wheel torque DODGE NEON 2000 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 813 of 1285

(3) Start the two rear crossmember mounting bolts

into the tapping plates mounted in the body. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 5). The left side bolt is located in the

same location on the other side of the vehicle. Next,

install the two front mounting bolts attaching front

suspension crossmember to frame rails of vehicle.

Lightly tighten all four mounting bolts to a approxi-

mately 2 N´m (20 in. lbs.) to hold the front suspen-

sion crossmember in position.

NOTE: When reinstalling the front suspension

crossmember back in the vehicle, it is very impor-

tant that the crossmember be attached to the body

in exactly the same spot as when it was removed.

Otherwise, the vehicle's wheel alignment settings

(caster and camber) will be lost.

(4) Using a soft face hammer, tap the front suspen-

sion crossmember back-and-forth or side-to-side until

it is aligned with the previously scribed positioning

marks on the body of the vehicle (Fig. 6). Once the

front suspension crossmember is correctly positioned,

tighten the rear two crossmember mounting bolts to

a torque of 203 N´m (150 ft. lbs.), then tighten the

front two crossmember mounting bolts to a torque of

142 N´m (105 ft. lbs.).

(5) Tighten the lower control arm front pivot bolts

to a torque of 163 N´m (120 ft. lbs.).

(6) Attach the steering gear to the front suspen-

sion crossmember (Fig. 4). Install the four power

steering gear mounting bolts. Tighten the mounting

bolts to a torque of 61 N´m (45 ft. lbs.).

(7) Remove the wire or cord suspending the power

steering gear to the underbody.

(8) If the vehicle is equipped with a power steering

fluid cooler, install the two screws securing the cooler

to the front suspension crossmember. They are

located behind the cooler.

(9)

Install each ball joint stud into the steering

knuckle aligning the bolt hole in the knuckle boss with

the notch formed in the side of the ball joint stud.

(10) Install a new ball joint stud pinch bolt and

nut (Fig. 2). Tighten the nut to a torque of 95 N´m

(70 ft. lbs.).

(11) Fasten the engine torque strut to the right

forward corner of the front suspension crossmember

using its mounting bolt (Fig. 5). Follow the procedure

described in the ENGINE service manual group to

properly align and tighten the torque strut and it's

mounting bolts.

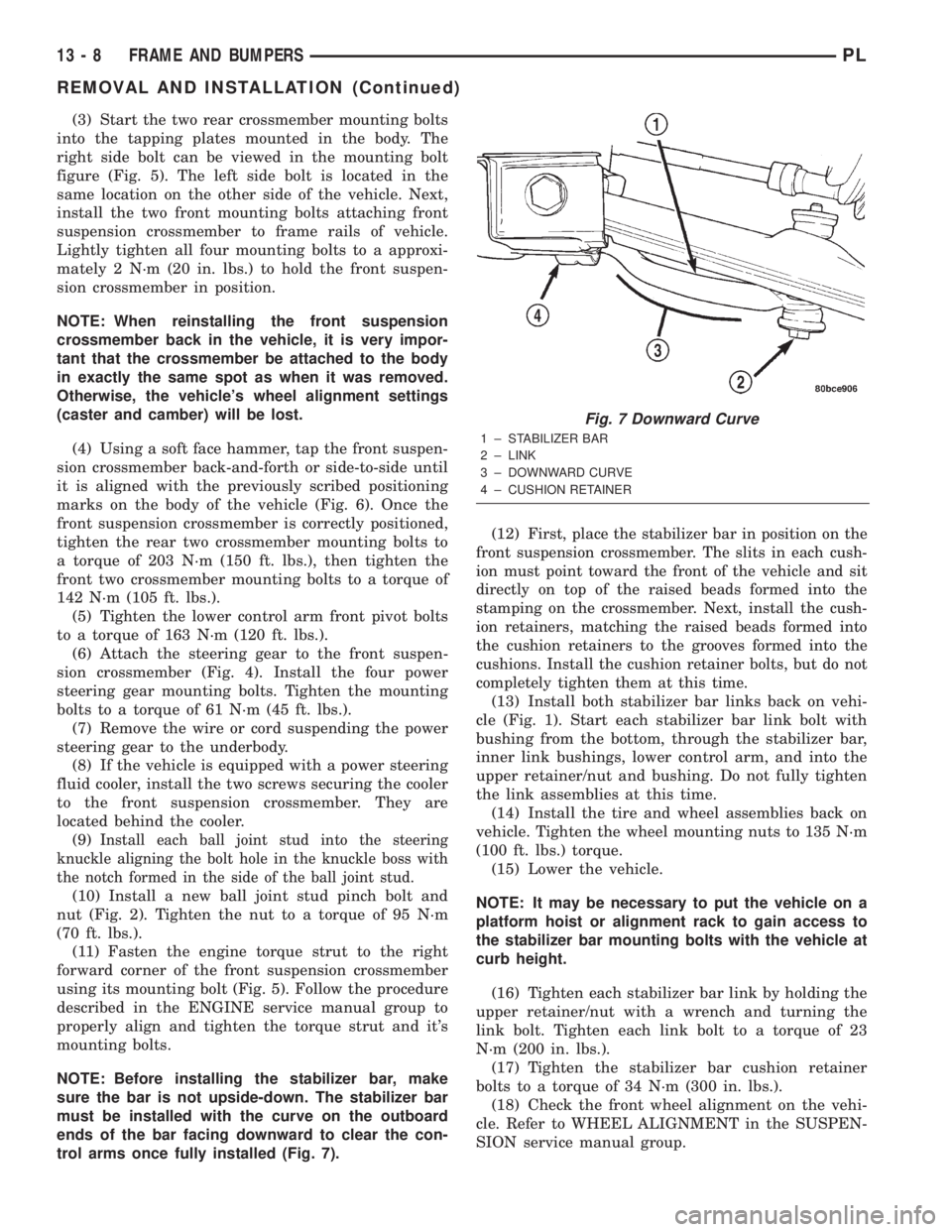

NOTE: Before installing the stabilizer bar, make

sure the bar is not upside-down. The stabilizer bar

must be installed with the curve on the outboard

ends of the bar facing downward to clear the con-

trol arms once fully installed (Fig. 7).(12)

First, place the stabilizer bar in position on the

front suspension crossmember. The slits in each cush-

ion must point toward the front of the vehicle and sit

directly on top of the raised beads formed into the

stamping on the crossmember. Next, install the cush-

ion retainers, matching the raised beads formed into

the cushion retainers to the grooves formed into the

cushions. Install the cushion retainer bolts, but do not

completely tighten them at this time.

(13) Install both stabilizer bar links back on vehi-

cle (Fig. 1). Start each stabilizer bar link bolt with

bushing from the bottom, through the stabilizer bar,

inner link bushings, lower control arm, and into the

upper retainer/nut and bushing. Do not fully tighten

the link assemblies at this time.

(14) Install the tire and wheel assemblies back on

vehicle. Tighten the wheel mounting nuts to 135 N´m

(100 ft. lbs.) torque.

(15) Lower the vehicle.

NOTE: It may be necessary to put the vehicle on a

platform hoist or alignment rack to gain access to

the stabilizer bar mounting bolts with the vehicle at

curb height.

