drain bolt DODGE RAM 1500 1998 2.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1700 of 2627

HOSES - LINK/COIL

REMOVAL

REMOVAL - RETURN HOSE - GEAR TO

COOLER

(1) Drain and siphon the power steering system.

(2) Raise and support the vehicle.

(3) Disconnect the return hose at the cooler.

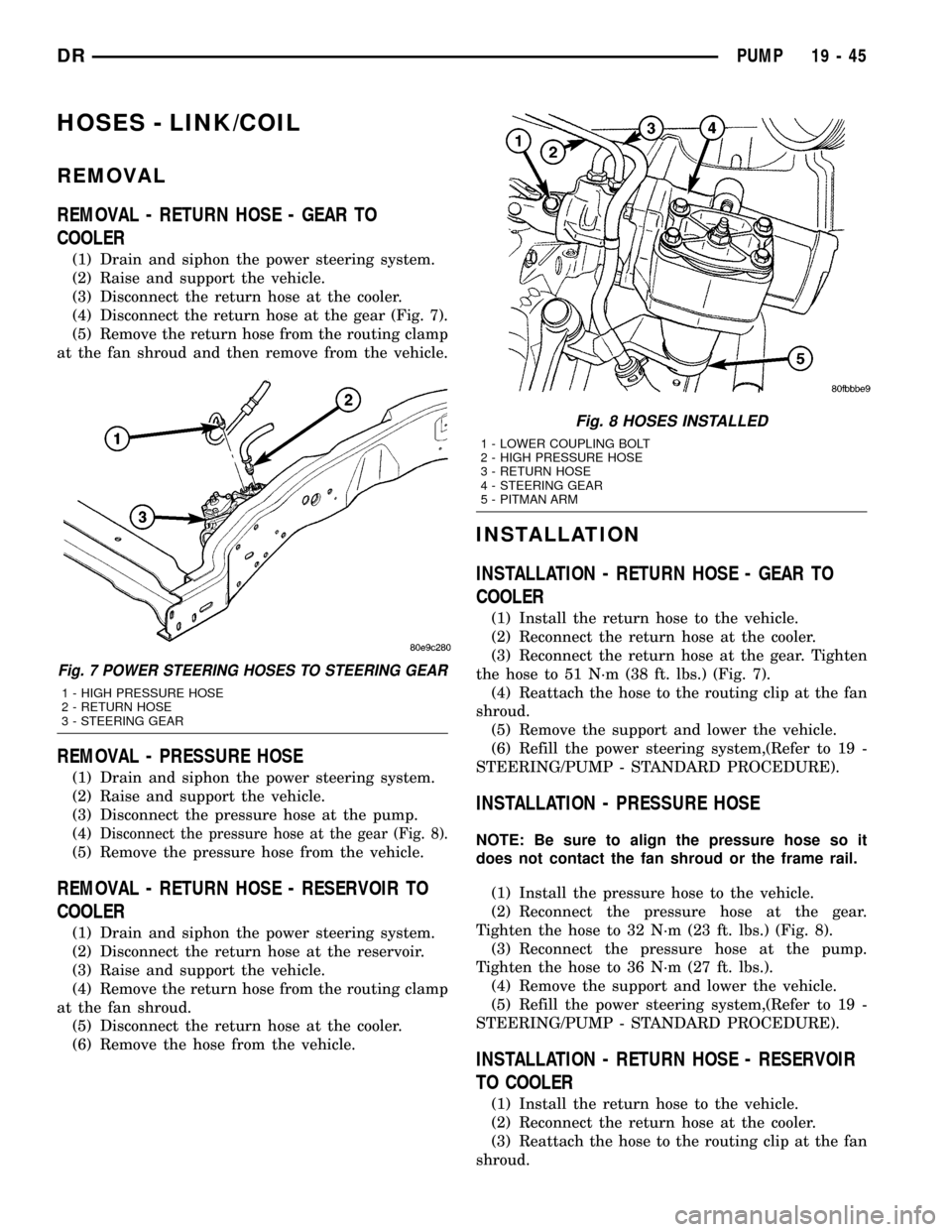

(4) Disconnect the return hose at the gear (Fig. 7).

(5) Remove the return hose from the routing clamp

at the fan shroud and then remove from the vehicle.

REMOVAL - PRESSURE HOSE

(1) Drain and siphon the power steering system.

(2) Raise and support the vehicle.

(3) Disconnect the pressure hose at the pump.

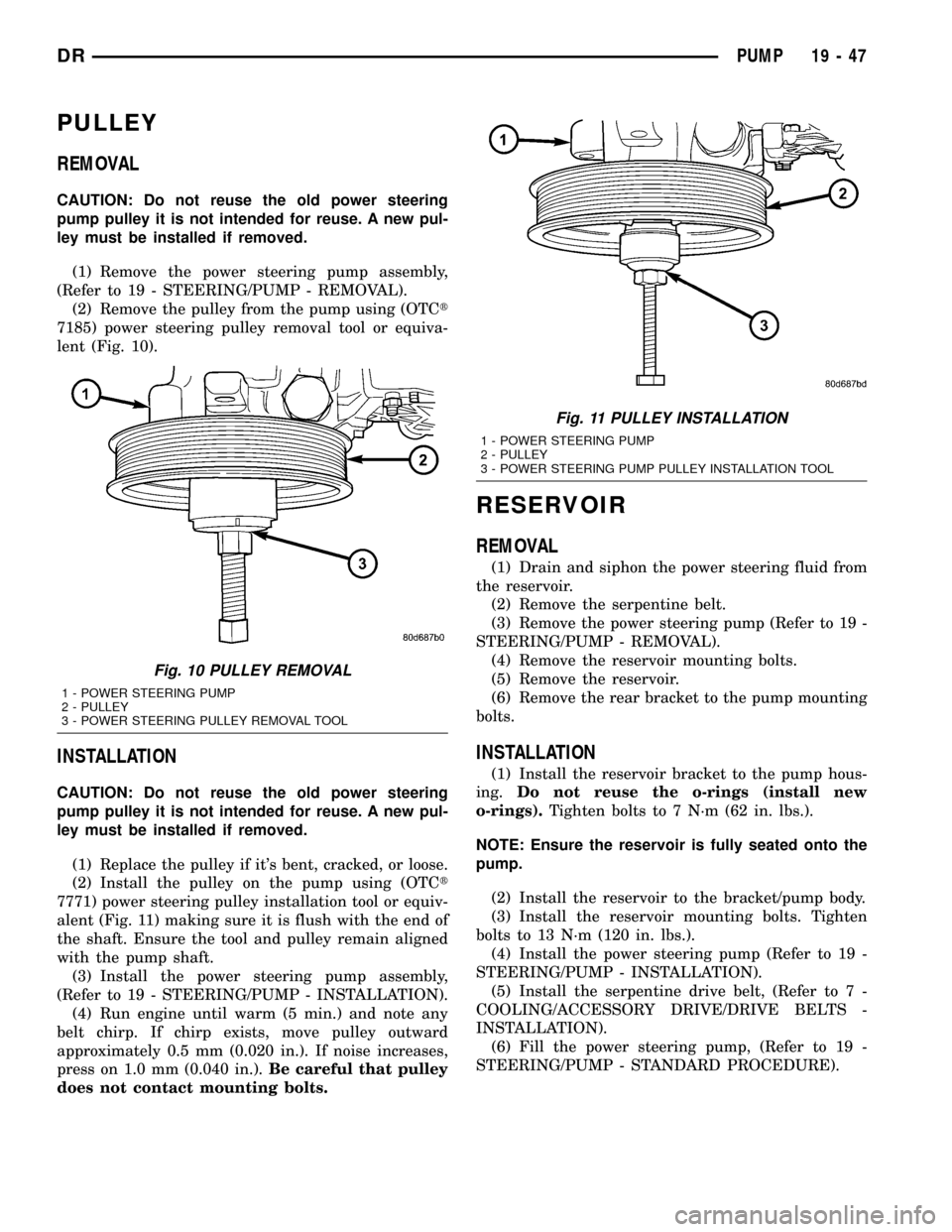

(4)

Disconnect the pressure hose at the gear (Fig. 8).

