mirror DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1 of 1285

GROUP TAB LOCATORINIntroductionINaIntroduction0Lubrication and Maintenance2Suspension3Differential and Driveline5Brakes6Clutch7Cooling8ABattery8BStarting8CCharging System8DIgnition System8EInstrument Panel and Systems8EaInstrument Panel and Systems8FAudio System8GHorns8HVehicle Speed Control System8JTurn Signal and Flashers8KWindshield Wipers and Washers8LLamps8LaLamps8MRestraint System8NElectrically Heated Systems8OPower Distribution Systems8PPower Door Locks8QImmobilizer System8SPower Windows8TPower Mirrors8TaPower Mirrors8UChime Warning/Reminder System8WWiring Diagrams - LHD and RHD9Engine11Exhaust System13Frame and Bumpers14Fuel System19Steering21Transaxle22Tires and Wheels23Body24Heating and Air Conditioning24aHeating and Air Conditioning25Emission Control Systems

Page 214 of 1285

be checked. To determine if a high current draw con-

dition exists first check the vehicle with a test lamp.

(1) Verify that all electrical accessories are OFF.

²Remove key from ignition switch

²Turn off all lights

²Trunk lid is closed

²Engine compartment hood lamp is disconnected

or lamp removed

²Map lamp on rear view mirror

²Glove box door is closed

²Sun visor vanity lights are OFF

²All doors are closed

²Allow the ignition key lamp system to time out

in approximately 30 seconds, if equipped.

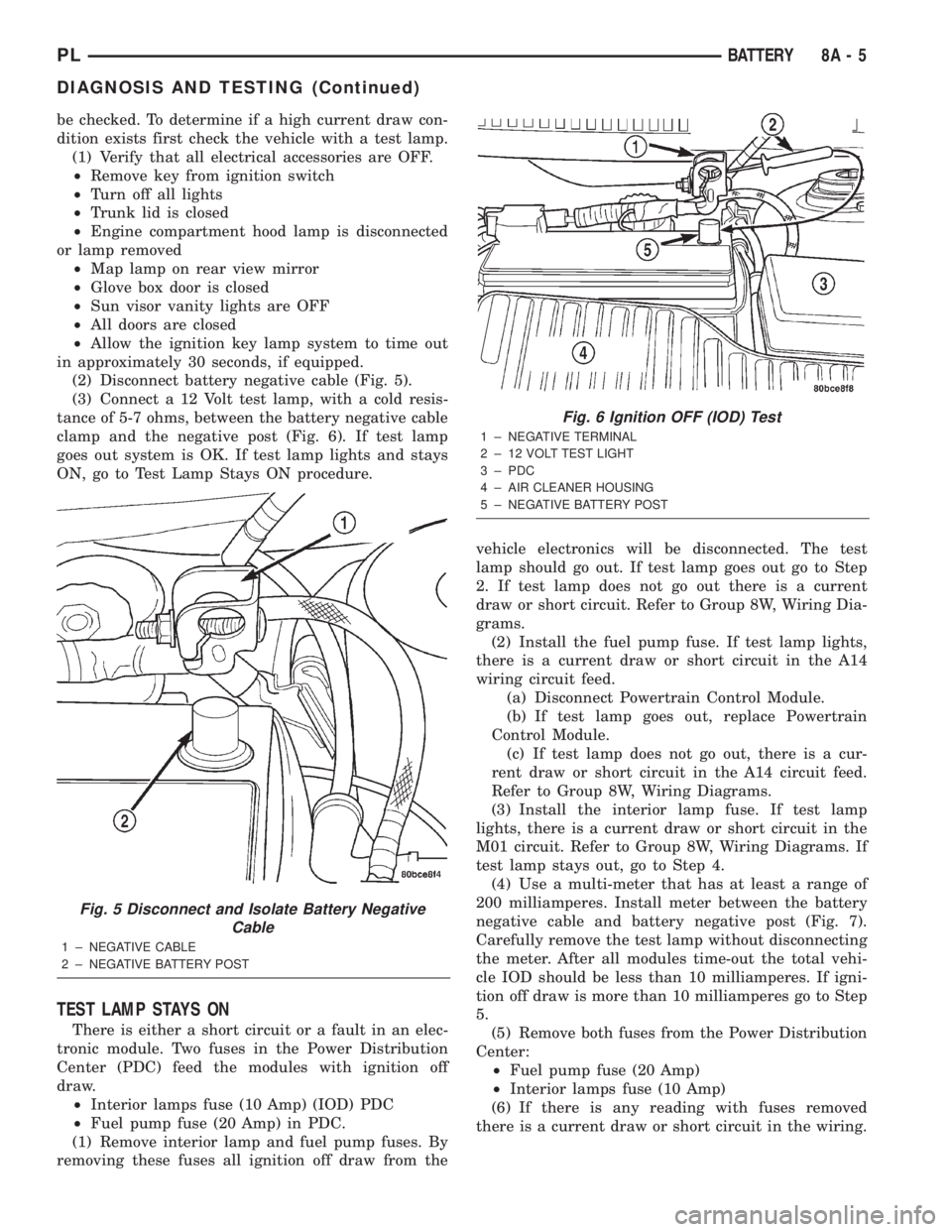

(2) Disconnect battery negative cable (Fig. 5).

(3) Connect a 12 Volt test lamp, with a cold resis-

tance of 5-7 ohms, between the battery negative cable

clamp and the negative post (Fig. 6). If test lamp

goes out system is OK. If test lamp lights and stays

ON, go to Test Lamp Stays ON procedure.

TEST LAMP STAYS ON

There is either a short circuit or a fault in an elec-

tronic module. Two fuses in the Power Distribution

Center (PDC) feed the modules with ignition off

draw.

²Interior lamps fuse (10 Amp) (IOD) PDC

²Fuel pump fuse (20 Amp) in PDC.

