DODGE RAM 1500 1998 2.G Workshop Manual

Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 111 of 2627

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

3 - 30 FRONT AXLE - C205FDR

FRONT AXLE - C205F (Continued)

Page 112 of 2627

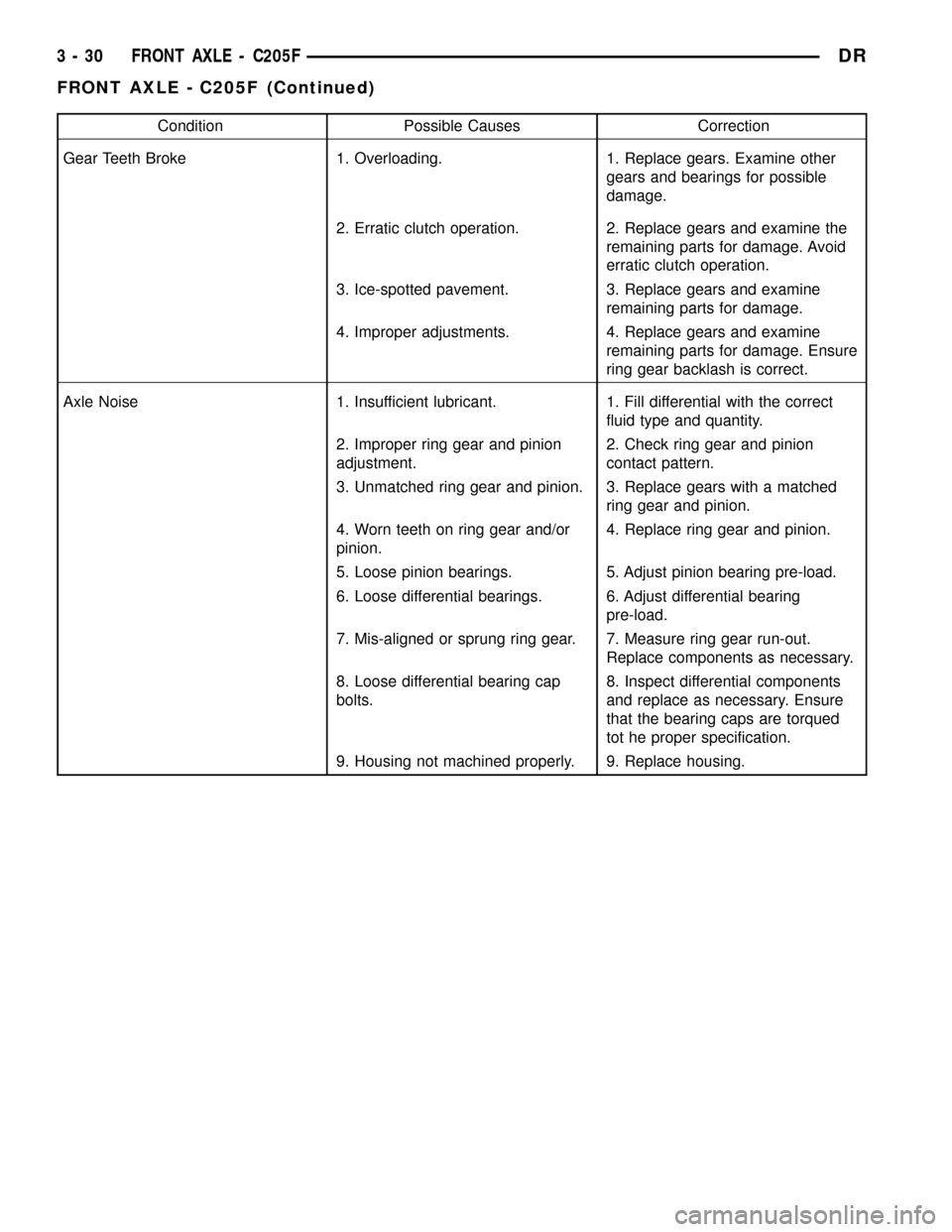

REMOVAL

(1) With vehicle in neutral, position vehicle on

hoist.

(2) Remove axle half shafts.

(3) Remove exhaust crossover.

(4) Mark front propeller shaft and remove shaft.

(5) Remove suspension crossmember mounting

bolts (Fig. 1) and remove crossmember.

(6) Support axle with hydraulic jack.