(16) Tighten each stabilizer bar link by holding the

upper retainer/nut with a wrench and turning the

link bolt. Tighten each link bolt to a torque of 23

N´m (200 in. lbs.).

(17) Tighten the stabilizer bar cushion retainer

bolts to a torque of 34 N´m (300 in. lbs.).

(18) Check the front wheel alignment on the vehi-

cle. Refer to WHEEL ALIGNMENT in the SUSPEN-

SION service manual group.

Fig. 7 Downward Curve

1 ± STABILIZER BAR

2 ± LINK

3 ± DOWNWARD CURVE

4 ± CUSHION RETAINER

13 - 8 FRAME AND BUMPERSPL

REMOVAL AND INSTALLATION (Continued)

Page 838 of 1285

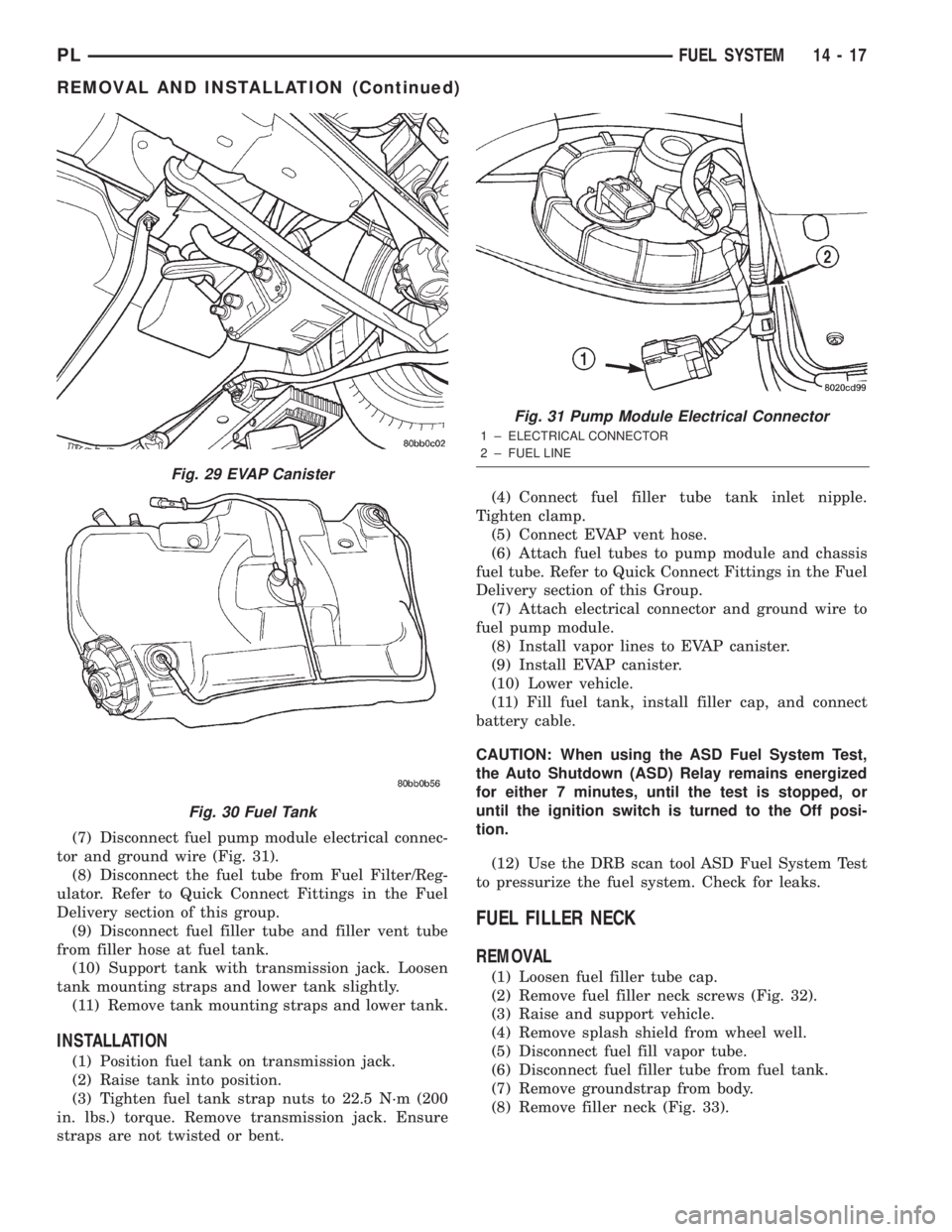

(7) Disconnect fuel pump module electrical connec-

tor and ground wire (Fig. 31).

(8) Disconnect the fuel tube from Fuel Filter/Reg-

ulator. Refer to Quick Connect Fittings in the Fuel

Delivery section of this group.

(9) Disconnect fuel filler tube and filler vent tube

from filler hose at fuel tank.

(10) Support tank with transmission jack. Loosen

tank mounting straps and lower tank slightly.

(11) Remove tank mounting straps and lower tank.

INSTALLATION

(1) Position fuel tank on transmission jack.

(2) Raise tank into position.

(3) Tighten fuel tank strap nuts to 22.5 N´m (200

in. lbs.) torque. Remove transmission jack. Ensure

straps are not twisted or bent.(4) Connect fuel filler tube tank inlet nipple.

Tighten clamp.

(5) Connect EVAP vent hose.

(6) Attach fuel tubes to pump module and chassis

fuel tube. Refer to Quick Connect Fittings in the Fuel

Delivery section of this Group.

(7) Attach electrical connector and ground wire to

fuel pump module.

(8) Install vapor lines to EVAP canister.

(9) Install EVAP canister.

(10) Lower vehicle.

(11) Fill fuel tank, install filler cap, and connect

battery cable.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.

(12) Use the DRB scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

FUEL FILLER NECK

REMOVAL

(1) Loosen fuel filler tube cap.

(2) Remove fuel filler neck screws (Fig. 32).

(3) Raise and support vehicle.

(4) Remove splash shield from wheel well.

(5) Disconnect fuel fill vapor tube.

(6) Disconnect fuel filler tube from fuel tank.

(7) Remove groundstrap from body.

(8) Remove filler neck (Fig. 33).

Fig. 29 EVAP Canister

Fig. 30 Fuel Tank

Fig. 31 Pump Module Electrical Connector

1 ± ELECTRICAL CONNECTOR

2 ± FUEL LINE

PLFUEL SYSTEM 14 - 17

REMOVAL AND INSTALLATION (Continued)

Page 872 of 1285

STEERING

TABLE OF CONTENTS

page page

POWER STEERING......................... 1

POWER STEERING PUMP.................. 16STEERING GEAR.......................... 21

STEERING COLUMN....................... 29

POWER STEERING

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

POWER STEERING SYSTEM................1

POWER STEERING FLUID HOSES............2

POWER STEERING FLUID COOLER...........2

POWER STEERING FLUID PRESSURE

SWITCH...............................3

DIAGNOSIS AND TESTING

STEERING SYSTEM DIAGNOSIS CHARTS......4

POWER STEERING SYSTEM FLOW AND

PRESSURE TEST........................9

SERVICE PROCEDURES

POWER STEERING SYSTEM FLUID LEVEL

CHECK...............................11REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS........11

POWER STEERING FLUID PRESSURE HOSE . . . 11

POWER STEERING FLUID RETURN HOSE.....12

POWER STEERING FLUID COOLER..........13

POWER STEERING FLUID PRESSURE

SWITCH..............................14

SPECIFICATIONS

POWER STEERING FASTENER TORQUE

SPECIFICATIONS.......................15

SPECIAL TOOLS

POWER STEERING.......................15

DESCRIPTION AND OPERATION

POWER STEERING SYSTEM

Turning of the steering wheel is converted into lin-

ear travel through the meshing of the helical pinion

teeth with the rack teeth within the steering gear.

