Engine torque spec DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 362 of 2627

DIAGNOSIS AND TESTING - THERMOSTAT

The cooling system used with the diesel engine

provides the extra coolant capacity and extra cooling

protection needed for higher GVWR (Gross Vehicle

Weight Rating) and GCWR (Gross Combined Weight

Rating) vehicles.

This system capacity will not effect warm up or

cold weather operating characteristics if the thermo-

stat is operating properly. This is because coolant

will be held in the engine until it reaches the ther-

mostat ªsetº temperature.

Diesel engines, due to their inherent efficiency are

slower to warm up than gasoline powered engines,

and will operate at lower temperatures when the

vehicle is unloaded. Because of this, lower tempera-

ture gauge readings for diesel versus gasoline

engines may, at times be normal.

Typically, complaints of low engine coolant temper-

ature are observed as low heater output when com-

bined with cool or cold outside temperatures.

To help promote faster engine warm-up, the elec-

tric engine block heater must be used with cool or

cold outside temperatures. This will help keep the

engine coolant warm when the vehicle is parked.

A ªCold Weather Coverº is available from the parts

department through the Mopar Accessories product

line. This accessory cover is designed to block airflow

entering the radiator and engine compartment to

promote faster engine warm-up. It attaches to the

front of the vehicle at the grill opening.The cover is

to be used with cool or cold temperatures only.

If used with high outside temperatures, serious

engine damage could result.Refer to the litera-

ture supplied with the cover for additional informa-

tion.

(1) To determine if the thermostat is defective, it

must be removed from the vehicle (Refer to 7 -

COOLING/ENGINE/ENGINE COOLANT THERMO-

STAT - REMOVAL).

(2) After the thermostat has been removed, exam-

ine the thermostat and inside of thermostat housing

for contaminants. If contaminants are found, the

thermostat may already be in a ªstuck openº position.

Flush the cooling system before replacing thermostat

(Refer to 7 - COOLING - STANDARD PROCE-

DURE).

(3) Place the thermostat into a container filled

with water.

(4) Place the container on a hot plate or other suit-

able heating device.

(5) Place a commercially available radiator ther-

mometer into the water.

(6) Apply heat to the water while observing the

thermostat and thermometer.

(7) The thermostat will begin to open at 85.5 -

89.4ÉC. (186 - 193ÉF ). If the valve starts to movebefore this temperature is reached, it is opening too

early. Replace thermostat. The thermostat should be

fully open (valve will stop moving) at 97ÉC (207ÉF). If

the valve is still moving when the water temperature

reaches 97ÉC (207ÉF), it is opening too late. Replace

thermostat. If the valve refuses to move at any time,

replace thermostat.

REMOVAL

WARNING: DO NOT LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND PRES-

SURIZED. SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.

Do not waste reusable coolant. If the solution is

clean, drain the coolant into a clean container for

reuse.

(1) Disconnect the battery negative cables.

(2) Drain cooling system until coolant level is

below thermostat (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094).

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with a matching number or letter.

(3) Remove radiator hose clamp and hose from

thermostat housing.

(4) Remove the three (3) water outlet-to-cylinder

head bolts and remove the water outlet connector

(Fig. 26).

(5) Clean the mating surfaces of the water outlet

connector and clean the thermostat seat groove at

the top of the thermostat housing (Fig. 26).

INSTALLATION

(1) Inspect thermostat seal for cuts or nicks.

Replace if damaged.

(2) Install the thermostat into the groove in the

top of the cylinder head (Fig. 26).

(3) Install the thermostat housing and bolts.

Tighten the bolts to 10 N´m (89 in. lbs.) torque.

(4) Install the radiator upper hose and clamp.

(5) Fill the cooling system with coolant (Refer to 7

- COOLING - STANDARD PROCEDURE).

(6) Connect the battery negative cables.

DRENGINE 7 - 47

ENGINE COOLANT THERMOSTAT - 5.9L DIESEL (Continued)

Page 364 of 2627

The DTC can also be accessed through the DRB

scan tool. Refer to the appropriate Powertrain Diag-

nostic Procedures information for diagnostic informa-

tion and operation of the DRB scan tool.

REMOVAL

WARNING: DO NOT LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND PRES-

SURIZED. SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.

Do not waste reusable coolant. If the solution is

clean, drain the coolant into a clean container for

reuse.

If the thermostat is being replaced, be sure that

the replacement is the specified thermostat for the

vehicle model and engine type.

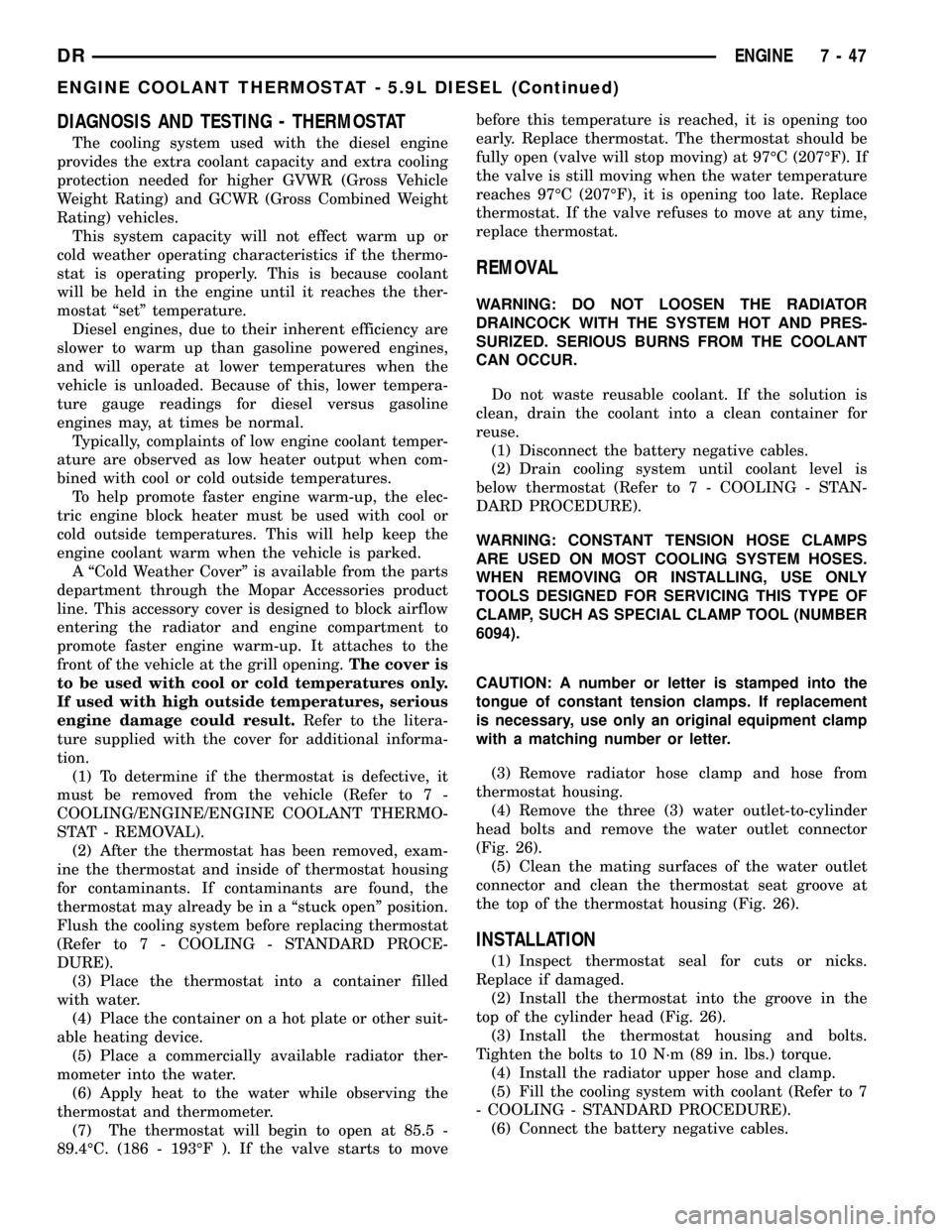

A rubber lip-type seal with a metal shoulder is

pressed into the intake manifold beneath the thermo-

stat (Fig. 28).