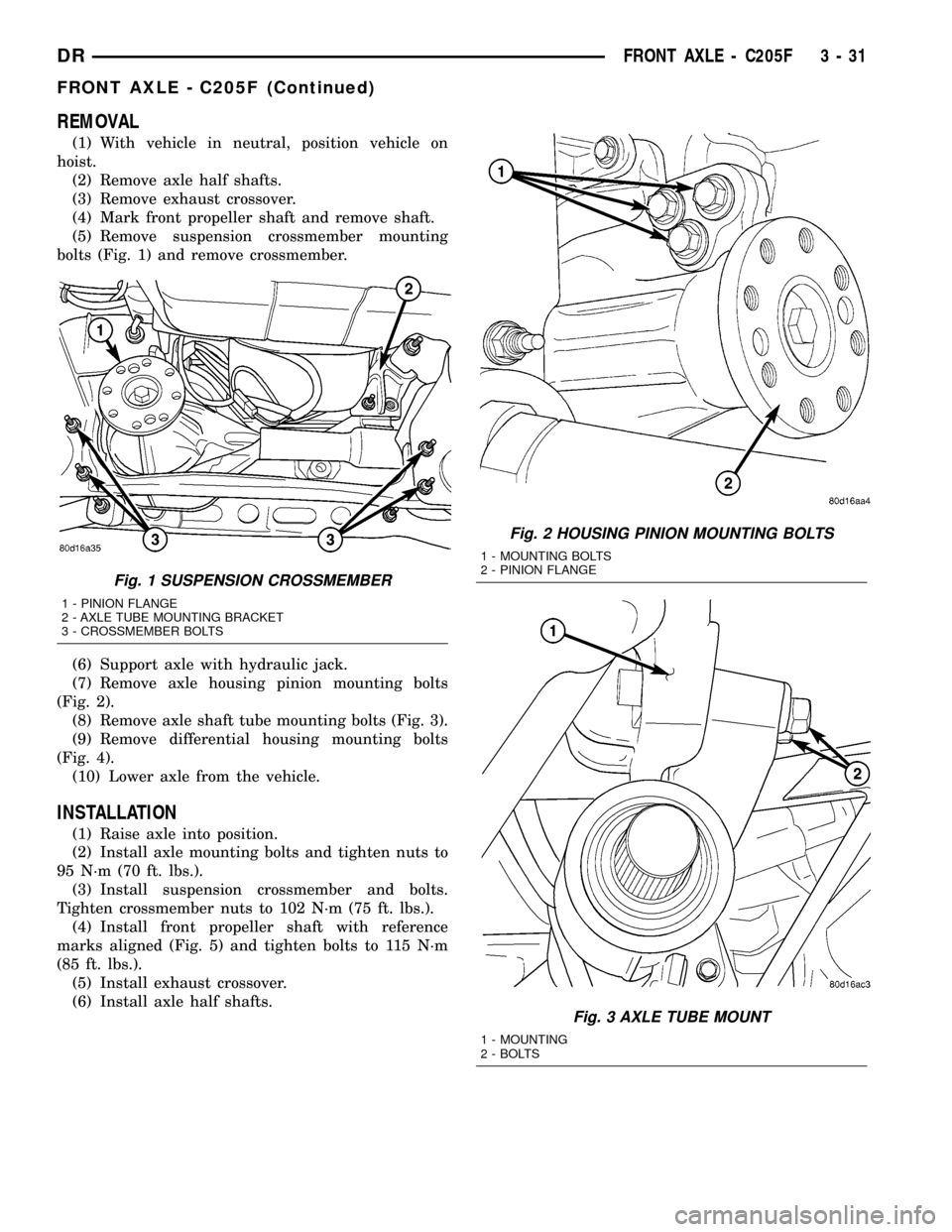

(7) Remove axle housing pinion mounting bolts

(Fig. 2).

(8) Remove axle shaft tube mounting bolts (Fig. 3).

(9) Remove differential housing mounting bolts

(Fig. 4).

(10) Lower axle from the vehicle.

INSTALLATION

(1) Raise axle into position.

(2) Install axle mounting bolts and tighten nuts to

95 N´m (70 ft. lbs.).

(3) Install suspension crossmember and bolts.

Tighten crossmember nuts to 102 N´m (75 ft. lbs.).

(4) Install front propeller shaft with reference

marks aligned (Fig. 5) and tighten bolts to 115 N´m

(85 ft. lbs.).

(5) Install exhaust crossover.

(6) Install axle half shafts.

Fig. 1 SUSPENSION CROSSMEMBER

1 - PINION FLANGE

2 - AXLE TUBE MOUNTING BRACKET

3 - CROSSMEMBER BOLTS

Fig. 2 HOUSING PINION MOUNTING BOLTS

1 - MOUNTING BOLTS

2 - PINION FLANGE

Fig. 3 AXLE TUBE MOUNT

1 - MOUNTING

2 - BOLTS

DRFRONT AXLE - C205F 3 - 31

FRONT AXLE - C205F (Continued)

Page 113 of 2627

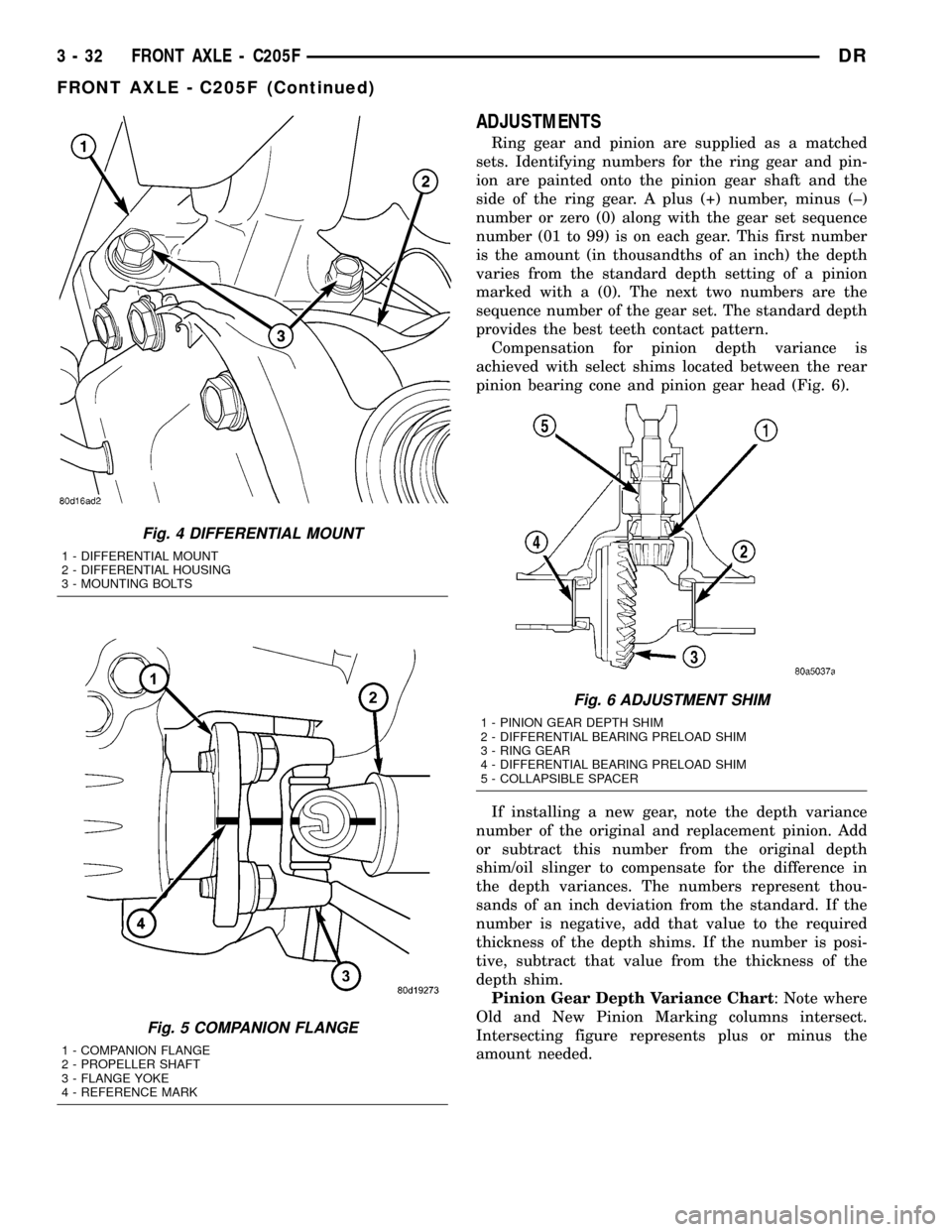

ADJUSTMENTS

Ring gear and pinion are supplied as a matched

sets. Identifying numbers for the ring gear and pin-

ion are painted onto the pinion gear shaft and the

side of the ring gear. A plus (+) number, minus (±)

number or zero (0) along with the gear set sequence

number (01 to 99) is on each gear. This first number

is the amount (in thousandths of an inch) the depth

varies from the standard depth setting of a pinion

marked with a (0). The next two numbers are the

sequence number of the gear set. The standard depth

provides the best teeth contact pattern.

