wheel torque DODGE NEON 2000 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 736 of 1285

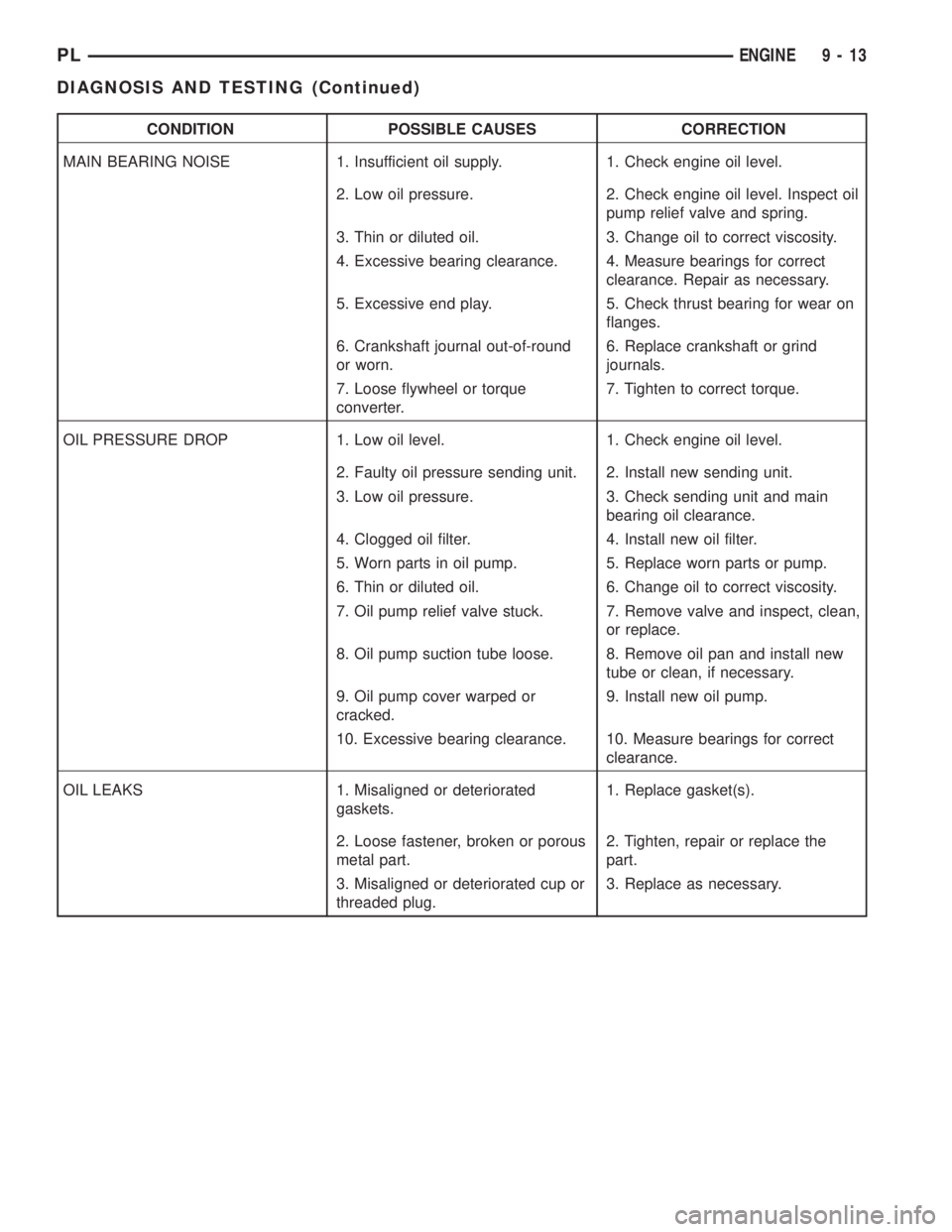

CONDITION POSSIBLE CAUSES CORRECTION

MAIN BEARING NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Excessive bearing clearance. 4. Measure bearings for correct

clearance. Repair as necessary.

5. Excessive end play. 5. Check thrust bearing for wear on

flanges.

6. Crankshaft journal out-of-round

or worn.6. Replace crankshaft or grind

journals.

7. Loose flywheel or torque

converter.7. Tighten to correct torque.

OIL PRESSURE DROP 1. Low oil level. 1. Check engine oil level.

2. Faulty oil pressure sending unit. 2. Install new sending unit.

3. Low oil pressure. 3. Check sending unit and main

bearing oil clearance.

4. Clogged oil filter. 4. Install new oil filter.

5. Worn parts in oil pump. 5. Replace worn parts or pump.

6. Thin or diluted oil. 6. Change oil to correct viscosity.

7. Oil pump relief valve stuck. 7. Remove valve and inspect, clean,

or replace.

8. Oil pump suction tube loose. 8. Remove oil pan and install new

tube or clean, if necessary.

9. Oil pump cover warped or

cracked.9. Install new oil pump.

10. Excessive bearing clearance. 10. Measure bearings for correct

clearance.

OIL LEAKS 1. Misaligned or deteriorated

gaskets.1. Replace gasket(s).

2. Loose fastener, broken or porous

metal part.2. Tighten, repair or replace the

part.

3. Misaligned or deteriorated cup or

threaded plug.3. Replace as necessary.

PLENGINE 9 - 13

DIAGNOSIS AND TESTING (Continued)

Page 739 of 1285

CRANKSHAFT

A nodular cast iron crankshaft is used. The engine

has five main bearings. The number three main is

flanged to control thrust. The mains and connecting

rod journals have undercut fillet radiuses that are

deep rolled for added strength. To optimize bearing

loading, eight counterweights are used. Hydrody-

namic seals provide end sealing, where the crank-

shaft exits the block. Anaerobic gasket material is

used for parting line sealing. A sintered iron timing

belt sprocket is mounted on the crankshaft nose. This

sprocket transmits crankshaft movement, via timing

belt to the camshaft sprocket providing timed valve

actuation.

PISTONS

The engineDOES NOThave provision for a free

wheeling valve train. Non free wheeling valve train

means, in the event of a broken timing belt pistons

will contact the valves. The engine uses pressed-in

piston pins to attach forged powdered metal connect-

ing rods. The connecting rods are a cracked cap

design and are not repairable. Hex head cap screw

are used to provide alignment and durability in the

assembly. Pistons and connecting rods are serviced as

an assembly.

PISTON RINGS

The piston rings include a molybdenum faced top

ring for reliable compression sealing and a taper

faced intermediate ring for additional cylinder pres-

sure control. Oil Control Ring Package consist of two

steel rails and an expander spacer.

CYLINDER HEAD

The aluminum cylinder head features a Single

Over Head Camshaft (SOHC), four-valves per cylin-

der, cross flow design. The valves are arranged in

two inline banks, with the two intake per cylinder

facing toward the radiator. The exhaust valves facing

toward the dash panel. Rocker arm shafts mount

directly to the cylinder head. It incorporates powder

metal valve guides and seats. The hollow rocker arm

shafts supplies oil to the hydraulic lash adjusters,

camshaft and valve mechanisms.

CAMSHAFT

The nodular iron camshaft has five bearing jour-

nals and three cam lobes per cylinder. Provision for a

cam position sensor is provided on the camshaft at

the rear of cylinder head which also acts as thrust

plate. A hydrodynamic oil seal is used for oil control

at the front of the camshaft.