(1) Remove interior lamp and fuel pump fuses. By

removing these fuses all ignition off draw from thevehicle electronics will be disconnected. The test

lamp should go out. If test lamp goes out go to Step

2. If test lamp does not go out there is a current

draw or short circuit. Refer to Group 8W, Wiring Dia-

grams.

(2) Install the fuel pump fuse. If test lamp lights,

there is a current draw or short circuit in the A14

wiring circuit feed.

(a) Disconnect Powertrain Control Module.

(b) If test lamp goes out, replace Powertrain

Control Module.

(c) If test lamp does not go out, there is a cur-

rent draw or short circuit in the A14 circuit feed.

Refer to Group 8W, Wiring Diagrams.

(3) Install the interior lamp fuse. If test lamp

lights, there is a current draw or short circuit in the

M01 circuit. Refer to Group 8W, Wiring Diagrams. If

test lamp stays out, go to Step 4.

(4) Use a multi-meter that has at least a range of

200 milliamperes. Install meter between the battery

negative cable and battery negative post (Fig. 7).

Carefully remove the test lamp without disconnecting

the meter. After all modules time-out the total vehi-

cle IOD should be less than 10 milliamperes. If igni-

tion off draw is more than 10 milliamperes go to Step

5.

(5) Remove both fuses from the Power Distribution

Center:

²Fuel pump fuse (20 Amp)

²Interior lamps fuse (10 Amp)

(6) If there is any reading with fuses removed

there is a current draw or short circuit in the wiring.

Fig. 5 Disconnect and Isolate Battery Negative

Cable

1 ± NEGATIVE CABLE

2 ± NEGATIVE BATTERY POST

Fig. 6 Ignition OFF (IOD) Test

1 ± NEGATIVE TERMINAL

2 ± 12 VOLT TEST LIGHT

3 ± PDC

4 ± AIR CLEANER HOUSING

5 ± NEGATIVE BATTERY POST

PLBATTERY 8A - 5

DIAGNOSIS AND TESTING (Continued)

Page 255 of 1285

(19) Disconnect one left side harness connector at

top left of instrument panel for vanity and rear view

mirrors.

(20) Pull off the hvac control head knobs.

(21) Remove two screws retaining the top front of

the center bezel.

(22) Using a trim stick, gently pry out on the

instrument panel center bezel and remove.

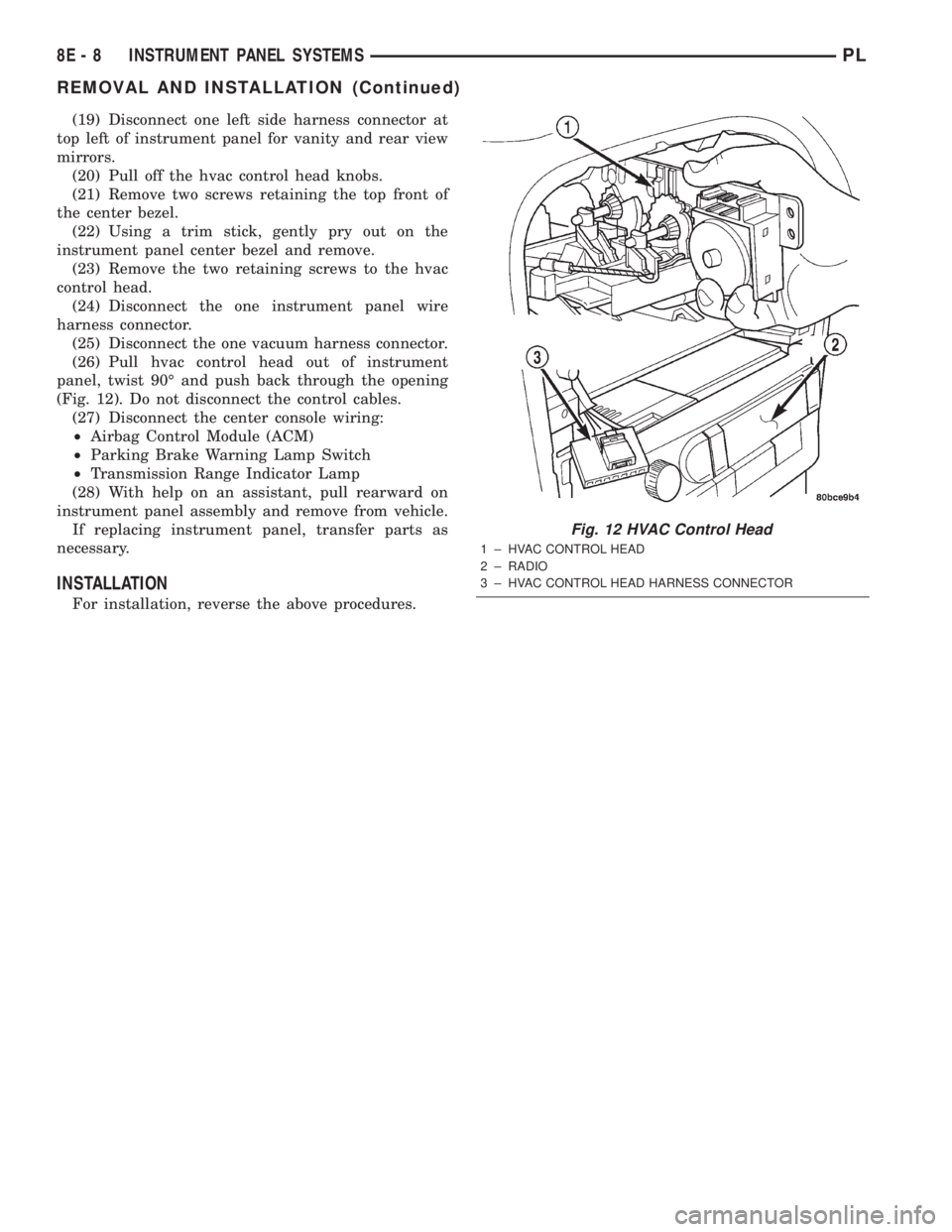

(23) Remove the two retaining screws to the hvac

control head.