(5) Remove the pressure hose from the vehicle.

REMOVAL - RETURN HOSE - RESERVOIR TO

COOLER

(1) Drain and siphon the power steering system.

(2) Disconnect the return hose at the reservoir.

(3) Raise and support the vehicle.

(4) Remove the return hose from the routing clamp

at the fan shroud.

(5) Disconnect the return hose at the cooler.

(6) Remove the hose from the vehicle.

INSTALLATION

INSTALLATION - RETURN HOSE - GEAR TO

COOLER

(1) Install the return hose to the vehicle.

(2) Reconnect the return hose at the cooler.

(3) Reconnect the return hose at the gear. Tighten

the hose to 51 N´m (38 ft. lbs.) (Fig. 7).

(4) Reattach the hose to the routing clip at the fan

shroud.

(5) Remove the support and lower the vehicle.

(6) Refill the power steering system,(Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

INSTALLATION - PRESSURE HOSE

NOTE: Be sure to align the pressure hose so it

does not contact the fan shroud or the frame rail.

(1) Install the pressure hose to the vehicle.

(2) Reconnect the pressure hose at the gear.

Tighten the hose to 32 N´m (23 ft. lbs.) (Fig. 8).

(3) Reconnect the pressure hose at the pump.

Tighten the hose to 36 N´m (27 ft. lbs.).

(4) Remove the support and lower the vehicle.

(5) Refill the power steering system,(Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

INSTALLATION - RETURN HOSE - RESERVOIR

TO COOLER

(1) Install the return hose to the vehicle.

(2) Reconnect the return hose at the cooler.

(3) Reattach the hose to the routing clip at the fan

shroud.

Fig. 7 POWER STEERING HOSES TO STEERING GEAR

1 - HIGH PRESSURE HOSE

2 - RETURN HOSE

3 - STEERING GEAR

Fig. 8 HOSES INSTALLED

1 - LOWER COUPLING BOLT

2 - HIGH PRESSURE HOSE

3 - RETURN HOSE

4 - STEERING GEAR

5 - PITMAN ARM

DRPUMP 19 - 45

Page 1702 of 2627

PULLEY

REMOVAL

CAUTION: Do not reuse the old power steering

pump pulley it is not intended for reuse. A new pul-

ley must be installed if removed.

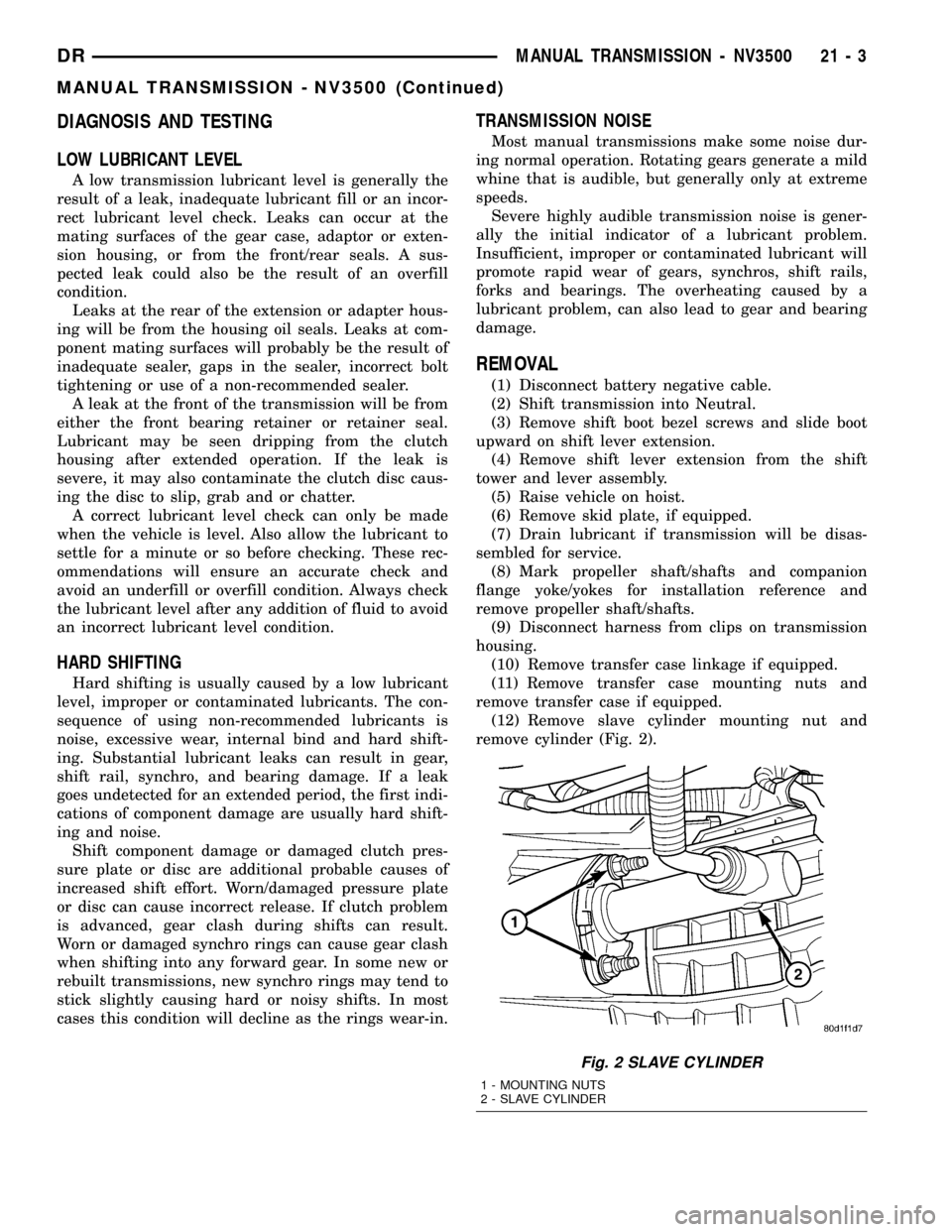

(1) Remove the power steering pump assembly,

(Refer to 19 - STEERING/PUMP - REMOVAL).

(2) Remove the pulley from the pump using (OTCt

7185) power steering pulley removal tool or equiva-

lent (Fig. 10).

INSTALLATION

CAUTION: Do not reuse the old power steering

pump pulley it is not intended for reuse. A new pul-

ley must be installed if removed.

(1) Replace the pulley if it's bent, cracked, or loose.

(2) Install the pulley on the pump using (OTCt

7771) power steering pulley installation tool or equiv-

alent (Fig. 11) making sure it is flush with the end of

the shaft. Ensure the tool and pulley remain aligned

with the pump shaft.

(3) Install the power steering pump assembly,

(Refer to 19 - STEERING/PUMP - INSTALLATION).

