goal for the charging system is called ªtarget charg-

ing voltage.º The PCM monitors battery voltage. If

the sensed voltage is 0.5 volts or lower than the tar-

get voltage, the PCM grounds the field winding until

sensed battery voltage is 0.5 volts above target volt-

age.

IDLE AIR CONTROL MOTORÐPCM OUTPUT

DESCRIPTION

The Idle Air Control (IAC) motor is mounted on the

throttle body. The PCM operates the idle air control

motor (Fig. 24).

OPERATION

The PCM adjusts engine idle speed through the

idle air control motor to compensate for engine load,

coolant temperature or barometric pressure changes.

The throttle body has an air bypass passage that

provides air for the engine during closed throttle idle.

The idle air control motor pintle protrudes into the

air bypass passage and regulates air flow through it.

The PCM adjusts engine idle speed by moving the

IAC motor pintle in and out of the bypass passage.

The adjustments are based on inputs the PCM

receives. The inputs are from the throttle position

sensor, crankshaft position sensor, coolant tempera-

ture sensor, MAP sensor, vehicle speed sensor and

various switch operations (brake, park/neutral, air

conditioning).

When engine rpm is above idle speed, the IAC is

used for the following functions:

²Off-idle dashpot

²Deceleration air flow control

²A/C compressor load control (also opens the pas-

sage slightly before the compressor is engaged so

that the engine rpm does not dip down when the

compressor engages)

Target Idle

Target idle is determined by the following inputs:

²Gear position

²ECT Sensor

²Battery voltage

²Ambient/Battery Temperature Sensor

²VSS

²TPS

²MAP Sensor

Fig. 23 Proportional Purge Solenoid

PLFUEL SYSTEM 14 - 39

DESCRIPTION AND OPERATION (Continued)

Page 862 of 1285

stroke. One plug is the cylinder under compression,

the other cylinder fires on the exhaust stroke. Coil

number one fires cylinders 1 and 4. Coil number two

fires cylinders 2 and 3. The PCM determines which

of the coils to charge and fire at the correct time.

The Auto Shutdown (ASD) relay provides battery

voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil. When

the PCM breaks the contact, the energy in the coil

primary transfers to the secondary causing the

spark. The PCM will de-energize the ASD relay if it

does not receive the crankshaft position sensor and

camshaft position sensor inputs. Refer to Auto Shut-

down (ASD) RelayÐPCM Output in this section for

relay operation.

Base timing is non-adjustable, but is set from the

factory at approximately 10ÉBTDC when the engine

is warm and idling.

There is an adaptive dwell strategy that runs dwell

from 4 to 6 msec when rpm is below 3,000 and bat-

tery voltage is 12-14 volts. During cranking, dwell

can be as much as 200 msec. The adaptive dwell is

driven by the sensed current flow through the injec-

tor drivers. Current flow is limited to 8 amps.

The low resistance of the primary coils can allow

current flow in excess of 15 amps. The PCM has a

current sensing device in the coil output circuit. As

dwell time starts, the PCM allows current to flow.

When the sensing device registers 8 amps, the PCM

begins to regulate current flow to maintain and not

exceed 8 amps through the remainder of the dwell

time. This prevents the PCM from being damaged by

excess current flow.

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUT

OPERATION

The PCM supplies the malfunction indicator (check

engine) lamp on/off signal to the instrument panel

through the PCI Bus. The PCI Bus is a communica-

tions port. Various modules use the PCI Bus to

exchange information.

The Check Engine lamp comes on each time the

ignition key is turned ON and stays on for 3 seconds

as a bulb test.

The Malfunction Indicator Lamp (MIL) stays on

continuously, when the PCM has entered a Limp-In

mode or identified a failed emission component. Dur-

ing Limp-in Mode, the PCM attempts to keep the

system operational. The MIL signals the need for

immediate service. In limp-in mode, the PCM com-

pensates for the failure of certain components that

send incorrect signals. The PCM substitutes for the

incorrect signals with inputs from other sensors.

If the PCM detects active engine misfire severe

enough to cause catalyst damage, it flashes the MIL.

At the same time the PCM also sets a Diagnostic

Trouble Code (DTC).

For signals that can trigger the MIL (Check

Engine Lamp) refer to the On-Board Diagnos-

tics section.

SPEED CONTROLÐPCM INPUT

OPERATION

The speed control system provides five separate

voltages (inputs) to the Powertrain Control Module

(PCM). The voltages correspond to the ON, OFF,

SET, RESUME, CANCEL, and COAST.

