service DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1746 of 2627

MANUAL TRANSMISSION - NV4500

TABLE OF CONTENTS

page page

MANUAL TRANSMISSION - NV4500

DESCRIPTION.........................43

OPERATION...........................43

DIAGNOSIS AND TESTING................44

REMOVAL.............................44

DISASSEMBLY.........................46

CLEANING............................62

INSPECTION..........................62

ASSEMBLY............................63

INSTALLATION.........................80

SPECIFICATIONS.......................81

SPECIAL TOOLS.......................81ADAPTER HOUSING SEAL

REMOVAL.............................85

INSTALLATION.........................85

EXTENSION HOUSING SEAL

REMOVAL.............................85

INSTALLATION.........................85

SHIFT MECHANISM

REMOVAL.............................86

INSTALLATION.........................87

SHIFT COVER

REMOVAL.............................87

INSTALLATION.........................87

MANUAL TRANSMISSION -

NV4500

DESCRIPTION

The NV4500 is a five speed constant mesh manual

transmission. All gear ranges including reverse are

synchronized. Fifth gear is an overdrive range. The

transmission has a cast iron gear case and aluminum

shift cover.

Two versions are used, a standard duty for 5.7L

applications and a heavy duty for V10 and Cummins

diesel applications. Main difference is a larger diam-

eter input shaft, for the heavy duty model.

Tapered roller bearings support the drive gear,

mainshaft and countershaft in the gear case. Roller

bearings in the drive gear support the forward end of

the mainshaft. The mainshaft gears are all supported

on caged type roller bearings. Drive gear thrust reac-

tion is controlled by a needle type thrust bearing.

The bearing is located at the forward end of the

mainshaft.

The transmission is a top loader style. The shift

lever is located in a shifter tower which is bolted to

the shift cover and operates the shift forks and rails

directly. The shift forks and rails are all located

within the aluminum cover which is bolted to the top

of the gear case.

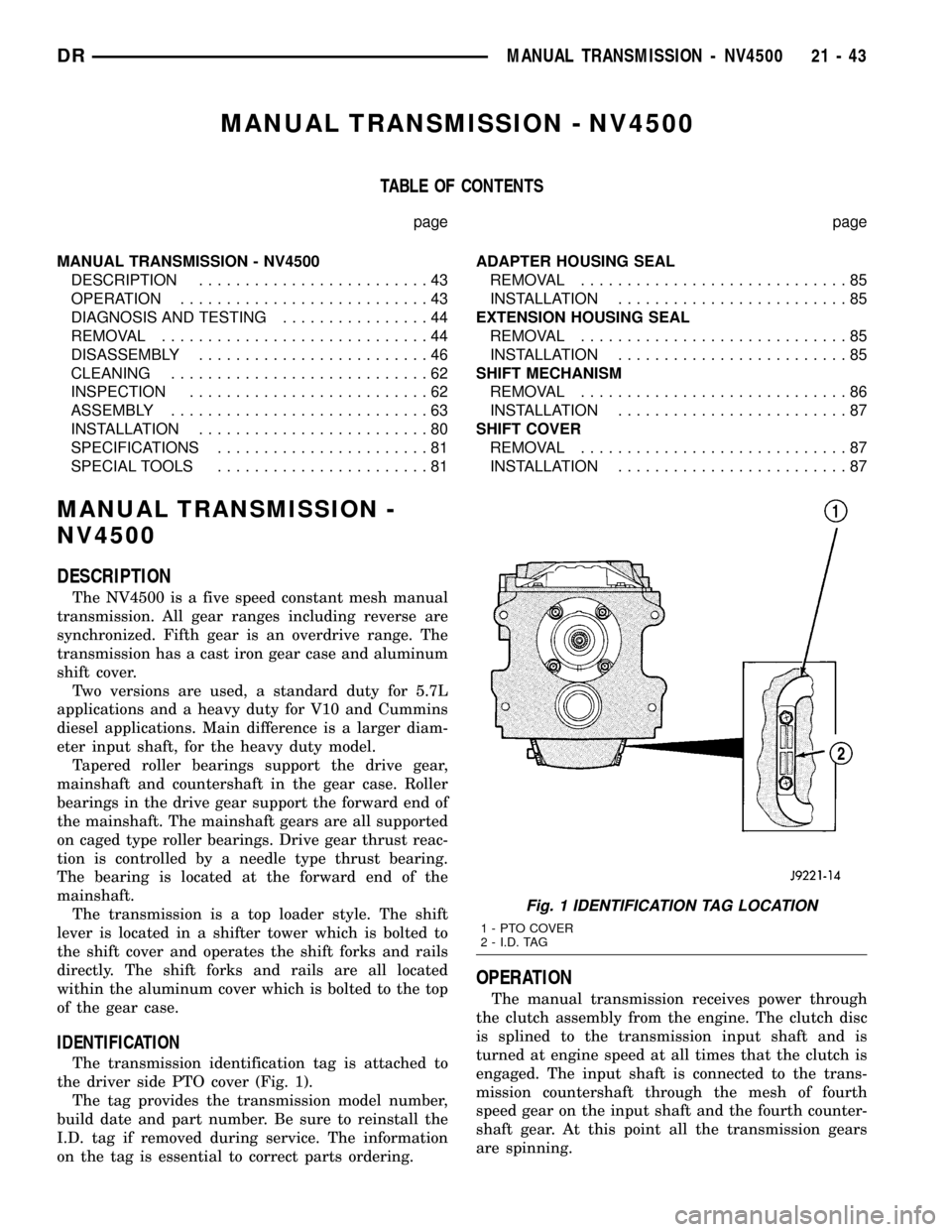

IDENTIFICATION

The transmission identification tag is attached to

the driver side PTO cover (Fig. 1).

The tag provides the transmission model number,

build date and part number. Be sure to reinstall the

I.D. tag if removed during service. The information

on the tag is essential to correct parts ordering.

OPERATION

The manual transmission receives power through

the clutch assembly from the engine. The clutch disc

is splined to the transmission input shaft and is

turned at engine speed at all times that the clutch is

engaged. The input shaft is connected to the trans-

mission countershaft through the mesh of fourth

speed gear on the input shaft and the fourth counter-

shaft gear. At this point all the transmission gears

are spinning.