(24) Disconnect the one instrument panel wire

harness connector.

(25) Disconnect the one vacuum harness connector.

(26) Pull hvac control head out of instrument

panel, twist 90É and push back through the opening

(Fig. 12). Do not disconnect the control cables.

(27) Disconnect the center console wiring:

²Airbag Control Module (ACM)

²Parking Brake Warning Lamp Switch

²Transmission Range Indicator Lamp

(28) With help on an assistant, pull rearward on

instrument panel assembly and remove from vehicle.

If replacing instrument panel, transfer parts as

necessary.

INSTALLATION

For installation, reverse the above procedures.

Fig. 12 HVAC Control Head

1 ± HVAC CONTROL HEAD

2 ± RADIO

3 ± HVAC CONTROL HEAD HARNESS CONNECTOR

8E - 8 INSTRUMENT PANEL SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 382 of 1285

POWER MIRRORS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

INTRODUCTION..........................1

DIAGNOSIS AND TESTING

MIRROR SWITCH TEST....................1

POWER MIRROR MOTOR..................2

REMOVAL AND INSTALLATION

INSIDE MIRROR/READING LAMPS

ASSEMBLY.............................2INSIDE MIRROR/READING LAMPS

BULB/LENS............................3

MIRROR SWITCH.........................3

POWER MIRROR ASSEMBLY................3

DESCRIPTION AND OPERATION

INTRODUCTION

Electrically operated power mirrors are available

on all car lines. The mirrors are controlled by a sin-

gle switch assembly located on the driver's door trim

panel. The push button rocker switch uses L (left)

and R (right) for mirror selection and a button to

push for the desired direction of mirror movement.

The motors which operate the mirrors are part of

the mirror assembly and cannot be replaced sepa-

rately.

The Ignition Off Draw fuse is included in the

power mirror circuity and should be checked if the

mirrors are inoperative.

DIAGNOSIS AND TESTING

MIRROR SWITCH TEST

(1) Remove power mirror switch from mounting

position. Refer to Mirror Switch Removal and Instal-

lation in this section.

(2) Using an ohmmeter, test for continuity between

the terminals of the switch as shown in the Mirror

Switch Continuity table.

(3) If test results are not obtained as shown in the

Mirror Switch Continuity table, replace the switch.

Refer to Group 8W-Wiring Diagrams for Connector

Pin-Outs and Circuit Diagrams.