The speed control ON voltage informs the PCM

that the speed control system has been activated.

The speed control SET voltage informs the PCM that

a fixed vehicle speed has been selected. The speed

control RESUME voltage indicates the previous fixed

speed is requested. The speed control CANCEL volt-

age tells the PCM to deactivate but retain set speed

in memory (same as depressing the brake pedal). The

speed control COAST voltage informs the PCM to

coast down to a new desired speed. The speed control

OFF voltage tells the PCM that the speed control

system has deactivated. Refer to the Speed Control

section for more speed control information.

SCI RECEIVEÐPCM OUTPUT

OPERATION

SCI Receive is the serial data communication

receive circuit for the DRB scan tool. The Powertrain

Fig. 27 Ignition Coil Pack

PLFUEL SYSTEM 14 - 41

DESCRIPTION AND OPERATION (Continued)

Page 914 of 1285

TRANSAXLE

TABLE OF CONTENTS

page page

NV T350 (A-578) MANUAL TRANSAXLE........ 131TH AUTOMATIC TRANSAXLE.............. 54

NV T350 (A-578) MANUAL TRANSAXLE

TABLE OF CONTENTS

page page

GENERAL INFORMATION

NV T350 (A578) MANUAL TRANSAXLE.........1

TRANSAXLE IDENTIFICATION................2

FLUID REQUIREMENTS....................2

SPECIAL ADDITIVES.......................2

SEALANTS..............................2

GEAR RATIOS............................2

GEARSHIFT PATTERN......................3

DIAGNOSIS AND TESTING

COMMON PROBLEM CAUSES...............3

HARD SHIFTING..........................3

NOISY OPERATION........................3

SLIPS OUT OF GEAR......................3

LOW LUBRICANT LEVEL....................4

FLUID LEAKS............................4

CLUTCH PROBLEMS.......................4

SERVICE PROCEDURES

FLUID DRAIN AND FILL.....................4

REMOVAL AND INSTALLATION

GEARSHIFT KNOB........................4

GEARSHIFT BOOT........................5

GEARSHIFT CABLE ASSEMBLY..............6

GEARSHIFT MECHANISM REPLACEMENT......9

VEHICLE SPEED SENSOR AND DRIVE

PINION...............................11

BACK-UP LAMP SWITCH...................12CROSSOVER LEVER......................12

SELECTOR LEVER.......................12

AXLE SHAFT SEALS......................13

SHIFT SHAFT SEALS......................13

TRANSAXLE............................14

DISASSEMBLY AND ASSEMBLY

TRANSAXLE............................18

INPUT SHAFT...........................31

OUTPUT SHAFT.........................36

DIFFERENTIAL..........................36

SYNCHRONIZER.........................41

SHIFT RAILS OVERHAUL..................42

TRANSAXLE CASE OVERHAUL..............42

CLEANING AND INSPECTION

TRANSAXLE............................48

SYNCHRONIZER.........................48

ADJUSTMENTS

GEARSHIFT CROSSOVER CABLE...........49

BEARING ADJUSTMENT PROCEDURE........50

DIFFERENTIAL BEARING PRELOAD

ADJUSTMENT..........................50

SPECIFICATIONS

NV T350 (A-578) SPECIFICATIONS...........51

SPECIAL TOOLS

NV T350 (A-578) MANUAL TRANSAXLE........52

GENERAL INFORMATION

NV T350 (A578) MANUAL TRANSAXLE

The NV T350 (A-578) transaxle is a fully synchro-

nized (except reverse), constant-mesh transaxle. The

transaxle case is constructed of die-cast aluminum,

and is a two-piece design (bell housing case half and

rear housing case half) with a steel end plate bearing

cover. All forward gears are in constant-mesh witheach other, which eliminates the need to move gears

together for engagement. This feature improves

response and eliminates gear ªclashº noises. The

reverse idler gear is supported and rotates on a spin-

dle idler shaft. Depending on application, a reverse

gear brake/blocking ring is available on some units

for shifting ease.

