check engine DODGE NEON SRT 2004 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: NEON SRT, Model: DODGE NEON SRT 2004 2.GPages: 200, PDF Size: 3.23 MB

Page 149 of 200

Engine Coolant Disposal

Used ethylene glycol based engine coolant is a regulated

substance requiring proper disposal. Check with your

local authorities to determine the disposal rules for your

community. Do not store ethylene glycol based engine

coolant in open containers or allow it to remain in

puddles on the ground. Prevent ingestion by animals or

children. If ingested by a child, contact a physician

immediately.

Selection Of Coolant

Use only the manufacturers recommended coolant, refer

to Recommended Fluids, Lubricants and Genuine Parts

for correct coolant type.

CAUTION!

Mixing of coolants other than specified (non-

HOAT), may result in engine damage that may not

be covered under the new vehicle warranty, and

decreased corrosion protection. If a non-HOAT cool-

ant is introduced into the cooling system in an

emergency, it should be replaced with the specified

coolant as soon as possible.

Do not use plain water alone or alcohol base anti-

freeze products. Do not use additional rust inhibi-

tors or antirust products, as they may not be compat-

ible with the radiator coolant and may plug the

radiator.

This vehicle has not been designed for use with

Propylene Glycol based coolants. Use of Propylene

Glycol based coolants is not recommended.

