Trans temp DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2102 of 2627

A solenoid can also be described by the method by

which it is controlled. Some of the possibilities

include variable force, pulse-width modulated, con-

stant ON, or duty cycle. The variable force and pulse-

width modulated versions utilize similar methods to

control the current flow through the solenoid to posi-

tion the solenoid plunger at a desired position some-

where between full ON and full OFF. The constant

ON and duty cycled versions control the voltage

across the solenoid to allow either full flow or no flow

through the solenoid's valve.

OPERATION

When an electrical current is applied to the sole-

noid coil, a magnetic field is created which produces

an attraction to the plunger, causing the plunger to

move and work against the spring pressure and the

load applied by the fluid the valve is controlling. The

plunger is normally directly attached to the valve

which it is to operate. When the current is removed

from the coil, the attraction is removed and the

plunger will return to its original position due to

spring pressure.

The plunger is made of a conductive material and

accomplishes this movement by providing a path for

the magnetic field to flow. By keeping the air gap

between the plunger and the coil to the minimum

necessary to allow free movement of the plunger, the

magnetic field is maximized.

TORQUE CONVERTER

DESCRIPTION

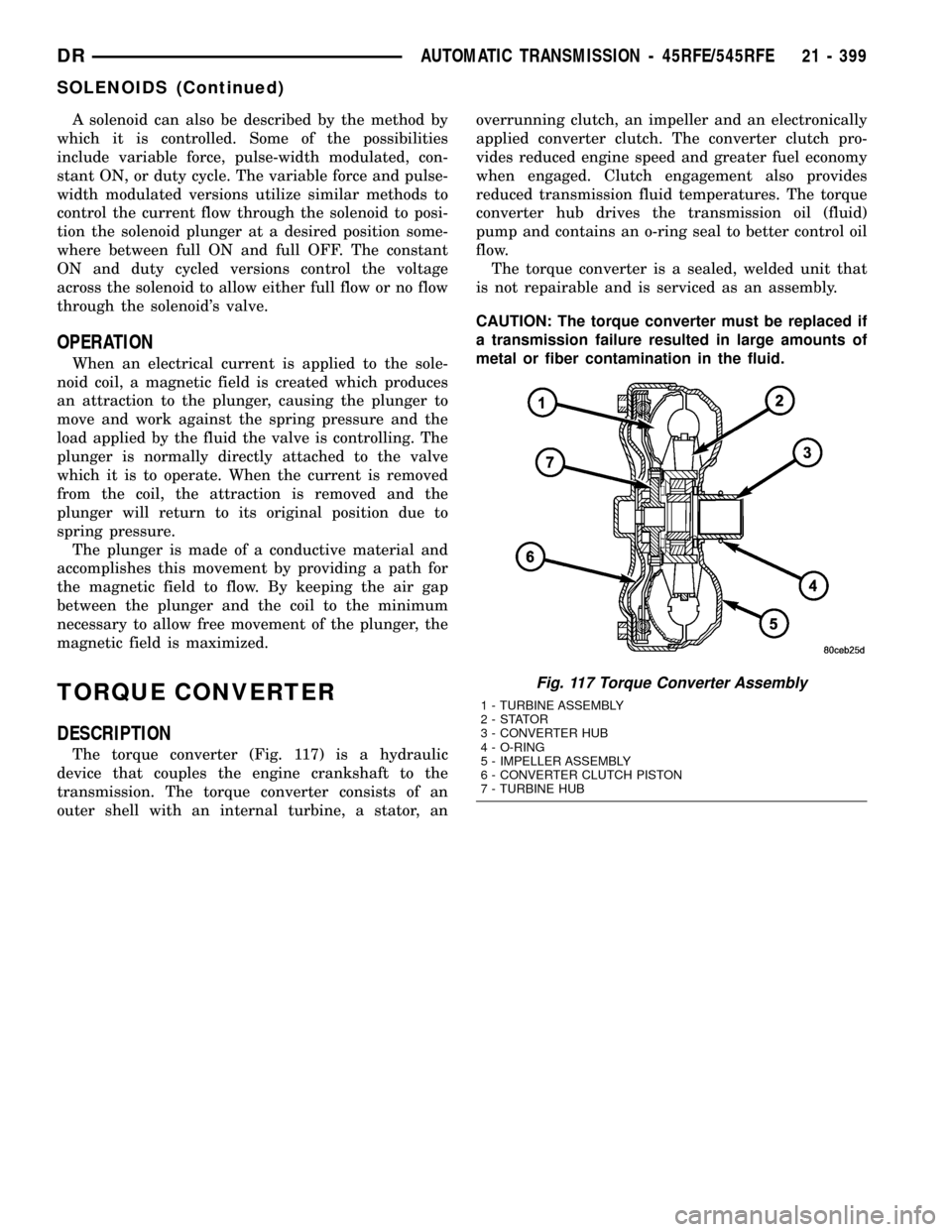

The torque converter (Fig. 117) is a hydraulic

device that couples the engine crankshaft to the

transmission. The torque converter consists of an

outer shell with an internal turbine, a stator, anoverrunning clutch, an impeller and an electronically

applied converter clutch. The converter clutch pro-

vides reduced engine speed and greater fuel economy

when engaged. Clutch engagement also provides

reduced transmission fluid temperatures. The torque

converter hub drives the transmission oil (fluid)

pump and contains an o-ring seal to better control oil

flow.

The torque converter is a sealed, welded unit that

is not repairable and is serviced as an assembly.

CAUTION: The torque converter must be replaced if

a transmission failure resulted in large amounts of

metal or fiber contamination in the fluid.

Fig. 117 Torque Converter Assembly

1 - TURBINE ASSEMBLY

2-STATOR

3 - CONVERTER HUB

4 - O-RING

5 - IMPELLER ASSEMBLY

6 - CONVERTER CLUTCH PISTON

7 - TURBINE HUB

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 399

SOLENOIDS (Continued)