Fig. 1 IDENTIFICATION TAG LOCATION

1 - PTO COVER

2 - I.D. TAG

DRMANUAL TRANSMISSION - NV4500 21 - 43

Page 1764 of 2627

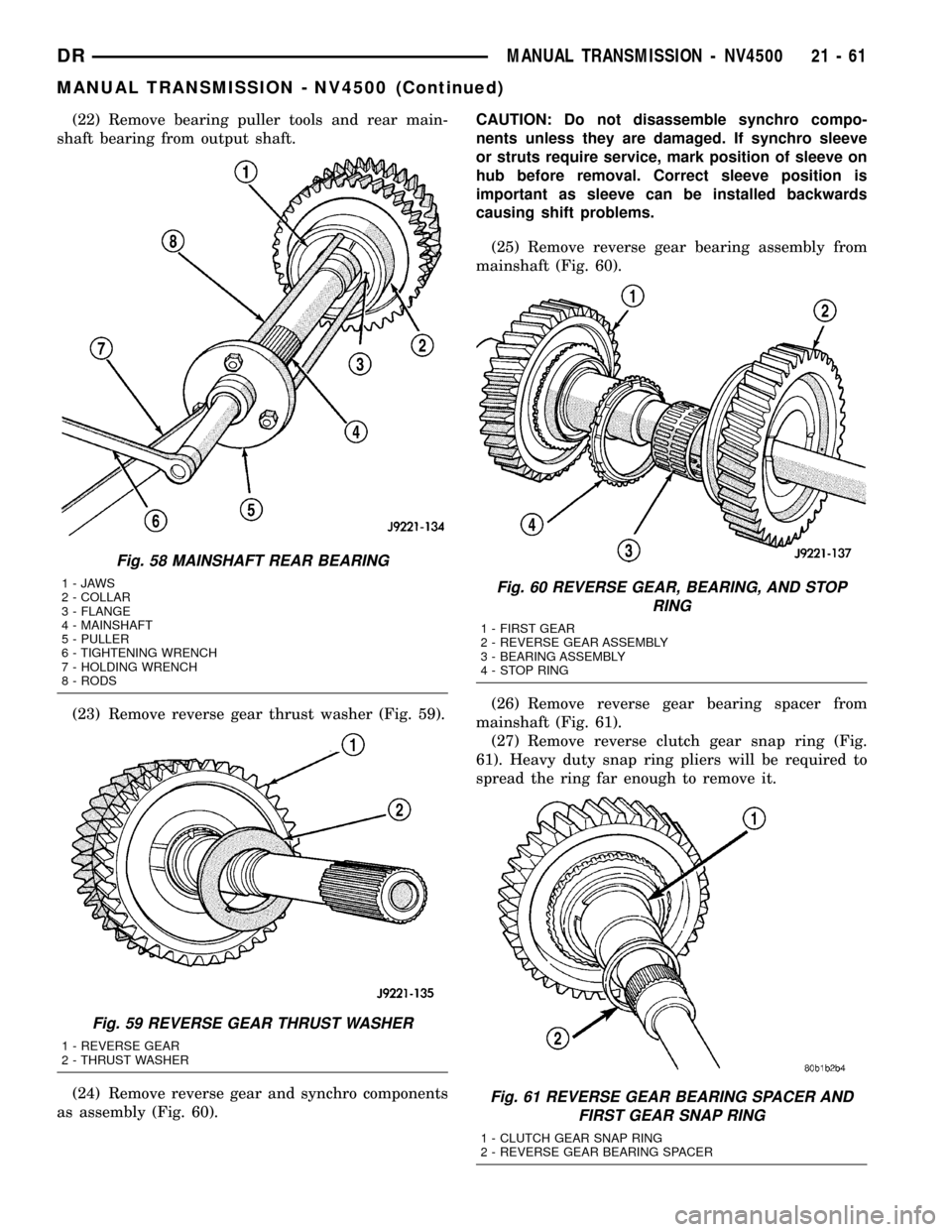

(22) Remove bearing puller tools and rear main-

shaft bearing from output shaft.

(23) Remove reverse gear thrust washer (Fig. 59).

(24) Remove reverse gear and synchro components

as assembly (Fig. 60).CAUTION: Do not disassemble synchro compo-

nents unless they are damaged. If synchro sleeve

or struts require service, mark position of sleeve on

hub before removal. Correct sleeve position is

important as sleeve can be installed backwards

causing shift problems.

(25) Remove reverse gear bearing assembly from

mainshaft (Fig. 60).

(26) Remove reverse gear bearing spacer from

mainshaft (Fig. 61).

(27) Remove reverse clutch gear snap ring (Fig.

61). Heavy duty snap ring pliers will be required to

spread the ring far enough to remove it.

Fig. 58 MAINSHAFT REAR BEARING

1-JAWS

2 - COLLAR

3 - FLANGE

4 - MAINSHAFT

5 - PULLER

6 - TIGHTENING WRENCH

7 - HOLDING WRENCH

8 - RODS

Fig. 59 REVERSE GEAR THRUST WASHER

1 - REVERSE GEAR

2 - THRUST WASHER

Fig. 60 REVERSE GEAR, BEARING, AND STOP

RING

1 - FIRST GEAR

2 - REVERSE GEAR ASSEMBLY

3 - BEARING ASSEMBLY

4 - STOP RING

Fig. 61 REVERSE GEAR BEARING SPACER AND

FIRST GEAR SNAP RING

1 - CLUTCH GEAR SNAP RING

2 - REVERSE GEAR BEARING SPACER

DRMANUAL TRANSMISSION - NV4500 21 - 61

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1770 of 2627

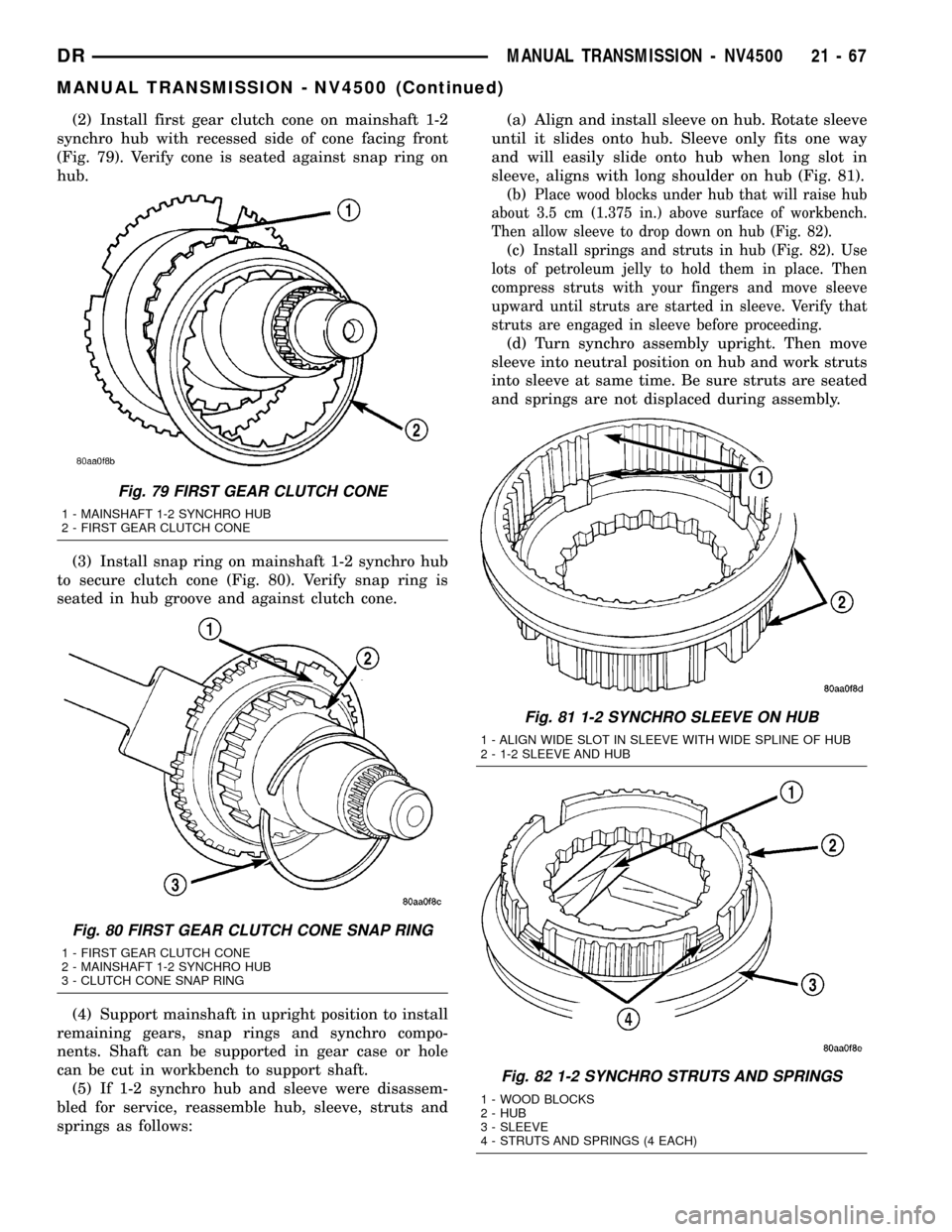

(2) Install first gear clutch cone on mainshaft 1-2

synchro hub with recessed side of cone facing front

(Fig. 79). Verify cone is seated against snap ring on

hub.