VALVES

Four valves per cylinder are actuated by roller

rocker arms/hydraulic lash adjusters assemblies

which pivot on rocker arm shafts. All valves have

chrome plated valve stems. Viton rubber valve stem

seals are integral with spring seats. Valve springs,

spring retainers, and locks are conventional design.

INTAKE MANIFOLD

The intake manifold is a molded plastic composi-

tion, attached to the cylinder head with five fasten-

ers. This long branch design enhances low and mid-

range torque.

EXHAUST MANIFOLD

The exhaust manifold is made of nodular cast iron

for strength and high temperatures. Exhaust gasses

exit the manifold into an articulated joint connection

and exhaust pipe.

COMPONENT REPLACEMENT

If any of the following parts have been changed or

replaced:

²Camshaft

²Camshaft Position Sensor

²Camshaft Position Sensor Target Magnet

²Cylinder Block

²Cylinder Head

²Water Pump

²Powertrain Control Module (PCM)

²Timing Belt and Timing Belt Tensioner

The camshaft and crankshaft timing relearn proce-

dure must be performed. Refer to the component

Removal and Installation procedure in this section.

9 - 16 2.0L SOHC ENGINEPL

DESCRIPTION AND OPERATION (Continued)

Page 744 of 1285

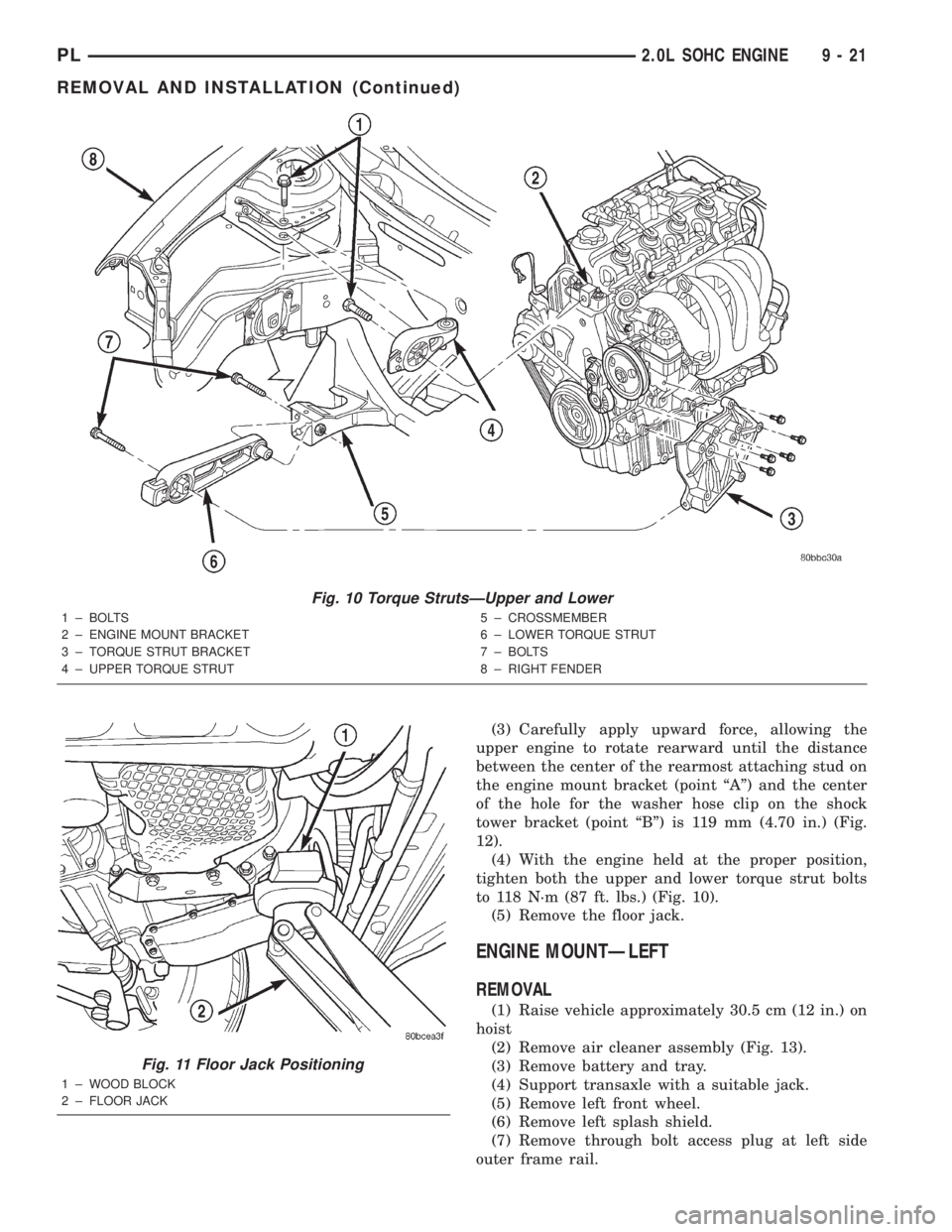

(3) Carefully apply upward force, allowing the

upper engine to rotate rearward until the distance

between the center of the rearmost attaching stud on

the engine mount bracket (point ªAº) and the center

of the hole for the washer hose clip on the shock

tower bracket (point ªBº) is 119 mm (4.70 in.) (Fig.

12).

(4) With the engine held at the proper position,

tighten both the upper and lower torque strut bolts

to 118 N´m (87 ft. lbs.) (Fig. 10).

(5) Remove the floor jack.

ENGINE MOUNTÐLEFT

REMOVAL

(1) Raise vehicle approximately 30.5 cm (12 in.) on

hoist

(2) Remove air cleaner assembly (Fig. 13).

(3) Remove battery and tray.

(4) Support transaxle with a suitable jack.

(5) Remove left front wheel.

(6) Remove left splash shield.

(7) Remove through bolt access plug at left side

outer frame rail.

Fig. 10 Torque StrutsÐUpper and Lower

1 ± BOLTS

2 ± ENGINE MOUNT BRACKET

3 ± TORQUE STRUT BRACKET

4 ± UPPER TORQUE STRUT5 ± CROSSMEMBER

6 ± LOWER TORQUE STRUT

7 ± BOLTS

8 ± RIGHT FENDER

Fig. 11 Floor Jack Positioning

1 ± WOOD BLOCK

2 ± FLOOR JACK

PL2.0L SOHC ENGINE 9 - 21

REMOVAL AND INSTALLATION (Continued)

Page 749 of 1285

(4) Discharge air conditioning system, if equipped.

Refer to Group 24, Heating and Air Conditioning for

procedure.

(5) Disconnect the following: air intake duct at

intake manifold, throttle cables, electrical connectors

from throttle body and air cleaner housing.

(6) Remove air cleaner housing assembly.

(7) Remove upper radiator hose and fan module.

Refer to Group 7, Cooling System for procedure.

(8) Remove lower radiator hose.

(9) Disconnect automatic transmission cooler lines

and plug, if equipped.

(10) Disconnect shift linkage, electrical connectors,

and clutch cable, if equipped with manual transaxle.

(11) Disconnect engine wiring harness.

(12) Disconnect positive cable from Power Distri-

bution Center (PDC) and ground wire from vehicle

body.