(4) Run engine until warm (5 min.) and note any

belt chirp. If chirp exists, move pulley outward

approximately 0.5 mm (0.020 in.). If noise increases,

press on 1.0 mm (0.040 in.).Be careful that pulley

does not contact mounting bolts.

RESERVOIR

REMOVAL

(1) Drain and siphon the power steering fluid from

the reservoir.

(2) Remove the serpentine belt.

(3) Remove the power steering pump (Refer to 19 -

STEERING/PUMP - REMOVAL).

(4) Remove the reservoir mounting bolts.

(5) Remove the reservoir.

(6) Remove the rear bracket to the pump mounting

bolts.

INSTALLATION

(1) Install the reservoir bracket to the pump hous-

ing.Do not reuse the o-rings (install new

o-rings).Tighten bolts to 7 N´m (62 in. lbs.).

NOTE: Ensure the reservoir is fully seated onto the

pump.

(2) Install the reservoir to the bracket/pump body.

(3) Install the reservoir mounting bolts. Tighten

bolts to 13 N´m (120 in. lbs.).

(4) Install the power steering pump (Refer to 19 -

STEERING/PUMP - INSTALLATION).

(5) Install the serpentine drive belt, (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(6) Fill the power steering pump, (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

Fig. 10 PULLEY REMOVAL

1 - POWER STEERING PUMP

2 - PULLEY

3 - POWER STEERING PULLEY REMOVAL TOOL

Fig. 11 PULLEY INSTALLATION

1 - POWER STEERING PUMP

2 - PULLEY

3 - POWER STEERING PUMP PULLEY INSTALLATION TOOL

DRPUMP 19 - 47

Page 1706 of 2627

DIAGNOSIS AND TESTING

LOW LUBRICANT LEVEL

A low transmission lubricant level is generally the

result of a leak, inadequate lubricant fill or an incor-

rect lubricant level check. Leaks can occur at the

mating surfaces of the gear case, adaptor or exten-

sion housing, or from the front/rear seals. A sus-

pected leak could also be the result of an overfill

condition.

Leaks at the rear of the extension or adapter hous-

ing will be from the housing oil seals. Leaks at com-

ponent mating surfaces will probably be the result of

inadequate sealer, gaps in the sealer, incorrect bolt

tightening or use of a non-recommended sealer.

A leak at the front of the transmission will be from

either the front bearing retainer or retainer seal.

Lubricant may be seen dripping from the clutch

housing after extended operation. If the leak is

severe, it may also contaminate the clutch disc caus-

ing the disc to slip, grab and or chatter.

A correct lubricant level check can only be made

when the vehicle is level. Also allow the lubricant to

settle for a minute or so before checking. These rec-

ommendations will ensure an accurate check and

avoid an underfill or overfill condition. Always check

the lubricant level after any addition of fluid to avoid

an incorrect lubricant level condition.

HARD SHIFTING

Hard shifting is usually caused by a low lubricant

level, improper or contaminated lubricants. The con-

sequence of using non-recommended lubricants is

noise, excessive wear, internal bind and hard shift-

ing. Substantial lubricant leaks can result in gear,

shift rail, synchro, and bearing damage. If a leak

goes undetected for an extended period, the first indi-

cations of component damage are usually hard shift-

ing and noise.

Shift component damage or damaged clutch pres-

sure plate or disc are additional probable causes of

increased shift effort. Worn/damaged pressure plate

or disc can cause incorrect release. If clutch problem

is advanced, gear clash during shifts can result.

Worn or damaged synchro rings can cause gear clash

when shifting into any forward gear. In some new or

rebuilt transmissions, new synchro rings may tend to

stick slightly causing hard or noisy shifts. In most

cases this condition will decline as the rings wear-in.

TRANSMISSION NOISE

Most manual transmissions make some noise dur-

ing normal operation. Rotating gears generate a mild

whine that is audible, but generally only at extreme

speeds.

Severe highly audible transmission noise is gener-

ally the initial indicator of a lubricant problem.

Insufficient, improper or contaminated lubricant will

promote rapid wear of gears, synchros, shift rails,

forks and bearings. The overheating caused by a

lubricant problem, can also lead to gear and bearing

damage.

REMOVAL

(1) Disconnect battery negative cable.

(2) Shift transmission into Neutral.

(3) Remove shift boot bezel screws and slide boot

upward on shift lever extension.

(4) Remove shift lever extension from the shift

tower and lever assembly.

(5) Raise vehicle on hoist.

(6) Remove skid plate, if equipped.

(7) Drain lubricant if transmission will be disas-

sembled for service.

(8) Mark propeller shaft/shafts and companion

flange yoke/yokes for installation reference and

remove propeller shaft/shafts.

(9) Disconnect harness from clips on transmission

housing.

(10) Remove transfer case linkage if equipped.

(11) Remove transfer case mounting nuts and

remove transfer case if equipped.