Page 2105 of 2627

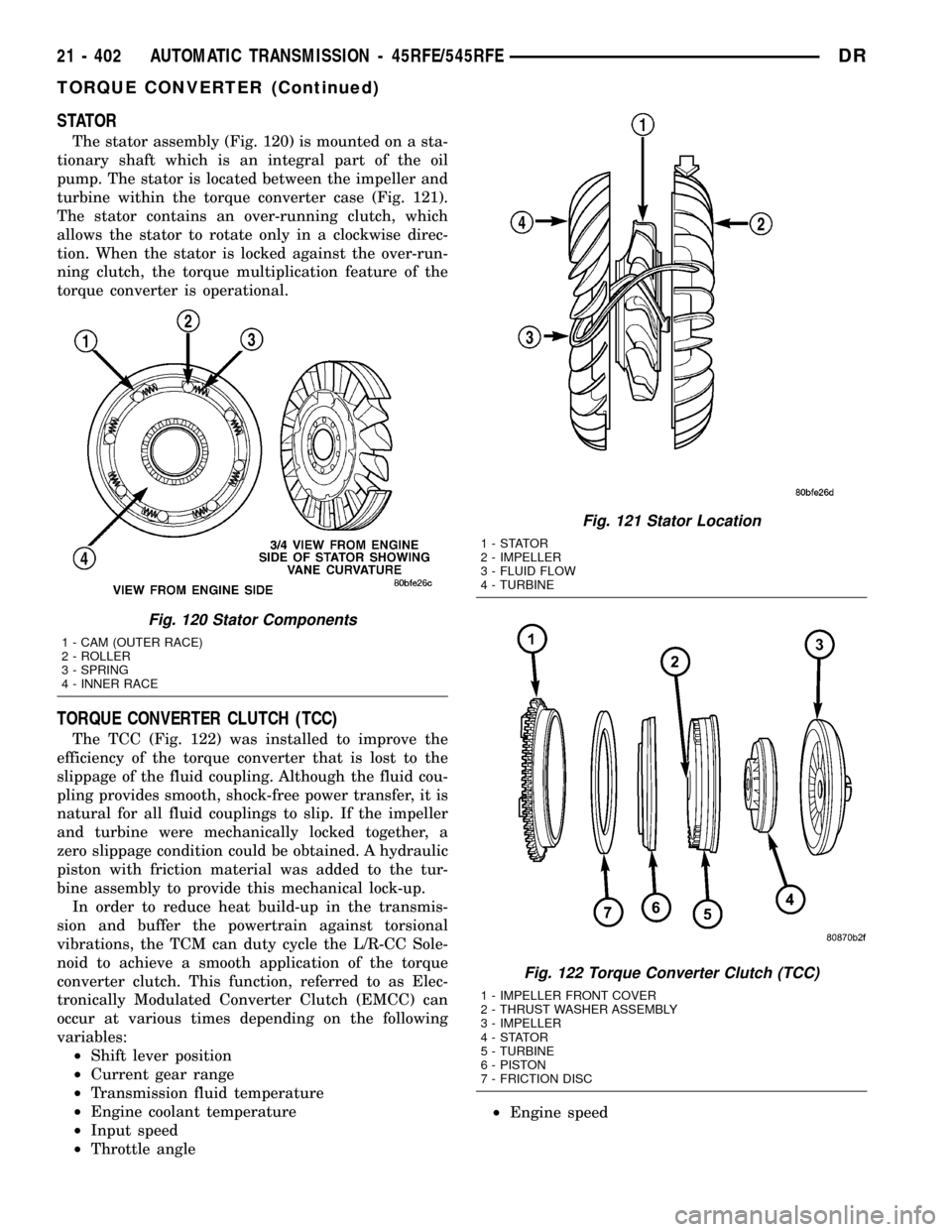

STATOR

The stator assembly (Fig. 120) is mounted on a sta-

tionary shaft which is an integral part of the oil

pump. The stator is located between the impeller and

turbine within the torque converter case (Fig. 121).

The stator contains an over-running clutch, which

allows the stator to rotate only in a clockwise direc-

tion. When the stator is locked against the over-run-

ning clutch, the torque multiplication feature of the

torque converter is operational.

TORQUE CONVERTER CLUTCH (TCC)

The TCC (Fig. 122) was installed to improve the

efficiency of the torque converter that is lost to the

slippage of the fluid coupling. Although the fluid cou-

pling provides smooth, shock-free power transfer, it is

natural for all fluid couplings to slip. If the impeller

and turbine were mechanically locked together, a

zero slippage condition could be obtained. A hydraulic

piston with friction material was added to the tur-

bine assembly to provide this mechanical lock-up.

In order to reduce heat build-up in the transmis-

sion and buffer the powertrain against torsional

vibrations, the TCM can duty cycle the L/R-CC Sole-

noid to achieve a smooth application of the torque

converter clutch. This function, referred to as Elec-

tronically Modulated Converter Clutch (EMCC) can

occur at various times depending on the following

variables:

²Shift lever position

²Current gear range

²Transmission fluid temperature

²Engine coolant temperature

²Input speed

²Throttle angle²Engine speed

Fig. 120 Stator Components

1 - CAM (OUTER RACE)

2 - ROLLER

3 - SPRING

4 - INNER RACE

Fig. 121 Stator Location

1-STATOR

2 - IMPELLER

3 - FLUID FLOW

4 - TURBINE

Fig. 122 Torque Converter Clutch (TCC)

1 - IMPELLER FRONT COVER

2 - THRUST WASHER ASSEMBLY

3 - IMPELLER

4-STATOR

5 - TURBINE

6 - PISTON

7 - FRICTION DISC

21 - 402 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

TORQUE CONVERTER (Continued)

Page 2107 of 2627

control switch is in the OFF position, the clutch will

engage after the shift to third gear.

The TCM controls the torque converter by way of

internal logic software. The programming of the soft-

ware provides the TCM with control over the L/R-CC

Solenoid. There are four output logic states that can

be applied as follows:

²No EMCC

²Partial EMCC

²Full EMCC

²Gradual-to-no EMCC

NO EMCC

Under No EMCC conditions, the L/R Solenoid is

OFF. There are several conditions that can result in

NO EMCC operations. No EMCC can be initiated

due to a fault in the transmission or because the

TCM does not see the need for EMCC under current

driving conditions.

PARTIAL EMCC

Partial EMCC operation modulates the L/R Sole-

noid (duty cycle) to obtain partial torque converter

clutch application. Partial EMCC operation is main-

tained until Full EMCC is called for and actuated.

During Partial EMCC some slip does occur. Partial

EMCC will usually occur at low speeds, low load and

light throttle situations.

FULL EMCC

During Full EMCC operation, the TCM increases

the L/R Solenoid duty cycle to full ON after Partial

EMCC control brings the engine speed within thedesired slip range of transmission input speed rela-

tive to engine rpm.

GRADUAL-TO-NO EMCC

This operation is to soften the change from Full or

Partial EMCC to No EMCC. This is done at mid-

throttle by decreasing the L/R Solenoid duty cycle.

REMOVAL

(1) Remove transmission and torque converter

from vehicle.

(2) Place a suitable drain pan under the converter

housing end of the transmission.

CAUTION: Verify that transmission is secure on the

lifting device or work surface, the center of gravity

of the transmission will shift when the torque con-

verter is removed creating an unstable condition.

The torque converter is a heavy unit. Use caution

when separating the torque converter from the

transmission.

(3) Pull the torque converter forward until the cen-

ter hub clears the oil pump seal.

(4) Separate the torque converter from the trans-

mission.

INSTALLATION

Check converter hub and drive flats for sharp

edges, burrs, scratches, or nicks. Polish the hub and

flats with 320/400 grit paper or crocus cloth if neces-

sary. Verify that the converter hub o-ring is properly

installed and is free from debris. The hub must be

smooth to avoid damaging the pump seal at installa-

tion.

(1) Lubricate oil pump seal lip with transmission

fluid.

(2) Place torque converter in position on transmis-

sion.

CAUTION: Do not damage oil pump seal or con-

verter hub o-ring while inserting torque converter

into the front of the transmission.

(3) Align torque converter to oil pump seal open-

ing.

(4) Insert torque converter hub into oil pump.

(5) While pushing torque converter inward, rotate

converter until converter is fully seated in the oil

pump gears.