(1) Disconnect negative battery cable at battery.

(2) Drain cooling system until coolant level is

below thermostat (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

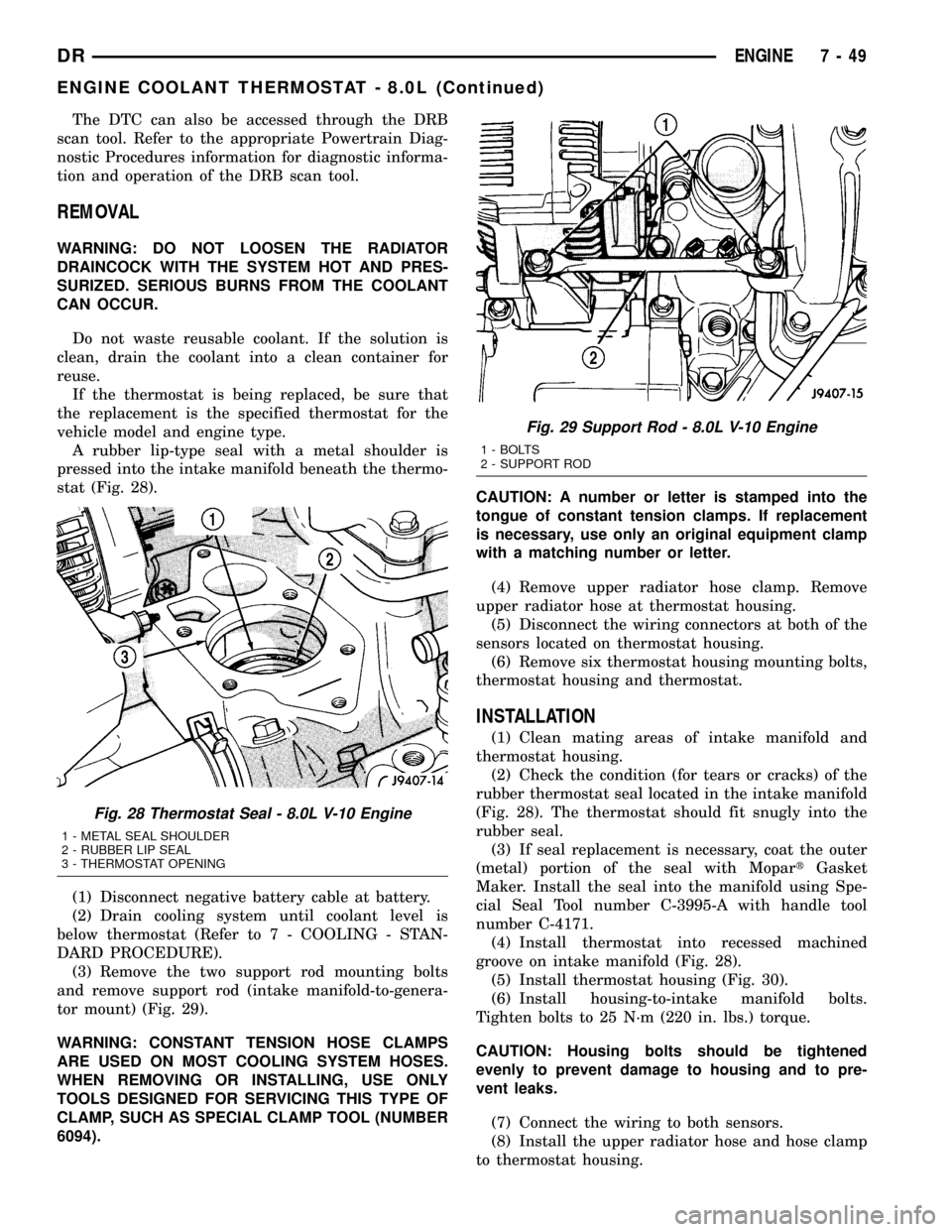

(3) Remove the two support rod mounting bolts

and remove support rod (intake manifold-to-genera-

tor mount) (Fig. 29).

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094).CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with a matching number or letter.

(4) Remove upper radiator hose clamp. Remove

upper radiator hose at thermostat housing.

(5) Disconnect the wiring connectors at both of the

sensors located on thermostat housing.

(6) Remove six thermostat housing mounting bolts,

thermostat housing and thermostat.

INSTALLATION

(1) Clean mating areas of intake manifold and

thermostat housing.

(2) Check the condition (for tears or cracks) of the

rubber thermostat seal located in the intake manifold

(Fig. 28). The thermostat should fit snugly into the

rubber seal.

(3) If seal replacement is necessary, coat the outer

(metal) portion of the seal with MopartGasket

Maker. Install the seal into the manifold using Spe-

cial Seal Tool number C-3995-A with handle tool

number C-4171.

(4) Install thermostat into recessed machined

groove on intake manifold (Fig. 28).

(5) Install thermostat housing (Fig. 30).

(6) Install housing-to-intake manifold bolts.

Tighten bolts to 25 N´m (220 in. lbs.) torque.

CAUTION: Housing bolts should be tightened

evenly to prevent damage to housing and to pre-

vent leaks.

(7) Connect the wiring to both sensors.

(8) Install the upper radiator hose and hose clamp

to thermostat housing.

Fig. 28 Thermostat Seal - 8.0L V-10 Engine

1 - METAL SEAL SHOULDER

2 - RUBBER LIP SEAL

3 - THERMOSTAT OPENING

Fig. 29 Support Rod - 8.0L V-10 Engine

1 - BOLTS

2 - SUPPORT ROD

DRENGINE 7 - 49

ENGINE COOLANT THERMOSTAT - 8.0L (Continued)

Page 372 of 2627

INSTALLATION

(1) Install rubber insulators to alignment dowels

at lower part of radiator.

(2) Lower the radiator into position while guiding

the two alignment dowels into lower radiator sup-

port. Different alignment holes are provided in the

lower radiator support for each engine application.

(3) Install two upper radiator mounting bolts.

Tighten bolts to 11.8 N´m (105 in. lbs.) torque.

(4) Connect both radiator hoses and install hose

clamps.

(5) Connect transmission cooler lines to transmis-

sion cooler. Inspect quick connect fittings for debris

and install until an audible ªclickº is heard. Pull

apart to verify connection.

(6) Position power steering cooler on the radiator

and tighten nuts to 10 N´m (90 in. lbs.)