The NV T350 (A-578) transaxle also incorporates an

open differential, which converts power from the output

shaft pinion gear to the differential ring gear. The dif-

PLTRANSAXLE 21 - 1

Page 967 of 1285

31TH AUTOMATIC TRANSAXLE

TABLE OF CONTENTS

page page

GENERAL INFORMATION

IN VEHICLE SERVICE.....................55

FLUID REQUIREMENTS...................55

DESCRIPTION AND OPERATION

31TH GENERAL INFORMATION..............55

FLUID LEVEL AND CONDITION..............56

TORQUE CONVERTER CLUTCH.............56

HYDRAULIC CONTROL SYSTEM.............56

PRESSURE SUPPLY SYSTEM...............56

PRESSURE REGULATING VALVES...........56

FLOW CONTROL VALVES..................56

CLUTCHES, BAND SERVOS, AND

ACCUMULATOR........................57

BRAKE TRANSMISSION SHIFT INTERLOCK

SYSTEM..............................57

GEARSHIFT AND PARKING LOCK CONTROLS . . 57

COOLER BYPASS VALVE..................57

TORQUE CONVERTER CLUTCH SOLENOID

WIRING CONNECTOR...................58

GOVERNOR.............................58

DIAGNOSIS AND TESTING

TRANSAXLE PRELIMINARY DIAGNOSIS.......58

ROAD TEST.............................65

HYDRAULIC PRESSURE TESTS.............66

CLUTCH AND SERVO AIR PRESSURE TESTS . . 68

FLUID LEAKAGE-TRANSAXLE TORQUE

CONVERTER HOUSING AREA.............70

BRAKE TRANSMISSION SHIFT INTERLOCK....70

SERVICE PROCEDURES

TRANSAXLE FLUID AND FILTER SERVICE.....70

ALUMINUM THREAD REPAIR...............71

FLUSHING COOLERS AND TUBES...........72

OIL PUMP VOLUME CHECK................72

REMOVAL AND INSTALLATION

GEARSHIFT CABLE.......................73

GEARSHIFT MECHANISM..................76

THROTTLE VALVE (KICKDOWN) CABLE.......77

BRAKE TRANSMISSION SHIFT INTERLOCK

CABLE...............................79

INTERLOCK MECHANISM..................82

VEHICLE SPEED SENSOR PINION GEAR......83

PARK/NEUTRAL STARTING AND BACK-UP

LAMP SWITCH.........................84TRANSAXLE AND TORQUE CONVERTER......84

PUMP OIL SEAL.........................88

DISASSEMBLY AND ASSEMBLY

TRANSAXLE............................89

VALVE BODY............................91

OIL PUMP.............................104

FRONT CLUTCH........................105

REAR CLUTCH ASSEMBLY................108

FRONT PLANETARY AND ANNULUS

GEAR-RECONDITION...................110