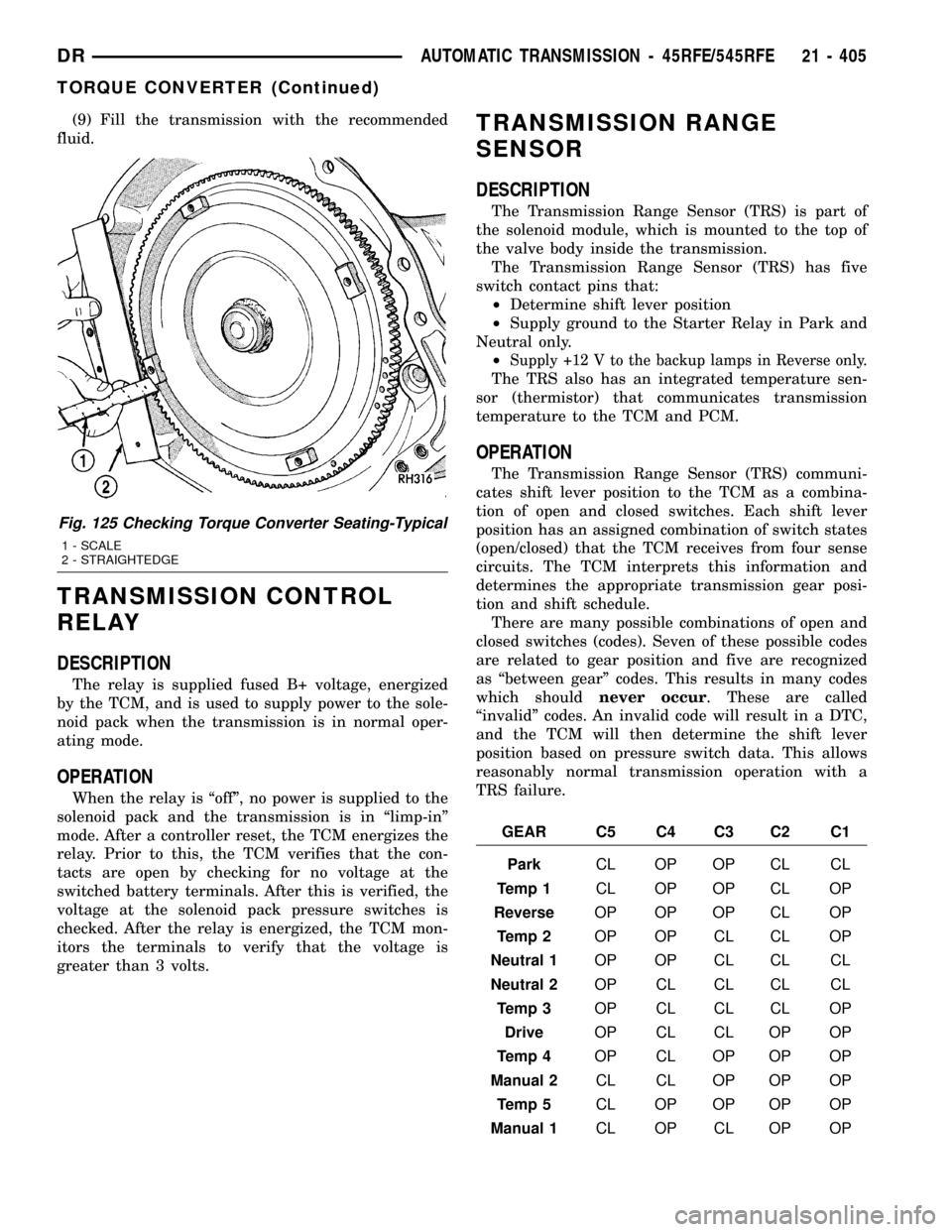

(6) Check converter seating with a scale and

straightedge (Fig. 125). Surface of converter lugs

should be at least 13 mm (1/2 in.) to rear of straight-

edge when converter is fully seated.

(7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing.

(8) Install the transmission in the vehicle.

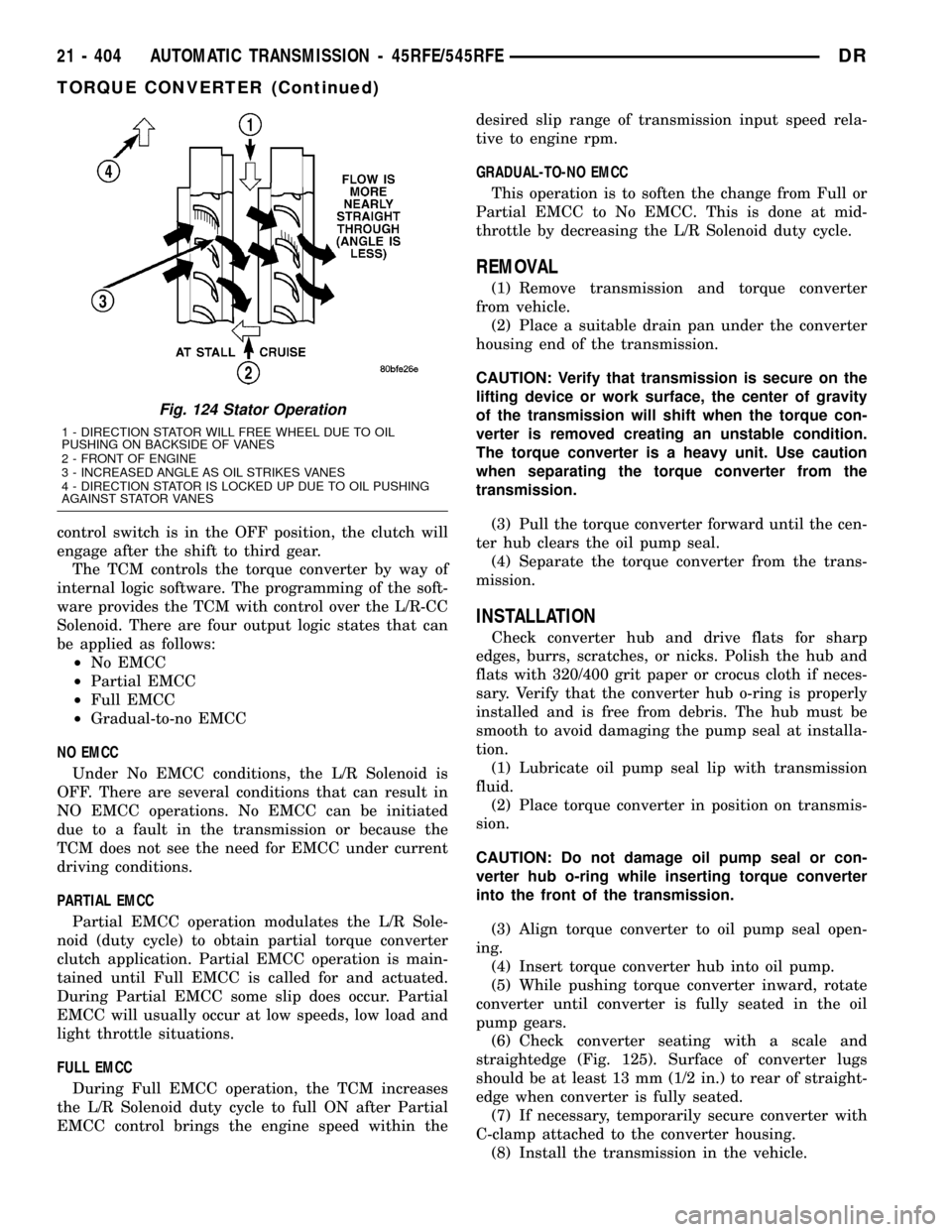

Fig. 124 Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2 - FRONT OF ENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

21 - 404 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

TORQUE CONVERTER (Continued)

Page 2108 of 2627

(9) Fill the transmission with the recommended

fluid.

TRANSMISSION CONTROL

RELAY

DESCRIPTION

The relay is supplied fused B+ voltage, energized

by the TCM, and is used to supply power to the sole-

noid pack when the transmission is in normal oper-

ating mode.

OPERATION

When the relay is ªoffº, no power is supplied to the

solenoid pack and the transmission is in ªlimp-inº

mode. After a controller reset, the TCM energizes the

relay. Prior to this, the TCM verifies that the con-

tacts are open by checking for no voltage at the

switched battery terminals. After this is verified, the

voltage at the solenoid pack pressure switches is

checked. After the relay is energized, the TCM mon-

itors the terminals to verify that the voltage is

greater than 3 volts.

TRANSMISSION RANGE

SENSOR

DESCRIPTION

The Transmission Range Sensor (TRS) is part of

the solenoid module, which is mounted to the top of

the valve body inside the transmission.

The Transmission Range Sensor (TRS) has five

switch contact pins that:

²Determine shift lever position

²Supply ground to the Starter Relay in Park and

Neutral only.

²

Supply +12 V to the backup lamps in Reverse only.

The TRS also has an integrated temperature sen-

sor (thermistor) that communicates transmission

temperature to the TCM and PCM.

OPERATION

The Transmission Range Sensor (TRS) communi-

cates shift lever position to the TCM as a combina-

tion of open and closed switches. Each shift lever

position has an assigned combination of switch states

(open/closed) that the TCM receives from four sense

circuits. The TCM interprets this information and

determines the appropriate transmission gear posi-

tion and shift schedule.