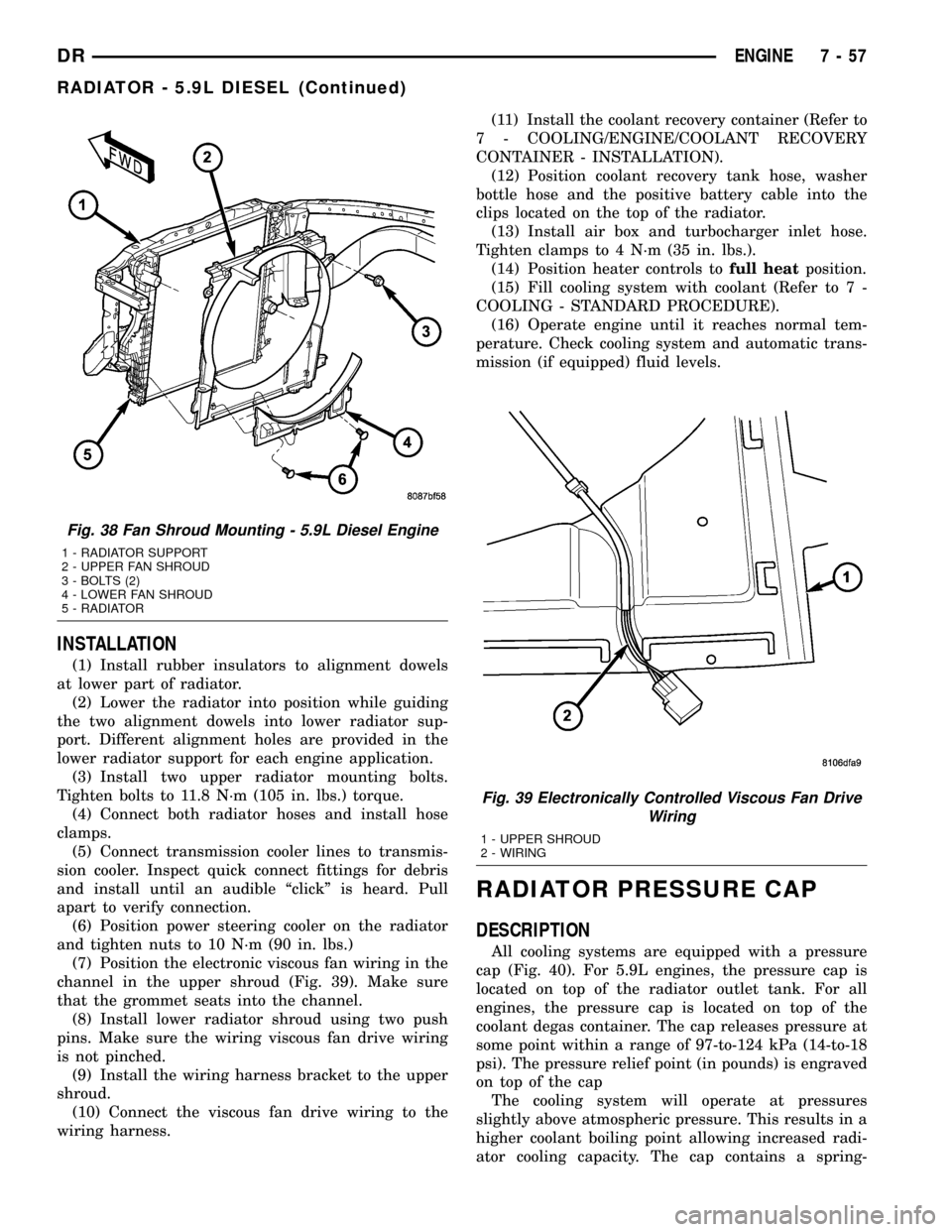

(7) Position the electronic viscous fan wiring in the

channel in the upper shroud (Fig. 39). Make sure

that the grommet seats into the channel.

(8) Install lower radiator shroud using two push

pins. Make sure the wiring viscous fan drive wiring

is not pinched.

(9) Install the wiring harness bracket to the upper

shroud.

(10) Connect the viscous fan drive wiring to the

wiring harness.(11) Install the coolant recovery container (Refer to

7 - COOLING/ENGINE/COOLANT RECOVERY

CONTAINER - INSTALLATION).

(12) Position coolant recovery tank hose, washer

bottle hose and the positive battery cable into the

clips located on the top of the radiator.

(13) Install air box and turbocharger inlet hose.

Tighten clamps to 4 N´m (35 in. lbs.).

(14) Position heater controls tofull heatposition.

(15) Fill cooling system with coolant (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(16) Operate engine until it reaches normal tem-

perature. Check cooling system and automatic trans-

mission (if equipped) fluid levels.

RADIATOR PRESSURE CAP

DESCRIPTION

All cooling systems are equipped with a pressure

cap (Fig. 40). For 5.9L engines, the pressure cap is

located on top of the radiator outlet tank. For all

engines, the pressure cap is located on top of the

coolant degas container. The cap releases pressure at

some point within a range of 97-to-124 kPa (14-to-18

psi). The pressure relief point (in pounds) is engraved

on top of the cap

The cooling system will operate at pressures

slightly above atmospheric pressure. This results in a

higher coolant boiling point allowing increased radi-

ator cooling capacity. The cap contains a spring-

Fig. 38 Fan Shroud Mounting - 5.9L Diesel Engine

1 - RADIATOR SUPPORT

2 - UPPER FAN SHROUD

3 - BOLTS (2)

4 - LOWER FAN SHROUD

5 - RADIATOR

Fig. 39 Electronically Controlled Viscous Fan Drive

Wiring

1 - UPPER SHROUD

2 - WIRING

DRENGINE 7 - 57

RADIATOR - 5.9L DIESEL (Continued)

Page 377 of 2627

(3) Spin the water pump to be sure that the pump

impeller does not rub against the timing chain case/

cover.

(4) Connect the radiator lower hose to the water

pump.

(5) Relax the tension from the belt tensioner (Fig.

46). Install the drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

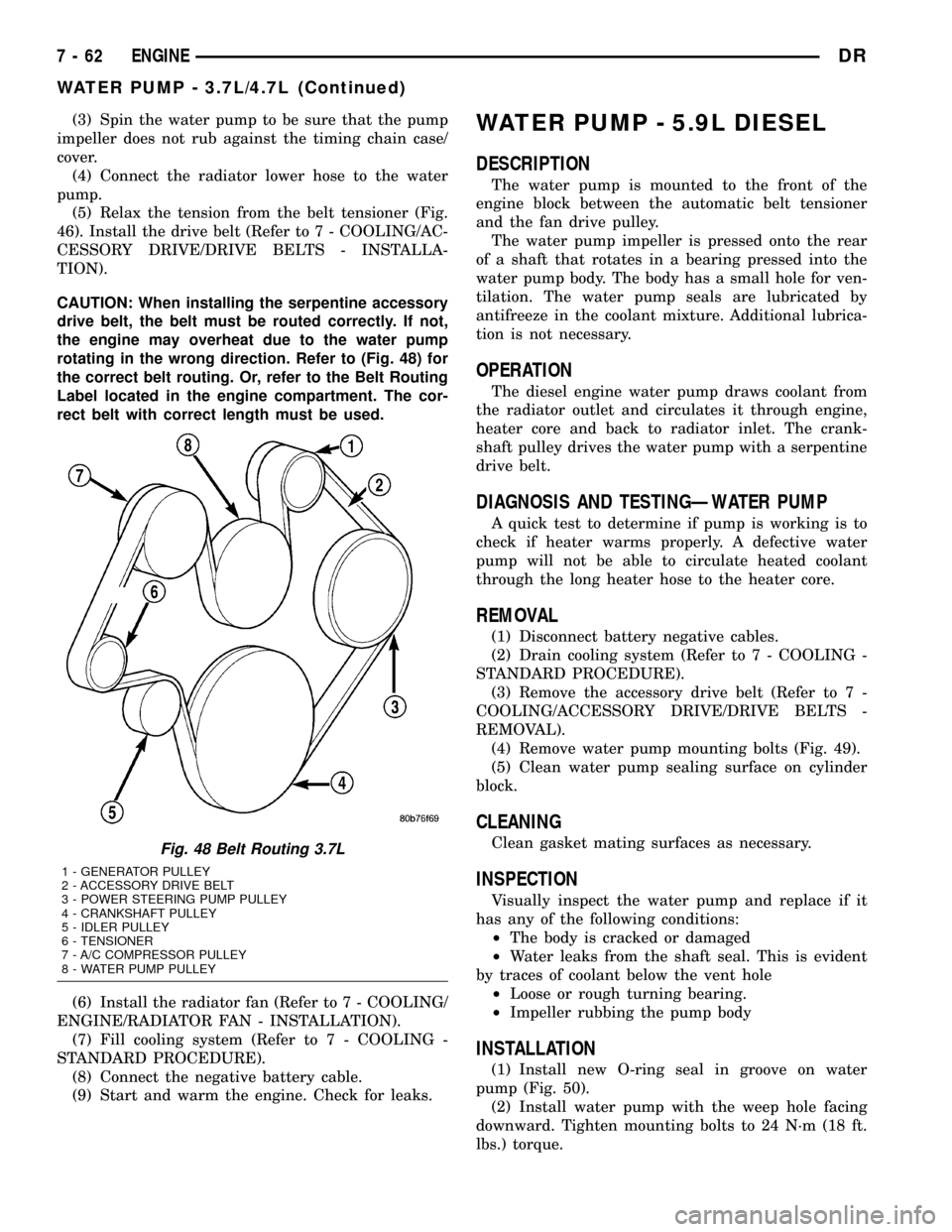

CAUTION: When installing the serpentine accessory

drive belt, the belt must be routed correctly. If not,

the engine may overheat due to the water pump

rotating in the wrong direction. Refer to (Fig. 48) for

the correct belt routing. Or, refer to the Belt Routing

Label located in the engine compartment. The cor-

rect belt with correct length must be used.

