DODGE NEON 2000 Service Repair Manual

Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 941 of 1285

(14) Remove gear case from bench fixture.

(15) Install gear case in a holding fixture with end

cover facing down.

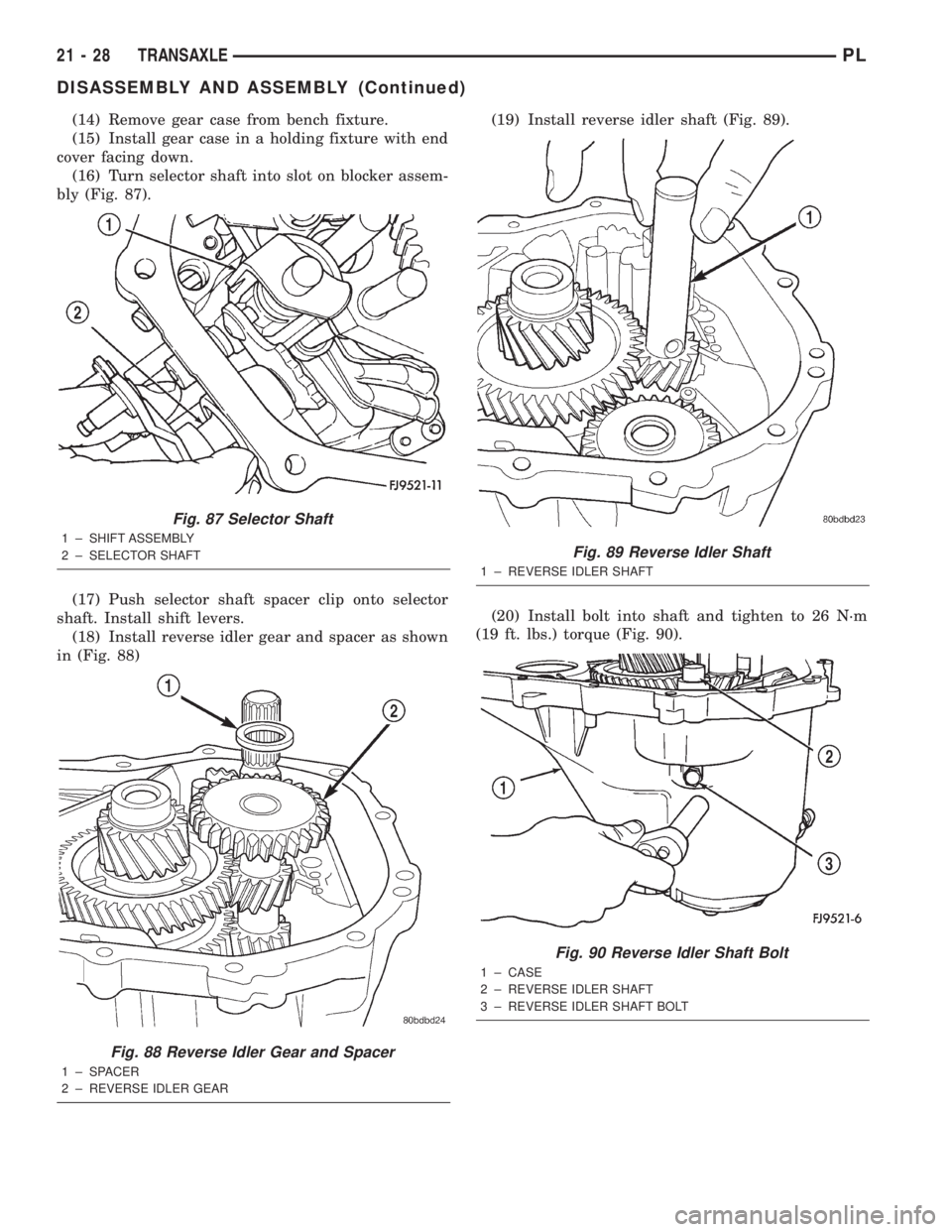

(16) Turn selector shaft into slot on blocker assem-

bly (Fig. 87).

(17) Push selector shaft spacer clip onto selector

shaft. Install shift levers.

(18) Install reverse idler gear and spacer as shown

in (Fig. 88)(19) Install reverse idler shaft (Fig. 89).

(20) Install bolt into shaft and tighten to 26 N´m

(19 ft. lbs.) torque (Fig. 90).