PLPOWER MIRRORS 8T - 1

Page 383 of 1285

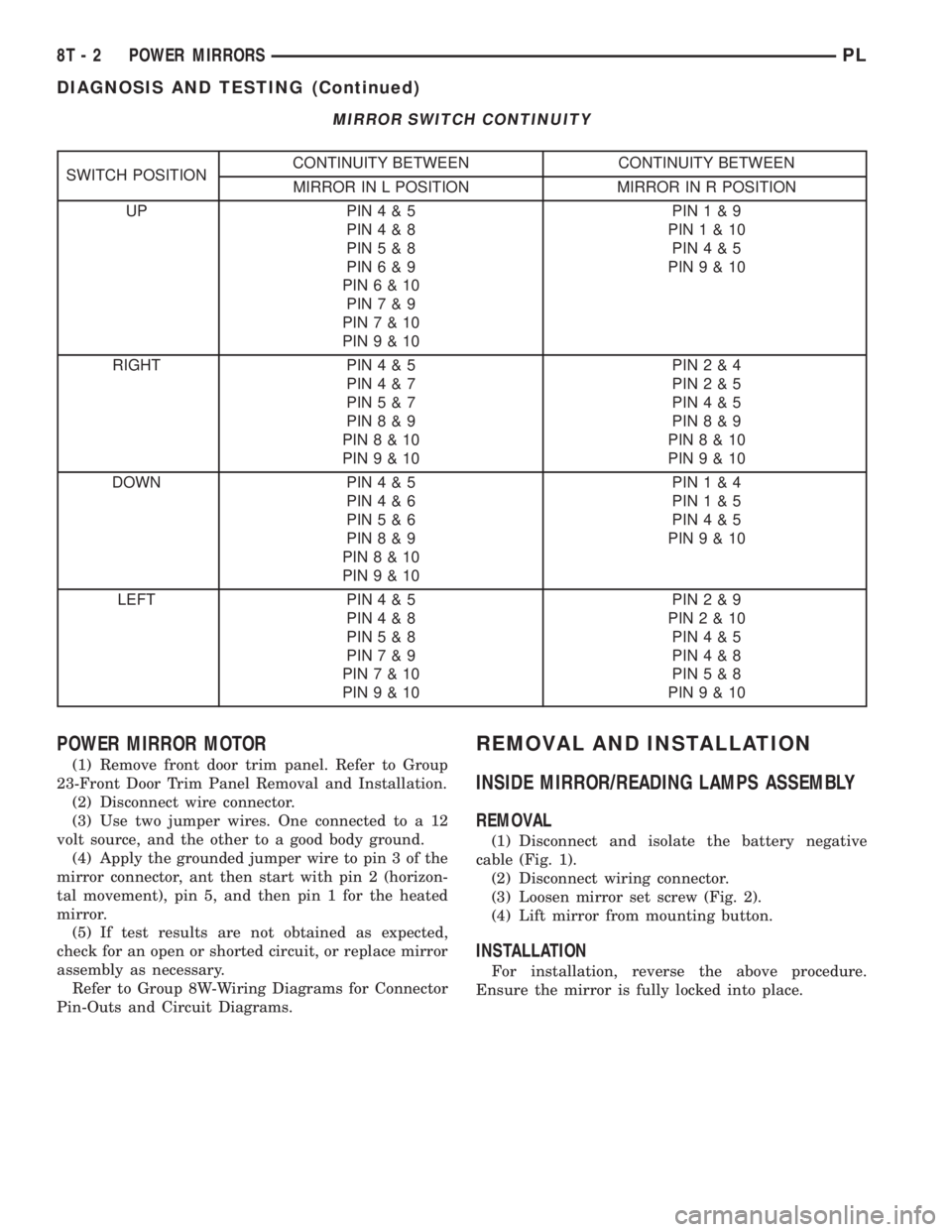

MIRROR SWITCH CONTINUITY

SWITCH POSITIONCONTINUITY BETWEEN CONTINUITY BETWEEN

MIRROR IN L POSITION MIRROR IN R POSITION

UP PIN4&5

PIN4&8

PIN5&8

PIN6&9

PIN6&10

PIN7&9

PIN7&10

PIN9&10PIN1&9

PIN1&10

PIN4&5

PIN9&10

RIGHT PIN4&5

PIN4&7

PIN5&7

PIN8&9

PIN8&10

PIN9&10PIN2&4

PIN2&5

PIN4&5

PIN8&9

PIN8&10

PIN9&10

DOWN PIN4&5

PIN4&6

PIN5&6

PIN8&9

PIN8&10

PIN9&10PIN1&4

PIN1&5

PIN4&5

PIN9&10

LEFT PIN4&5

PIN4&8

PIN5&8

PIN7&9

PIN7&10

PIN9&10PIN2&9

PIN2&10

PIN4&5

PIN4&8

PIN5&8

PIN9&10

POWER MIRROR MOTOR

(1) Remove front door trim panel. Refer to Group

23-Front Door Trim Panel Removal and Installation.

(2) Disconnect wire connector.

(3) Use two jumper wires. One connected to a 12

volt source, and the other to a good body ground.

(4) Apply the grounded jumper wire to pin 3 of the

mirror connector, ant then start with pin 2 (horizon-

tal movement), pin 5, and then pin 1 for the heated

mirror.

(5) If test results are not obtained as expected,

check for an open or shorted circuit, or replace mirror

assembly as necessary.

Refer to Group 8W-Wiring Diagrams for Connector

Pin-Outs and Circuit Diagrams.

REMOVAL AND INSTALLATION

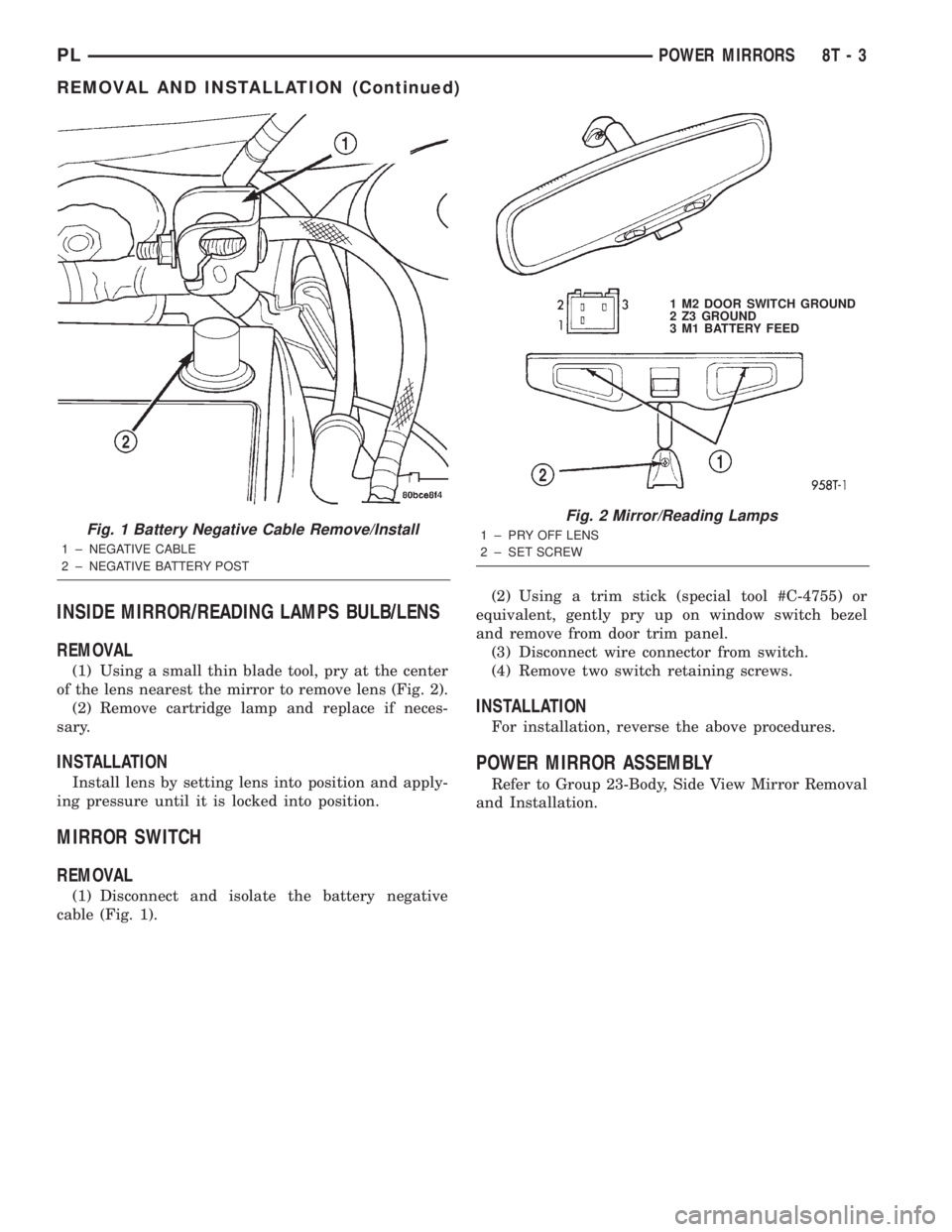

INSIDE MIRROR/READING LAMPS ASSEMBLY

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 1).