Compensation for pinion depth variance is

achieved with select shims located between the rear

pinion bearing cone and pinion gear head (Fig. 6).

If installing a new gear, note the depth variance

number of the original and replacement pinion. Add

or subtract this number from the original depth

shim/oil slinger to compensate for the difference in

the depth variances. The numbers represent thou-

sands of an inch deviation from the standard. If the

number is negative, add that value to the required

thickness of the depth shims. If the number is posi-

tive, subtract that value from the thickness of the

depth shim.

Pinion Gear Depth Variance Chart: Note where

Old and New Pinion Marking columns intersect.

Intersecting figure represents plus or minus the

amount needed.

Fig. 4 DIFFERENTIAL MOUNT

1 - DIFFERENTIAL MOUNT

2 - DIFFERENTIAL HOUSING

3 - MOUNTING BOLTS

Fig. 5 COMPANION FLANGE

1 - COMPANION FLANGE

2 - PROPELLER SHAFT

3 - FLANGE YOKE

4 - REFERENCE MARK

Fig. 6 ADJUSTMENT SHIM

1 - PINION GEAR DEPTH SHIM

2 - DIFFERENTIAL BEARING PRELOAD SHIM

3 - RING GEAR

4 - DIFFERENTIAL BEARING PRELOAD SHIM

5 - COLLAPSIBLE SPACER

3 - 32 FRONT AXLE - C205FDR

FRONT AXLE - C205F (Continued)

Page 114 of 2627

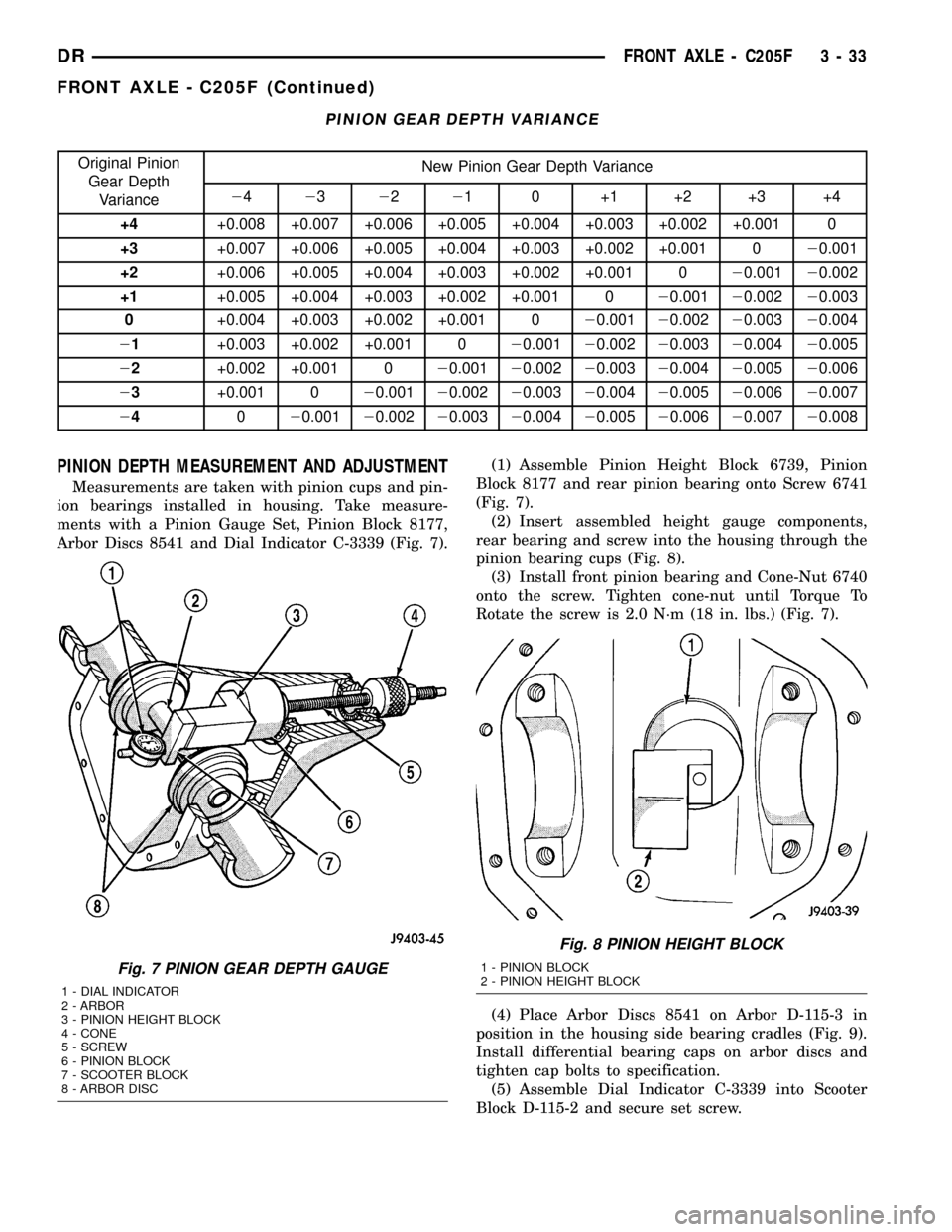

PINION GEAR DEPTH VARIANCE

Original Pinion

Gear Depth

VarianceNew Pinion Gear Depth Variance

24232221 0 +1 +2 +3 +4

+4+0.008 +0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 0

+3+0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 020.001

+2+0.006 +0.005 +0.004 +0.003 +0.002 +0.001 020.00120.002

+1+0.005 +0.004 +0.003 +0.002 +0.001 020.00120.00220.003

0+0.004 +0.003 +0.002 +0.001 020.00120.00220.00320.004

21+0.003 +0.002 +0.001 020.00120.00220.00320.00420.005

22+0.002 +0.001 020.00120.00220.00320.00420.00520.006

23+0.001 020.00120.00220.00320.00420.00520.00620.007

24020.00120.00220.00320.00420.00520.00620.00720.008

PINION DEPTH MEASUREMENT AND ADJUSTMENT

Measurements are taken with pinion cups and pin-

ion bearings installed in housing. Take measure-

ments with a Pinion Gauge Set, Pinion Block 8177,

Arbor Discs 8541 and Dial Indicator C-3339 (Fig. 7).(1) Assemble Pinion Height Block 6739, Pinion

Block 8177 and rear pinion bearing onto Screw 6741

(Fig. 7).

(2) Insert assembled height gauge components,

rear bearing and screw into the housing through the

pinion bearing cups (Fig. 8).

(3) Install front pinion bearing and Cone-Nut 6740

onto the screw. Tighten cone-nut until Torque To

Rotate the screw is 2.0 N´m (18 in. lbs.) (Fig. 7).

(4) Place Arbor Discs 8541 on Arbor D-115-3 in

position in the housing side bearing cradles (Fig. 9).