There are many possible combinations of open and

closed switches (codes). Seven of these possible codes

are related to gear position and five are recognized

as ªbetween gearº codes. This results in many codes

which shouldnever occur. These are called

ªinvalidº codes. An invalid code will result in a DTC,

and the TCM will then determine the shift lever

position based on pressure switch data. This allows

reasonably normal transmission operation with a

TRS failure.

GEAR C5 C4 C3 C2 C1

ParkCL OP OP CL CL

Temp 1CL OP OP CL OP

ReverseOP OP OP CL OP

Temp 2OP OP CL CL OP

Neutral 1OP OP CL CL CL

Neutral 2OP CL CL CL CL

Temp 3OP CL CL CL OP

DriveOP CL CL OP OP

Temp 4OP CL OP OP OP

Manual 2CL CL OP OP OP

Temp 5CL OP OP OP OP

Manual 1CL OP CL OP OP

Fig. 125 Checking Torque Converter Seating-Typical

1 - SCALE

2 - STRAIGHTEDGE

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 405

TORQUE CONVERTER (Continued)

Page 2111 of 2627

INSTALLATION

(1) Place TRS selector plate in the PARK position.

(2) Position the transmission solenoid/TRS assem-

bly onto the valve body. Be sure that both alignment

dowels are fully seated in the valve body and that

the TRS switch contacts are properly positioned in

the selector plate

(3) Install the screws to hold the transmission

solenoid/TRS assembly onto the valve body.

(4) Tighten the solenoid assembly screws adjacent

to the arrows cast into the bottom of the valve body

first. Tighten the screws to 5.7 N´m (50 in.lbs.).

(5) Tighten the remainder of the solenoid assembly

screws to 5.7 N´m (50 in.lbs.).

(6) Install the valve body into the transmission.

TRANSMISSION

TEMPERATURE SENSOR

DESCRIPTION

The transmission temperature sensor is a ther-

mistor that is integral to the Transmission Range

Sensor (TRS).

OPERATION

The transmission temperature sensor is used by

the TCM to sense the temperature of the fluid in the

sump. Since fluid temperature can affect transmis-

sion shift quality and convertor lock up, the TCM

requires this information to determine which shift

schedule to operate in.

Calculated Temperature

A failure in the temperature sensor or circuit will

result in calculated temperature being substituted for

actual temperature. Calculated temperature is a pre-

dicted fluid temperature which is calculated from a

combination of inputs:

²Battery (ambient) temperature

²Engine coolant temperature

²In-gear run time since start-up

VALVE BODY

DESCRIPTION

The valve body consists of a cast aluminum valve

body, a separator plate, and a transfer plate. The

valve body contains valves and check balls that con-

trol fluid delivery to the torque converter clutch,

bands, and frictional clutches. The valve body con-

tains the following components (Fig. 129) and (Fig.

130):

²Solenoid switch valve

²Manual valve

²Low/reverse switch valve

²5 Accumulators

²7 check balls

OPERATION

NOTE: Refer to the Hydraulic Schematics for a

visual aid in determining valve location, operation

and design.

SOLENOID SWITCH VALVE

The Solenoid Switch Valve (SSV) controls the direc-

tion of the transmission fluid when the L/R-TCC sole-

noid is energized.

When shifting into 1st gear, a special hydraulic

sequence is performed to ensure SSV movement into

the downshifted position. The L/R pressure switch is

monitored to confirm SSV movement. If the move-

ment is not confirmed (the L/R pressure switch does

not close), 2nd gear is substituted for 1st. A DTC will

be set after three unsuccessful attempts are made to

get into 1st gear in one given key start.

MANUAL VALVE

The manual valve is a relay valve. The purpose of

the manual valve is to direct fluid to the correct cir-

cuit needed for a specific gear or driving range. The

manual valve, as the name implies, is manually oper-

ated by the driver with a lever located on the top of

the valve body. The valve is connected mechanically

by a cable to the gearshift mechanism. The valve is

held in each of its positions by a roller detent spring

(Fig. 131) that engages the ªroostercombº of the TRS

selector plate.

21 - 408 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

TRANSMISSION SOLENOID/TRS ASSEMBLY (Continued)

Page 2117 of 2627

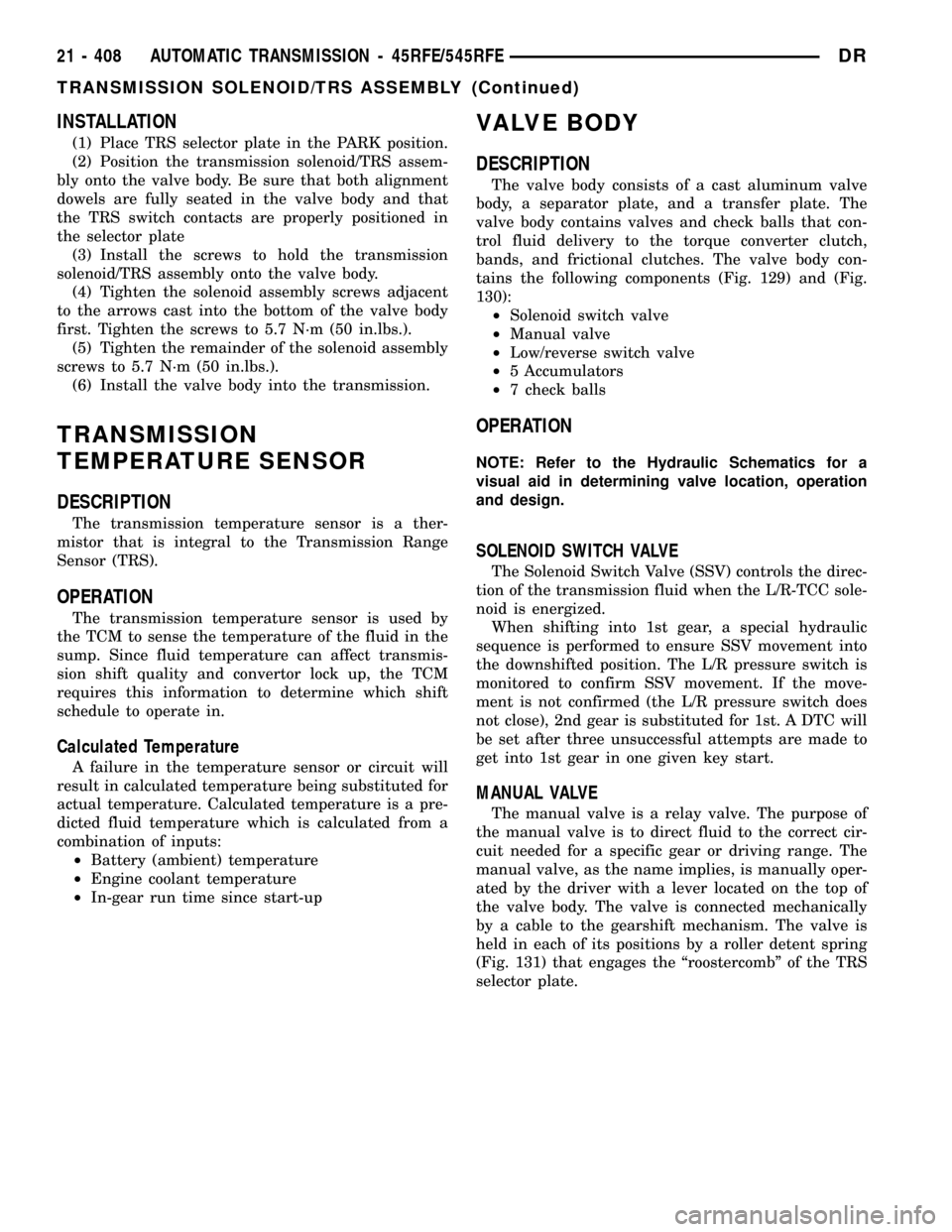

Inspect all the fluid seals on the valve body (Fig.

141). Replace any seals that are cracked, distorted, or

damaged in any way. These seals pass fluid pressure

directly to the clutches. Any pressure leak at these

points, may cause transmission performance prob-

lems.