Fig. 87 Selector Shaft

1 ± SHIFT ASSEMBLY

2 ± SELECTOR SHAFT

Fig. 88 Reverse Idler Gear and Spacer

1 ± SPACER

2 ± REVERSE IDLER GEAR

Fig. 89 Reverse Idler Shaft

1 ± REVERSE IDLER SHAFT

Fig. 90 Reverse Idler Shaft Bolt

1 ± CASE

2 ± REVERSE IDLER SHAFT

3 ± REVERSE IDLER SHAFT BOLT

21 - 28 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 942 of 1285

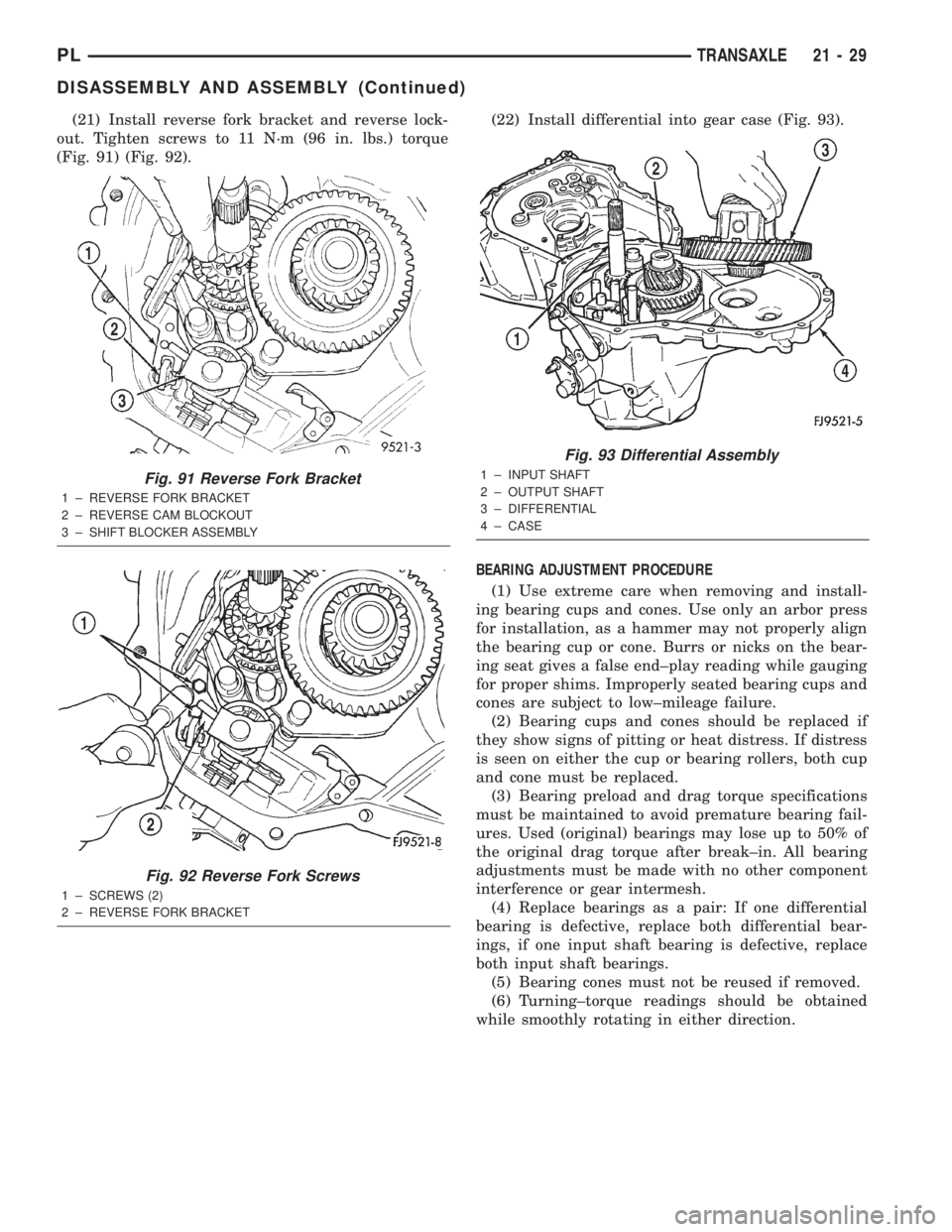

(21) Install reverse fork bracket and reverse lock-

out. Tighten screws to 11 N´m (96 in. lbs.) torque

(Fig. 91) (Fig. 92).(22) Install differential into gear case (Fig. 93).