LOW/REVERSE (REAR) SERVO-

RECONDITION........................112

ACCUMULATOR-RECONDITION............113

KICKDOWN SERVO (CONTROLLED LOAD)-

RECONDITION........................113

TRANSFER SHAFT REPAIR................114

PARKING PAWL.........................121

OUTPUT SHAFT REPAIR..................121

DIFFERENTIAL REPAIR...................129

CLEANING AND INSPECTION

VALVE BODY...........................135

ADJUSTMENTS

GEARSHIFT CABLE......................135

THROTTLE VALVE CABLE ADJUSTMENT

PROCEDURE.........................136

BRAKE TRANSMISSION SHIFT INTERLOCK

SYSTEM.............................137

BAND ADJUSTMENT.....................138

HYDRAULIC CONTROL PRESSURE

ADJUSTMENTS.......................138

BEARING ADJUSTMENT PROCEDURES......138

OUTPUT SHAFT BEARING................139

DIFFERENTIAL BEARING.................139

TRANSFER SHAFT BEARING..............140

SCHEMATICS AND DIAGRAMS

31TH TRANSAXLE HYDRAULIC SCHEMATIC . . 142

SPECIFICATIONS

31TH AUTOMATIC TRANSAXLE.............150

31TH TRANSAXLE TORQUE SPECIFICATIONS . 150

SPECIAL TOOLS

31TH AUTOMATIC TRANSAXLE.............151

21 - 54 TRANSAXLEPL

Page 1097 of 1285

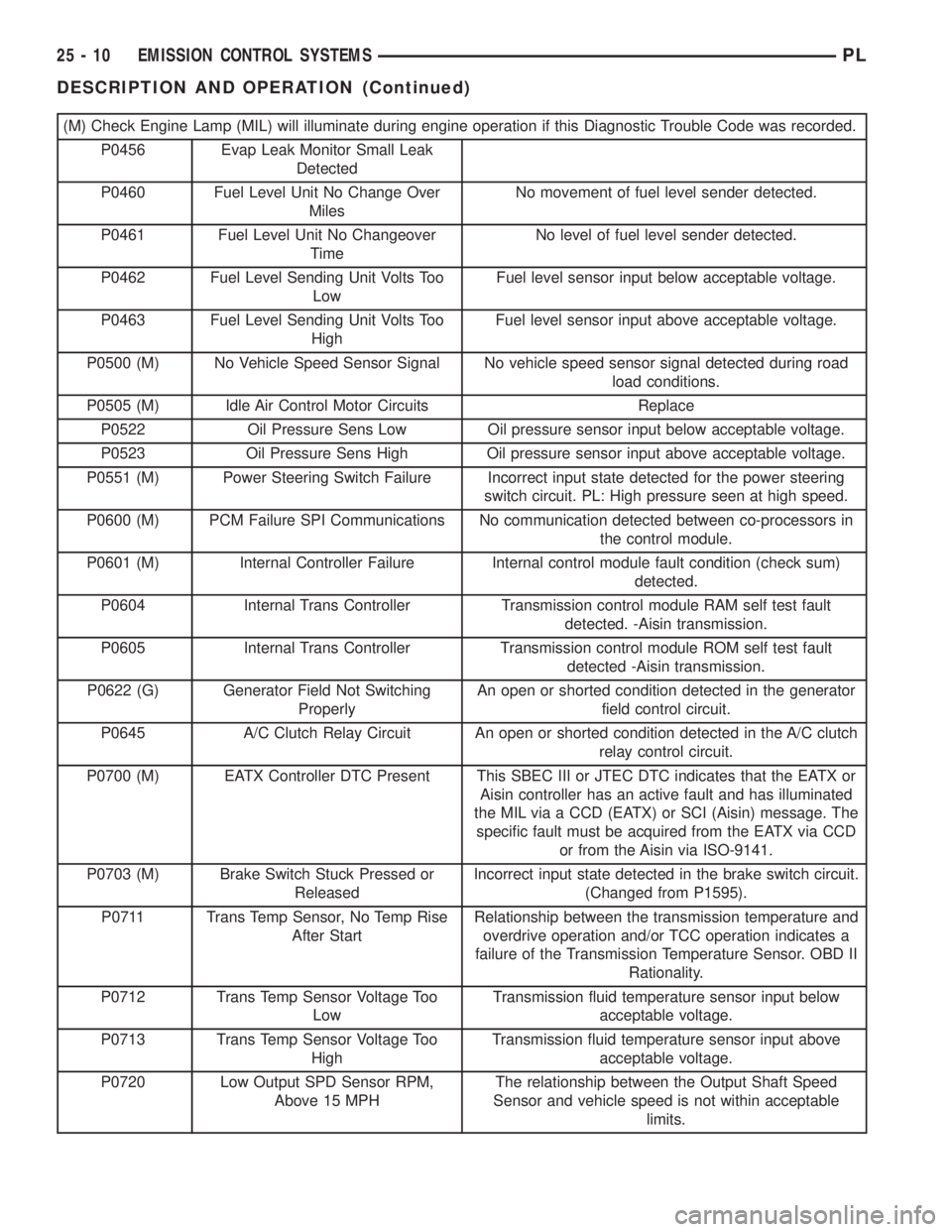

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

P0456 Evap Leak Monitor Small Leak

Detected

P0460 Fuel Level Unit No Change Over

MilesNo movement of fuel level sender detected.

P0461 Fuel Level Unit No Changeover

TimeNo level of fuel level sender detected.

P0462 Fuel Level Sending Unit Volts Too

LowFuel level sensor input below acceptable voltage.

P0463 Fuel Level Sending Unit Volts Too

HighFuel level sensor input above acceptable voltage.

P0500 (M) No Vehicle Speed Sensor Signal No vehicle speed sensor signal detected during road

load conditions.

P0505 (M) Idle Air Control Motor Circuits Replace

P0522 Oil Pressure Sens Low Oil pressure sensor input below acceptable voltage.

P0523 Oil Pressure Sens High Oil pressure sensor input above acceptable voltage.

P0551 (M) Power Steering Switch Failure Incorrect input state detected for the power steering

switch circuit. PL: High pressure seen at high speed.

P0600 (M) PCM Failure SPI Communications No communication detected between co-processors in

the control module.