(2) Disconnect wiring connector.

(3) Loosen mirror set screw (Fig. 2).

(4) Lift mirror from mounting button.

INSTALLATION

For installation, reverse the above procedure.

Ensure the mirror is fully locked into place.

8T - 2 POWER MIRRORSPL

DIAGNOSIS AND TESTING (Continued)

Page 384 of 1285

INSIDE MIRROR/READING LAMPS BULB/LENS

REMOVAL

(1) Using a small thin blade tool, pry at the center

of the lens nearest the mirror to remove lens (Fig. 2).

(2) Remove cartridge lamp and replace if neces-

sary.

INSTALLATION

Install lens by setting lens into position and apply-

ing pressure until it is locked into position.

MIRROR SWITCH

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 1).(2) Using a trim stick (special tool #C-4755) or

equivalent, gently pry up on window switch bezel

and remove from door trim panel.

(3) Disconnect wire connector from switch.

(4) Remove two switch retaining screws.

INSTALLATION

For installation, reverse the above procedures.

POWER MIRROR ASSEMBLY

Refer to Group 23-Body, Side View Mirror Removal

and Installation.

Fig. 1 Battery Negative Cable Remove/Install

1 ± NEGATIVE CABLE

2 ± NEGATIVE BATTERY POST

Fig. 2 Mirror/Reading Lamps

1 ± PRY OFF LENS

2 ± SET SCREW1 M2 DOOR SWITCH GROUND

2 Z3 GROUND

3 M1 BATTERY FEED

PLPOWER MIRRORS 8T - 3

REMOVAL AND INSTALLATION (Continued)

Page 386 of 1285

POWER MIRRORS

TABLE OF CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION..........................1

DIAGNOSIS AND TESTING

POWER FOLD AWAY MIRROR SWITCH TEST...1POWER FOLD AWAY MIRROR MOTOR........1

REMOVAL AND INSTALLATION

POWER FOLD-AWAY MIRROR SWITCH.......1

POWER FOLD-AWAY MIRROR...............2

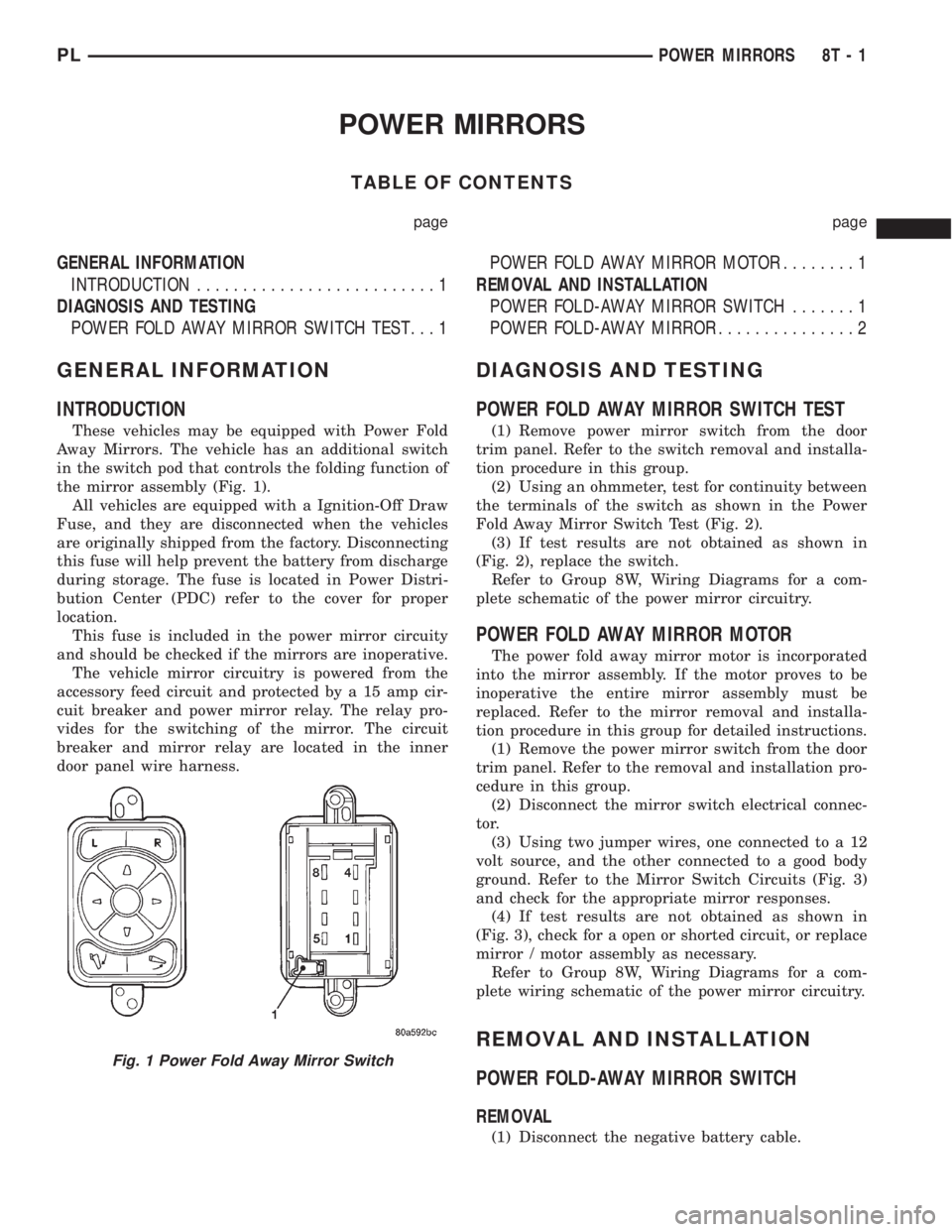

GENERAL INFORMATION

INTRODUCTION

These vehicles may be equipped with Power Fold

Away Mirrors. The vehicle has an additional switch

in the switch pod that controls the folding function of

the mirror assembly (Fig. 1).