Power assist steering is provided by an open-cen-

ter, rotary-type control valve. It is used to direct

power steering fluid from the power steering pump to

either side of the integral steering rack piston. Road

feel is controlled by the diameter of a torsion bar

which initially steers the vehicle. As steering effort

increases as in a turn, the torsion bar twists, causing

relative rotary motion between the rotary valve body

and valve spool. This movement directs fluid behind

the integral rack piston, which in turn builds up

hydraulic pressure and assists in the turning effort.

This vehicle comes with power steering as stan-

dard equipment and it is the only steering systemavailable. The power steering system consists of

these major components:

²POWER STEERING PUMP

²POWER STEERING GEAR

²POWER STEERING FLUID RESERVOIR

(mounted on the pump)

²POWER STEERING FLUID PRESSURE HOSE

²POWER STEERING FLUID RETURN HOSE

²POWER STEERING FLUID COOLER (on some

models)

For information on the first two components, refer

to their respective sections within this service man-

ual group. Information on the third component can

be found in POWER STEERING PUMP. Information

on all other components can be found in this section

of this service manual group.

PLSTEERING 19 - 1

Page 876 of 1285

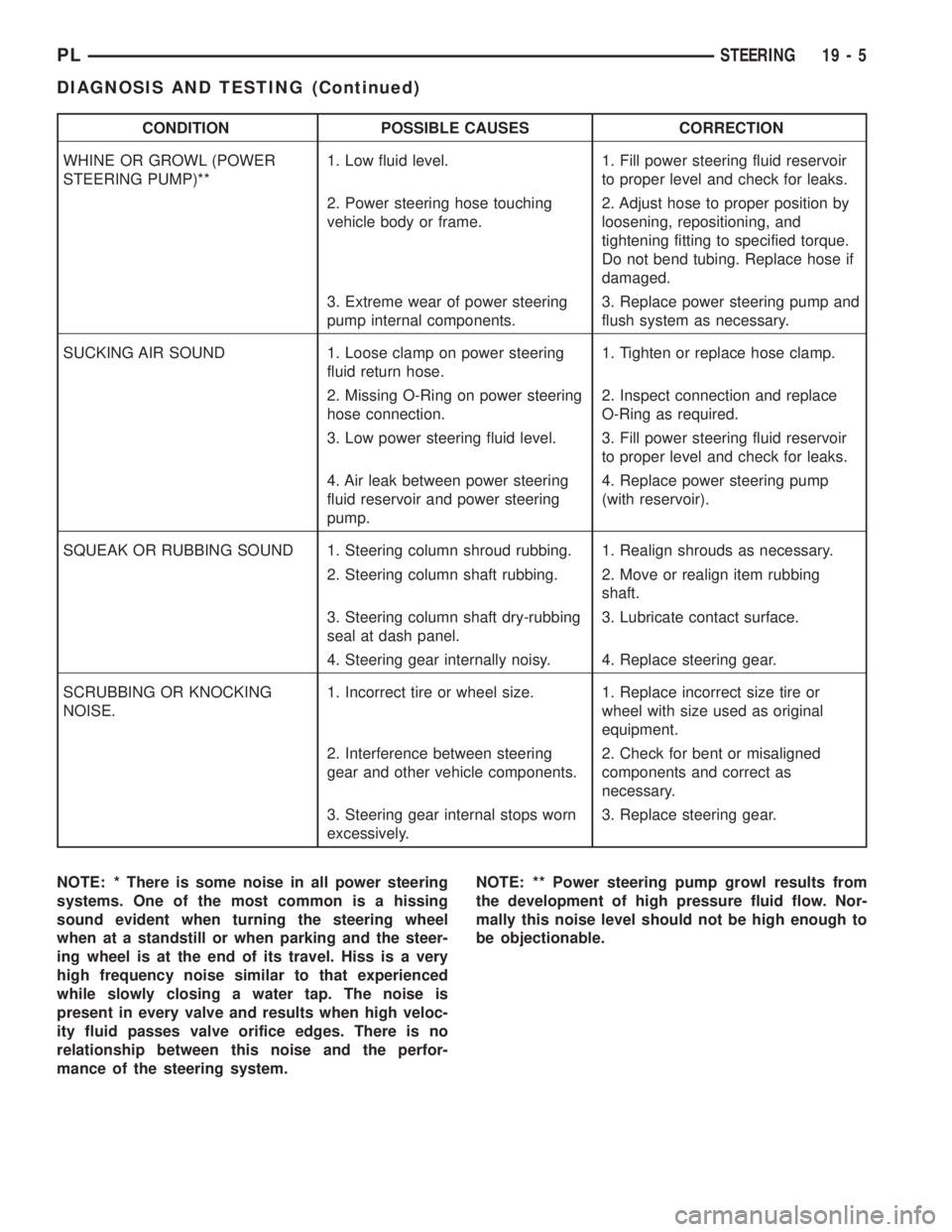

CONDITION POSSIBLE CAUSES CORRECTION

WHINE OR GROWL (POWER

STEERING PUMP)**1. Low fluid level. 1. Fill power steering fluid reservoir

to proper level and check for leaks.

2. Power steering hose touching

vehicle body or frame.2. Adjust hose to proper position by

loosening, repositioning, and

tightening fitting to specified torque.

Do not bend tubing. Replace hose if

damaged.

3. Extreme wear of power steering

pump internal components.3. Replace power steering pump and

flush system as necessary.

SUCKING AIR SOUND 1. Loose clamp on power steering

fluid return hose.1. Tighten or replace hose clamp.

2. Missing O-Ring on power steering

hose connection.2. Inspect connection and replace

O-Ring as required.

3. Low power steering fluid level. 3. Fill power steering fluid reservoir

to proper level and check for leaks.

4. Air leak between power steering

fluid reservoir and power steering

pump.4. Replace power steering pump

(with reservoir).

SQUEAK OR RUBBING SOUND 1. Steering column shroud rubbing. 1. Realign shrouds as necessary.

2. Steering column shaft rubbing. 2. Move or realign item rubbing

shaft.

3. Steering column shaft dry-rubbing

seal at dash panel.3. Lubricate contact surface.

4. Steering gear internally noisy. 4. Replace steering gear.

SCRUBBING OR KNOCKING

NOISE.1. Incorrect tire or wheel size. 1. Replace incorrect size tire or

wheel with size used as original

equipment.

2. Interference between steering

gear and other vehicle components.2. Check for bent or misaligned

components and correct as

necessary.

3. Steering gear internal stops worn

excessively.3. Replace steering gear.