(13) Disconnect ground wire from the vehicle body-

to-engine at the right side strut tower.

(14) Disconnect heater hoses.

(15) Disconnect vacuum hose from brake booster.

(16) Disconnect coolant reserve/recovery hose.

(17) Remove accessory drive belts. Refer to Group

7, Cooling System for procedure.

(18) Remove power steering pump and reservoir

and set them aside.

(19) Hoist vehicle and remove right inner splash

shield.

(20) Drain engine oil.

(21) Remove front wheels.

(22) Remove axle shafts. Refer to Group 3, Differ-

ential and Driveline for procedure.

(23) Disconnect exhaust system from manifold.

(24) Disconnect the downstream oxygen sensor

connector.

(25) Remove lower engine torque strut.

(26) Remove structural collar. Refer to procedure

in this section.

(27) Lower vehicle and remove A/C compressor.

(28) Raise vehicle enough to allow engine dolly

and cradle, Special Tools 6135 and 6710 to be

installed under vehicle.

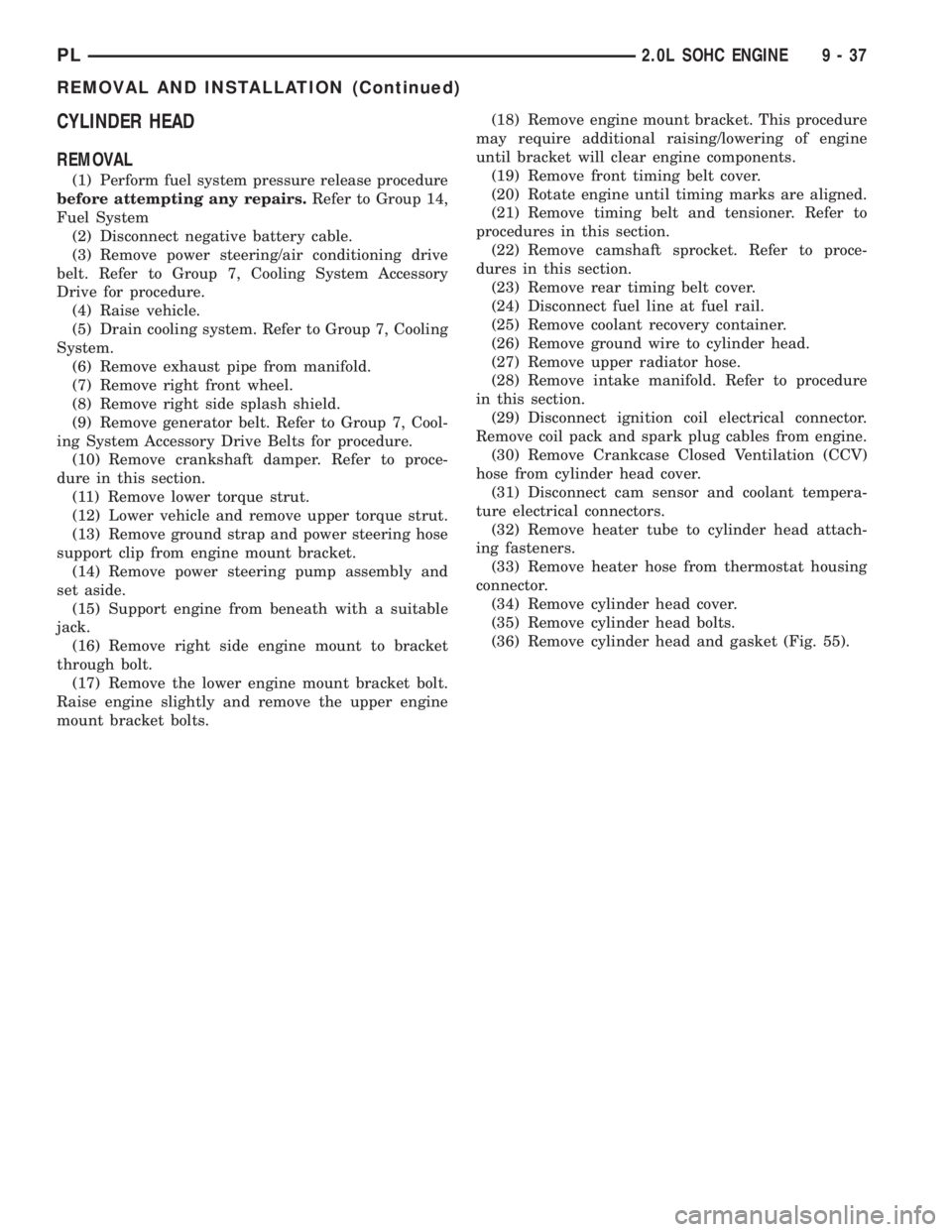

(29) Loosen engine support posts to allow move-

ment for positioning onto engine locating holes and

flange on the engine bedplate. Lower vehicle and

position cradle until the engine is resting on support

posts (Fig. 26). Tighten mounts to cradle frame. This

will keep support posts from moving when removing

or installing engine and transmission.

(30) Install safety straps around the engine to cra-

dle (Fig. 26). Tighten straps and lock them into posi-

tion.

WARNING: Safety straps MUST be used.(31) Raise vehicle enough to see if straps are tight

enough to hold cradle assembly to engine.

(32) Lower vehicle so weight of the engine and

transmission ONLY is on the cradle assembly.

(33) Remove the upper engine torque strut.