P0601 (M) Internal Controller Failure Internal control module fault condition (check sum)

detected.

P0604 Internal Trans Controller Transmission control module RAM self test fault

detected. -Aisin transmission.

P0605 Internal Trans Controller Transmission control module ROM self test fault

detected -Aisin transmission.

P0622 (G) Generator Field Not Switching

ProperlyAn open or shorted condition detected in the generator

field control circuit.

P0645 A/C Clutch Relay Circuit An open or shorted condition detected in the A/C clutch

relay control circuit.

P0700 (M) EATX Controller DTC Present This SBEC III or JTEC DTC indicates that the EATX or

Aisin controller has an active fault and has illuminated

the MIL via a CCD (EATX) or SCI (Aisin) message. The

specific fault must be acquired from the EATX via CCD

or from the Aisin via ISO-9141.

P0703 (M) Brake Switch Stuck Pressed or

ReleasedIncorrect input state detected in the brake switch circuit.

(Changed from P1595).

P0711 Trans Temp Sensor, No Temp Rise

After StartRelationship between the transmission temperature and

overdrive operation and/or TCC operation indicates a

failure of the Transmission Temperature Sensor. OBD II

Rationality.

P0712 Trans Temp Sensor Voltage Too

LowTransmission fluid temperature sensor input below

acceptable voltage.

P0713 Trans Temp Sensor Voltage Too

HighTransmission fluid temperature sensor input above

acceptable voltage.

P0720 Low Output SPD Sensor RPM,

Above 15 MPHThe relationship between the Output Shaft Speed

Sensor and vehicle speed is not within acceptable

limits.