Install differential bearing caps on arbor discs and

tighten cap bolts to specification.

(5) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

Fig. 7 PINION GEAR DEPTH GAUGE

1 - DIAL INDICATOR

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

Fig. 8 PINION HEIGHT BLOCK

1 - PINION BLOCK

2 - PINION HEIGHT BLOCK

DRFRONT AXLE - C205F 3 - 33

FRONT AXLE - C205F (Continued)

Page 115 of 2627

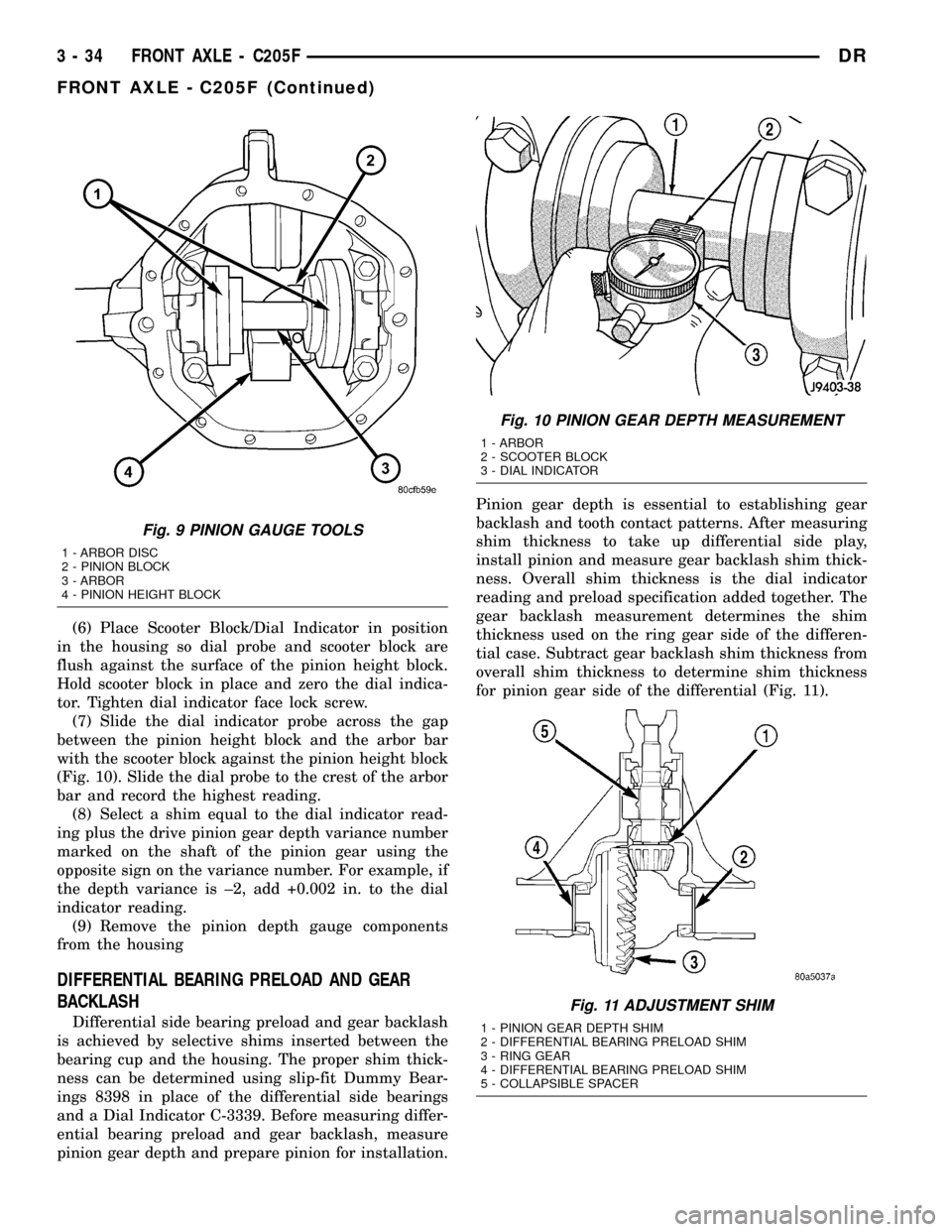

(6) Place Scooter Block/Dial Indicator in position

in the housing so dial probe and scooter block are

flush against the surface of the pinion height block.

Hold scooter block in place and zero the dial indica-

tor. Tighten dial indicator face lock screw.

(7) Slide the dial indicator probe across the gap

between the pinion height block and the arbor bar

with the scooter block against the pinion height block

(Fig. 10). Slide the dial probe to the crest of the arbor

bar and record the highest reading.

(8) Select a shim equal to the dial indicator read-

ing plus the drive pinion gear depth variance number

marked on the shaft of the pinion gear using the

opposite sign on the variance number. For example, if

the depth variance is ±2, add +0.002 in. to the dial

indicator reading.