(3) Install snap ring on mainshaft 1-2 synchro hub

to secure clutch cone (Fig. 80). Verify snap ring is

seated in hub groove and against clutch cone.

(4) Support mainshaft in upright position to install

remaining gears, snap rings and synchro compo-

nents. Shaft can be supported in gear case or hole

can be cut in workbench to support shaft.

(5) If 1-2 synchro hub and sleeve were disassem-

bled for service, reassemble hub, sleeve, struts and

springs as follows:(a) Align and install sleeve on hub. Rotate sleeve

until it slides onto hub. Sleeve only fits one way

and will easily slide onto hub when long slot in

sleeve, aligns with long shoulder on hub (Fig. 81).

(b)

Place wood blocks under hub that will raise hub

about 3.5 cm (1.375 in.) above surface of workbench.

Then allow sleeve to drop down on hub (Fig. 82).

(c)Install springs and struts in hub (Fig. 82). Use

lots of petroleum jelly to hold them in place. Then

compress struts with your fingers and move sleeve

upward until struts are started in sleeve. Verify that

struts are engaged in sleeve before proceeding.

(d) Turn synchro assembly upright. Then move

sleeve into neutral position on hub and work struts

into sleeve at same time. Be sure struts are seated

and springs are not displaced during assembly.

Fig. 79 FIRST GEAR CLUTCH CONE

1 - MAINSHAFT 1-2 SYNCHRO HUB

2 - FIRST GEAR CLUTCH CONE

Fig. 80 FIRST GEAR CLUTCH CONE SNAP RING

1 - FIRST GEAR CLUTCH CONE

2 - MAINSHAFT 1-2 SYNCHRO HUB

3 - CLUTCH CONE SNAP RING

Fig. 81 1-2 SYNCHRO SLEEVE ON HUB

1 - ALIGN WIDE SLOT IN SLEEVE WITH WIDE SPLINE OF HUB

2 - 1-2 SLEEVE AND HUB

Fig. 82 1-2 SYNCHRO STRUTS AND SPRINGS

1 - WOOD BLOCKS

2 - HUB

3 - SLEEVE

4 - STRUTS AND SPRINGS (4 EACH)

DRMANUAL TRANSMISSION - NV4500 21 - 67

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1774 of 2627

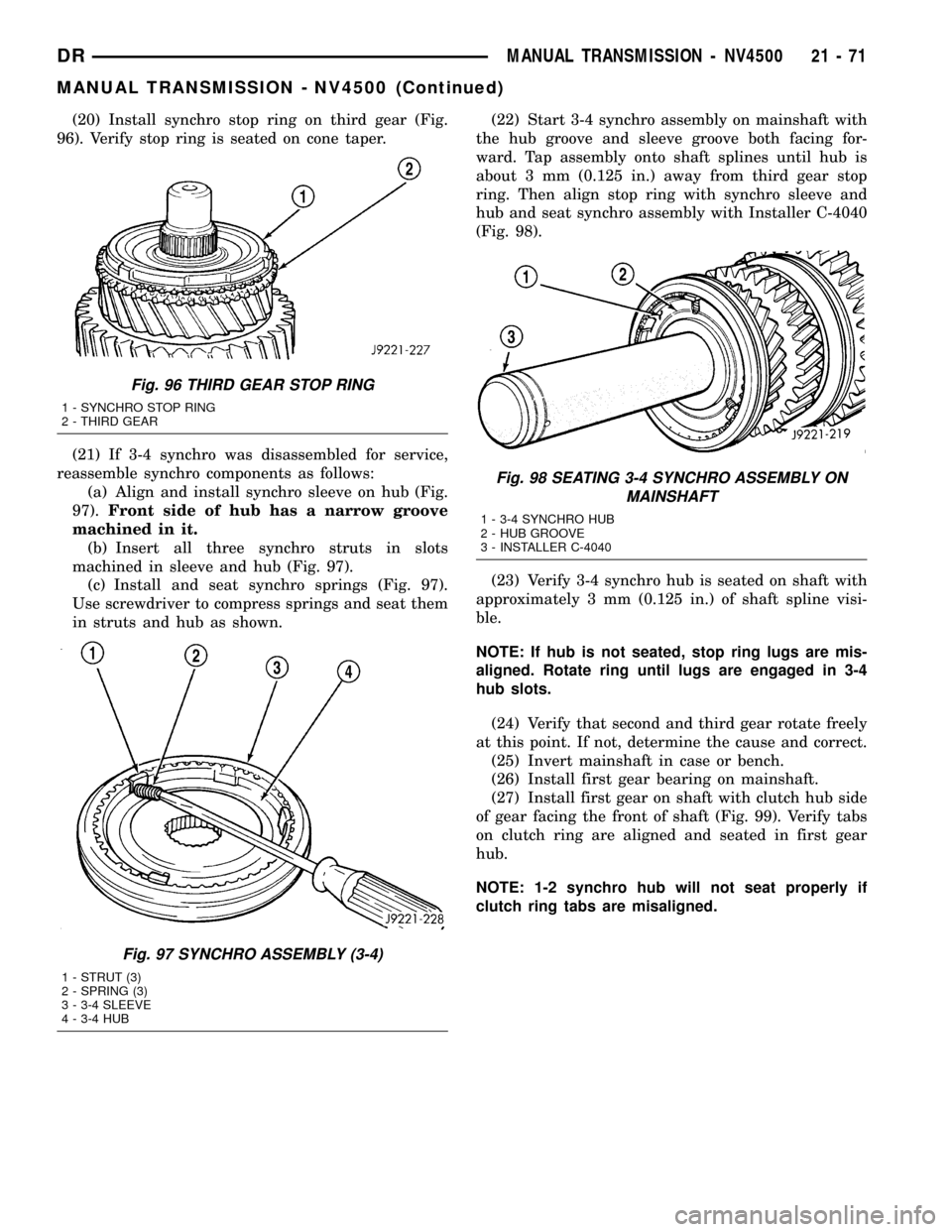

(20) Install synchro stop ring on third gear (Fig.

96). Verify stop ring is seated on cone taper.

(21) If 3-4 synchro was disassembled for service,

reassemble synchro components as follows:

(a) Align and install synchro sleeve on hub (Fig.

97).Front side of hub has a narrow groove

machined in it.

(b) Insert all three synchro struts in slots

machined in sleeve and hub (Fig. 97).

(c) Install and seat synchro springs (Fig. 97).

Use screwdriver to compress springs and seat them

in struts and hub as shown.(22) Start 3-4 synchro assembly on mainshaft with

the hub groove and sleeve groove both facing for-

ward. Tap assembly onto shaft splines until hub is

about 3 mm (0.125 in.) away from third gear stop

ring. Then align stop ring with synchro sleeve and

hub and seat synchro assembly with Installer C-4040

(Fig. 98).

(23) Verify 3-4 synchro hub is seated on shaft with

approximately 3 mm (0.125 in.) of shaft spline visi-

ble.