MAINTAINING YOUR VEHICLE 149

7

Page 151 of 200

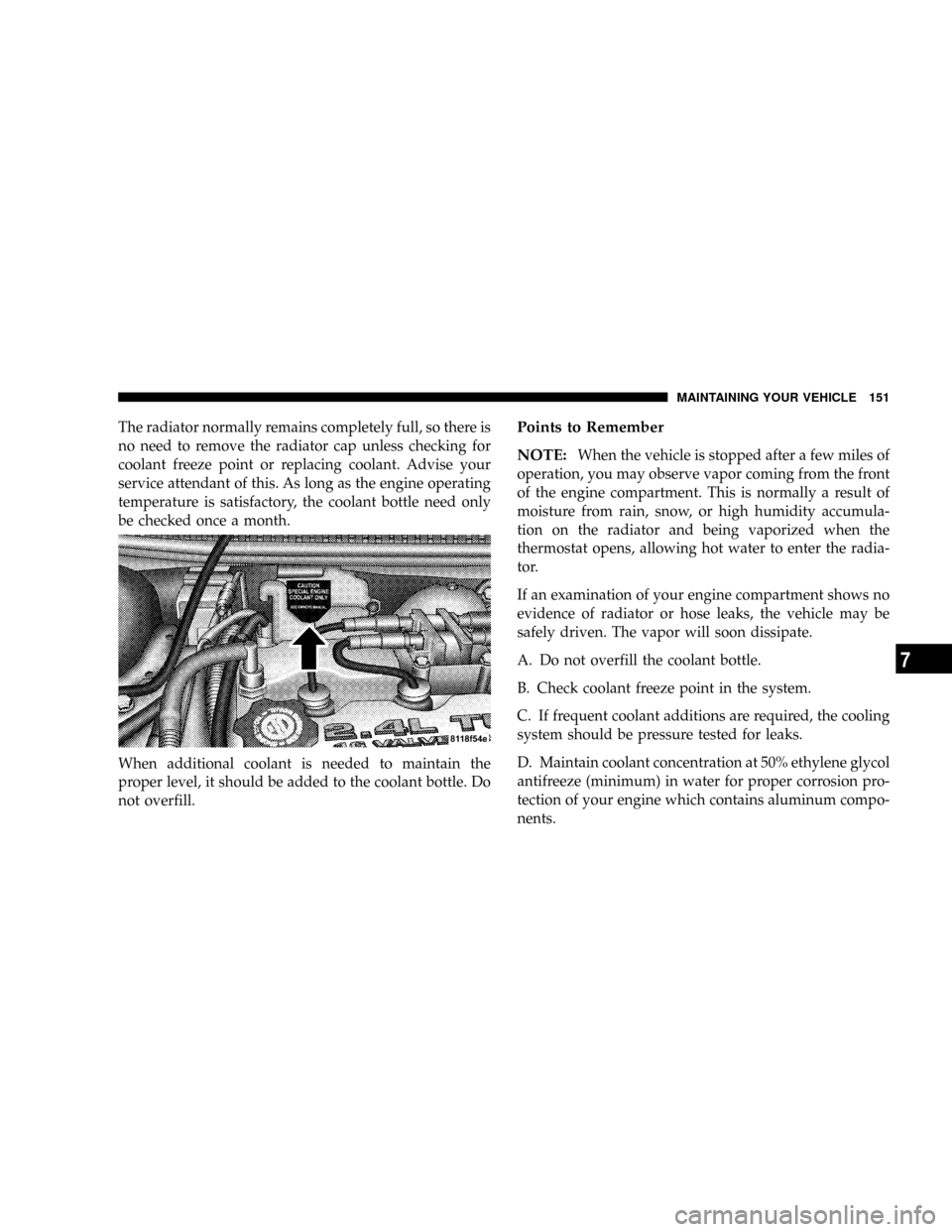

The radiator normally remains completely full, so there is

no need to remove the radiator cap unless checking for

coolant freeze point or replacing coolant. Advise your

service attendant of this. As long as the engine operating

temperature is satisfactory, the coolant bottle need only

be checked once a month.

When additional coolant is needed to maintain the

proper level, it should be added to the coolant bottle. Do

not overfill.Points to Remember

NOTE:

When the vehicle is stopped after a few miles of

operation, you may observe vapor coming from the front

of the engine compartment. This is normally a result of

moisture from rain, snow, or high humidity accumula-

tion on the radiator and being vaporized when the

thermostat opens, allowing hot water to enter the radia-

tor.

If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

A. Do not overfill the coolant bottle.

B. Check coolant freeze point in the system.

C. If frequent coolant additions are required, the cooling

system should be pressure tested for leaks.

D. Maintain coolant concentration at 50% ethylene glycol

antifreeze (minimum) in water for proper corrosion pro-

tection of your engine which contains aluminum compo-

nents.

MAINTAINING YOUR VEHICLE 151

7

Page 153 of 200

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically.

Suggested service intervals can be found in the Mainte-

nance Section.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

Brake and Power Steering System Hoses

When servicing the vehicle for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,

cracking, checking, tears, cuts, abrasions, and excessive

swelling suggest deterioration of the rubber. Particularattention should be made to examining those hose sur-

faces nearest to high heat sources, such as the exhaust

manifold.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

Insure nylon tubing in these areas has not melted or

collapsed.

NOTE:Often, fluids such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to ease the assembly of hoses to couplings. There-

fore, oil wetness at the hose-coupling area is not neces-

sarily an indication of leakage. Actual dripping of hot

fluid when systems are under pressure (during vehicle

operation) should be noted before hose is replaced based

on leakage.

NOTE:Inspection of brake hoses should be done

whenever the brake system is serviced and every engine

oil change.

MAINTAINING YOUR VEHICLE 153

7

Page 155 of 200

WARNING!

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts and the

brake fluid catching fire.

Use only brake fluid that has been in a tightly closed

container to avoid contamination from foreign matter.

Do not allow petroleum based fluid to contaminate the

brake fluid as seal damage will result!

Manual Transaxle

Lubricant Selection

Use only manufacturers recommended transmission

fluid, refer to Recommended Fluids, Lubricants and

Genuine Parts for correct fluid type.

Fluid Level Check

Check the fluid level by removing the fill plug. The fluid

level should be between the bottom of the fill hole and a

point not more that 3/16º (4.76 mm) below the bottom of

the hole.Add fluid, if necessary, to maintain the proper level.

Frequency of Fluid Change

Under normal operating conditions, the fluid installed at

the factory will give satisfactory lubrication for the life of

the vehicle. Fluid changes are not necessary unless the

following conditions exist:

²The lubricant has become contaminated with water. If

contaminated with water, the fluid should be changed

immediately.

²If severe usage has occurred, refer to Maintenance

Schedule ªBº in Section 8 of this manual.

Appearance Care and Protection from Corrosion

Protection of Body and Paint from Corrosion

Vehicle body car requirements vary according to geo-

graphic locations and usage. Chemicals that make roads

passable in snow and ice, and those that are sprayed on

trees and road surfaces during other seasons, are highly

corrosive to the metal in you vehicle. Outside parking,

which exposes your vehicle to airborne contaminants,

road surfaces on which the vehicle is operated, extreme

MAINTAINING YOUR VEHICLE 155

7

Page 169 of 200

NOTE:IfANYof these apply to you then change your

engine oil every 3,000 miles (5 000 km) or 3 months,

whichever comes first and follow schedule ªBº of the

9Maintenance Schedules9section of this manual.