(9) Remove the pinion depth gauge components

from the housing

DIFFERENTIAL BEARING PRELOAD AND GEAR

BACKLASH

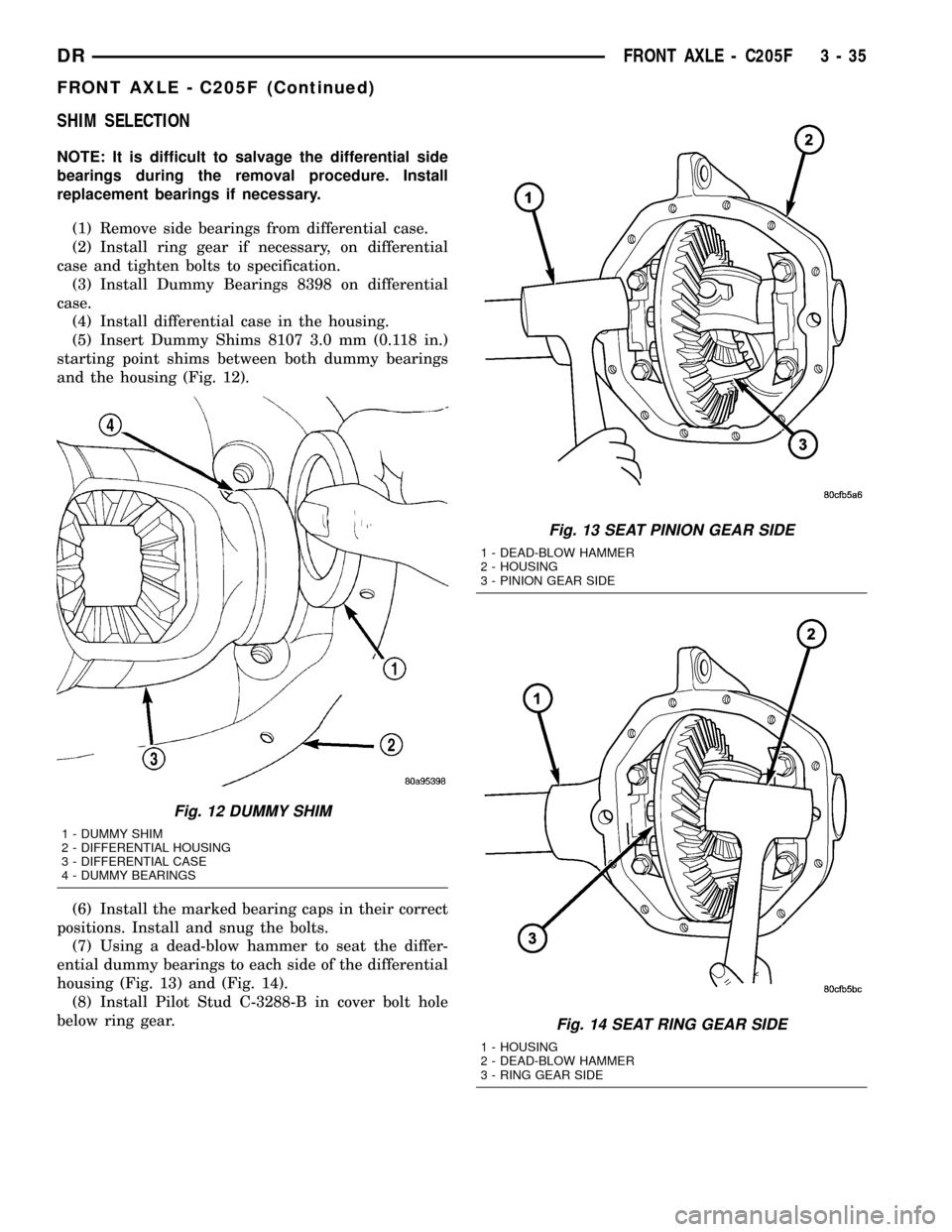

Differential side bearing preload and gear backlash

is achieved by selective shims inserted between the

bearing cup and the housing. The proper shim thick-

ness can be determined using slip-fit Dummy Bear-

ings 8398 in place of the differential side bearings

and a Dial Indicator C-3339. Before measuring differ-

ential bearing preload and gear backlash, measure

pinion gear depth and prepare pinion for installation.Pinion gear depth is essential to establishing gear

backlash and tooth contact patterns. After measuring

shim thickness to take up differential side play,

install pinion and measure gear backlash shim thick-

ness. Overall shim thickness is the dial indicator

reading and preload specification added together. The

gear backlash measurement determines the shim

thickness used on the ring gear side of the differen-

tial case. Subtract gear backlash shim thickness from

overall shim thickness to determine shim thickness

for pinion gear side of the differential (Fig. 11).

Fig. 9 PINION GAUGE TOOLS

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

Fig. 10 PINION GEAR DEPTH MEASUREMENT

1 - ARBOR

2 - SCOOTER BLOCK

3 - DIAL INDICATOR

Fig. 11 ADJUSTMENT SHIM

1 - PINION GEAR DEPTH SHIM

2 - DIFFERENTIAL BEARING PRELOAD SHIM

3 - RING GEAR

4 - DIFFERENTIAL BEARING PRELOAD SHIM

5 - COLLAPSIBLE SPACER

3 - 34 FRONT AXLE - C205FDR

FRONT AXLE - C205F (Continued)

Page 116 of 2627

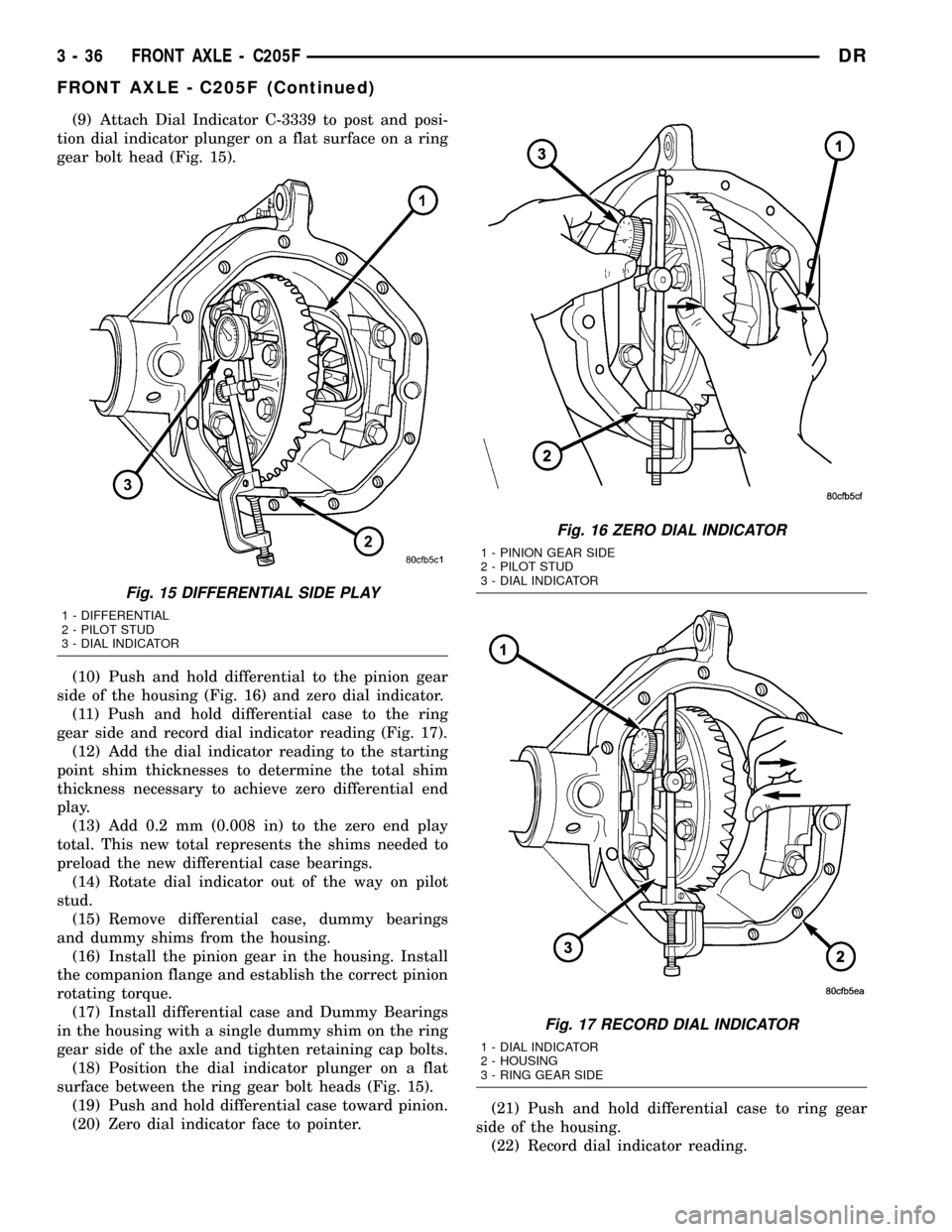

SHIM SELECTION

NOTE: It is difficult to salvage the differential side

bearings during the removal procedure. Install

replacement bearings if necessary.