ASSEMBLY

(1) Lubricate valves, springs, and the housing

valve bores with clean transmission fluid.

(2) Install solenoid switch valve, manual valve,

and the low/reverse switch valve into the valve body.

(3) Install the retainers to hold each valve into the

valve body.

(4) Install the valve body check balls into their

proper locations.

(5) Position the transfer plate onto the valve body.

(6) Install the screws to hold the transfer plate to

the valve body. Tighten the screws to 5.6 N´m (50 in.

lbs.).

(7) Install the accumulator pistons and springs

into the valve body in the location from which they

were removed. Note that all accumulators except the

overdrive have two springs. The overdrive accumula-

tor piston has only one spring.

(8) Position the accumulator cover onto the valve

body.(9) Install the screws to hold the accumulator

cover onto the valve body. Tighten the screws to 8

N´m (70 in. lbs.).

(10) Install the TRS selector plate onto the valve

body and the manual valve.

(11) Install the solenoid and pressure switch

assembly onto the valve body.

(12) Install the screws to hold the solenoid and

pressure switch assembly onto the valve body.

Tighten the screws to 5.7 N´m (50 in. lbs.). Tighten

the screws adjacent to the arrows cast into the bot-

tom of the transfer plate first.

(13) Position the detent spring onto the valve body.

(14) Install the screw to hold the detent spring

onto the valve body. Tighten the screw to 4.5 N´m (40

in. lbs.).

(15) Install new clutch passage seals onto the

valve body, if necessary

INSTALLATION

(1) Check condition of seals on valve body and the

solenoid and pressure switch assembly. Replace seals

if cut or worn.

(2) Place TRS selector plate in the PARK position.

(3) Place the transmission in the PARK position.

(4) Lubricate seal on the solenoid and pressure

switch assembly connector with petroleum jelly.

(5) Position valve body in transmission and align

the manual lever on the valve body to the pin on the

transmission manual shift lever.

(6) Seat valve body in case and install one or two

bolts to hold valve body in place.

(7) Tighten valve body bolts alternately and evenly

to 12 N´m (105 in. lbs.) torque.

(8) Install a new primary oil filter seal in the oil

pump inlet bore. Seat the seal in the bore with the

butt end of a hammer, or other suitable tool.

CAUTION: The primary oil filter seal MUST be fully

installed flush against the oil pump body. DO NOT

install the seal onto the filter neck and attempt to

install the filter and seal as an assembly. Damage to

the transmission will result.

(9) Place replacement filter in position on valve

body and into the oil pump.

(10) Install screw to hold filter to valve body.

Tighten screw to 4.5 N´m (40 in. lbs.) torque.

(11) Connect the solenoid and pressure switch

assembly connector.

(12) Install oil pan. Tighten pan bolts to 12 N´m

(105 in. lbs.) torque.

(13) Lower vehicle and fill transmission with

MopartATF +4.

(14) Check and adjust gearshift cable, if necessary.

Fig. 141 Valve Body Seals

1 - UNDERDRIVE ACCUMULATOR (2 SPRINGS)

2 - 4TH CLUTCH ACCUMULATOR (2 SPRINGS)

3 - 2ND CLUTCH ACCUMULATOR (2 SPRINGS)

4 - LOW REVERSE ACCUMULATOR (2 SPRINGS)

5 - LOW/REVERSE PASSAGE SEAL

6 - 2ND CLUTCH PASSAGE SEAL

7 - 4TH CLUTCH PASSAGE SEAL

8 - OVERDRIVE ACCUMULATOR (1 SPRING)

21 - 414 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

VALVE BODY (Continued)

Page 2119 of 2627

power in off road situations. Low range reduction

ratio is 2.72:1.

SHIFT MECHANISM

The transfer case is operated by an adjustable floor

mounted shift linkage. The transfer case shift lever

is directly attached to the shift sector. The sectoroperates the range and mode forks within the trans-

fer case.

A straight line shift pattern is used with a NEU-

TRAL detent. Lever range positions are imprinted in

the shift knob.

SHIFTING

The transfer case can be shifted between the 2H

and 4H operating ranges while the vehicle is in

motion. The vehicle must have the transmission

placed in NEUTRAL, or the clutch depressed in the

case of a manual transmission, and be moving less

than 2-3 MPH when shifting into and out of the 4L

operating range.

DIAGNOSIS AND TESTING - TRANSFER CASE -

NV241 GENII

Before beginning repair on a suspected transfer

case malfunction, check all other driveline compo-

nents beforehand.

The actual cause of a problem may be related to

such items as: front hubs, axles, propeller shafts,

wheels and tires, transmission, or clutch instead. If

all other driveline components are in good condition

and operating properly, refer to the Diagnosis Chart

for further information.

DIAGNOSIS CHART

Condition Possible Cause Correction

Transfer Case difficult to shift or will

not shift into desired range.1) Vehicle speed too great to permit

shifting.1) Stop vehicle and shift into

desired range. Or, reduce speed to

below 3-4 km/h (2-3 mph) before

attempting the shift.

2) If vehicle was operated for an

extended period in 4H on a dry

paved surface, the driveline torque

load may be causing a bind.2) Stop vehicle and shift the

transmission into neutral. Shift the

transfer case to 2H and operate

vehicle in 2H on dry paved

surfaces.

3) Transfer case external shift

linkage binding.3) Lubricate, repair, or replace

linkage bushings, or tighten loose

components as necessary.

4) Insufficient or incorrect lubricant. 4) Drain and refill to edge of fill hole

with MoparTATF +4, Automatic

Transmission fluid.

5) Internal components binding,

worn, or damaged.5) Disassemble the transfer case

and replace worn or damaged

components as necessary.

Transfer Case noisy in all operating

ranges.1) Insufficient or incorrect lubricant. 1) Drain and refill to edge of fill hole

with MoparTATF +4, Automatic

Transmission fluid.