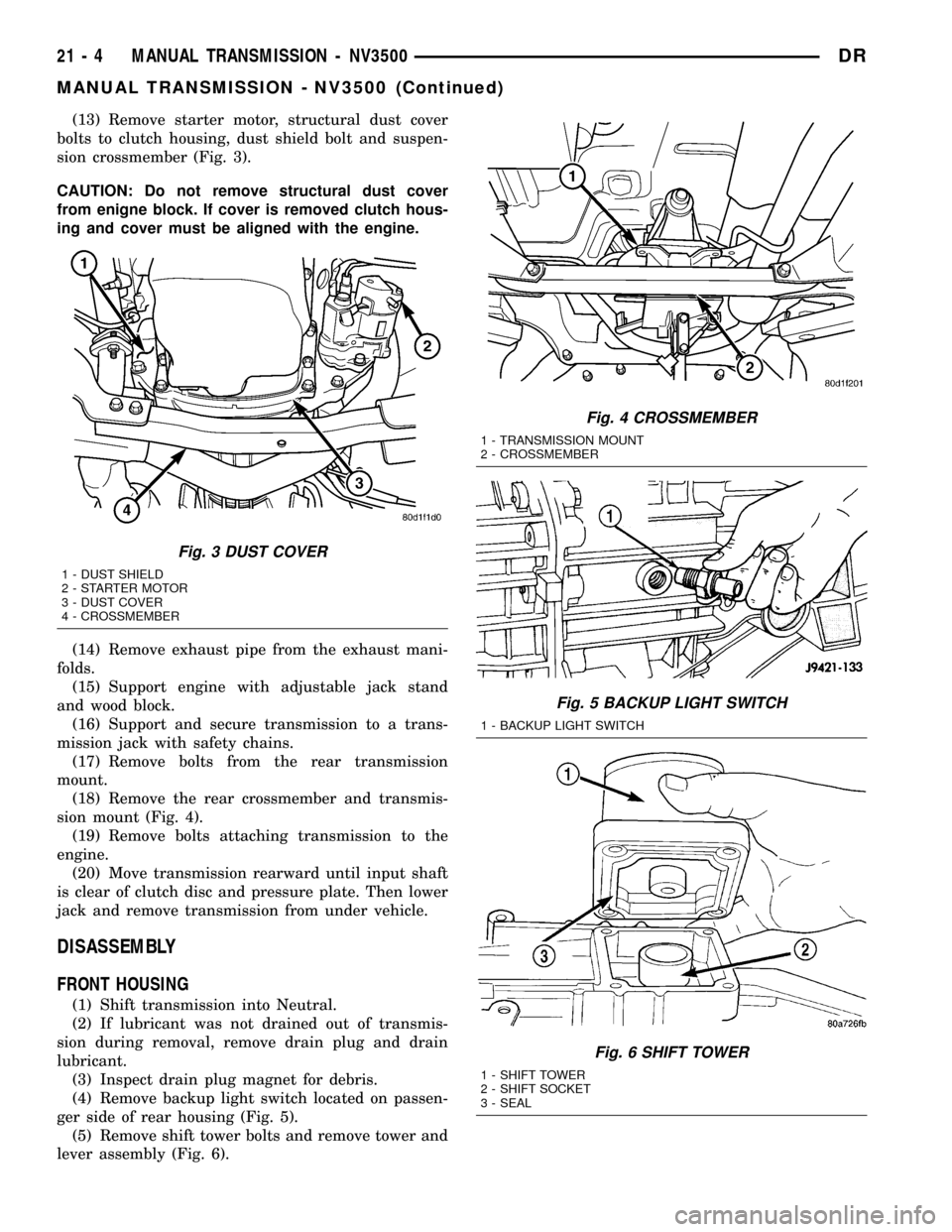

(12) Remove slave cylinder mounting nut and

remove cylinder (Fig. 2).

Fig. 2 SLAVE CYLINDER

1 - MOUNTING NUTS

2 - SLAVE CYLINDER

DRMANUAL TRANSMISSION - NV3500 21 - 3

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1707 of 2627

(13) Remove starter motor, structural dust cover

bolts to clutch housing, dust shield bolt and suspen-

sion crossmember (Fig. 3).

CAUTION: Do not remove structural dust cover

from enigne block. If cover is removed clutch hous-

ing and cover must be aligned with the engine.

(14) Remove exhaust pipe from the exhaust mani-

folds.

(15) Support engine with adjustable jack stand

and wood block.

(16) Support and secure transmission to a trans-

mission jack with safety chains.

(17) Remove bolts from the rear transmission

mount.

(18) Remove the rear crossmember and transmis-

sion mount (Fig. 4).

(19) Remove bolts attaching transmission to the

engine.

(20) Move transmission rearward until input shaft

is clear of clutch disc and pressure plate. Then lower

jack and remove transmission from under vehicle.

DISASSEMBLY

FRONT HOUSING

(1) Shift transmission into Neutral.

(2) If lubricant was not drained out of transmis-

sion during removal, remove drain plug and drain

lubricant.

(3) Inspect drain plug magnet for debris.

(4) Remove backup light switch located on passen-

ger side of rear housing (Fig. 5).

(5) Remove shift tower bolts and remove tower and

lever assembly (Fig. 6).

Fig. 3 DUST COVER

1 - DUST SHIELD

2 - STARTER MOTOR

3 - DUST COVER

4 - CROSSMEMBER

Fig. 4 CROSSMEMBER

1 - TRANSMISSION MOUNT

2 - CROSSMEMBER

Fig. 5 BACKUP LIGHT SWITCH

1 - BACKUP LIGHT SWITCH

Fig. 6 SHIFT TOWER

1 - SHIFT TOWER

2 - SHIFT SOCKET

3 - SEAL

21 - 4 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1743 of 2627

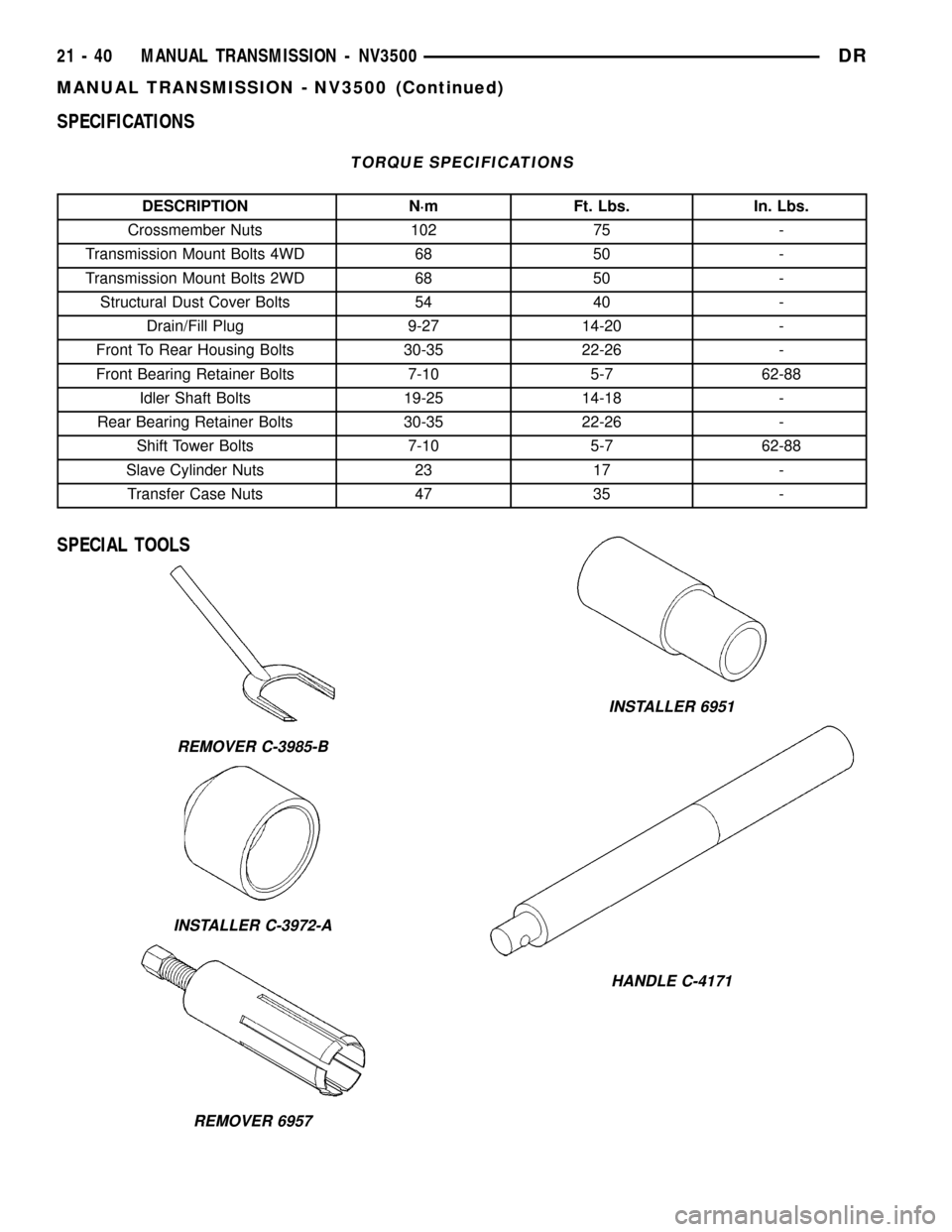

SPECIFICATIONS

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Crossmember Nuts 102 75 -

Transmission Mount Bolts 4WD 68 50 -

Transmission Mount Bolts 2WD 68 50 -

Structural Dust Cover Bolts 54 40 -

Drain/Fill Plug 9-27 14-20 -

Front To Rear Housing Bolts 30-35 22-26 -

Front Bearing Retainer Bolts 7-10 5-7 62-88

Idler Shaft Bolts 19-25 14-18 -

Rear Bearing Retainer Bolts 30-35 22-26 -

Shift Tower Bolts 7-10 5-7 62-88

Slave Cylinder Nuts 23 17 -

Transfer Case Nuts 47 35 -

SPECIAL TOOLS

REMOVER C-3985-B

INSTALLER C-3972-A

REMOVER 6957

INSTALLER 6951

HANDLE C-4171

21 - 40 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1748 of 2627

(5) Remove shift tower and isolator plate from

transmission shift cover.