BEARING ADJUSTMENT PROCEDURE

(1) Use extreme care when removing and install-

ing bearing cups and cones. Use only an arbor press

for installation, as a hammer may not properly align

the bearing cup or cone. Burrs or nicks on the bear-

ing seat gives a false end±play reading while gauging

for proper shims. Improperly seated bearing cups and

cones are subject to low±mileage failure.

(2) Bearing cups and cones should be replaced if

they show signs of pitting or heat distress. If distress

is seen on either the cup or bearing rollers, both cup

and cone must be replaced.

(3) Bearing preload and drag torque specifications

must be maintained to avoid premature bearing fail-

ures. Used (original) bearings may lose up to 50% of

the original drag torque after break±in. All bearing

adjustments must be made with no other component

interference or gear intermesh.

(4) Replace bearings as a pair: If one differential

bearing is defective, replace both differential bear-

ings, if one input shaft bearing is defective, replace

both input shaft bearings.

(5) Bearing cones must not be reused if removed.

(6) Turning±torque readings should be obtained

while smoothly rotating in either direction.

Fig. 91 Reverse Fork Bracket

1 ± REVERSE FORK BRACKET

2 ± REVERSE CAM BLOCKOUT

3 ± SHIFT BLOCKER ASSEMBLY

Fig. 92 Reverse Fork Screws

1 ± SCREWS (2)

2 ± REVERSE FORK BRACKET

Fig. 93 Differential Assembly

1 ± INPUT SHAFT

2 ± OUTPUT SHAFT

3 ± DIFFERENTIAL

4 ± CASE

PLTRANSAXLE 21 - 29

DISASSEMBLY AND ASSEMBLY (Continued)