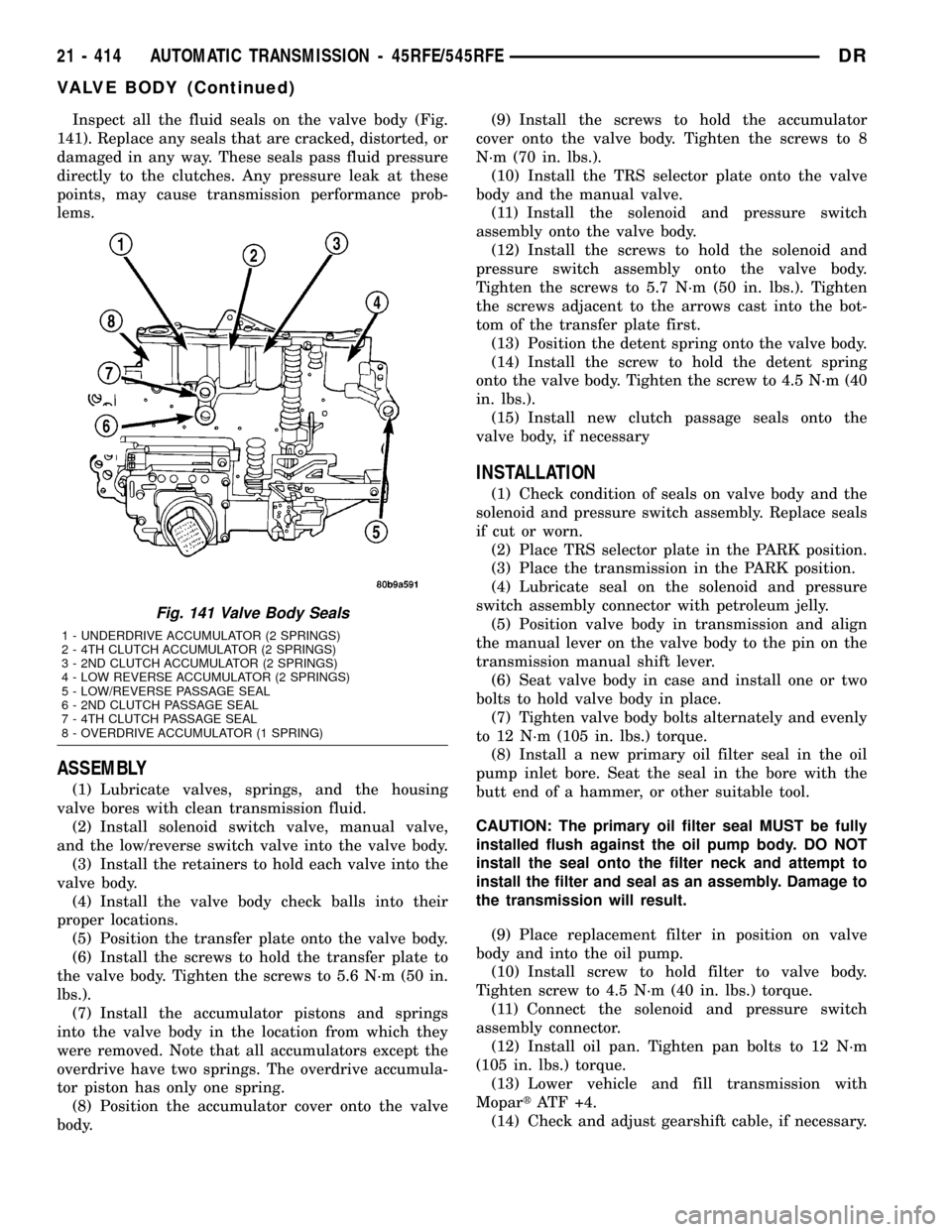

Fig. 2 Transfer Case - Rear View

1 - TRANSFER CASE

2 - IDENTIFICATION TAG

21 - 416 TRANSFER CASE - NV241 GENIIDR

TRANSFER CASE - NV241 GENII (Continued)

Page 2131 of 2627

DRIVE CHAIN

Examine the drive chain and shaft bearings.

replace the chain if stretched, distorted, or if any of

the links bind. Replace the bearings if rough, or

noisy.

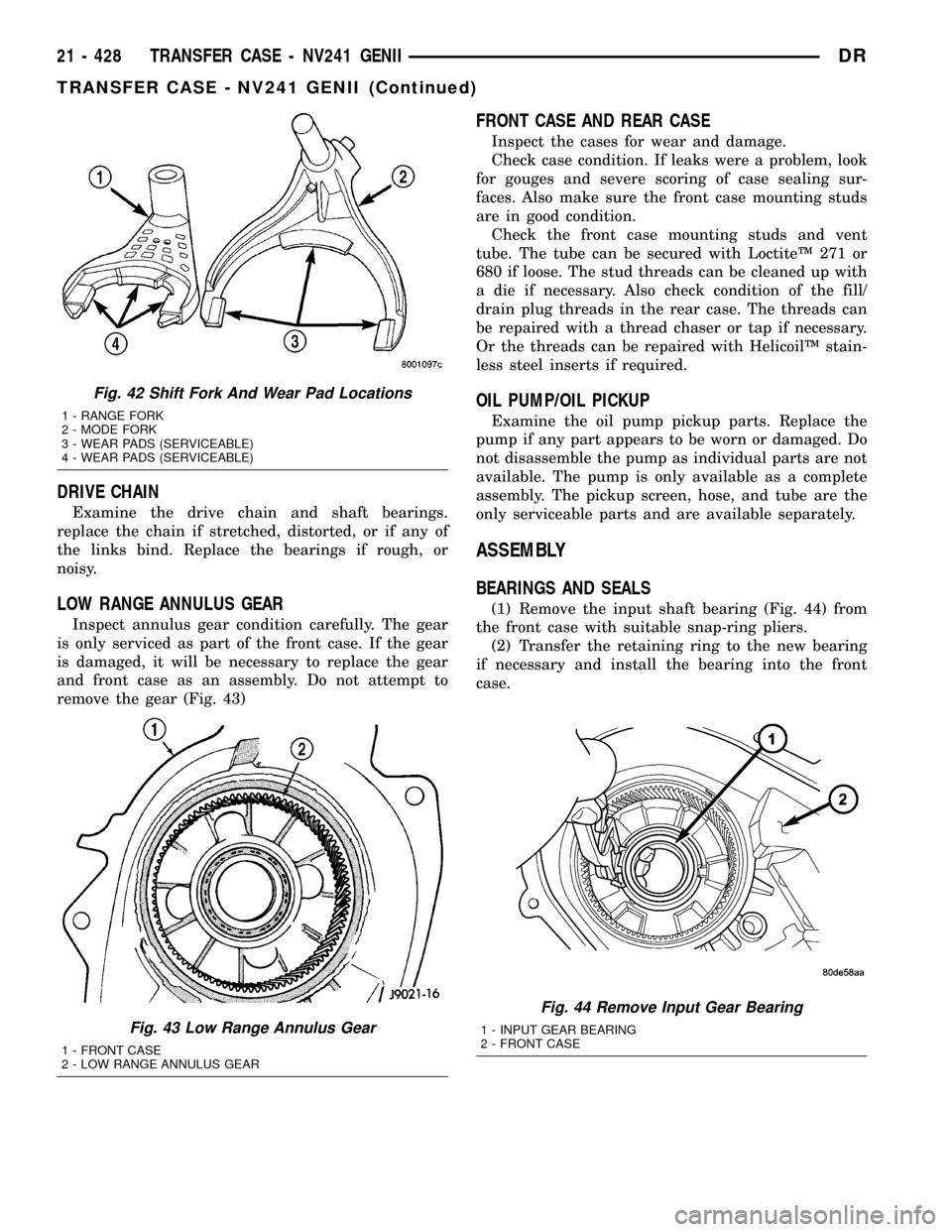

LOW RANGE ANNULUS GEAR

Inspect annulus gear condition carefully. The gear

is only serviced as part of the front case. If the gear

is damaged, it will be necessary to replace the gear

and front case as an assembly. Do not attempt to

remove the gear (Fig. 43)

FRONT CASE AND REAR CASE

Inspect the cases for wear and damage.

Check case condition. If leaks were a problem, look

for gouges and severe scoring of case sealing sur-

faces. Also make sure the front case mounting studs

are in good condition.

Check the front case mounting studs and vent

tube. The tube can be secured with LoctiteŸ 271 or

680 if loose. The stud threads can be cleaned up with

a die if necessary. Also check condition of the fill/

drain plug threads in the rear case. The threads can

be repaired with a thread chaser or tap if necessary.

Or the threads can be repaired with HelicoilŸ stain-

less steel inserts if required.

OIL PUMP/OIL PICKUP

Examine the oil pump pickup parts. Replace the

pump if any part appears to be worn or damaged. Do

not disassemble the pump as individual parts are not

available. The pump is only available as a complete

assembly. The pickup screen, hose, and tube are the

only serviceable parts and are available separately.

ASSEMBLY

BEARINGS AND SEALS

(1) Remove the input shaft bearing (Fig. 44) from

the front case with suitable snap-ring pliers.

(2) Transfer the retaining ring to the new bearing

if necessary and install the bearing into the front

case.