(6) Raise and support vehicle.

(7) Remove skid plate, if equipped.

(8) Mark propeller shaft and axle yokes for instal-

lation reference and remove shaft/shafts.

(9) Remove exhaust system Y-pipe.

(10) Disconnect speed sensor and backup light

switch connectors.

(11) Support engine with safety stand and a wood

block.

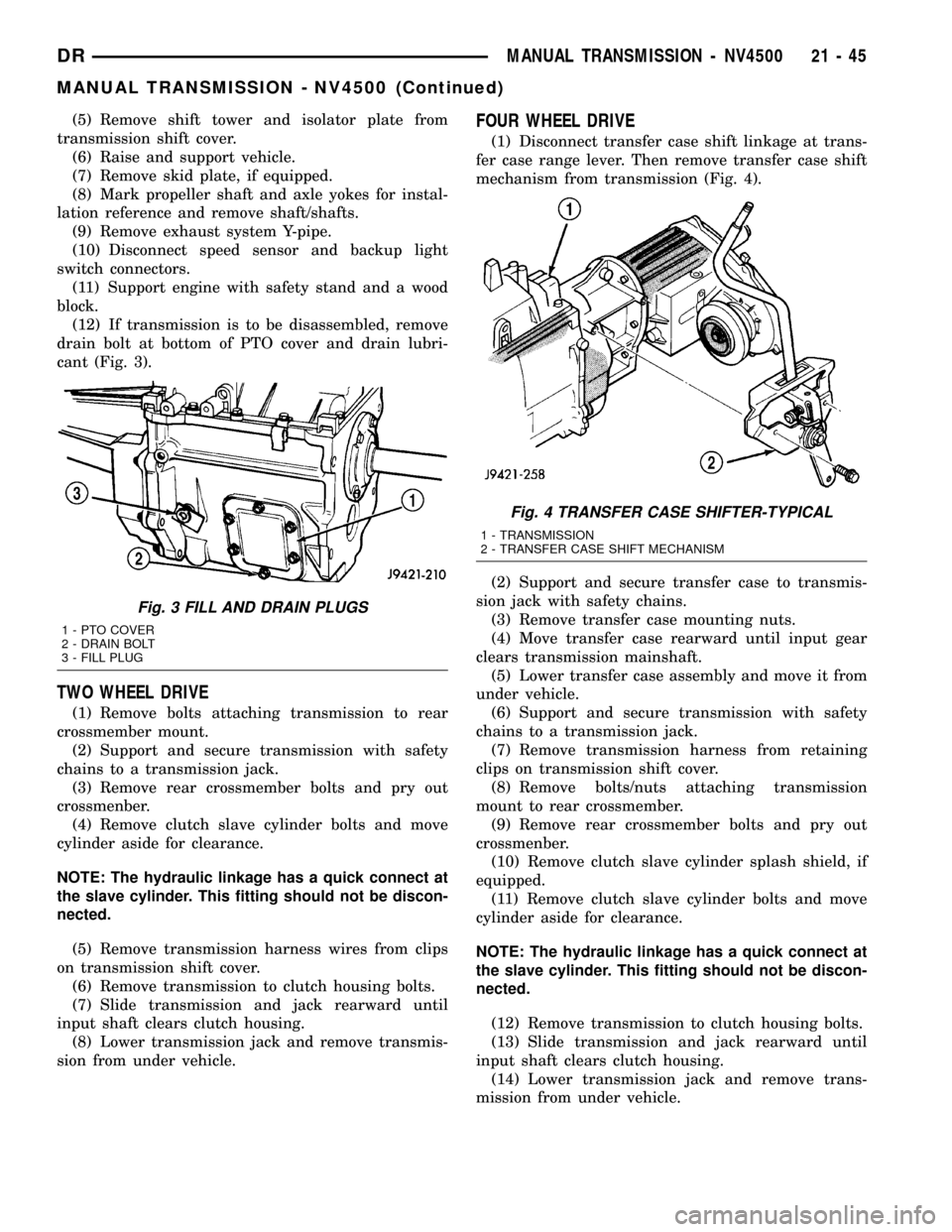

(12) If transmission is to be disassembled, remove

drain bolt at bottom of PTO cover and drain lubri-

cant (Fig. 3).

TWO WHEEL DRIVE

(1) Remove bolts attaching transmission to rear

crossmember mount.

(2) Support and secure transmission with safety

chains to a transmission jack.

(3) Remove rear crossmember bolts and pry out

crossmenber.

(4) Remove clutch slave cylinder bolts and move

cylinder aside for clearance.

NOTE: The hydraulic linkage has a quick connect at

the slave cylinder. This fitting should not be discon-

nected.

(5) Remove transmission harness wires from clips

on transmission shift cover.

(6) Remove transmission to clutch housing bolts.

(7) Slide transmission and jack rearward until

input shaft clears clutch housing.

(8) Lower transmission jack and remove transmis-

sion from under vehicle.

FOUR WHEEL DRIVE

(1) Disconnect transfer case shift linkage at trans-

fer case range lever. Then remove transfer case shift

mechanism from transmission (Fig. 4).

(2) Support and secure transfer case to transmis-

sion jack with safety chains.

(3) Remove transfer case mounting nuts.

(4) Move transfer case rearward until input gear

clears transmission mainshaft.

(5) Lower transfer case assembly and move it from

under vehicle.

(6) Support and secure transmission with safety

chains to a transmission jack.

(7) Remove transmission harness from retaining

clips on transmission shift cover.

(8) Remove bolts/nuts attaching transmission

mount to rear crossmember.

(9) Remove rear crossmember bolts and pry out

crossmenber.

(10) Remove clutch slave cylinder splash shield, if

equipped.

(11) Remove clutch slave cylinder bolts and move

cylinder aside for clearance.

NOTE: The hydraulic linkage has a quick connect at

the slave cylinder. This fitting should not be discon-

nected.

(12) Remove transmission to clutch housing bolts.

(13) Slide transmission and jack rearward until

input shaft clears clutch housing.

(14) Lower transmission jack and remove trans-

mission from under vehicle.