Page 943 of 1285

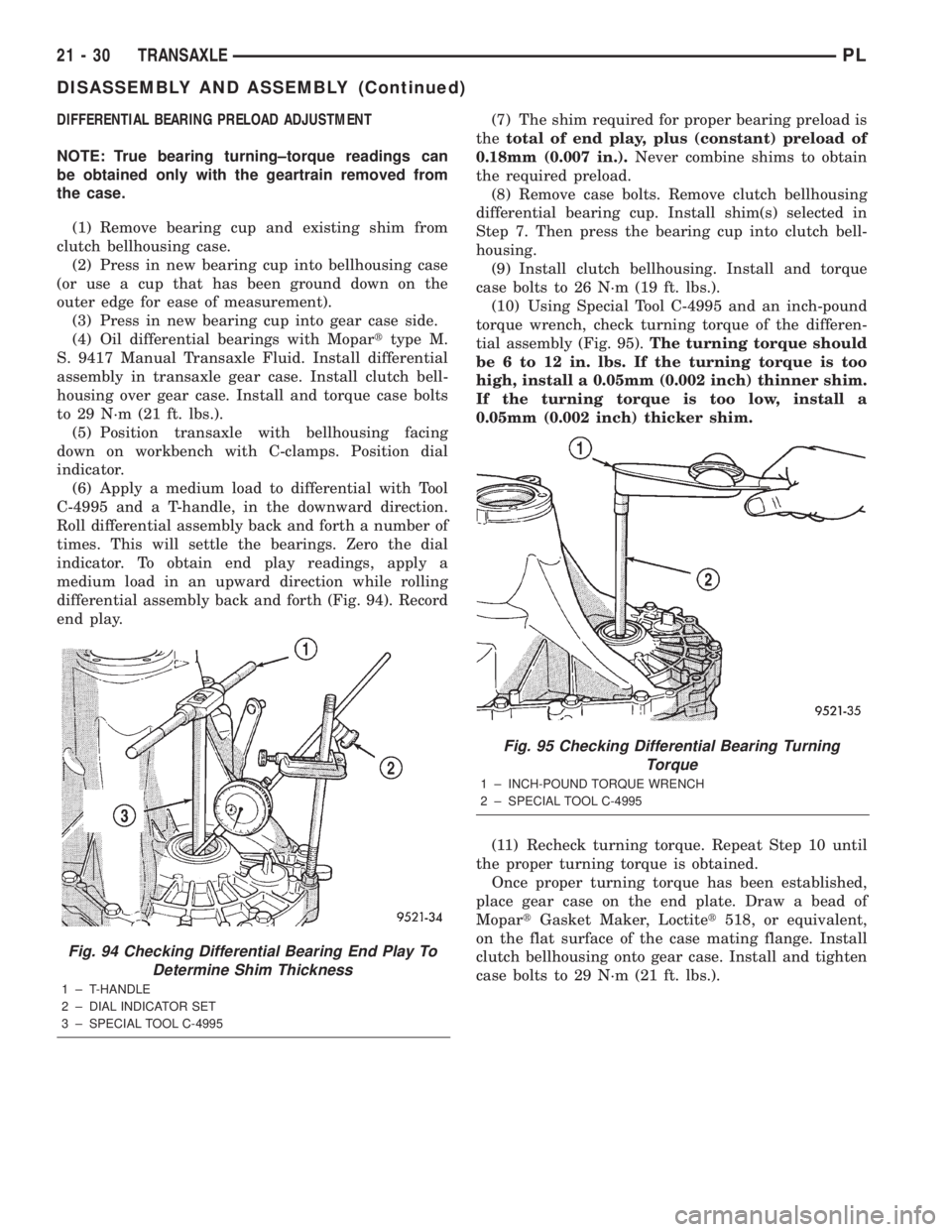

DIFFERENTIAL BEARING PRELOAD ADJUSTMENT

NOTE: True bearing turning±torque readings can

be obtained only with the geartrain removed from

the case.

(1) Remove bearing cup and existing shim from

clutch bellhousing case.

(2) Press in new bearing cup into bellhousing case

(or use a cup that has been ground down on the

outer edge for ease of measurement).

(3) Press in new bearing cup into gear case side.

(4) Oil differential bearings with Moparttype M.

S. 9417 Manual Transaxle Fluid. Install differential

assembly in transaxle gear case. Install clutch bell-

housing over gear case. Install and torque case bolts

to 29 N´m (21 ft. lbs.).

(5) Position transaxle with bellhousing facing

down on workbench with C-clamps. Position dial

indicator.

(6) Apply a medium load to differential with Tool

C-4995 and a T-handle, in the downward direction.

Roll differential assembly back and forth a number of

times. This will settle the bearings. Zero the dial

indicator. To obtain end play readings, apply a

medium load in an upward direction while rolling

differential assembly back and forth (Fig. 94). Record

end play.(7) The shim required for proper bearing preload is

thetotal of end play, plus (constant) preload of

0.18mm (0.007 in.).Never combine shims to obtain

the required preload.

(8) Remove case bolts. Remove clutch bellhousing

differential bearing cup. Install shim(s) selected in

Step 7. Then press the bearing cup into clutch bell-

housing.

(9) Install clutch bellhousing. Install and torque

case bolts to 26 N´m (19 ft. lbs.).

(10) Using Special Tool C-4995 and an inch-pound

torque wrench, check turning torque of the differen-

tial assembly (Fig. 95).The turning torque should

be 6 to 12 in. lbs. If the turning torque is too

high, install a 0.05mm (0.002 inch) thinner shim.

If the turning torque is too low, install a

0.05mm (0.002 inch) thicker shim.

(11) Recheck turning torque. Repeat Step 10 until

the proper turning torque is obtained.

Once proper turning torque has been established,

place gear case on the end plate. Draw a bead of

MopartGasket Maker, Loctitet518, or equivalent,

on the flat surface of the case mating flange. Install

clutch bellhousing onto gear case. Install and tighten

case bolts to 29 N´m (21 ft. lbs.).

Fig. 94 Checking Differential Bearing End Play To

Determine Shim Thickness

1 ± T-HANDLE

2 ± DIAL INDICATOR SET

3 ± SPECIAL TOOL C-4995

Fig. 95 Checking Differential Bearing Turning

Torque

1 ± INCH-POUND TORQUE WRENCH

2 ± SPECIAL TOOL C-4995

21 - 30 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 944 of 1285

INPUT SHAFT

DISASSEMBLY

Before disassembly of the input shaft, it is neces-

sary to check the synchronizer stop ring gap. Use a

feeler gauge to measure the gaps between the stop

rings and the speed gears. The correct gaps are listed

below:

²1stÐ1.04-1.72 mm (0.041-0.069 in).

²2ndÐ0.94-1.72 mm (0.038-0.069 in).

²3rdÐ1.37-1.93 mm (0.054-0.076 in).

²4thÐ1.41-1.97 mm (0.056-0.078 in).

²5thÐ1.37-1.93 mm (0.054-0.076 in).