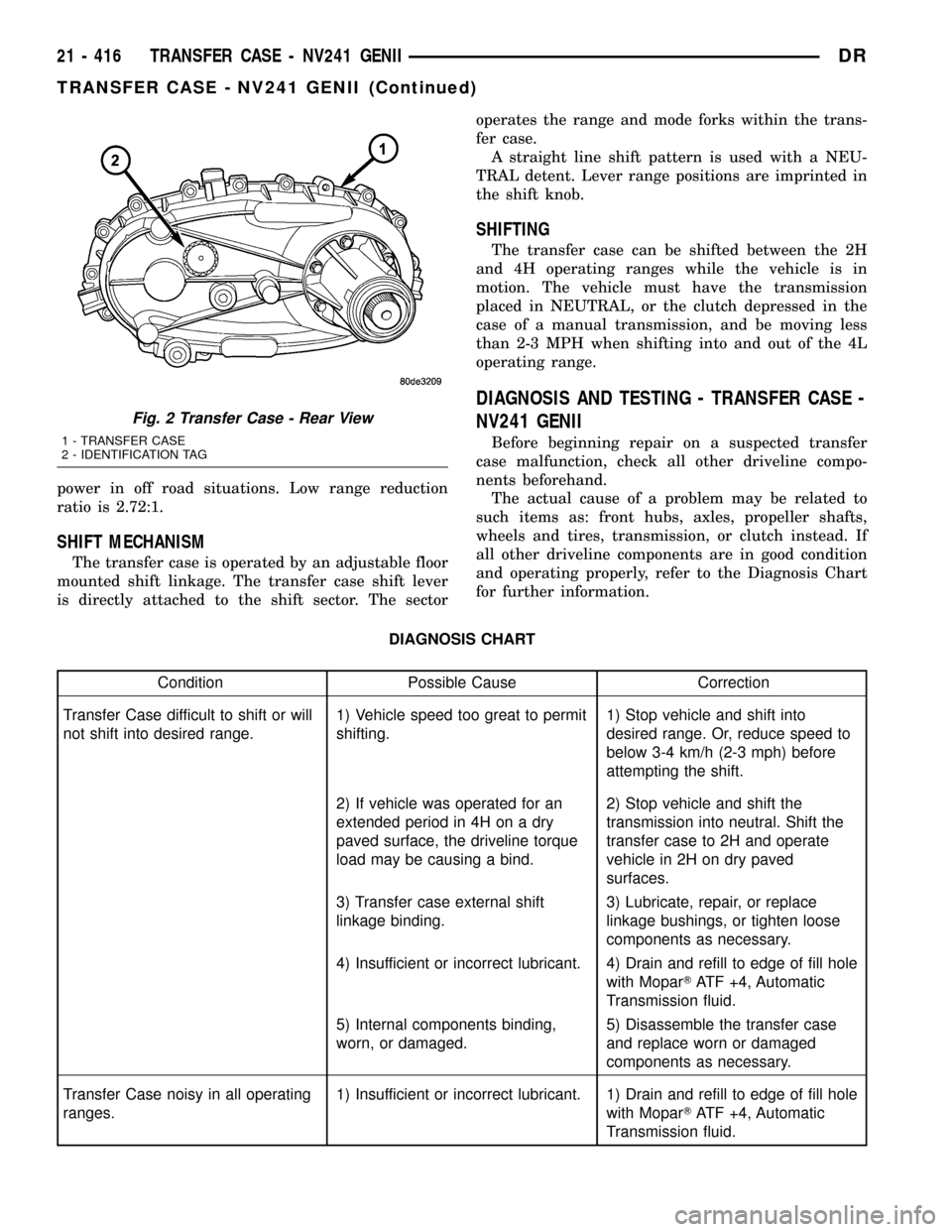

Fig. 42 Shift Fork And Wear Pad Locations

1 - RANGE FORK

2 - MODE FORK

3 - WEAR PADS (SERVICEABLE)

4 - WEAR PADS (SERVICEABLE)

Fig. 43 Low Range Annulus Gear

1 - FRONT CASE

2 - LOW RANGE ANNULUS GEAR

Fig. 44 Remove Input Gear Bearing

1 - INPUT GEAR BEARING

2 - FRONT CASE

21 - 428 TRANSFER CASE - NV241 GENIIDR

TRANSFER CASE - NV241 GENII (Continued)

Page 2152 of 2627

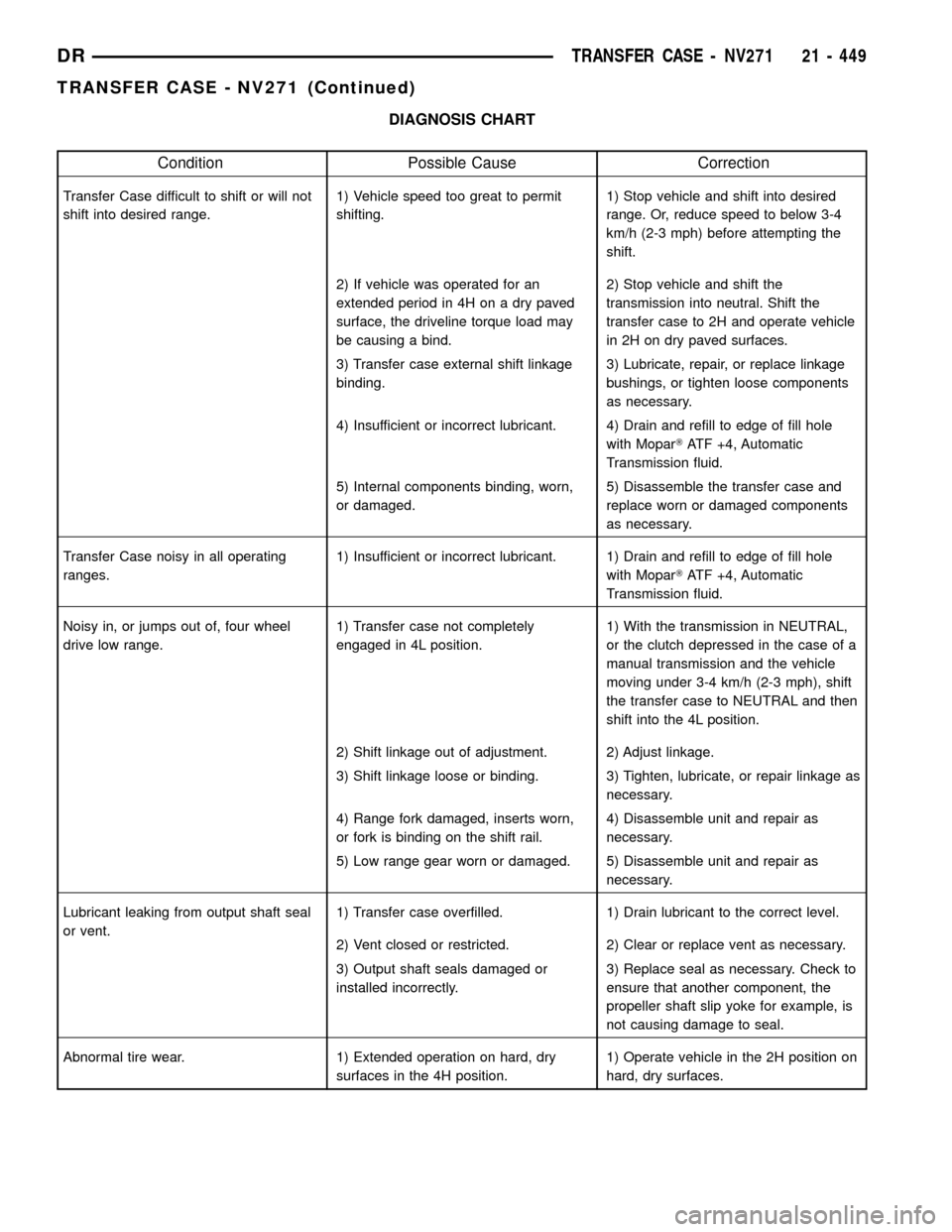

DIAGNOSIS CHART

Condition Possible Cause Correction

Transfer Case difficult to shift or will not

shift into desired range.1) Vehicle speed too great to permit

shifting.1) Stop vehicle and shift into desired

range. Or, reduce speed to below 3-4

km/h (2-3 mph) before attempting the

shift.

2) If vehicle was operated for an

extended period in 4H on a dry paved

surface, the driveline torque load may

be causing a bind.2) Stop vehicle and shift the

transmission into neutral. Shift the

transfer case to 2H and operate vehicle

in 2H on dry paved surfaces.

3) Transfer case external shift linkage

binding.3) Lubricate, repair, or replace linkage

bushings, or tighten loose components

as necessary.