NOTE: * There is some noise in all power steering

systems. One of the most common is a hissing

sound evident when turning the steering wheel

when at a standstill or when parking and the steer-

ing wheel is at the end of its travel. Hiss is a very

high frequency noise similar to that experienced

while slowly closing a water tap. The noise is

present in every valve and results when high veloc-

ity fluid passes valve orifice edges. There is no

relationship between this noise and the perfor-

mance of the steering system.NOTE: ** Power steering pump growl results from

the development of high pressure fluid flow. Nor-

mally this noise level should not be high enough to

be objectionable.

PLSTEERING 19 - 5

DIAGNOSIS AND TESTING (Continued)

Page 877 of 1285

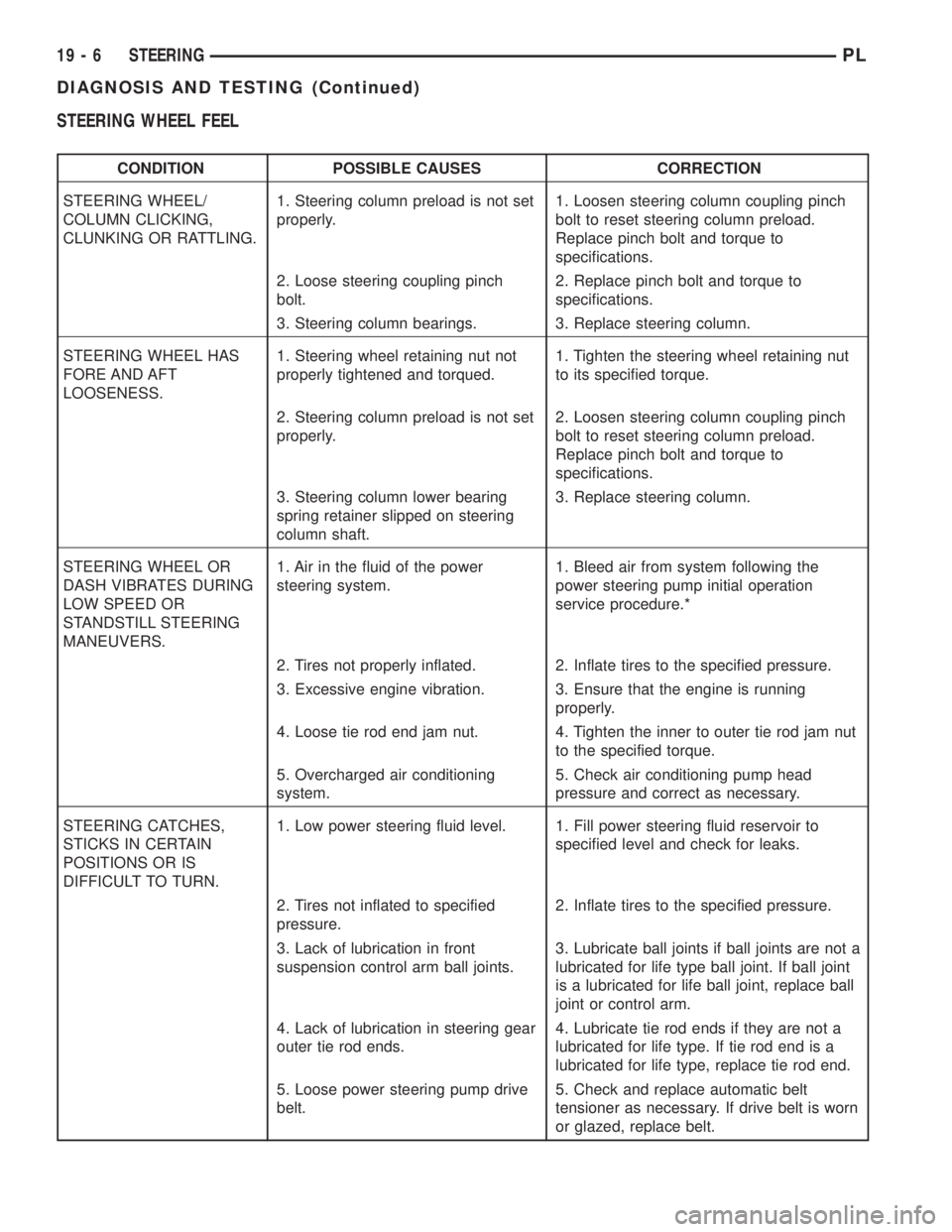

STEERING WHEEL FEEL

CONDITION POSSIBLE CAUSES CORRECTION

STEERING WHEEL/

COLUMN CLICKING,

CLUNKING OR RATTLING.1. Steering column preload is not set

properly.1. Loosen steering column coupling pinch

bolt to reset steering column preload.

Replace pinch bolt and torque to

specifications.

2. Loose steering coupling pinch

bolt.2. Replace pinch bolt and torque to

specifications.

3. Steering column bearings. 3. Replace steering column.

STEERING WHEEL HAS

FORE AND AFT

LOOSENESS.1. Steering wheel retaining nut not

properly tightened and torqued.1. Tighten the steering wheel retaining nut

to its specified torque.

2. Steering column preload is not set

properly.2. Loosen steering column coupling pinch

bolt to reset steering column preload.

Replace pinch bolt and torque to

specifications.

3. Steering column lower bearing

spring retainer slipped on steering

column shaft.3. Replace steering column.

STEERING WHEEL OR

DASH VIBRATES DURING

LOW SPEED OR

STANDSTILL STEERING

MANEUVERS.1. Air in the fluid of the power

steering system.1. Bleed air from system following the

power steering pump initial operation

service procedure.*

2. Tires not properly inflated. 2. Inflate tires to the specified pressure.

3. Excessive engine vibration. 3. Ensure that the engine is running

properly.

4. Loose tie rod end jam nut. 4. Tighten the inner to outer tie rod jam nut

to the specified torque.

5. Overcharged air conditioning

system.5. Check air conditioning pump head

pressure and correct as necessary.

STEERING CATCHES,

STICKS IN CERTAIN

POSITIONS OR IS

DIFFICULT TO TURN.1. Low power steering fluid level. 1. Fill power steering fluid reservoir to

specified level and check for leaks.

2. Tires not inflated to specified

pressure.2. Inflate tires to the specified pressure.

3. Lack of lubrication in front

suspension control arm ball joints.3. Lubricate ball joints if ball joints are not a

lubricated for life type ball joint. If ball joint

is a lubricated for life ball joint, replace ball

joint or control arm.

4. Lack of lubrication in steering gear

outer tie rod ends.4. Lubricate tie rod ends if they are not a

lubricated for life type. If tie rod end is a

lubricated for life type, replace tie rod end.

5. Loose power steering pump drive

belt.5. Check and replace automatic belt

tensioner as necessary. If drive belt is worn

or glazed, replace belt.