All vehicles are equipped with a Ignition-Off Draw

Fuse, and they are disconnected when the vehicles

are originally shipped from the factory. Disconnecting

this fuse will help prevent the battery from discharge

during storage. The fuse is located in Power Distri-

bution Center (PDC) refer to the cover for proper

location.

This fuse is included in the power mirror circuity

and should be checked if the mirrors are inoperative.

The vehicle mirror circuitry is powered from the

accessory feed circuit and protected by a 15 amp cir-

cuit breaker and power mirror relay. The relay pro-

vides for the switching of the mirror. The circuit

breaker and mirror relay are located in the inner

door panel wire harness.

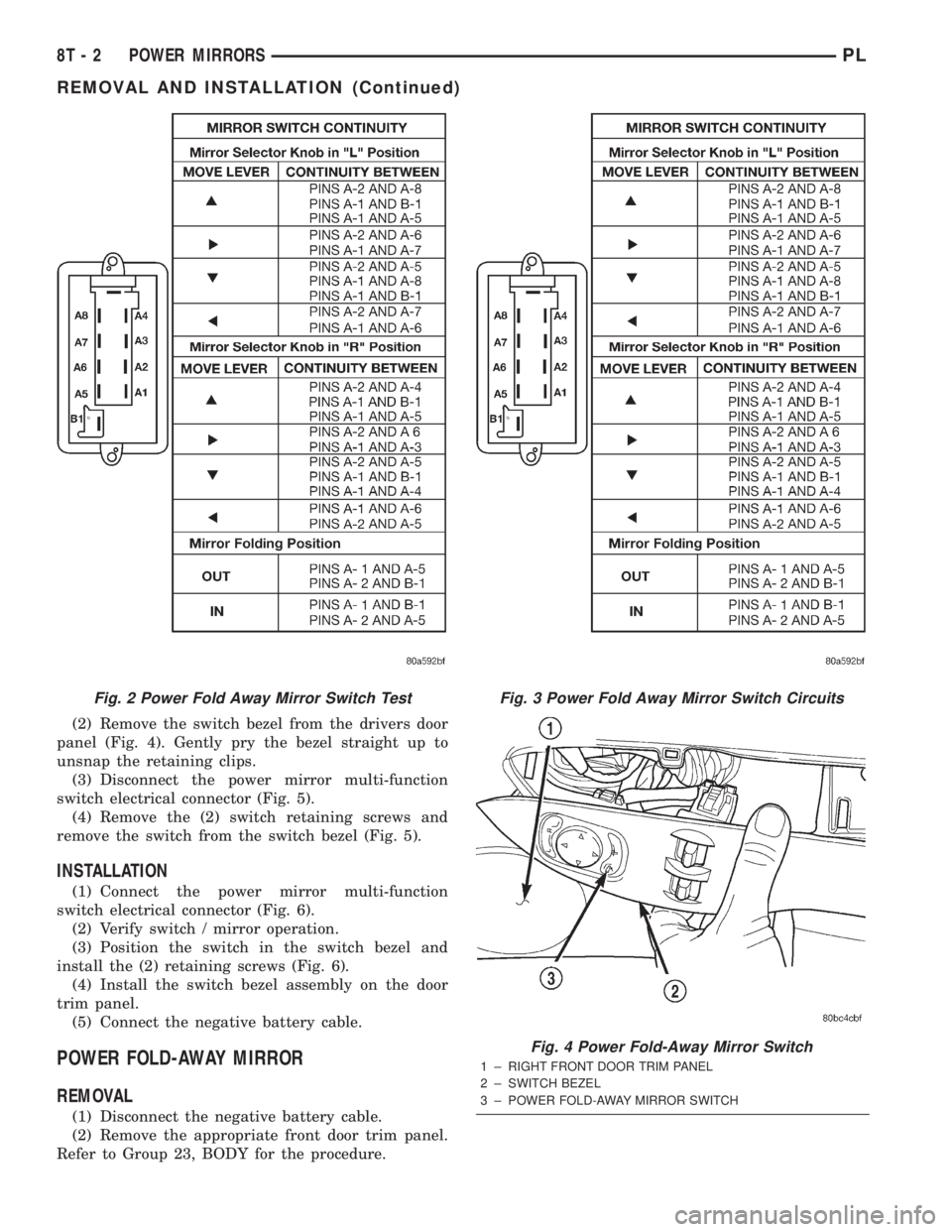

DIAGNOSIS AND TESTING

POWER FOLD AWAY MIRROR SWITCH TEST

(1) Remove power mirror switch from the door

trim panel. Refer to the switch removal and installa-

tion procedure in this group.

(2) Using an ohmmeter, test for continuity between

the terminals of the switch as shown in the Power

Fold Away Mirror Switch Test (Fig. 2).

(3) If test results are not obtained as shown in

(Fig. 2), replace the switch.

Refer to Group 8W, Wiring Diagrams for a com-

plete schematic of the power mirror circuitry.

POWER FOLD AWAY MIRROR MOTOR

The power fold away mirror motor is incorporated

into the mirror assembly. If the motor proves to be

inoperative the entire mirror assembly must be

replaced. Refer to the mirror removal and installa-

tion procedure in this group for detailed instructions.

(1) Remove the power mirror switch from the door

trim panel. Refer to the removal and installation pro-

cedure in this group.

(2) Disconnect the mirror switch electrical connec-

tor.