If a stop ring gap does not fall within the specifi-

cations, it must be inspected for wear and replaced.

If the 1st or 2nd synchronizer stop ring is worn

beyond specifications, the complete output shaft

assembly must be replaced.

The input shaft incorporates the 3rd, 4th, and 5th

speed gears and synchronizers on the assembly (Fig.

96).(1) Install bearing splitter behind 5th speed gear.

Remove snap ring at 5th synchronizer hub on input

shaft (Fig. 97).

(2) Remove synchronizer and gear using shop

press (Fig. 98).

Fig. 96 Input Shaft

1 ± INPUT SHAFT

2 ± STOP RING

3 ± SLEEVE

4 ± 5TH SPEED GEAR

5 ± STOP RING

6 ± SLEEVE

7 ± 4TH SPEED GEAR

8 ± STOP RING

9 ± 3RD SPEED GEAR

Fig. 97 5th Synchro and Hub Snap Ring Removal

1 ± SNAP RING PLIERS

2 ± INPUT SHAFT

3 ± BEARING SPLITTER

4 ± SNAP RING

Fig. 98 Remove Synchronizer Using Shop Press

1 ± PRESS RAM

2 ± INPUT SHAFT

3 ± BEARING SPLITTER

4 ± SYNCHRONIZER ASSEMBLY

PLTRANSAXLE 21 - 31

DISASSEMBLY AND ASSEMBLY (Continued)

Page 945 of 1285

(3) Remove caged needle bearing (Fig. 99).

(4) Remove 4-5 gears split thrust washer ring (Fig.

100).(5) Remove split thrust washer (Fig. 101).

(6) Remove split thrust washer separation pin

(Fig. 102).

Fig. 99 Caged Needle Bearing Removal

1 ± INPUT SHAFT

2 ± CAGED NEEDLE BEARING

Fig. 100 Split Thrust Washer Ring Removal

1 ± SPLIT THRUST WASHER RING

2 ± INPUT SHAFT

Fig. 101 Split Thrust Washer Removal

1 ± INPUT SHAFT

2 ± SPLIT THRUST WASHER

Fig. 102 Split Thrust Washer Separation Pin

1 ± SEPARATION PIN

2 ± INPUT SHAFT

3 ± PLIERS

21 - 32 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 946 of 1285

(7) Remove 4th gear (Fig. 103).

(8) Remove 4th gear caged needle bearing (Fig.

104). Check the caged needle bearing for a broken

retention spring.(9) Remove blocking ring. Remove 3-4 synchronizer

hub retaining snap ring (Fig. 105).

(10) Install input shaft in shop press. Using bear-

ing splitter, remove 3-4 synchronizer and 3rd gear

(Fig. 106).

(11) Remove 3rd gear caged needle bearing (Fig.

107). Check the caged needle bearing for a broken

retention spring.

(12) Inspect the input shaft for worn or damaged

bearing races or chipped gear teeth. Replace as nec-

essary.

Fig. 103 4th Gear Removal

1 ± INPUT SHAFT

2 ± 4TH GEAR

Fig. 104 Caged Needle Bearing Removal

1 ± INPUT SHAFT

2 ± CAGED NEEDLE BEARING

Fig. 105 3-4 Synchronizer Hub Snap Ring

1 ± SNAP RING PLIERS

2 ± SYNCHRO SNAP RING

3 ± SYNCHRONIZER ASSEMBLY

Fig. 106 3rd Gear Removal

1 ± PRESS RAM

2 ± INPUT SHAFT

3 ± 3RD GEAR

4 ± SYNCHRONIZER ASSEMBLY

PLTRANSAXLE 21 - 33

DISASSEMBLY AND ASSEMBLY (Continued)

Page 947 of 1285

ASSEMBLY

The snap rings that are used on the input shaft

are available in select fit sizes. Use the thickest snap

ring that fits in each snap ring groove.

(1) Place input shaft into shop press.

(2) Install 3rd gear caged needle bearing on input

shaft.

(3) Install 3rd gear and 3-4 synchronizer onto

input shaft. Install Tool #C-3717 over input shaft and

press on synchronizer hub and 3rd gear (Fig. 108).

The synchronizer hub has the letterUstamped on

the top face of the hub. This designates that the hub

must be installed with theUfacing upward.(4) Install 3-4 synchronizer snap ring into slot on

input shaft.

(5) Install blocking ring into 3-4 synchronizer.