(1) Remove side bearings from differential case.

(2) Install ring gear if necessary, on differential

case and tighten bolts to specification.

(3) Install Dummy Bearings 8398 on differential

case.

(4) Install differential case in the housing.

(5) Insert Dummy Shims 8107 3.0 mm (0.118 in.)

starting point shims between both dummy bearings

and the housing (Fig. 12).

(6) Install the marked bearing caps in their correct

positions. Install and snug the bolts.

(7) Using a dead-blow hammer to seat the differ-

ential dummy bearings to each side of the differential

housing (Fig. 13) and (Fig. 14).

(8) Install Pilot Stud C-3288-B in cover bolt hole

below ring gear.

Fig. 12 DUMMY SHIM

1 - DUMMY SHIM

2 - DIFFERENTIAL HOUSING

3 - DIFFERENTIAL CASE

4 - DUMMY BEARINGS

Fig. 13 SEAT PINION GEAR SIDE

1 - DEAD-BLOW HAMMER

2 - HOUSING

3 - PINION GEAR SIDE

Fig. 14 SEAT RING GEAR SIDE

1 - HOUSING

2 - DEAD-BLOW HAMMER

3 - RING GEAR SIDE

DRFRONT AXLE - C205F 3 - 35

FRONT AXLE - C205F (Continued)

Page 117 of 2627

(9) Attach Dial Indicator C-3339 to post and posi-

tion dial indicator plunger on a flat surface on a ring

gear bolt head (Fig. 15).

(10) Push and hold differential to the pinion gear

side of the housing (Fig. 16) and zero dial indicator.

(11) Push and hold differential case to the ring

gear side and record dial indicator reading (Fig. 17).

(12) Add the dial indicator reading to the starting

point shim thicknesses to determine the total shim

thickness necessary to achieve zero differential end

play.

(13) Add 0.2 mm (0.008 in) to the zero end play

total. This new total represents the shims needed to

preload the new differential case bearings.

(14) Rotate dial indicator out of the way on pilot

stud.

(15) Remove differential case, dummy bearings

and dummy shims from the housing.

(16) Install the pinion gear in the housing. Install

the companion flange and establish the correct pinion

rotating torque.

(17) Install differential case and Dummy Bearings

in the housing with a single dummy shim on the ring

gear side of the axle and tighten retaining cap bolts.

(18) Position the dial indicator plunger on a flat

surface between the ring gear bolt heads (Fig. 15).

(19) Push and hold differential case toward pinion.

(20) Zero dial indicator face to pointer.(21) Push and hold differential case to ring gear

side of the housing.

(22) Record dial indicator reading.

Fig. 15 DIFFERENTIAL SIDE PLAY

1 - DIFFERENTIAL

2 - PILOT STUD

3 - DIAL INDICATOR

Fig. 16 ZERO DIAL INDICATOR

1 - PINION GEAR SIDE

2 - PILOT STUD

3 - DIAL INDICATOR

Fig. 17 RECORD DIAL INDICATOR

1 - DIAL INDICATOR

2 - HOUSING

3 - RING GEAR SIDE

3 - 36 FRONT AXLE - C205FDR

FRONT AXLE - C205F (Continued)

Page 118 of 2627

(23) Subtract 0.05 mm (0.002 in.) from the dial

indicator reading to compensate for backlash between

ring and pinion gears. Add the resulting measure-

ment to the thickness of the single dummy shim.

This is the thickness of shim required to achieve

proper backlash.

(24) Subtract the backlash shim thickness from

the total preload shim thickness. The remainder is

the shim thickness required on the pinion side of the

housing.

(25) Rotate dial indicator out of the way on pilot

stud.

(26) Remove differential case, dummy bearings

and dummy shim from the housing.

(27) Install new side bearing cones and cups on

differential case.

(28) Install Spreader W-129-B and Adapter Plates

8142-A on the housing and spread open enough to

receive differential case.

CAUTION: Never spread over 0.50 mm (0.020 in). If

the housing is over-spread, it could be distorted or

damaged.

(29) Place the side bearing shims in the differen-

tial housing against the housing shoulder.

(30) Install the differential case in the housing.

(31) Rotate the differential case several times to

seat the side bearings.