(3) Using two jumper wires, one connected to a 12

volt source, and the other connected to a good body

ground. Refer to the Mirror Switch Circuits (Fig. 3)

and check for the appropriate mirror responses.

(4) If test results are not obtained as shown in

(Fig. 3), check for a open or shorted circuit, or replace

mirror / motor assembly as necessary.

Refer to Group 8W, Wiring Diagrams for a com-

plete wiring schematic of the power mirror circuitry.

REMOVAL AND INSTALLATION

POWER FOLD-AWAY MIRROR SWITCH

REMOVAL

(1) Disconnect the negative battery cable.

Fig. 1 Power Fold Away Mirror Switch

PLPOWER MIRRORS 8T - 1

Page 387 of 1285

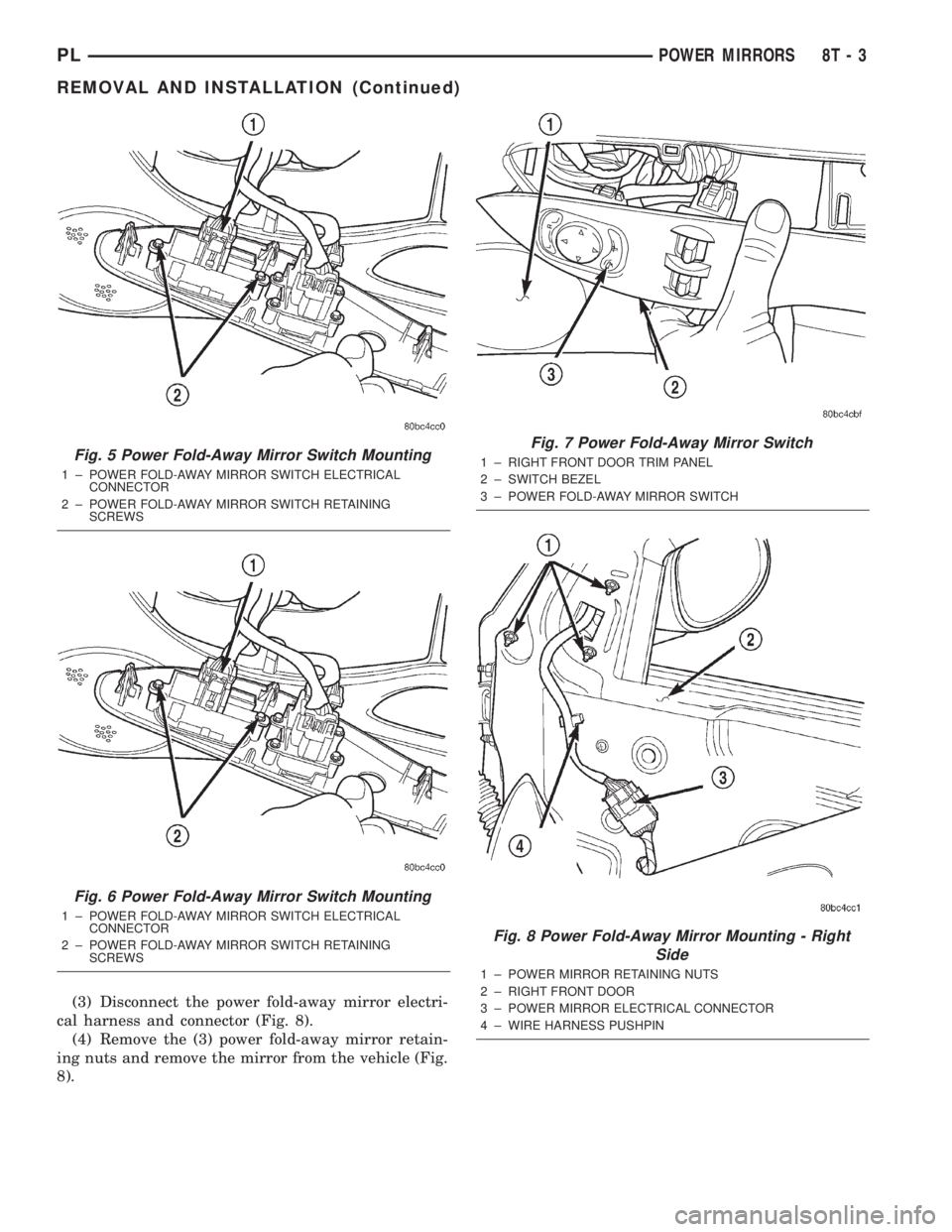

(2) Remove the switch bezel from the drivers door

panel (Fig. 4). Gently pry the bezel straight up to

unsnap the retaining clips.

(3) Disconnect the power mirror multi-function

switch electrical connector (Fig. 5).

(4) Remove the (2) switch retaining screws and

remove the switch from the switch bezel (Fig. 5).

INSTALLATION

(1) Connect the power mirror multi-function

switch electrical connector (Fig. 6).

(2) Verify switch / mirror operation.

(3) Position the switch in the switch bezel and

install the (2) retaining screws (Fig. 6).

(4) Install the switch bezel assembly on the door

trim panel.

(5) Connect the negative battery cable.

POWER FOLD-AWAY MIRROR

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the appropriate front door trim panel.

Refer to Group 23, BODY for the procedure.

Fig. 2 Power Fold Away Mirror Switch TestFig. 3 Power Fold Away Mirror Switch Circuits

Fig. 4 Power Fold-Away Mirror Switch

1 ± RIGHT FRONT DOOR TRIM PANEL

2 ± SWITCH BEZEL

3 ± POWER FOLD-AWAY MIRROR SWITCH

8T - 2 POWER MIRRORSPL

REMOVAL AND INSTALLATION (Continued)

Page 388 of 1285

(3) Disconnect the power fold-away mirror electri-

cal harness and connector (Fig. 8).