Fig. 3 FILL AND DRAIN PLUGS

1 - PTO COVER

2 - DRAIN BOLT

3 - FILL PLUG

Fig. 4 TRANSFER CASE SHIFTER-TYPICAL

1 - TRANSMISSION

2 - TRANSFER CASE SHIFT MECHANISM

DRMANUAL TRANSMISSION - NV4500 21 - 45

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1784 of 2627

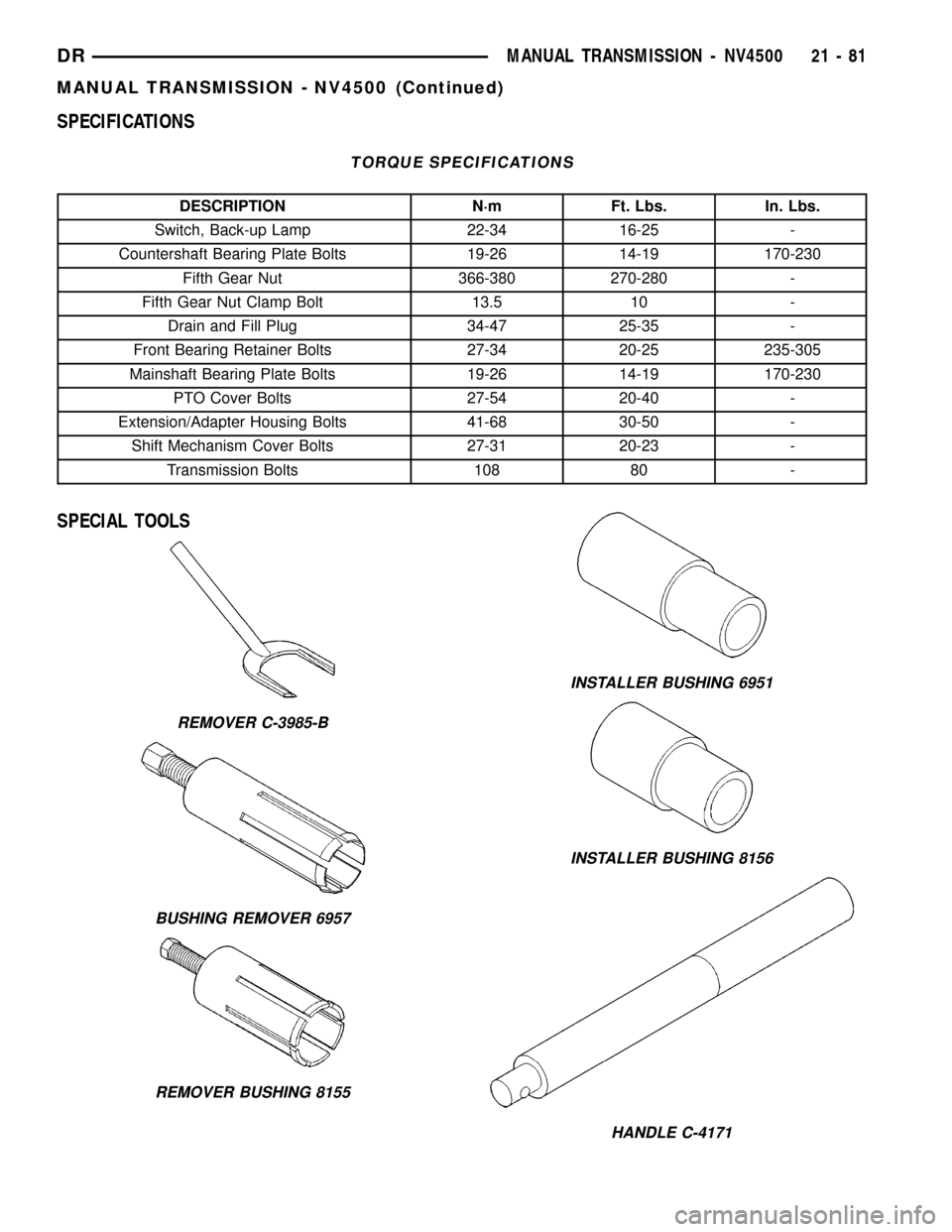

SPECIFICATIONS

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Switch, Back-up Lamp 22-34 16-25 -