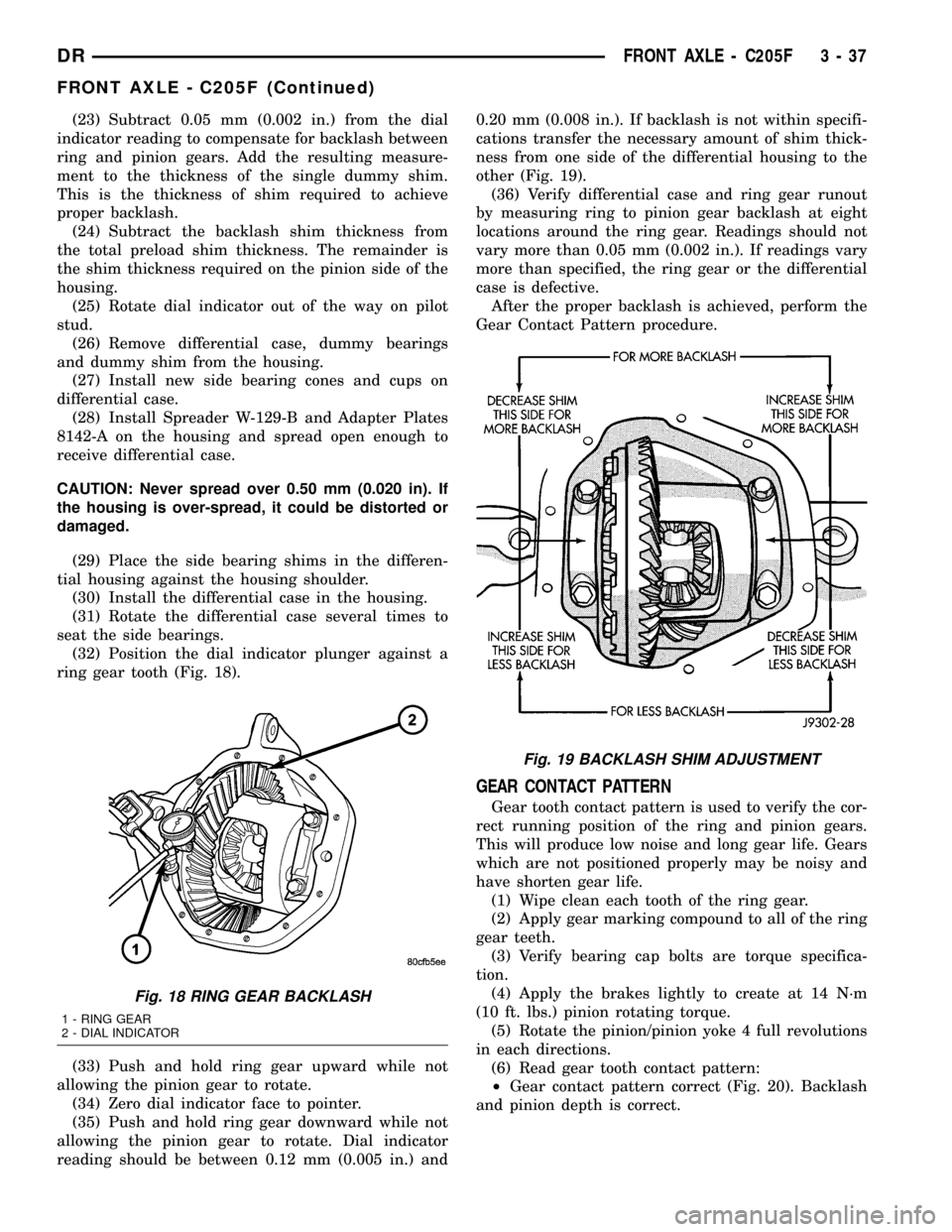

(32) Position the dial indicator plunger against a

ring gear tooth (Fig. 18).

(33) Push and hold ring gear upward while not

allowing the pinion gear to rotate.

(34) Zero dial indicator face to pointer.

(35) Push and hold ring gear downward while not

allowing the pinion gear to rotate. Dial indicator

reading should be between 0.12 mm (0.005 in.) and0.20 mm (0.008 in.). If backlash is not within specifi-

cations transfer the necessary amount of shim thick-

ness from one side of the differential housing to the

other (Fig. 19).

(36) Verify differential case and ring gear runout

by measuring ring to pinion gear backlash at eight

locations around the ring gear. Readings should not

vary more than 0.05 mm (0.002 in.). If readings vary

more than specified, the ring gear or the differential

case is defective.

After the proper backlash is achieved, perform the

Gear Contact Pattern procedure.

GEAR CONTACT PATTERN

Gear tooth contact pattern is used to verify the cor-

rect running position of the ring and pinion gears.

This will produce low noise and long gear life. Gears

which are not positioned properly may be noisy and

have shorten gear life.

(1) Wipe clean each tooth of the ring gear.

(2) Apply gear marking compound to all of the ring

gear teeth.

(3) Verify bearing cap bolts are torque specifica-

tion.

(4) Apply the brakes lightly to create at 14 N´m

(10 ft. lbs.) pinion rotating torque.

(5) Rotate the pinion/pinion yoke 4 full revolutions

in each directions.

(6) Read gear tooth contact pattern:

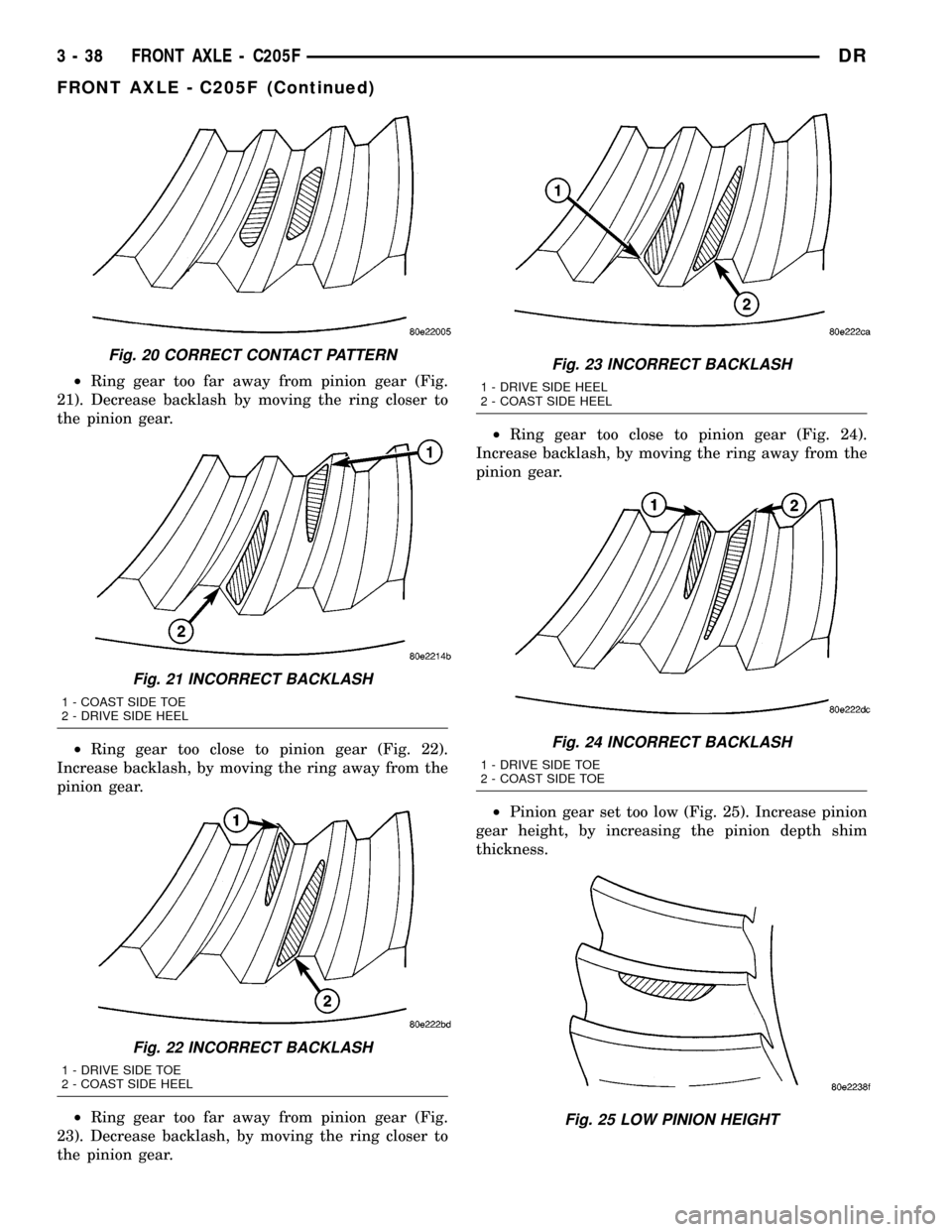

²Gear contact pattern correct (Fig. 20). Backlash

and pinion depth is correct.