Install 4th gear caged needle bearing.

(6) Install 4th gear onto input shaft.

(7) Install 4-5 split thrust washer separation pin

(Fig. 109).

(8) Install split thrust washer onto input shaft

(Fig. 110).

Fig. 107 3rd Gear Caged Needle Bearing

1 ± INPUT SHAFT

2 ± 3RD GEAR CAGED NEEDLE BEARING

Fig. 108 Press On 3rd Gear Synchronizer Hub

1 ± PRESS RAM

2 ± SPECIAL TOOL C-3717

3 ± BEARING SPLITTER

4 ± 3RD GEAR SYNCHRONIZER ASSEMBLY

Fig. 109 Split Thrust Washer Separation Pin

Installation

1 ± SEPARATION PIN

2 ± INPUT SHAFT

3 ± PLIERS

Fig. 110 Split Thrust Washer Installation

1 ± INPUT SHAFT

2 ± SPLIT THRUST WASHER

21 - 34 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 948 of 1285

(9) Install split thrust washer retaining ring (Fig.

111).

(10) Install 5th gear caged needle bearing (Fig.

112).

(11) Using special tool #C-3717, install 5th speed

gear and synchronizer (Fig. 113). The 5th gear syn-

chronizer hub has the letterSstamped on the top

face of the hub. This designates that the hub must be

installed with theSfacing upward.

(12) Install 5th gear synchronizer snap ring (Fig.

114).

Fig. 111 Retaining Ring Installation

1 ± SPLIT THRUST WASHER RING

2 ± INPUT SHAFT

Fig. 112 Caged Needle Bearing Installation

1 ± INPUT SHAFT

2 ± CAGED NEEDLE BEARING

Fig. 113 5th Speed Gear Installation

1 ± PRESS RAM

2 ± SPECIAL TOOL C-3717

3 ± SYNCHRONIZER ASSEMBLY

4 ± BEARING SPLITTER

5 ± 5TH SPEED GEAR

Fig. 114 5th Gear Synchronizer Snap Ring

Installation

1 ± SNAP RING PLIERS

2 ± INPUT SHAFT

3 ± BEARING SPLITTER

4 ± SNAP RING

PLTRANSAXLE 21 - 35

DISASSEMBLY AND ASSEMBLY (Continued)