25 - 10 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1107 of 1285

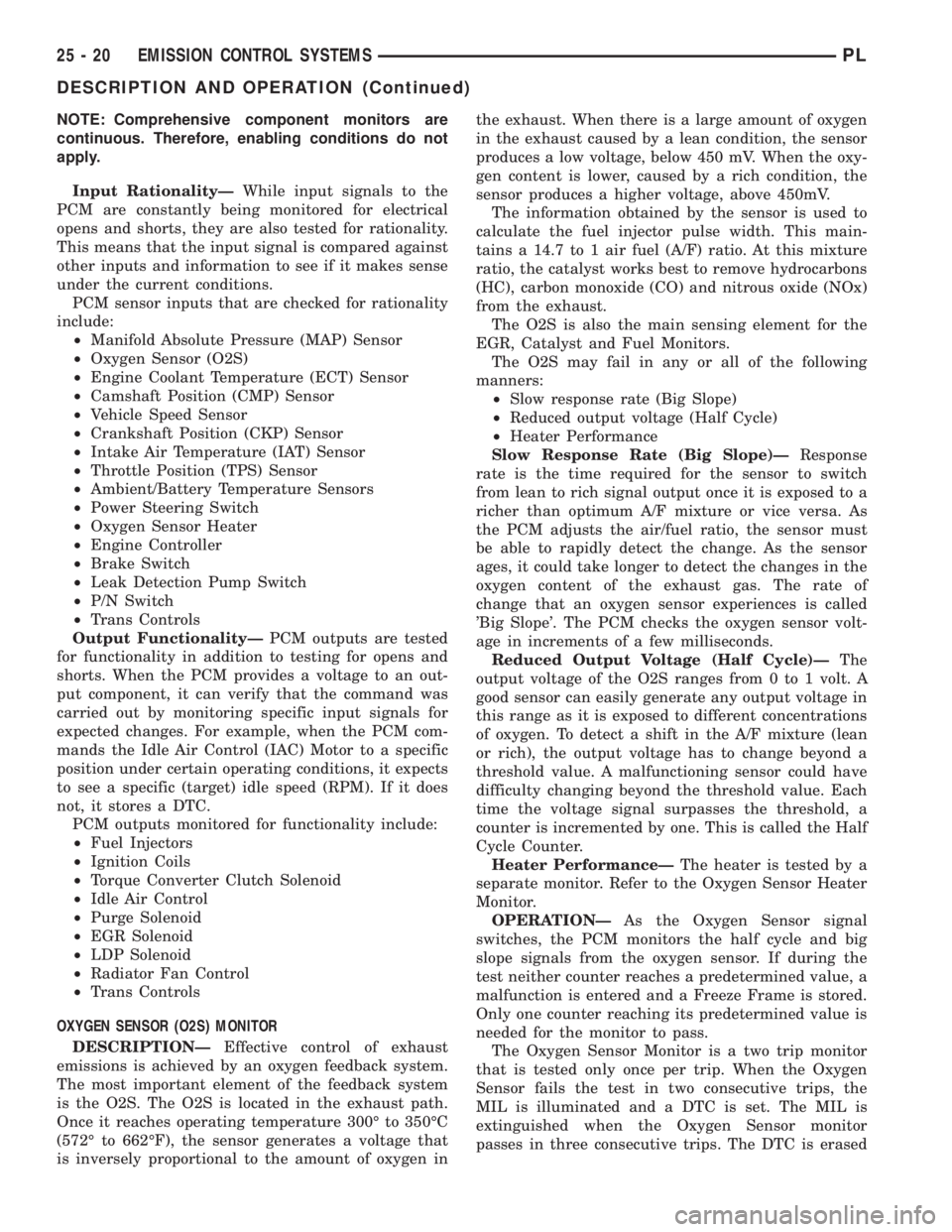

NOTE: Comprehensive component monitors are

continuous. Therefore, enabling conditions do not

apply.

Input RationalityÐWhile input signals to the

PCM are constantly being monitored for electrical

opens and shorts, they are also tested for rationality.

This means that the input signal is compared against

other inputs and information to see if it makes sense

under the current conditions.

PCM sensor inputs that are checked for rationality

include:

²Manifold Absolute Pressure (MAP) Sensor

²Oxygen Sensor (O2S)

²Engine Coolant Temperature (ECT) Sensor

²Camshaft Position (CMP) Sensor

²Vehicle Speed Sensor

²Crankshaft Position (CKP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Ambient/Battery Temperature Sensors

²Power Steering Switch

²Oxygen Sensor Heater

²Engine Controller

²Brake Switch

²Leak Detection Pump Switch

²P/N Switch

²Trans Controls

Output FunctionalityÐPCM outputs are tested

for functionality in addition to testing for opens and

shorts. When the PCM provides a voltage to an out-

put component, it can verify that the command was

carried out by monitoring specific input signals for

expected changes. For example, when the PCM com-

mands the Idle Air Control (IAC) Motor to a specific

position under certain operating conditions, it expects

to see a specific (target) idle speed (RPM). If it does

not, it stores a DTC.

PCM outputs monitored for functionality include:

²Fuel Injectors

²Ignition Coils

²Torque Converter Clutch Solenoid

²Idle Air Control

²Purge Solenoid

²EGR Solenoid

²LDP Solenoid

²Radiator Fan Control

²Trans Controls

OXYGEN SENSOR (O2S) MONITOR

DESCRIPTIONÐEffective control of exhaust

emissions is achieved by an oxygen feedback system.

The most important element of the feedback system

is the O2S. The O2S is located in the exhaust path.

Once it reaches operating temperature 300É to 350ÉC

(572É to 662ÉF), the sensor generates a voltage that

is inversely proportional to the amount of oxygen inthe exhaust. When there is a large amount of oxygen

in the exhaust caused by a lean condition, the sensor

produces a low voltage, below 450 mV. When the oxy-

gen content is lower, caused by a rich condition, the

sensor produces a higher voltage, above 450mV.

The information obtained by the sensor is used to

calculate the fuel injector pulse width. This main-

tains a 14.7 to 1 air fuel (A/F) ratio. At this mixture

ratio, the catalyst works best to remove hydrocarbons

(HC), carbon monoxide (CO) and nitrous oxide (NOx)

from the exhaust.

The O2S is also the main sensing element for the

EGR, Catalyst and Fuel Monitors.

The O2S may fail in any or all of the following

manners:

²Slow response rate (Big Slope)

²Reduced output voltage (Half Cycle)

²Heater Performance

Slow Response Rate (Big Slope)ÐResponse

rate is the time required for the sensor to switch

from lean to rich signal output once it is exposed to a

richer than optimum A/F mixture or vice versa. As

the PCM adjusts the air/fuel ratio, the sensor must

be able to rapidly detect the change. As the sensor

ages, it could take longer to detect the changes in the

oxygen content of the exhaust gas. The rate of

change that an oxygen sensor experiences is called

'Big Slope'. The PCM checks the oxygen sensor volt-

age in increments of a few milliseconds.