(4) Remove the (3) power fold-away mirror retain-

ing nuts and remove the mirror from the vehicle (Fig.

8).

Fig. 5 Power Fold-Away Mirror Switch Mounting

1 ± POWER FOLD-AWAY MIRROR SWITCH ELECTRICAL

CONNECTOR

2 ± POWER FOLD-AWAY MIRROR SWITCH RETAINING

SCREWS

Fig. 6 Power Fold-Away Mirror Switch Mounting

1 ± POWER FOLD-AWAY MIRROR SWITCH ELECTRICAL

CONNECTOR

2 ± POWER FOLD-AWAY MIRROR SWITCH RETAINING

SCREWS

Fig. 7 Power Fold-Away Mirror Switch

1 ± RIGHT FRONT DOOR TRIM PANEL

2 ± SWITCH BEZEL

3 ± POWER FOLD-AWAY MIRROR SWITCH

Fig. 8 Power Fold-Away Mirror Mounting - Right

Side

1 ± POWER MIRROR RETAINING NUTS

2 ± RIGHT FRONT DOOR

3 ± POWER MIRROR ELECTRICAL CONNECTOR

4 ± WIRE HARNESS PUSHPIN

PLPOWER MIRRORS 8T - 3

REMOVAL AND INSTALLATION (Continued)

Page 389 of 1285

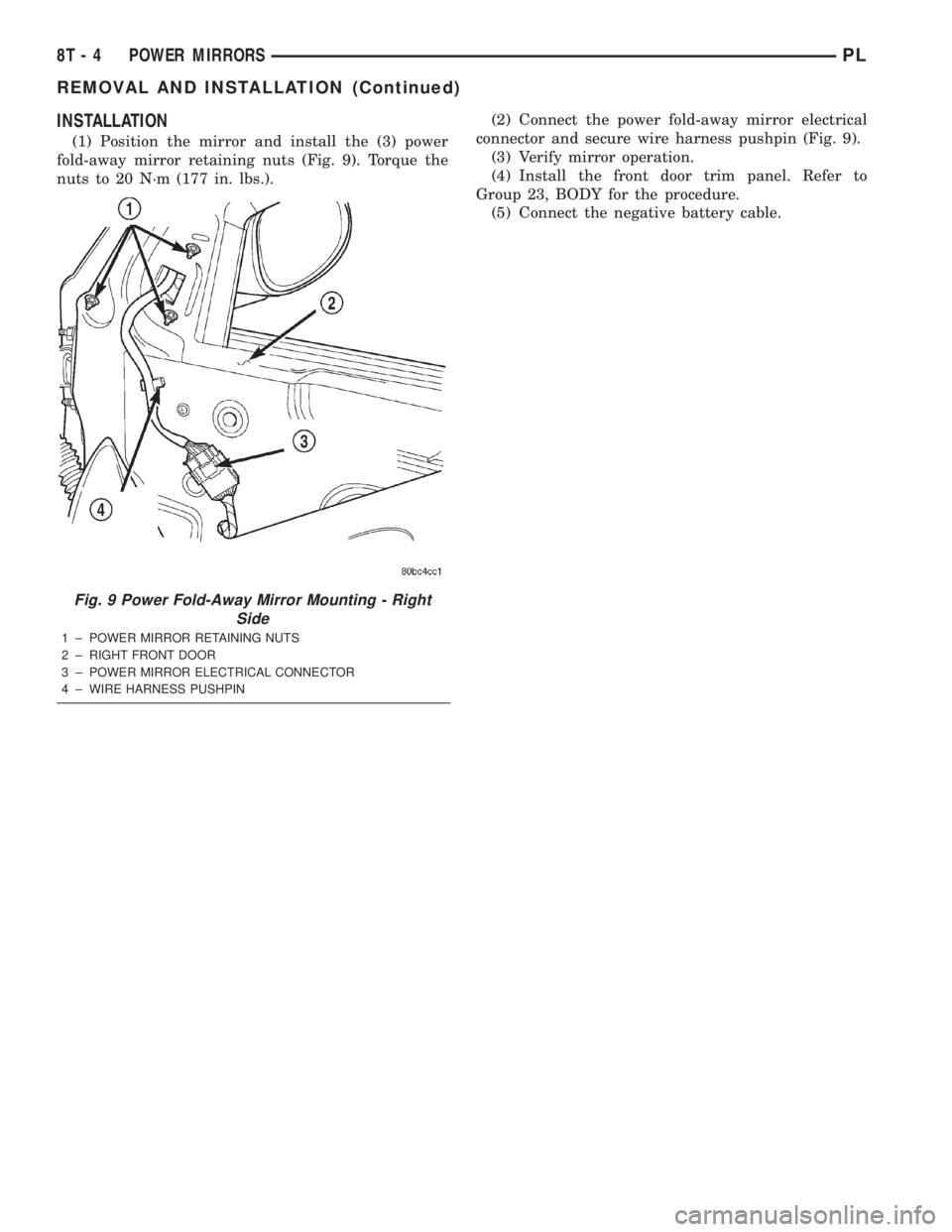

INSTALLATION

(1) Position the mirror and install the (3) power

fold-away mirror retaining nuts (Fig. 9). Torque the

nuts to 20 N´m (177 in. lbs.).(2) Connect the power fold-away mirror electrical

connector and secure wire harness pushpin (Fig. 9).

(3) Verify mirror operation.

(4) Install the front door trim panel. Refer to

Group 23, BODY for the procedure.

(5) Connect the negative battery cable.

Fig. 9 Power Fold-Away Mirror Mounting - Right

Side

1 ± POWER MIRROR RETAINING NUTS

2 ± RIGHT FRONT DOOR

3 ± POWER MIRROR ELECTRICAL CONNECTOR

4 ± WIRE HARNESS PUSHPIN

8T - 4 POWER MIRRORSPL

REMOVAL AND INSTALLATION (Continued)