19 - 6 STEERINGPL

DIAGNOSIS AND TESTING (Continued)

Page 879 of 1285

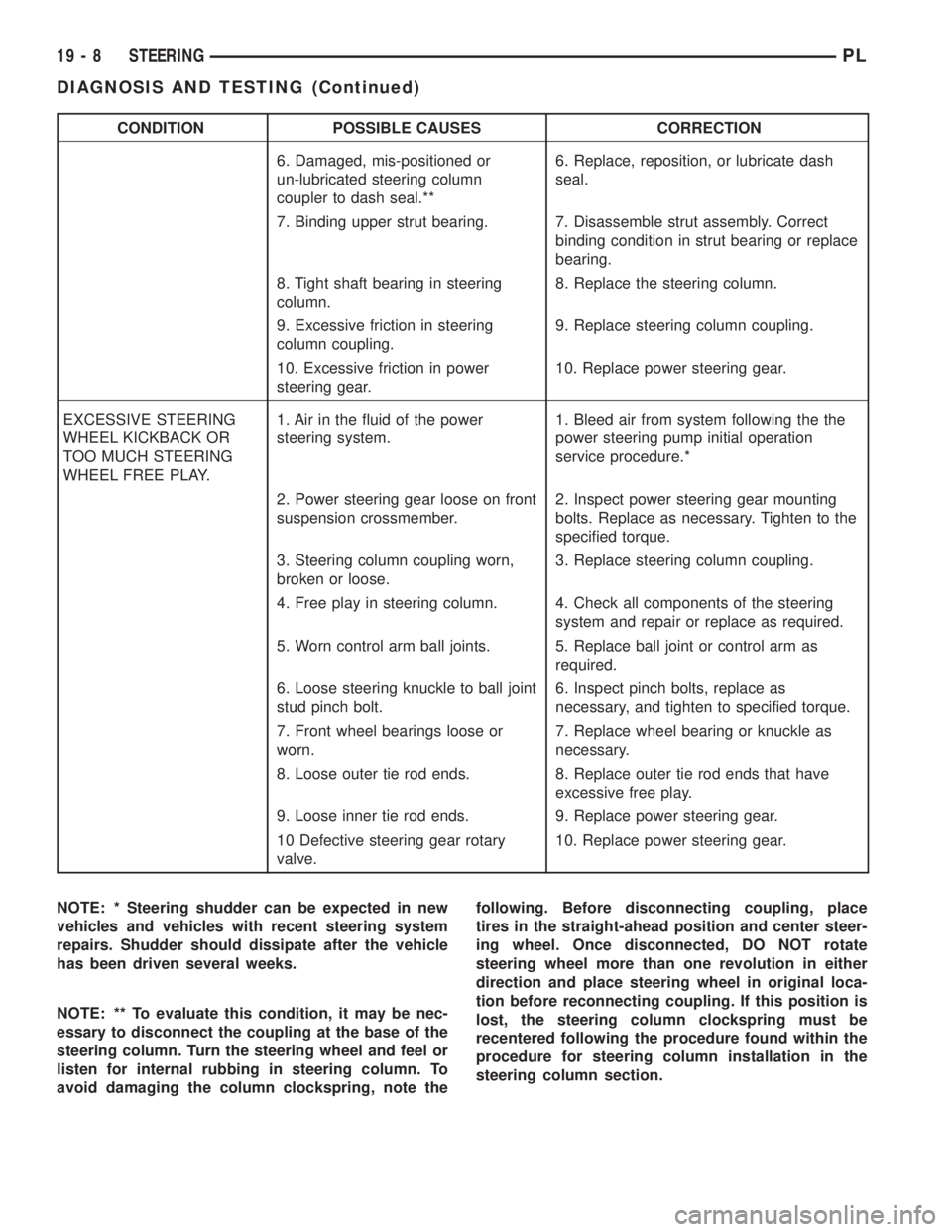

CONDITION POSSIBLE CAUSES CORRECTION

6. Damaged, mis-positioned or

un-lubricated steering column

coupler to dash seal.**6. Replace, reposition, or lubricate dash

seal.

7. Binding upper strut bearing. 7. Disassemble strut assembly. Correct

binding condition in strut bearing or replace

bearing.

8. Tight shaft bearing in steering

column.8. Replace the steering column.

9. Excessive friction in steering

column coupling.9. Replace steering column coupling.

10. Excessive friction in power

steering gear.10. Replace power steering gear.

EXCESSIVE STEERING

WHEEL KICKBACK OR

TOO MUCH STEERING

WHEEL FREE PLAY.1. Air in the fluid of the power

steering system.1. Bleed air from system following the the

power steering pump initial operation

service procedure.*

2. Power steering gear loose on front

suspension crossmember.2. Inspect power steering gear mounting

bolts. Replace as necessary. Tighten to the

specified torque.

3. Steering column coupling worn,

broken or loose.3. Replace steering column coupling.

4. Free play in steering column. 4. Check all components of the steering

system and repair or replace as required.

5. Worn control arm ball joints. 5. Replace ball joint or control arm as

required.

6. Loose steering knuckle to ball joint

stud pinch bolt.6. Inspect pinch bolts, replace as

necessary, and tighten to specified torque.

7. Front wheel bearings loose or

worn.7. Replace wheel bearing or knuckle as

necessary.

8. Loose outer tie rod ends. 8. Replace outer tie rod ends that have

excessive free play.

9. Loose inner tie rod ends. 9. Replace power steering gear.

10 Defective steering gear rotary

valve.10. Replace power steering gear.

NOTE: * Steering shudder can be expected in new

vehicles and vehicles with recent steering system

repairs. Shudder should dissipate after the vehicle

has been driven several weeks.

NOTE: ** To evaluate this condition, it may be nec-

essary to disconnect the coupling at the base of the

steering column. Turn the steering wheel and feel or

listen for internal rubbing in steering column. To

avoid damaging the column clockspring, note thefollowing. Before disconnecting coupling, place

tires in the straight-ahead position and center steer-

ing wheel. Once disconnected, DO NOT rotate

steering wheel more than one revolution in either

direction and place steering wheel in original loca-

tion before reconnecting coupling. If this position is

lost, the steering column clockspring must be

recentered following the procedure found within the

procedure for steering column installation in the

steering column section.

19 - 8 STEERINGPL

DIAGNOSIS AND TESTING (Continued)

Page 886 of 1285

(6) Start the engine and turn the steering wheel

several times stop-to-stop to bleed any air from the

fluid in the power steering system. Stop the engine,

check the fluid level, and inspect the system for

leaks.

SPECIFICATIONS

POWER STEERING FASTENER TORQUE

SPECIFICATIONS

DESCRIPTION TORQUE

POWER STEERING HOSE:

Tube Nuts............... 34N´m(25ft.lbs.)

Hose Routing Clip Bolt.... 12N´m(105 in. lbs.)

POWER STEERING COOLER:

Mounting Screws.......... 10N´m(90in.lbs.)

POWER STEERING FLUID PRESSURE

SWITCH:

Switch................... 8N´m(70in.lbs.)

POWER STEERING PUMP:

Pressure Hose Tube Nut.... 34N´m(25ft.lbs.)

Pressure Fitting........... 88N´m(65ft.lbs.)

Front Mounting Bolts..... 28N´m(250 in. lbs.)

Rear Mounting Bolt....... 28N´m(250 in. lbs.)

Rear Support Bracket To Engine Bolts . . 54 N´m

(40 ft. lbs.)