4) Insufficient or incorrect lubricant. 4) Drain and refill to edge of fill hole

with MoparTATF +4, Automatic

Transmission fluid.

5) Internal components binding, worn,

or damaged.5) Disassemble the transfer case and

replace worn or damaged components

as necessary.

Transfer Case noisy in all operating

ranges.1) Insufficient or incorrect lubricant. 1) Drain and refill to edge of fill hole

with MoparTATF +4, Automatic

Transmission fluid.

Noisy in, or jumps out of, four wheel

drive low range.1) Transfer case not completely

engaged in 4L position.1) With the transmission in NEUTRAL,

or the clutch depressed in the case of a

manual transmission and the vehicle

moving under 3-4 km/h (2-3 mph), shift

the transfer case to NEUTRAL and then

shift into the 4L position.

2) Shift linkage out of adjustment. 2) Adjust linkage.

3) Shift linkage loose or binding. 3) Tighten, lubricate, or repair linkage as

necessary.

4) Range fork damaged, inserts worn,

or fork is binding on the shift rail.4) Disassemble unit and repair as

necessary.

5) Low range gear worn or damaged. 5) Disassemble unit and repair as

necessary.

Lubricant leaking from output shaft seal

or vent.1) Transfer case overfilled. 1) Drain lubricant to the correct level.

2) Vent closed or restricted. 2) Clear or replace vent as necessary.

3) Output shaft seals damaged or

installed incorrectly.3) Replace seal as necessary. Check to

ensure that another component, the

propeller shaft slip yoke for example, is

not causing damage to seal.

Abnormal tire wear. 1) Extended operation on hard, dry

surfaces in the 4H position.1) Operate vehicle in the 2H position on

hard, dry surfaces.

DRTRANSFER CASE - NV271 21 - 449

TRANSFER CASE - NV271 (Continued)

Page 2164 of 2627

DRIVE CHAIN

Examine the drive chain and shaft bearings.

replace the chain if stretched, distorted, or if any of

the links bind. Replace the bearings if rough, or

noisy.

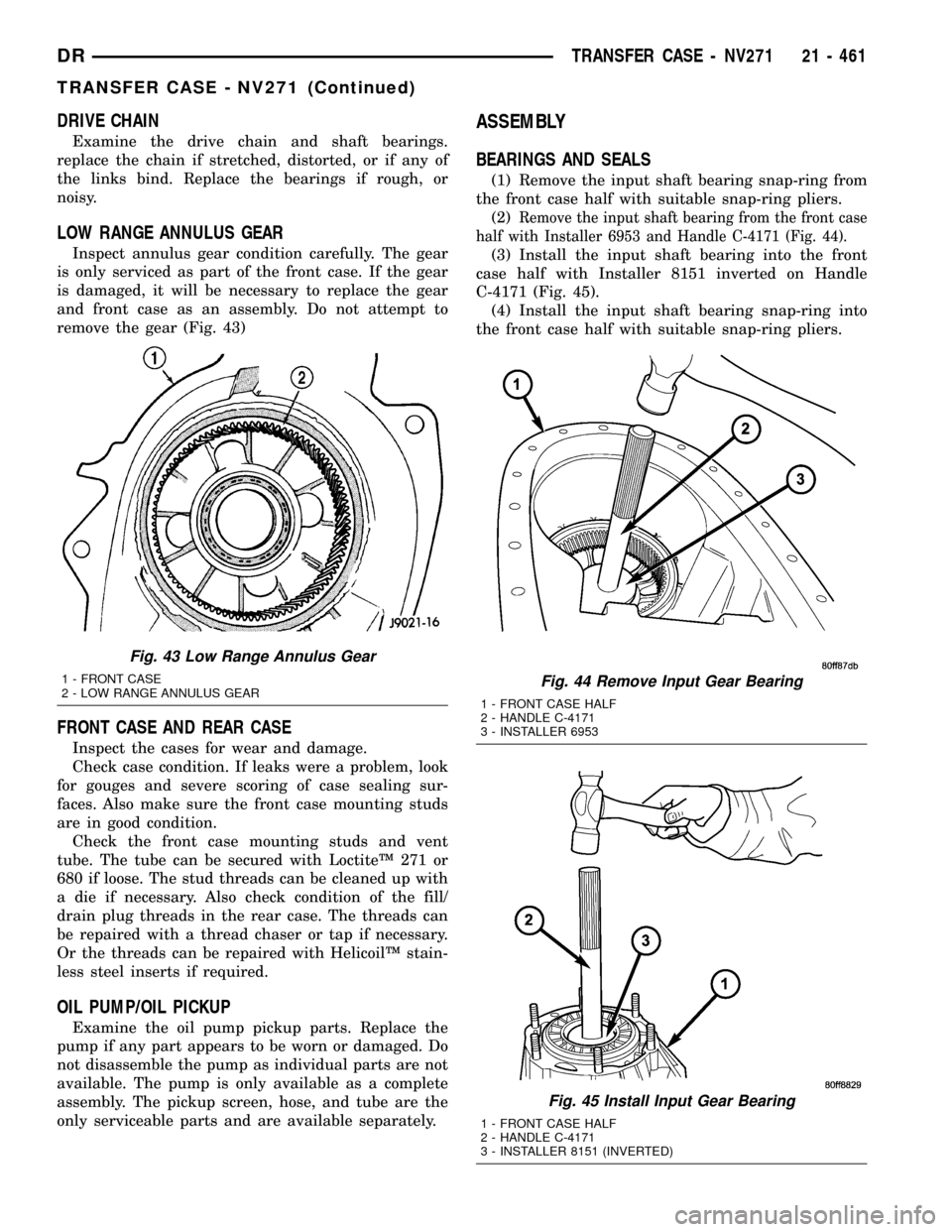

LOW RANGE ANNULUS GEAR

Inspect annulus gear condition carefully. The gear

is only serviced as part of the front case. If the gear

is damaged, it will be necessary to replace the gear

and front case as an assembly. Do not attempt to

remove the gear (Fig. 43)

FRONT CASE AND REAR CASE

Inspect the cases for wear and damage.

Check case condition. If leaks were a problem, look

for gouges and severe scoring of case sealing sur-

faces. Also make sure the front case mounting studs

are in good condition.

Check the front case mounting studs and vent

tube. The tube can be secured with LoctiteŸ 271 or

680 if loose. The stud threads can be cleaned up with

a die if necessary. Also check condition of the fill/

drain plug threads in the rear case. The threads can

be repaired with a thread chaser or tap if necessary.

Or the threads can be repaired with HelicoilŸ stain-

less steel inserts if required.

OIL PUMP/OIL PICKUP

Examine the oil pump pickup parts. Replace the

pump if any part appears to be worn or damaged. Do

not disassemble the pump as individual parts are not

available. The pump is only available as a complete

assembly. The pickup screen, hose, and tube are the

only serviceable parts and are available separately.

ASSEMBLY

BEARINGS AND SEALS

(1) Remove the input shaft bearing snap-ring from

the front case half with suitable snap-ring pliers.

(2)

Remove the input shaft bearing from the front case

half with Installer 6953 and Handle C-4171 (Fig. 44).

(3) Install the input shaft bearing into the front

case half with Installer 8151 inverted on Handle

C-4171 (Fig. 45).

(4) Install the input shaft bearing snap-ring into

the front case half with suitable snap-ring pliers.

Fig. 43 Low Range Annulus Gear

1 - FRONT CASE

2 - LOW RANGE ANNULUS GEARFig. 44 Remove Input Gear Bearing

1 - FRONT CASE HALF

2 - HANDLE C-4171

3 - INSTALLER 6953

Fig. 45 Install Input Gear Bearing

1 - FRONT CASE HALF

2 - HANDLE C-4171

3 - INSTALLER 8151 (INVERTED)

DRTRANSFER CASE - NV271 21 - 461

TRANSFER CASE - NV271 (Continued)