NOTE:Most vehicles are operated under the conditions

listed for Schedule9B9.

Second is ScheduleªAº. It is for vehicles that are not

operated under any of the conditions listed under Sched-

ule9B9

Use the schedule that best describes your driving condi-

tions. Where time and mileage are listed, follow the

interval that occurs first.

CAUTION!

Failure to perform the required maintenance items

may result in damage to the vehicle.

At Each Stop for Fuel

²

Check the engine oil level about 5 minutes after a fully

warmed engine is shut off. Checking the oil level while

the vehicle is on level ground will improve the accu-

racy of the oil level reading. Add oil only when the

level is at or below the ADD or MIN mark.

²Check the windshield washer solvent and add if

required.

Once a Month

²

Check tire pressure and look for unusual wear or

damage.

²Inspect the battery and clean and tighten the terminals

as required.

²Check the fluid levels of coolant reservoir, brake

master cylinder and transaxle and add as needed.

²Check all lights and all other electrical items for correct

operation.

²Check rubber seals on each side of the radiator for

proper fit.

MAINTENANCE SCHEDULES 169

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 170 of 200

At Each Oil Change

²

Change the engine oil filter.

²Inspect the exhaust system.

²Inspect the brake hoses.

²Inspect the CV joints and front suspension compo-

nents.

²Check the manual transaxle fluid level and fill plug

condition.

²Check the coolant level, hoses, and clamps.

²Rotate the tires at each oil change interval shown on

SCHEDULE ªAº 5,000 miles (8 000 km), or every other

interval shown on SCHEDULE ªBº 6,000 miles (10,000

km).

170 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 194 of 200

Downshifting........................... 92

Drive Belts............................ 140

Driving

On Slippery Surfaces.................. 128

Electric Remote Mirrors................... 48

Emergency, In Case of

Jacking............................. 122

Jump Starting........................ 125

Towing............................. 130

Emergency Trunk Release................. 15

Emission Control System Maintenance....... 168

Engine

Break-In Recommendations............... 42

Checking Oil Level.................... 137

Jump Starting........................ 125

Oil ..........................137,165,166

Oil Change Interval................... 138

Oil Filter............................ 166

Oil Selection......................... 138

Oil Synthetic......................... 139

Overheating......................... 120

Temperature Gauge.................... 67Timing Belt.......................... 142

Exhaust Gas Caution..................... 43

Exhaust System........................ 147

Filters

Air Cleaner.......................... 142

Engine Fuel......................... 142

Engine Oil.......................140,166

Flooded Engine Starting................... 88

Fluid, Brake........................... 166

Fluid Capacities........................ 165

Fluid Leaks............................ 44

Fluid Level Checks

Manual Transaxle..................... 155

Fog Lights...........................54,63

Freeing A Stuck Vehicle.................. 129

Fuel.............................. 113,166

Adding............................. 116

Filler Cap........................... 116

Filter.............................. 142

Gauge.............................. 65

Light............................... 65

Octane Rating........................ 113

194 INDEX

Page 197 of 200

Maintenance Procedures.................. 136

Maintenance Schedule

Schedule9A9......................... 178

Schedule9B9......................... 171

Maintenance Schedules.................. 168

Malfunction Indicator Light.............66,134

Manual, Service........................ 188

Manual Transaxle..................87,90,155

Fluid Level Check..................... 155

Frequency of Fluid Change.............. 155

Lubricant Selection.................... 155

Master Cylinder........................ 154

Mirrors............................... 47

Electric Remote....................... 48

Outside............................. 47

Rearview............................ 47

Modifications/Alterations, Vehicle............ 6

Mopar Parts........................136,187

Multi-Function Control Lever.............53,55

Occupant Restraints...................... 19

Odometer

Trip ................................ 66Oil, Engine........................... 137

Change Interval...................... 138

Checking........................... 137

Disposal............................ 140

Filter.............................. 140

Identification Logo.................... 139

Materials Added to.................... 139

Quality............................. 139

Recommendation..................... 138

Synthetic........................... 139

Oil Pressure Light....................... 64

Onboard Diagnostic System............... 134

Operator Manuals........................ 4

Outside Air Intake....................... 82

Overheating, Engine..................... 120

Owner's Manual......................4,188

Paint Care............................ 155

Panic Alarm........................... 17

Parking Brake.......................... 92

Passing Light........................... 55

Pets.................................. 42

Placard, Tire and Loading Information....... 100

INDEX 197

10