NOTE: If hub is not seated, stop ring lugs are mis-

aligned. Rotate ring until lugs are engaged in 3-4

hub slots.

(24) Verify that second and third gear rotate freely

at this point. If not, determine the cause and correct.

(25) Invert mainshaft in case or bench.

(26) Install first gear bearing on mainshaft.

(27) Install first gear on shaft with clutch hub side

of gear facing the front of shaft (Fig. 99). Verify tabs

on clutch ring are aligned and seated in first gear

hub.

NOTE: 1-2 synchro hub will not seat properly if

clutch ring tabs are misaligned.

Fig. 96 THIRD GEAR STOP RING

1 - SYNCHRO STOP RING

2 - THIRD GEAR

Fig. 97 SYNCHRO ASSEMBLY (3-4)

1 - STRUT (3)

2 - SPRING (3)

3 - 3-4 SLEEVE

4 - 3-4 HUB

Fig. 98 SEATING 3-4 SYNCHRO ASSEMBLY ON

MAINSHAFT

1 - 3-4 SYNCHRO HUB

2 - HUB GROOVE

3 - INSTALLER C-4040

DRMANUAL TRANSMISSION - NV4500 21 - 71

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1775 of 2627

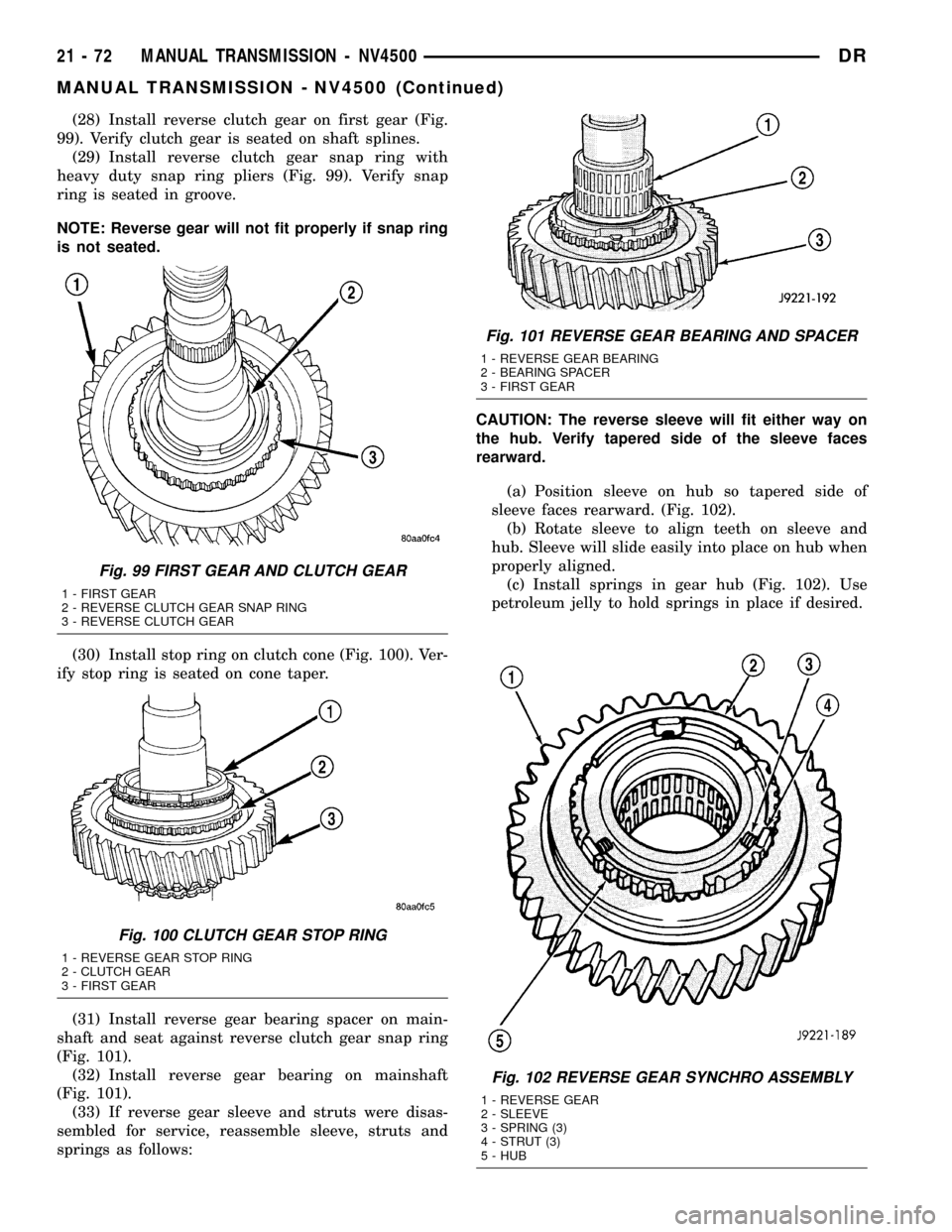

(28) Install reverse clutch gear on first gear (Fig.

99). Verify clutch gear is seated on shaft splines.

(29) Install reverse clutch gear snap ring with

heavy duty snap ring pliers (Fig. 99). Verify snap

ring is seated in groove.

NOTE: Reverse gear will not fit properly if snap ring

is not seated.

(30) Install stop ring on clutch cone (Fig. 100). Ver-

ify stop ring is seated on cone taper.

(31) Install reverse gear bearing spacer on main-

shaft and seat against reverse clutch gear snap ring

(Fig. 101).

(32) Install reverse gear bearing on mainshaft

(Fig. 101).

(33) If reverse gear sleeve and struts were disas-

sembled for service, reassemble sleeve, struts and

springs as follows:CAUTION: The reverse sleeve will fit either way on

the hub. Verify tapered side of the sleeve faces

rearward.

(a) Position sleeve on hub so tapered side of

sleeve faces rearward. (Fig. 102).

(b) Rotate sleeve to align teeth on sleeve and

hub. Sleeve will slide easily into place on hub when

properly aligned.

(c) Install springs in gear hub (Fig. 102). Use

petroleum jelly to hold springs in place if desired.

Fig. 102 REVERSE GEAR SYNCHRO ASSEMBLY

1 - REVERSE GEAR

2 - SLEEVE

3 - SPRING (3)

4 - STRUT (3)

5 - HUB

Fig. 99 FIRST GEAR AND CLUTCH GEAR

1 - FIRST GEAR

2 - REVERSE CLUTCH GEAR SNAP RING

3 - REVERSE CLUTCH GEAR

Fig. 100 CLUTCH GEAR STOP RING

1 - REVERSE GEAR STOP RING

2 - CLUTCH GEAR

3 - FIRST GEAR

Fig. 101 REVERSE GEAR BEARING AND SPACER

1 - REVERSE GEAR BEARING

2 - BEARING SPACER

3 - FIRST GEAR

21 - 72 MANUAL TRANSMISSION - NV4500DR

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1846 of 2627

(3) Have helper start and run engine at 1600 rpm

for test.

(4)

Move transmission shift lever four detents rear-

ward from full forward position. This is Reverse range.

(5) Move transmission throttle lever fully forward

then fully rearward and note reading at Gauge

C-3293-SP.

(6) Pressure should be 145 - 175 psi (1000-1207

kPa) with throttle lever forward and increase to 230 -

280 psi (1586-1931 kPa) as lever is gradually moved

rearward.

Test Five - Governor Pressure

This test checks governor operation by measuring

governor pressure response to changes in vehicle

speed. It is usually not necessary to check governor

operation unless shift speeds are incorrect or if the

transmission will not downshift. The test should be

performed on the road or on a hoist that will allow

the rear wheels to rotate freely.