Page 949 of 1285

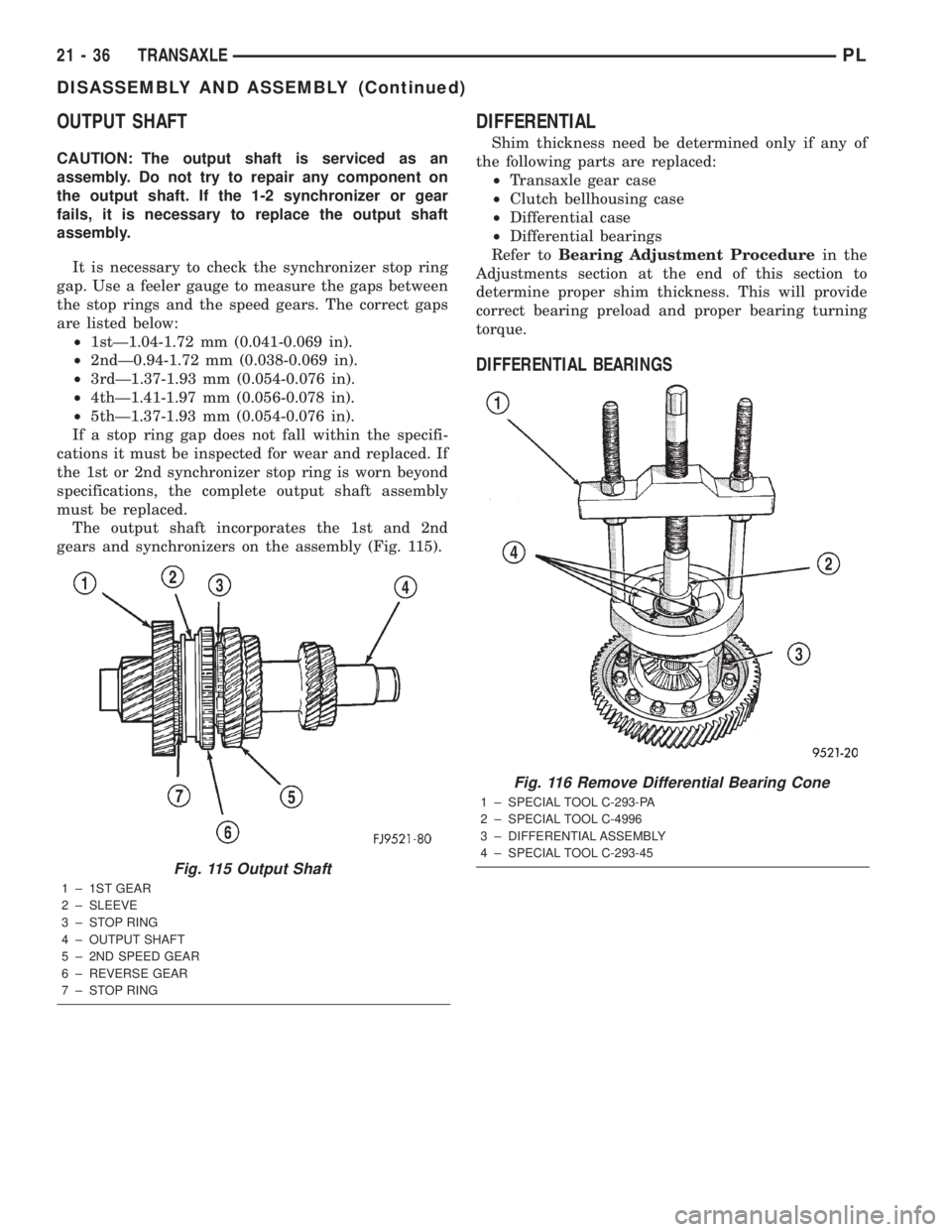

OUTPUT SHAFT

CAUTION: The output shaft is serviced as an

assembly. Do not try to repair any component on

the output shaft. If the 1-2 synchronizer or gear

fails, it is necessary to replace the output shaft

assembly.

It is necessary to check the synchronizer stop ring

gap. Use a feeler gauge to measure the gaps between

the stop rings and the speed gears. The correct gaps

are listed below:

²1stÐ1.04-1.72 mm (0.041-0.069 in).

²2ndÐ0.94-1.72 mm (0.038-0.069 in).

²3rdÐ1.37-1.93 mm (0.054-0.076 in).

²4thÐ1.41-1.97 mm (0.056-0.078 in).

²5thÐ1.37-1.93 mm (0.054-0.076 in).

If a stop ring gap does not fall within the specifi-

cations it must be inspected for wear and replaced. If

the 1st or 2nd synchronizer stop ring is worn beyond

specifications, the complete output shaft assembly

must be replaced.

The output shaft incorporates the 1st and 2nd

gears and synchronizers on the assembly (Fig. 115).

DIFFERENTIAL

Shim thickness need be determined only if any of

the following parts are replaced:

²Transaxle gear case

²Clutch bellhousing case

²Differential case

²Differential bearings

Refer toBearing Adjustment Procedurein the

Adjustments section at the end of this section to

determine proper shim thickness. This will provide

correct bearing preload and proper bearing turning

torque.

DIFFERENTIAL BEARINGS

Fig. 115 Output Shaft

1 ± 1ST GEAR

2 ± SLEEVE

3 ± STOP RING

4 ± OUTPUT SHAFT

5 ± 2ND SPEED GEAR

6 ± REVERSE GEAR

7 ± STOP RING

Fig. 116 Remove Differential Bearing Cone

1 ± SPECIAL TOOL C-293-PA

2 ± SPECIAL TOOL C-4996

3 ± DIFFERENTIAL ASSEMBLY

4 ± SPECIAL TOOL C-293-45

21 - 36 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 950 of 1285

RING GEAR

CAUTION: Always install new ring gear bolts.

Tighten ring gear bolts to 81 N´m (60 ft. lbs.) torque.