Fig. 18 RING GEAR BACKLASH

1 - RING GEAR

2 - DIAL INDICATOR

Fig. 19 BACKLASH SHIM ADJUSTMENT

DRFRONT AXLE - C205F 3 - 37

FRONT AXLE - C205F (Continued)

Page 119 of 2627

²Ring gear too far away from pinion gear (Fig.

21). Decrease backlash by moving the ring closer to

the pinion gear.

²Ring gear too close to pinion gear (Fig. 22).

Increase backlash, by moving the ring away from the

pinion gear.

²Ring gear too far away from pinion gear (Fig.

23). Decrease backlash, by moving the ring closer to

the pinion gear.²Ring gear too close to pinion gear (Fig. 24).

Increase backlash, by moving the ring away from the

pinion gear.

²Pinion gear set too low (Fig. 25). Increase pinion

gear height, by increasing the pinion depth shim

thickness.

Fig. 20 CORRECT CONTACT PATTERN

Fig. 21 INCORRECT BACKLASH

1 - COAST SIDE TOE

2 - DRIVE SIDE HEEL

Fig. 22 INCORRECT BACKLASH

1 - DRIVE SIDE TOE

2 - COAST SIDE HEEL

Fig. 23 INCORRECT BACKLASH

1 - DRIVE SIDE HEEL

2 - COAST SIDE HEEL

Fig. 24 INCORRECT BACKLASH

1 - DRIVE SIDE TOE

2 - COAST SIDE TOE

Fig. 25 LOW PINION HEIGHT

3 - 38 FRONT AXLE - C205FDR

FRONT AXLE - C205F (Continued)

Page 120 of 2627

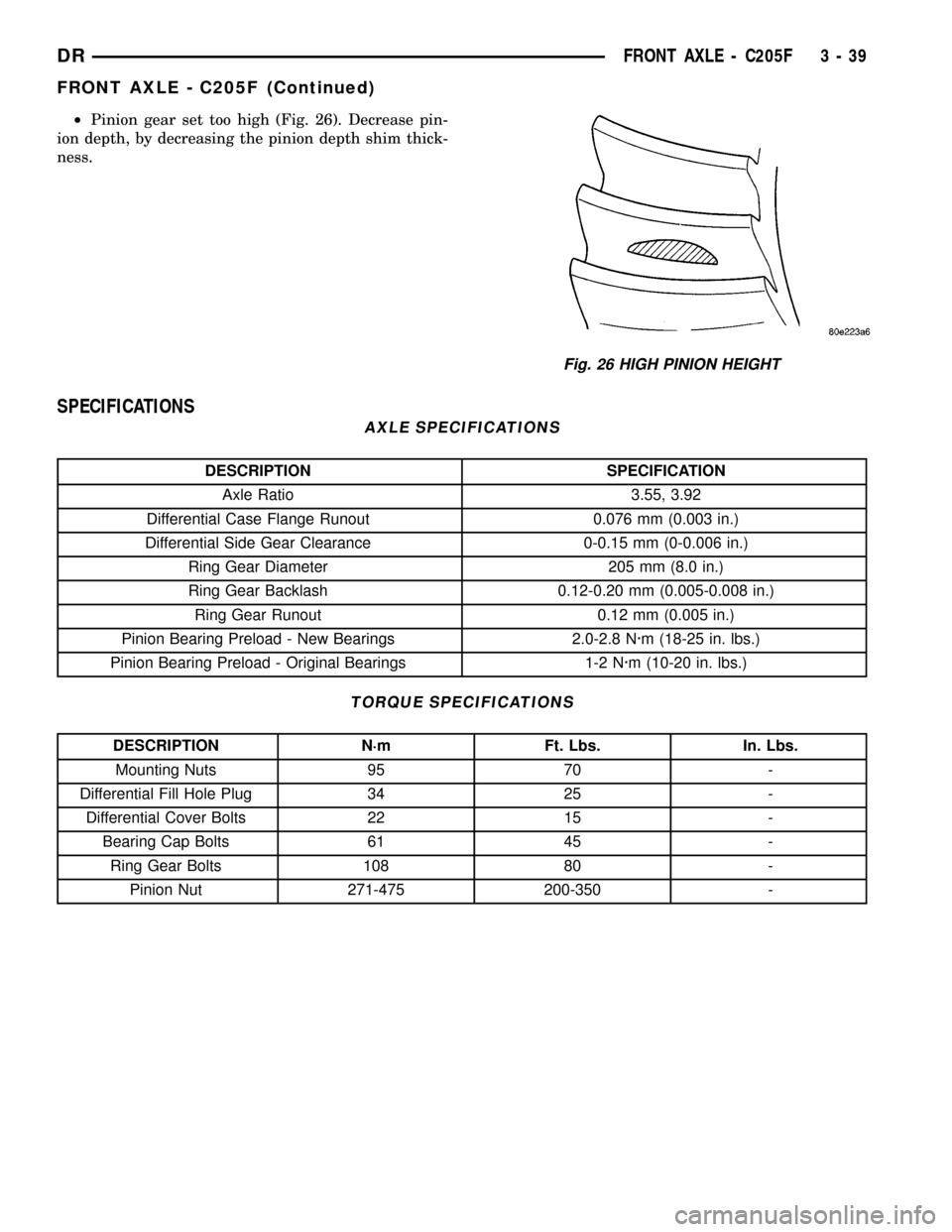

²Pinion gear set too high (Fig. 26). Decrease pin-

ion depth, by decreasing the pinion depth shim thick-

ness.

SPECIFICATIONS

AXLE SPECIFICATIONS

DESCRIPTION SPECIFICATION

Axle Ratio 3.55, 3.92

Differential Case Flange Runout 0.076 mm (0.003 in.)

Differential Side Gear Clearance 0-0.15 mm (0-0.006 in.)

Ring Gear Diameter 205 mm (8.0 in.)

Ring Gear Backlash 0.12-0.20 mm (0.005-0.008 in.)

Ring Gear Runout 0.12 mm (0.005 in.)

Pinion Bearing Preload - New Bearings 2.0-2.8 N´m (18-25 in. lbs.)

Pinion Bearing Preload - Original Bearings 1-2 N´m (10-20 in. lbs.)

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Mounting Nuts 95 70 -

Differential Fill Hole Plug 34 25 -

Differential Cover Bolts 22 15 -

Bearing Cap Bolts 61 45 -

Ring Gear Bolts 108 80 -

Pinion Nut 271-475 200-350 -

Fig. 26 HIGH PINION HEIGHT

DRFRONT AXLE - C205F 3 - 39

FRONT AXLE - C205F (Continued)