(1) Move 100 psi Test Gauge C-3292 to governor

pressure port.

(2) Move transmission shift lever two detents rear-

ward from full forward position. This is D range.

(3) Have helper start and run engine at curb idle

speed. Then firmly apply service brakes so wheels

will not rotate.

(4) Note governor pressure:

²

Governor pressure should be no more than 20.6

kPa (3 psi) at curb idle speed and wheels not rotating.

²If pressure exceeds 20.6 kPa (3 psi), a fault

exists in governor pressure control system.

(5) Release brakes, slowly increase engine speed,

and observe speedometer and pressure test gauge (do

not exceed 30 mph on speedometer). Governor pres-

sure should increase in proportion to vehicle speed.

Or approximately 6.89 kPa (1 psi) for every 1 mph.

(6) Governor pressure rise should be smooth and

drop back to no more than 20.6 kPa (3 psi), after

engine returns to curb idle and brakes are applied to

prevent wheels from rotating.

(7)

Compare results of pressure test with analysis

chart.

Test Six - Transmission In Overdrive Fourth Gear

This test checks line pressure at the overdrive

clutch in fourth gear range. Use 300 psi Test Gauge

C-3293-SP for this test. The test should be performed

on the road or on a chassis dyno.

(1)

Remove tachometer; it is not needed for this test.

(2) Move 300 psi Gauge to overdrive clutch pres-

sure test port. Then remove other gauge and reinstall

test port plug.

(3) Lower vehicle.

(4) Turn OD switch on.(5) Secure test gauge so it can be viewed from

drivers seat.

(6) Start engine and shift into D range.

(7) Increase vehicle speed gradually until 3-4 shift

occurs and note gauge pressure.

(8) Pressure should be 524-565 kPa (76-82 psi)

with closed throttle and increase to 690-896 kPa

(100-130 psi) at 1/2 to 3/4 throttle. Note that pres-

sure can increase to around 965 kPa (140 psi) at full

throttle.

(9) Return to shop or move vehicle off chassis

dyno.

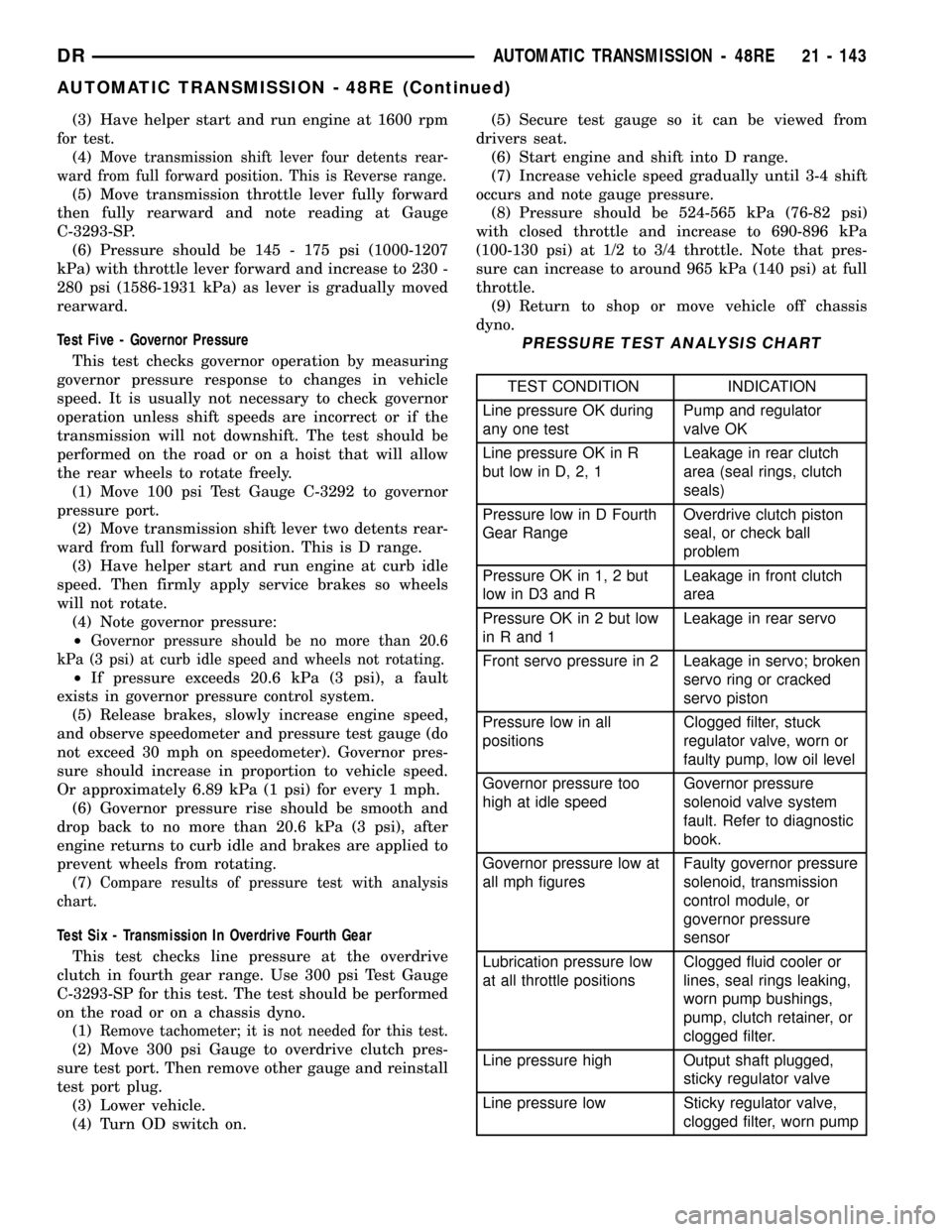

PRESSURE TEST ANALYSIS CHART

TEST CONDITION INDICATION

Line pressure OK during

any one testPump and regulator

valve OK

Line pressure OK in R

but low in D, 2, 1Leakage in rear clutch

area (seal rings, clutch

seals)

Pressure low in D Fourth

Gear RangeOverdrive clutch piston

seal, or check ball

problem

Pressure OK in 1, 2 but

low in D3 and RLeakage in front clutch

area

Pressure OK in 2 but low

in R and 1Leakage in rear servo

Front servo pressure in 2 Leakage in servo; broken

servo ring or cracked

servo piston

Pressure low in all

positionsClogged filter, stuck

regulator valve, worn or

faulty pump, low oil level

Governor pressure too

high at idle speedGovernor pressure

solenoid valve system

fault. Refer to diagnostic

book.

Governor pressure low at

all mph figuresFaulty governor pressure

solenoid, transmission

control module, or

governor pressure

sensor

Lubrication pressure low

at all throttle positionsClogged fluid cooler or

lines, seal rings leaking,

worn pump bushings,

pump, clutch retainer, or

clogged filter.