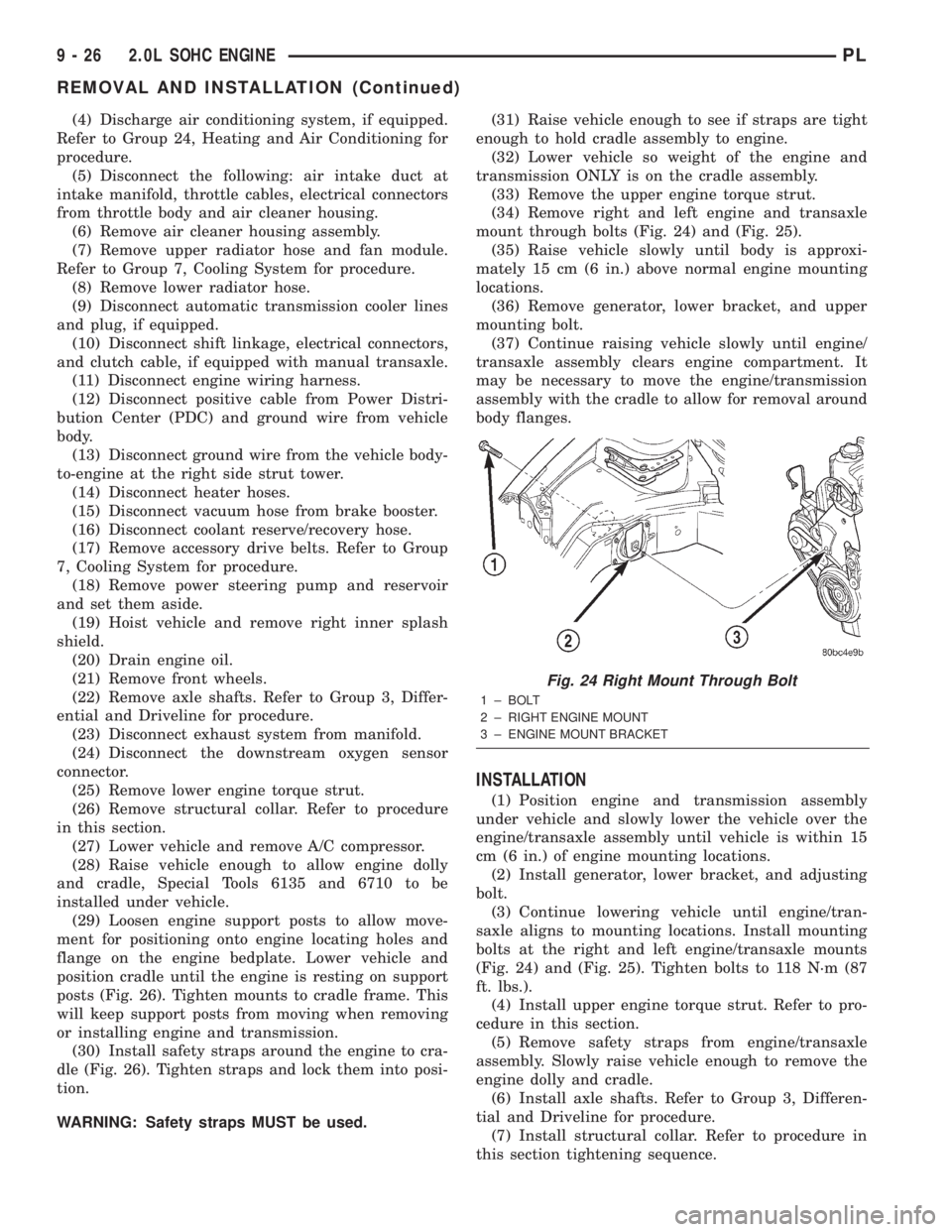

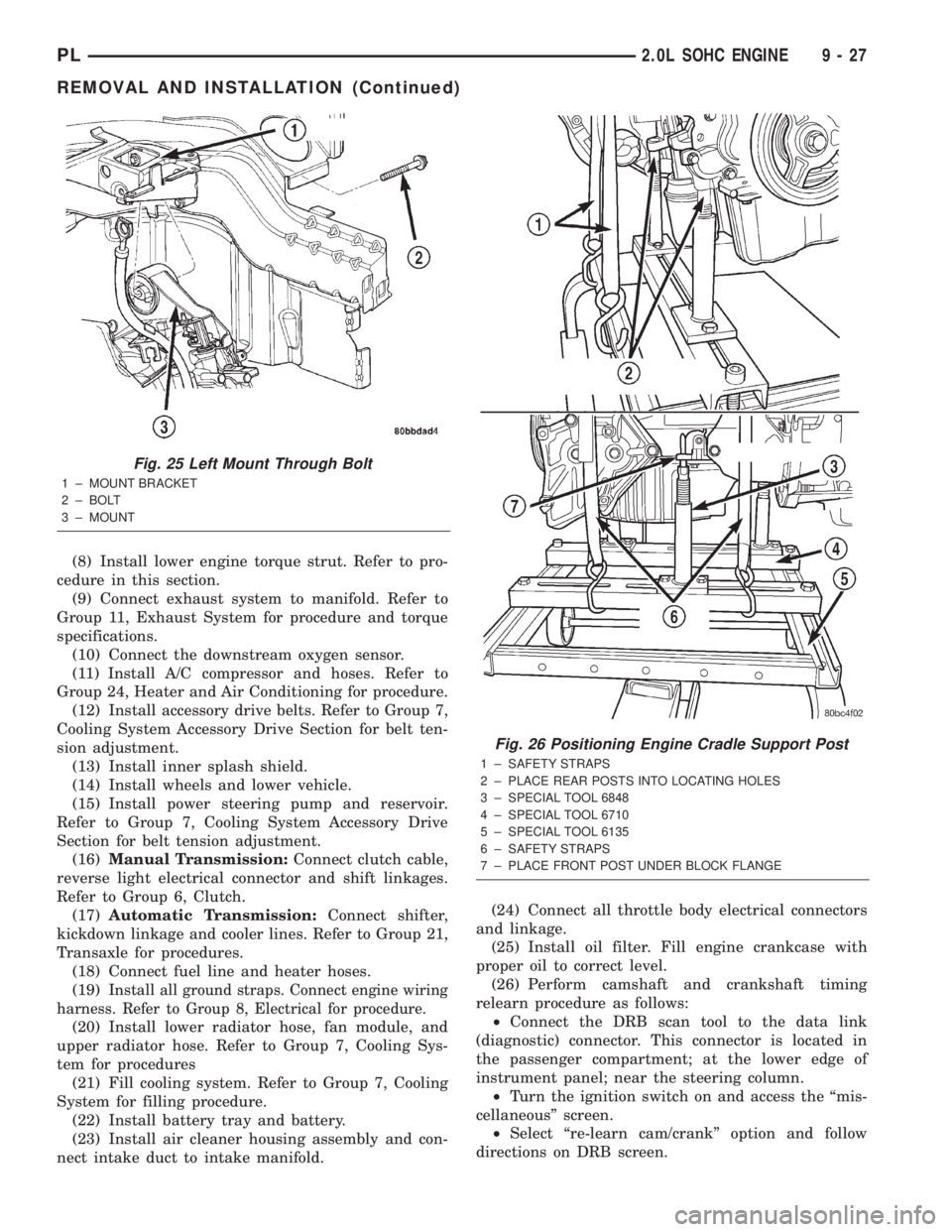

(34) Remove right and left engine and transaxle

mount through bolts (Fig. 24) and (Fig. 25).

(35) Raise vehicle slowly until body is approxi-

mately 15 cm (6 in.) above normal engine mounting

locations.

(36) Remove generator, lower bracket, and upper

mounting bolt.

(37) Continue raising vehicle slowly until engine/

transaxle assembly clears engine compartment. It

may be necessary to move the engine/transmission

assembly with the cradle to allow for removal around

body flanges.

INSTALLATION

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine/transaxle assembly until vehicle is within 15

cm (6 in.) of engine mounting locations.

(2) Install generator, lower bracket, and adjusting

bolt.

(3) Continue lowering vehicle until engine/tran-

saxle aligns to mounting locations. Install mounting

bolts at the right and left engine/transaxle mounts

(Fig. 24) and (Fig. 25). Tighten bolts to 118 N´m (87

ft. lbs.).

(4) Install upper engine torque strut. Refer to pro-

cedure in this section.

(5) Remove safety straps from engine/transaxle

assembly. Slowly raise vehicle enough to remove the

engine dolly and cradle.

(6) Install axle shafts. Refer to Group 3, Differen-

tial and Driveline for procedure.

(7) Install structural collar. Refer to procedure in

this section tightening sequence.

Fig. 24 Right Mount Through Bolt

1 ± BOLT

2 ± RIGHT ENGINE MOUNT

3 ± ENGINE MOUNT BRACKET

9 - 26 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 750 of 1285

(8) Install lower engine torque strut. Refer to pro-

cedure in this section.

(9) Connect exhaust system to manifold. Refer to

Group 11, Exhaust System for procedure and torque

specifications.