(6) Install the radiator fan (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION).

(7) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(8) Connect the negative battery cable.

(9) Start and warm the engine. Check for leaks.WATER PUMP - 5.9L DIESEL

DESCRIPTION

The water pump is mounted to the front of the

engine block between the automatic belt tensioner

and the fan drive pulley.

The water pump impeller is pressed onto the rear

of a shaft that rotates in a bearing pressed into the

water pump body. The body has a small hole for ven-

tilation. The water pump seals are lubricated by

antifreeze in the coolant mixture. Additional lubrica-

tion is not necessary.

OPERATION

The diesel engine water pump draws coolant from

the radiator outlet and circulates it through engine,

heater core and back to radiator inlet. The crank-

shaft pulley drives the water pump with a serpentine

drive belt.

DIAGNOSIS AND TESTINGÐWATER PUMP

A quick test to determine if pump is working is to

check if heater warms properly. A defective water

pump will not be able to circulate heated coolant

through the long heater hose to the heater core.

REMOVAL

(1) Disconnect battery negative cables.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove water pump mounting bolts (Fig. 49).

(5) Clean water pump sealing surface on cylinder

block.

CLEANING

Clean gasket mating surfaces as necessary.

INSPECTION

Visually inspect the water pump and replace if it

has any of the following conditions:

²The body is cracked or damaged

²Water leaks from the shaft seal. This is evident

by traces of coolant below the vent hole

²Loose or rough turning bearing.

²Impeller rubbing the pump body

INSTALLATION

(1) Install new O-ring seal in groove on water

pump (Fig. 50).

(2) Install water pump with the weep hole facing

downward. Tighten mounting bolts to 24 N´m (18 ft.

lbs.) torque.

Fig. 48 Belt Routing 3.7L

1 - GENERATOR PULLEY

2 - ACCESSORY DRIVE BELT

3 - POWER STEERING PUMP PULLEY

4 - CRANKSHAFT PULLEY

5 - IDLER PULLEY

6 - TENSIONER

7 - A/C COMPRESSOR PULLEY

8 - WATER PUMP PULLEY

7 - 62 ENGINEDR

WATER PUMP - 3.7L/4.7L (Continued)

Page 381 of 2627

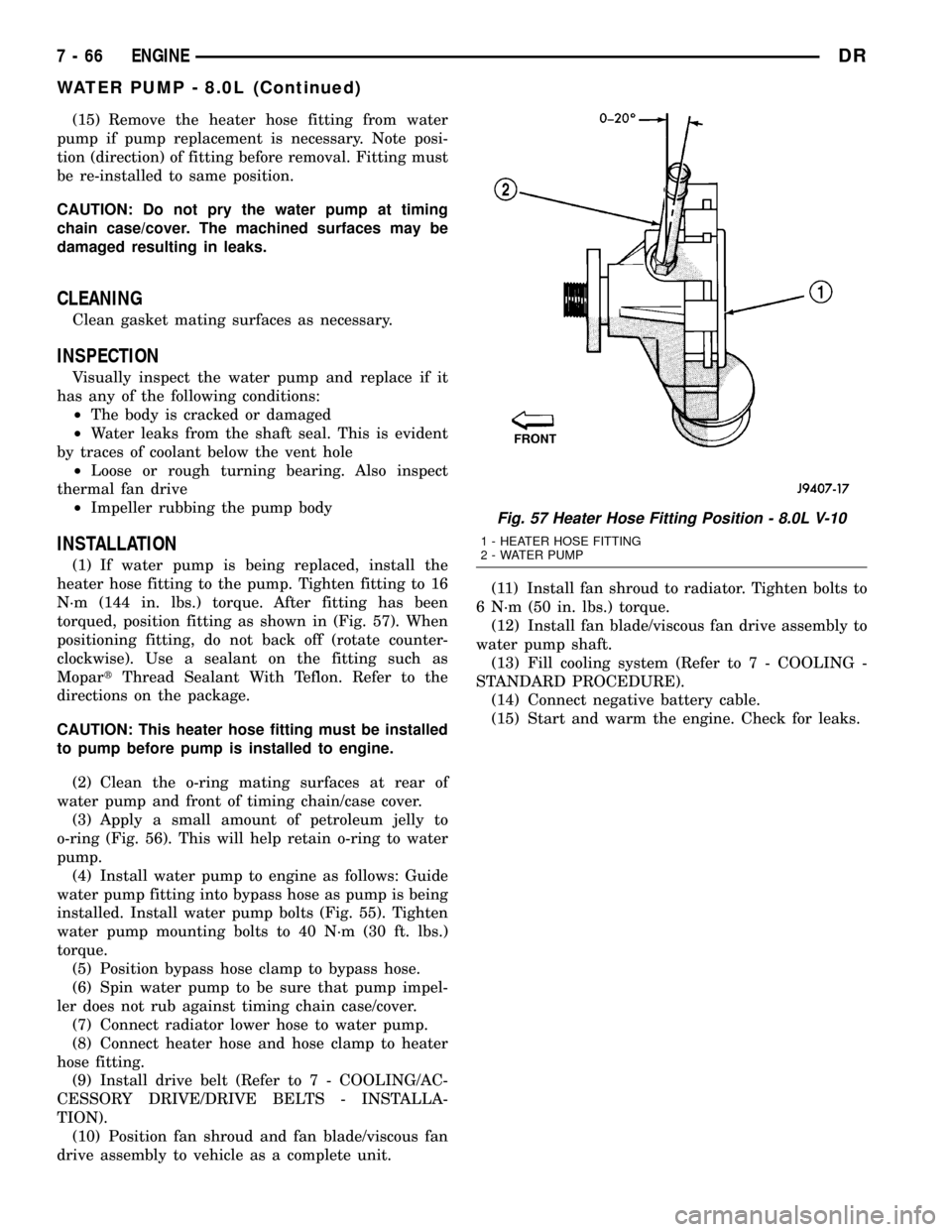

(15) Remove the heater hose fitting from water

pump if pump replacement is necessary. Note posi-

tion (direction) of fitting before removal. Fitting must

be re-installed to same position.

CAUTION: Do not pry the water pump at timing

chain case/cover. The machined surfaces may be

damaged resulting in leaks.

CLEANING

Clean gasket mating surfaces as necessary.

INSPECTION

Visually inspect the water pump and replace if it

has any of the following conditions:

²The body is cracked or damaged

²Water leaks from the shaft seal. This is evident

by traces of coolant below the vent hole

²Loose or rough turning bearing. Also inspect

thermal fan drive

²Impeller rubbing the pump body

INSTALLATION

(1) If water pump is being replaced, install the

heater hose fitting to the pump. Tighten fitting to 16

N´m (144 in. lbs.) torque. After fitting has been

torqued, position fitting as shown in (Fig. 57). When

positioning fitting, do not back off (rotate counter-

clockwise). Use a sealant on the fitting such as

MopartThread Sealant With Teflon. Refer to the

directions on the package.

CAUTION: This heater hose fitting must be installed

to pump before pump is installed to engine.