Reduced Output Voltage (Half Cycle)ÐThe

output voltage of the O2S ranges from 0 to 1 volt. A

good sensor can easily generate any output voltage in

this range as it is exposed to different concentrations

of oxygen. To detect a shift in the A/F mixture (lean

or rich), the output voltage has to change beyond a

threshold value. A malfunctioning sensor could have

difficulty changing beyond the threshold value. Each

time the voltage signal surpasses the threshold, a

counter is incremented by one. This is called the Half

Cycle Counter.

Heater PerformanceÐThe heater is tested by a

separate monitor. Refer to the Oxygen Sensor Heater

Monitor.

OPERATIONÐAs the Oxygen Sensor signal

switches, the PCM monitors the half cycle and big

slope signals from the oxygen sensor. If during the

test neither counter reaches a predetermined value, a

malfunction is entered and a Freeze Frame is stored.

Only one counter reaching its predetermined value is

needed for the monitor to pass.

The Oxygen Sensor Monitor is a two trip monitor

that is tested only once per trip. When the Oxygen

Sensor fails the test in two consecutive trips, the

MIL is illuminated and a DTC is set. The MIL is

extinguished when the Oxygen Sensor monitor

passes in three consecutive trips. The DTC is erased

25 - 20 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1110 of 1285

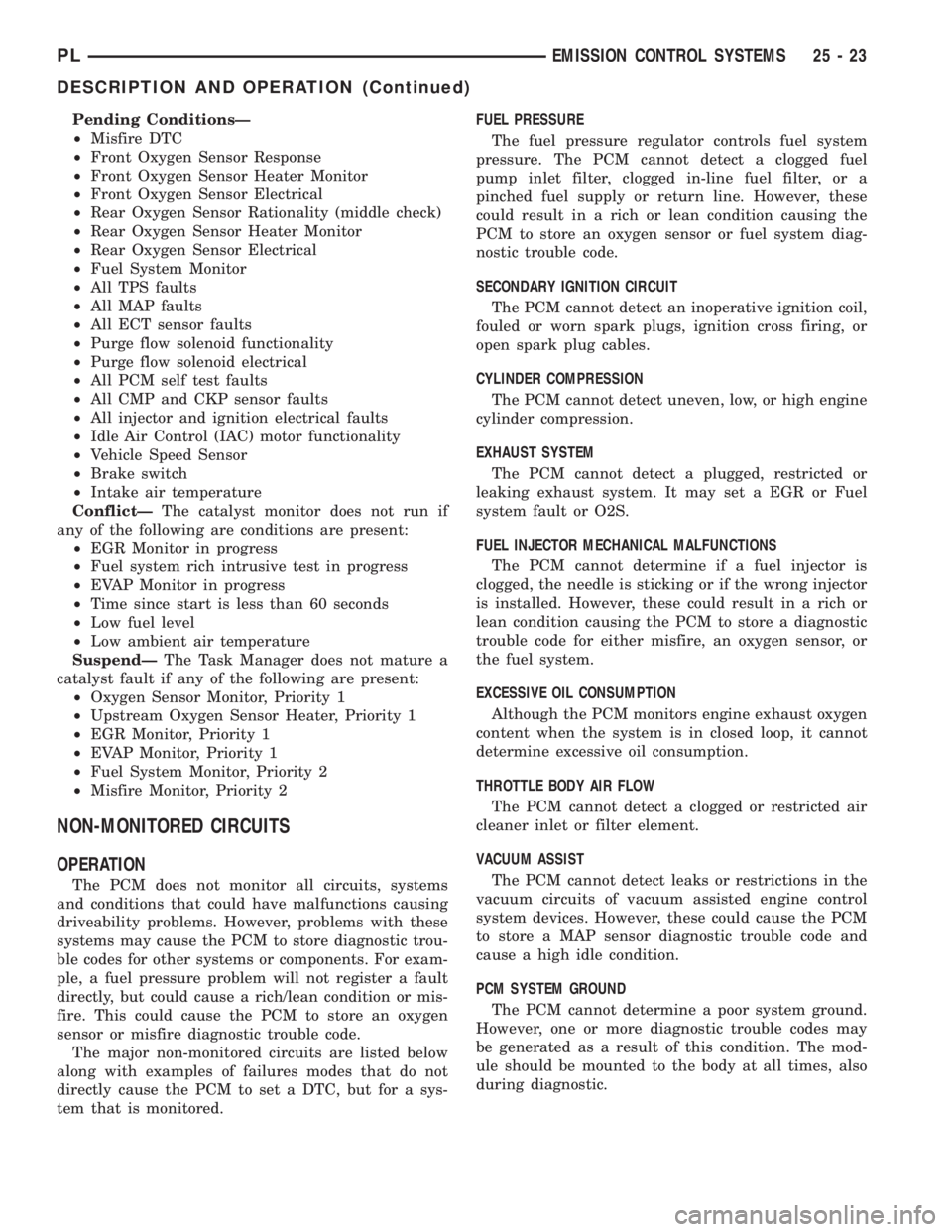

Pending ConditionsÐ

²Misfire DTC

²Front Oxygen Sensor Response

²Front Oxygen Sensor Heater Monitor

²Front Oxygen Sensor Electrical

²Rear Oxygen Sensor Rationality (middle check)

²Rear Oxygen Sensor Heater Monitor

²Rear Oxygen Sensor Electrical

²Fuel System Monitor

²All TPS faults

²All MAP faults

²All ECT sensor faults

²Purge flow solenoid functionality

²Purge flow solenoid electrical

²All PCM self test faults

²All CMP and CKP sensor faults

²All injector and ignition electrical faults

²Idle Air Control (IAC) motor functionality

²Vehicle Speed Sensor

²Brake switch

²Intake air temperature

ConflictÐThe catalyst monitor does not run if

any of the following are conditions are present:

²EGR Monitor in progress

²Fuel system rich intrusive test in progress

²EVAP Monitor in progress

²Time since start is less than 60 seconds

²Low fuel level

²Low ambient air temperature

SuspendÐThe Task Manager does not mature a

catalyst fault if any of the following are present:

²Oxygen Sensor Monitor, Priority 1

²Upstream Oxygen Sensor Heater, Priority 1

²EGR Monitor, Priority 1

²EVAP Monitor, Priority 1

²Fuel System Monitor, Priority 2