Countershaft Bearing Plate Bolts 19-26 14-19 170-230

Fifth Gear Nut 366-380 270-280 -

Fifth Gear Nut Clamp Bolt 13.5 10 -

Drain and Fill Plug 34-47 25-35 -

Front Bearing Retainer Bolts 27-34 20-25 235-305

Mainshaft Bearing Plate Bolts 19-26 14-19 170-230

PTO Cover Bolts 27-54 20-40 -

Extension/Adapter Housing Bolts 41-68 30-50 -

Shift Mechanism Cover Bolts 27-31 20-23 -

Transmission Bolts 108 80 -

SPECIAL TOOLS

REMOVER C-3985-B

BUSHING REMOVER 6957

REMOVER BUSHING 8155

INSTALLER BUSHING 6951

INSTALLER BUSHING 8156

HANDLE C-4171

DRMANUAL TRANSMISSION - NV4500 21 - 81

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1791 of 2627

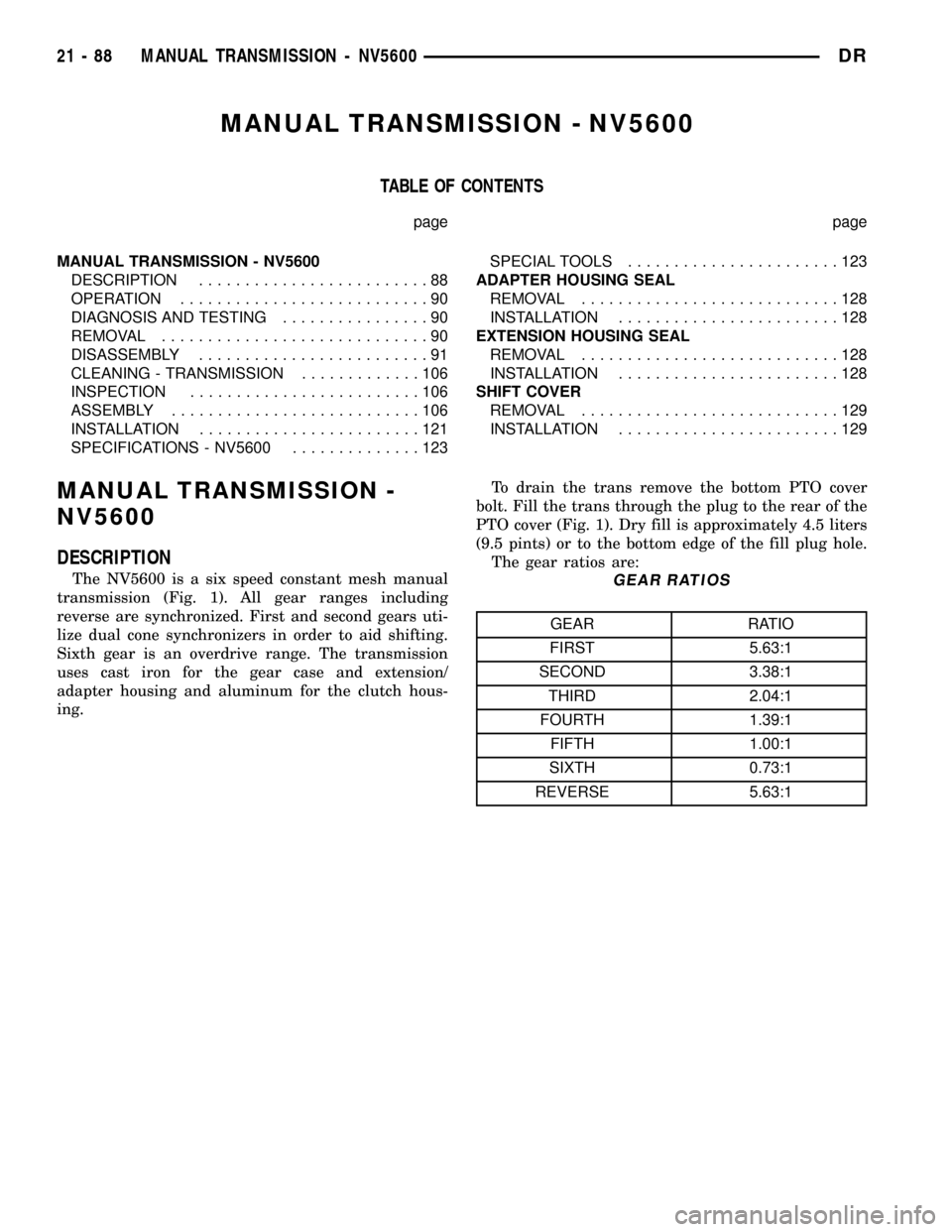

MANUAL TRANSMISSION - NV5600

TABLE OF CONTENTS

page page

MANUAL TRANSMISSION - NV5600

DESCRIPTION.........................88

OPERATION...........................90

DIAGNOSIS AND TESTING................90

REMOVAL.............................90

DISASSEMBLY.........................91

CLEANING - TRANSMISSION.............106

INSPECTION.........................106

ASSEMBLY...........................106

INSTALLATION........................121

SPECIFICATIONS - NV5600..............123SPECIAL TOOLS.......................123

ADAPTER HOUSING SEAL

REMOVAL............................128

INSTALLATION........................128

EXTENSION HOUSING SEAL

REMOVAL............................128

INSTALLATION........................128

SHIFT COVER

REMOVAL............................129

INSTALLATION........................129

MANUAL TRANSMISSION -

NV5600

DESCRIPTION

The NV5600 is a six speed constant mesh manual

transmission (Fig. 1). All gear ranges including

reverse are synchronized. First and second gears uti-

lize dual cone synchronizers in order to aid shifting.

Sixth gear is an overdrive range. The transmission

uses cast iron for the gear case and extension/

adapter housing and aluminum for the clutch hous-

ing.To drain the trans remove the bottom PTO cover

bolt. Fill the trans through the plug to the rear of the

PTO cover (Fig. 1). Dry fill is approximately 4.5 liters

(9.5 pints) or to the bottom edge of the fill plug hole.

The gear ratios are:GEAR RATIOS

GEAR RATIO

FIRST 5.63:1

SECOND 3.38:1

THIRD 2.04:1

FOURTH 1.39:1

FIFTH 1.00:1

SIXTH 0.73:1

REVERSE 5.63:1

21 - 88 MANUAL TRANSMISSION - NV5600DR

Page 1794 of 2627

(2) Remove screws attaching shift boot to floorpan.

Then slide boot upward on the shift lever.

(3) Remove the bolts holding the shift tower to the

isolator plate and transmission gear case.

(4) Remove the shift tower and isolator plate from

the transmission gear case.

(5) Raise and support vehicle.

(6) Remove skid plate, if equipped.

(7) Mark propeller shaft/shafts and axle yokes for

installation reference.

(8) Remove propeller shaft.

(9) Disconnect and remove exhaust system as nec-

essary.

(10) Disconnect wires at backup light switch.

(11) Support engine with adjustable safety stand

and wood block.

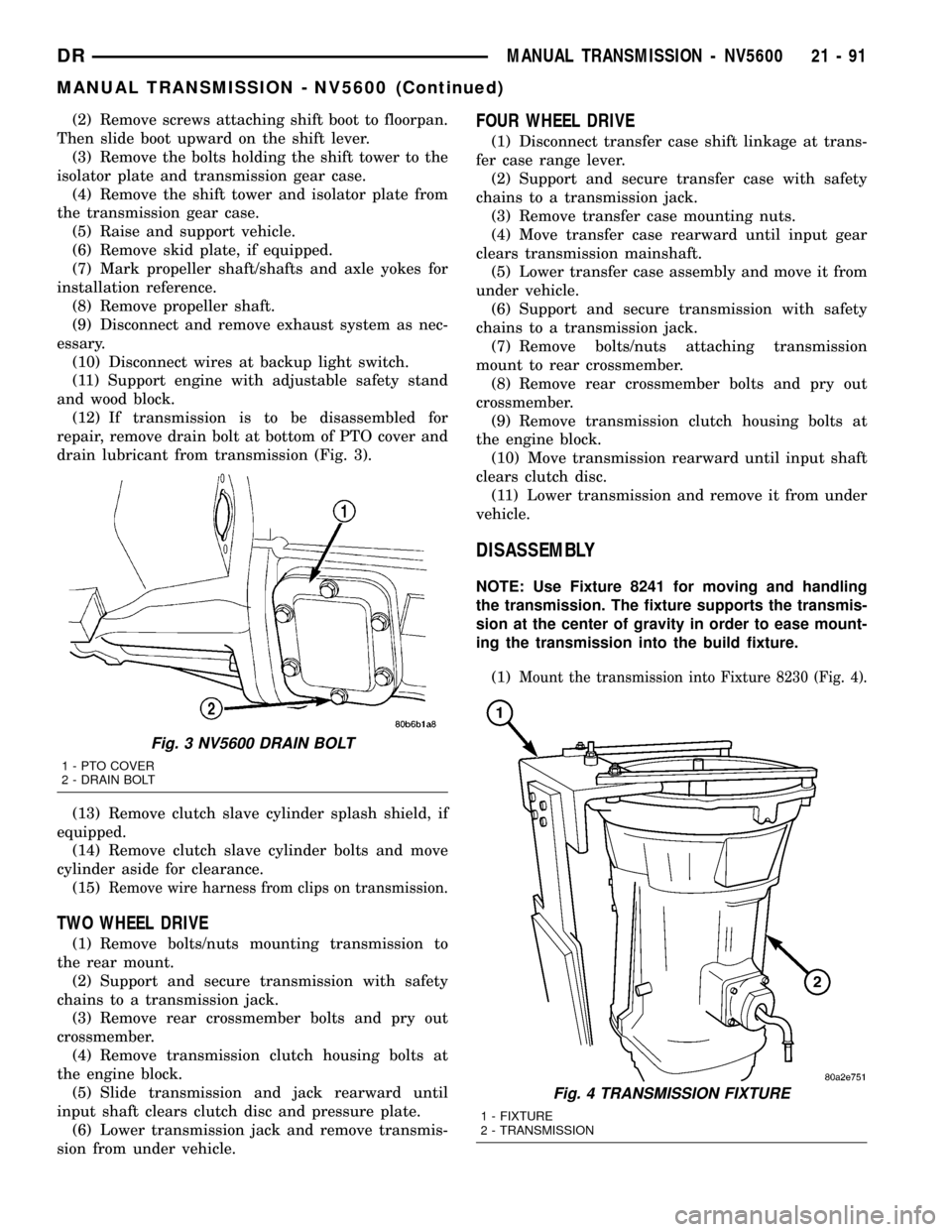

(12) If transmission is to be disassembled for

repair, remove drain bolt at bottom of PTO cover and

drain lubricant from transmission (Fig. 3).

(13) Remove clutch slave cylinder splash shield, if

equipped.

(14) Remove clutch slave cylinder bolts and move

cylinder aside for clearance.

(15)

Remove wire harness from clips on transmission.

TWO WHEEL DRIVE

(1) Remove bolts/nuts mounting transmission to

the rear mount.

(2) Support and secure transmission with safety

chains to a transmission jack.

(3) Remove rear crossmember bolts and pry out

crossmember.

(4) Remove transmission clutch housing bolts at

the engine block.

(5) Slide transmission and jack rearward until

input shaft clears clutch disc and pressure plate.

(6) Lower transmission jack and remove transmis-

sion from under vehicle.

FOUR WHEEL DRIVE

(1) Disconnect transfer case shift linkage at trans-

fer case range lever.