(2) Clean the o-ring mating surfaces at rear of

water pump and front of timing chain/case cover.

(3) Apply a small amount of petroleum jelly to

o-ring (Fig. 56). This will help retain o-ring to water

pump.

(4) Install water pump to engine as follows: Guide

water pump fitting into bypass hose as pump is being

installed. Install water pump bolts (Fig. 55). Tighten

water pump mounting bolts to 40 N´m (30 ft. lbs.)

torque.

(5) Position bypass hose clamp to bypass hose.

(6) Spin water pump to be sure that pump impel-

ler does not rub against timing chain case/cover.

(7) Connect radiator lower hose to water pump.

(8) Connect heater hose and hose clamp to heater

hose fitting.

(9) Install drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

(10) Position fan shroud and fan blade/viscous fan

drive assembly to vehicle as a complete unit.(11) Install fan shroud to radiator. Tighten bolts to

6 N´m (50 in. lbs.) torque.

(12) Install fan blade/viscous fan drive assembly to

water pump shaft.

(13) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(14) Connect negative battery cable.

(15) Start and warm the engine. Check for leaks.

Fig. 57 Heater Hose Fitting Position - 8.0L V-10

1 - HEATER HOSE FITTING

2 - WATER PUMP

7 - 66 ENGINEDR

WATER PUMP - 8.0L (Continued)

Page 412 of 2627

FRONT CONTROL MODULE

DESCRIPTION

The Front Control Module (FCM) is a micro con-

troller based module located in the left front corner

of the engine compartment. On this model the inte-

grated power module must be positioned aside in

order to access the front control module. The front

control module mates to the power distribution cen-

ter to form the Integrated Power Module (IPM). The

integrated power module connects directly to the bat-

tery and provides the primary means of circuit pro-

tection and power distribution for all vehicle

electrical systems. The front control module controls

power to some of these vehicle systems electrical and

electromechanical loads based on inputs received

from hard wired switch inputs and data received on

the PCI bus circuit (J1850).

For information on theIntegrated Power Mod-

ule Refer to the Power Distribution Sectionof

the service manual.

OPERATION

As messages are sent over the PCI bus circuit, the

front control module reads these messages and con-

trols power to some of the vehicles electrical systems

by completing the circuit to ground (low side driver)

or completing the circuit to 12 volt power (high side

driver). The following functions areControlledby

the Front Control Module:

²Headlamp Power with Voltage Regulation

²Windshield Wiper ªON/OFFº Relay Actuation

²Windshield Wiper ªHI/LOº Relay Actuation

²Windshield Washer Pump Motor

²Fog Lamp Relay Actuation

²Park Lamp Relay Actuation

²Horn Relay Actuation

The following inputs areReceived/Monitoredby

the Front Control Module:

²B+ Connection Detection

²Power Ground

²Ambient Temperature Sensing

²Ignition Switch Run

²Washer Fluid Level Switch

²Windshield Wiper Park Switch

²PCI Bus Circuit

DIAGNOSIS AND TESTING - FRONT CONTROL

MODULE

The front control module is a printed circuit board

based module with a on-board micro-processor. The

front control module interfaces with other electronic

modules in the vehicle via the Programmable Com-

munications Interface (PCI) data bus (J1850). In

order to obtain conclusive testing the Programmable

Communications Interface (PCI) data bus network

and all of the electronic modules that provide inputs

to, or receive outputs from the front control module

must be checked. All PCI (J1850) communication

faults must be resolved prior to further diagnosing

any front control module related issues.

The front control module was designed to be diag-

nosed with an appropriate diagnostic scan tool, such

as the DRB IIIt. The most reliable, efficient, and

accurate means to diagnose the front control module

requires the use of a DRB IIItscan tool and the

proper Body Diagnostic Procedures manual.

Before any testing of the front control module is

attempted, the battery should be fully charged and

all wire harness and ground connections inspected

around the affected areas on the vehicle.

REMOVAL

(1) Disconnect the positive and negative battery

cables from the battery.

(2) Partially remove the integrated power module

from the engine compartment (Refer to 8 - ELECTRI-

CAL/POWER DISTRIBUTION/INTEGRATED

POWER MODULE - REMOVAL).

(3) Remove the front control module retaining

screws.

(4) Using both hands, pull the front control module

straightfrom the integrated power module assembly

to disconnect the 49-way electrical connector and

remove the front control module from the vehicle.

INSTALLATION

(1) Install the front control module on the inte-

grated power module assembly by pushing the

49-way electrical connector straight in.

(2) Install the front control module retaining

screws. Torque the screws to 7 in. lbs.

(3) Install the integrated power module (Refer to 8

- ELECTRICAL/POWER DISTRIBUTION/INTE-

GRATED POWER MODULE - INSTALLATION).

(4) Connect the positive and negative battery

cables.

DRELECTRONIC CONTROL MODULES 8E - 5

Page 419 of 2627

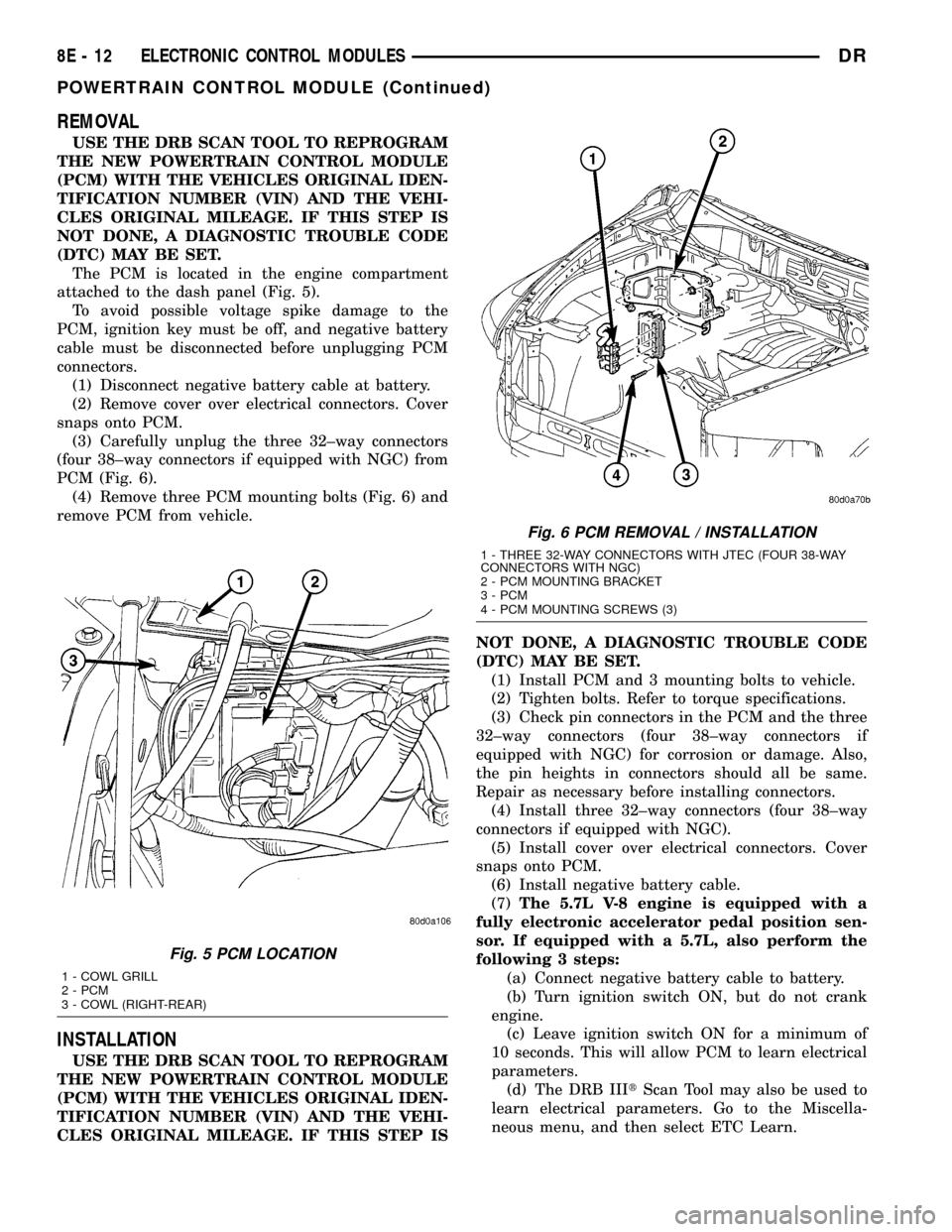

REMOVAL

USE THE DRB SCAN TOOL TO REPROGRAM

THE NEW POWERTRAIN CONTROL MODULE

(PCM) WITH THE VEHICLES ORIGINAL IDEN-

TIFICATION NUMBER (VIN) AND THE VEHI-

CLES ORIGINAL MILEAGE. IF THIS STEP IS

NOT DONE, A DIAGNOSTIC TROUBLE CODE

(DTC) MAY BE SET.