Line pressure high Output shaft plugged,

sticky regulator valve

Line pressure low Sticky regulator valve,

clogged filter, worn pump

DRAUTOMATIC TRANSMISSION - 48RE 21 - 143

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 1849 of 2627

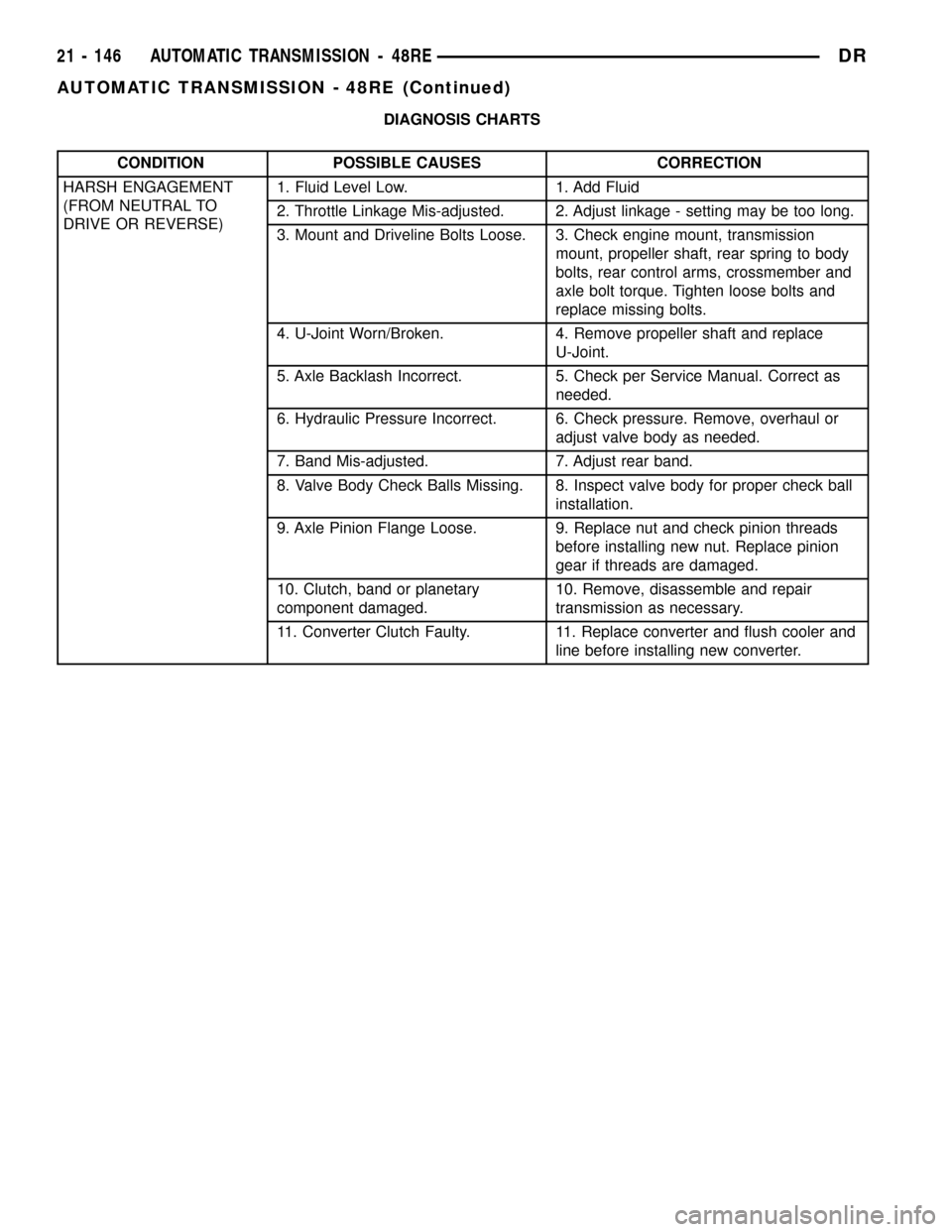

DIAGNOSIS CHARTS

CONDITION POSSIBLE CAUSES CORRECTION

HARSH ENGAGEMENT

(FROM NEUTRAL TO

DRIVE OR REVERSE)1. Fluid Level Low. 1. Add Fluid

2. Throttle Linkage Mis-adjusted. 2. Adjust linkage - setting may be too long.

3. Mount and Driveline Bolts Loose. 3. Check engine mount, transmission

mount, propeller shaft, rear spring to body

bolts, rear control arms, crossmember and

axle bolt torque. Tighten loose bolts and

replace missing bolts.

4. U-Joint Worn/Broken. 4. Remove propeller shaft and replace

U-Joint.

5. Axle Backlash Incorrect. 5. Check per Service Manual. Correct as

needed.

6. Hydraulic Pressure Incorrect. 6. Check pressure. Remove, overhaul or

adjust valve body as needed.

7. Band Mis-adjusted. 7. Adjust rear band.

8. Valve Body Check Balls Missing. 8. Inspect valve body for proper check ball

installation.

9. Axle Pinion Flange Loose. 9. Replace nut and check pinion threads

before installing new nut. Replace pinion

gear if threads are damaged.

10. Clutch, band or planetary

component damaged.10. Remove, disassemble and repair

transmission as necessary.

11. Converter Clutch Faulty. 11. Replace converter and flush cooler and

line before installing new converter.