²Misfire Monitor, Priority 2

NON-MONITORED CIRCUITS

OPERATION

The PCM does not monitor all circuits, systems

and conditions that could have malfunctions causing

driveability problems. However, problems with these

systems may cause the PCM to store diagnostic trou-

ble codes for other systems or components. For exam-

ple, a fuel pressure problem will not register a fault

directly, but could cause a rich/lean condition or mis-

fire. This could cause the PCM to store an oxygen

sensor or misfire diagnostic trouble code.

The major non-monitored circuits are listed below

along with examples of failures modes that do not

directly cause the PCM to set a DTC, but for a sys-

tem that is monitored.FUEL PRESSURE

The fuel pressure regulator controls fuel system

pressure. The PCM cannot detect a clogged fuel

pump inlet filter, clogged in-line fuel filter, or a

pinched fuel supply or return line. However, these

could result in a rich or lean condition causing the

PCM to store an oxygen sensor or fuel system diag-

nostic trouble code.

SECONDARY IGNITION CIRCUIT

The PCM cannot detect an inoperative ignition coil,

fouled or worn spark plugs, ignition cross firing, or

open spark plug cables.

CYLINDER COMPRESSION

The PCM cannot detect uneven, low, or high engine

cylinder compression.

EXHAUST SYSTEM

The PCM cannot detect a plugged, restricted or

leaking exhaust system. It may set a EGR or Fuel

system fault or O2S.

FUEL INJECTOR MECHANICAL MALFUNCTIONS

The PCM cannot determine if a fuel injector is

clogged, the needle is sticking or if the wrong injector

is installed. However, these could result in a rich or

lean condition causing the PCM to store a diagnostic

trouble code for either misfire, an oxygen sensor, or

the fuel system.

EXCESSIVE OIL CONSUMPTION

Although the PCM monitors engine exhaust oxygen

content when the system is in closed loop, it cannot

determine excessive oil consumption.

THROTTLE BODY AIR FLOW

The PCM cannot detect a clogged or restricted air

cleaner inlet or filter element.

VACUUM ASSIST

The PCM cannot detect leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices. However, these could cause the PCM

to store a MAP sensor diagnostic trouble code and

cause a high idle condition.

PCM SYSTEM GROUND

The PCM cannot determine a poor system ground.

However, one or more diagnostic trouble codes may

be generated as a result of this condition. The mod-

ule should be mounted to the body at all times, also

during diagnostic.

PLEMISSION CONTROL SYSTEMS 25 - 23

DESCRIPTION AND OPERATION (Continued)