(10) Connect the downstream oxygen sensor.

(11) Install A/C compressor and hoses. Refer to

Group 24, Heater and Air Conditioning for procedure.

(12) Install accessory drive belts. Refer to Group 7,

Cooling System Accessory Drive Section for belt ten-

sion adjustment.

(13) Install inner splash shield.

(14) Install wheels and lower vehicle.

(15) Install power steering pump and reservoir.

Refer to Group 7, Cooling System Accessory Drive

Section for belt tension adjustment.

(16)Manual Transmission:Connect clutch cable,

reverse light electrical connector and shift linkages.

Refer to Group 6, Clutch.

(17)Automatic Transmission:Connect shifter,

kickdown linkage and cooler lines. Refer to Group 21,

Transaxle for procedures.

(18) Connect fuel line and heater hoses.

(19)

Install all ground straps. Connect engine wiring

harness. Refer to Group 8, Electrical for procedure.

(20) Install lower radiator hose, fan module, and

upper radiator hose. Refer to Group 7, Cooling Sys-

tem for procedures

(21) Fill cooling system. Refer to Group 7, Cooling

System for filling procedure.

(22) Install battery tray and battery.

(23) Install air cleaner housing assembly and con-

nect intake duct to intake manifold.(24) Connect all throttle body electrical connectors

and linkage.

(25) Install oil filter. Fill engine crankcase with

proper oil to correct level.

(26) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

Fig. 25 Left Mount Through Bolt

1 ± MOUNT BRACKET

2 ± BOLT

3 ± MOUNT

Fig. 26 Positioning Engine Cradle Support Post

1 ± SAFETY STRAPS

2 ± PLACE REAR POSTS INTO LOCATING HOLES

3 ± SPECIAL TOOL 6848

4 ± SPECIAL TOOL 6710

5 ± SPECIAL TOOL 6135

6 ± SAFETY STRAPS

7 ± PLACE FRONT POST UNDER BLOCK FLANGE

PL2.0L SOHC ENGINE 9 - 27

REMOVAL AND INSTALLATION (Continued)

Page 760 of 1285

CYLINDER HEAD

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs.Refer to Group 14,

Fuel System

(2) Disconnect negative battery cable.

(3) Remove power steering/air conditioning drive

belt. Refer to Group 7, Cooling System Accessory

Drive for procedure.

(4) Raise vehicle.

(5) Drain cooling system. Refer to Group 7, Cooling

System.

(6) Remove exhaust pipe from manifold.

(7) Remove right front wheel.

(8) Remove right side splash shield.

(9) Remove generator belt. Refer to Group 7, Cool-

ing System Accessory Drive Belts for procedure.

(10) Remove crankshaft damper. Refer to proce-

dure in this section.

(11) Remove lower torque strut.

(12) Lower vehicle and remove upper torque strut.

(13) Remove ground strap and power steering hose

support clip from engine mount bracket.

(14) Remove power steering pump assembly and

set aside.

(15) Support engine from beneath with a suitable

jack.

(16) Remove right side engine mount to bracket

through bolt.

(17) Remove the lower engine mount bracket bolt.

Raise engine slightly and remove the upper engine

mount bracket bolts.(18) Remove engine mount bracket. This procedure

may require additional raising/lowering of engine

until bracket will clear engine components.

(19) Remove front timing belt cover.

(20) Rotate engine until timing marks are aligned.

(21) Remove timing belt and tensioner. Refer to

procedures in this section.

(22) Remove camshaft sprocket. Refer to proce-

dures in this section.

(23) Remove rear timing belt cover.

(24) Disconnect fuel line at fuel rail.

(25) Remove coolant recovery container.

(26) Remove ground wire to cylinder head.

(27) Remove upper radiator hose.

(28) Remove intake manifold. Refer to procedure

in this section.

(29) Disconnect ignition coil electrical connector.

Remove coil pack and spark plug cables from engine.

(30) Remove Crankcase Closed Ventilation (CCV)

hose from cylinder head cover.

(31) Disconnect cam sensor and coolant tempera-

ture electrical connectors.

(32) Remove heater tube to cylinder head attach-

ing fasteners.

(33) Remove heater hose from thermostat housing

connector.

(34) Remove cylinder head cover.

(35) Remove cylinder head bolts.

(36) Remove cylinder head and gasket (Fig. 55).

PL2.0L SOHC ENGINE 9 - 37

REMOVAL AND INSTALLATION (Continued)

Page 763 of 1285

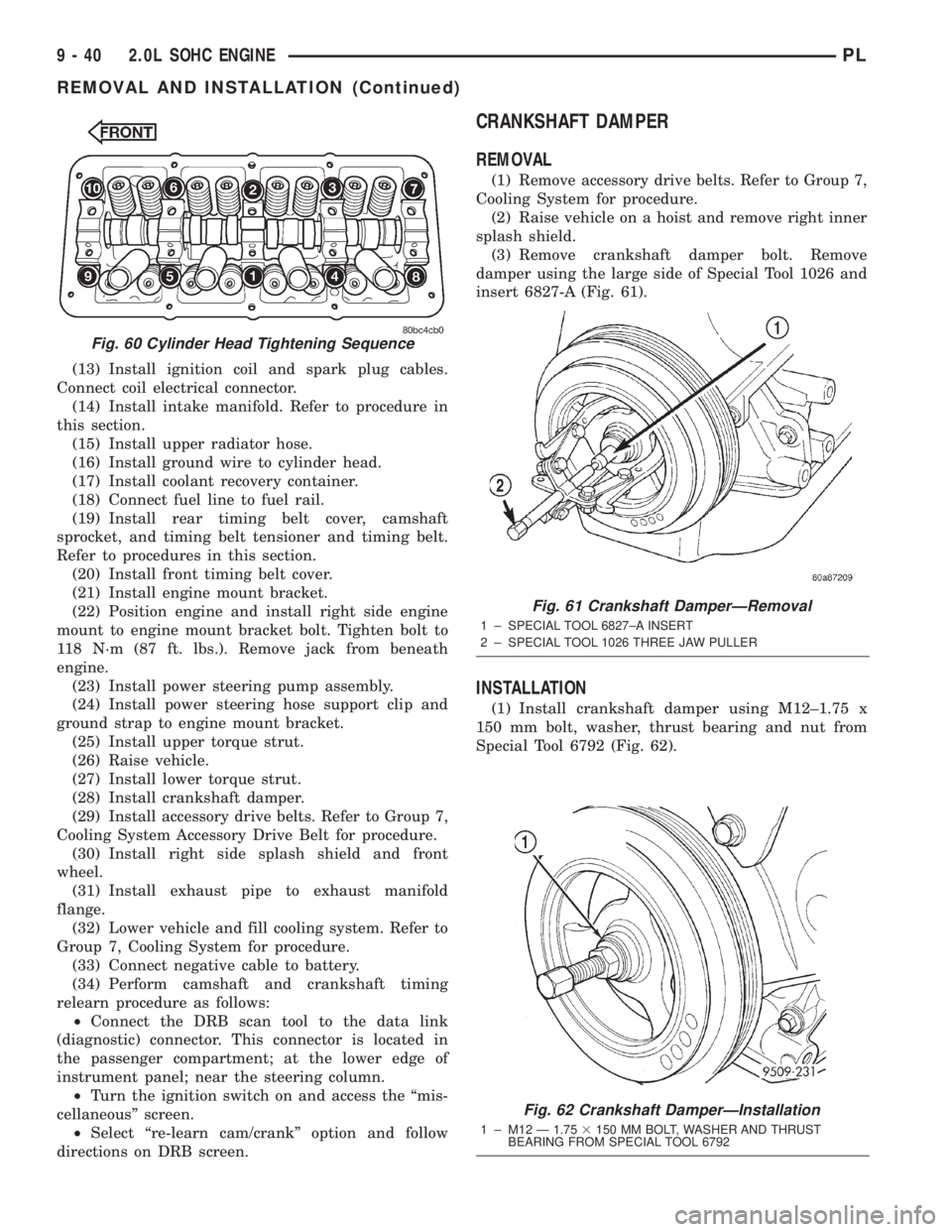

(13) Install ignition coil and spark plug cables.