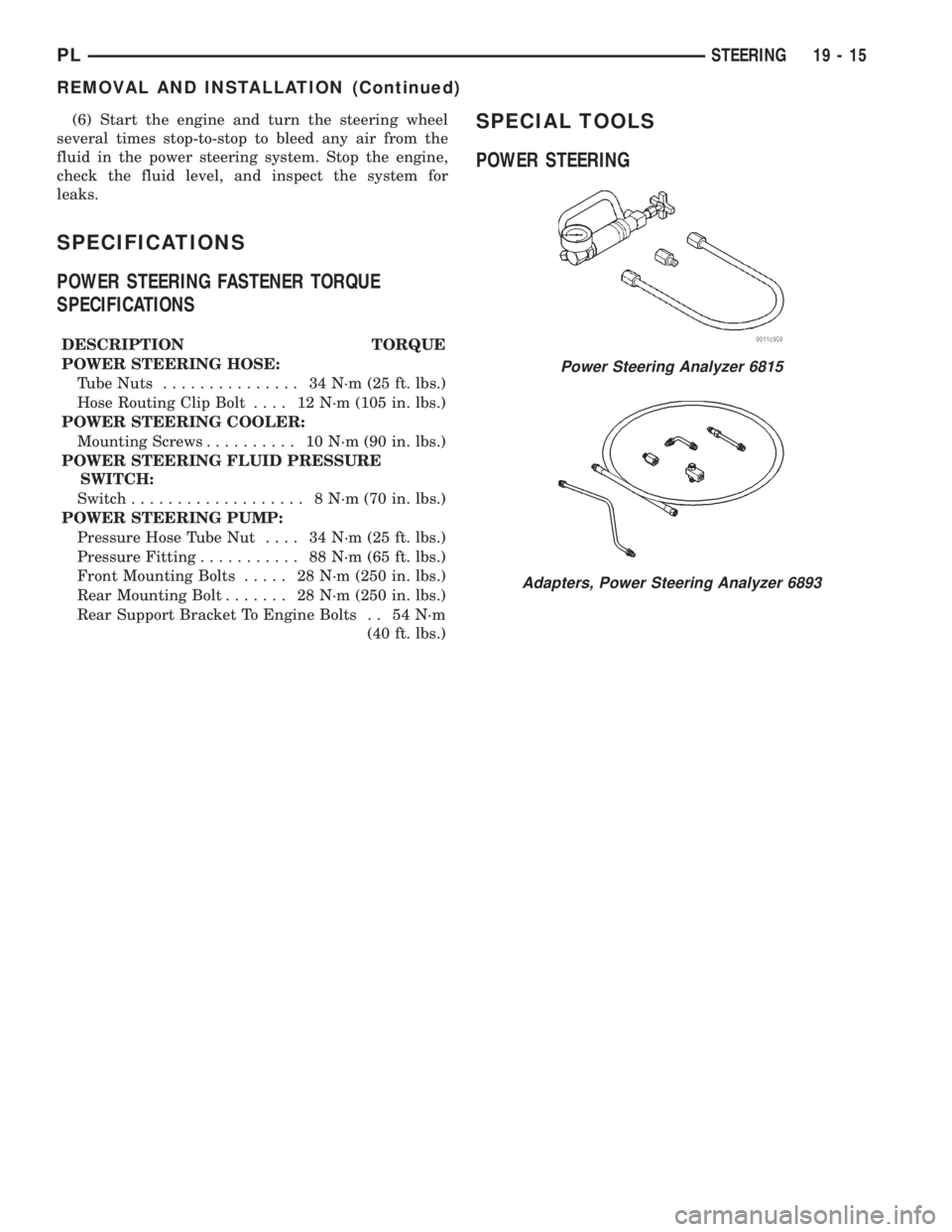

SPECIAL TOOLS

POWER STEERING

Power Steering Analyzer 6815

Adapters, Power Steering Analyzer 6893

PLSTEERING 19 - 15

REMOVAL AND INSTALLATION (Continued)

Page 892 of 1285

STEERING GEAR

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

POWER STEERING GEAR..................21

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS........22

POWER STEERING GEAR..................22

OUTER TIE ROD.........................26SPECIFICATIONS

POWER STEERING GEAR FASTENER

TORQUE SPECIFICATIONS...............28

SPECIAL TOOLS

POWER STEERING GEAR..................28

DESCRIPTION AND OPERATION

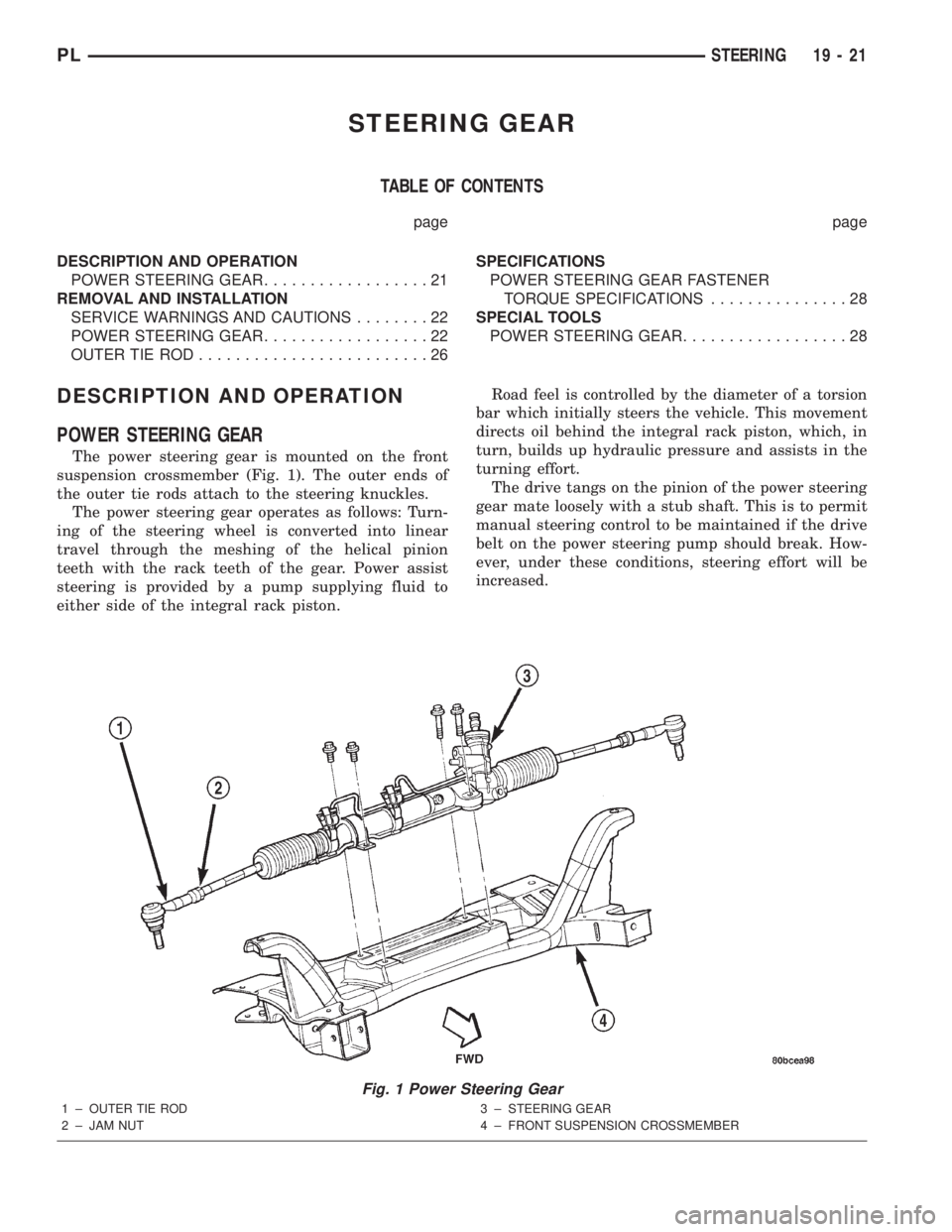

POWER STEERING GEAR

The power steering gear is mounted on the front

suspension crossmember (Fig. 1). The outer ends of

the outer tie rods attach to the steering knuckles.