21 - 146 AUTOMATIC TRANSMISSION - 48REDR

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 1851 of 2627

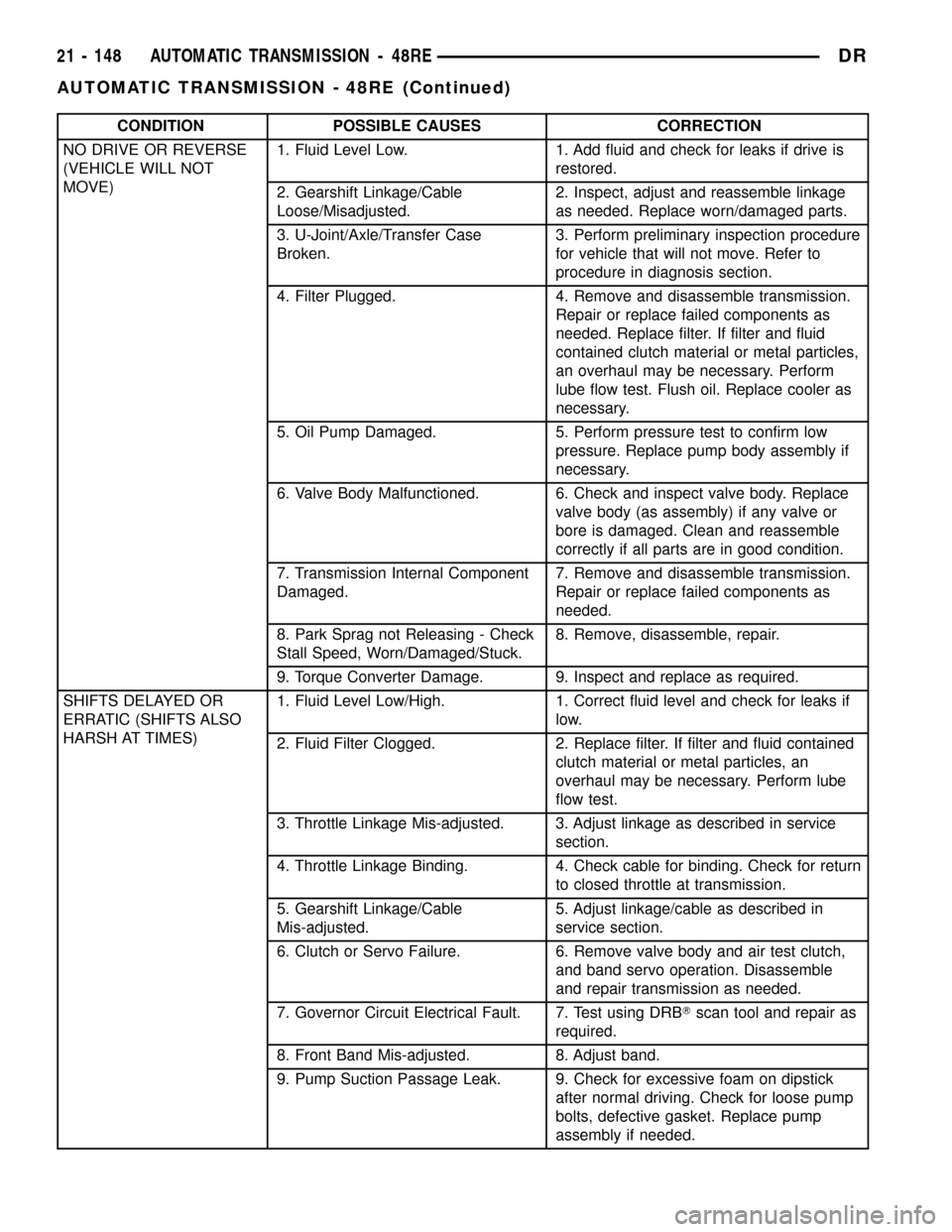

CONDITION POSSIBLE CAUSES CORRECTION

NO DRIVE OR REVERSE

(VEHICLE WILL NOT

MOVE)1. Fluid Level Low. 1. Add fluid and check for leaks if drive is

restored.

2. Gearshift Linkage/Cable

Loose/Misadjusted.2. Inspect, adjust and reassemble linkage

as needed. Replace worn/damaged parts.

3. U-Joint/Axle/Transfer Case

Broken.3. Perform preliminary inspection procedure

for vehicle that will not move. Refer to

procedure in diagnosis section.

4. Filter Plugged. 4. Remove and disassemble transmission.

Repair or replace failed components as

needed. Replace filter. If filter and fluid

contained clutch material or metal particles,

an overhaul may be necessary. Perform

lube flow test. Flush oil. Replace cooler as

necessary.

5. Oil Pump Damaged. 5. Perform pressure test to confirm low

pressure. Replace pump body assembly if

necessary.

6. Valve Body Malfunctioned. 6. Check and inspect valve body. Replace

valve body (as assembly) if any valve or

bore is damaged. Clean and reassemble

correctly if all parts are in good condition.

7. Transmission Internal Component

Damaged.7. Remove and disassemble transmission.

Repair or replace failed components as

needed.

8. Park Sprag not Releasing - Check

Stall Speed, Worn/Damaged/Stuck.8. Remove, disassemble, repair.

9. Torque Converter Damage. 9. Inspect and replace as required.

SHIFTS DELAYED OR

ERRATIC (SHIFTS ALSO

HARSH AT TIMES)1. Fluid Level Low/High. 1. Correct fluid level and check for leaks if

low.

2. Fluid Filter Clogged. 2. Replace filter. If filter and fluid contained

clutch material or metal particles, an

overhaul may be necessary. Perform lube

flow test.

3. Throttle Linkage Mis-adjusted. 3. Adjust linkage as described in service

section.

4. Throttle Linkage Binding. 4. Check cable for binding. Check for return

to closed throttle at transmission.

5. Gearshift Linkage/Cable

Mis-adjusted.5. Adjust linkage/cable as described in

service section.

6. Clutch or Servo Failure. 6. Remove valve body and air test clutch,

and band servo operation. Disassemble

and repair transmission as needed.

7. Governor Circuit Electrical Fault. 7. Test using DRBTscan tool and repair as

required.

8. Front Band Mis-adjusted. 8. Adjust band.

9. Pump Suction Passage Leak. 9. Check for excessive foam on dipstick

after normal driving. Check for loose pump

bolts, defective gasket. Replace pump

assembly if needed.

21 - 148 AUTOMATIC TRANSMISSION - 48REDR

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 1852 of 2627

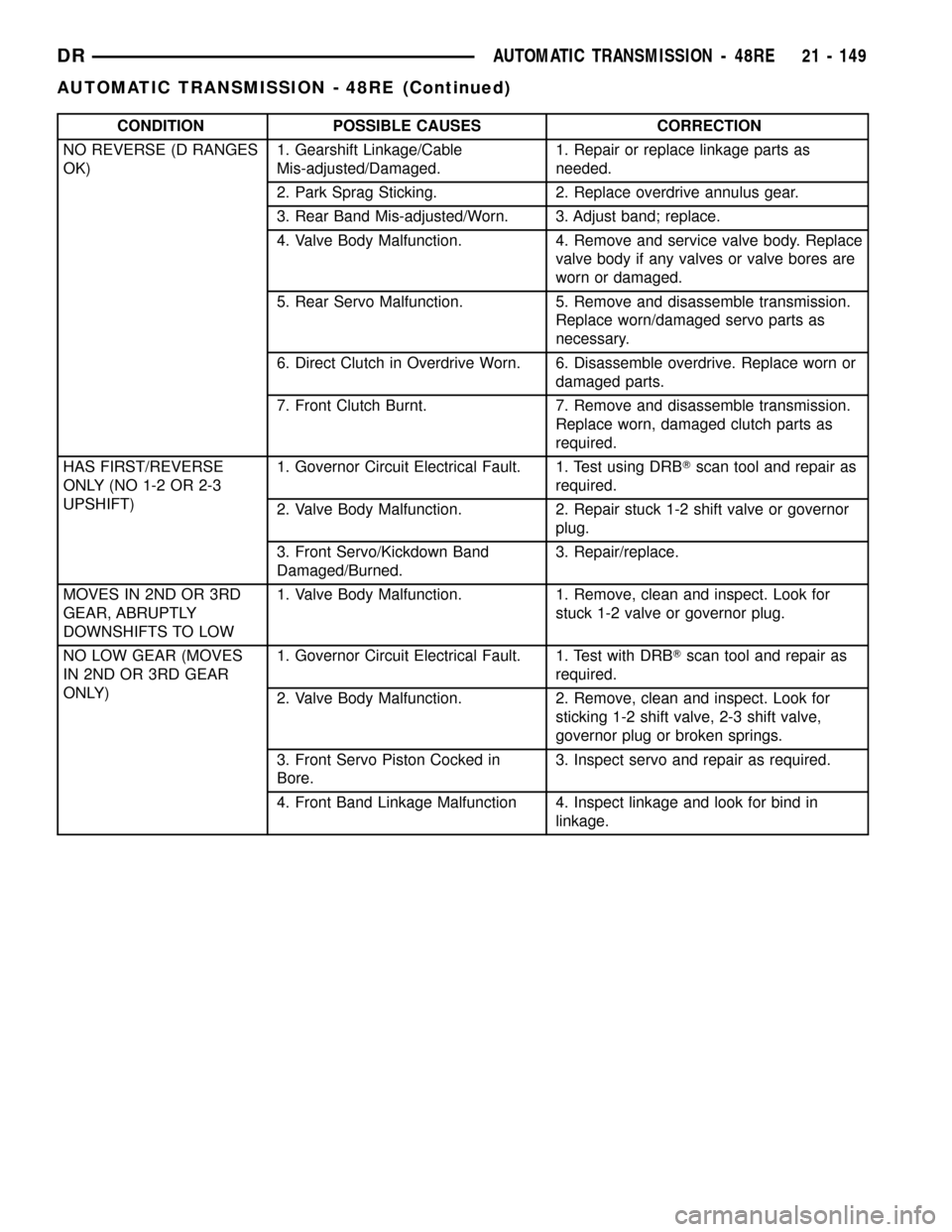

CONDITION POSSIBLE CAUSES CORRECTION

NO REVERSE (D RANGES

OK)1. Gearshift Linkage/Cable

Mis-adjusted/Damaged.1. Repair or replace linkage parts as

needed.