The PCM is located in the engine compartment

attached to the dash panel (Fig. 5).

To avoid possible voltage spike damage to the

PCM, ignition key must be off, and negative battery

cable must be disconnected before unplugging PCM

connectors.

(1) Disconnect negative battery cable at battery.

(2) Remove cover over electrical connectors. Cover

snaps onto PCM.

(3) Carefully unplug the three 32±way connectors

(four 38±way connectors if equipped with NGC) from

PCM (Fig. 6).

(4) Remove three PCM mounting bolts (Fig. 6) and

remove PCM from vehicle.

INSTALLATION

USE THE DRB SCAN TOOL TO REPROGRAM

THE NEW POWERTRAIN CONTROL MODULE

(PCM) WITH THE VEHICLES ORIGINAL IDEN-

TIFICATION NUMBER (VIN) AND THE VEHI-

CLES ORIGINAL MILEAGE. IF THIS STEP ISNOT DONE, A DIAGNOSTIC TROUBLE CODE

(DTC) MAY BE SET.

(1) Install PCM and 3 mounting bolts to vehicle.

(2) Tighten bolts. Refer to torque specifications.

(3) Check pin connectors in the PCM and the three

32±way connectors (four 38±way connectors if

equipped with NGC) for corrosion or damage. Also,

the pin heights in connectors should all be same.

Repair as necessary before installing connectors.

(4) Install three 32±way connectors (four 38±way

connectors if equipped with NGC).

(5) Install cover over electrical connectors. Cover

snaps onto PCM.

(6) Install negative battery cable.

(7)The 5.7L V-8 engine is equipped with a

fully electronic accelerator pedal position sen-

sor. If equipped with a 5.7L, also perform the

following 3 steps:

(a) Connect negative battery cable to battery.

(b) Turn ignition switch ON, but do not crank

engine.

(c) Leave ignition switch ON for a minimum of

10 seconds. This will allow PCM to learn electrical

parameters.

(d) The DRB IIItScan Tool may also be used to

learn electrical parameters. Go to the Miscella-

neous menu, and then select ETC Learn.

Fig. 5 PCM LOCATION

1 - COWL GRILL

2 - PCM

3 - COWL (RIGHT-REAR)

Fig. 6 PCM REMOVAL / INSTALLATION

1 - THREE 32-WAY CONNECTORS WITH JTEC (FOUR 38-WAY

CONNECTORS WITH NGC)

2 - PCM MOUNTING BRACKET

3 - PCM

4 - PCM MOUNTING SCREWS (3)

8E - 12 ELECTRONIC CONTROL MODULESDR

POWERTRAIN CONTROL MODULE (Continued)

Page 427 of 2627

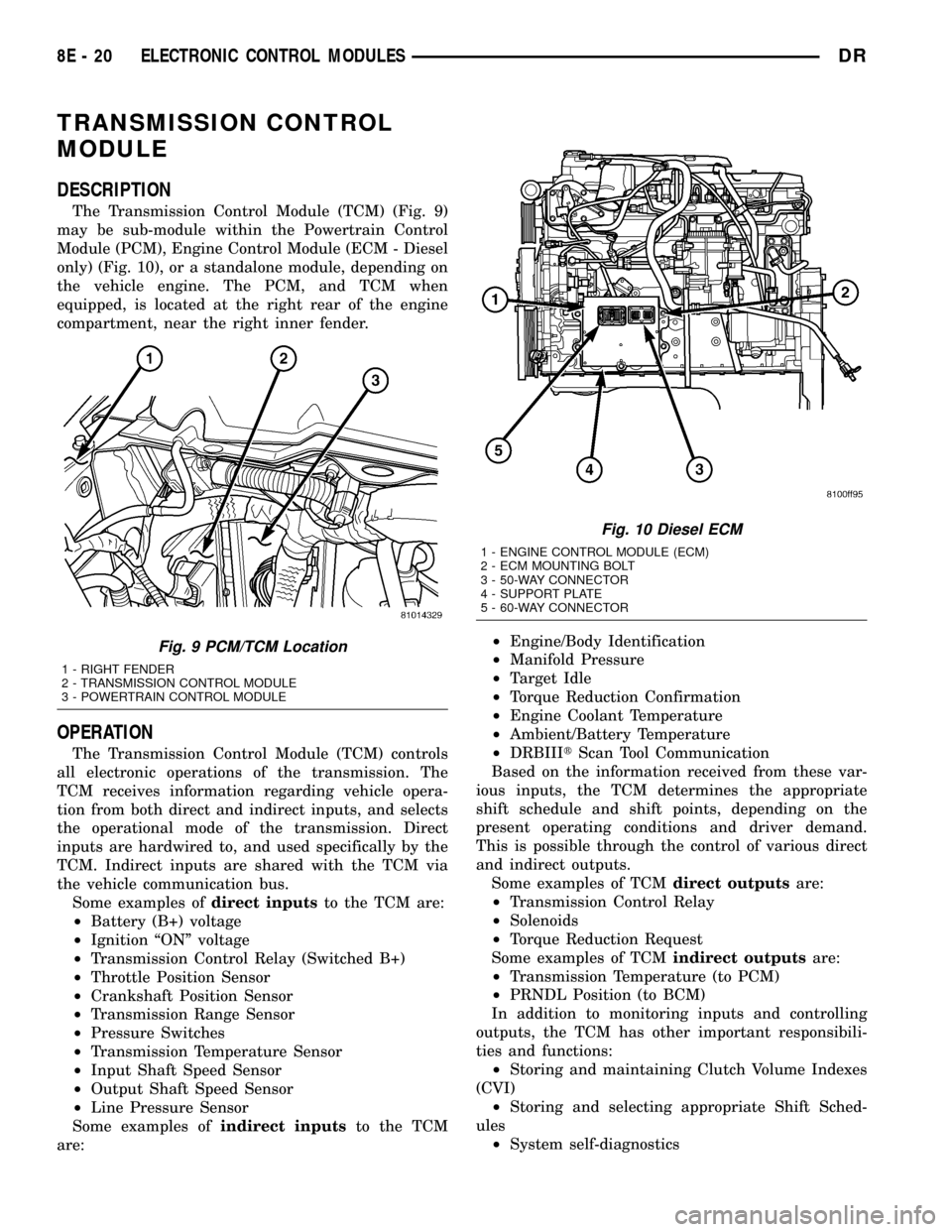

TRANSMISSION CONTROL

MODULE

DESCRIPTION

The Transmission Control Module (TCM) (Fig. 9)

may be sub-module within the Powertrain Control

Module (PCM), Engine Control Module (ECM - Diesel

only) (Fig. 10), or a standalone module, depending on

the vehicle engine. The PCM, and TCM when

equipped, is located at the right rear of the engine

compartment, near the right inner fender.