The power steering gear operates as follows: Turn-

ing of the steering wheel is converted into linear

travel through the meshing of the helical pinion

teeth with the rack teeth of the gear. Power assist

steering is provided by a pump supplying fluid to

either side of the integral rack piston.Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. This movement

directs oil behind the integral rack piston, which, in

turn, builds up hydraulic pressure and assists in the

turning effort.

The drive tangs on the pinion of the power steering

gear mate loosely with a stub shaft. This is to permit

manual steering control to be maintained if the drive

belt on the power steering pump should break. How-

ever, under these conditions, steering effort will be

increased.

Fig. 1 Power Steering Gear

1 ± OUTER TIE ROD

2 ± JAM NUT3 ± STEERING GEAR

4 ± FRONT SUSPENSION CROSSMEMBER

PLSTEERING 19 - 21

Page 895 of 1285

(13) If the vehicle is equipped with a power steer-

ing fluid cooler, remove the two screws securing the

cooler to the front suspension crossmember. They are

located behind the cooler and can be accessed from

above. Allow the cooler to hang out of the way.

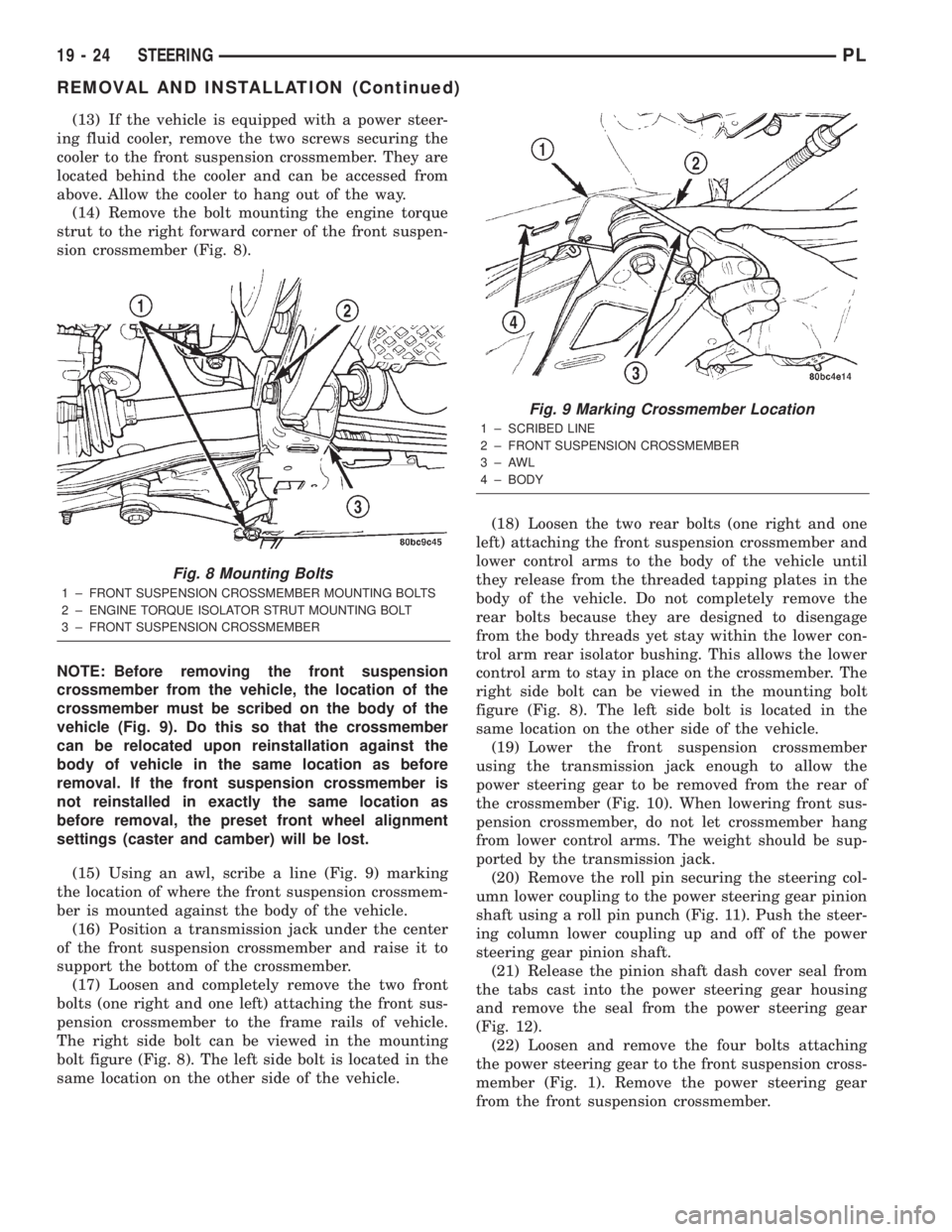

(14) Remove the bolt mounting the engine torque

strut to the right forward corner of the front suspen-

sion crossmember (Fig. 8).

NOTE: Before removing the front suspension

crossmember from the vehicle, the location of the

crossmember must be scribed on the body of the

vehicle (Fig. 9). Do this so that the crossmember

can be relocated upon reinstallation against the

body of vehicle in the same location as before

removal. If the front suspension crossmember is

not reinstalled in exactly the same location as

before removal, the preset front wheel alignment

settings (caster and camber) will be lost.