(2) Support and secure transfer case with safety

chains to a transmission jack.

(3) Remove transfer case mounting nuts.

(4) Move transfer case rearward until input gear

clears transmission mainshaft.

(5) Lower transfer case assembly and move it from

under vehicle.

(6) Support and secure transmission with safety

chains to a transmission jack.

(7) Remove bolts/nuts attaching transmission

mount to rear crossmember.

(8) Remove rear crossmember bolts and pry out

crossmember.

(9) Remove transmission clutch housing bolts at

the engine block.

(10) Move transmission rearward until input shaft

clears clutch disc.

(11) Lower transmission and remove it from under

vehicle.

DISASSEMBLY

NOTE: Use Fixture 8241 for moving and handling

the transmission. The fixture supports the transmis-

sion at the center of gravity in order to ease mount-

ing the transmission into the build fixture.

(1)

Mount the transmission into Fixture 8230 (Fig. 4).

Fig. 3 NV5600 DRAIN BOLT

1 - PTO COVER

2 - DRAIN BOLT

Fig. 4 TRANSMISSION FIXTURE

1 - FIXTURE

2 - TRANSMISSION

DRMANUAL TRANSMISSION - NV5600 21 - 91

MANUAL TRANSMISSION - NV5600 (Continued)

Page 1848 of 2627

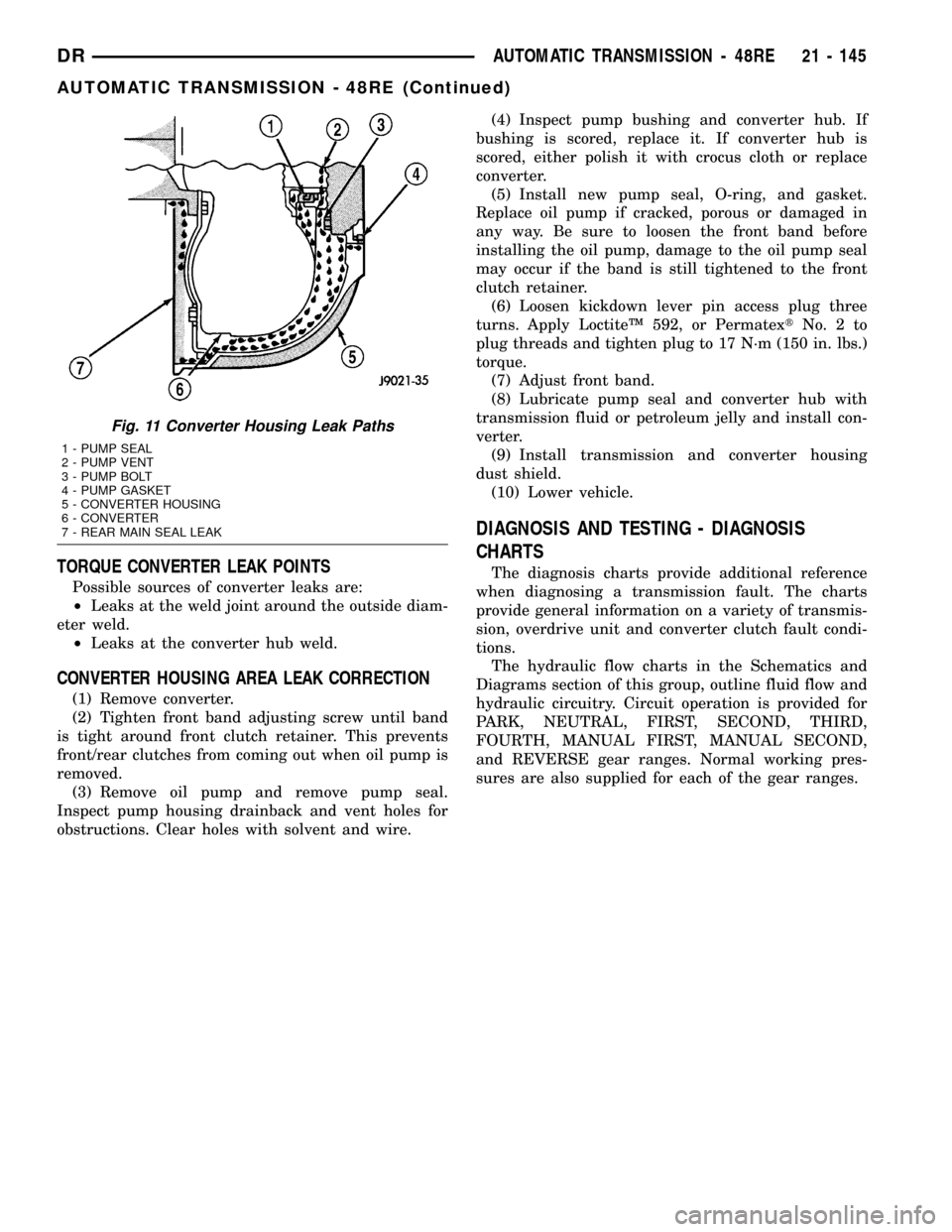

TORQUE CONVERTER LEAK POINTS

Possible sources of converter leaks are:

²Leaks at the weld joint around the outside diam-

eter weld.

²Leaks at the converter hub weld.

CONVERTER HOUSING AREA LEAK CORRECTION

(1) Remove converter.

(2) Tighten front band adjusting screw until band

is tight around front clutch retainer. This prevents

front/rear clutches from coming out when oil pump is

removed.

(3) Remove oil pump and remove pump seal.

Inspect pump housing drainback and vent holes for

obstructions. Clear holes with solvent and wire.(4) Inspect pump bushing and converter hub. If

bushing is scored, replace it. If converter hub is

scored, either polish it with crocus cloth or replace

converter.

(5) Install new pump seal, O-ring, and gasket.

Replace oil pump if cracked, porous or damaged in

any way. Be sure to loosen the front band before

installing the oil pump, damage to the oil pump seal

may occur if the band is still tightened to the front

clutch retainer.

(6) Loosen kickdown lever pin access plug three

turns. Apply LoctiteŸ 592, or PermatextNo.2to

plug threads and tighten plug to 17 N´m (150 in. lbs.)

torque.

(7) Adjust front band.

(8) Lubricate pump seal and converter hub with

transmission fluid or petroleum jelly and install con-

verter.

(9) Install transmission and converter housing

dust shield.

(10) Lower vehicle.

DIAGNOSIS AND TESTING - DIAGNOSIS

CHARTS

The diagnosis charts provide additional reference

when diagnosing a transmission fault. The charts

provide general information on a variety of transmis-

sion, overdrive unit and converter clutch fault condi-

tions.

The hydraulic flow charts in the Schematics and

Diagrams section of this group, outline fluid flow and

hydraulic circuitry. Circuit operation is provided for

PARK, NEUTRAL, FIRST, SECOND, THIRD,

FOURTH, MANUAL FIRST, MANUAL SECOND,

and REVERSE gear ranges. Normal working pres-

sures are also supplied for each of the gear ranges.

Fig. 11 Converter Housing Leak Paths

1 - PUMP SEAL

2 - PUMP VENT

3 - PUMP BOLT

4 - PUMP GASKET

5 - CONVERTER HOUSING

6 - CONVERTER

7 - REAR MAIN SEAL LEAK

DRAUTOMATIC TRANSMISSION - 48RE 21 - 145

AUTOMATIC TRANSMISSION - 48RE (Continued)