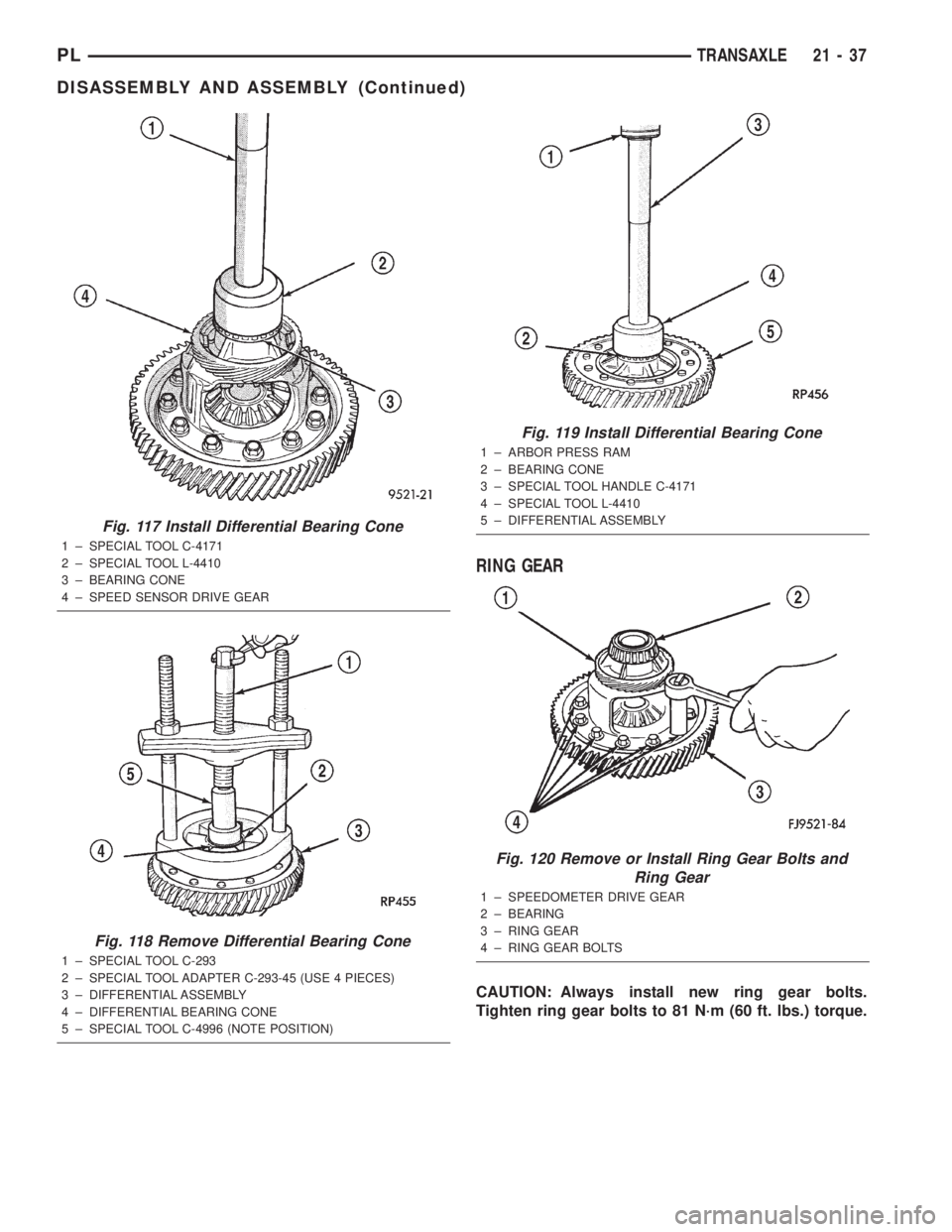

Fig. 117 Install Differential Bearing Cone

1 ± SPECIAL TOOL C-4171

2 ± SPECIAL TOOL L-4410

3 ± BEARING CONE

4 ± SPEED SENSOR DRIVE GEAR

Fig. 118 Remove Differential Bearing Cone

1 ± SPECIAL TOOL C-293

2 ± SPECIAL TOOL ADAPTER C-293-45 (USE 4 PIECES)

3 ± DIFFERENTIAL ASSEMBLY

4 ± DIFFERENTIAL BEARING CONE

5 ± SPECIAL TOOL C-4996 (NOTE POSITION)

Fig. 119 Install Differential Bearing Cone

1 ± ARBOR PRESS RAM

2 ± BEARING CONE

3 ± SPECIAL TOOL HANDLE C-4171

4 ± SPECIAL TOOL L-4410

5 ± DIFFERENTIAL ASSEMBLY

Fig. 120 Remove or Install Ring Gear Bolts and

Ring Gear

1 ± SPEEDOMETER DRIVE GEAR

2 ± BEARING

3 ± RING GEAR

4 ± RING GEAR BOLTS

PLTRANSAXLE 21 - 37

DISASSEMBLY AND ASSEMBLY (Continued)