Connect coil electrical connector.

(14) Install intake manifold. Refer to procedure in

this section.

(15) Install upper radiator hose.

(16) Install ground wire to cylinder head.

(17) Install coolant recovery container.

(18) Connect fuel line to fuel rail.

(19) Install rear timing belt cover, camshaft

sprocket, and timing belt tensioner and timing belt.

Refer to procedures in this section.

(20) Install front timing belt cover.

(21) Install engine mount bracket.

(22) Position engine and install right side engine

mount to engine mount bracket bolt. Tighten bolt to

118 N´m (87 ft. lbs.). Remove jack from beneath

engine.

(23) Install power steering pump assembly.

(24) Install power steering hose support clip and

ground strap to engine mount bracket.

(25) Install upper torque strut.

(26) Raise vehicle.

(27) Install lower torque strut.

(28) Install crankshaft damper.

(29) Install accessory drive belts. Refer to Group 7,

Cooling System Accessory Drive Belt for procedure.

(30) Install right side splash shield and front

wheel.

(31) Install exhaust pipe to exhaust manifold

flange.

(32) Lower vehicle and fill cooling system. Refer to

Group 7, Cooling System for procedure.

(33) Connect negative cable to battery.

(34) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

CRANKSHAFT DAMPER

REMOVAL

(1) Remove accessory drive belts. Refer to Group 7,

Cooling System for procedure.

(2) Raise vehicle on a hoist and remove right inner

splash shield.

(3) Remove crankshaft damper bolt. Remove

damper using the large side of Special Tool 1026 and

insert 6827-A (Fig. 61).

INSTALLATION

(1) Install crankshaft damper using M12±1.75 x

150 mm bolt, washer, thrust bearing and nut from

Special Tool 6792 (Fig. 62).

Fig. 62 Crankshaft DamperÐInstallation

1 ± M12 Ð 1.753150 MM BOLT, WASHER AND THRUST

BEARING FROM SPECIAL TOOL 6792

Fig. 60 Cylinder Head Tightening Sequence

Fig. 61 Crankshaft DamperÐRemoval

1 ± SPECIAL TOOL 6827±A INSERT

2 ± SPECIAL TOOL 1026 THREE JAW PULLER

9 - 40 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 775 of 1285

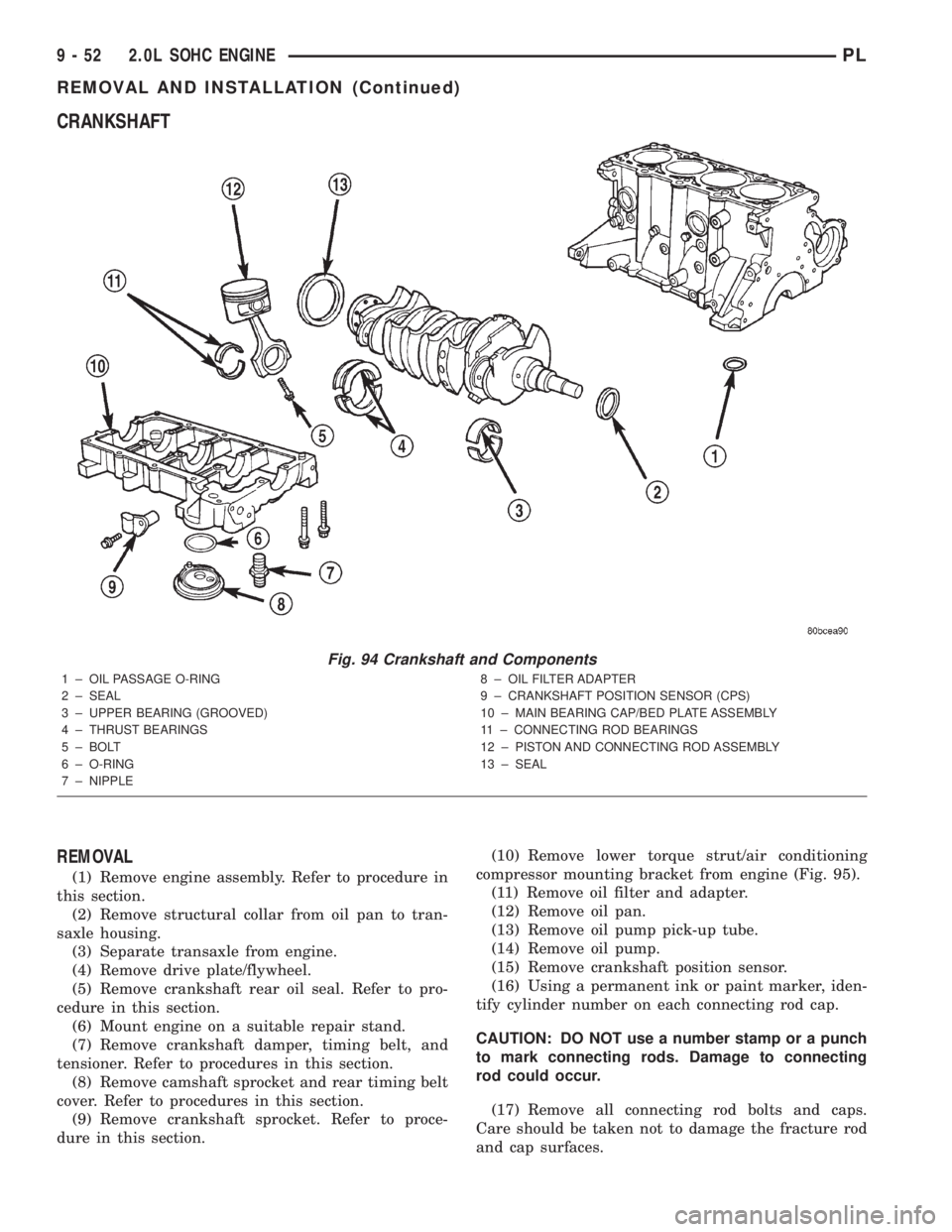

CRANKSHAFT

REMOVAL

(1) Remove engine assembly. Refer to procedure in

this section.

(2) Remove structural collar from oil pan to tran-

saxle housing.

(3) Separate transaxle from engine.

(4) Remove drive plate/flywheel.

(5) Remove crankshaft rear oil seal. Refer to pro-

cedure in this section.

(6) Mount engine on a suitable repair stand.