OPERATION

The Transmission Control Module (TCM) controls

all electronic operations of the transmission. The

TCM receives information regarding vehicle opera-

tion from both direct and indirect inputs, and selects

the operational mode of the transmission. Direct

inputs are hardwired to, and used specifically by the

TCM. Indirect inputs are shared with the TCM via

the vehicle communication bus.

Some examples ofdirect inputsto the TCM are:

²Battery (B+) voltage

²Ignition ªONº voltage

²Transmission Control Relay (Switched B+)

²Throttle Position Sensor

²Crankshaft Position Sensor

²Transmission Range Sensor

²Pressure Switches

²Transmission Temperature Sensor

²Input Shaft Speed Sensor

²Output Shaft Speed Sensor

²Line Pressure Sensor

Some examples ofindirect inputsto the TCM

are:²Engine/Body Identification

²Manifold Pressure

²Target Idle

²Torque Reduction Confirmation

²Engine Coolant Temperature

²Ambient/Battery Temperature

²DRBIIItScan Tool Communication

Based on the information received from these var-

ious inputs, the TCM determines the appropriate

shift schedule and shift points, depending on the

present operating conditions and driver demand.

This is possible through the control of various direct

and indirect outputs.

Some examples of TCMdirect outputsare:

²Transmission Control Relay

²Solenoids

²Torque Reduction Request

Some examples of TCMindirect outputsare:

²Transmission Temperature (to PCM)

²PRNDL Position (to BCM)

In addition to monitoring inputs and controlling

outputs, the TCM has other important responsibili-

ties and functions:

²Storing and maintaining Clutch Volume Indexes

(CVI)

²Storing and selecting appropriate Shift Sched-

ules

²System self-diagnostics

Fig. 9 PCM/TCM Location

1 - RIGHT FENDER

2 - TRANSMISSION CONTROL MODULE

3 - POWERTRAIN CONTROL MODULE

Fig. 10 Diesel ECM

1 - ENGINE CONTROL MODULE (ECM)

2 - ECM MOUNTING BOLT

3 - 50-WAY CONNECTOR

4 - SUPPORT PLATE

5 - 60-WAY CONNECTOR

8E - 20 ELECTRONIC CONTROL MODULESDR

Page 450 of 2627

CHARGING

TABLE OF CONTENTS

page page

CHARGING

DESCRIPTION.........................19

OPERATION...........................19

DIAGNOSIS AND TESTING - CHARGING

SYSTEM............................19

SPECIFICATIONS

GENERATOR RATINGS.................20

SPECIFICATIONS - TORQUE - GENERATOR

/ CHARGING SYSTEM..................20

BATTERY TEMPERATURE SENSOR

DESCRIPTION.........................21OPERATION...........................21

REMOVAL.............................21

INSTALLATION.........................21

GENERATOR

DESCRIPTION.........................21

OPERATION...........................21

REMOVAL.............................22

INSTALLATION.........................24

VOLTAGE REGULATOR

DESCRIPTION.........................25

OPERATION...........................25

CHARGING

DESCRIPTION

The charging system consists of:

²Generator

²Electronic Voltage Regulator (EVR) circuitry

within the Powertrain Control Module (PCM). Elec-

tronic Control Module (ECM) for diesel engines.

²Ignition switch

²Battery (refer to 8, Battery for information)

²Battery temperature sensor

²Check Gauges Lamp (if equipped)

²Voltmeter (refer to 8, Instrument Panel and

Gauges for information)

²Wiring harness and connections (refer to 8, Wir-

ing Diagrams for information)

OPERATION

The charging system is turned on and off with the

ignition switch. The system is on when the engine is

running and the ASD relay is energized. When the

ASD relay is on, voltage is supplied to the ASD relay

sense circuit at the PCM (ECM Diesel). This voltage

is connected through the PCM (ECM Diesel) and sup-

plied to one of the generator field terminals (Gen.

Source +) at the back of the generator.

The amount of direct current produced by the gen-

erator is controlled by the EVR (field control) cir-

cuitry contained within the PCM (ECM Diesel). This

circuitry is connected in series with the second rotor

field terminal and ground.

A battery temperature sensor, located in the bat-

tery tray housing, is used to sense battery tempera-

ture. This temperature data, along with data from

monitored line voltage, is used by the PCM (ECM

Diesel) to vary the battery charging rate. This isdone by cycling the ground path to control the

strength of the rotor magnetic field. The PCM then

compensates and regulates generator current output

accordingly.

All vehicles are equipped with On-Board Diagnos-

tics (OBD). All OBD-sensed systems, including EVR

(field control) circuitry, are monitored by the PCM

(ECM Diesel). Each monitored circuit is assigned a

Diagnostic Trouble Code (DTC). The PCM will store a

DTC in electronic memory for certain failures it

detects.

The Check Gauges Lamp (if equipped) monitors:

charging system voltage,engine coolant tempera-

ture and engine oil pressure. If an extreme condition

is indicated, the lamp will be illuminated. This is

done as reminder to check the three gauges. The sig-

nal to activate the lamp is sent via the CCD bus cir-

cuits. The lamp is located on the instrument panel.

Refer to 8, Instrument Panel and Gauges for addi-

tional information.

DIAGNOSIS AND TESTING - CHARGING

SYSTEM

The following procedures may be used to diagnose

the charging system if:

²the check gauges lamp (if equipped) is illumi-

nated with the engine running

²the voltmeter (if equipped) does not register

properly

²an undercharged or overcharged battery condi-

tion occurs.

Remember that an undercharged battery is often

caused by:

²accessories being left on with the engine not

running

DRCHARGING 8F - 19

Page 451 of 2627

²a faulty or improperly adjusted switch that

allows a lamp to stay on. Refer to Ignition-Off Draw

Test in 8, Battery for more information.

INSPECTION

The PCM (Powertrain Control Module), or ECM

(Diesel) monitors critical input and output circuits of

the charging system, making sure they are opera-

tional. A Diagnostic Trouble Code (DTC) is assigned

to each input and output circuit monitored by the

On-Board Diagnostic (OBD) system. Some charging

system circuits are checked continuously, and some

are checked only under certain conditions.

Refer to Diagnostic Trouble Codes in; Powertrain

Control Module; Electronic Control Modules for more

DTC information. This will include a complete list of

DTC's including DTC's for the charging system.

To perform a complete test of the charging system,

refer to the appropriate Powertrain Diagnostic Proce-

dures service manual and the DRBtscan tool. Per-

form the following inspections before attaching the

scan tool.

(1) Inspect the battery condition. Refer to 8, Bat-

tery for procedures.(2) Inspect condition of battery cable terminals,

battery posts, connections at engine block, starter

solenoid and relay. They should be clean and tight.

Repair as required.

(3) Inspect all fuses in both the fuseblock and

Power Distribution Center (PDC) for tightness in

receptacles. They should be properly installed and

tight. Repair or replace as required.

(4) Inspect generator mounting bolts for tightness.

Replace or tighten bolts if required. Refer to the Gen-

erator Removal/Installation section of this group for

torque specifications.

(5) Inspect generator drive belt condition and ten-

sion. Tighten or replace belt as required. Refer to

Belt Tension Specifications in 7, Cooling System.

(6) Inspect automatic belt tensioner (if equipped).

Refer to 7, Cooling System for information.

(7) Inspect generator electrical connections at gen-

erator field, battery output, and ground terminal (if

equipped). Also check generator ground wire connec-

tion at engine (if equipped). They should all be clean

and tight. Repair as required.