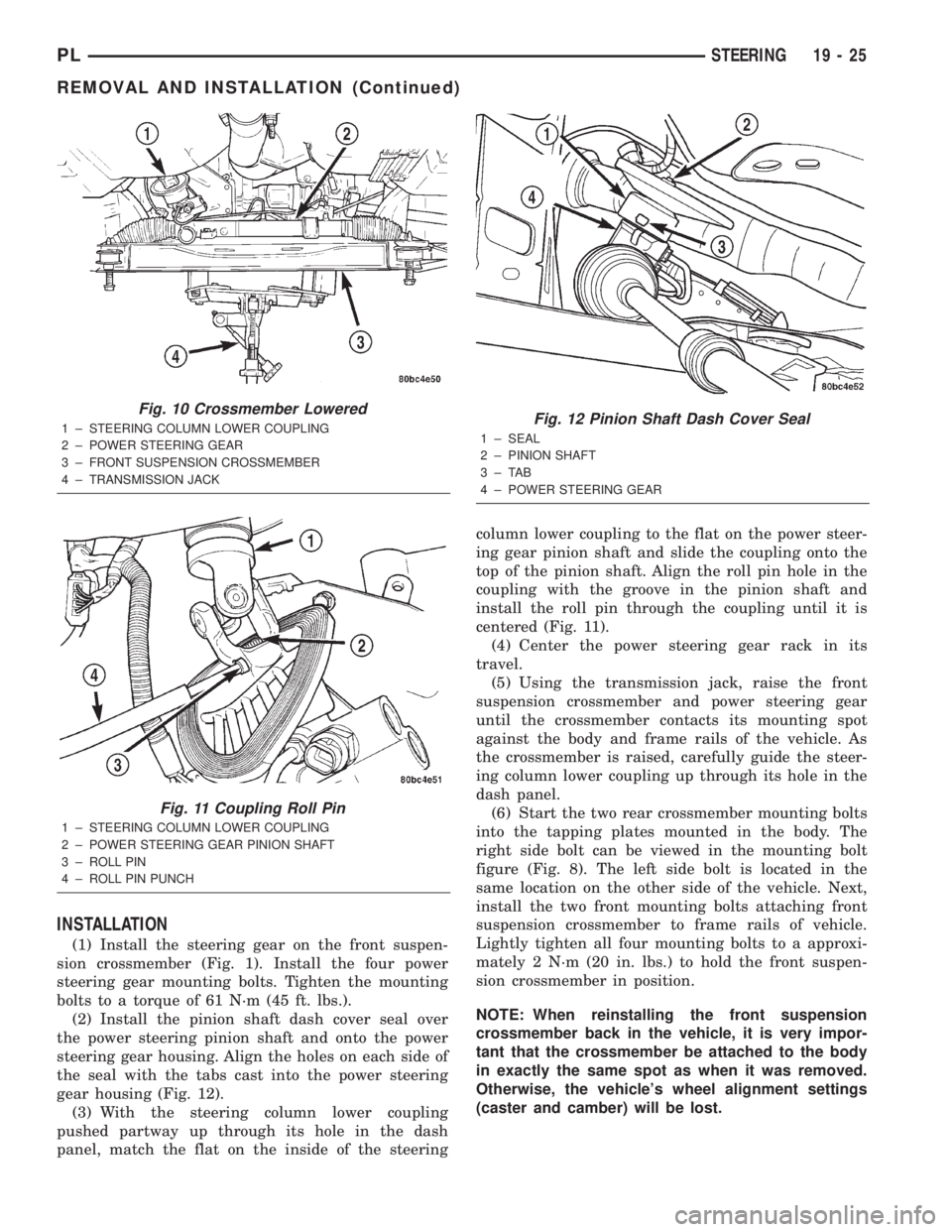

(15) Using an awl, scribe a line (Fig. 9) marking

the location of where the front suspension crossmem-

ber is mounted against the body of the vehicle.

(16) Position a transmission jack under the center

of the front suspension crossmember and raise it to

support the bottom of the crossmember.

(17) Loosen and completely remove the two front

bolts (one right and one left) attaching the front sus-

pension crossmember to the frame rails of vehicle.

The right side bolt can be viewed in the mounting

bolt figure (Fig. 8). The left side bolt is located in the

same location on the other side of the vehicle.(18) Loosen the two rear bolts (one right and one

left) attaching the front suspension crossmember and

lower control arms to the body of the vehicle until

they release from the threaded tapping plates in the

body of the vehicle. Do not completely remove the

rear bolts because they are designed to disengage

from the body threads yet stay within the lower con-

trol arm rear isolator bushing. This allows the lower

control arm to stay in place on the crossmember. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 8). The left side bolt is located in the

same location on the other side of the vehicle.

(19) Lower the front suspension crossmember

using the transmission jack enough to allow the

power steering gear to be removed from the rear of

the crossmember (Fig. 10). When lowering front sus-

pension crossmember, do not let crossmember hang

from lower control arms. The weight should be sup-

ported by the transmission jack.

(20) Remove the roll pin securing the steering col-

umn lower coupling to the power steering gear pinion

shaft using a roll pin punch (Fig. 11). Push the steer-

ing column lower coupling up and off of the power

steering gear pinion shaft.

(21) Release the pinion shaft dash cover seal from

the tabs cast into the power steering gear housing

and remove the seal from the power steering gear

(Fig. 12).

(22) Loosen and remove the four bolts attaching

the power steering gear to the front suspension cross-

member (Fig. 1). Remove the power steering gear

from the front suspension crossmember.

Fig. 8 Mounting Bolts

1 ± FRONT SUSPENSION CROSSMEMBER MOUNTING BOLTS

2 ± ENGINE TORQUE ISOLATOR STRUT MOUNTING BOLT

3 ± FRONT SUSPENSION CROSSMEMBER

Fig. 9 Marking Crossmember Location

1 ± SCRIBED LINE

2 ± FRONT SUSPENSION CROSSMEMBER

3±AWL

4 ± BODY

19 - 24 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 896 of 1285

INSTALLATION

(1) Install the steering gear on the front suspen-

sion crossmember (Fig. 1). Install the four power

steering gear mounting bolts. Tighten the mounting

bolts to a torque of 61 N´m (45 ft. lbs.).

(2) Install the pinion shaft dash cover seal over

the power steering pinion shaft and onto the power

steering gear housing. Align the holes on each side of

the seal with the tabs cast into the power steering

gear housing (Fig. 12).

(3) With the steering column lower coupling

pushed partway up through its hole in the dash

panel, match the flat on the inside of the steeringcolumn lower coupling to the flat on the power steer-

ing gear pinion shaft and slide the coupling onto the

top of the pinion shaft. Align the roll pin hole in the

coupling with the groove in the pinion shaft and

install the roll pin through the coupling until it is

centered (Fig. 11).

(4) Center the power steering gear rack in its

travel.

(5) Using the transmission jack, raise the front

suspension crossmember and power steering gear

until the crossmember contacts its mounting spot

against the body and frame rails of the vehicle. As

the crossmember is raised, carefully guide the steer-

ing column lower coupling up through its hole in the

dash panel.

(6) Start the two rear crossmember mounting bolts

into the tapping plates mounted in the body. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 8). The left side bolt is located in the

same location on the other side of the vehicle. Next,

install the two front mounting bolts attaching front

suspension crossmember to frame rails of vehicle.

Lightly tighten all four mounting bolts to a approxi-

mately 2 N´m (20 in. lbs.) to hold the front suspen-

sion crossmember in position.

NOTE: When reinstalling the front suspension

crossmember back in the vehicle, it is very impor-

tant that the crossmember be attached to the body

in exactly the same spot as when it was removed.

Otherwise, the vehicle's wheel alignment settings

(caster and camber) will be lost.

Fig. 10 Crossmember Lowered

1 ± STEERING COLUMN LOWER COUPLING

2 ± POWER STEERING GEAR

3 ± FRONT SUSPENSION CROSSMEMBER

4 ± TRANSMISSION JACK

Fig. 11 Coupling Roll Pin

1 ± STEERING COLUMN LOWER COUPLING

2 ± POWER STEERING GEAR PINION SHAFT

3 ± ROLL PIN

4 ± ROLL PIN PUNCH

Fig. 12 Pinion Shaft Dash Cover Seal

1 ± SEAL

2 ± PINION SHAFT

3±TAB

4 ± POWER STEERING GEAR

PLSTEERING 19 - 25

REMOVAL AND INSTALLATION (Continued)