(7) Remove crankshaft damper, timing belt, and

tensioner. Refer to procedures in this section.

(8) Remove camshaft sprocket and rear timing belt

cover. Refer to procedures in this section.

(9) Remove crankshaft sprocket. Refer to proce-

dure in this section.(10) Remove lower torque strut/air conditioning

compressor mounting bracket from engine (Fig. 95).

(11) Remove oil filter and adapter.

(12) Remove oil pan.

(13) Remove oil pump pick-up tube.

(14) Remove oil pump.

(15) Remove crankshaft position sensor.

(16) Using a permanent ink or paint marker, iden-

tify cylinder number on each connecting rod cap.

CAUTION: DO NOT use a number stamp or a punch

to mark connecting rods. Damage to connecting

rod could occur.

(17) Remove all connecting rod bolts and caps.

Care should be taken not to damage the fracture rod

and cap surfaces.

Fig. 94 Crankshaft and Components

1 ± OIL PASSAGE O-RING

2 ± SEAL

3 ± UPPER BEARING (GROOVED)

4 ± THRUST BEARINGS

5 ± BOLT

6 ± O-RING

7 ± NIPPLE8 ± OIL FILTER ADAPTER

9 ± CRANKSHAFT POSITION SENSOR (CPS)

10 ± MAIN BEARING CAP/BED PLATE ASSEMBLY

11 ± CONNECTING ROD BEARINGS

12 ± PISTON AND CONNECTING ROD ASSEMBLY

13 ± SEAL

9 - 52 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 810 of 1285

FRAMES

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

FRONT SUSPENSION......................5

REMOVAL AND INSTALLATION

FRONT SUSPENSION CROSSMEMBER........5SPECIFICATIONS

FRAME DIMENSIONS......................9

STRUCTURAL DIMENSIONS................13

TORQUE SPECIFICATIONS.................15

DESCRIPTION AND OPERATION

FRONT SUSPENSION

The front suspension crossmember must be prop-

erly installed to achieve design camber, caster set-

tings and wheel stagger. The crossmember can be

installed out of position on the frame rails due to its

design. Bolts and cage nuts hold the rear of the

crossmember to the frame torque boxes. Bolts and

J-nuts hold the front of the crossmember to the

frame rails. No designed in locating device is used to

position the crossmember in the vehicle. Before

removing the crossmember mark the frame torque

box around the rear mounting location to aid instal-

lation. A crossmember that is removed during service

must be installed in the same position from which it

was removed. To verify that crossmember is in the

proper position, refer to the dimensions provided.

Front end dimensions are gauged from the principal

locating point (PLP) holes located under the frame

torque boxes rearward of the front wheels. After

removal and installation of the crossmember is per-

formed, verify that front suspension alignment is

within specifications. If camber, caster settings and

wheel stagger is not within specifications, loosen and

reposition crossmember to bring suspension within

specifications. Refer to Group 2, Front Suspension for

additional information.

REMOVAL AND INSTALLATION

FRONT SUSPENSION CROSSMEMBER

CAUTION: If the front suspension crossmember is

being replaced due to collision damage, inspect the

steering column lower coupling for damage. Refer

to STEERING COLUMN in the STEERING service

manual group for the procedure.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.

(2) Remove both front tire and wheel assemblies

from the vehicle.

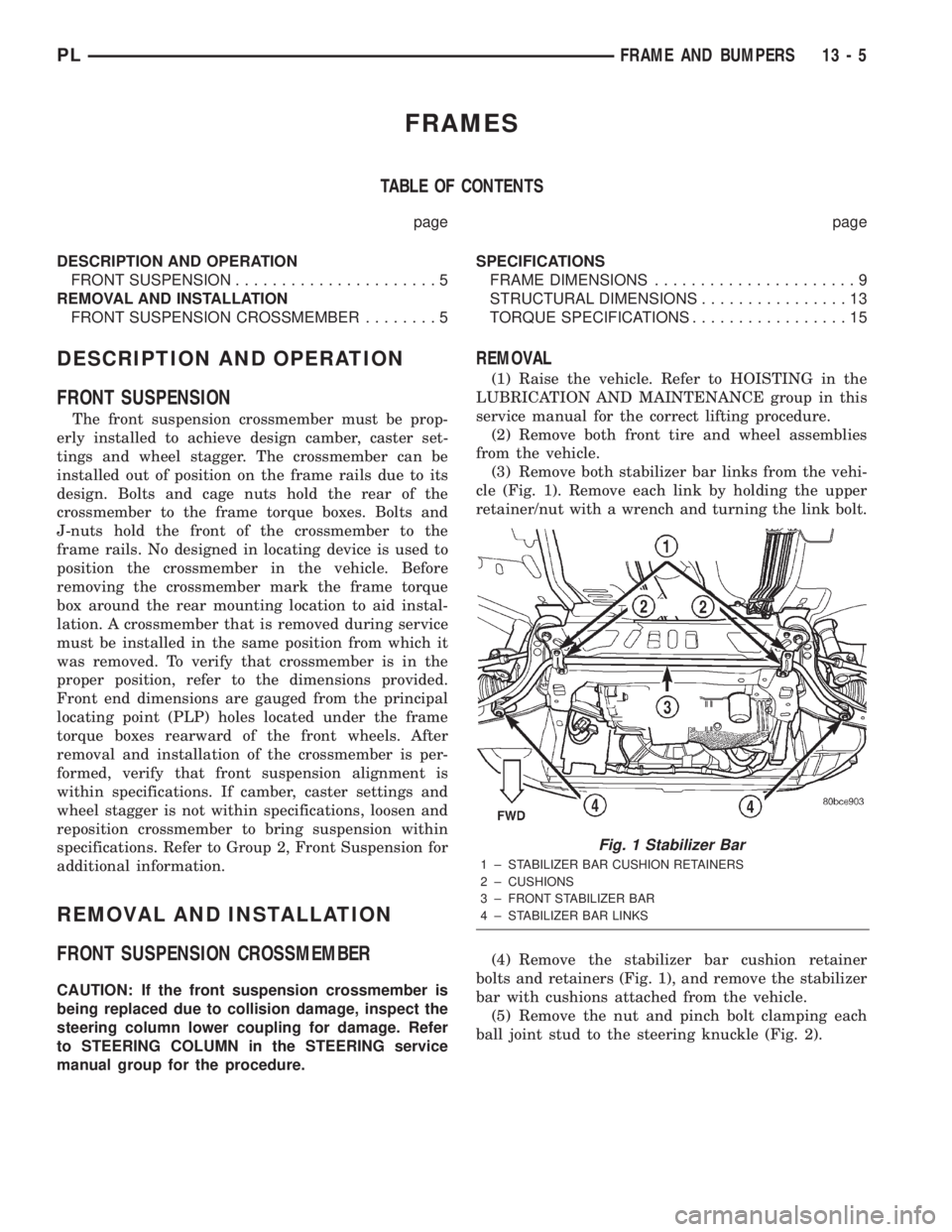

(3) Remove both stabilizer bar links from the vehi-

cle (Fig. 1). Remove each link by holding the upper

retainer/nut with a wrench and turning the link bolt.

(4) Remove the stabilizer bar cushion retainer

bolts and retainers (Fig. 1), and remove the stabilizer

bar with cushions attached from the vehicle.