2. Park Sprag Sticking. 2. Replace overdrive annulus gear.

3. Rear Band Mis-adjusted/Worn. 3. Adjust band; replace.

4. Valve Body Malfunction. 4. Remove and service valve body. Replace

valve body if any valves or valve bores are

worn or damaged.

5. Rear Servo Malfunction. 5. Remove and disassemble transmission.

Replace worn/damaged servo parts as

necessary.

6. Direct Clutch in Overdrive Worn. 6. Disassemble overdrive. Replace worn or

damaged parts.

7. Front Clutch Burnt. 7. Remove and disassemble transmission.

Replace worn, damaged clutch parts as

required.

HAS FIRST/REVERSE

ONLY (NO 1-2 OR 2-3

UPSHIFT)1. Governor Circuit Electrical Fault. 1. Test using DRBTscan tool and repair as

required.

2. Valve Body Malfunction. 2. Repair stuck 1-2 shift valve or governor

plug.

3. Front Servo/Kickdown Band

Damaged/Burned.3. Repair/replace.

MOVES IN 2ND OR 3RD

GEAR, ABRUPTLY

DOWNSHIFTS TO LOW1. Valve Body Malfunction. 1. Remove, clean and inspect. Look for

stuck 1-2 valve or governor plug.

NO LOW GEAR (MOVES

IN 2ND OR 3RD GEAR

ONLY)1. Governor Circuit Electrical Fault. 1. Test with DRBTscan tool and repair as

required.

2. Valve Body Malfunction. 2. Remove, clean and inspect. Look for

sticking 1-2 shift valve, 2-3 shift valve,

governor plug or broken springs.

3. Front Servo Piston Cocked in

Bore.3. Inspect servo and repair as required.

4. Front Band Linkage Malfunction 4. Inspect linkage and look for bind in

linkage.

DRAUTOMATIC TRANSMISSION - 48RE 21 - 149

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 1857 of 2627

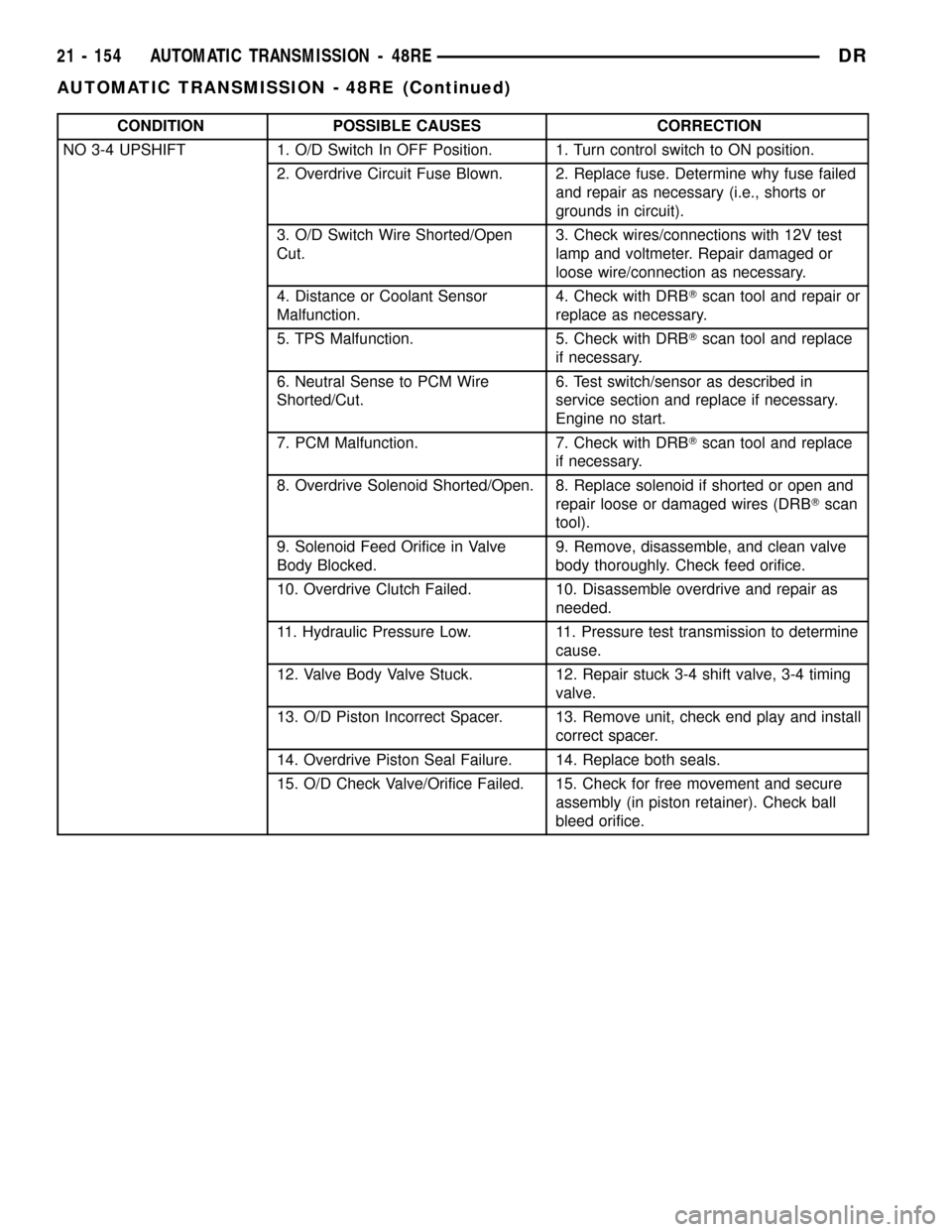

CONDITION POSSIBLE CAUSES CORRECTION

NO 3-4 UPSHIFT 1. O/D Switch In OFF Position. 1. Turn control switch to ON position.

2. Overdrive Circuit Fuse Blown. 2. Replace fuse. Determine why fuse failed

and repair as necessary (i.e., shorts or

grounds in circuit).

3. O/D Switch Wire Shorted/Open

Cut.3. Check wires/connections with 12V test

lamp and voltmeter. Repair damaged or

loose wire/connection as necessary.

4. Distance or Coolant Sensor

Malfunction.4. Check with DRBTscan tool and repair or

replace as necessary.

5. TPS Malfunction. 5. Check with DRBTscan tool and replace

if necessary.

6. Neutral Sense to PCM Wire

Shorted/Cut.6. Test switch/sensor as described in

service section and replace if necessary.

Engine no start.

7. PCM Malfunction. 7. Check with DRBTscan tool and replace

if necessary.

8. Overdrive Solenoid Shorted/Open. 8. Replace solenoid if shorted or open and

repair loose or damaged wires (DRBTscan

tool).

9. Solenoid Feed Orifice in Valve

Body Blocked.9. Remove, disassemble, and clean valve

body thoroughly. Check feed orifice.

10. Overdrive Clutch Failed. 10. Disassemble overdrive and repair as

needed.

11. Hydraulic Pressure Low. 11. Pressure test transmission to determine

cause.

12. Valve Body Valve Stuck. 12. Repair stuck 3-4 shift valve, 3-4 timing

valve.

13. O/D Piston Incorrect Spacer. 13. Remove unit, check end play and install

correct spacer.

14. Overdrive Piston Seal Failure. 14. Replace both seals.

15. O/D Check Valve/Orifice Failed. 15. Check for free movement and secure

assembly (in piston retainer). Check ball

bleed orifice.

21 - 154 AUTOMATIC TRANSMISSION - 48REDR

AUTOMATIC TRANSMISSION - 48RE (Continued)