SPECIFICATIONS

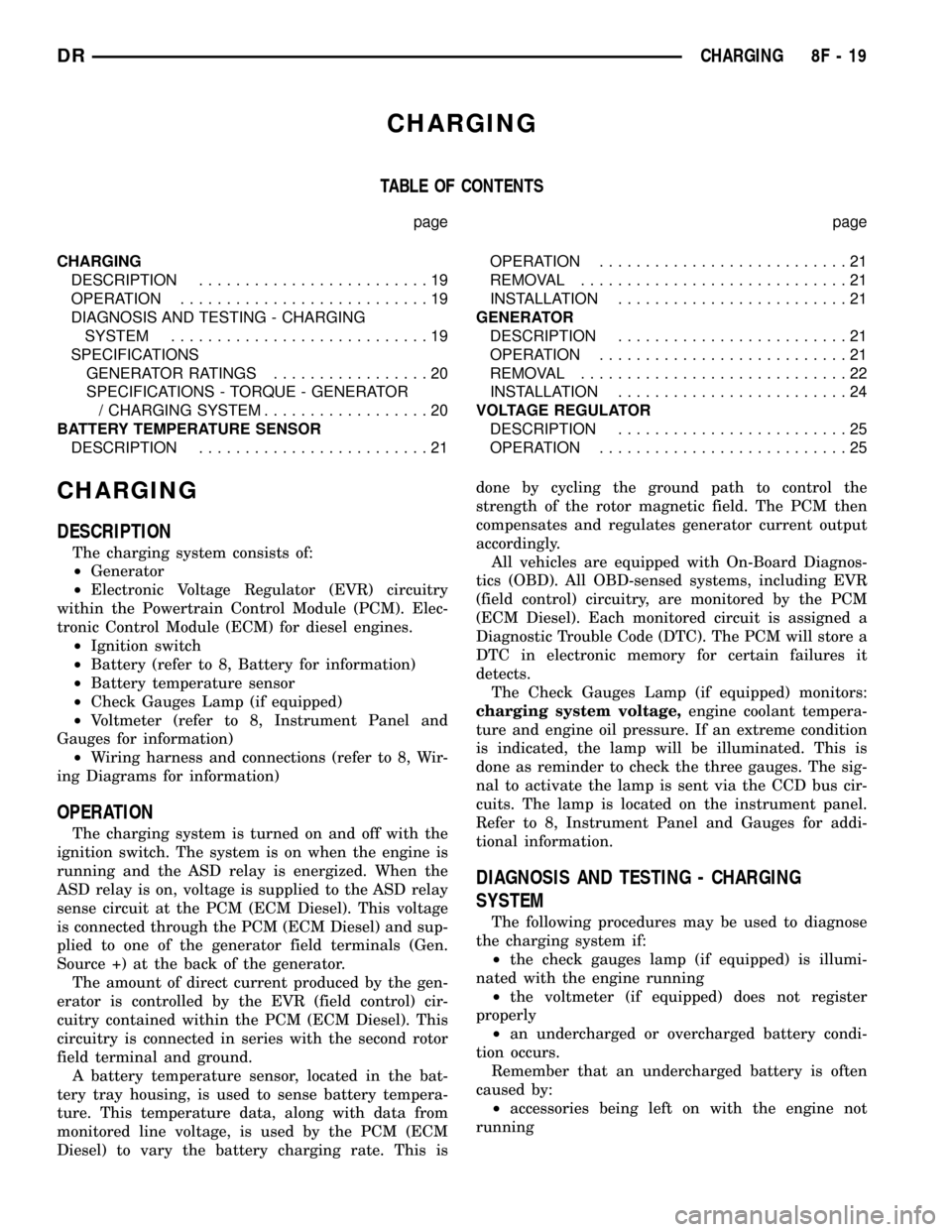

GENERATOR RATINGS

TYPE PART NUMBER RATED SAE AMPS ENGINES

DENSO 56029700AA 136 3.7L / 4.7L

BOSCH 56041120AC 136 3.7L / 4.7L

DENSO 56028696AA 136 5.7L Gas/5.9L Diesel

BOSCH 56028699AA 136 5.7L Gas/5.9L Diesel

SPECIFICATIONS - TORQUE - GENERATOR /

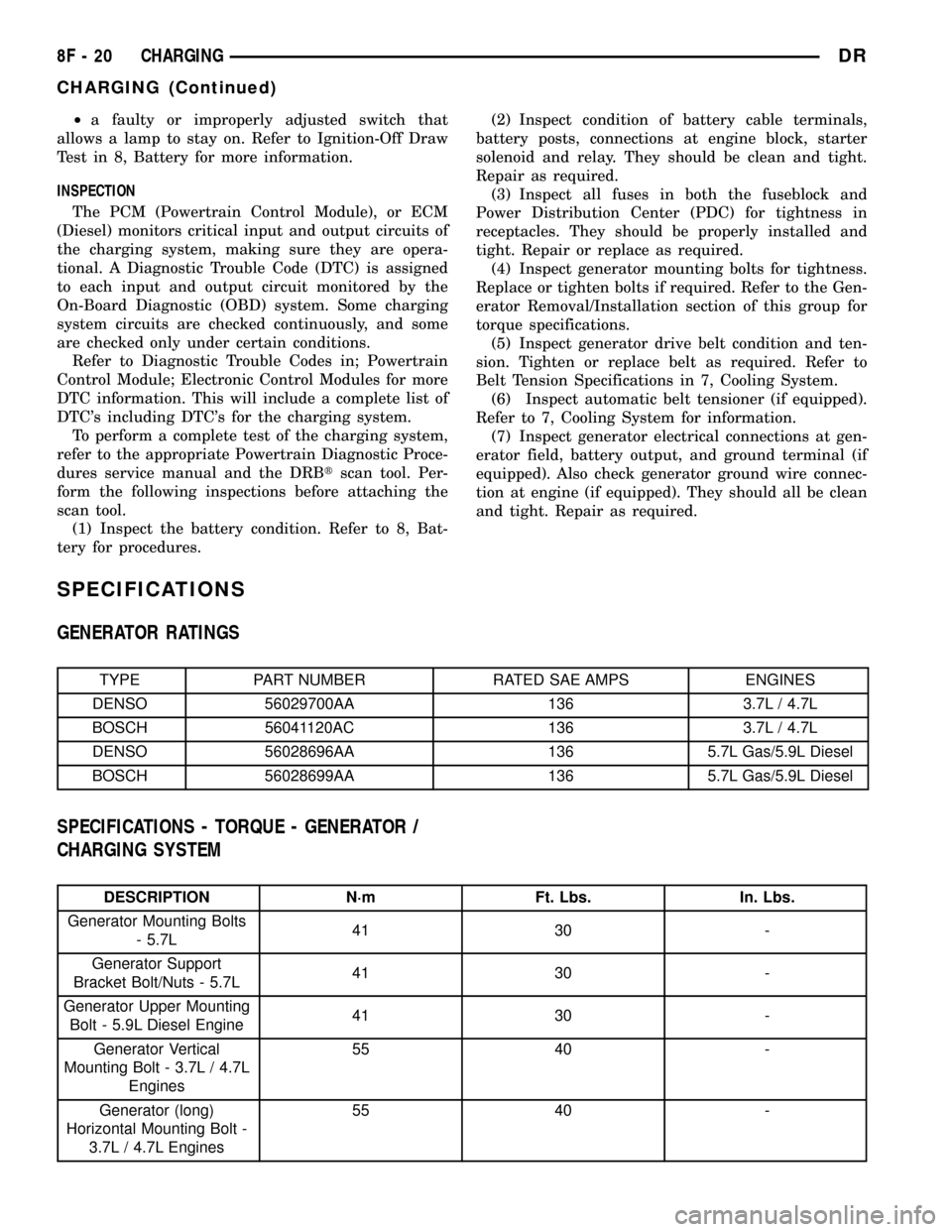

CHARGING SYSTEM

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Generator Mounting Bolts

- 5.7L41 30 -

Generator Support

Bracket Bolt/Nuts - 5.7L41 30 -

Generator Upper Mounting

Bolt - 5.9L Diesel Engine41 30 -

Generator Vertical

Mounting Bolt - 3.7L / 4.7L

Engines55 40 -

Generator (long)

Horizontal Mounting Bolt -

3.7L / 4.7L Engines55 40 -

8F - 20 CHARGINGDR

CHARGING (Continued)