(5) Remove the nut and pinch bolt clamping each

ball joint stud to the steering knuckle (Fig. 2).

Fig. 1 Stabilizer Bar

1 ± STABILIZER BAR CUSHION RETAINERS

2 ± CUSHIONS

3 ± FRONT STABILIZER BAR

4 ± STABILIZER BAR LINKS

PLFRAME AND BUMPERS 13 - 5

Page 811 of 1285

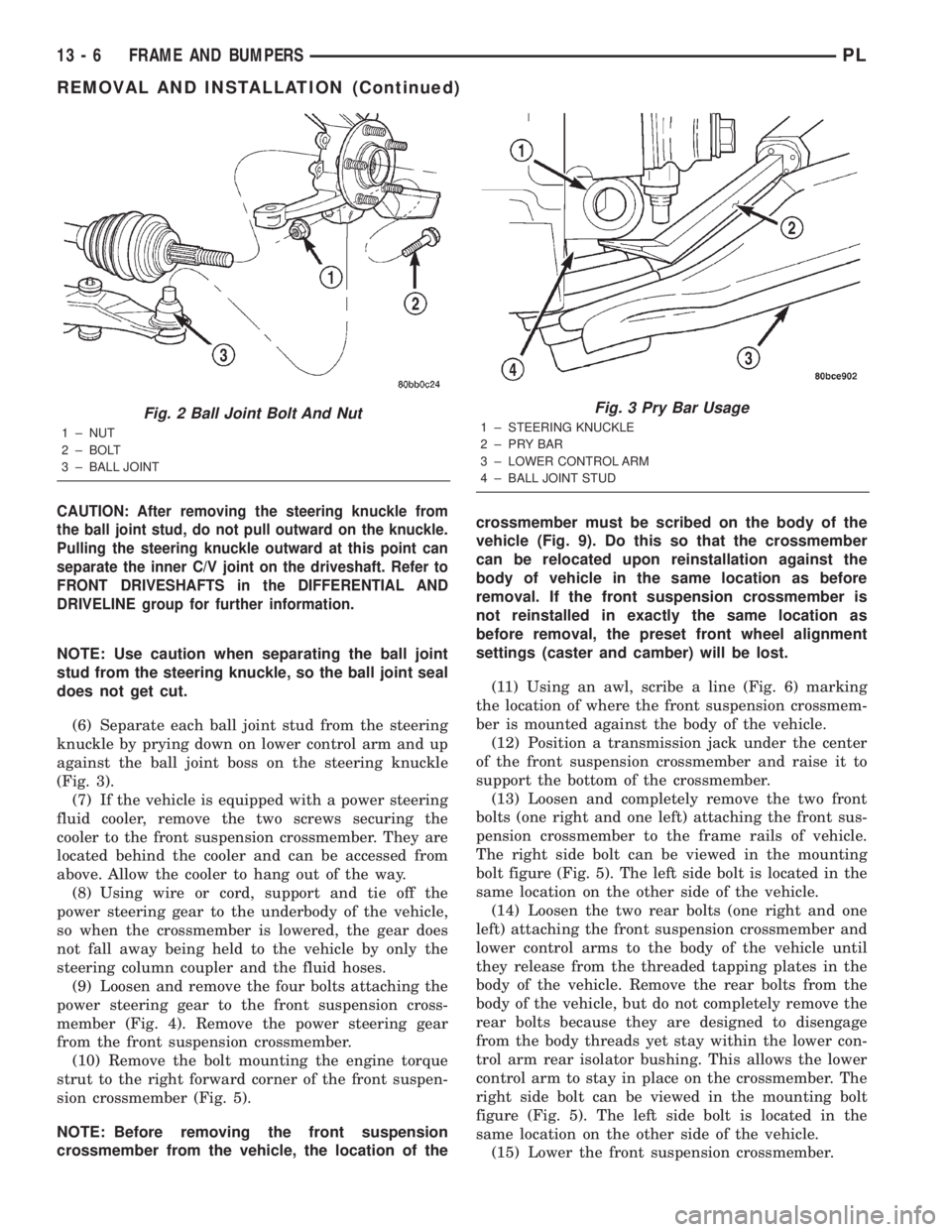

CAUTION: After removing the steering knuckle from

the ball joint stud, do not pull outward on the knuckle.

Pulling the steering knuckle outward at this point can

separate the inner C/V joint on the driveshaft. Refer to

FRONT DRIVESHAFTS in the DIFFERENTIAL AND

DRIVELINE group for further information.

NOTE: Use caution when separating the ball joint

stud from the steering knuckle, so the ball joint seal

does not get cut.

(6) Separate each ball joint stud from the steering

knuckle by prying down on lower control arm and up

against the ball joint boss on the steering knuckle

(Fig. 3).

(7) If the vehicle is equipped with a power steering

fluid cooler, remove the two screws securing the

cooler to the front suspension crossmember. They are

located behind the cooler and can be accessed from

above. Allow the cooler to hang out of the way.

(8) Using wire or cord, support and tie off the

power steering gear to the underbody of the vehicle,

so when the crossmember is lowered, the gear does

not fall away being held to the vehicle by only the

steering column coupler and the fluid hoses.

(9) Loosen and remove the four bolts attaching the

power steering gear to the front suspension cross-

member (Fig. 4). Remove the power steering gear

from the front suspension crossmember.

(10) Remove the bolt mounting the engine torque

strut to the right forward corner of the front suspen-

sion crossmember (Fig. 5).

NOTE: Before removing the front suspension

crossmember from the vehicle, the location of thecrossmember must be scribed on the body of the

vehicle (Fig. 9). Do this so that the crossmember

can be relocated upon reinstallation against the

body of vehicle in the same location as before

removal. If the front suspension crossmember is

not reinstalled in exactly the same location as

before removal, the preset front wheel alignment

settings (caster and camber) will be lost.

(11) Using an awl, scribe a line (Fig. 6) marking

the location of where the front suspension crossmem-

ber is mounted against the body of the vehicle.

(12) Position a transmission jack under the center

of the front suspension crossmember and raise it to

support the bottom of the crossmember.

(13) Loosen and completely remove the two front

bolts (one right and one left) attaching the front sus-

pension crossmember to the frame rails of vehicle.

The right side bolt can be viewed in the mounting

bolt figure (Fig. 5). The left side bolt is located in the

same location on the other side of the vehicle.

(14) Loosen the two rear bolts (one right and one

left) attaching the front suspension crossmember and

lower control arms to the body of the vehicle until

they release from the threaded tapping plates in the

body of the vehicle. Remove the rear bolts from the

body of the vehicle, but do not completely remove the

rear bolts because they are designed to disengage

from the body threads yet stay within the lower con-

trol arm rear isolator bushing. This allows the lower

control arm to stay in place on the crossmember. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 5). The left side bolt is located in the

same location on the other side of the vehicle.

(15) Lower the front suspension crossmember.

Fig. 2 Ball Joint Bolt And Nut

1 ± NUT

2 ± BOLT

3 ± BALL JOINT

Fig. 3 Pry Bar Usage

1 ± STEERING KNUCKLE

2±PRYBAR

3 ± LOWER CONTROL ARM

4 ± BALL JOINT STUD

13 - 6 FRAME AND BUMPERSPL

REMOVAL AND INSTALLATION (Continued)